Flux-switching type permanent magnet motor with permanent magnet fixing bosses

A technology of fixing the boss and switching the magnetic flux, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of hidden dangers in the normal operation of the motor, difficulty in fixing, and falling off of the motor, and achieve the winding process The effect of reducing difficulty, benefiting efficiency, and reducing the risk of radial shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

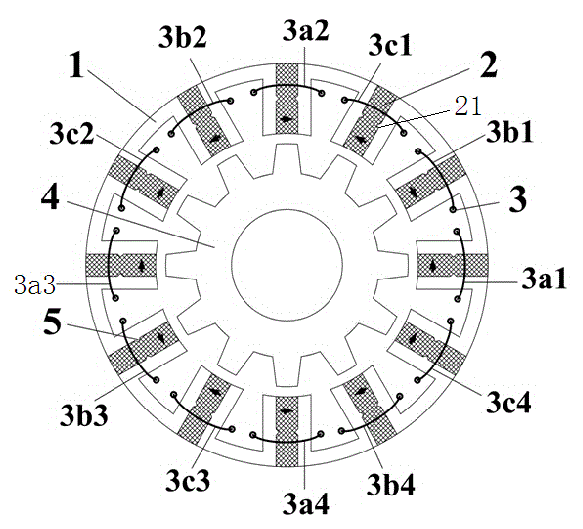

[0013] Taking a three-phase stator with twelve slots / rotor with ten poles and permanent magnet fixed bosses as an example, the flux switching type permanent magnet motor, the present invention is as follows: figure 1 As shown, "U" shaped magnetic core 1, permanent magnet 2, stator three-phase concentrated winding 3, first concentrated winding 3a1, second concentrated winding 3b1, third concentrated winding 3c1, fourth concentrated winding 3a2, fifth concentrated Winding 3b2, sixth concentrated winding 3c2, seventh concentrated winding 3a3, eighth concentrated winding 3b3, ninth concentrated winding 3c3, tenth concentrated winding 3a4, eleventh concentrated winding 3b4, twelfth concentrated winding 3c4, rotor core 4 and permanent magnet fixing boss 5.

[0014] The present invention is provided with the rotor iron core 4, the stator iron core that is arranged on the periphery of the rotor iron core 4 with the same core, the stator iron core is provided with several pairs of "U" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com