Novel rotor lamination structure

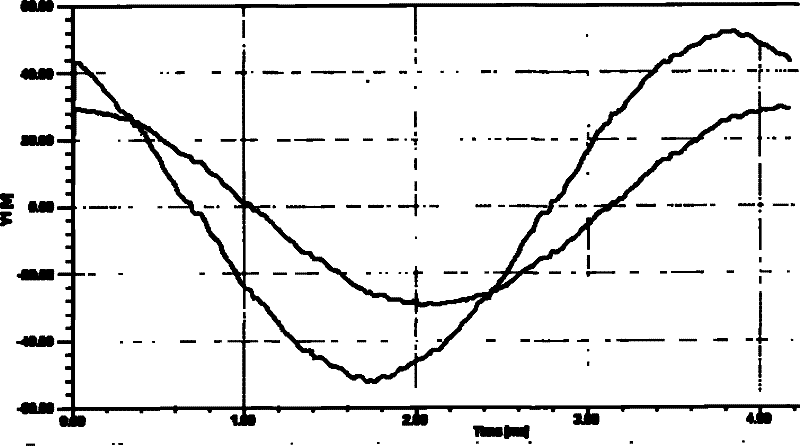

A rotor punching, a new type of technology, applied in the field of punching structure, can solve the problems of increasing the difficulty in the development and design of motor controllers, difficult back electromotive force, etc., and achieve the effects of large reluctance torque, high mechanical strength, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

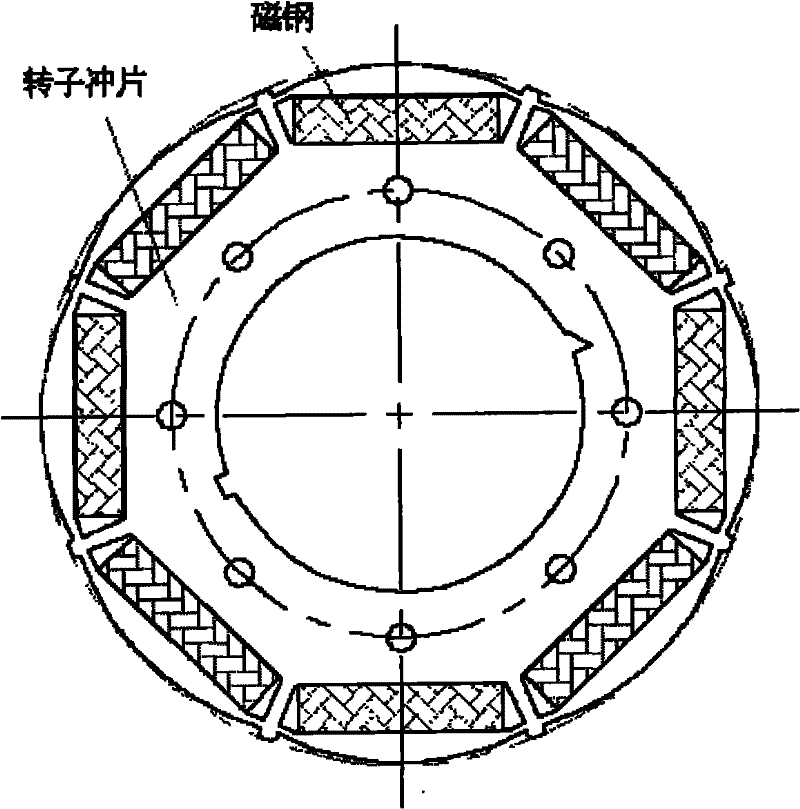

[0011] like figure 1 , When designing the rotor, the magnetic steel is embedded in the magnetic steel slot of the rotor core, and there are triangular slot gaps at both ends of the magnetic steel slot.

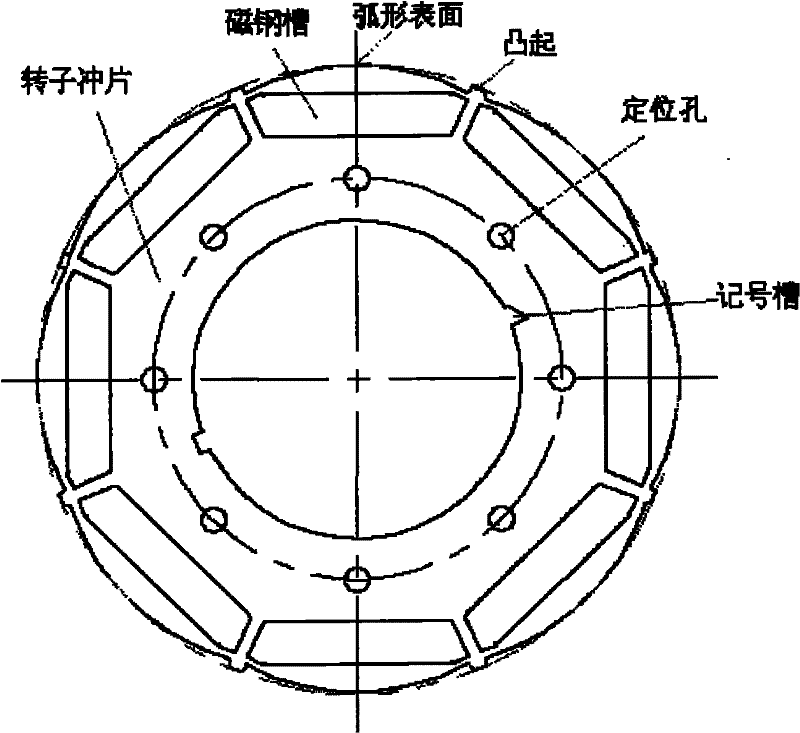

[0012] like figure 2 , its outer surface is an arc-shaped surface structure with eight sections evenly distributed. The position corresponding to the middle of the magnetic steel slot is the highest point of the arc-shaped surface; a bump. This structure can not only ensure that the rotor has sufficient mechanical strength at a relatively high speed, but also easily generate a back electromotive force with a sinusoidal waveform. In addition, eight positioning holes are evenly distributed in the middle part of the rotor punch; on the inner circle of the punch, there are a pair of marking grooves.

[0013] Utilize the technical solution described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com