Design method of five-phase permanent magnet fault-tolerant motor with high reluctance torque and high salient pole rate

A technology of permanent magnet fault tolerance and design method, which is applied in the direction of control of generators, motor generator control, magnetic circuit rotating parts, etc., and can solve the problems of low reluctance torque and saliency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

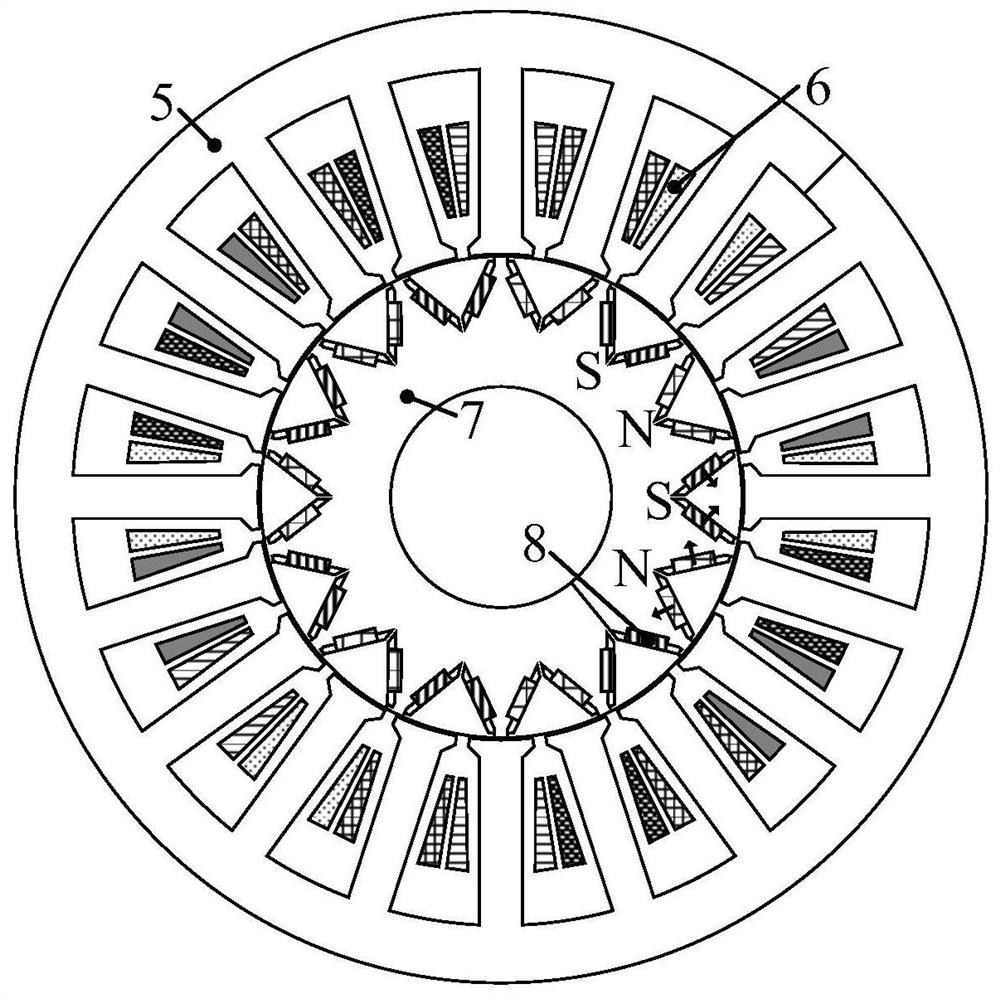

[0060] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

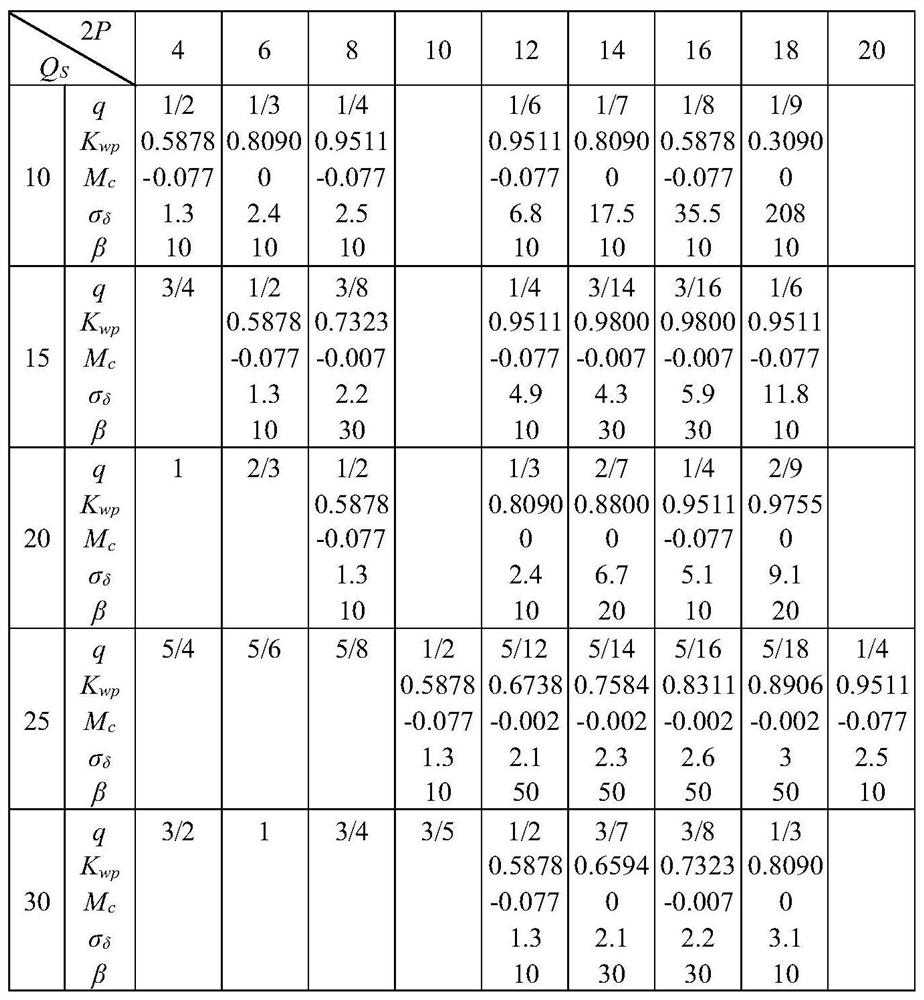

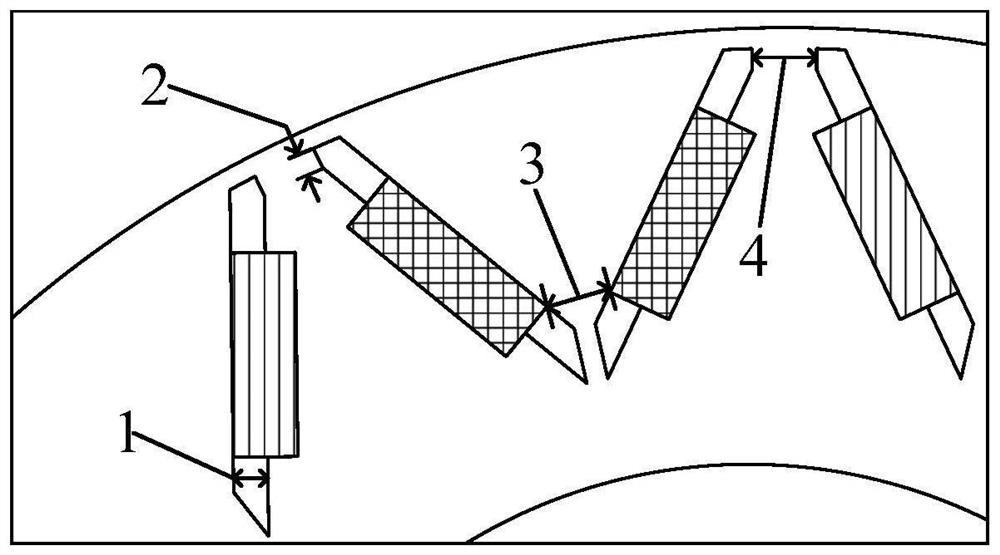

[0061] According to the relationship between the fault-tolerant performance of the five-phase permanent magnet motor and the self-inductance and mutual inductance of the motor, the present invention determines the basic slot and pole coordination of the permanent magnet fault-tolerant motor; considering the use of a stator with fractional slot concentrated windings, according to the motor winding factor and torque performance According to the relationship between slots and poles with high winding factor, the slot and pole coordination with high winding factor is selected; considering the leakage inductance coefficient and rotor loss, the slot and pole coordination with low leakage inductance coefficient and low rotor loss is determined; according to the principle of cogging torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com