Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Increase reluctance torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

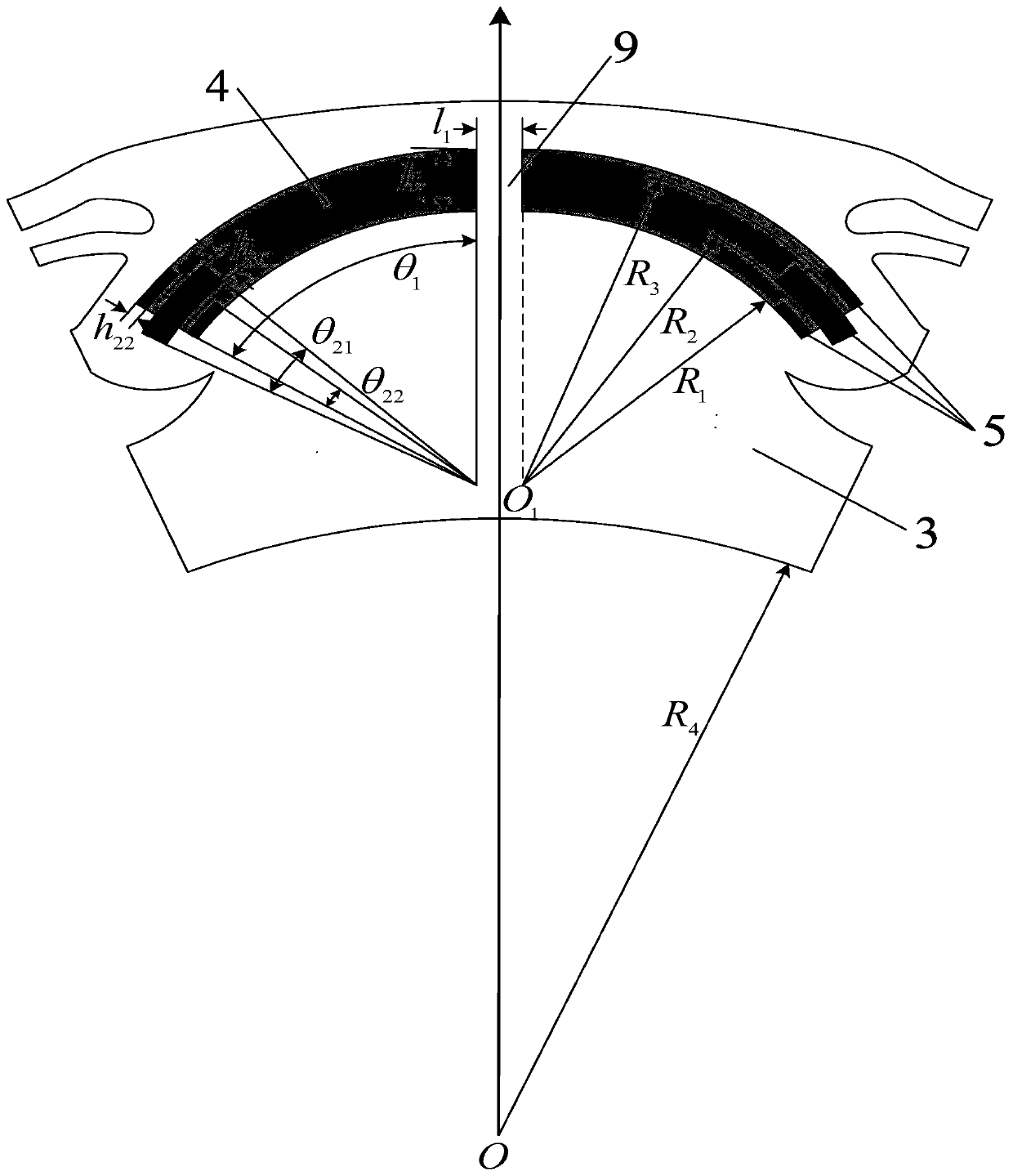

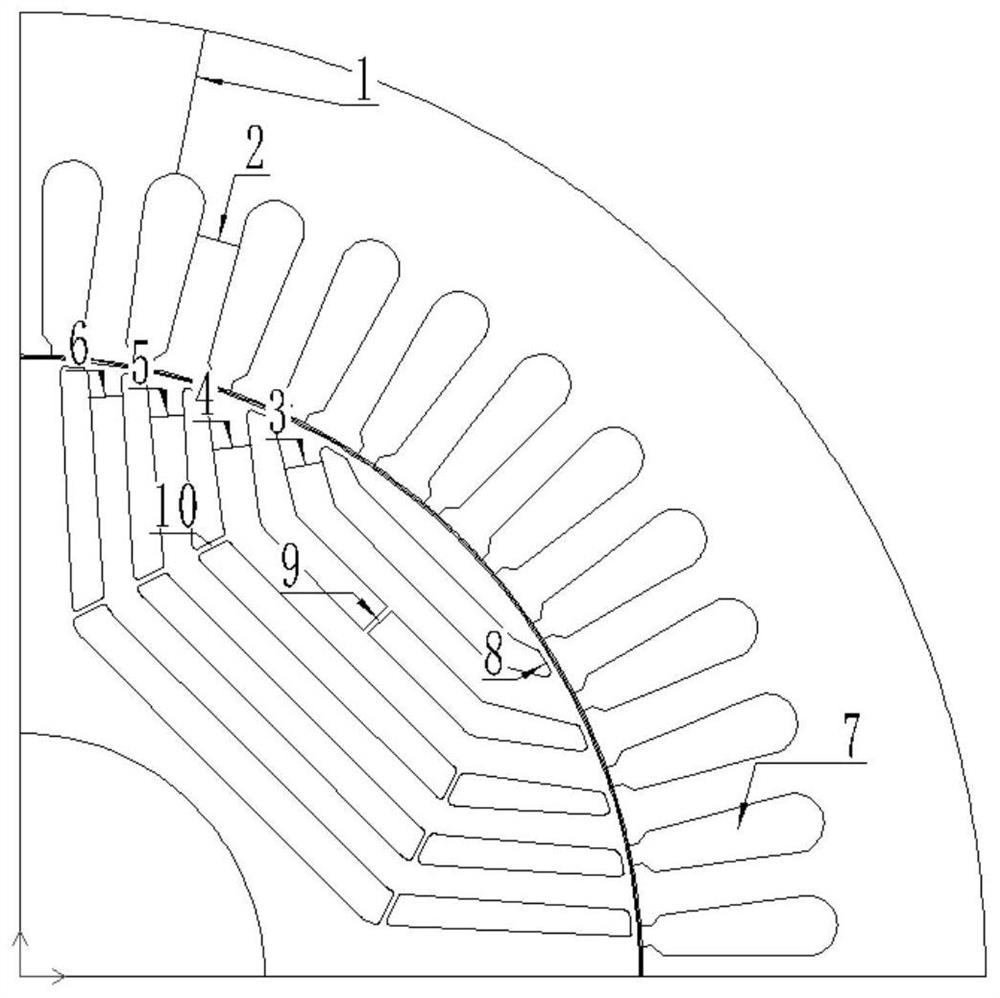

Built-in permanent magnet motor

ActiveCN103187844ASuppression of the air gap magnetic fieldImprove the problem of excessive cogging torqueMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsHarmonicPermanent magnet motor

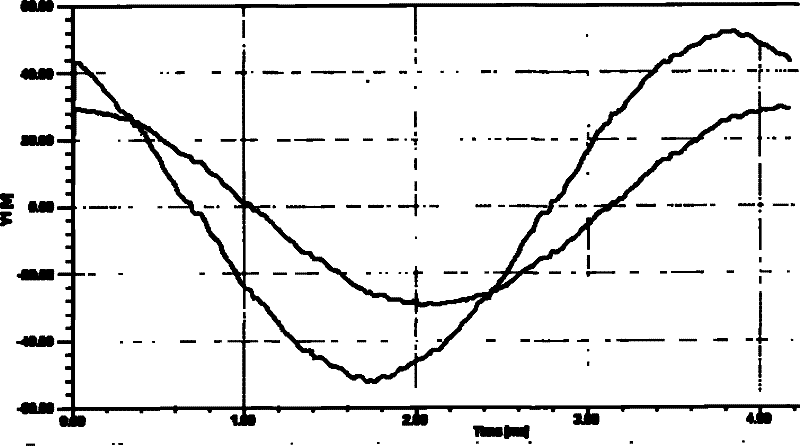

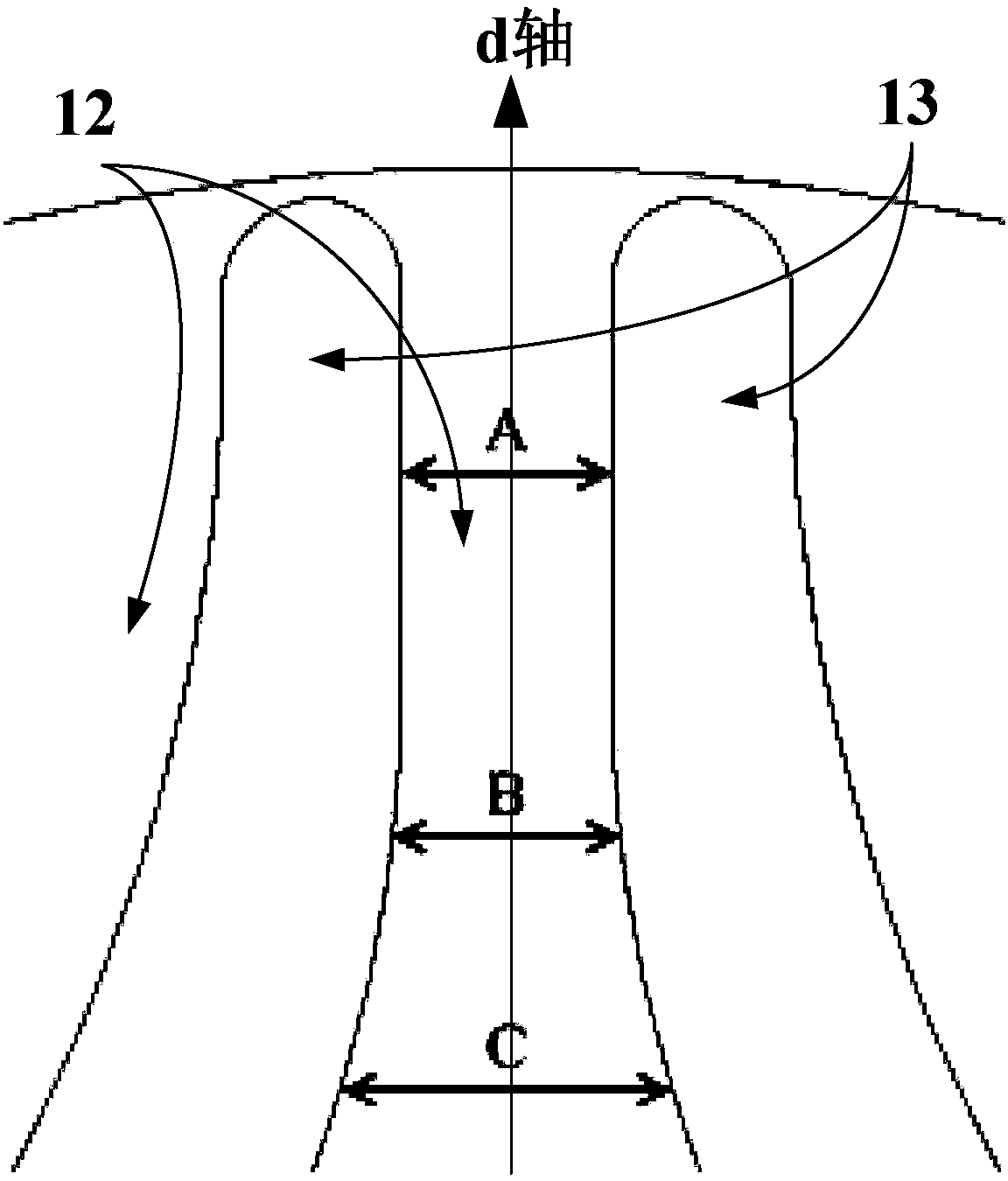

The invention discloses a built-in permanent magnet motor. Main polar faces and interpolar faces of a rotor of the motor are formed by connecting a plurality of arcs of eccentric circles not concentric with the circle center of the rotor, so that an air gap is adjusted, and a purpose of reducing a cogging torque of the motor is achieved, and higher harmonic during motor operation is reduced according to regular hierarchic air gap thickness variation. According to the motor, quadrature-axis inductance of the motor is increased in a mode of adopting the air gap thickness of the specific interpolar face and keeping the preset widths of the interpolar faces, so that a reluctance torque of the motor is increased, and torsion of the motor is increased.

Owner:ADLEE POWERTRONIC

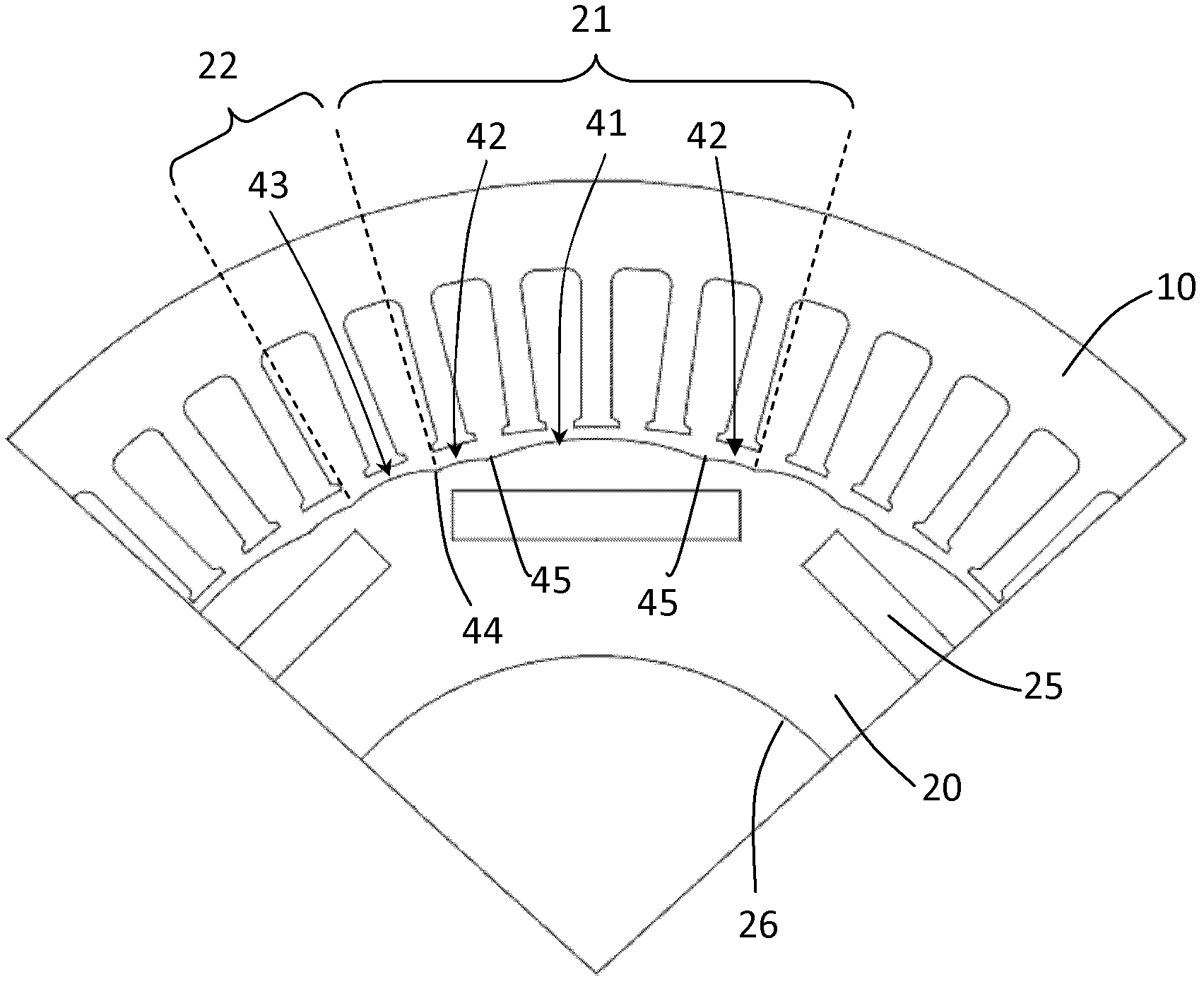

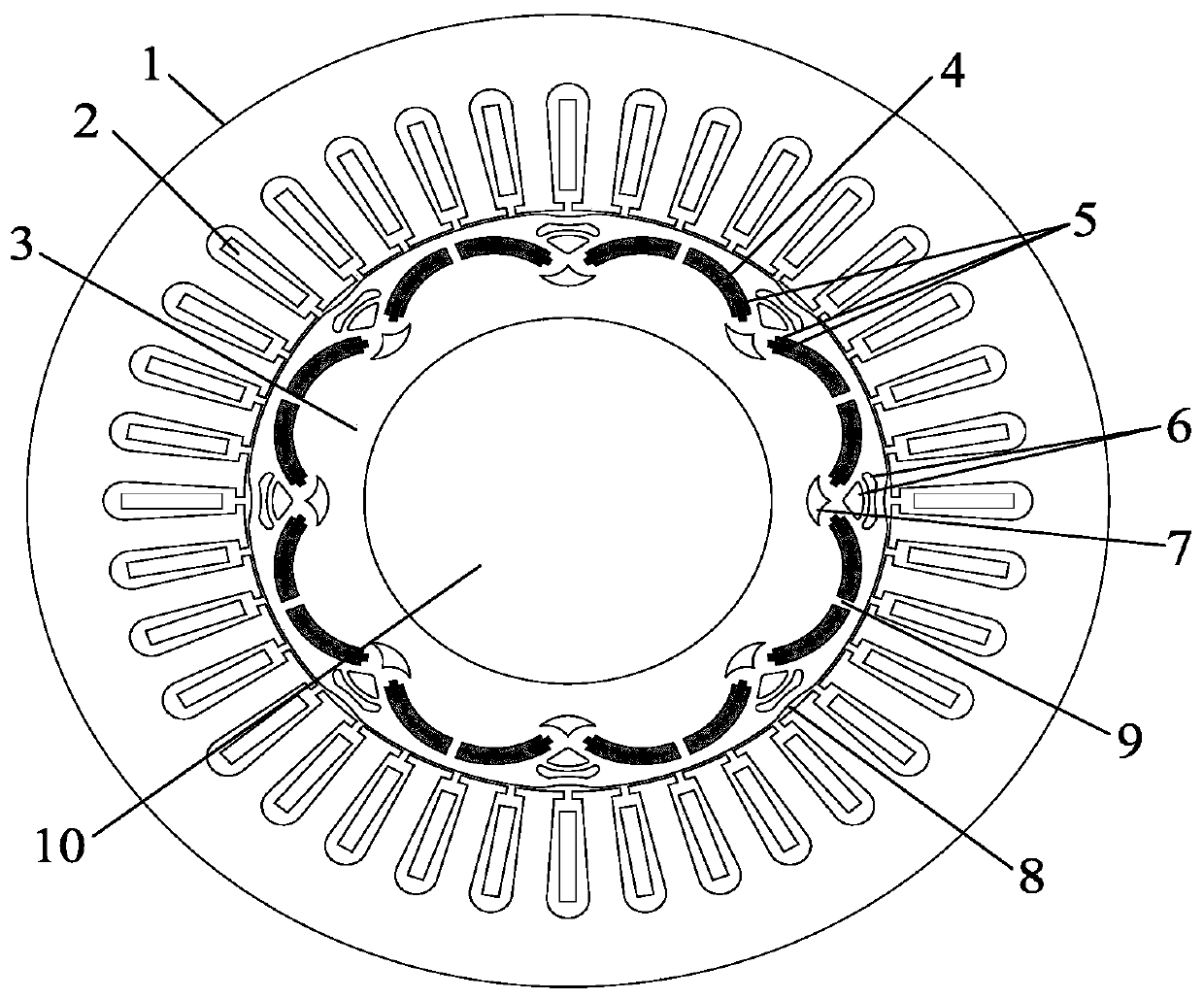

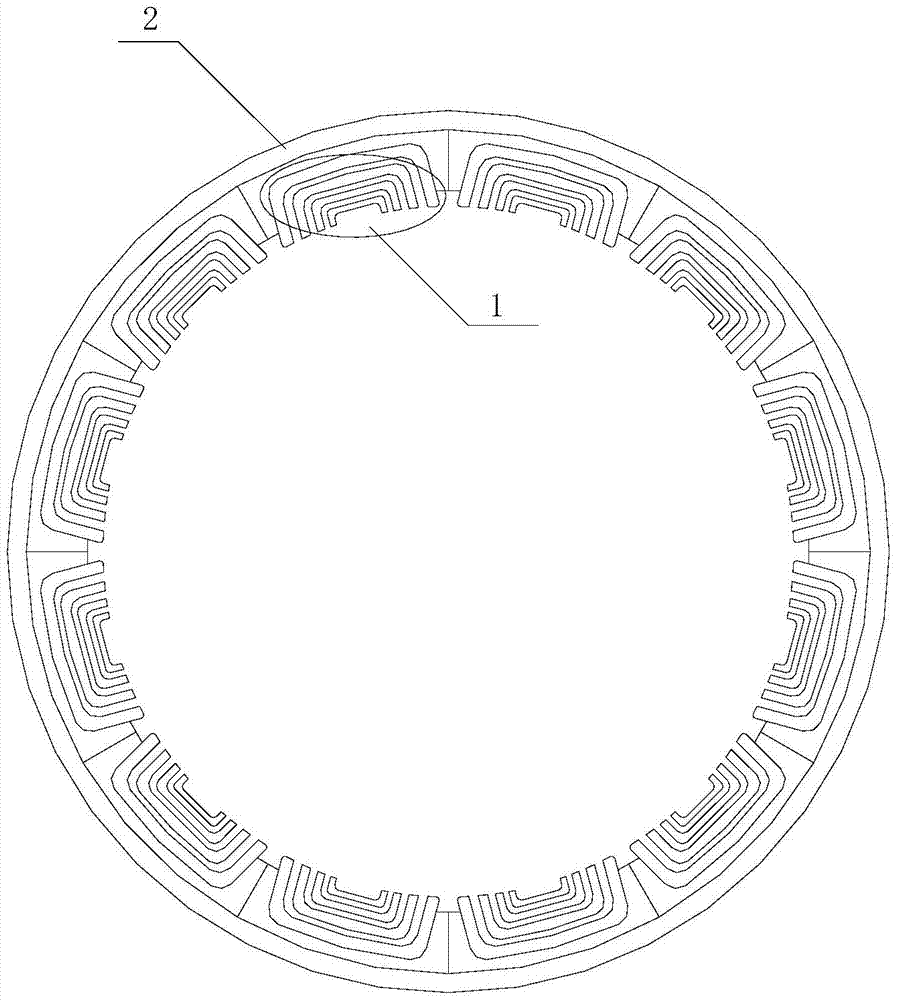

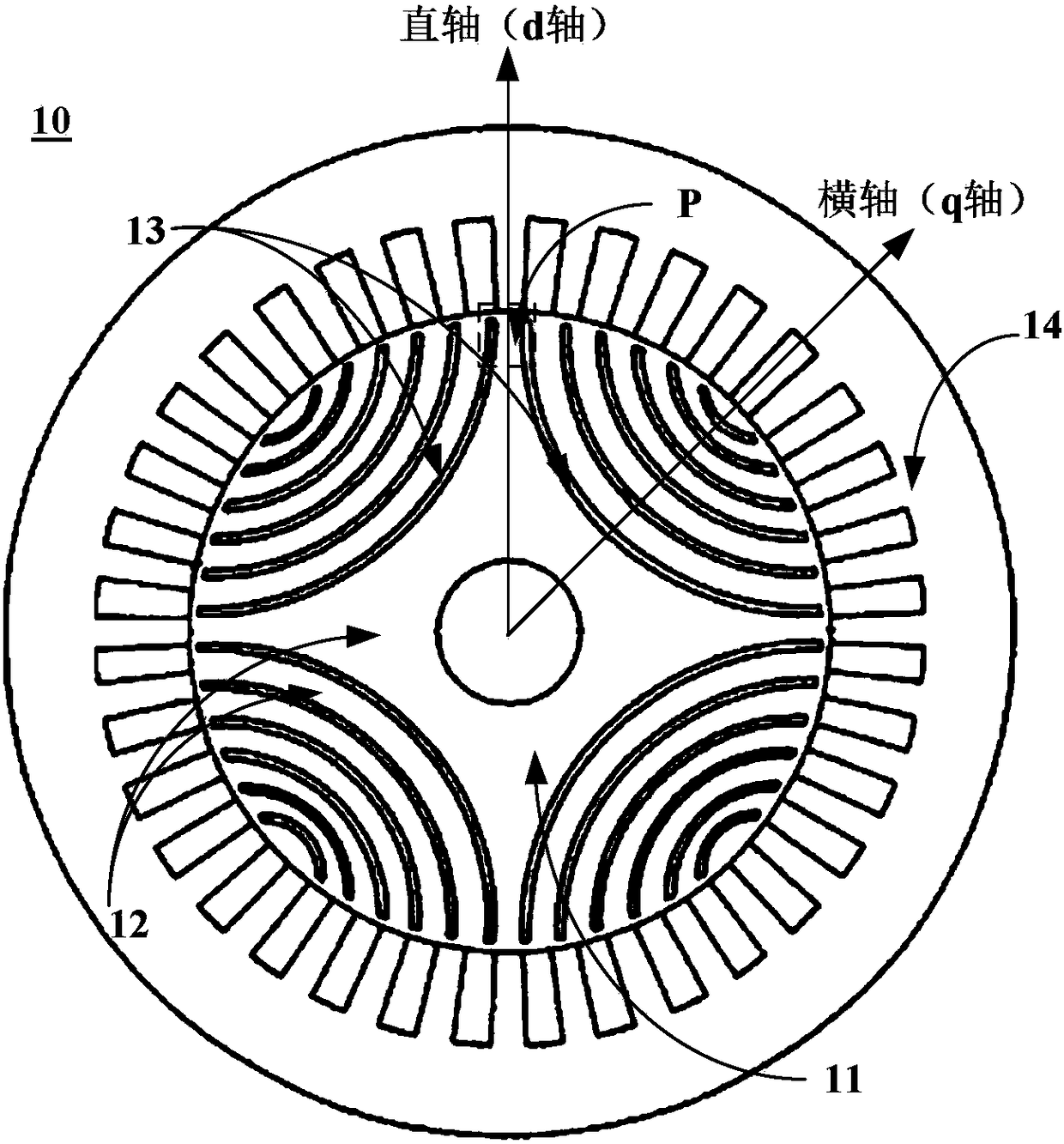

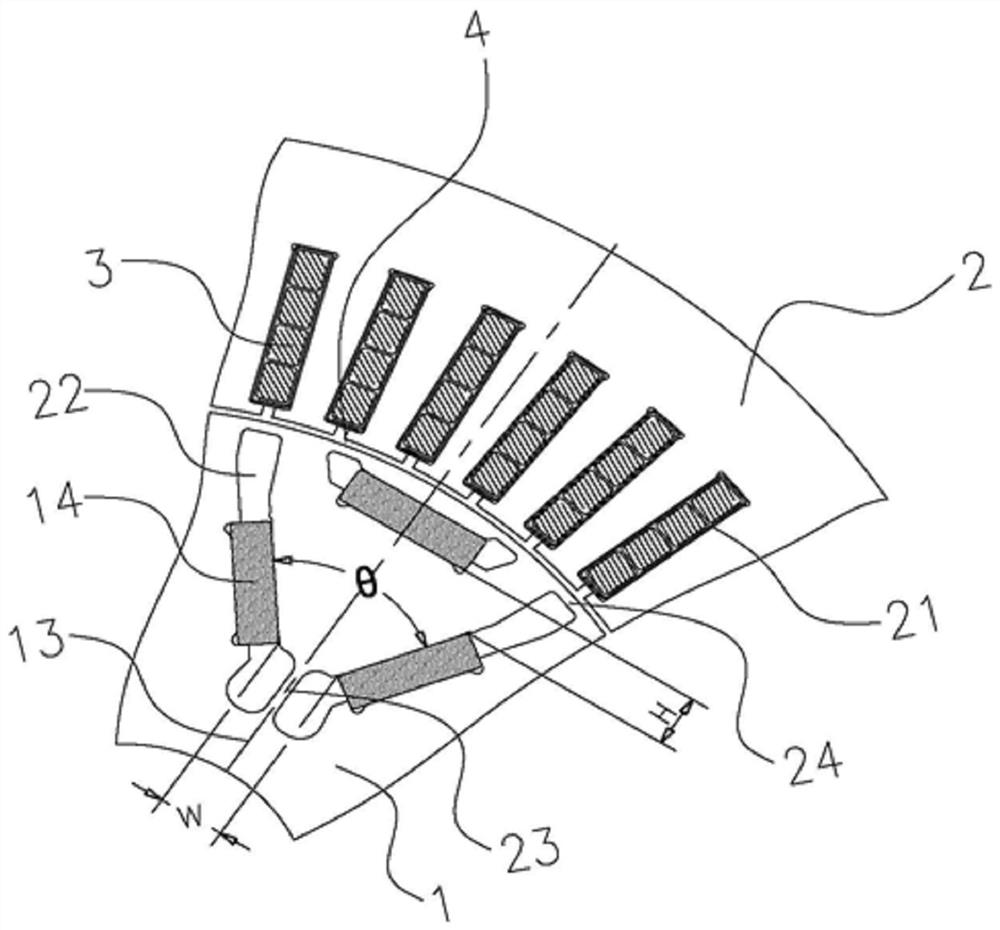

Fractional-slot concentrated winding permanent magnet synchronous motor and design method thereof for improving reluctance torque

InactiveCN108199509ALow failure rateReduce temperature riseMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorMetallic materials

The invention discloses fractional-slot concentrated winding permanent magnet synchronous motor and a design method thereof for improving reluctance torque. The fractional-slot concentrated winding permanent magnet synchronous motor comprises a stator and a rotor, wherein the stator is slotted along the peripheral direction to form fault-tolerant teeth and armature teeth arranged alternately; an armature winding is wound on the armature teeth, the fault-tolerant teeth and the armature teeth are different in widths, and the widths of the armature teeth are wider than those of the fault-tolerantteeth; the rotor consists of a permanent magnet, a rotor core and a magnetic obstacle, the permanent magnet is a double-layer permanent magnet, the rotor core is composed of a plurality of independent units, and during machining, the rotor is wrapped with a non-metal material to form a compact structure. The rotor core is segmented along the axis pole direction of the permanent magnet, and the width of the upper part of the magnetic obstacle during segmentation is narrower than that of the lower part. The permanent magnet synchronous motor has the advantages that the direct-axis inductance can be reduced through the special magnetic obstacle design, the influence on quadrature axis inductance can also be reduced as much as possible, and the subharmonic of the motor is free of obvious inhibition. Therefore, the reluctance torque of the motor can be improved effectively, and the iron loss and eddy-current loss of the motor are reduced.

Owner:JIANGSU UNIV

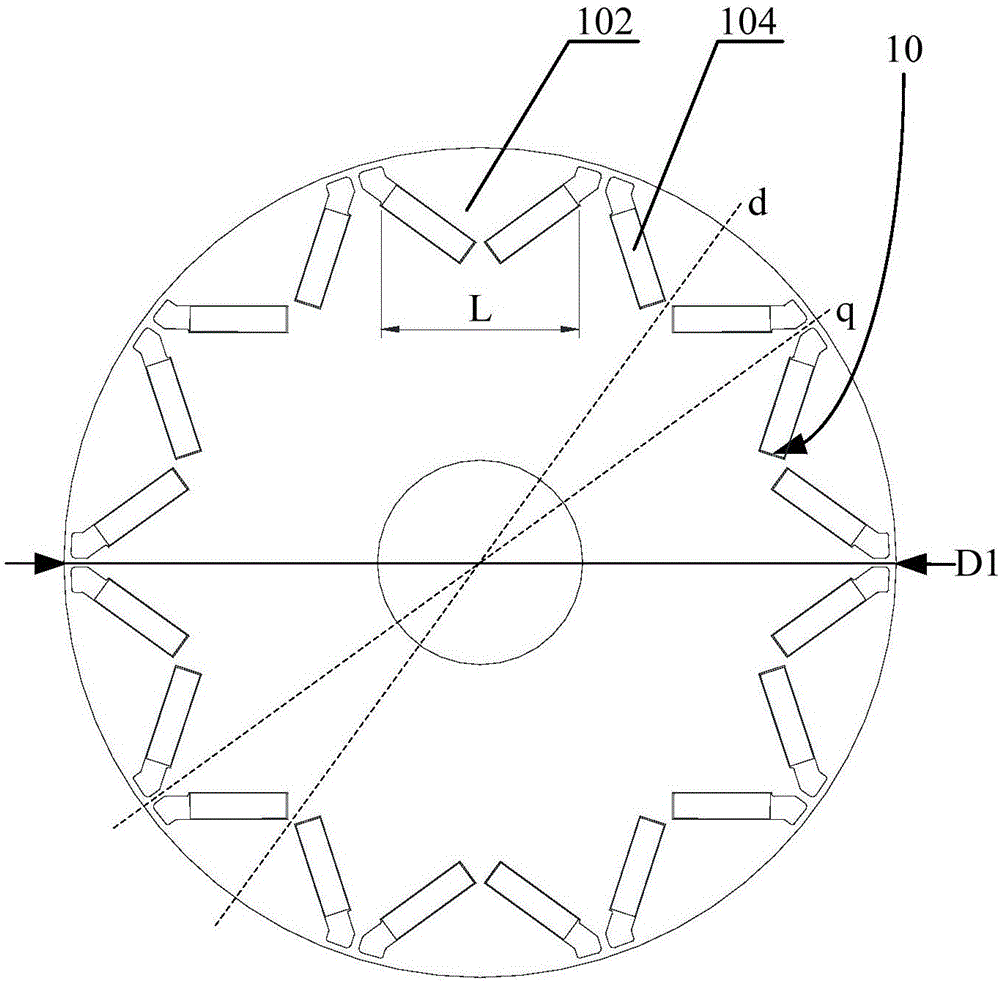

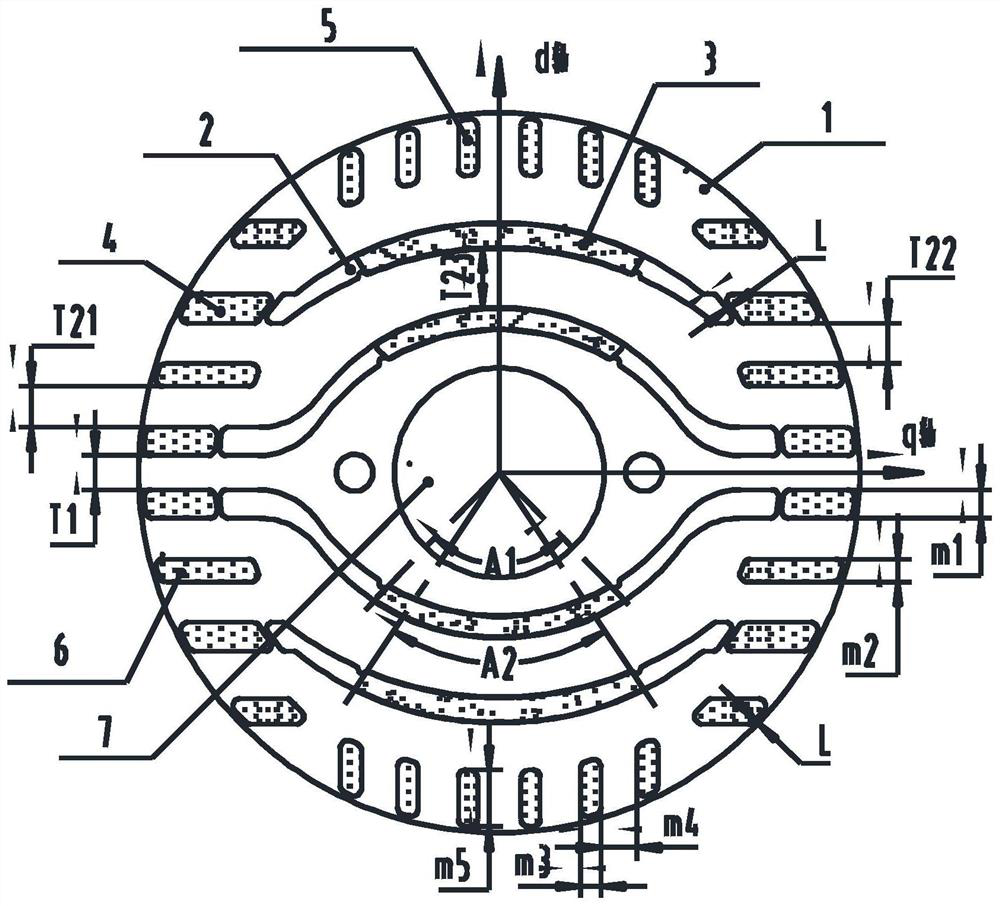

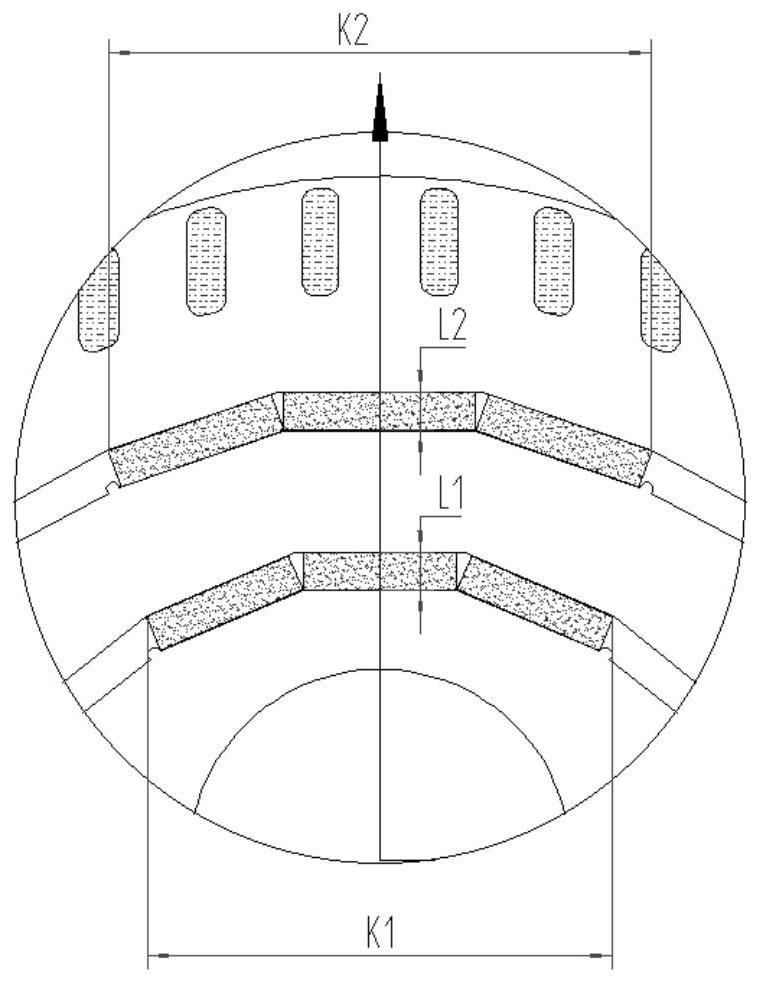

Motor rotor, permanent magnet motor and compressor

ActiveCN107528400AReduce volumeImprove power densityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsHigh power densityPhysics

The invention provides a motor rotor, a permanent magnet motor and a compressor. The motor rotor comprises a rotor iron core of which the end surface is provided with multiple sets of accommodating slots along the circumferential direction of the rotor iron core; and multiple permanent magnets which are correspondingly embedded in multiple sets of accommodating slots, and the permanent magnets in all sets of accommodating slots form magnetic poles, wherein the number of the magnetic poles is greater than or equal to eight and less than or equal to twelve, the distance between the two ends of the magnetic poles is L, the peripheral diameter of the rotor iron core is D1, and 0.18xD1<=L<=0.28xD1. With application of the technical scheme, the higher power density can be realized by limiting the dimension relationship between the peripheral diameter of the rotor iron core and the distance of the two ends of the magnetic poles with cooperation of increasing of the number of the magnetic poles; besides, the dimension of the motor rotor can be reduced by limiting the number of the magnetic poles so as to realize miniaturization of the motor.

Owner:GUANGDONG MEIZHI COMPRESSOR

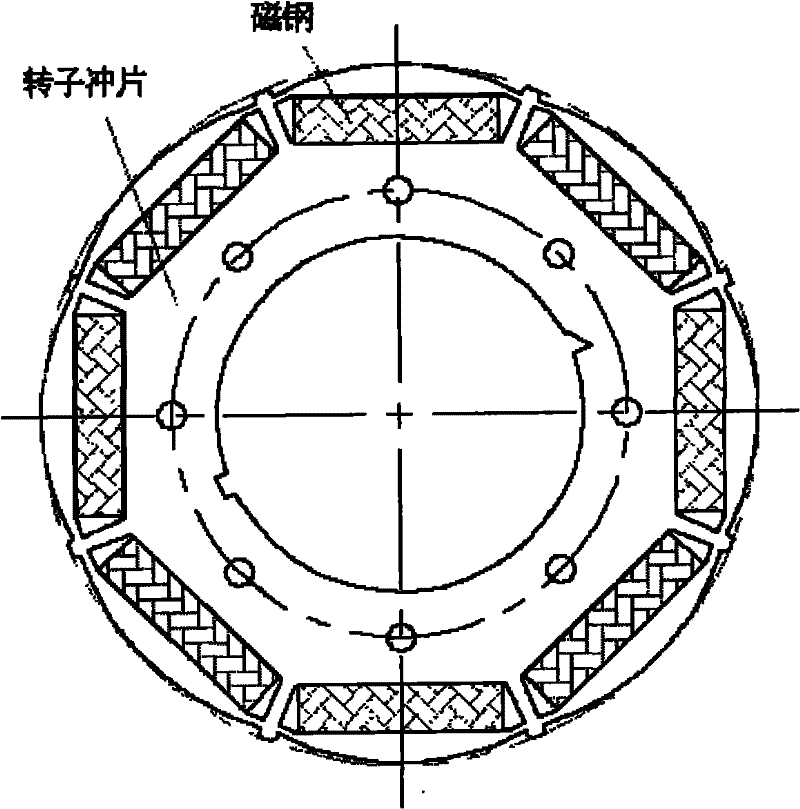

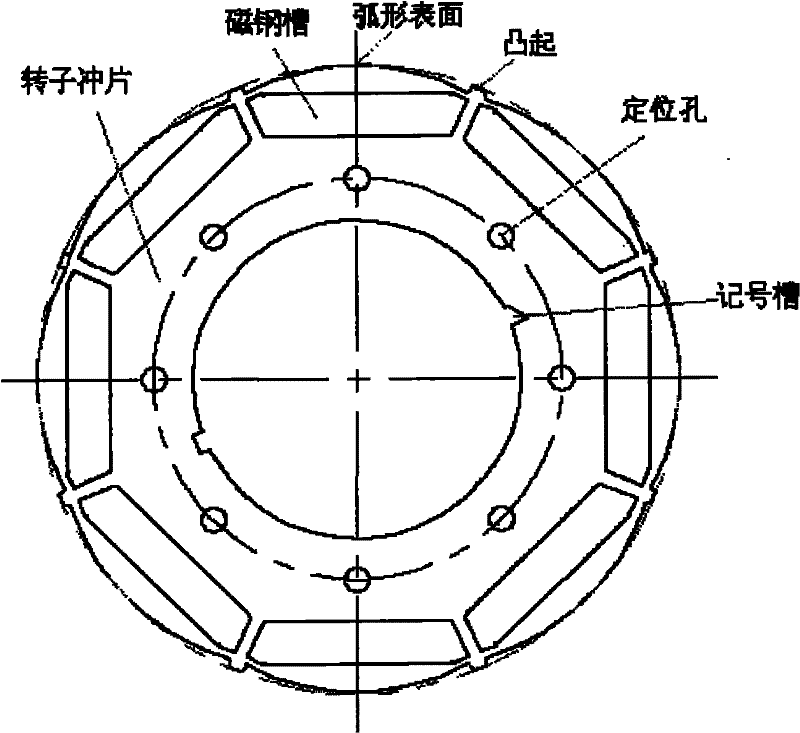

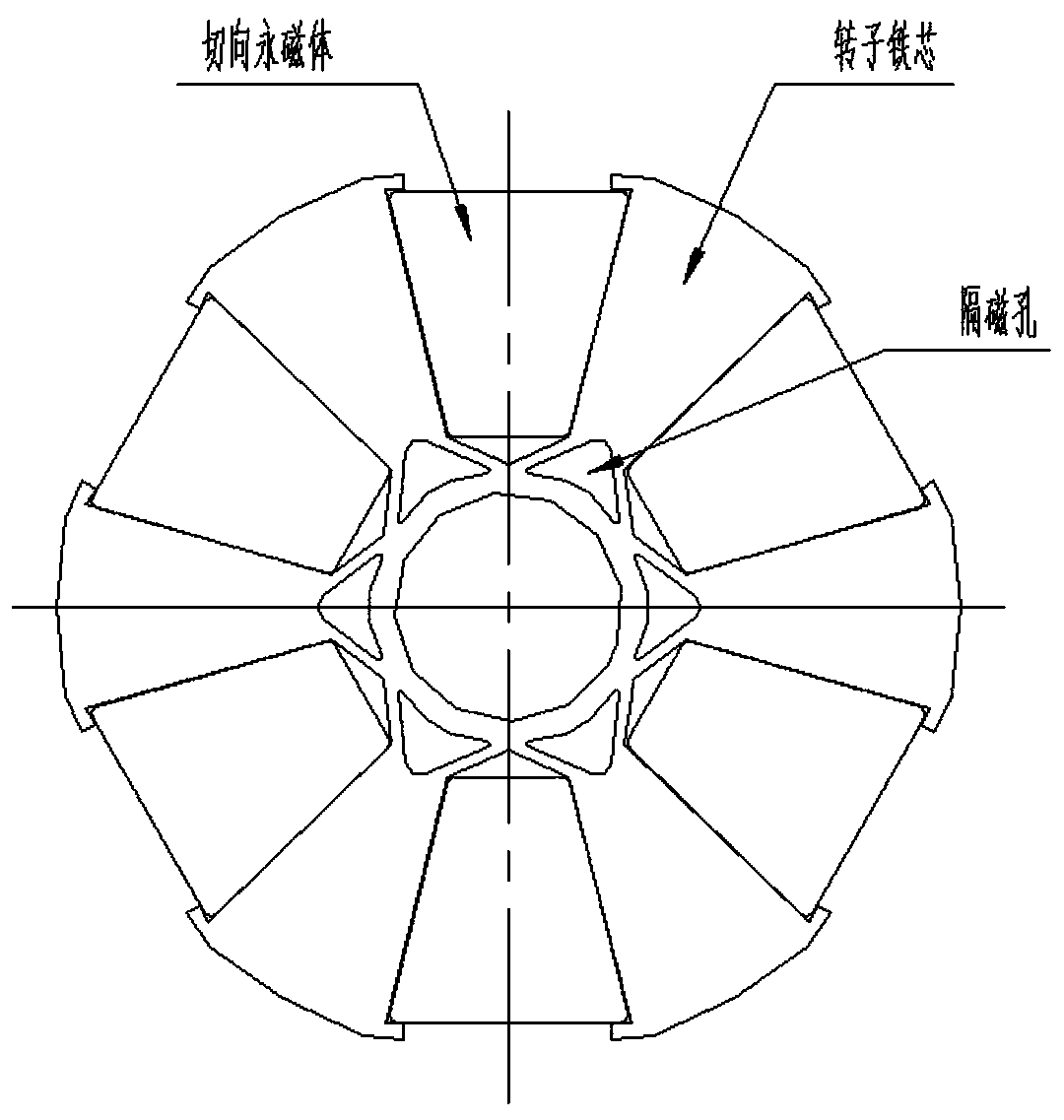

Novel rotor lamination structure

InactiveCN102214962AEasy to generate back EMFHigh mechanical strengthMagnetic circuit rotating partsEngineeringCounter-electromotive force

The invention relates to a novel rotor lamination structure which has the advantages of a surface type rotor magnetic path structure and a built-in type rotor magnetic path structure. The outer surface of the rotor lamination structure has eight uniformly distributed cambered surface structures; corresponding positions on the middle parts of magnetic steel slots are the highest points of cambered surfaces; and eight bulges are uniformly distributed at positions corresponding to gaps in the middle of every two adjacent magnetic steel slots. The novel rotor lamination structure can easily produce a back electromotive force with sine waveform, has high mechanical strength and a larger saliency ratio and is convenient for flux weakening speed expansion.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

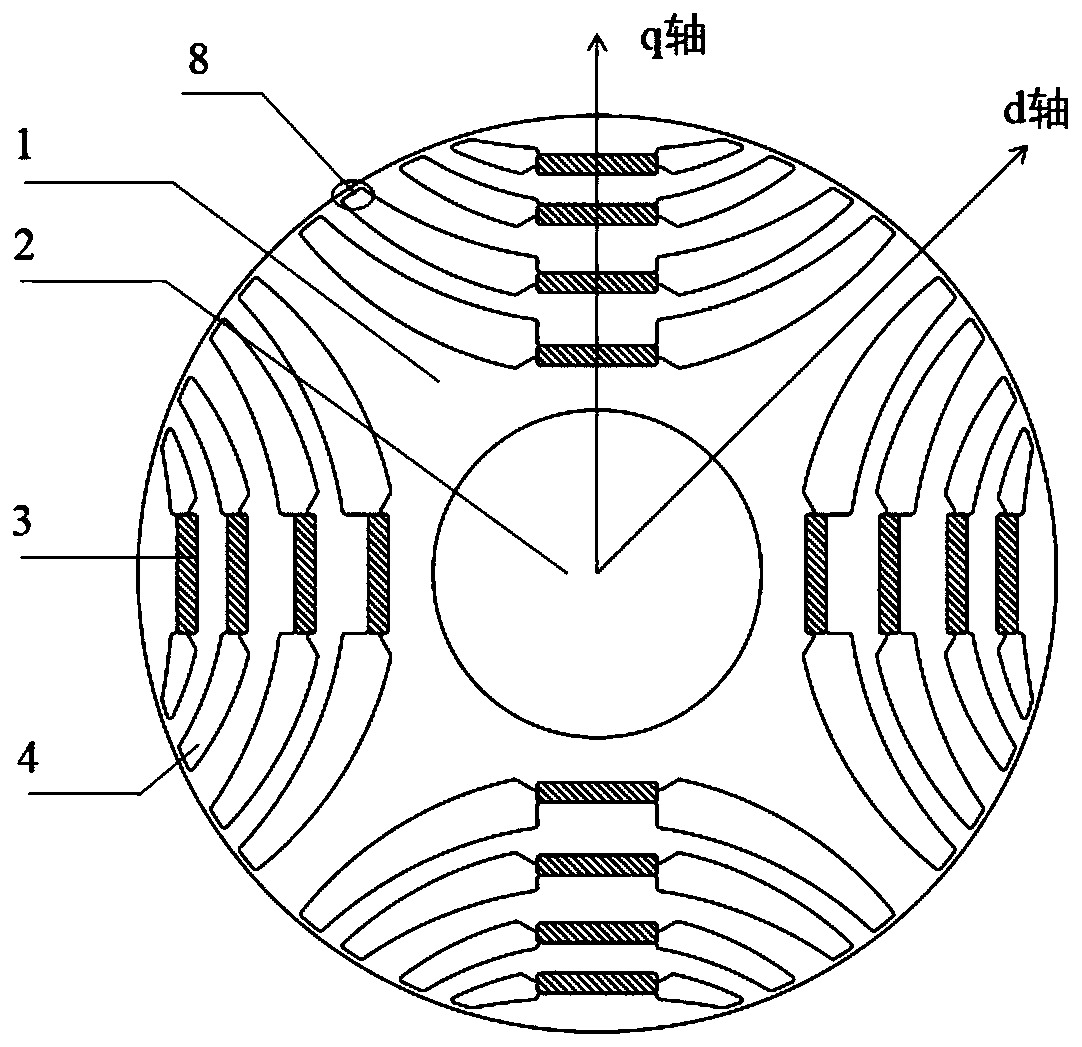

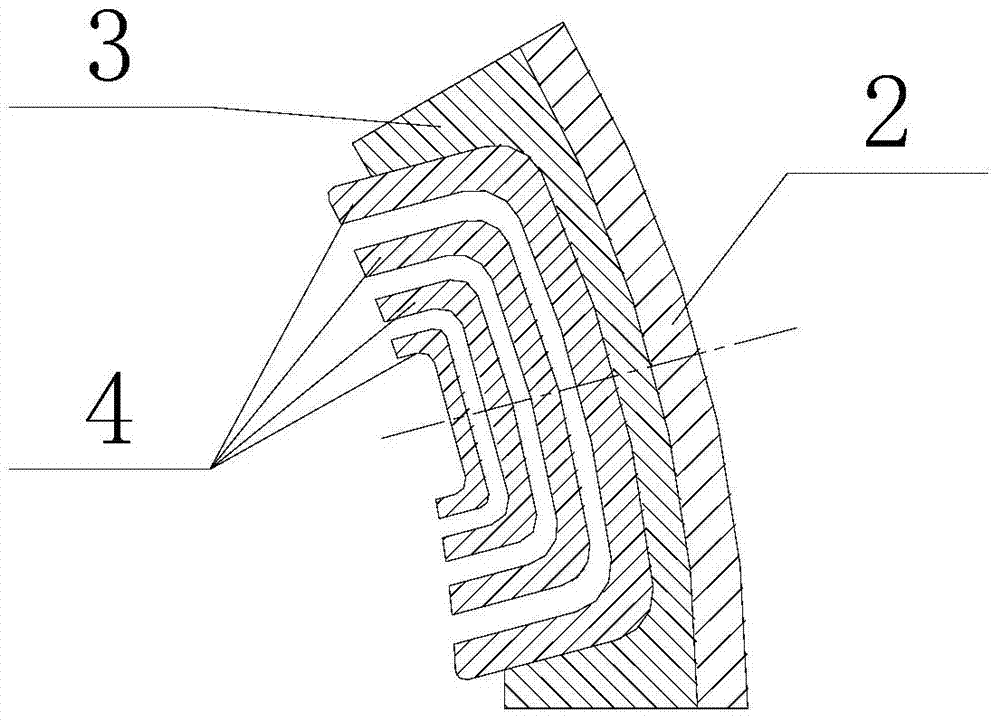

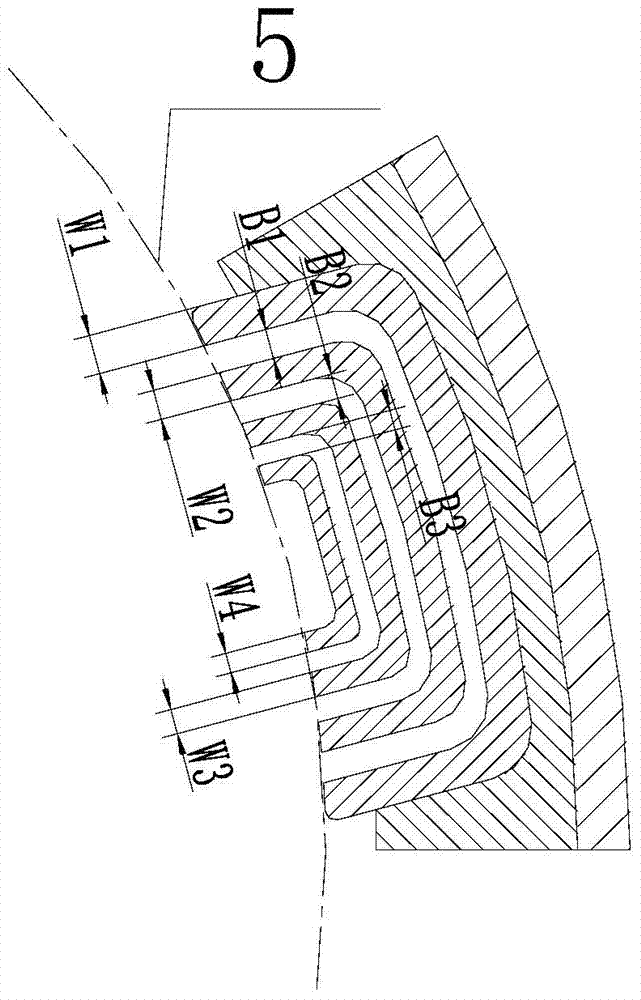

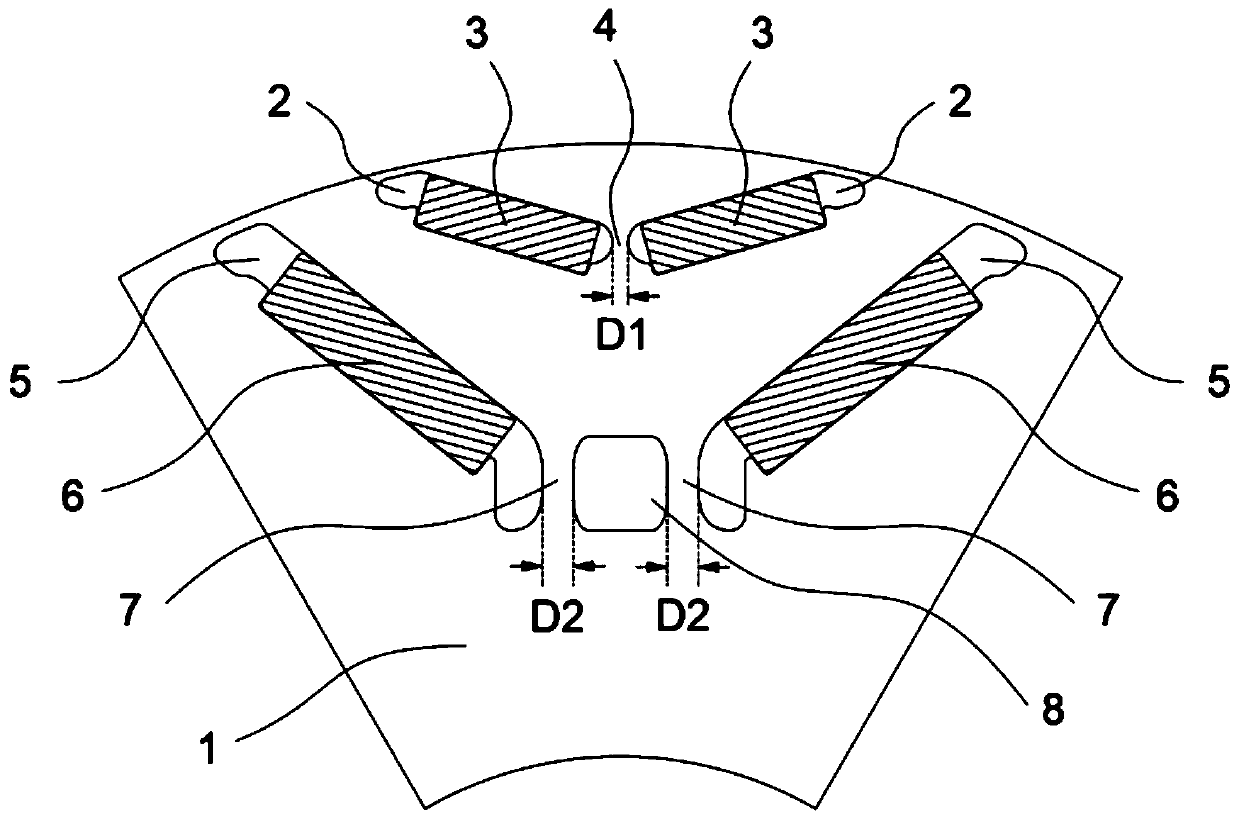

Rotor structure, permanent magnet auxiliary synchronous reluctance motor and electric vehicle

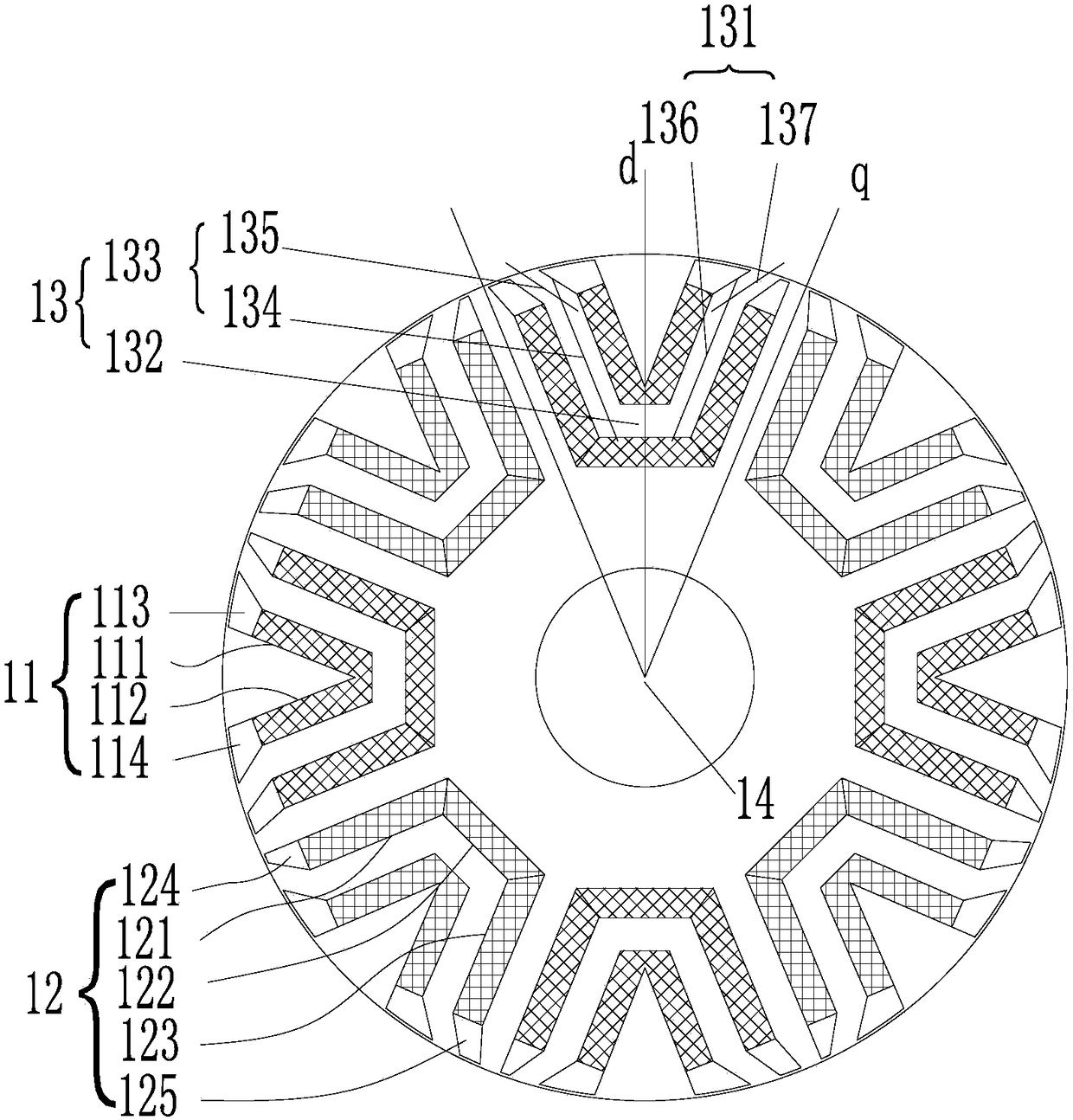

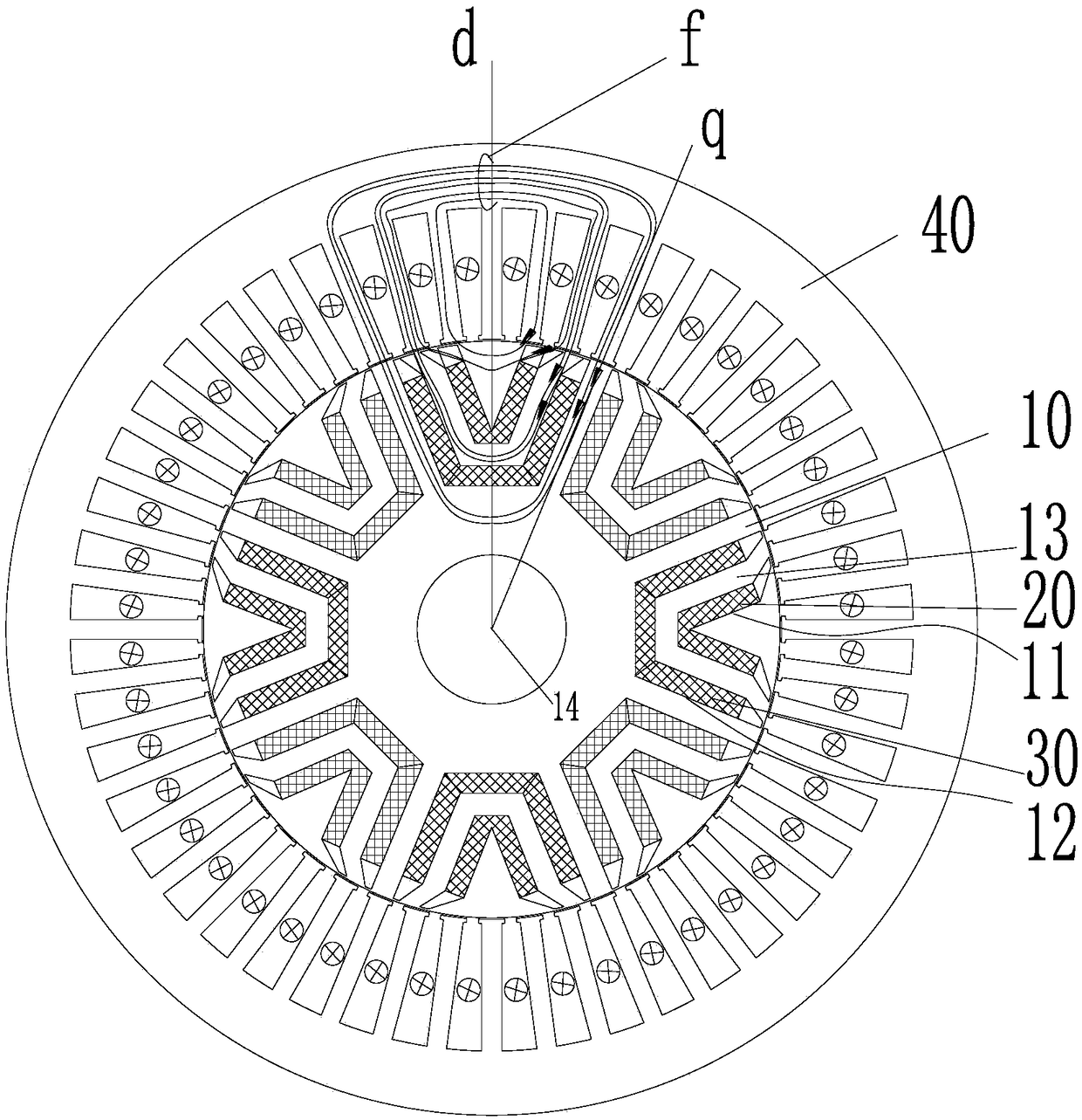

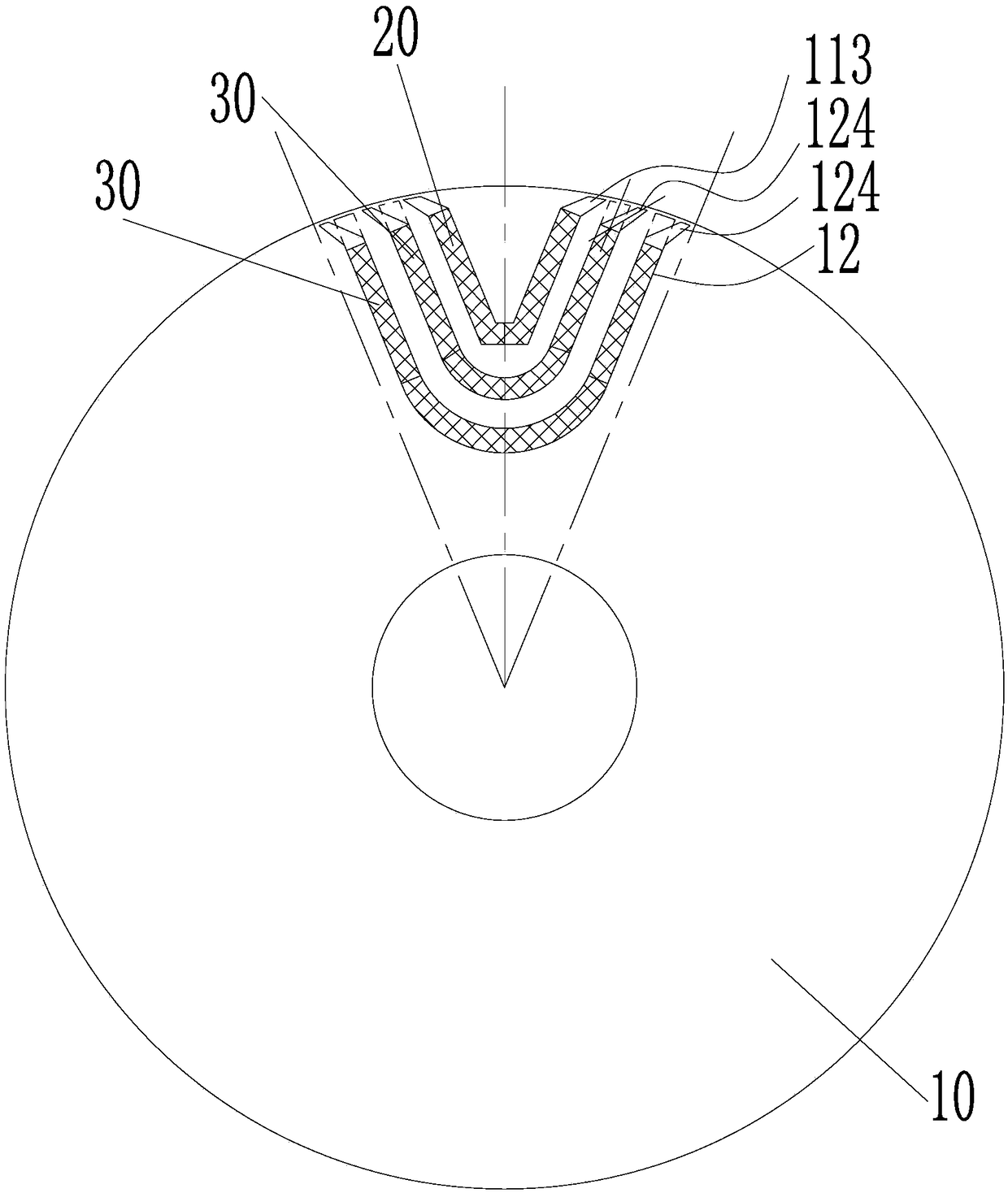

InactiveCN108566006AOptimized magnetic circuitIncrease reluctance torqueMagnetic circuit rotating partsElectric machinesSynchronous reluctance motorElectric machine

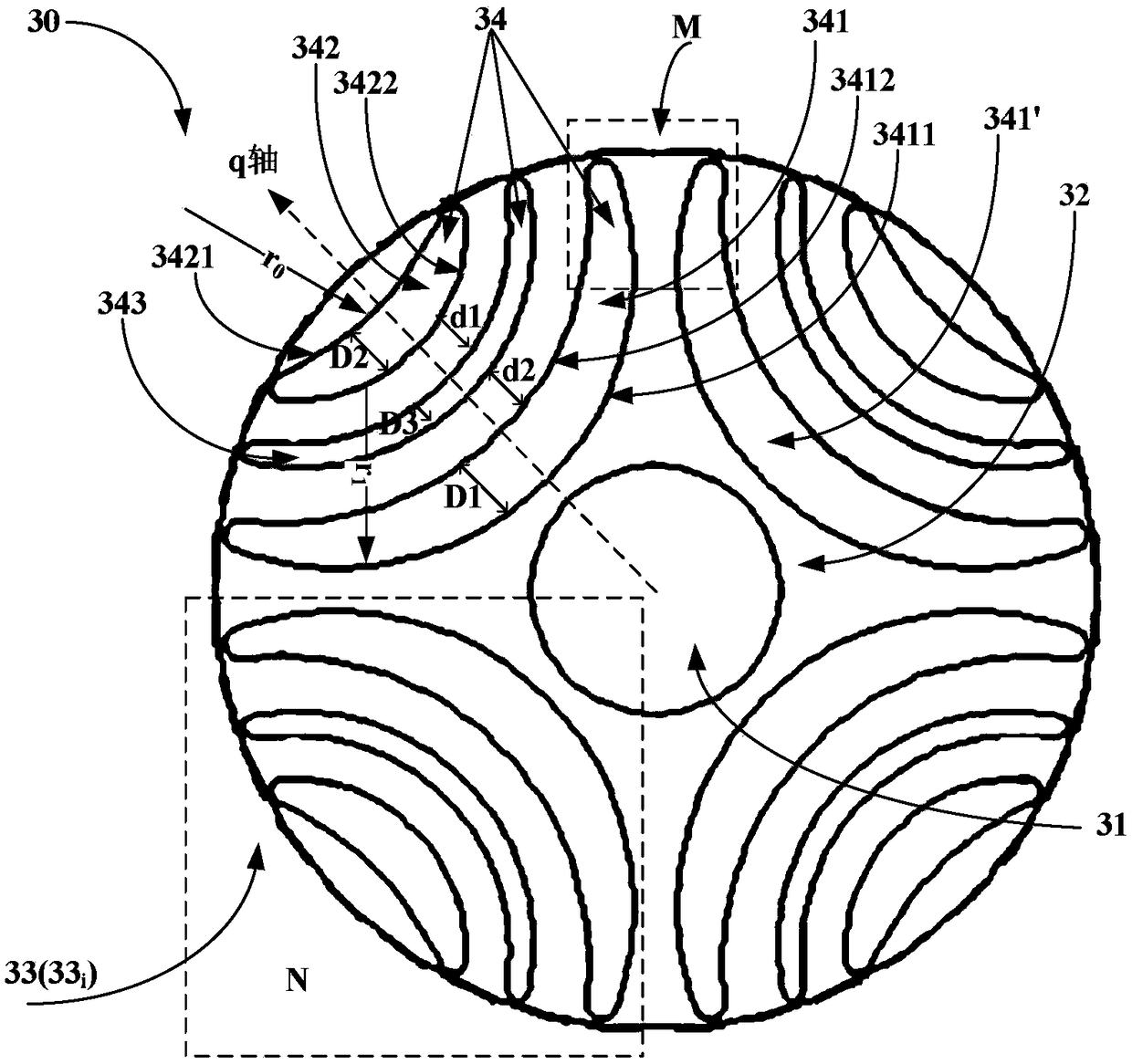

The present invention provides a rotor structure, a permanent magnet auxiliary synchronous reluctance motor and an electric vehicle. The rotor structure comprises a rotor body, the rotor body is provided with a permanent magnet slot group, the permanent magnet slot group comprises an outer layer of permanent magnet slot and an inner layer of permanent magnet slot, a magnetic conductive channel isformed between the adjacent outer layer of permanent magnet slot and inner layer of permanent magnet slot, at least one end of the magnetic conductive channel is provided with a deflection section, and a distance from the deflection section to a quadrature axis of the rotor body is gradually reduced outwards in a radial direction to allow the tail end of the magnetic conductive channel to be arranged close to the quadrature axis. The at least one end of the magnetic conductive channel is provided with the deflection section and the distance from the deflection section to the quadrature axis ofthe rotor body is gradually reduced outwards in a radial direction to optimize the magnetic circuit of the rotor structure and improve the reluctance torque of the motor, the shape of the permanent magnet slot is further improved to allow the whole demagnetization-resistant capacity of the rotor permanent magnet to be improved, reduce the motor torque pulsation, reduce the vibration and noise ofthe motor and improve the demagnetization-resistant capacity of the motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

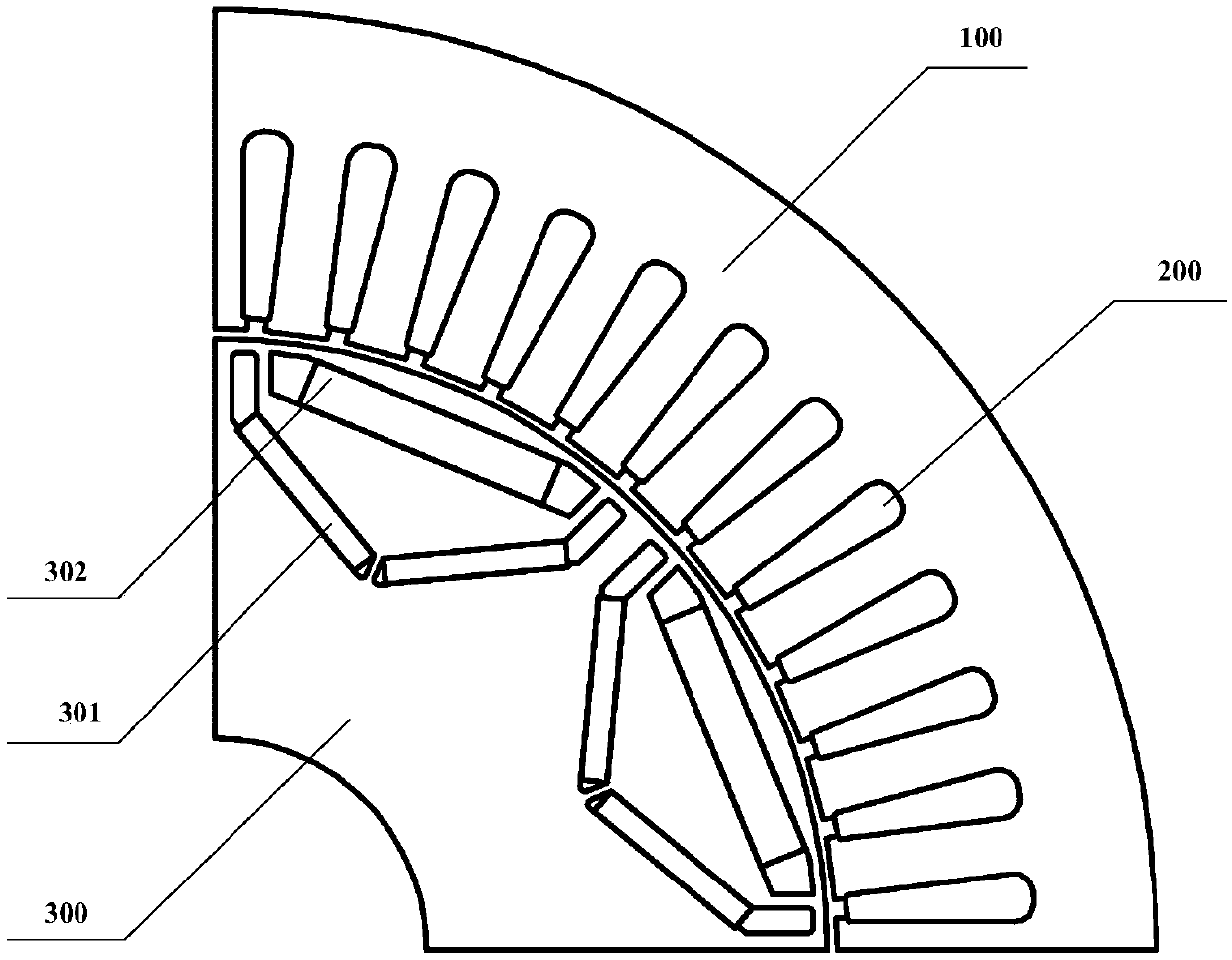

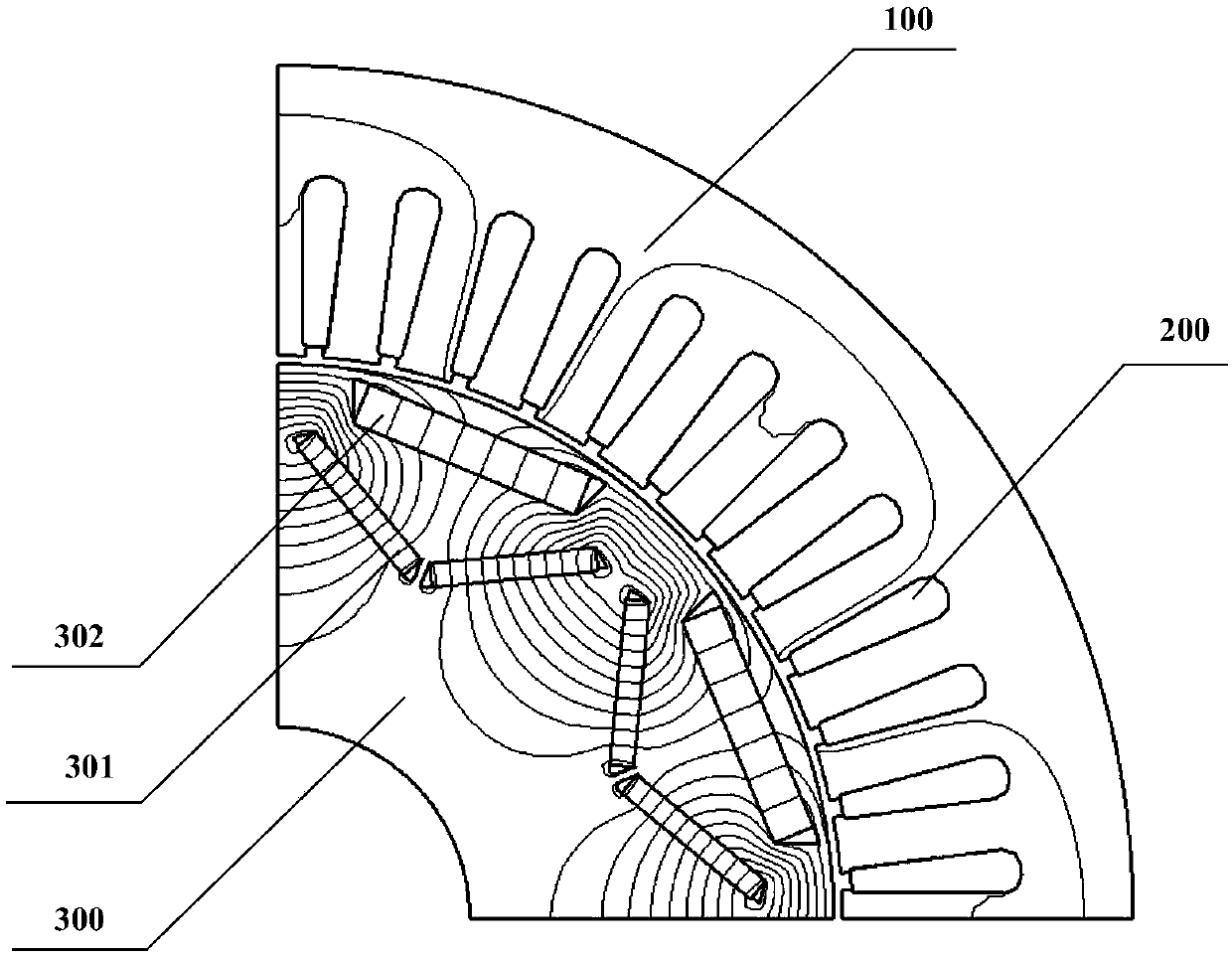

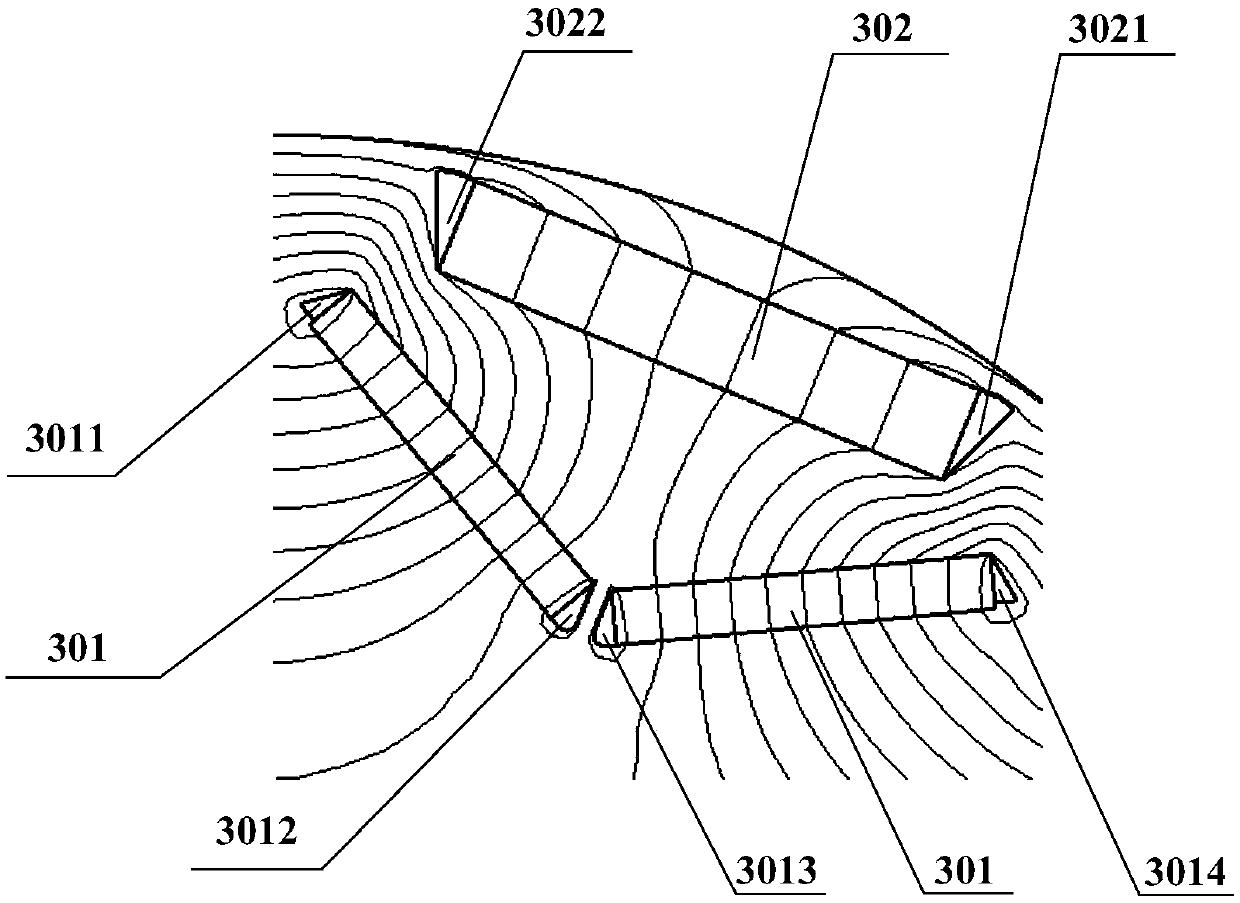

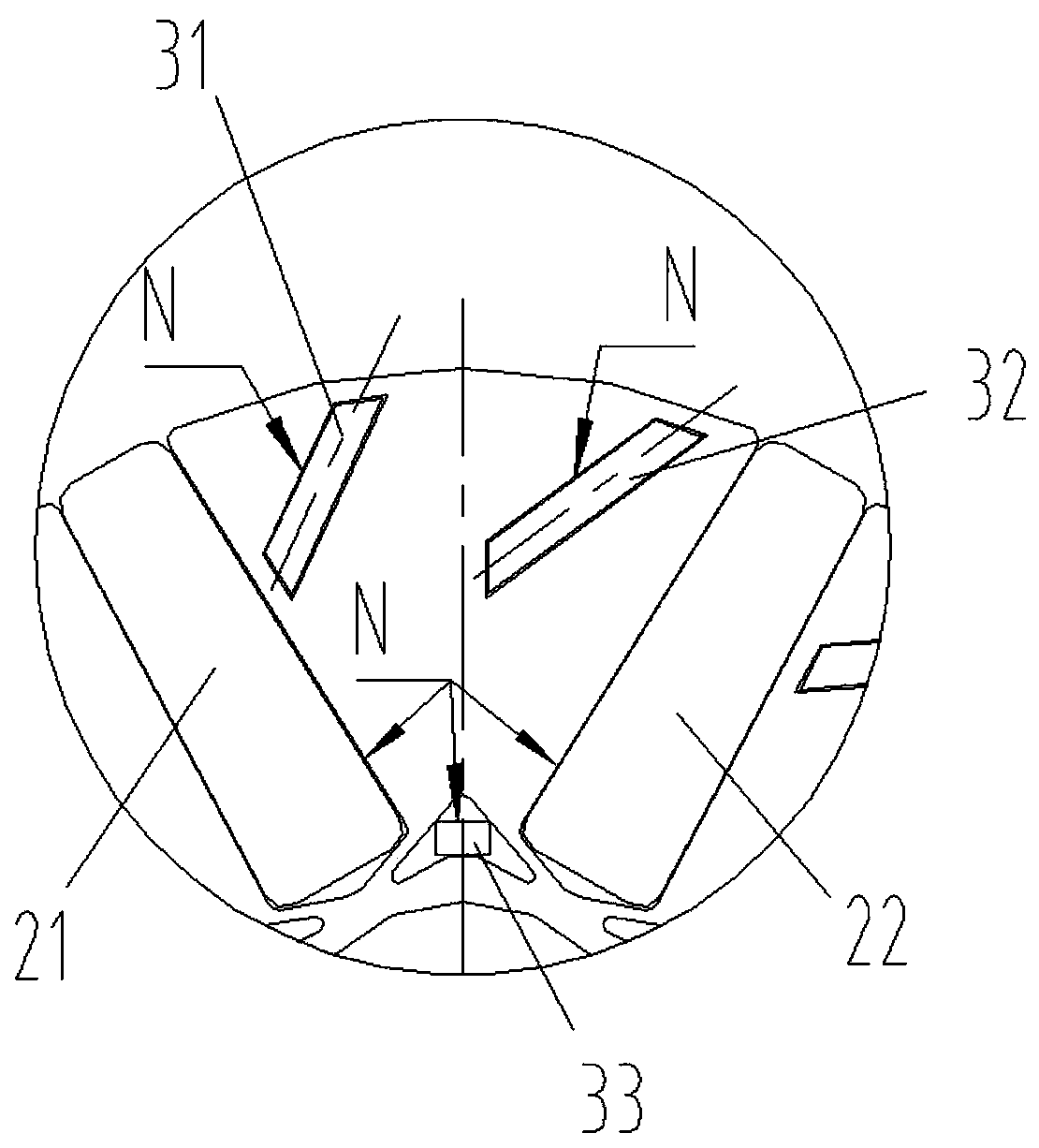

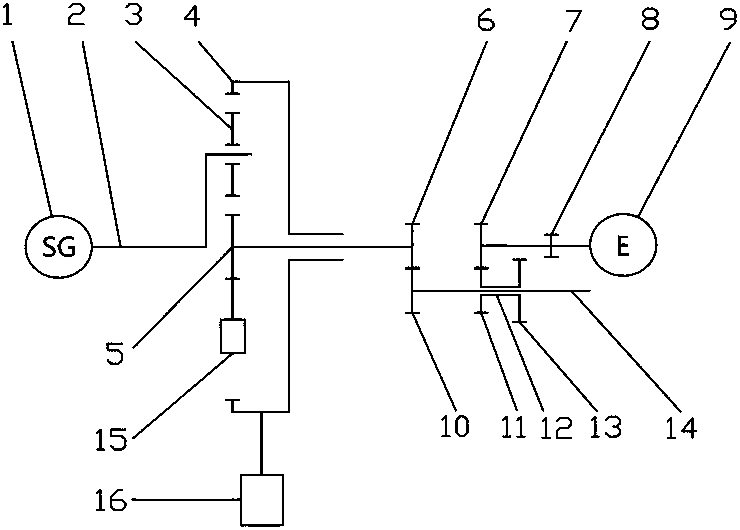

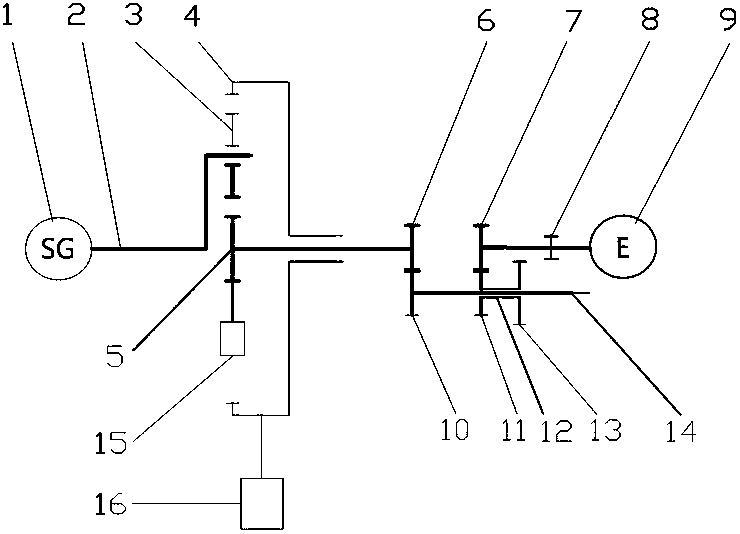

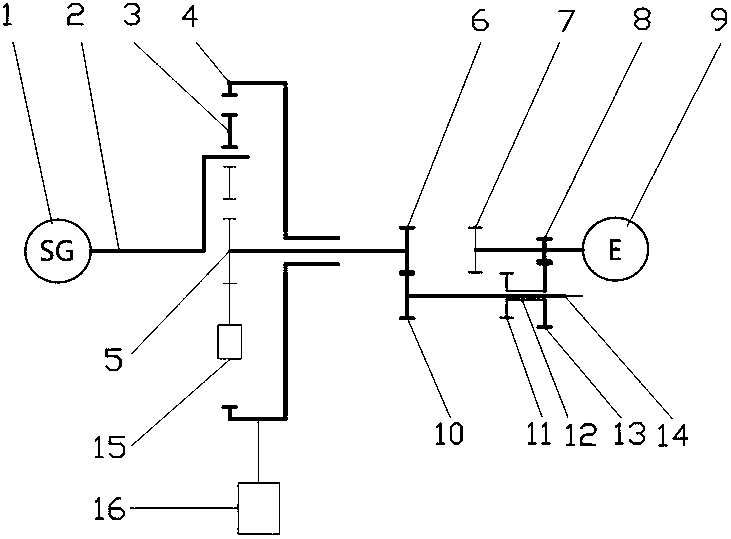

Series hybrid permanent magnet variable flux motor

ActiveCN109660042AIncrease the degree of magnetizationIncreased torque output capabilityMagnetic circuit rotating partsPhysicsStator

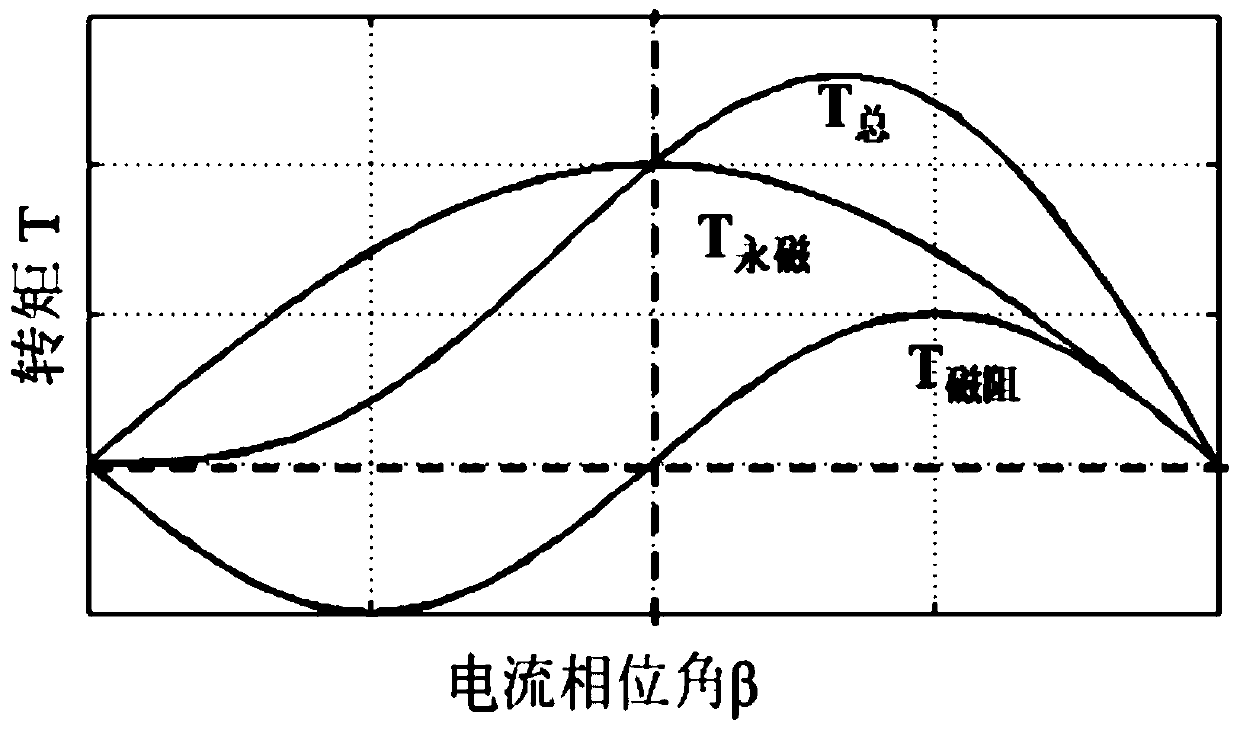

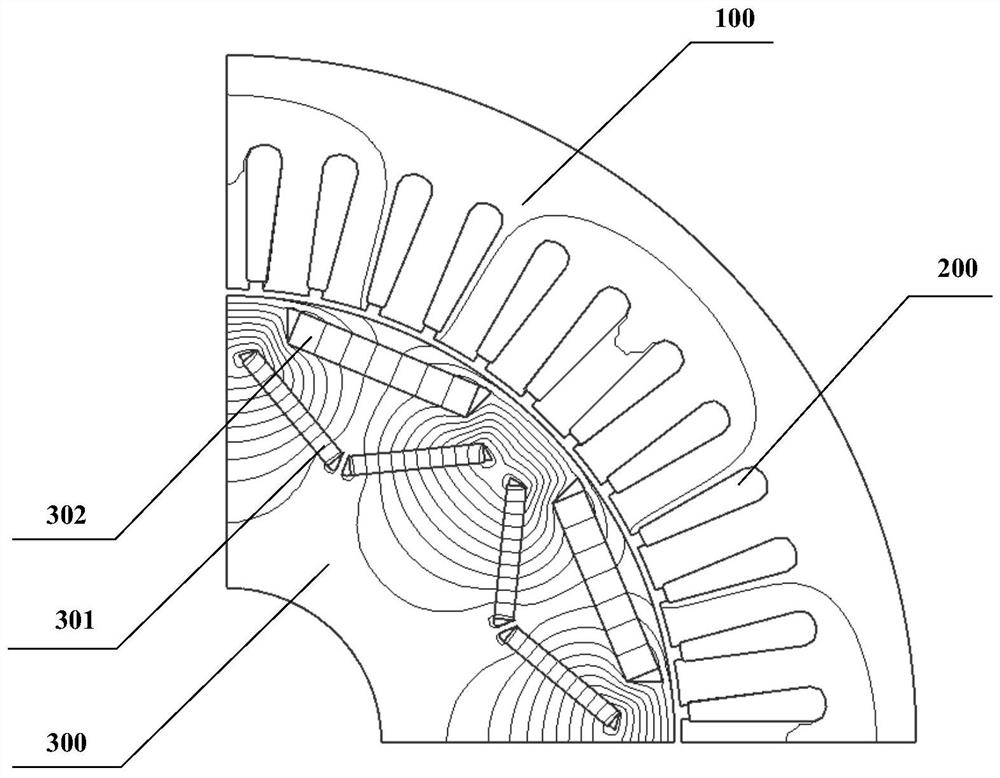

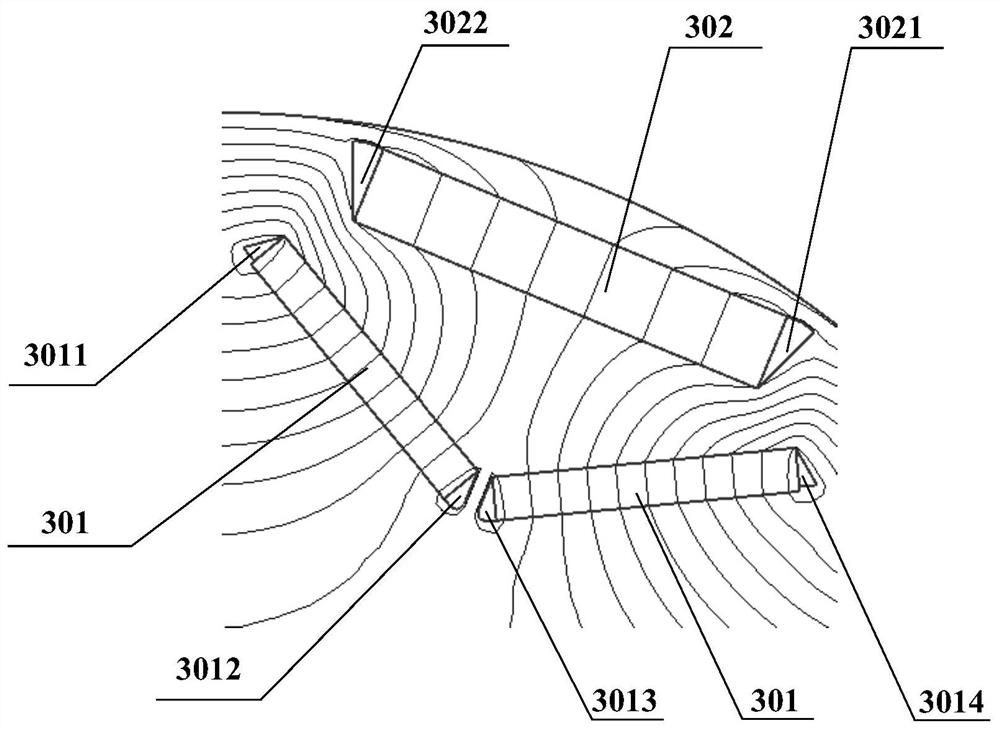

The invention discloses a series hybrid permanent magnet variable flux motor. The series hybrid permanent magnet variable flux motor comprises a stator (100), an armature winding (200) wound on the stator (100), and a rotor core (300), wherein three permanent magnets which are not in direct contact and placed separately are arranged under each pole of the rotor core (300), the second permanent magnet (302) is placed on the outer sides in a linear shape, the two first permanent magnets (301) are placed on the inner side in a ''V'' shape, the second permanent magnet (302) is a high-coercivity permanent magnet or a low-coercivity permanent magnet, and the first permanent magnets (301) are high-coercivity permanent magnets or low-coercivity permanent magnets. According to the series hybrid permanent magnet variable flux motor, the low-coercivity permanent magnets and the high-coercivity permanent magnets adopt special placement positions and manners, such that the motor is of a magnetic circuit series structure, the high-coercivity permanent magnets are used for increasing magnetism of the low-coercivity permanent magnets, the working points and magnetization degrees of the low-coercivity permanent magnets are increased, the torque output capability is improved, and the magnetizing current of the motor is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

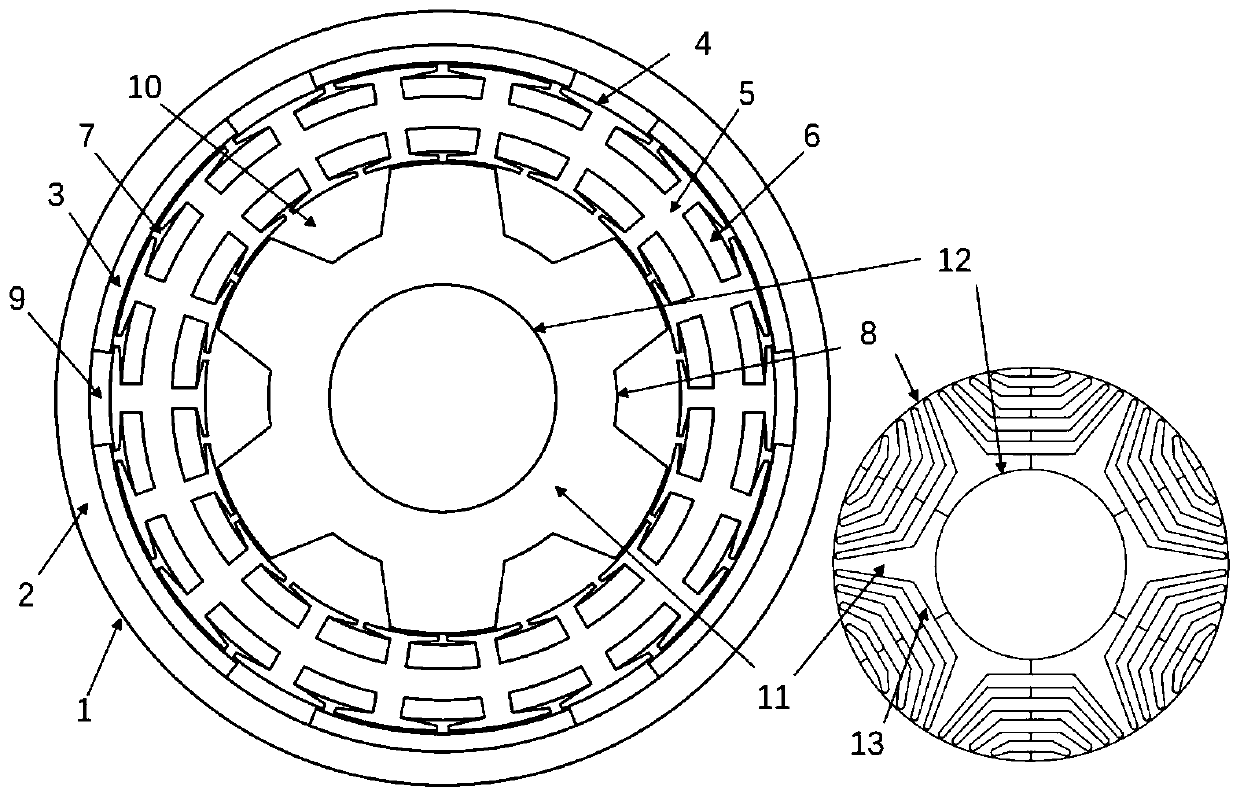

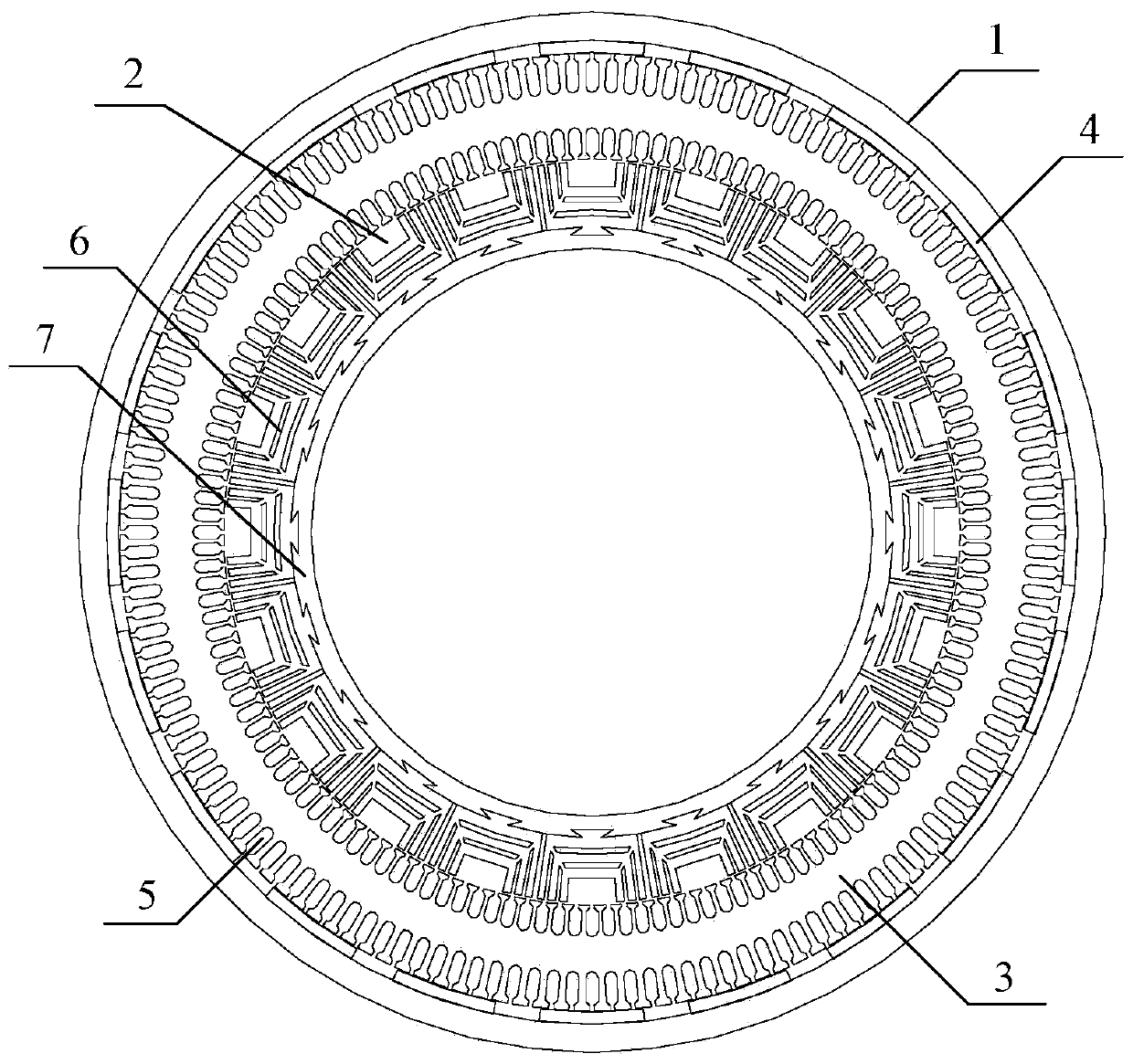

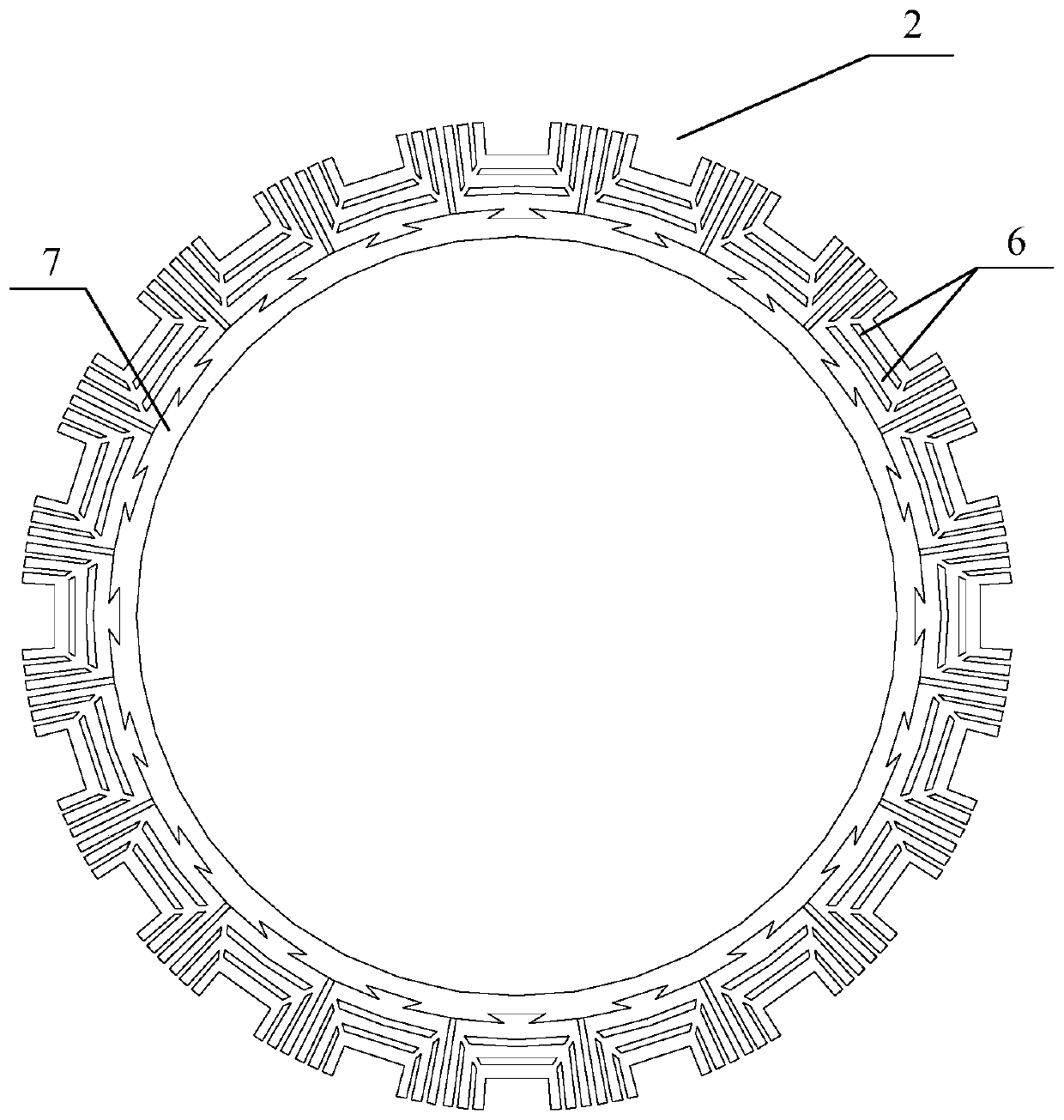

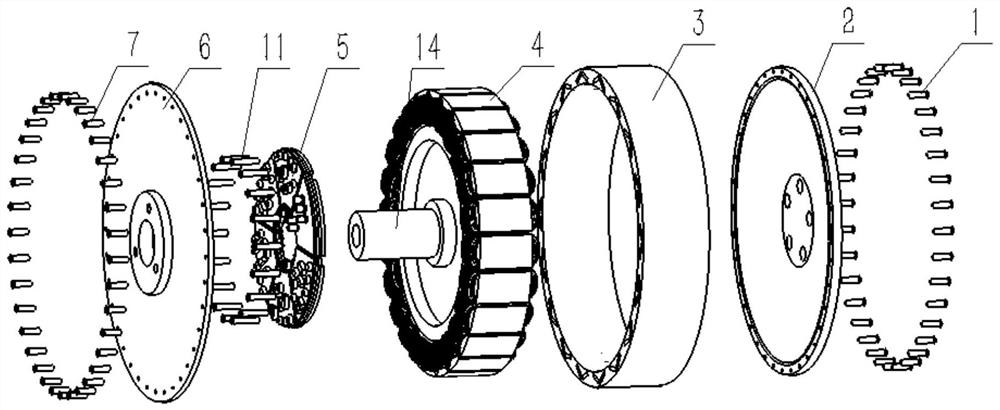

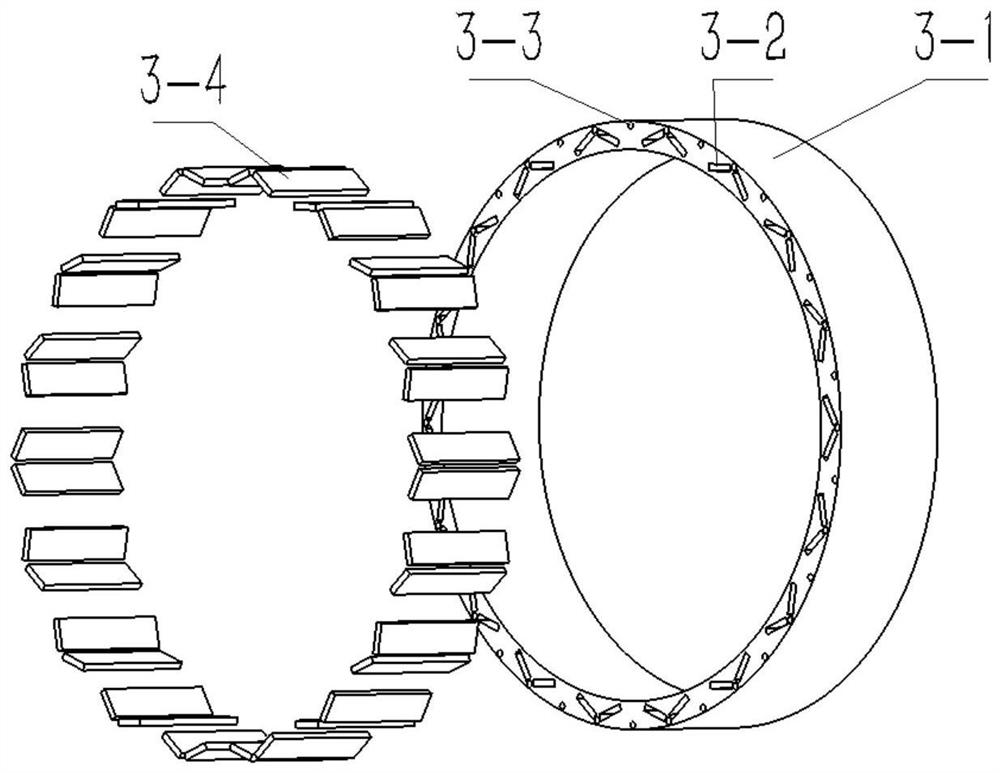

Birotor permanent magnet synchronous reluctance motor and configuration method

PendingCN110601481AIncreased torque densityHigh material utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorSynchronous reluctance motor

The invention discloses a birotor permanent magnet synchronous reluctance motor and a configuration method. A rotating shaft, a reluctance rotor, a stator and a permanent magnet rotor are sequentiallyarranged from inside to outside, wherein stator grooves are uniformly formed inside and outside the stator, the stator is arranged between the permanent magnet rotor and the reluctance rotor, a d axis is defined as a center line of ferrite of the permanent magnet rotor, a q axis is defined as a center line of a salient pole of the reluctance rotor, a mounting angle of the two rotors on the rotating shaft is defined as an included angle between the d axis and the q axis, a superposition mechanism of torque components is changed by adjusting the mounting angle between the permanent magnet rotorand the reluctance rotor, so the permanent magnet torque and the reluctance torque reach the maximum values at the same current phase angle. The motor is advantaged in that on the premise of not increasing mechanical manufacturing and cooling difficulty of the motor, the electromagnetic torque, the power density and the efficiency are comprehensively improved, the torque pulsation and other electromagnetic properties are inhibited, and the rotor is flexible in structural design, simple in machining process and high in mechanical strength.

Owner:SHANDONG UNIV

Quadrature-direct axis reluctance controllable permanent magnet brushless motor

ActiveCN110838780AHas initial magnetoresistive propertiesAdjust the main fluxSynchronous machine detailsMagnetic circuit rotating partsBrushless motorsMagnetic barrier

The invention discloses a quadrature-direct axis reluctance controllable permanent magnet brushless motor in the field of motor manufacturing. A stator core is arranged at the outermost part; eight groups of mixed permanent magnets are uniformly embedded in a rotor core along the circumferential direction; each group of mixed permanent magnets consists of two neodymium-iron-boron permanent magnetsand six aluminum-nickel-cobalt permanent magnets; three aluminum-nickel-cobalt permanent magnets are embedded in each neodymium-iron-boron permanent magnet; each group of mixed permanent magnets aresymmetrically arranged relative to the direct axis; a magnetic conductive bridge is formed between the two neodymium-iron-boron permanent magnets in each group of mixed permanent magnets; two adjacentgroups of mixed permanent magnets are symmetrically arranged relative to the quadrature axis; each neodymium-iron-boron permanent magnet and each aluminum-nickel-cobalt permanent magnet are of an arc-shaped structure; three aluminum-nickel-cobalt permanent magnets are embedded in one end, close to the quadrature axis, of each neodymium-iron-boron permanent magnet; one of the three aluminum-nickel-cobalt permanent magnet exists in each layer along the radial direction; and the rotor core between two adjacent groups of mixed permanent magnets is provided with multiple layers of inner and outermagnetic barriers which are symmetrically distributed relative to a quadrature axis, and variable permanent magnet torque is generated through the combined action of the two types of permanent magnets.

Owner:JIANGSU UNIV

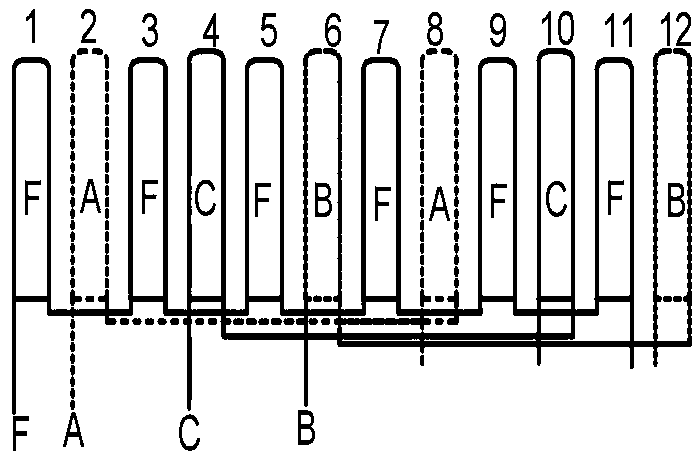

Design method of five-phase permanent magnet fault-tolerant motor with high reluctance torque and high salient pole rate

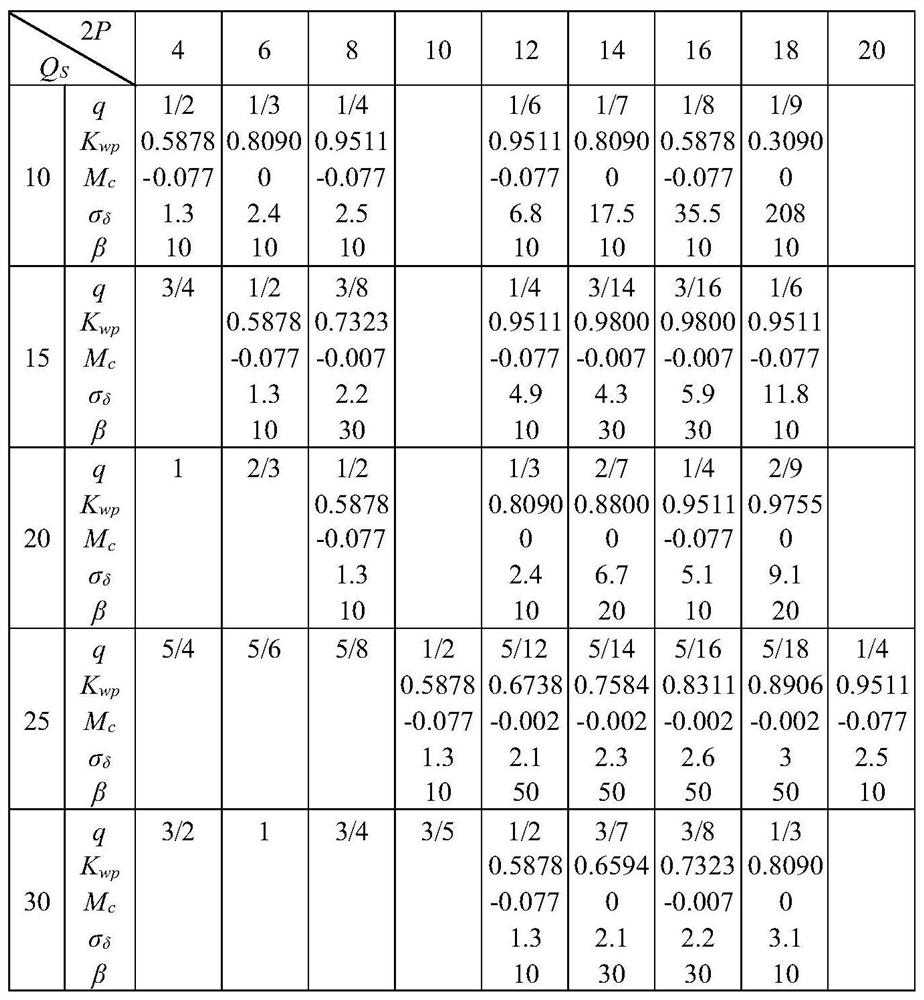

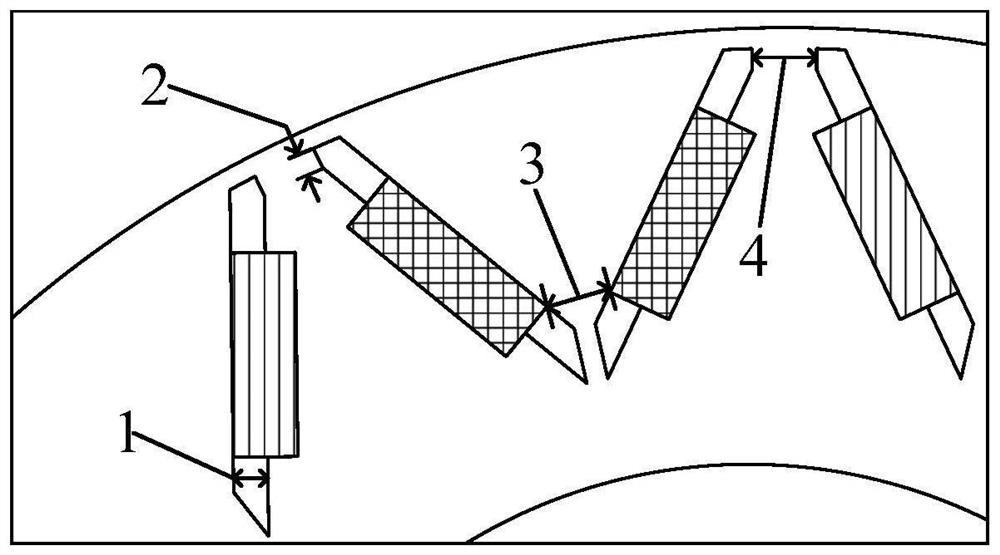

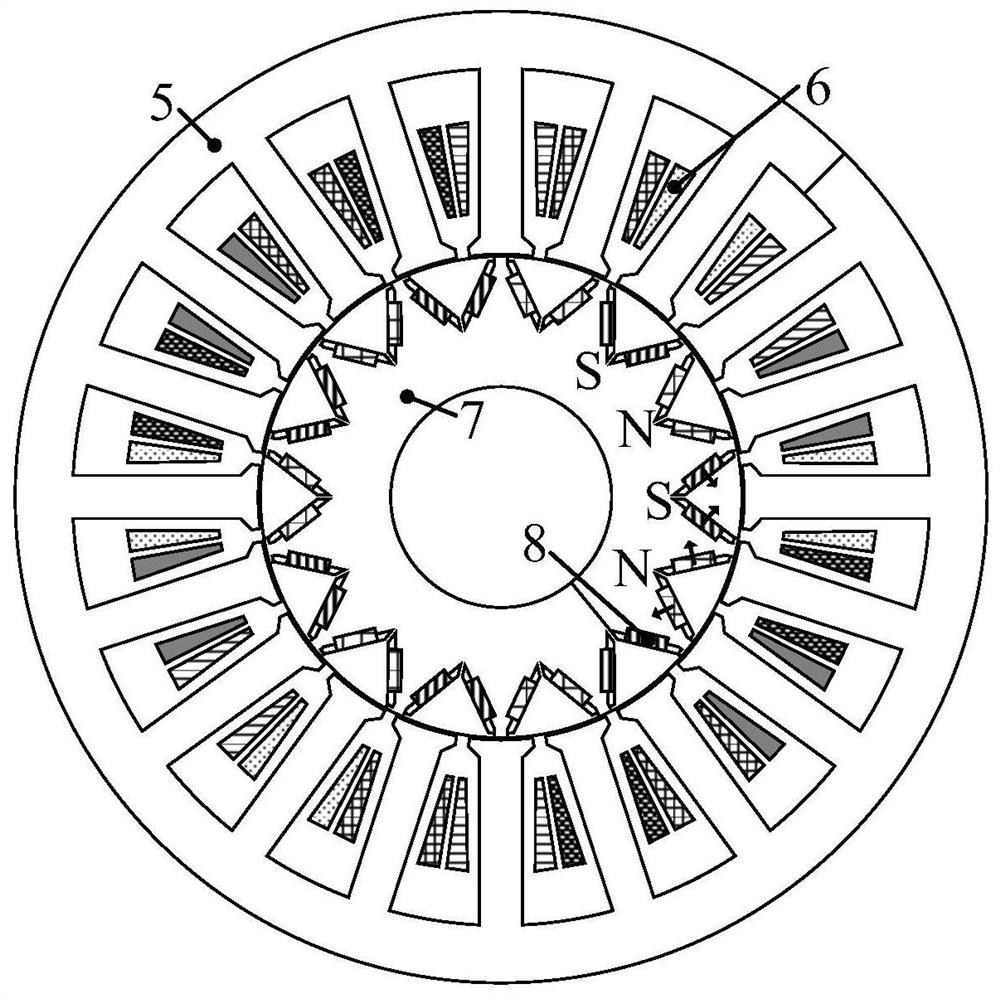

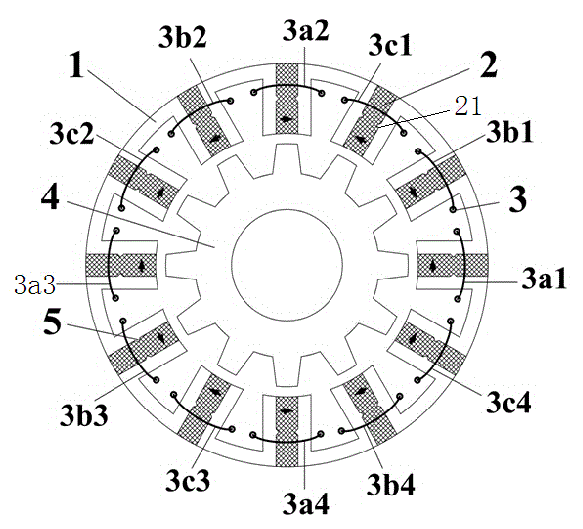

ActiveCN111654124AImprove fault toleranceIncreased torque output capabilityElectronic commutation motor controlMagnetic circuit rotating partsWinding factorMotor design

The invention discloses a design method of a five-phase permanent magnet fault-tolerant motor with high reluctance torque and high salient pole rate, and belongs to the technical field of motor manufacturing. The invention provides a novel method for selecting five-phase permanent magnet fault-tolerant motor slot pole cooperation. On the basis of determining the motor slot pole, the structure of the motor is designed, and through a multi-objective optimization method, the purposes of high reluctance torque and high salient pole rate are finally achieved. When the slot pole cooperation of the motor is selected, a slot pole matching selection method is provided by constructing a relationship between a mutual coupling coefficient and motor fault tolerance performance. According to the method,the slot poles with high fault-tolerant performance are selected for matching, and on the basis, factors such as a winding factor, a leakage inductance coefficient, rotor loss and cogging torque of the motor are comprehensively considered, so that the proposed motor design method can ensure excellent fault-tolerant performance while realizing high reluctance torque and high salient pole rate.

Owner:JIANGSU UNIV

Flux-switching type permanent magnet motor with permanent magnet fixing bosses

InactiveCN104600887AImprove installation accuracyPerformance is not affectedMagnetic circuit stationary partsFall riskPermanent magnet motor

The invention discloses a flux-switching type permanent magnet motor with permanent magnet fixing bosses and belongs to the technical field of manufacture and applications of motors. The motor is formed by a stator iron core, permanent magnets, an armature winding, a rotor iron core and the permanent magnet fixing bosses; the permanent magnets are fixed on a stator and tangentially magnetize alternately; the permanent magnet fixing bosses are arranged on contact surfaces of the stator iron core and the permanent magnets and towards the permanent magnets; the permanent magnet fixing bosses and the stator iron core are connected into a whole; a groove is formed in the permanent magnet; the size of the groove is matched with that of the permanent magnet fixing bosses. According to the flux-switching type permanent magnet motor with permanent magnet fixing bosses, the installation accuracy of the permanent magnet is greatly improved due to the permanent magnet fixing bosses, falling risks of the permanent magnet along the radial direction of the motor are reduced, and the motor reliability is improved.

Owner:扬州市新港电机有限公司 +1

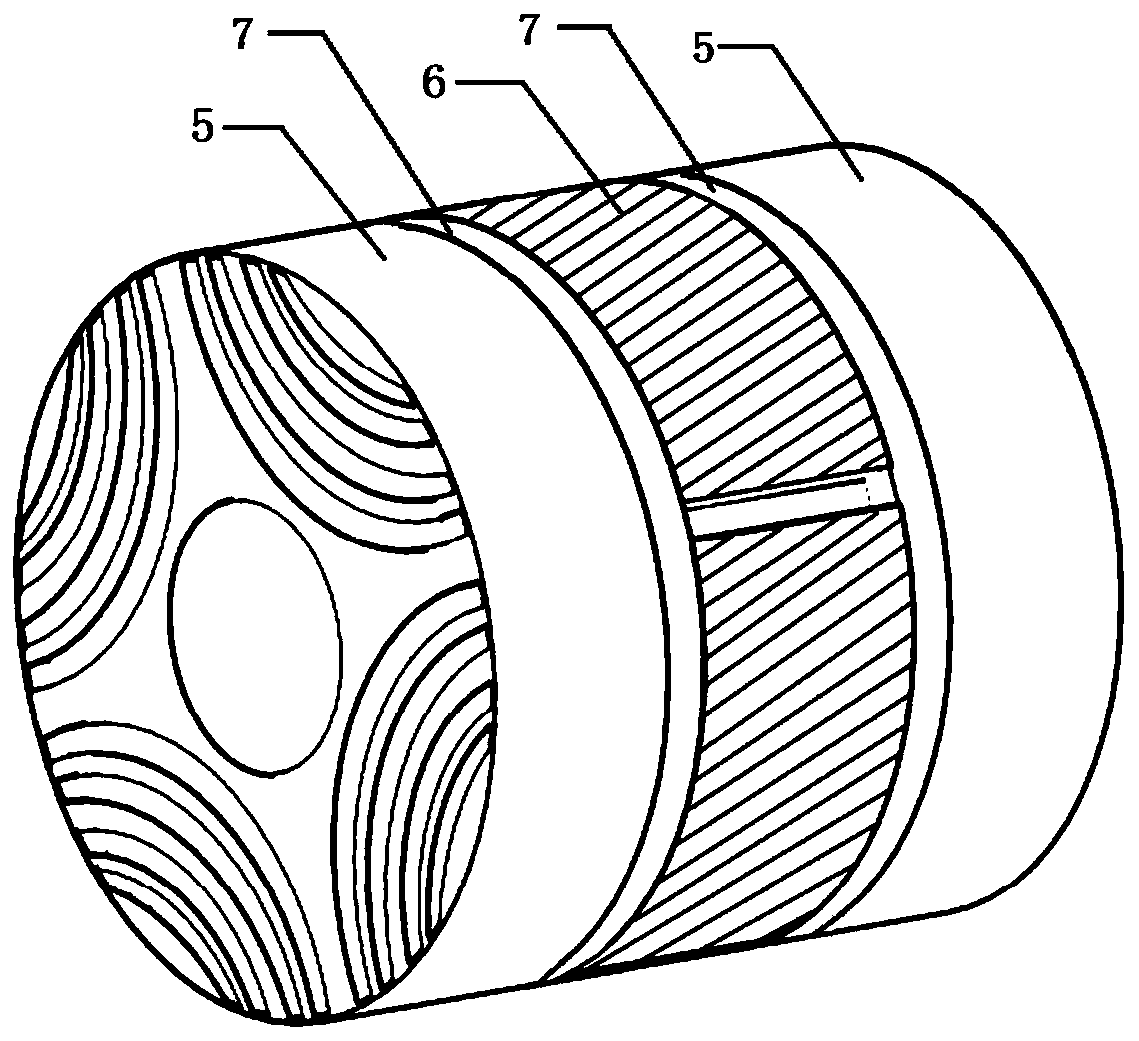

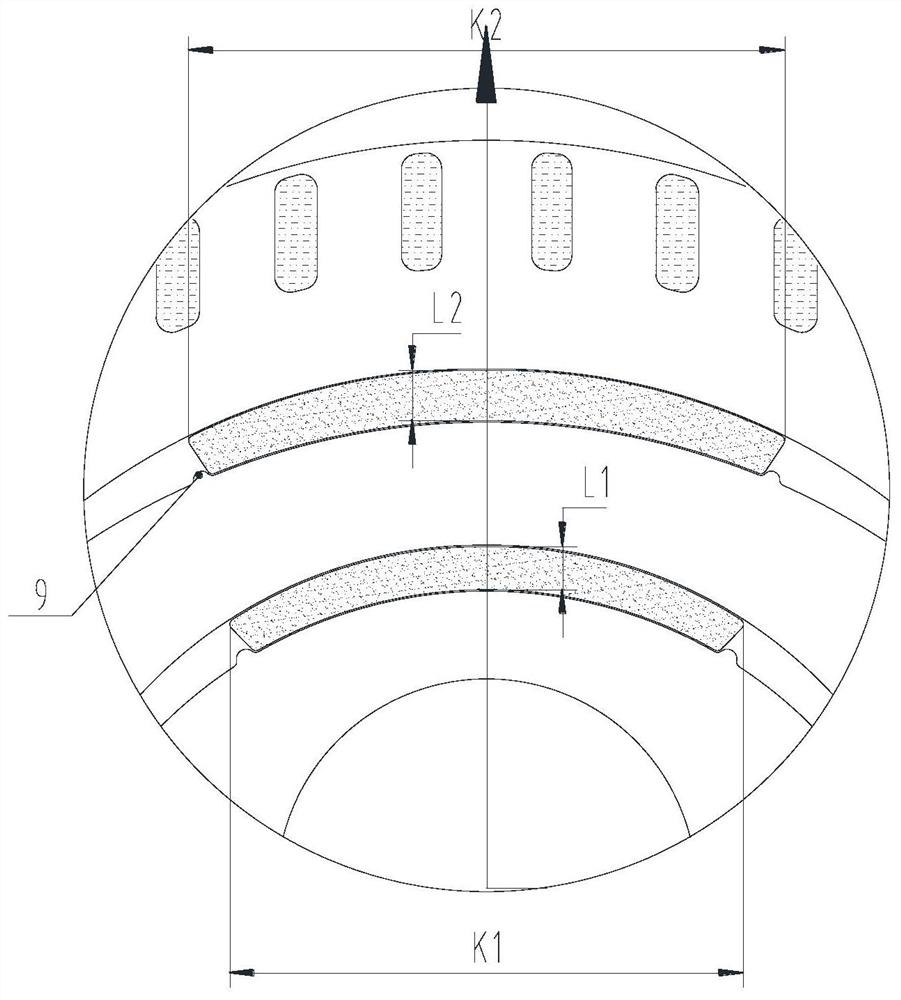

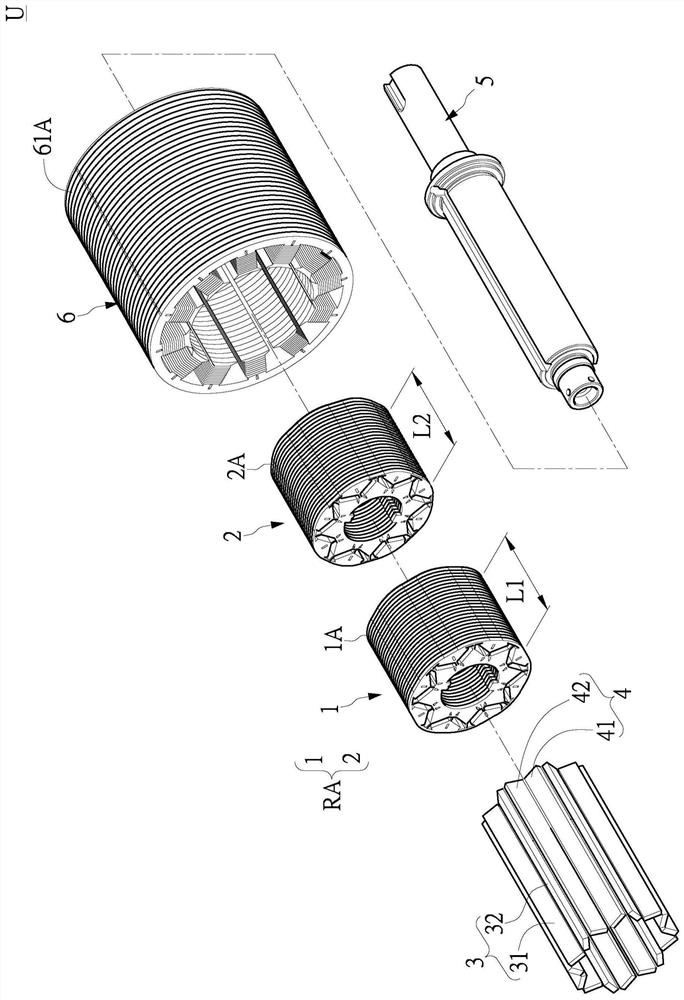

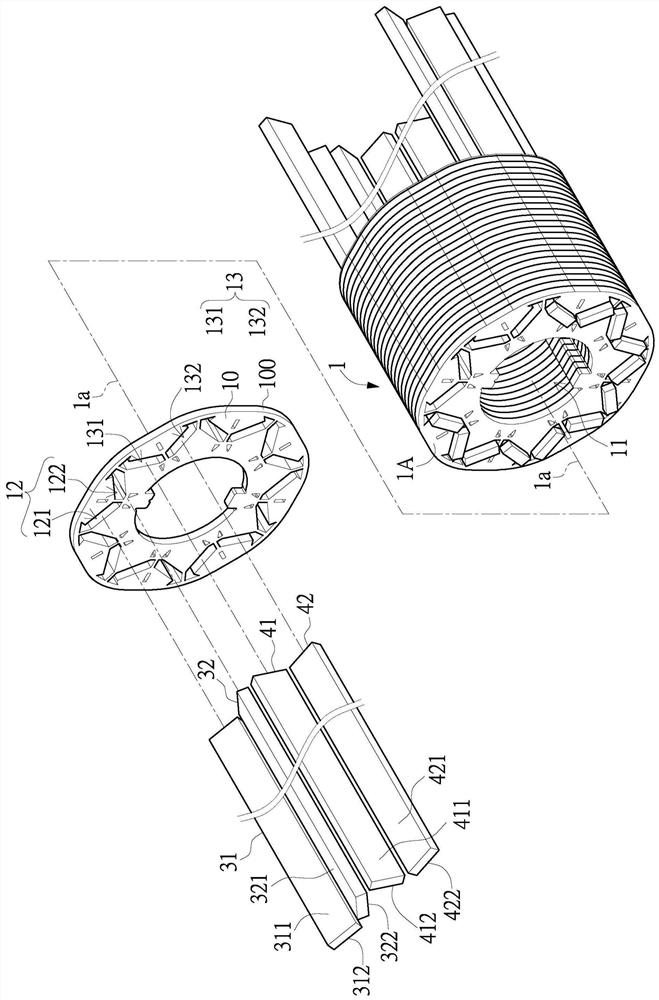

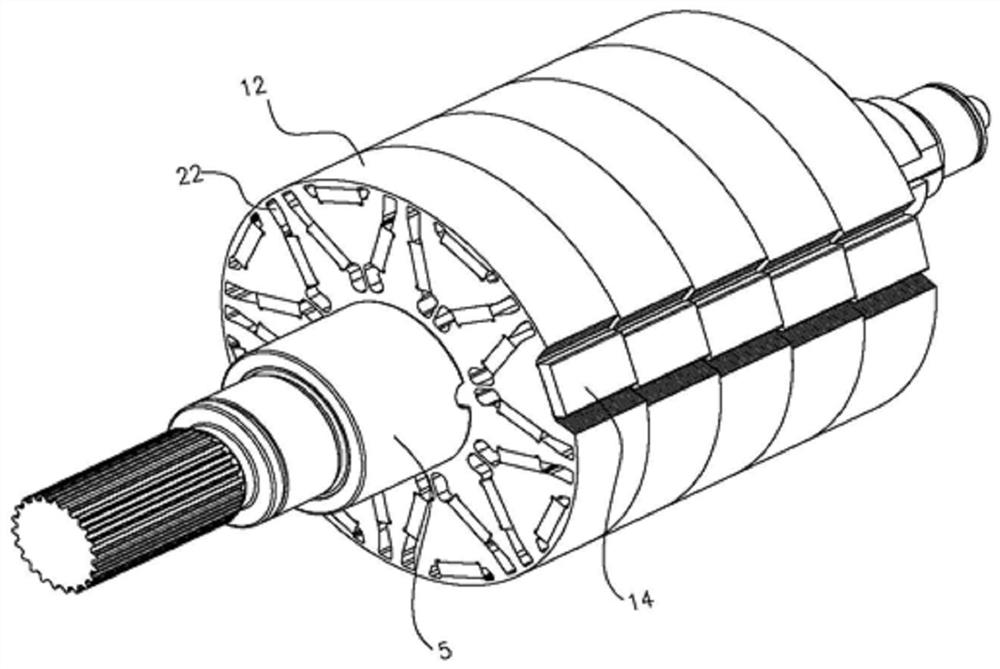

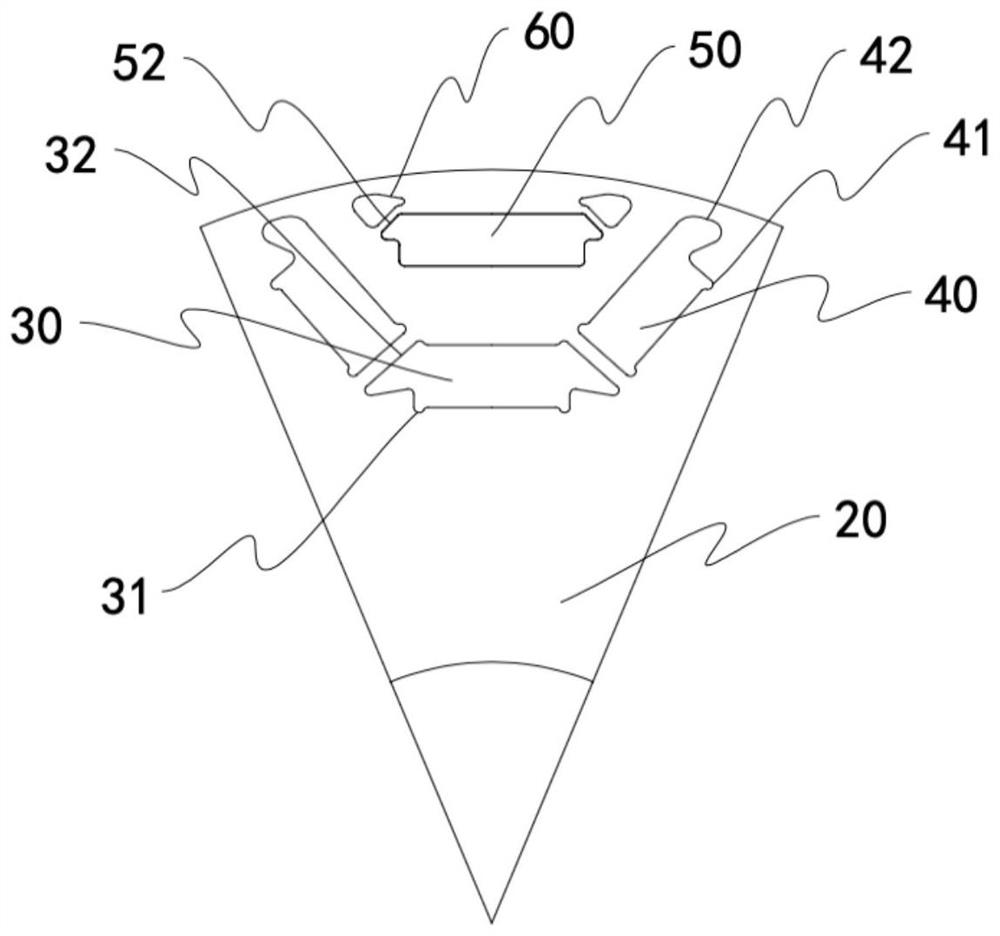

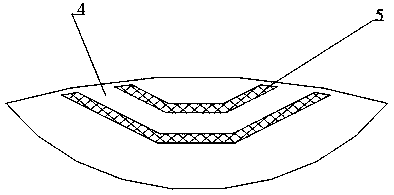

Axial composite permanent magnet auxiliary synchronous reluctance motor rotor

PendingCN111404340AReduce stressGuaranteed mechanical strengthMagnetic circuit rotating partsPermanent magnet rotorMagnetic barrier

The invention discloses an axial composite permanent magnet auxiliary synchronous reluctance motor rotor which comprises a rotating shaft, a plurality of reluctance rotors fixedly arranged on the rotating shaft in the axial direction and permanent magnet rotors arranged between the adjacent reluctance rotors. Each reluctance rotor comprises a reluctance rotor iron core and a plurality of magneticbarrier structures which are uniformly arranged along the circumferential direction of the reluctance rotor iron core. Each permanent magnet rotor comprises a permanent magnet rotor iron core and a plurality of permanent magnets uniformly arranged on the permanent magnet rotor iron core. By utilizing the axial composite permanent magnet auxiliary synchronous reluctance motor rotor, the problems ofinsufficient permanent magnet torque utilization, low mechanical strength and high processing cost of a radial composite permanent magnet auxiliary synchronous reluctance motor can be effectively solved, the reliability of a permanent magnet auxiliary synchronous reluctance motor is improved, and the application occasions of the permanent magnet auxiliary synchronous reluctance motor are also widened.

Owner:ZHEJIANG UNIV

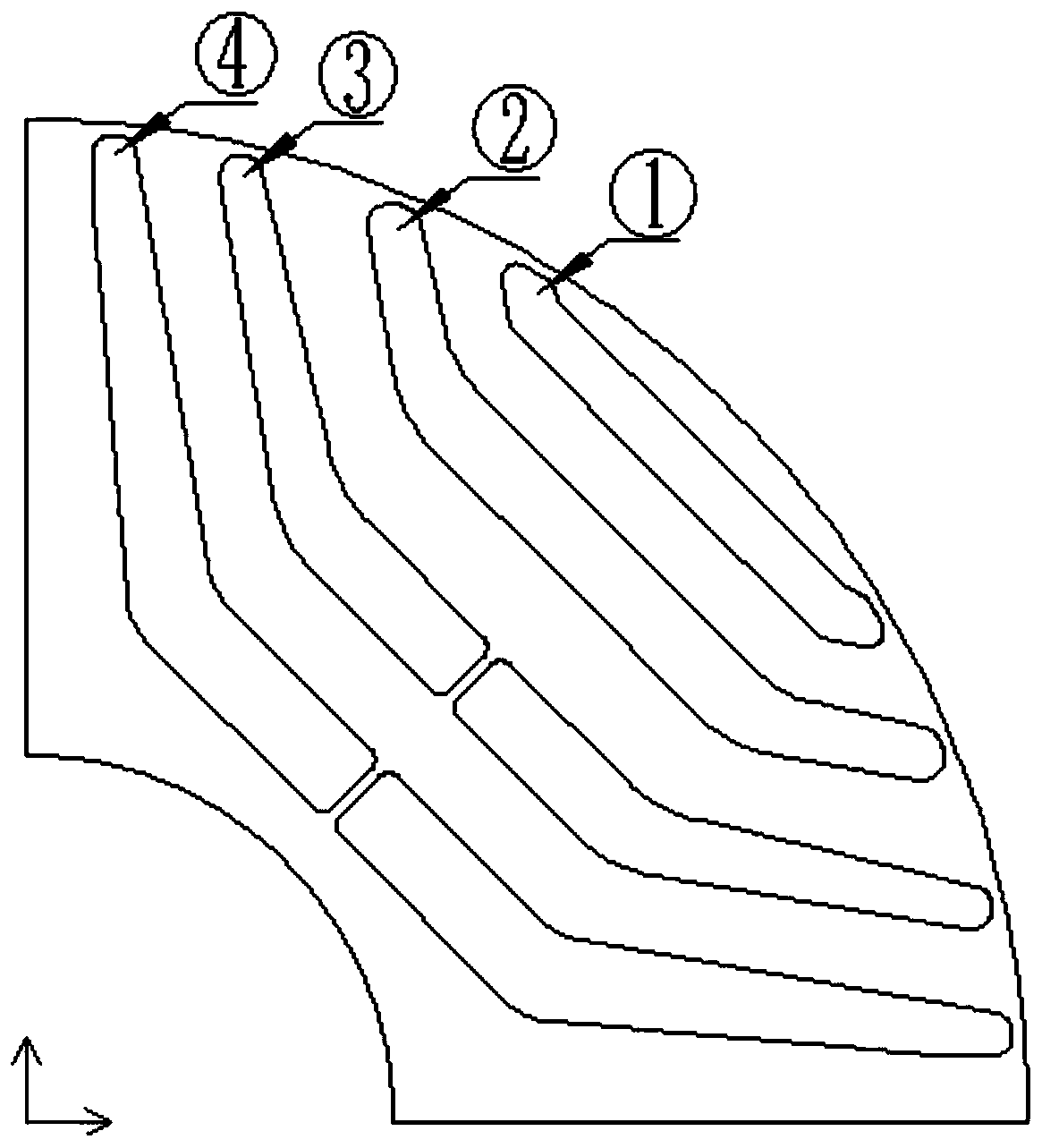

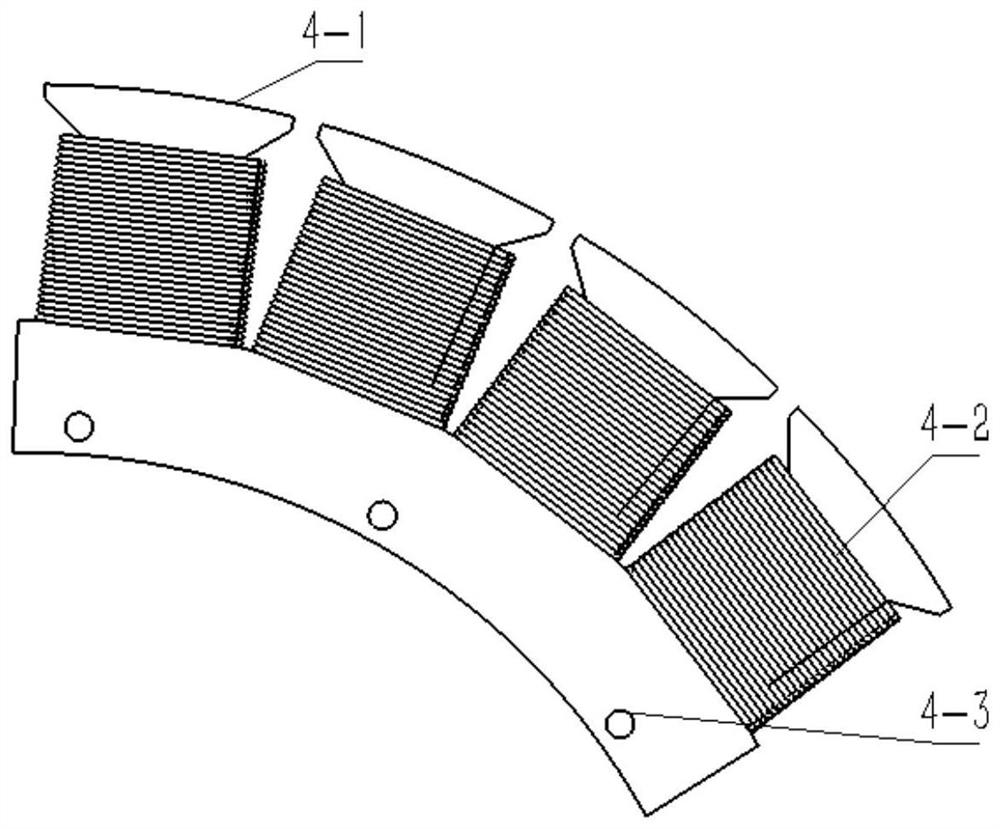

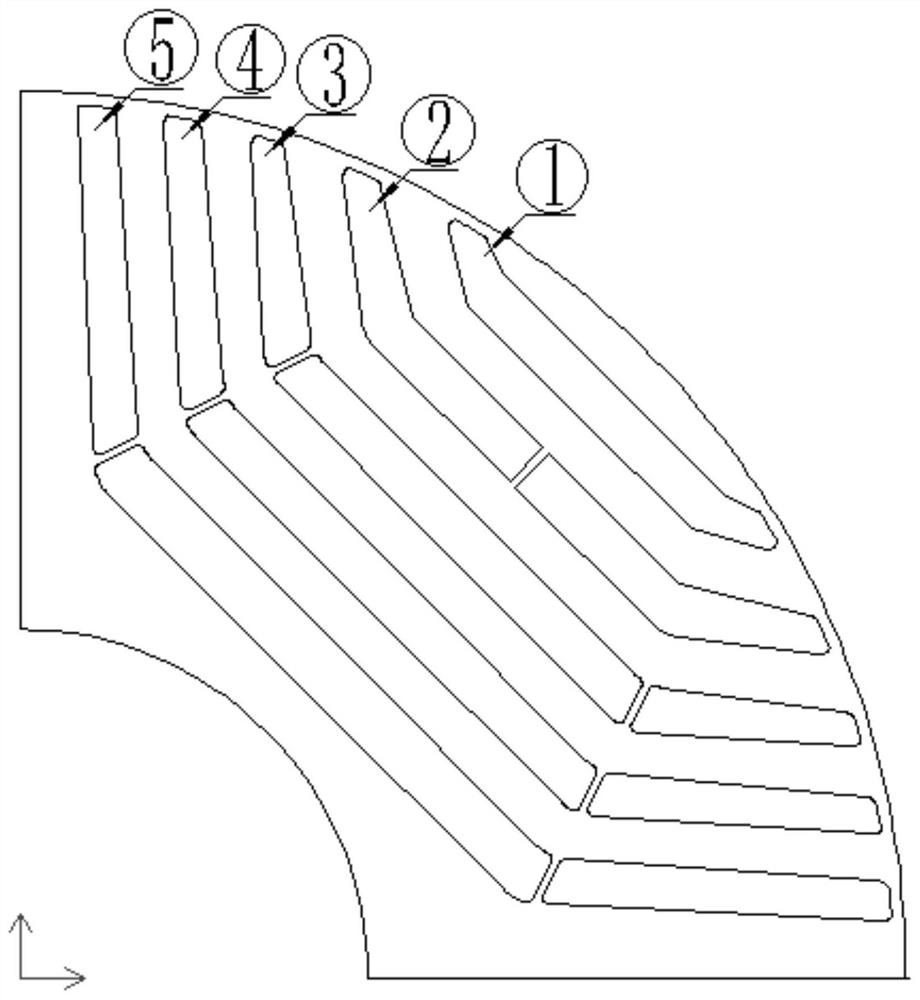

Outer rotor synchronous magnetic resistance motor rotor

ActiveCN103701236AImprove inductance variabilityIncrease reluctance torqueMagnetic circuit rotating partsHigh power densityEngineering

The invention provides an outer rotor synchronous magnetic resistance motor rotor, which comprises a rotor yoke, wherein an even number of magnetic pole units in uniform distribution along the circumference are arranged on the rotor yoke, each magnetic pole unit comprises an installing frame, a plurality of magnetic passages sequentially ranged in the radial direction are arranged in the installing frame, and gaps are arranged between the adjacent magnetic passages. The outer rotor synchronous magnetic resistance motor rotor has the beneficial effects that a magnetic-bridge-free structure is adopted, mutually connected magnetic guide parts are not adopted between the magnetic passages, and the alternating current and direct current axis inductance differences can be easily improved, so the magnetic resistance torque is increased, and the outer rotor synchronous magnetic resistance motor rotor is suitable for occasions requiring high-power density. In the weak link without stress concentration, the rigidity and the intensity of each magnetic passage used as a carrying main body can be guaranteed, and the outer rotor synchronous magnetic resistance motor rotor is suitable for being applied to large-torque or large-centrifugal-force occasions; the processing and the manufacturing are convenient, a plurality of magnetic pole units are spliced after the single processing of each magnetic pole unit is completed, the structure of each magnetic pole unit is simple, no complicated curve surface exits, the processing of single parts is convenient, complicated process measures are not needed, and the outer rotor synchronous magnetic resistance motor rotor is suitable for engineering application.

Owner:HANGZHOU EASITECH

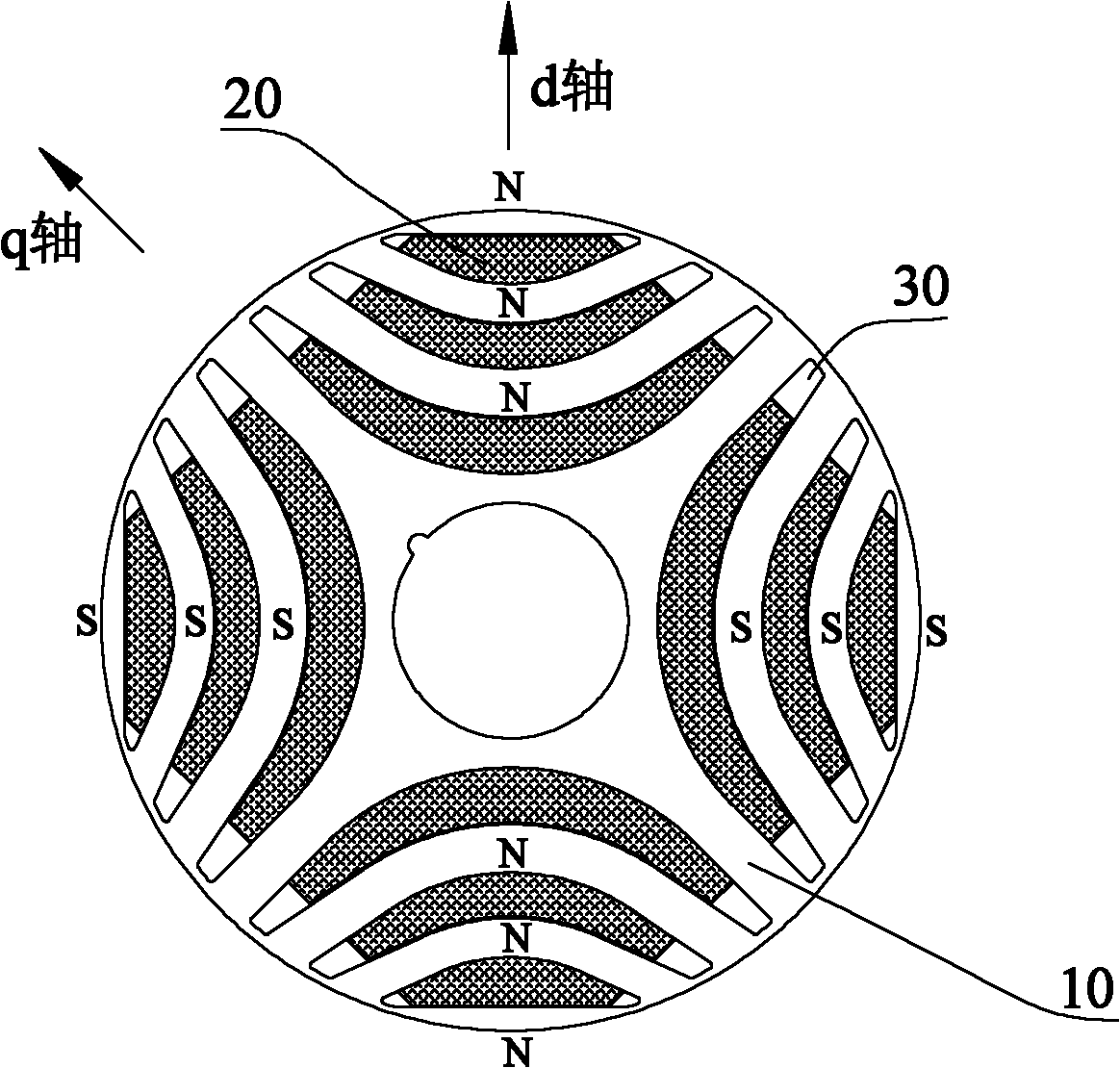

Motor rotor and motor with motor rotor

ActiveCN102761183AImprove efficiencyReduce dosageMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineRare earth

The invention provides a motor rotor and a motor with the motor rotor. The motor rotor provided by the invention comprises an iron core and permanent magnets which are arranged inside the iron core, wherein multiple groups of mounting grooves are arranged on the iron core along the circumferential direction of the iron core; each group of the mounting grooves comprises two or more mounting grooves which are arranged discontinuously in the radial direction of the iron core; multiple groups of the permanent magnets are arranged; and each permanent magnet in each group of the permanent magnets is correspondingly embedded in each mounting groove in each group of the mounting grooves. The motor provided by the invention comprises the motor rotor. According to the motor rotor and the motor withthe motor rotor, the reluctance torque of the motor rotor is improved, so that the output torque of the motor is improved and the efficiency of the motor is improved. In addition, the efficiency of the motor is improved without additionally arranging rare-earth permanent magnets, so that the rare-earth usage is reduced; on the one hand, the energy source is saved and the environmental burden is lightened; and on the other hand, the cost is reduced and the product competitiveness is promoted.

Owner:GREE ELECTRIC APPLIANCES INC +1

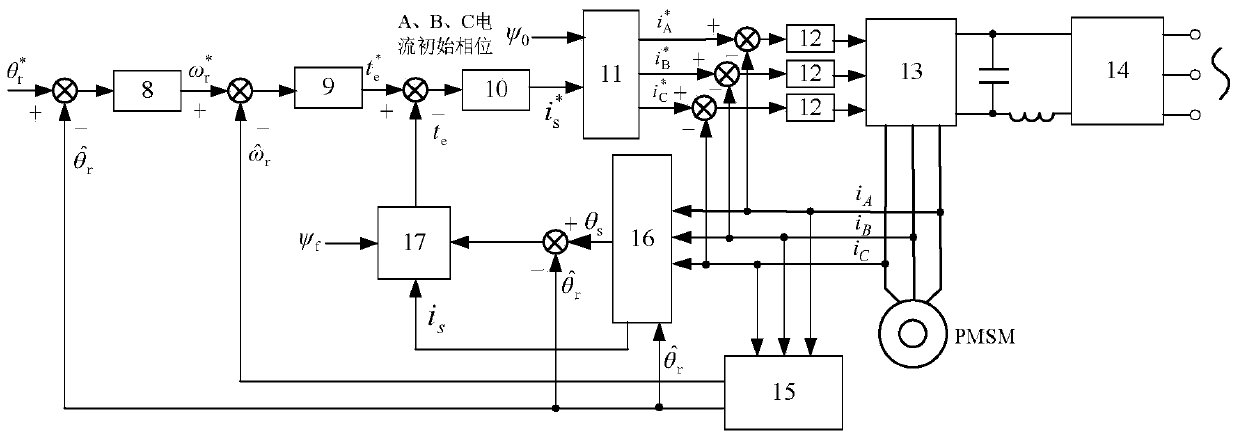

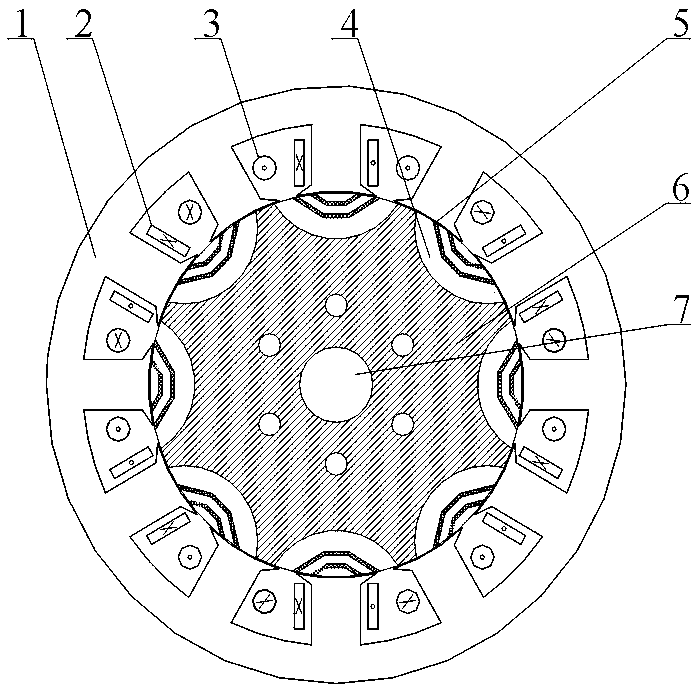

Permanent magnet/reluctance dual-rotor low-speed and high-torque synchronous motor and control system thereof

PendingCN109861477AStable structureIncreased torque densityElectronic commutation motor controlAC motor controlSynchronous motorControl vector

The present invention provides a permanent magnet / reluctance dual-rotor low-speed and high-torque synchronous motor and a control system thereof. The synchronous motor is mainly formed by an outer rotor (1), an inner rotor (2) and a stator (3). The stator (3) is arranged between the outer rotor (1) and the inner rotor (2). The method estimates the position of a reluctance rotor to obtain the position of the whole rotor to achieve sensorless control. The provided sensorless vector control method does not need coordinate transformation, is simple in structure and can overcome the problems of thecomplexity of the vector control and the high dependence on the motor parameters.

Owner:SHENYANG POLYTECHNIC UNIV

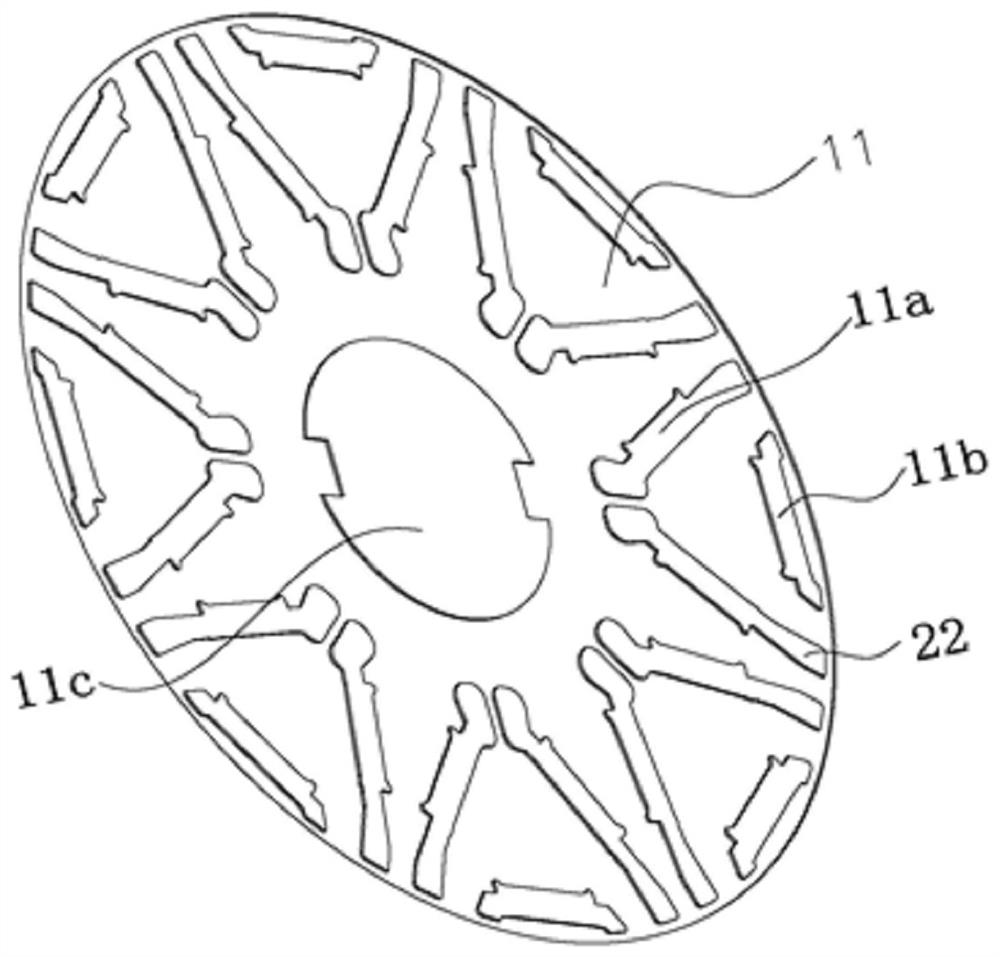

Rotor, motor comprising rotor and power device comprising motor

ActiveCN108512327AIncrease reluctance torqueReduce torque rippleMagnetic circuit rotating partsSynchronous machinesEngineeringMechanical engineering

The embodiment of the invention provides a rotor, a motor comprising the rotor and a power device comprising the motor. The rotor is located at the periphery of a rotating shaft of the motor and rotates together with the rotating shaft. The rotor is composed of electromagnetic steel plates laminated in the axial direction, each electromagnetic steel plate is provided with a through hole group penetrating through the electromagnetic steel plate in the axial direction, the through hole group has a plurality of through holes, and the plurality of through holes take an imaginary line extending inthe radial direction as a center line and are in an arc shape extending towards two sides and the radial outer side of the center line. In addition, the plurality of through holes are arranged in theradial direction, wherein the curvature radius of the arc-shaped surface, which is located at the radial inner side, of the through hole at the radial inner most side in the plurality of through holesis the minimum, and / or the curvature radius of the arc-shaped surface, which is located at the radial outer side, of the through hole at the radial outer most side in the plurality of through holes is the maximum. According to the structure of the rotor, the reluctance difference between the electromagnetic steel plates forming the rotor can be enlarged, so that the reluctance torque is increased, and the torque ripple is reduced.

Owner:NIPPON DENSAN CORP

A series hybrid permanent magnet variable flux motor

ActiveCN109660042BReduce the magnetizing currentWork lessMagnetic circuit rotating partsElectric machineCondensed matter physics

The invention discloses a serial hybrid permanent magnet variable flux motor, which comprises a stator (100), an armature winding (200) wound on the stator (100), and a rotor core (300). Each pole of (300) is provided with three permanent magnets that are not in direct contact and placed separately, wherein the second permanent magnet (302) is placed on the outside in a "one" shape, and the two first permanent magnets (301) are in a "V" shape. ” shape is placed on the inner side, the second permanent magnet (302) is a high coercive force permanent magnet or a low coercive force permanent magnet, and the first permanent magnet (301) is a high coercive force permanent magnet or a low coercive force permanent magnet force permanent magnet. In the motor of the present invention, the low coercive force permanent magnet and the high coercive force permanent magnet adopt special placement positions and methods, so that the motor is a magnetic circuit series structure, and the high coercive force permanent magnet acts on the low coercive force permanent magnet. The magnetization effect improves the working point and magnetization degree of the low-coercivity permanent magnet, improves the torque output capability, and reduces the magnetizing current of the motor.

Owner:HUAZHONG UNIV OF SCI & TECH

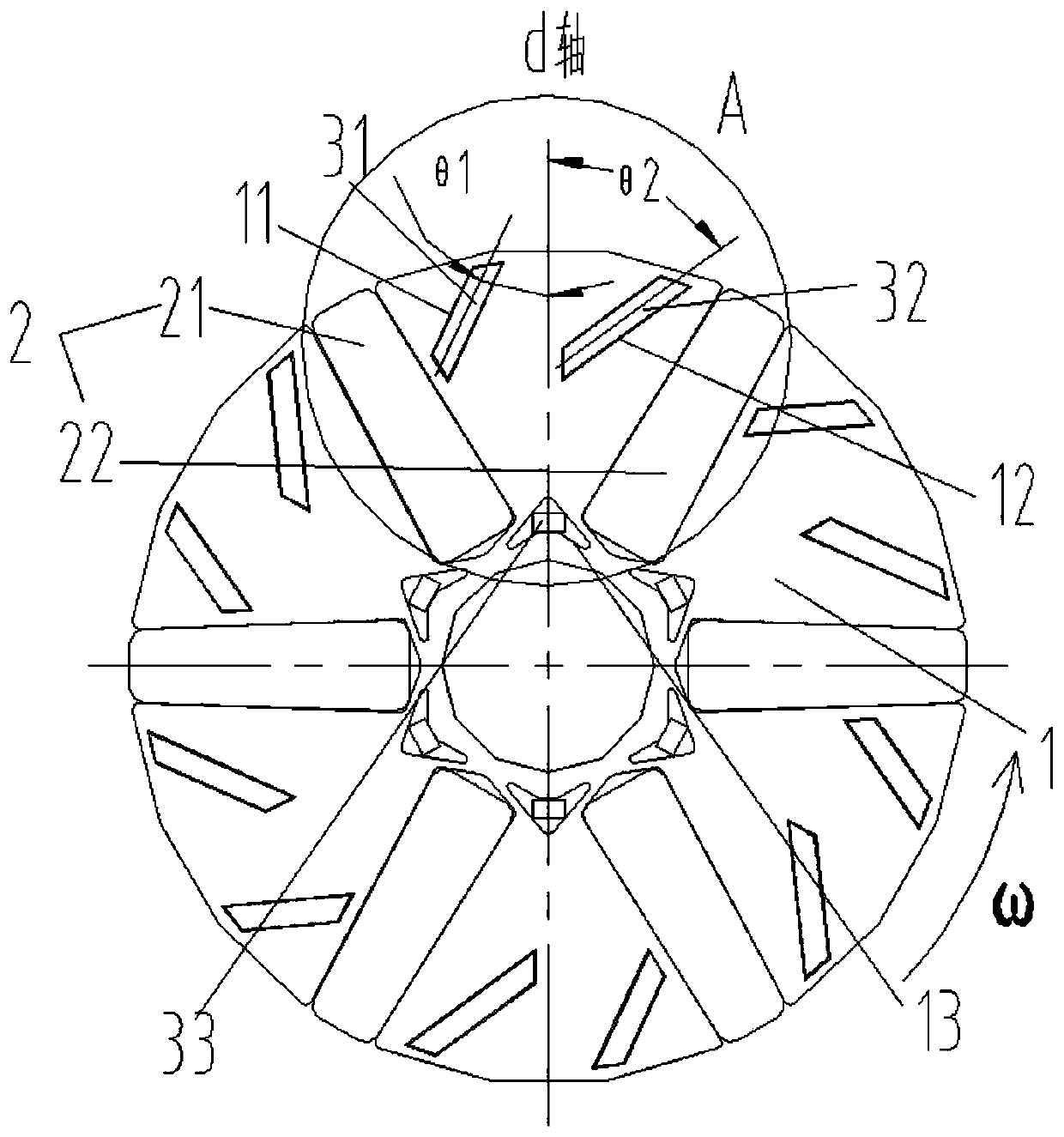

Motor rotor, motor and compressor

ActiveCN110611386ANo reduction in output torque capabilityIncrease reluctance torqueMagnetic circuit rotating partsElectrical polarityMagnetic isolation

The invention provides a motor rotor, a motor and a compressor. The motor rotor comprises a rotor core and M tangential permanent magnets arranged at intervals along a circumferential direction of therotor core, the tangential permanent magnets extend along a radial direction of the rotor core, and a first magnetic isolation groove is formed in the rotor core between any two adjacent tangential permanent magnets. On any section perpendicular to an axis of the rotor core, an included angle theta 1 which is larger than 0 degree and smaller than 90 degrees is formed between an extending direction of the first magnetic isolation groove and a d axis, the polarities of facing sides of any two adjacent tangential permanent magnets are the same, each first magnetic isolation groove is provided with a first end close to the axis of the rotor core and a second end away from the axis of the rotor core, and the first end is located in front of the second end in the rotating direction of the rotoriron core. The reluctance torque can be fully utilized to improve the output torque of the motor, the use amount of the permanent magnets is reduced, the utilization rate of the permanent magnets isimproved, and the manufacturing cost of the rotor and even the motor is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

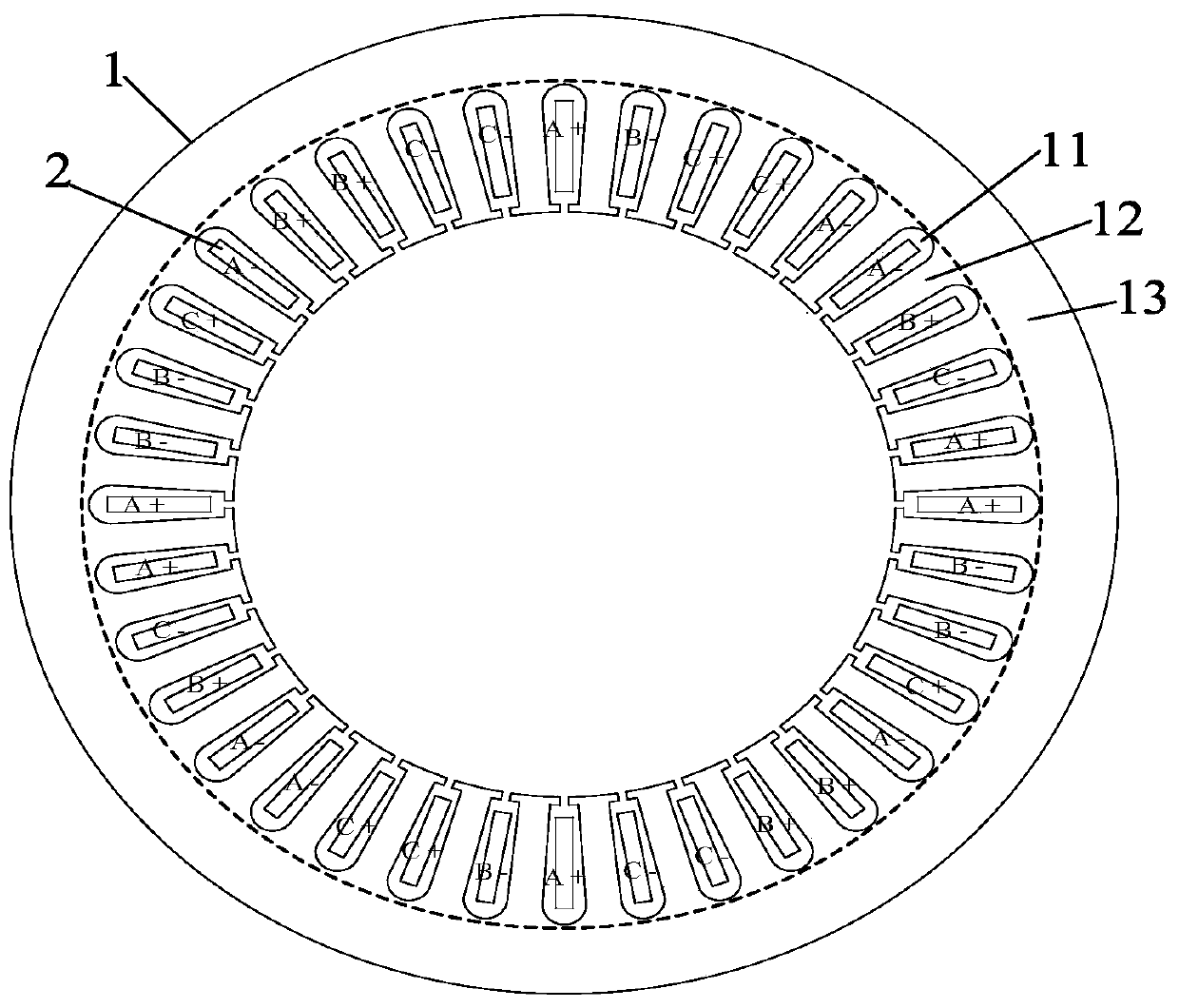

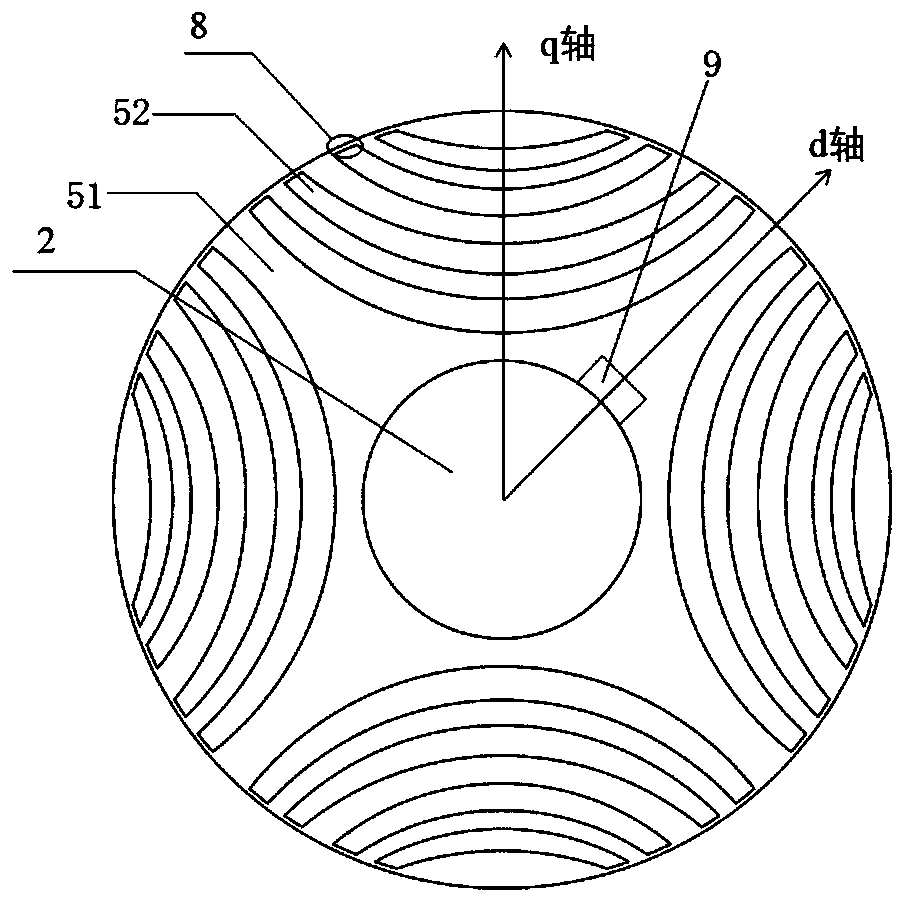

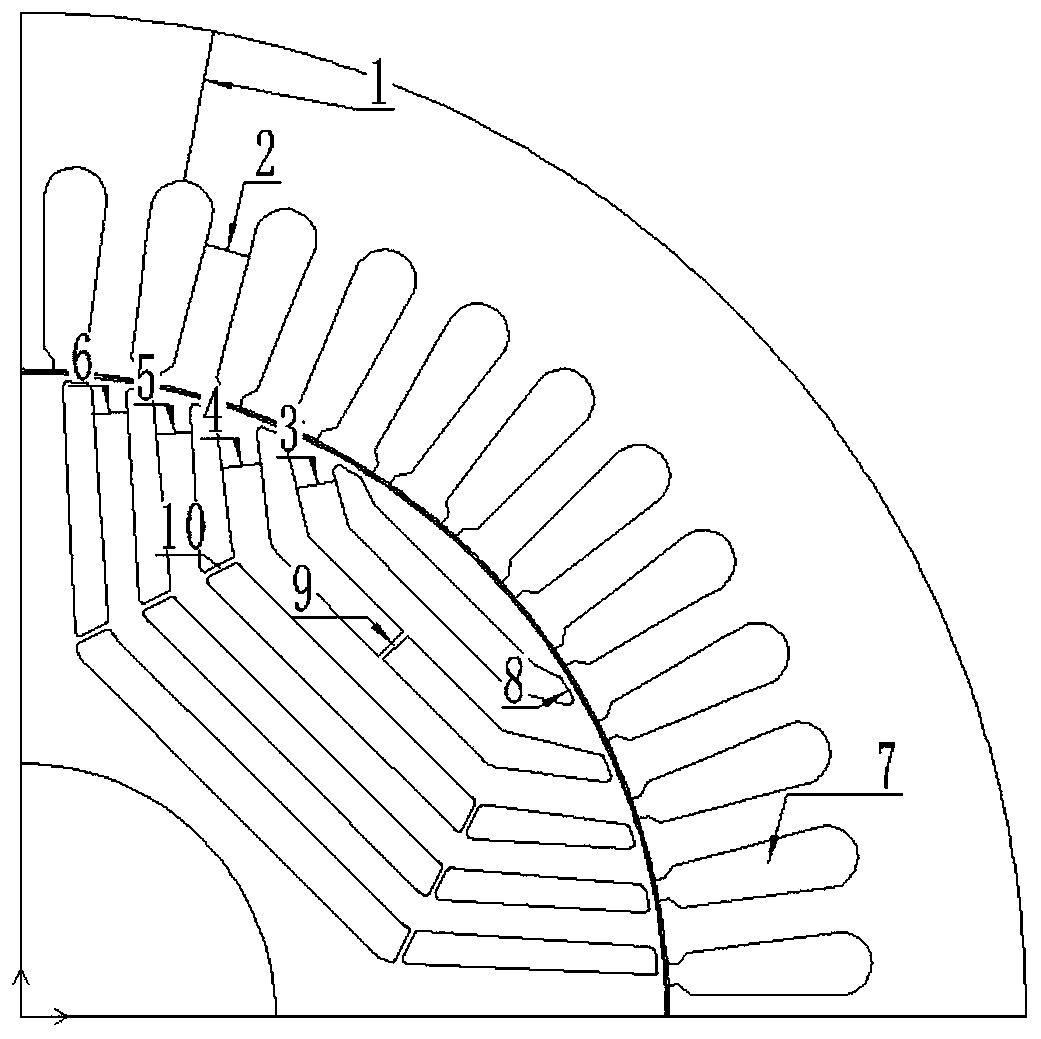

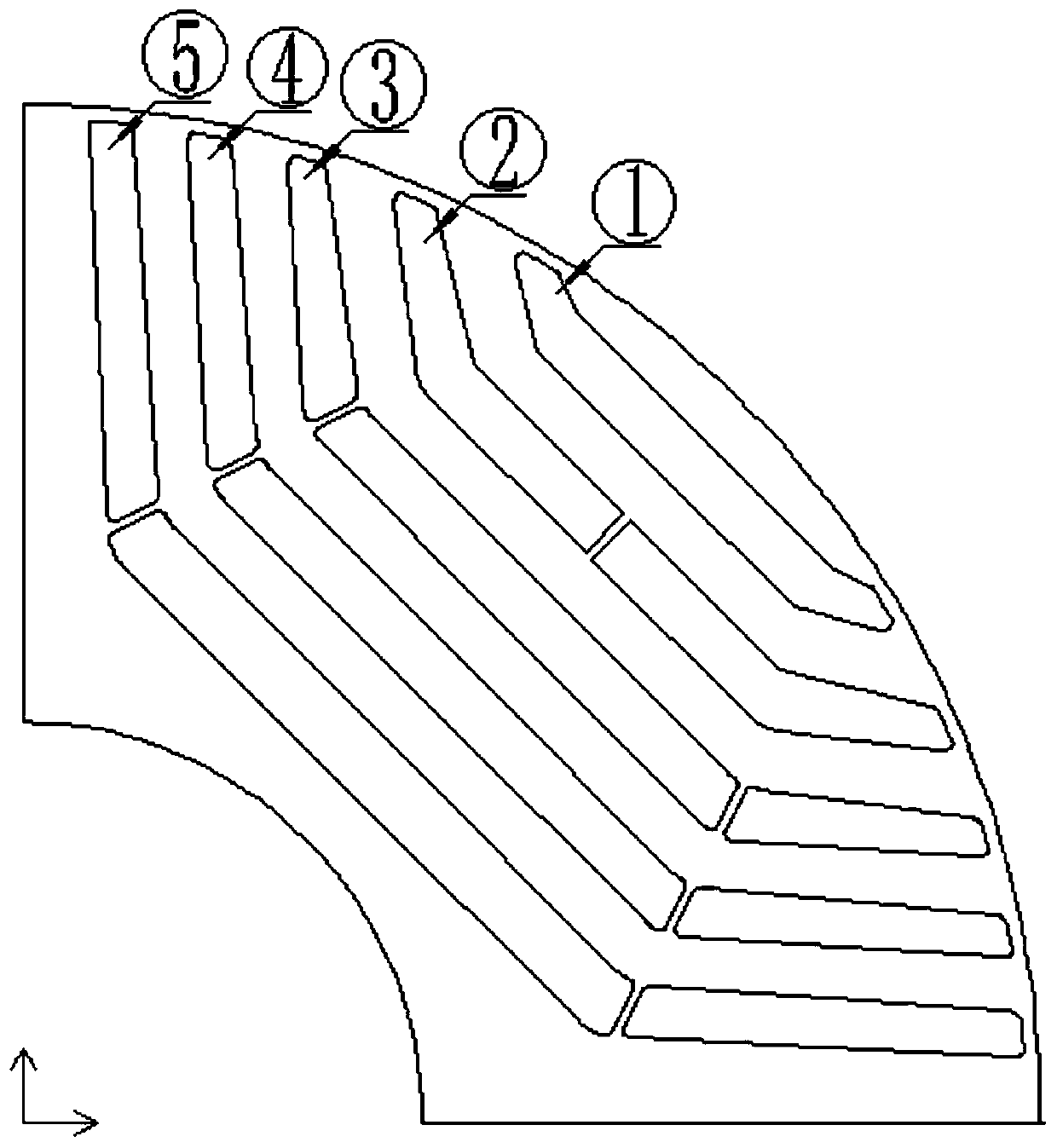

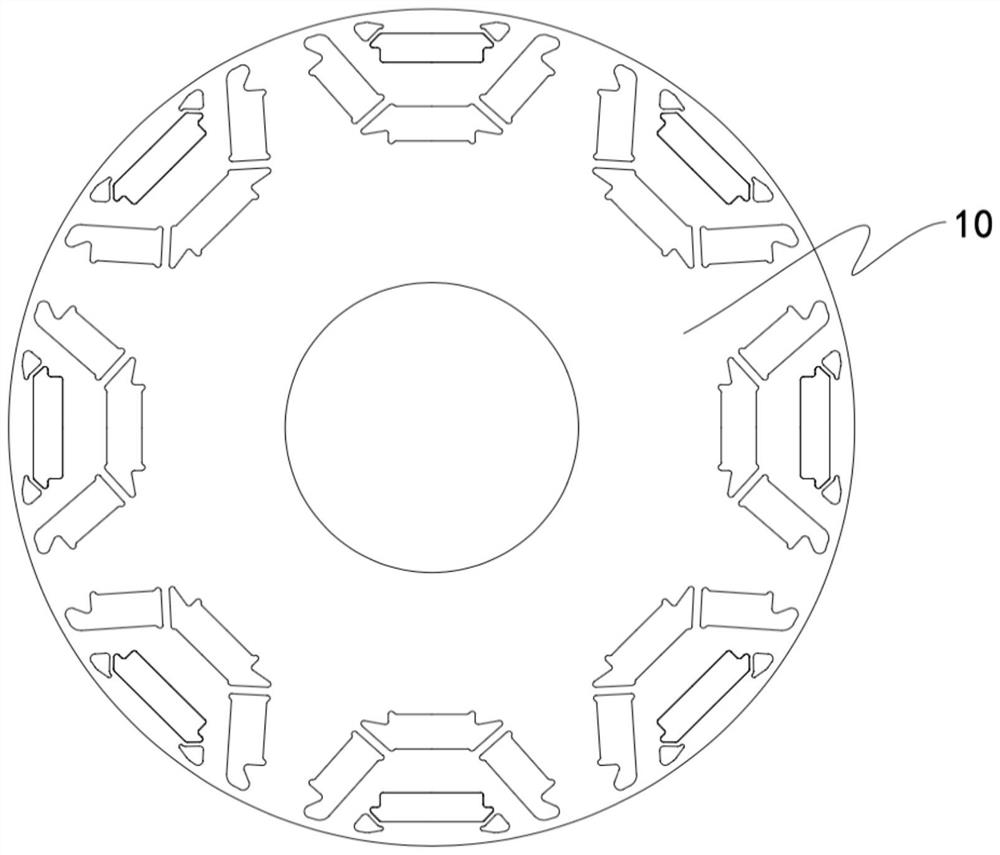

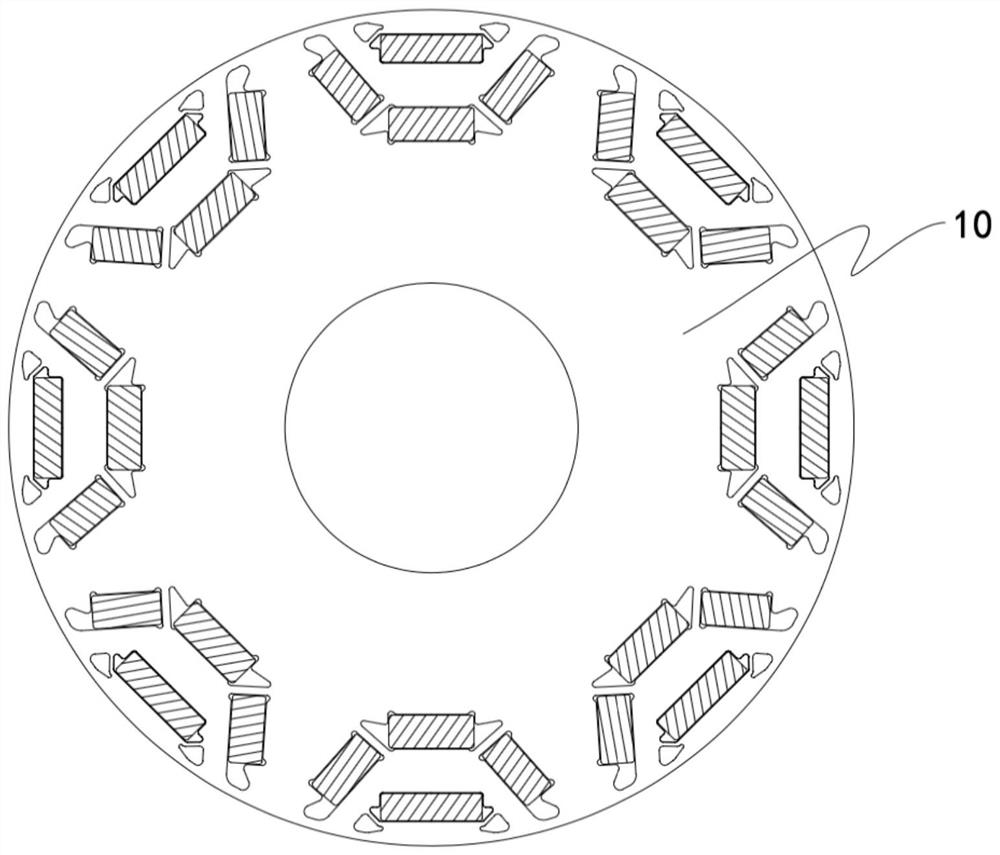

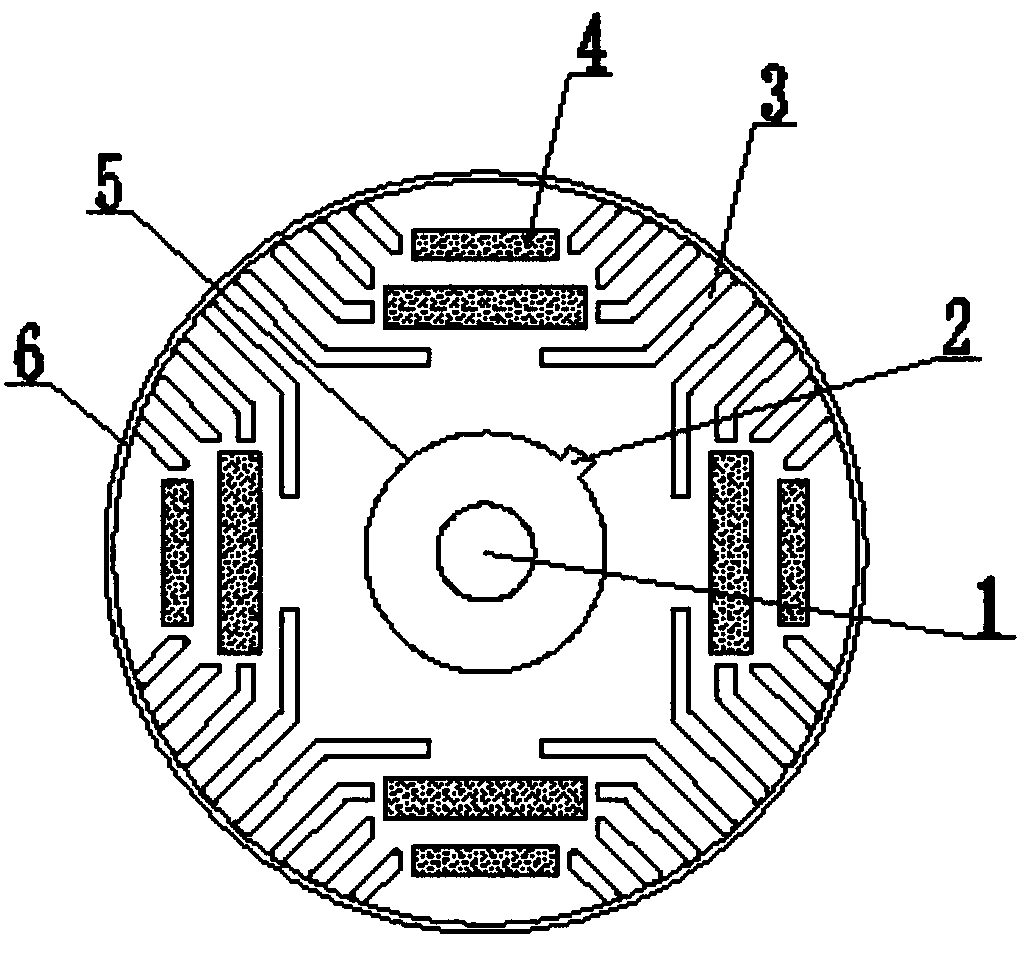

Stator and rotor structure of high-power-density reluctance motor

ActiveCN110932425ARaise the saliency ratioIncreased torque output capabilityMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringTorque ripple

The invention discloses a stator and rotor structure of a high-power-density reluctance motor. The structure comprises a stator and a rotor, the number of stator slots and the number of rotor magneticbridges meet the formula (1): Nr = Ns-4k (1), Ns is the number of stator slots corresponding to each pair of poles, Nr is the number of rotor magnetic bridges corresponding to each pair of poles, K is a positive integer, and the number of rotor magnetic bridges corresponding to each layer of rotor magnetic barriers is 2; the number of layers of the rotor magnetic barriers is Nr / 2, and then rounding is carried out; the opening angle alpha of the outermost layer magnetic bridge of the rotor meets the formula (2), wherein p is the number of pole pairs. According to the invention, the leakage flux of the motor can be reduced, the salient pole ratio of the motor is improved, the torque output capability of the motor is improved, and the torque ripple of the motor can be reduced.

Owner:HANGZHOU EASITECH

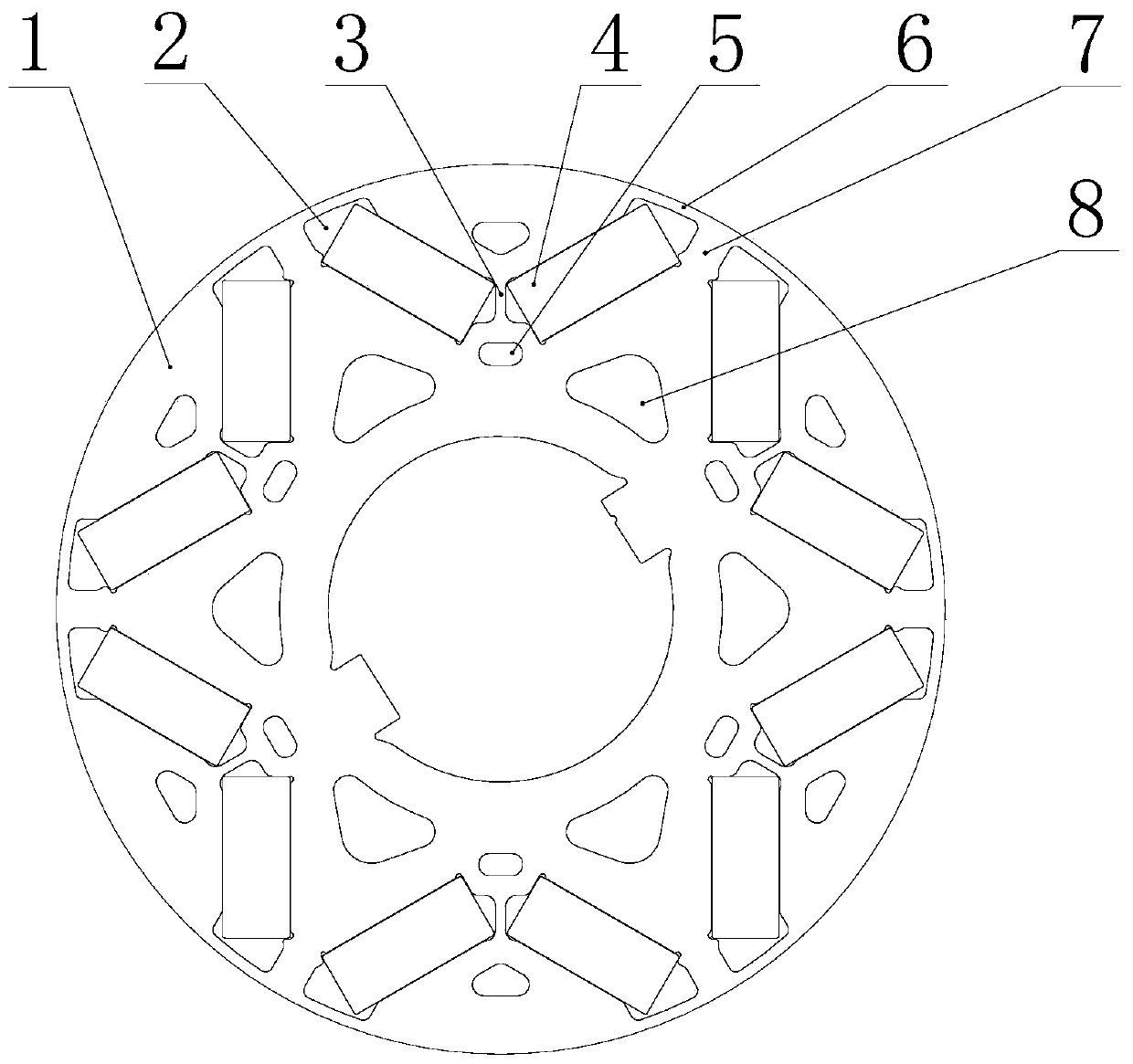

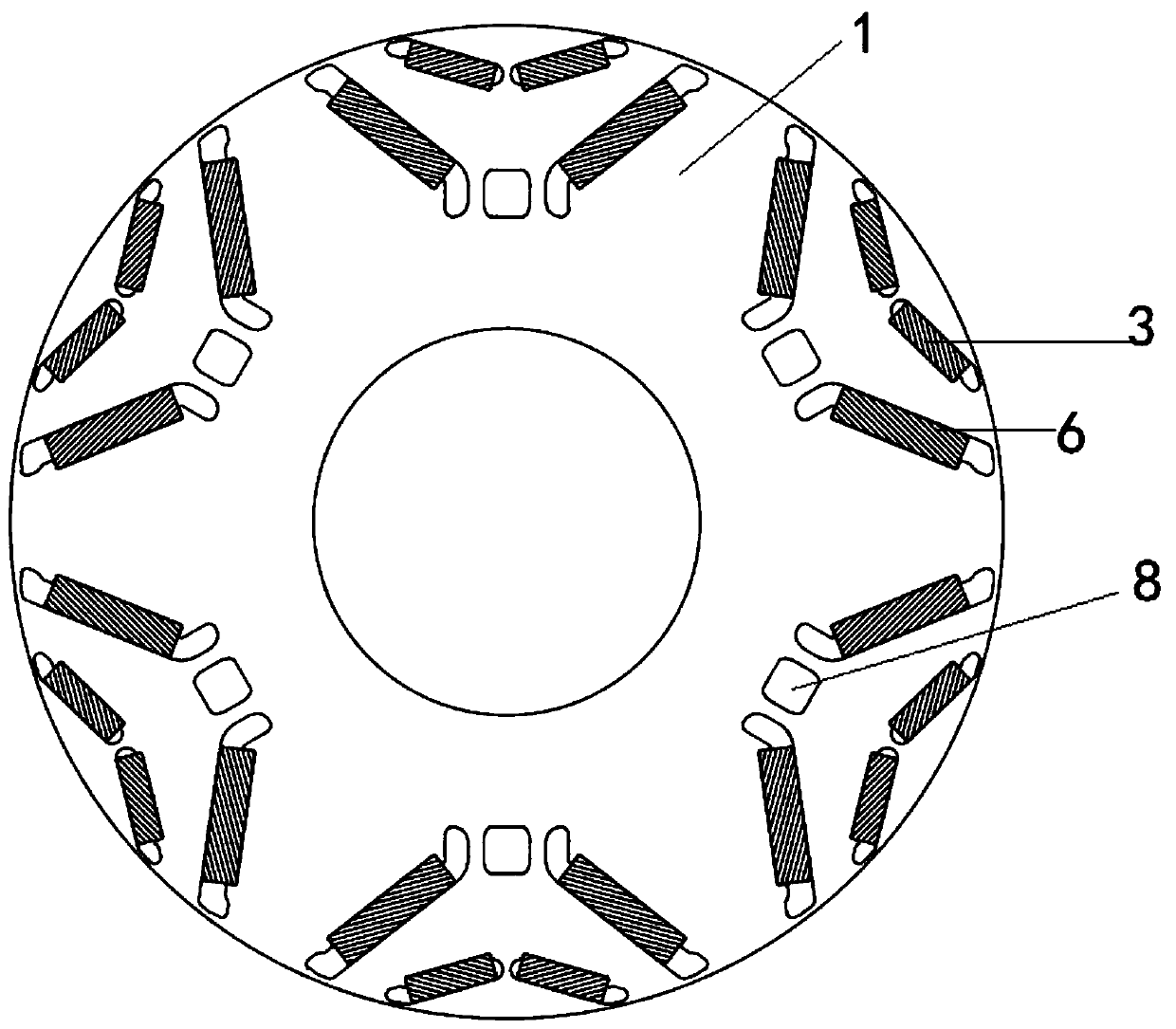

Rotor assembly and self-starting permanent magnet synchronous reluctance motor

InactiveCN112968551AIncrease reluctance torqueSynchronous machine detailsMagnetic circuit rotating partsSynchronous reluctance motorElectric machine

The invention provides a rotor assembly and a self-starting permanent magnet synchronous reluctance motor. The rotor assembly comprises a rotor core (1), on the cross section of the rotor core (1), the rotor core (1) is provided with slit grooves (2), q-axis squirrel cage grooves (4), independent squirrel cage grooves (6), d-axis squirrel cage grooves (5) and permanent magnets (3), the extension directions of the q-axis squirrel cage grooves (4) and the independent squirrel cage grooves (6) are parallel to the q-axis, and the d-axis squirrel cage grooves (5) extend in the direction parallel to the d-axis or extend in the radial direction of the rotor core (1). According to the rotor assembly provided by the invention, the q-axis magnetic flux can be increased, and meanwhile, the permanent magnet magnetic flux can smoothly enter the stator through the d axis, so that the permanent magnet torque and efficiency of the motor are improved.

Owner:GREE ELECTRIC APPLIANCES INC

High-reluctance torque driving motor of hybrid electric vehicle

InactiveCN111478539APrevent Fault PropagationAdjust the air gap magnetic field at any timeMagnetic circuit rotating partsElectric machinesElectric machinePermanent magnet synchronous motor

The invention provides a high-reluctance torque driving motor of a hybrid electric vehicle, and belongs to the technical field of vehicle motors. The permanent magnet synchronous motor is characterized by comprising a stator iron core, permanent magnets, armature windings, a multi-tooth-shaped block rotor, a magnetism adjusting winding, a non-magnetic-conductive rotor iron core and a shaft; 12 stator poles with the same width are arranged on the inner side of the stator iron core, and 8 multi-tooth-shaped block rotor iron cores capable of conducting magnetism are placed in the arc-shaped groove of the non-magnetic-conducting rotor; one magnetism adjusting winding is wound on the stator iron core every other stator pole, and armature windings are wound on the rest stator poles; a permanentmagnet is embedded in the middle of the pole body of the stator pole wound with the magnetism regulating winding; and the multi-tooth-shaped block rotor iron core is obtained by cutting a plurality ofU-shaped grooves in an outer arc line of the block rotor iron core, and each tooth groove of the multi-tooth-shaped block rotor iron core is filled with a non-magnetic light material. The multi-tooth-shaped block rotor iron core has the advantages that the multi-tooth-shaped block rotor iron core can change an air gap magnetic field of a motor, weaken harmonic waves in counter electromotive forceand reduce torque pulsation of the motor; and the embedded permanent magnet can improve the reluctance torque component of the motor.

Owner:SHANDONG UNIV OF TECH

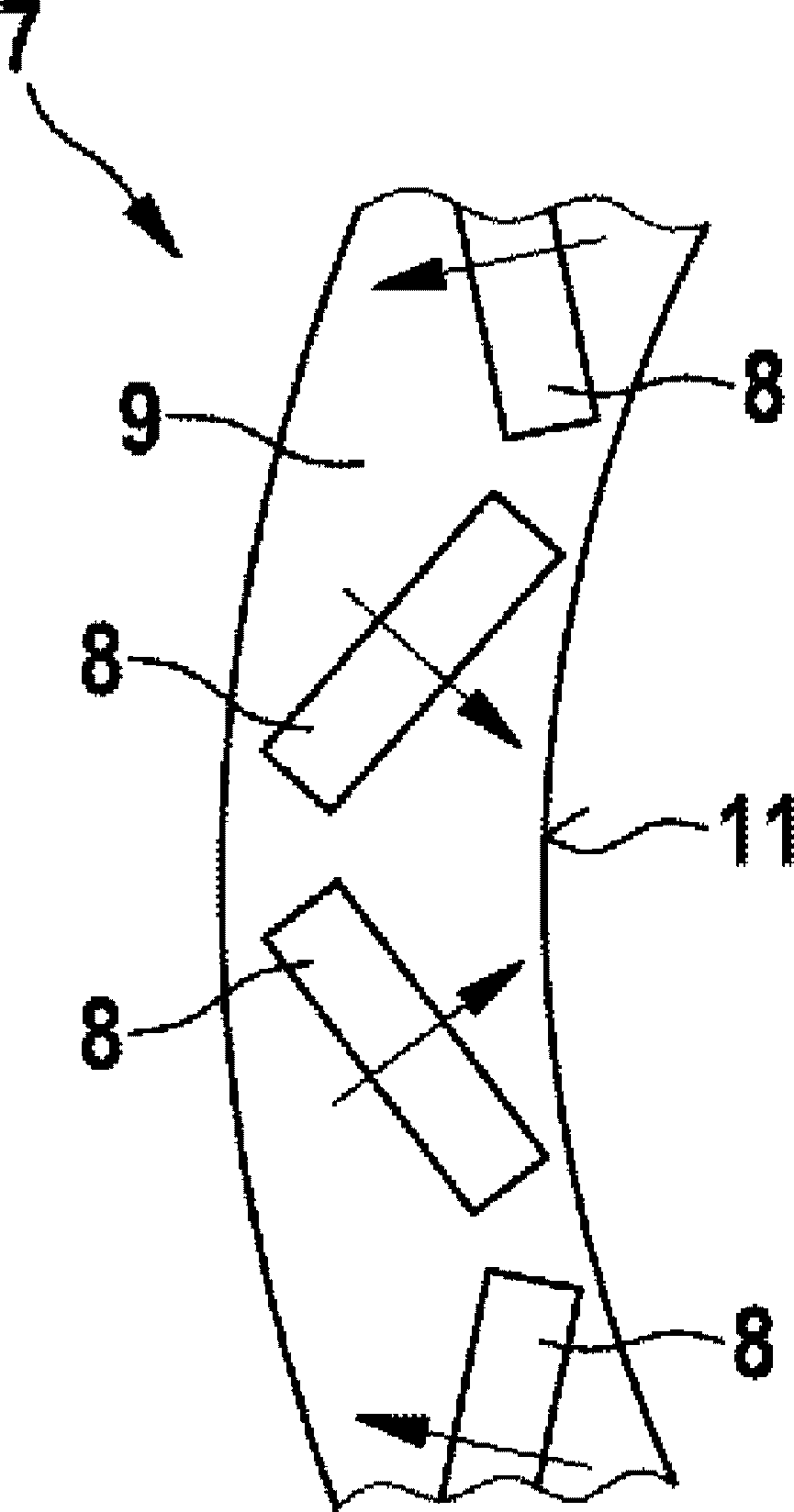

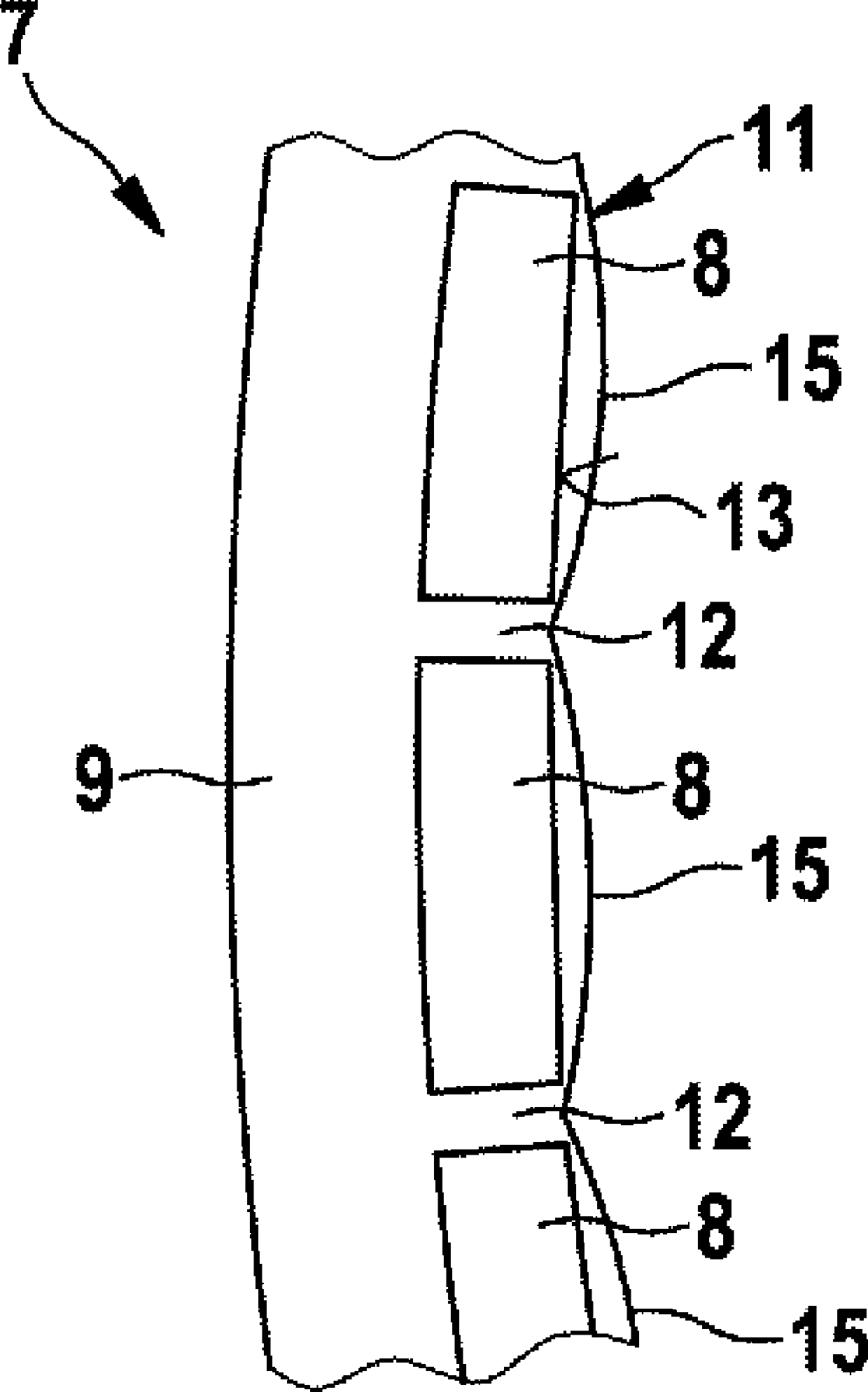

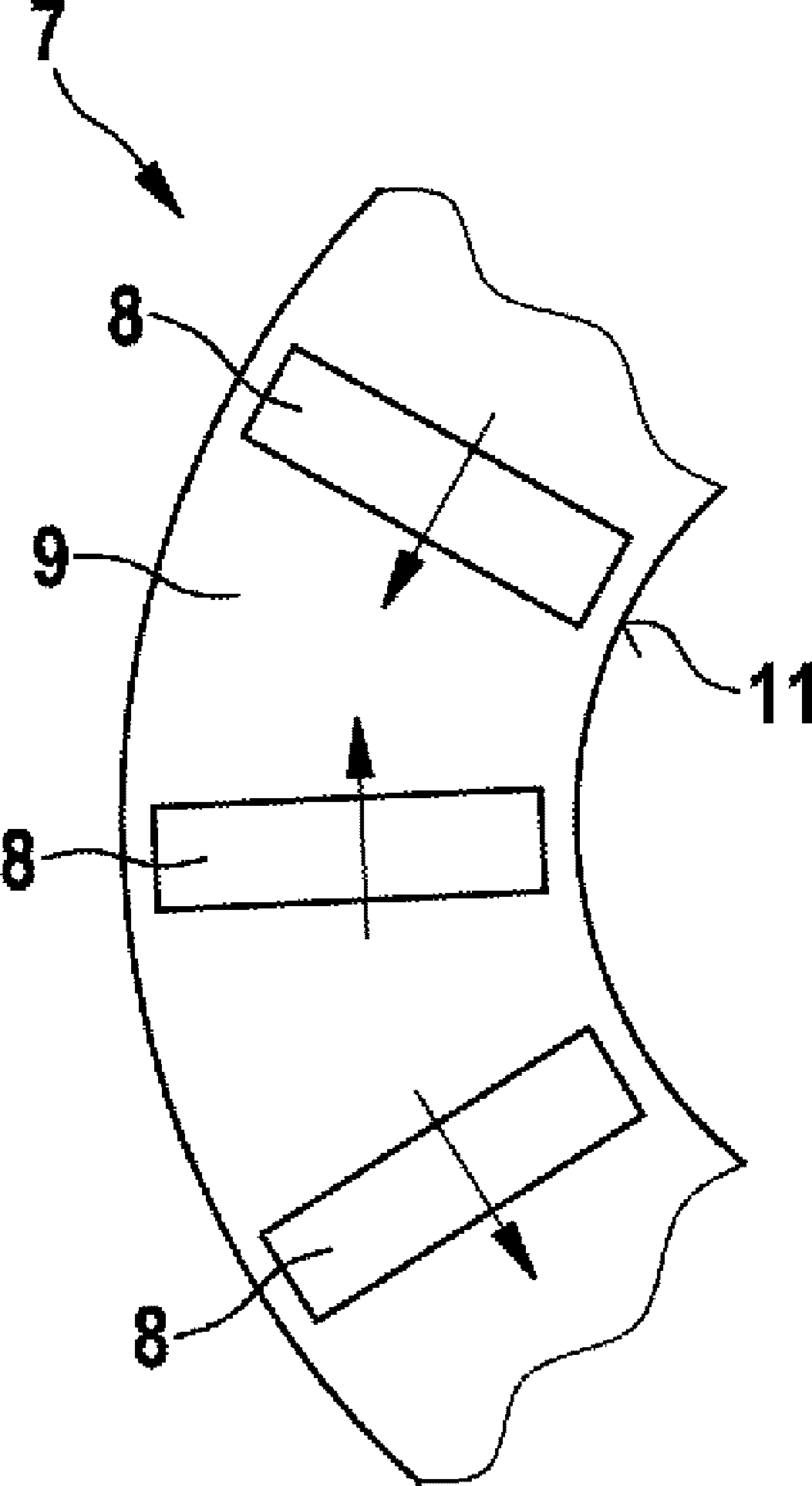

Electrically driven two-wheeled vehicle

InactiveCN104185591ASignificantly salientIncrease speedSpeed controllerMagnetic circuit rotating partsElectric machineEngineering

The invention relates to an electrically driven two-wheeled vehicle (1) comprising at least one electric machine (4) which has a stator (6) that is fixed to the axle and a rotor (7) that is fixed to the rim. The rotor (7) has a back iron ring (9) with a plurality of permanent magnets (8) which are distributed over the circumference of the back iron ring. The back iron ring (9) has pockets (10) on the back iron ring inner face (11) facing the stator (6), one permanent magnet (8), in particular a ferrite magnet, being at least substantially arranged in each said pocket. The invention further relates to a method for actuating such a two-wheeled vehicle.

Owner:ROBERT BOSCH GMBH

Rotary motor and rotor assembly thereof

ActiveCN112564343AIncrease reluctance torqueMagnetic circuit rotating partsElectric machineMagnetic reluctance

The invention discloses a rotary motor and a rotor assembly thereof. The rotor assembly comprises a first rotor. The first rotor comprises a first central shaft, a first rotor body, a first shaft hole, a plurality of first through hole groups, a plurality of second through hole groups and a first outer edge. The plurality of first through hole groups surround the first central shaft and are arranged at intervals. The plurality of second through hole groups surround the first central shaft and are arranged at intervals. One second perforation group is arranged between two adjacent first perforation groups. A first quadrature axis is defined between the adjacent first through hole group and second through hole group. The first through hole group defines a first straight axis, and the secondthrough hole group defines a second straight axis. The first outer edge includes a plurality of first sections respectively corresponding to a first quadrature axis, a plurality of second sections respectively corresponding to a first straight axis, and a plurality of third sections respectively corresponding to a second straight axis. The plurality of first sections are arranged in a protruding manner relative to the first rotor body. Therefore, the effect of enhancing the reluctance torque is achieved.

Owner:北京和山逢泰科技有限公司

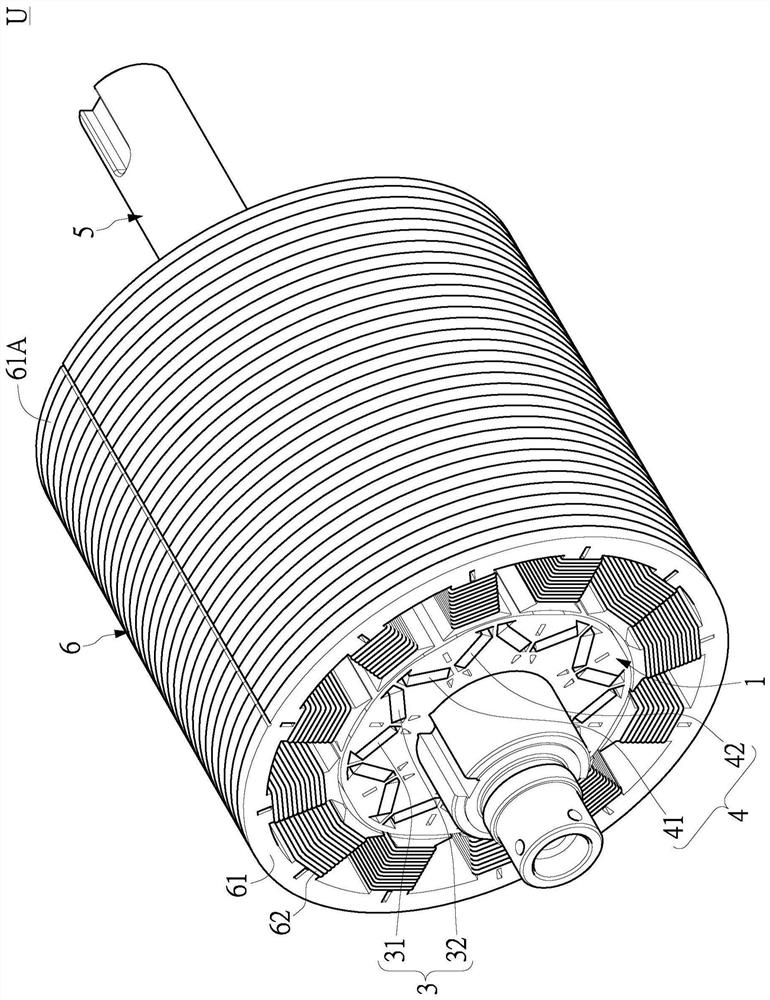

A highly integrated modular hub motor

ActiveCN111769688BPromote absorptionQuick changeAssociation with control/drive circuitsMagnetic circuit stationary partsElectric machineryEngineering

The invention provides a highly integrated modular hub motor, which belongs to the technical field of pure electric vehicles. The highly integrated modular hub motor includes an integrated motor and a parallel cooling system. The integrated motor includes a rotating assembly, a stator assembly, and a control module assembly. The stator assembly is located inside the rotating assembly, and the stator assembly is fixed on the axially outer side of the stator fixing sleeve. , the control module assembly is fixed inside the stator fixing sleeve; the cooling plate of the control module assembly is provided with a cooling pipeline A, and the stator fixing sleeve is provided with a cooling pipeline B, and the cooling pipeline B is connected in parallel with the cooling pipeline A to form a parallel connection cooling system. The invention has the performance of high integration and high-efficiency heat dissipation and cooling, and improves the adaptability of the whole motor to complex working conditions.

Owner:JIANGSU UNIV

Permanent magnet synchronous motor and rotor thereof

PendingCN114744795AReduce dosageImprove sinusoidalityMagnetic circuit rotating partsElectric machinesPermanent magnet synchronous motorMagnetic poles

The invention discloses a rotor of a permanent magnet synchronous motor. Each group of magnetic pole slots is divided into two inner magnetic pole slots positioned on the inner layer and one outer magnetic pole slot positioned on the outer layer along the radial direction of a rotor iron core sheet; two of the magnetic pole groups are first permanent magnets, the other one of the magnetic pole groups is a second permanent magnet, after the first permanent magnets are matched with the inner magnetic pole grooves, the two first permanent magnets are arranged in a V shape, and a magnetic pole straight shaft which is axially symmetric about the two first permanent magnets is arranged between the two first permanent magnets; at least one end of the inner magnetic pole groove extends to form a magnetic isolation groove located on the outer side of the first permanent magnet. After the second permanent magnets are matched with the outer magnetic pole grooves, the symmetry axes of the second permanent magnets coincide with the magnetic pole straight axes, and the distance between the second permanent magnets and the peripheral face of the rotor iron core piece is smaller than the distance between the first permanent magnets and the peripheral face of the rotor iron core piece. According to the invention, the counter electromotive force can be reduced, the no-load counter electromotive force waveform sinusoidal property is improved, the reluctance torque is improved, and the cogging torque is reduced.

Owner:成都华川电装有限责任公司

Rotor structure of a drive motor

ActiveCN108599416BReduce stress concentrationReduce the maximum stress valueMagnetic circuit rotating partsElectric machineryMagnetic reluctance

The invention discloses a rotor structure of a drive motor. The rotor structure comprises a rotor sheet and a plurality of V-shaped grooves, wherein the plurality of V-shaped grooves are circularly arrayed on the rotor sheet; a direct-axis reinforcing rib is arranged at a middle position of each of the V-shaped grooves; a rectangular magnetic steel is embedded into two edges of the each of the V-shaped grooves; and an unloading hole is formed below each of the direct-axis reinforcing ribs. According to the rotor structure, through the above structural design, the strength of the rotor structure is improved, an armature direct-axis magnetic circuit can be effectively hindered, the direct-axis inductance is reduced, the saliency ratio is improved, and the reluctance torque is improved; and furthermore, the leakage flux at the place is reduced, the utilization ratio of a magnet is improved, and the efficiency and performance of a motor applying the rotor are obviously improved.

Owner:深圳市泉胜新技术开发有限公司

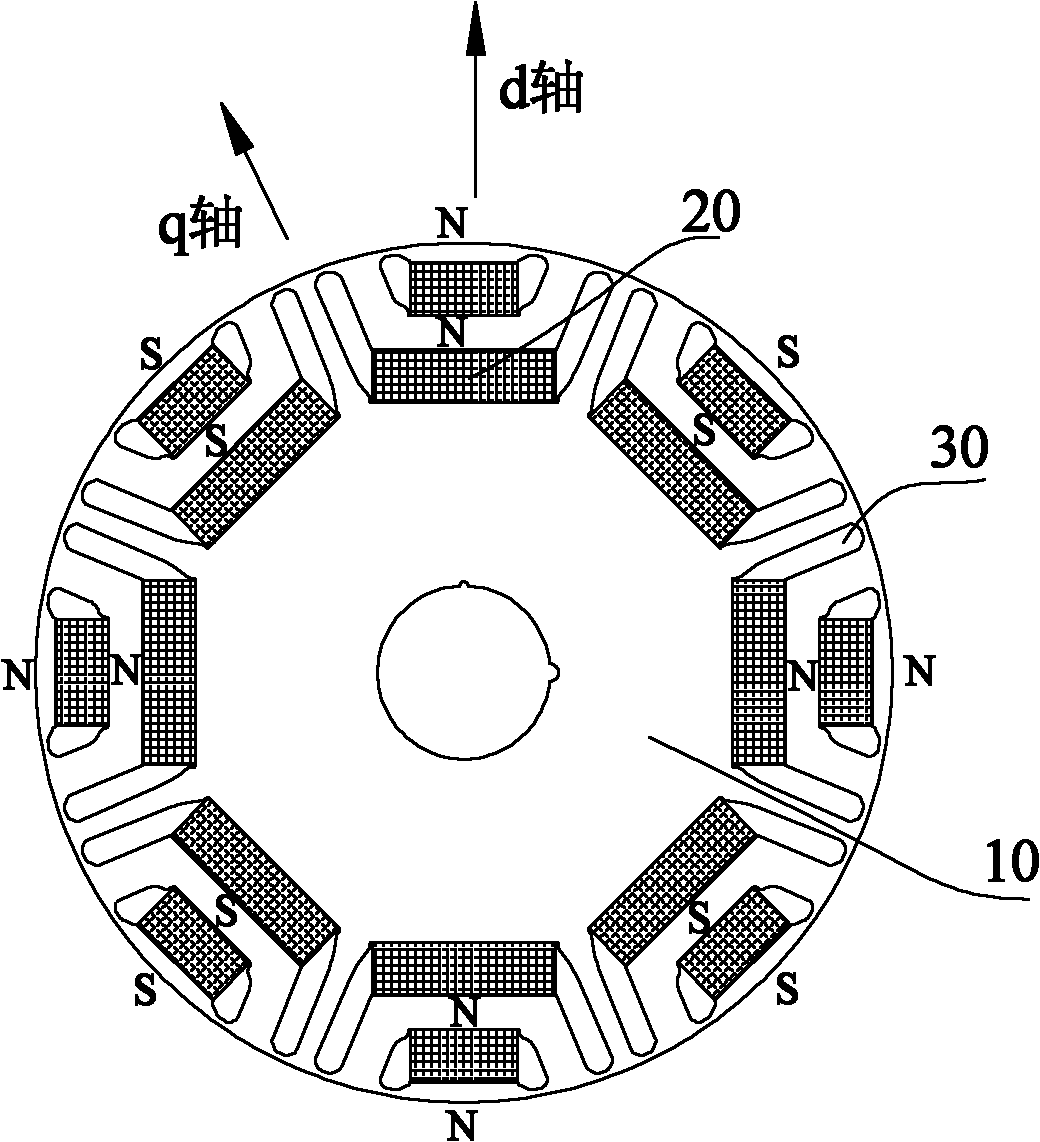

Rotor punching sheet structure of permanent magnet synchronous motor for electric motorcycle and rotor thereof

PendingCN114362400AReduce harmonic contentImprove efficiencySynchronous machine detailsMagnetic circuitPermanent magnet synchronous motorStructural engineering

The invention discloses a permanent magnet synchronous motor rotor punching sheet structure for an electric motorcycle, which comprises a punching sheet body, the punching sheet body is divided into a plurality of fan-shaped areas with the same shape and size, groove groups are arranged in the fan-shaped areas close to arc edges, and each groove group comprises an inner-layer groove body and an outer-layer groove body which are respectively used for installing magnetic steel. The outer groove body is arranged on one side, close to the arc edge of the fan-shaped area, of the inner groove body; the inner-layer groove body comprises an inner-layer middle groove and inner-layer side grooves formed in the two sides of the inner-layer middle groove, the inner-layer middle groove and the inner-layer side grooves are rectangular, the inner-layer middle groove is symmetrically formed in the center line of the fan-shaped area, and the two inner-layer side grooves are symmetrically formed in the two sides of the inner-layer middle groove with the center line of the fan-shaped area as the center; inner-layer middle magnetic isolation grooves are formed in the two side edges of the inner-layer middle groove correspondingly, and inner-layer side magnetic isolation grooves are formed in the side edges, away from the inner-layer middle groove, of the inner-layer side grooves; and the outer-layer groove bodies are symmetrically arranged at the center lines of the fan-shaped areas. The invention further discloses the permanent magnet synchronous motor rotor for the electric motorcycle.

Owner:擎风电驱动科技(常州)有限公司

A Stator-Rotor Structure of a High Power Density Reluctance Motor

ActiveCN110932425BReduce leakage fluxReduce torque fluctuationMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic barrierElectric machine

The invention discloses a stator and rotor structure of a high-power-density reluctance motor. The structure comprises a stator and a rotor, the number of stator slots and the number of rotor magneticbridges meet the formula (1): Nr = Ns-4k (1), Ns is the number of stator slots corresponding to each pair of poles, Nr is the number of rotor magnetic bridges corresponding to each pair of poles, K is a positive integer, and the number of rotor magnetic bridges corresponding to each layer of rotor magnetic barriers is 2; the number of layers of the rotor magnetic barriers is Nr / 2, and then rounding is carried out; the opening angle alpha of the outermost layer magnetic bridge of the rotor meets the formula (2), wherein p is the number of pole pairs. According to the invention, the leakage flux of the motor can be reduced, the salient pole ratio of the motor is improved, the torque output capability of the motor is improved, and the torque ripple of the motor can be reduced.

Owner:HANGZHOU EASITECH

Low-harmonic-content motor generator of electric automobile

InactiveCN111478543APrevent Fault PropagationAdjust the air gap magnetic field at any timeMagnetic circuit rotating partsElectric machinesMagnetic barrierElectric machine

The invention provides a low-harmonic-content motor generator of an electric automobile, and belongs to the technical field of automobile motors. The motor generator is characterized in that the motorgenerator comprises a stator iron core, an excitation winding, an armature winding, a block rotor, a non-magnetic rotor iron core and a shaft; and twelve stator poles with the same width are arrangedon the inner side of the stator iron core, eight block rotor iron cores capable of conducting magnetism are embedded in an arc-shaped groove of the non-magnetic rotor, the exciting windings and the armature windings are all centralized short-moment windings, the exciting windings are wound on the stator iron core at intervals, and the armature windings are wound on the stator poles between the two exciting windings. 1-4 parallel U-shaped air gap magnetic barriers are linearly cut out in each block rotor core, and the air inlet gap magnetic barrier is filled with a non-magnetic light material.The motor generator is a short magnetic circuit motor, and the iron loss is small under the same flux density; and the windings are short-moment windings and are not overlapped, so that heating of the motor is reduced. And the air gap magnetic barriers on the block rotors can effectively reduce even harmonics of the counter electromotive force of the motor, and the stability of operation is improved.

Owner:SHANDONG UNIV OF TECH

Permanent magnet motor rotor for automobile

PendingCN111064298AIncrease reluctance torqueEnsure safetyMagnetic circuit rotating partsElectric machineryMagneto

The invention provides a permanent magnet motor rotor for an automobile. The salient pole rate of a motor is further increased through a double-V-shaped topological structure, so the reluctance torqueand the power density of the motor are greatly increased; and the design of double parallel magnetic bridges improves the strength of the rotor, ensures the safety of the motor, and reduces the demagnetization risk of the motor. The permanent magnet motor rotor for the automobile adopts the double-layer V-shaped topological structure. The double-V-shaped rotor topological structure and the designof the parallel auxiliary magnetic bridges ensure the safety of the motor rotor structure and improve the power density of the motor.

Owner:WANXIANG

Synchronous reluctance permanent magnet motor rotor structure

PendingCN110971030AIncrease reluctance torqueImprove power densityMagnetic circuit rotating partsPunchingElectric machine

The invention discloses a synchronous reluctance permanent magnet motor rotor structure. The structure comprises a permanent magnet, a salient pole, punching sheet closed grooves, magnetic steel grooves, a rotor and a shell, the punching sheet closed grooves are formed in the inner side of the shell, the magnetic steel grooves are formed between the punching sheet closed grooves, the rotor is arranged in the shell, and the permanent magnet is arranged in the rotor. According to the invention, the permanent magnet is placed in the rotor, and the salient pole is added in the axial direction of the rotor to better increase the difference between the d-axis inductance and the q-axis inductance, so that the reluctance torque of the motor is more effectively improved, the power density of the motor is higher, the size of the motor is reduced, the starting performance of the motor is better, and the motor is suitable for wide popularization and application.

Owner:淮安精英电气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com