Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improved (cost) efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

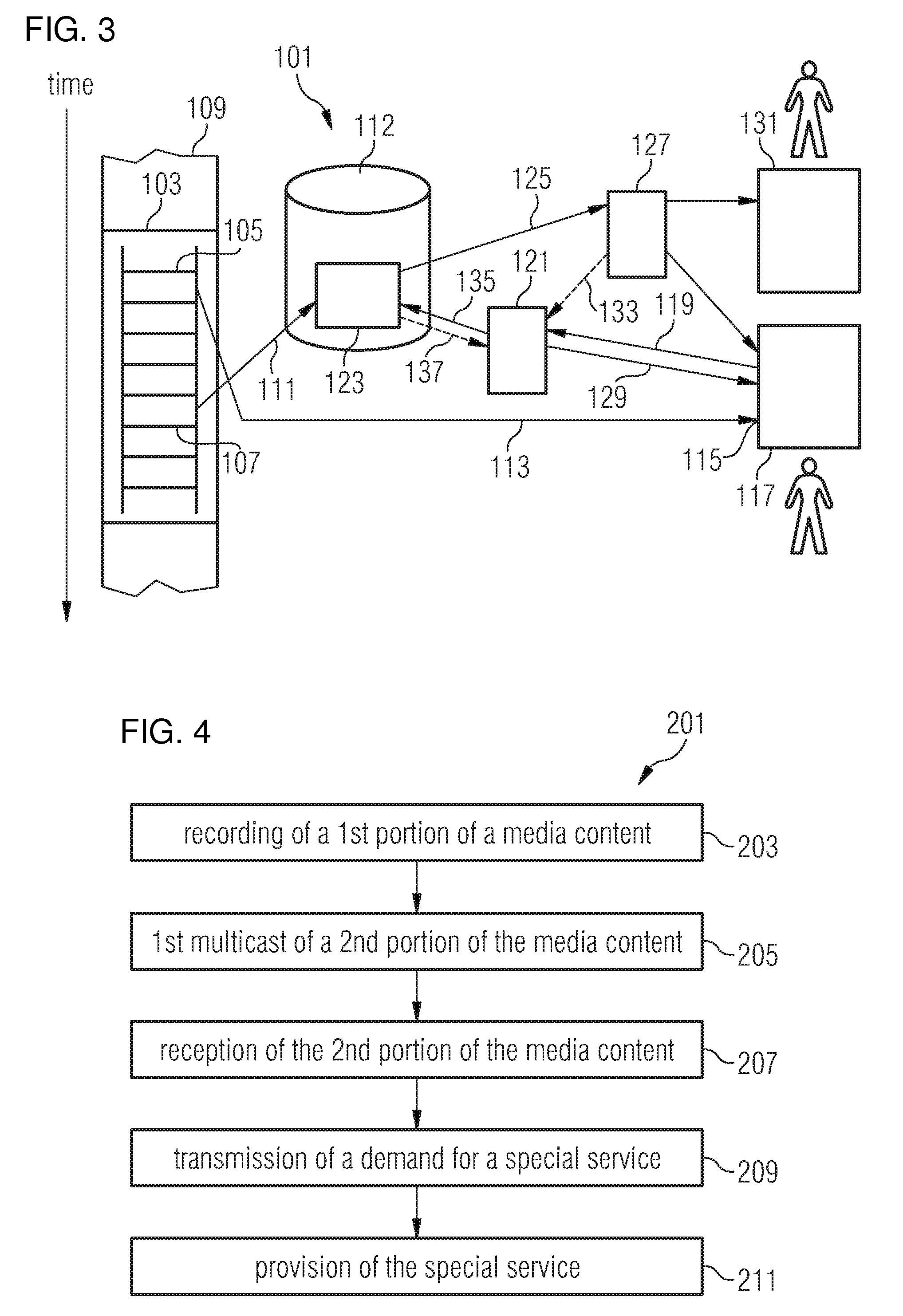

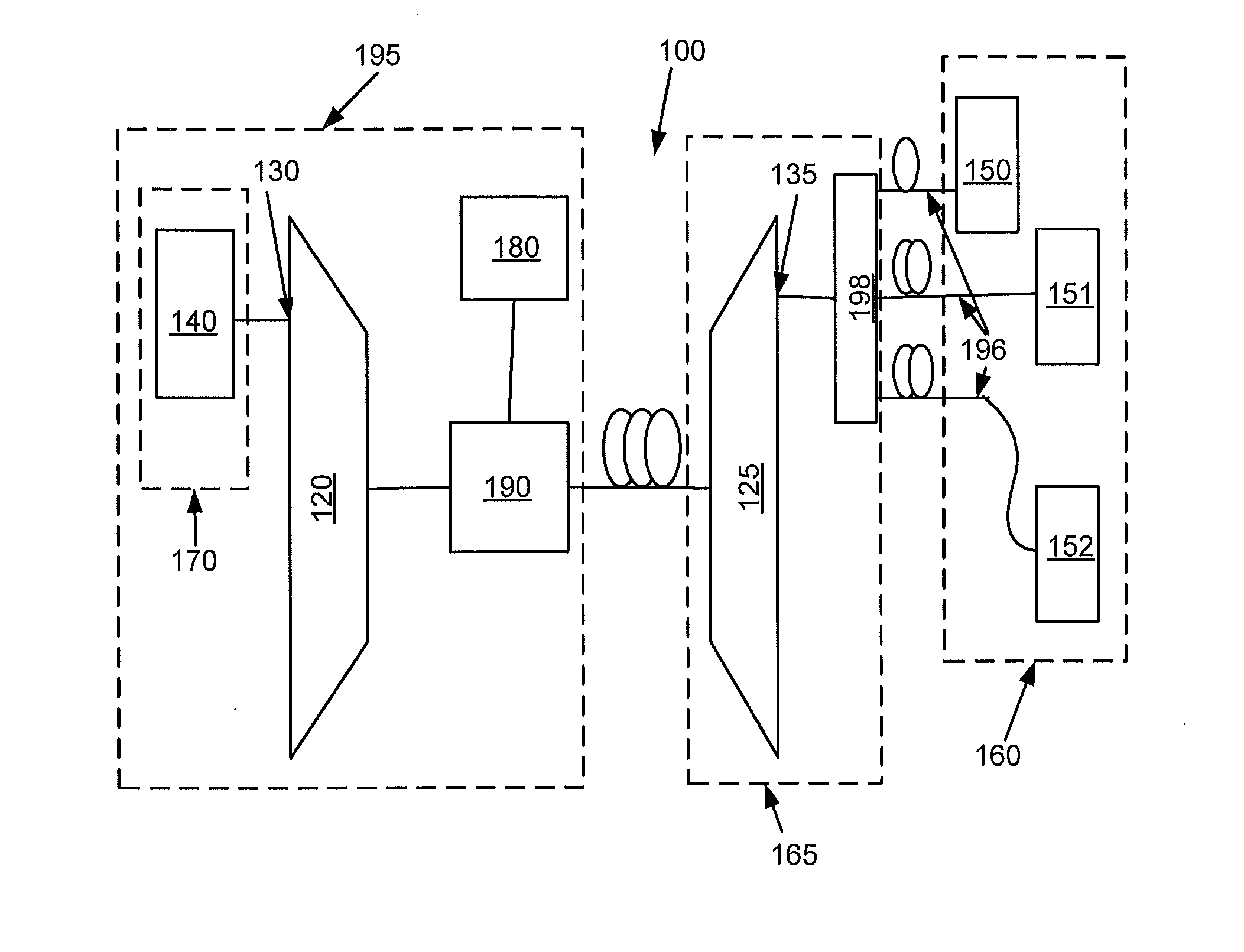

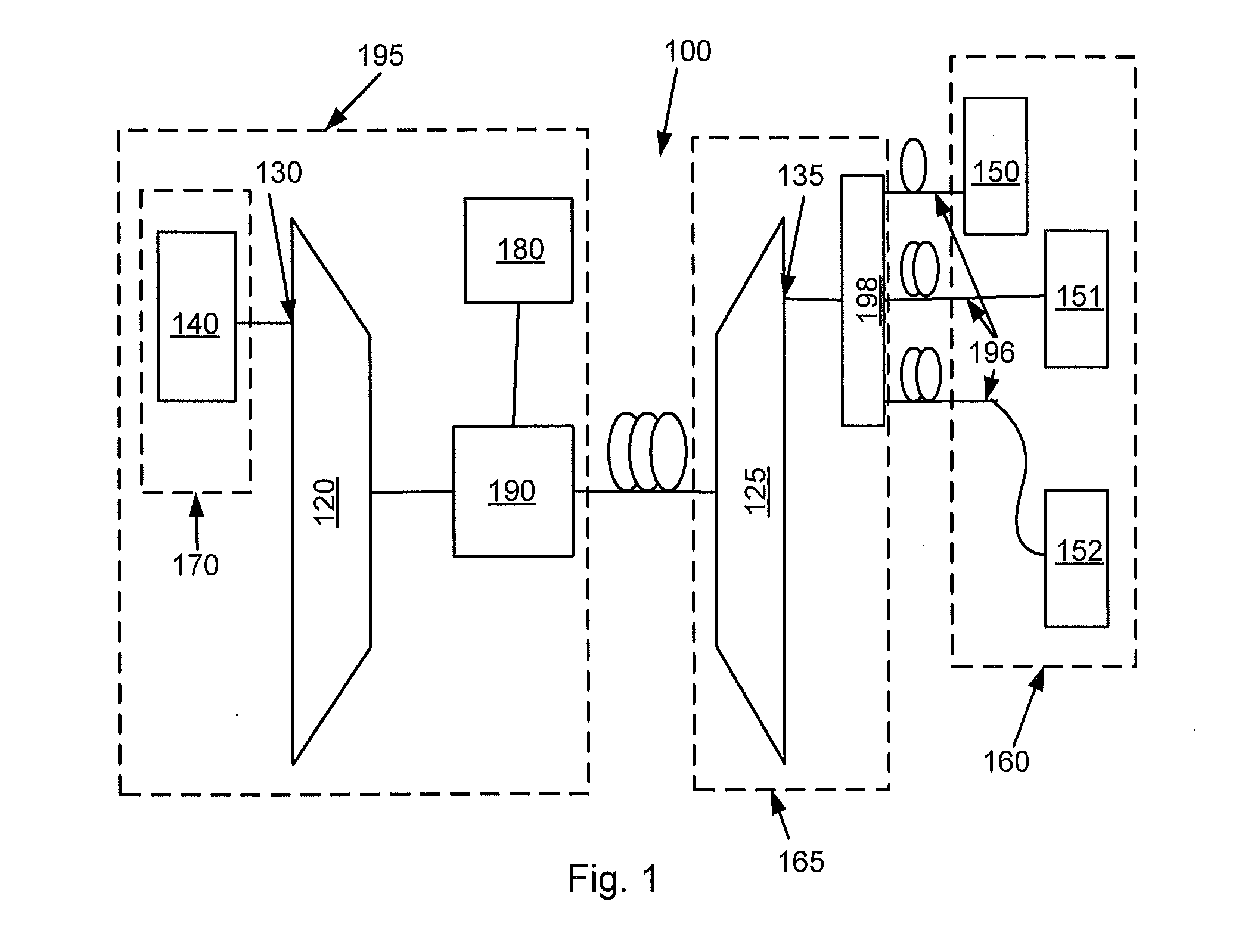

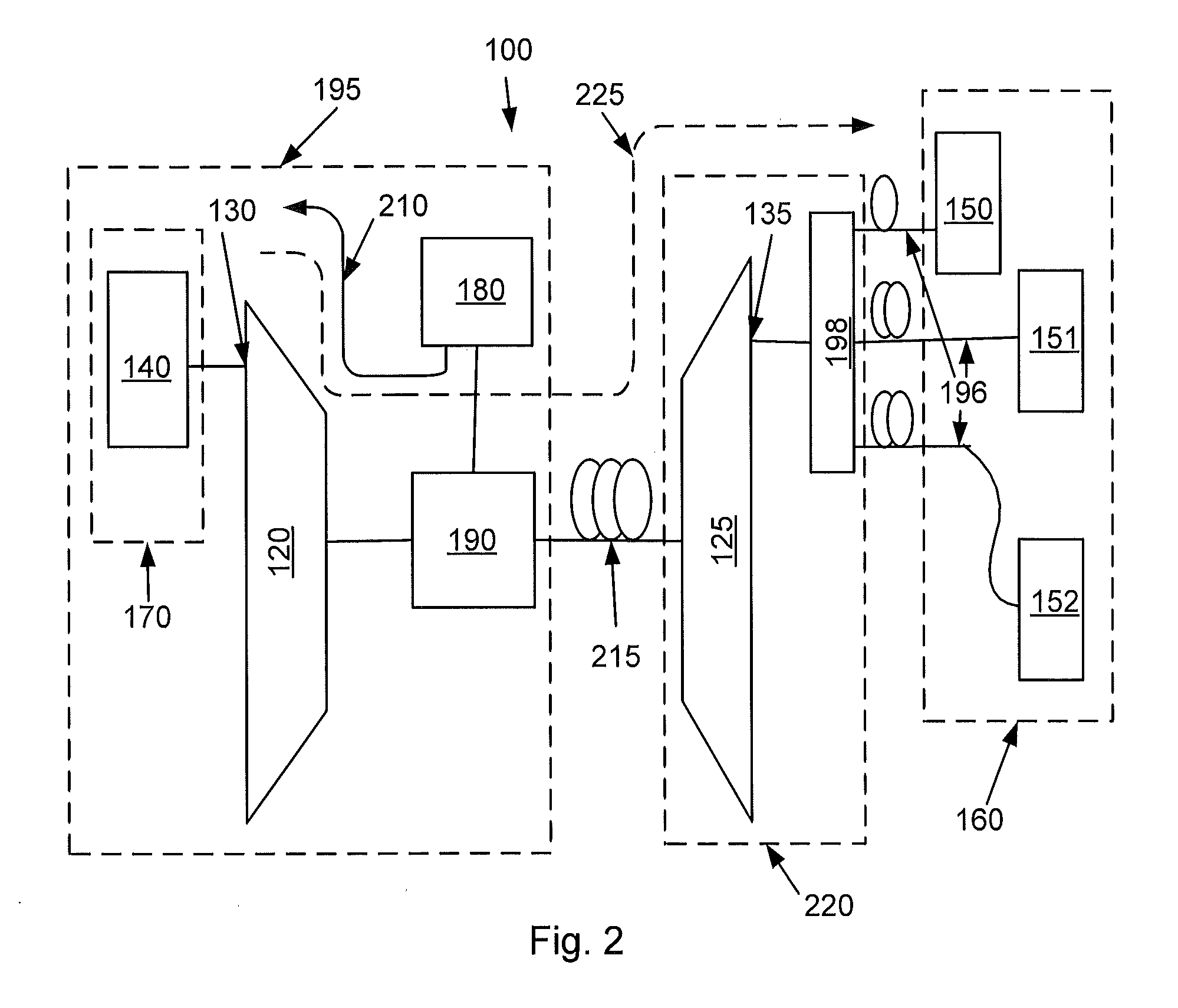

Load control for a television distribution system

InactiveUS20100293583A1Easy to optimizeImprove throughputAnalogue secracy/subscription systemsTwo-way working systemsService controlDistribution system

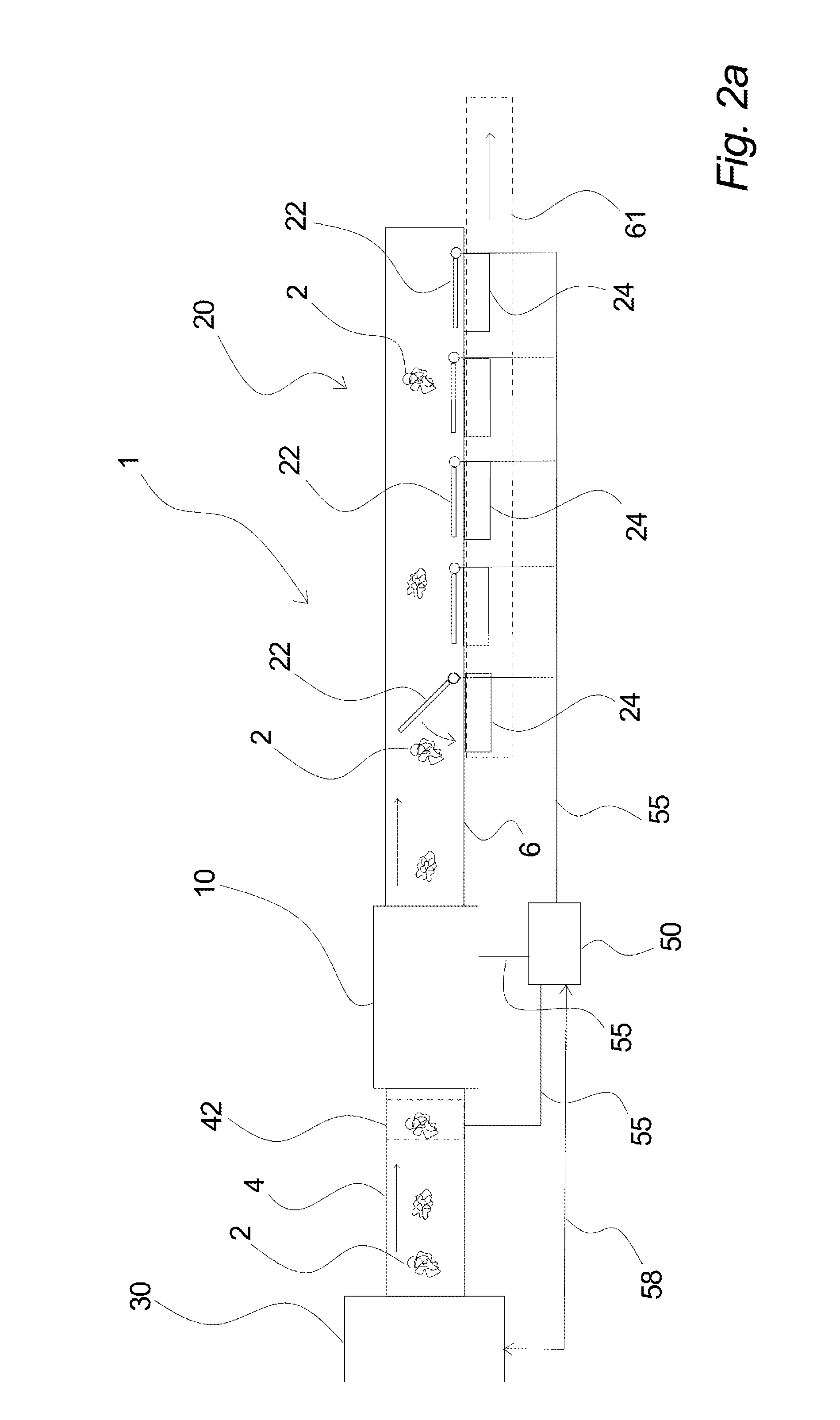

A method for distribution of media content 103 of a television program 109 comprises following steps: a recording 111 of first data 105 of the media content 103 on a storage medium (112), a first point-to-multipoint distribution 113 of second data 107 of said media content, a reception 115 of the second data 107 of said media content 103 using a first user equipment 117, a transmission of a demand 119 for a special service from the first user equipment 117 to a service control means 121, a detection of a load status of at least one network element 127, an execution of a load control action by the service control means 121 appropriate for changing the load of the at least one network element 127 in dependence on the detected load status, and a provision of the special service, wherein the at least one network element 127 is employed for providing the special service.

Owner:NOKIA SOLUTIONS & NETWORKS OY

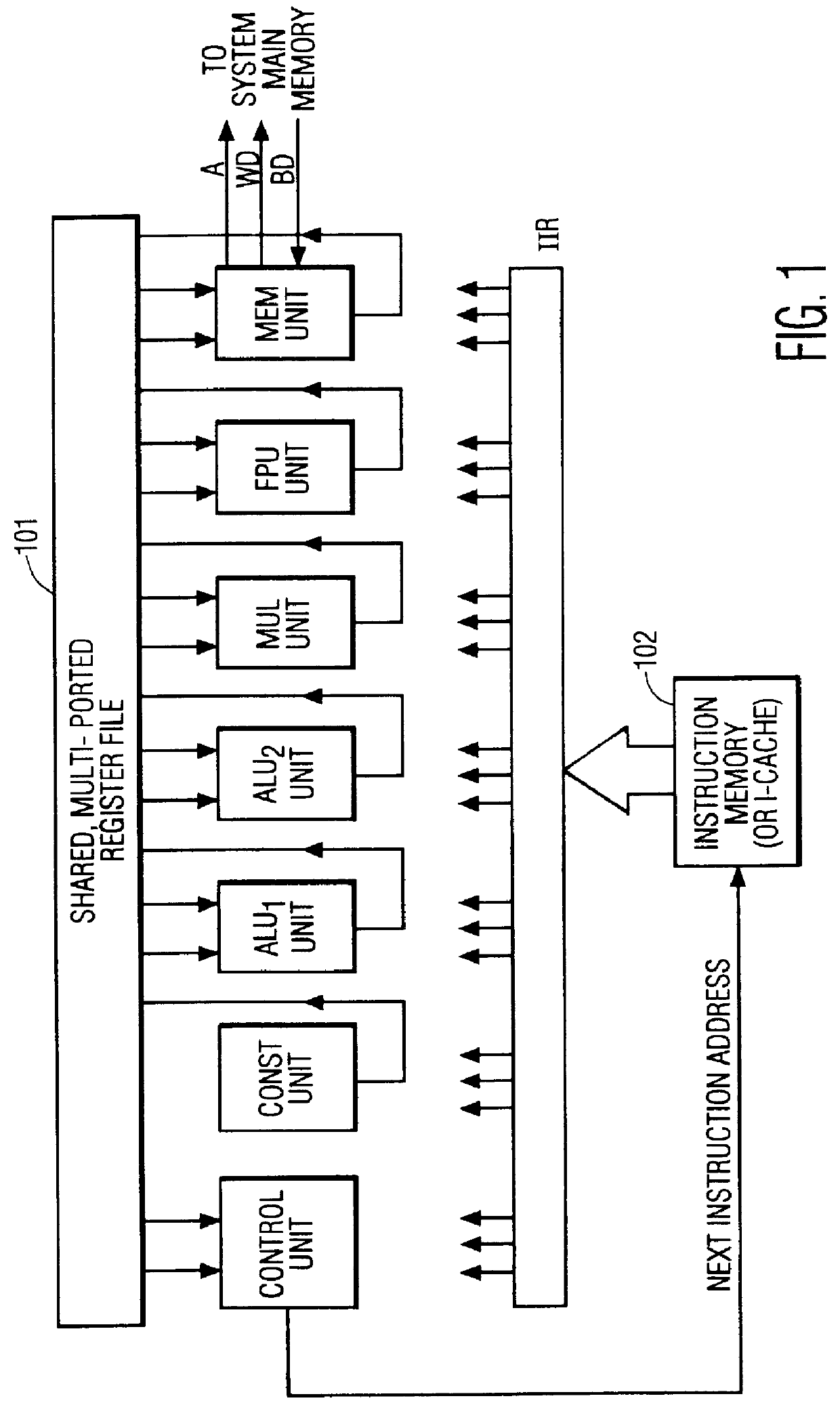

VLIW processor with write control unit for allowing less write buses than functional units

InactiveUS6044451AImproved cost-efficiencyRegister arrangementsGeneral purpose stored program computerProcessor registerUnit cost

Owner:FOOTHILLS IP LLC

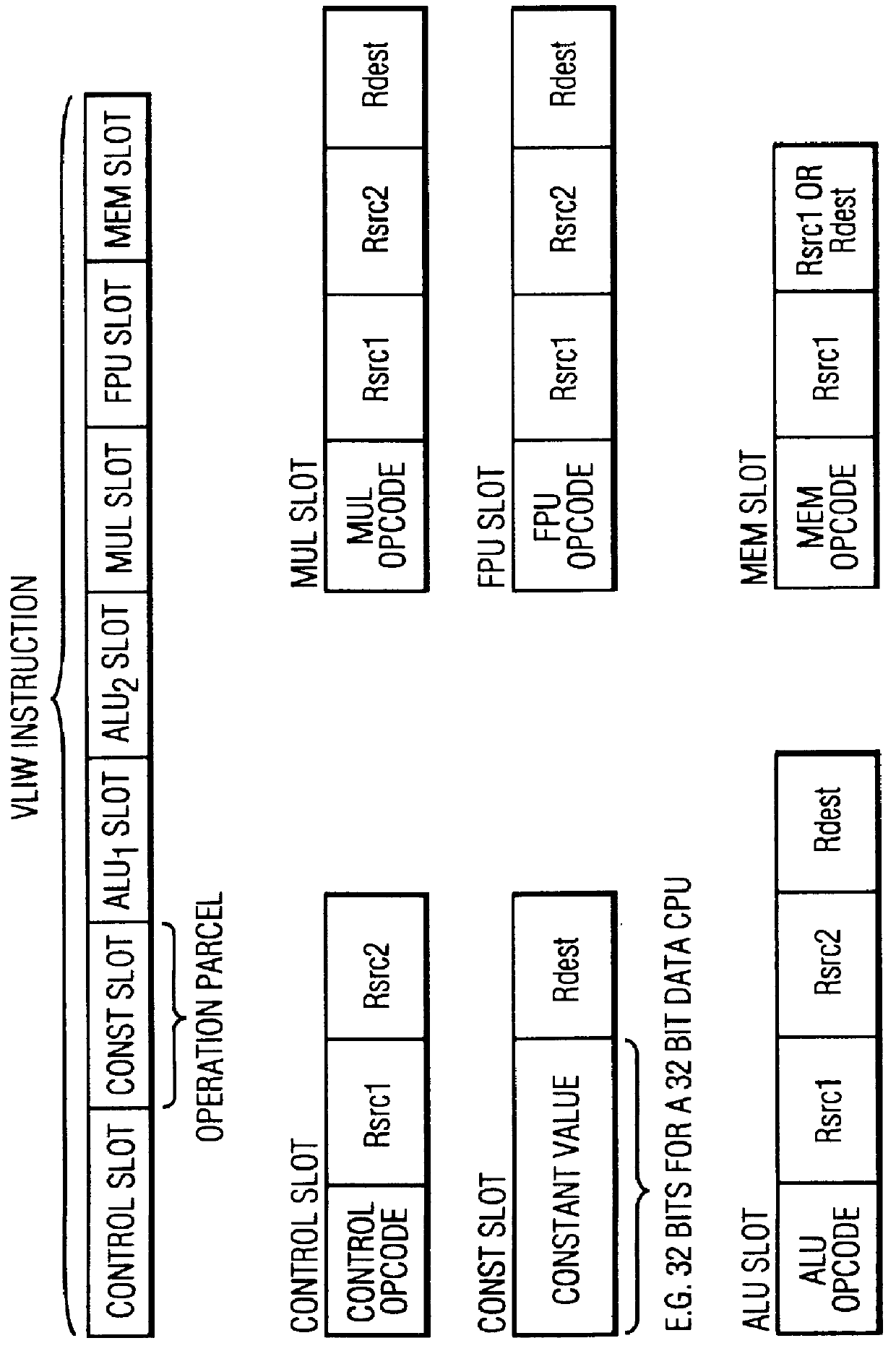

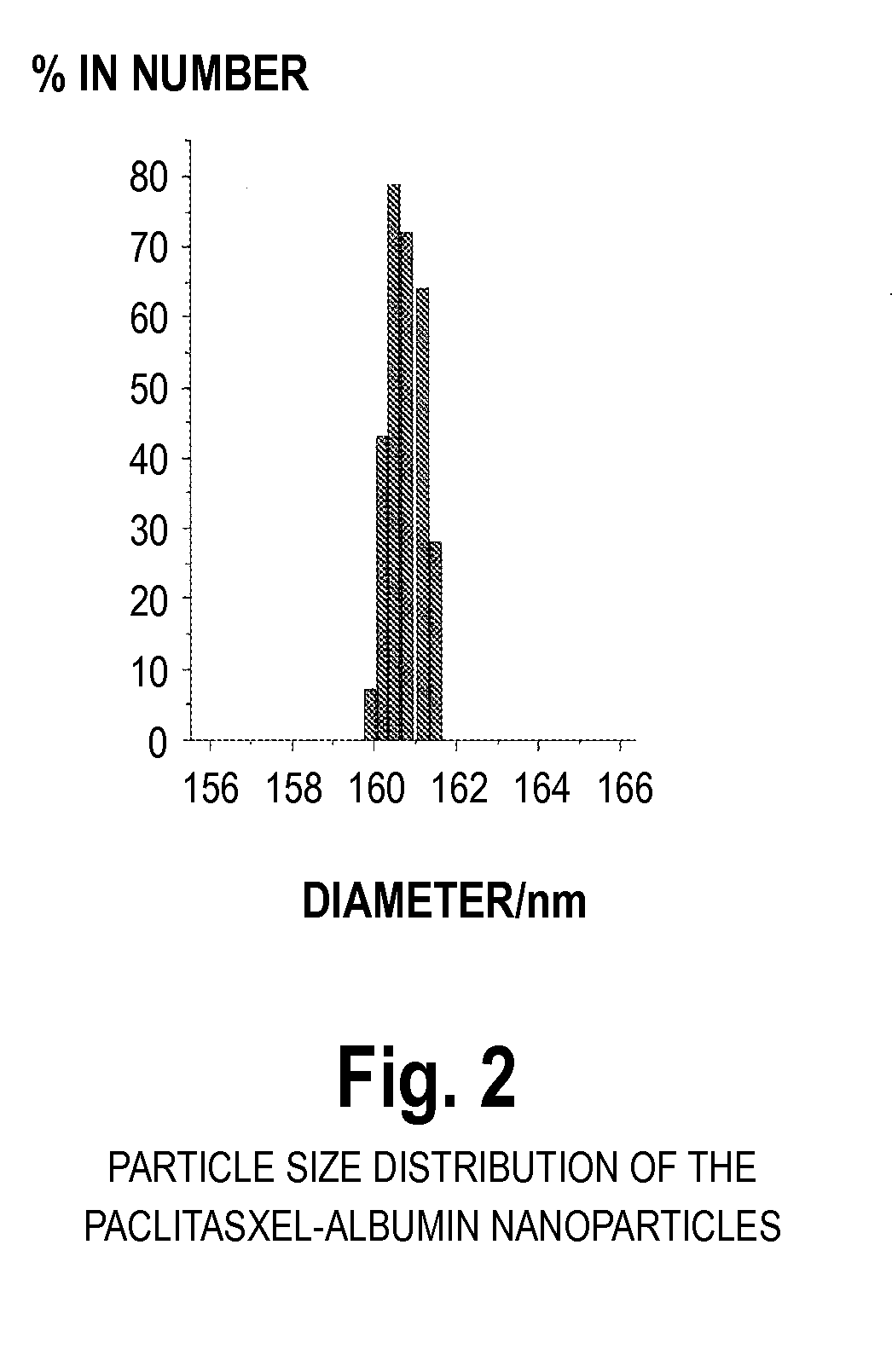

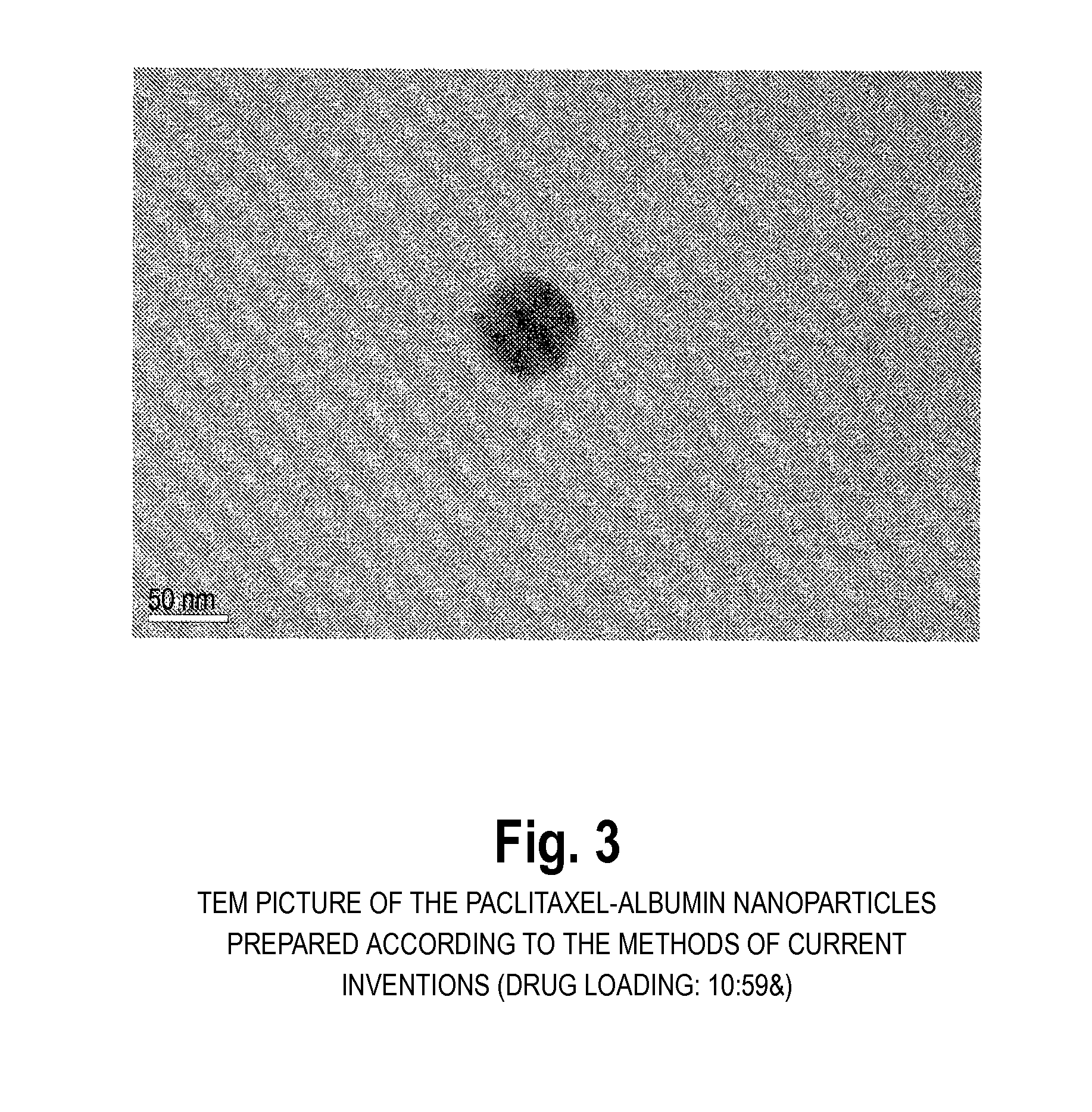

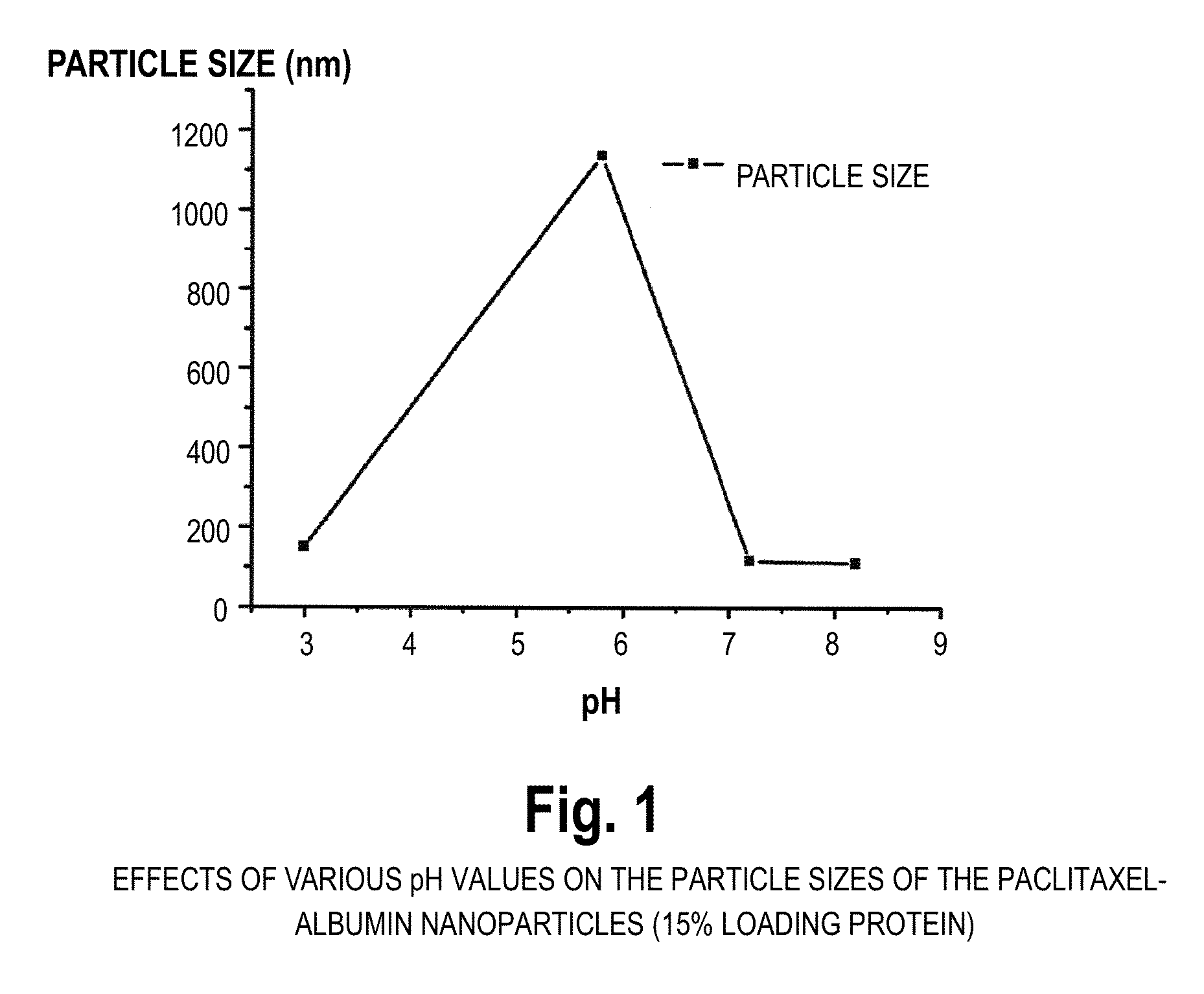

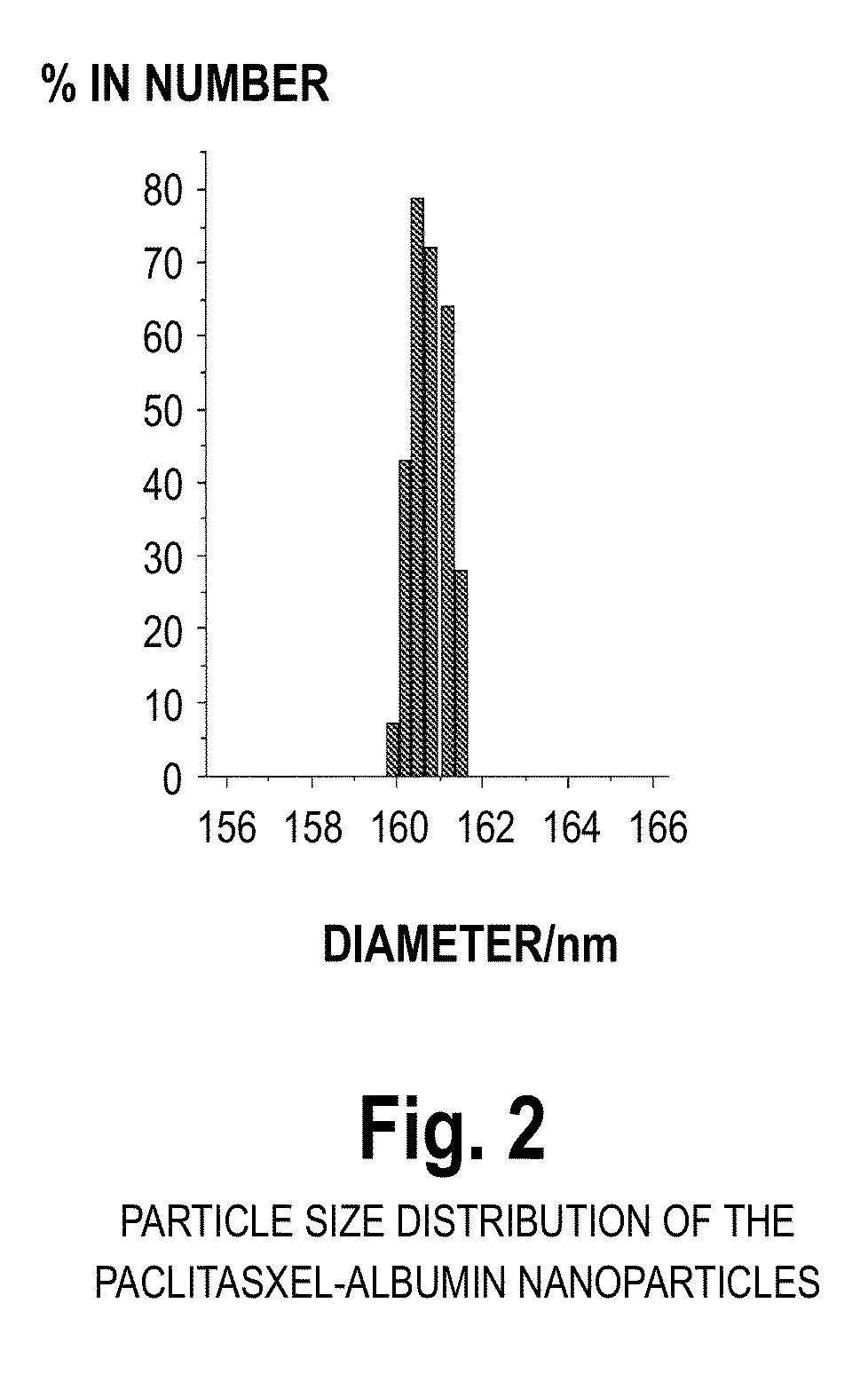

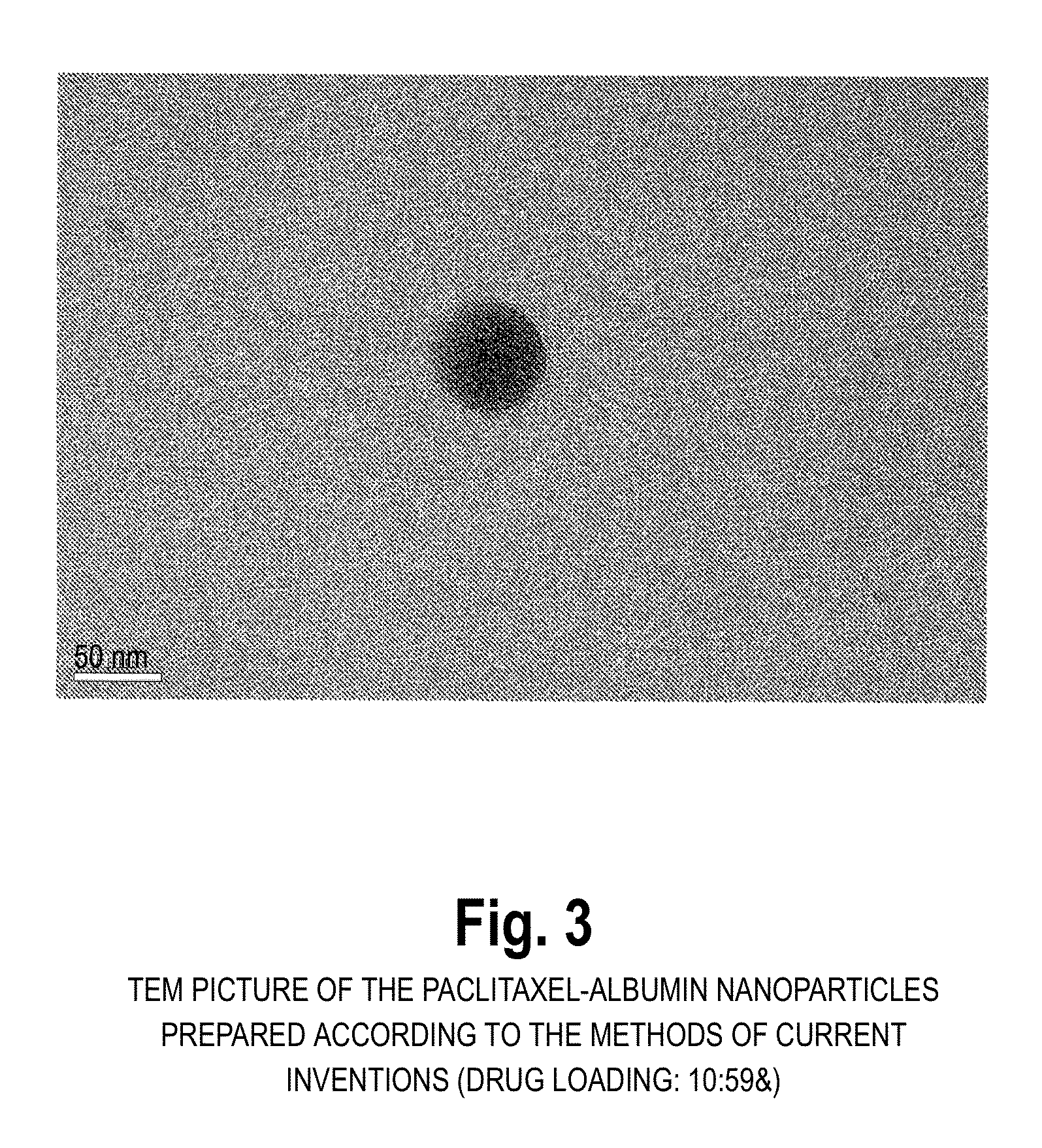

Methods for drug delivery comprising unfolding and folding proteins and peptide nanoparticles

ActiveUS20110059181A1Reduce the amount requiredImproved cost-efficiencyBiocidePowder deliveryNanoparticleActive agent

The present invention provides preparation methods of protein nanoparticles for in vivo delivery of pharmacologically active agents, wherein said methods are to encase pharmaceutically active agents into proteins or peptides to form nanoparticles by unfolding the protein, and subsequently refolding or assembling the protein to produce a pharmacologically active agent encased within a protein nanoparticle.

Owner:NANJING UNIV +1

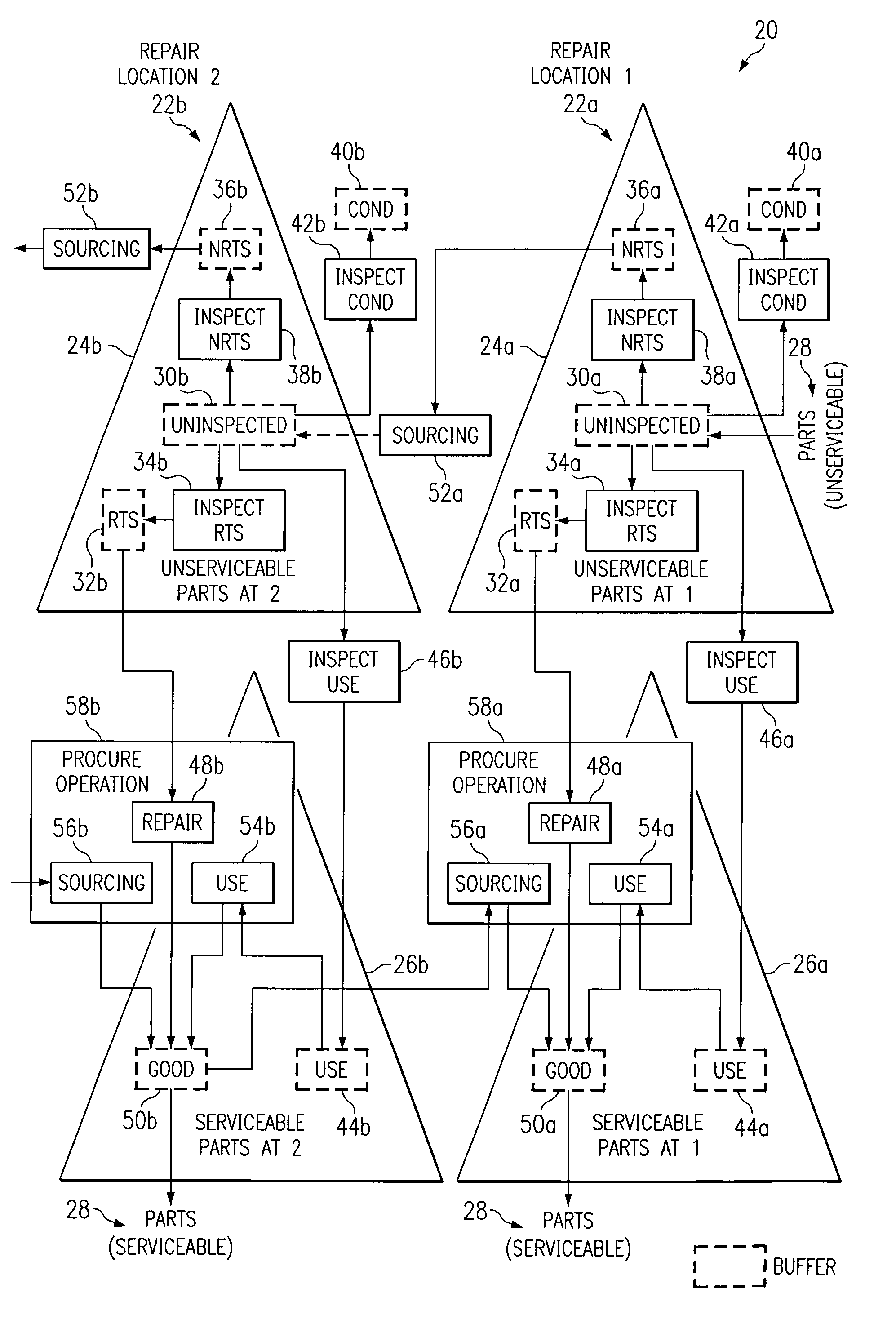

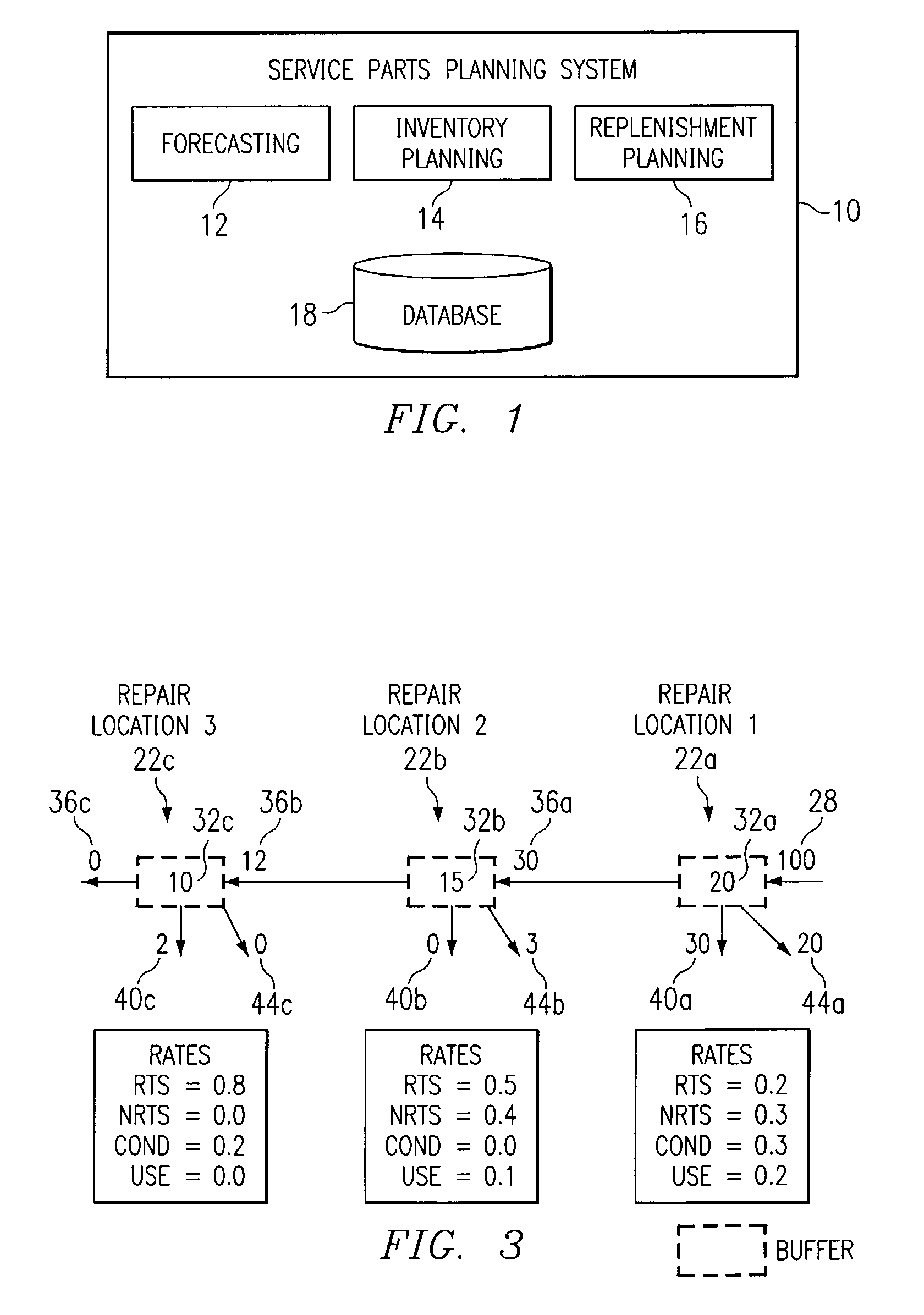

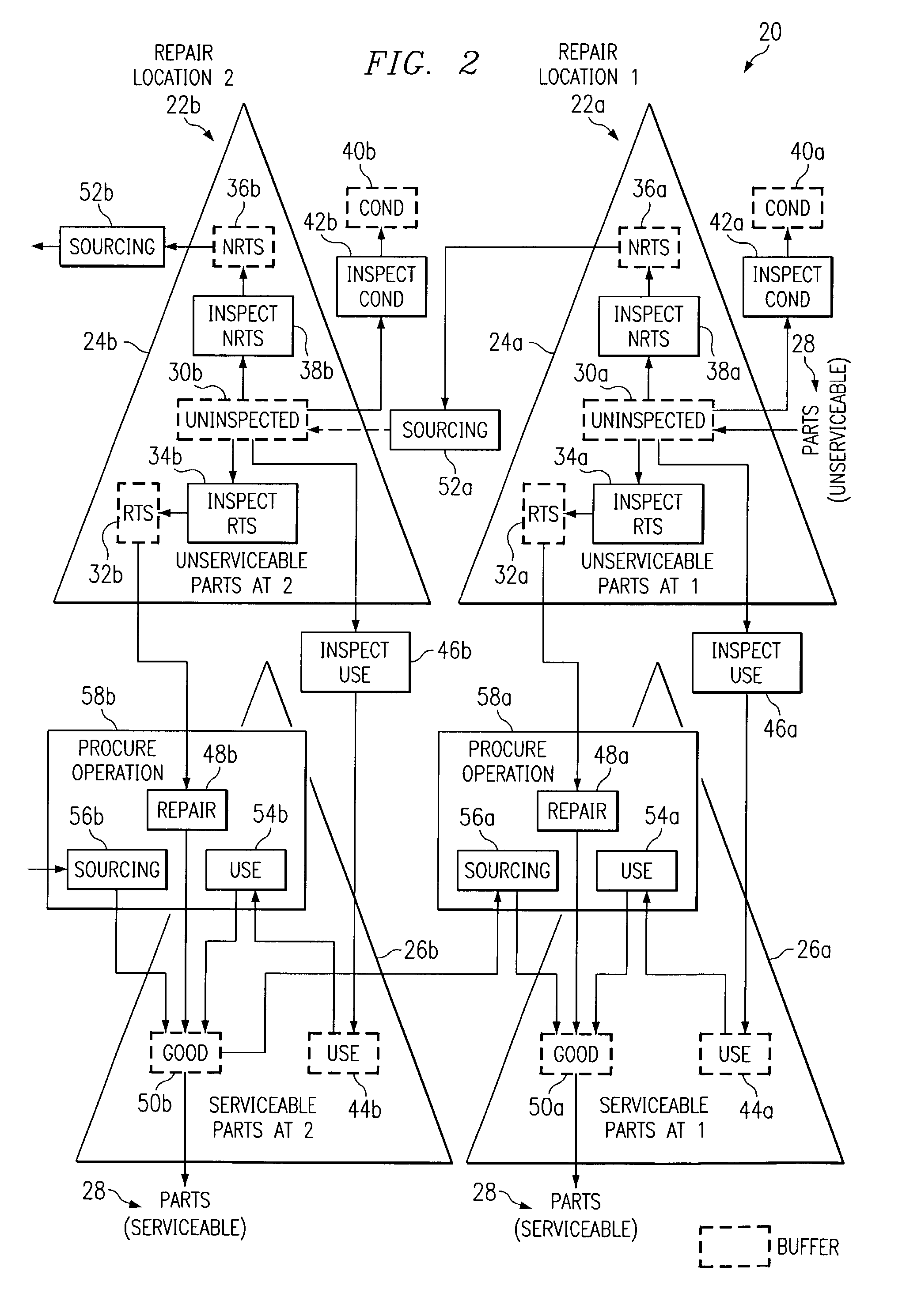

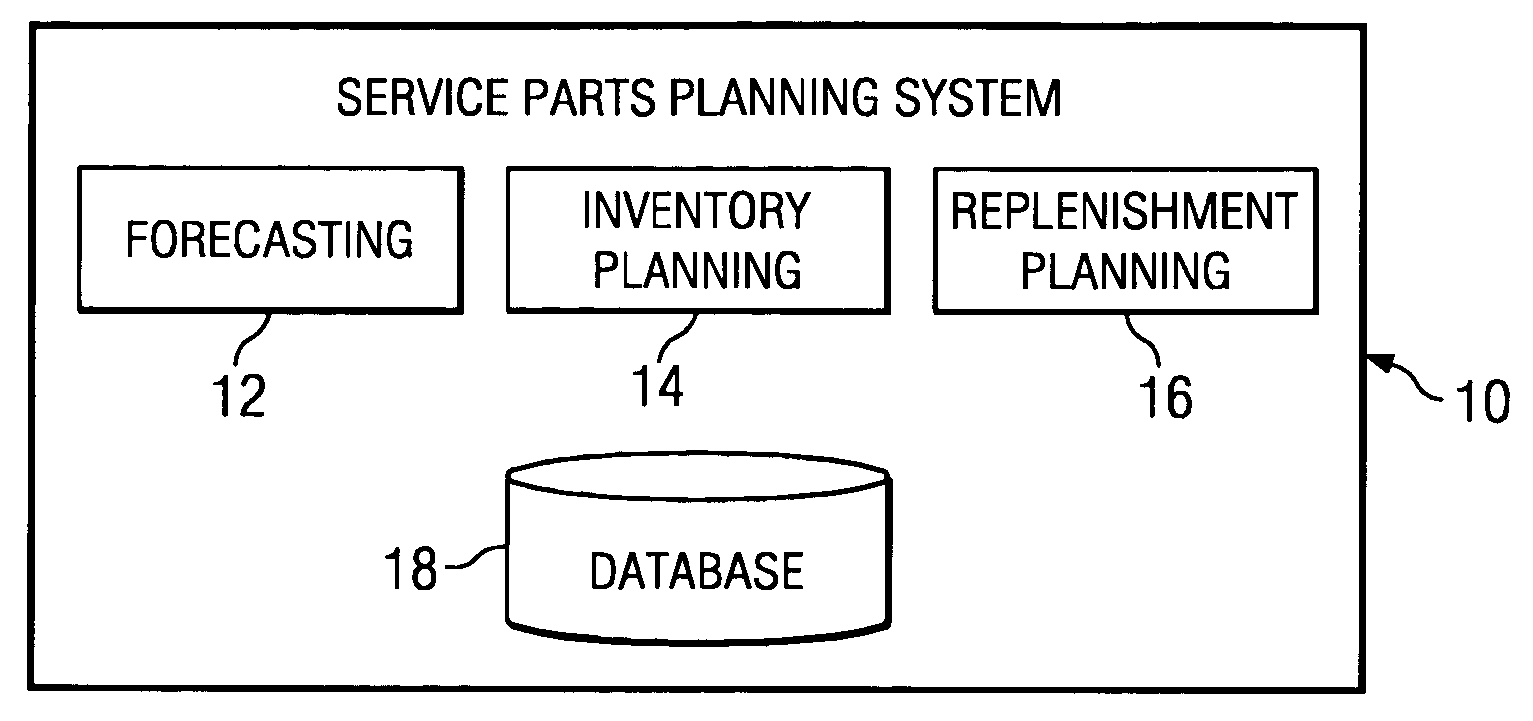

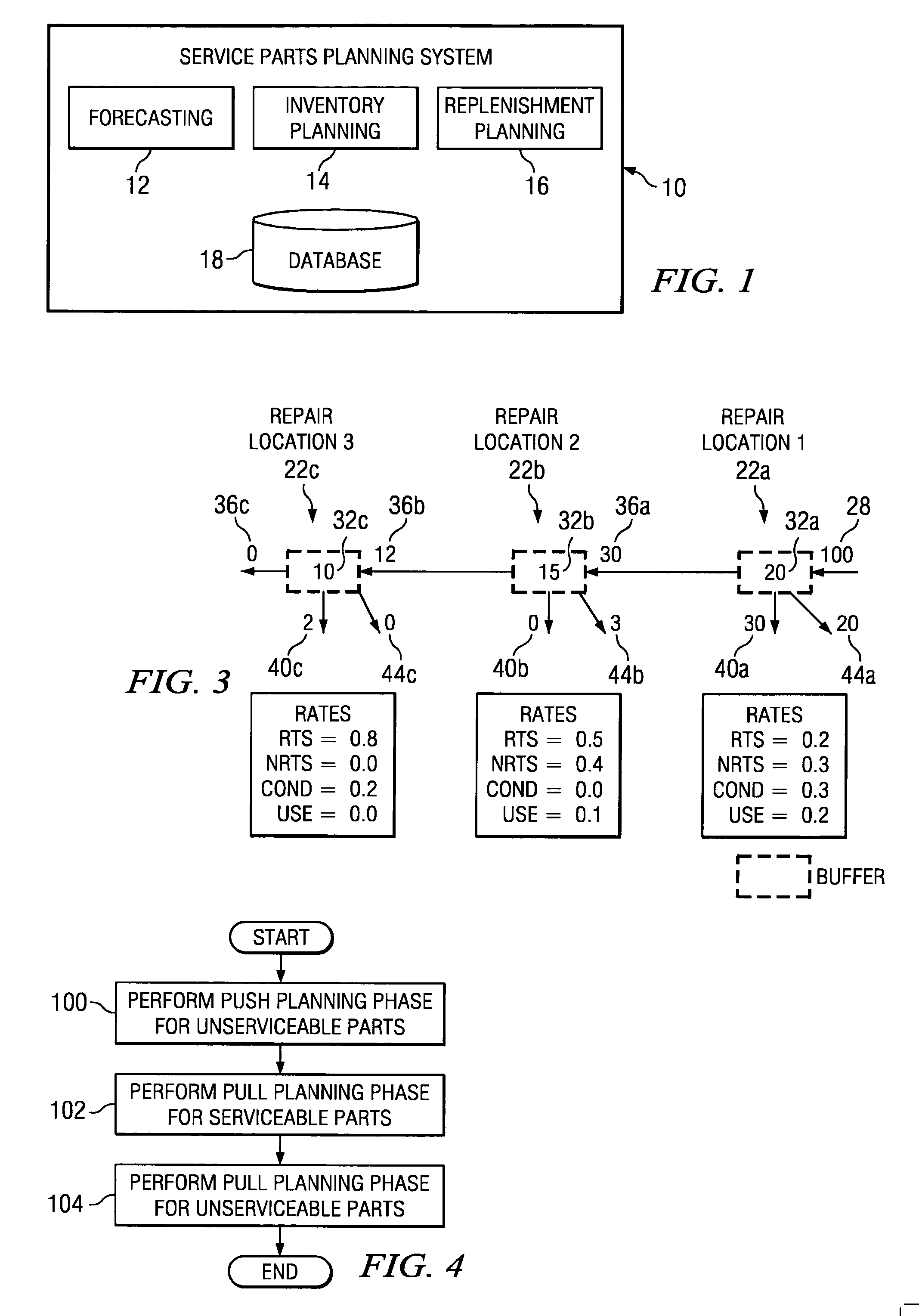

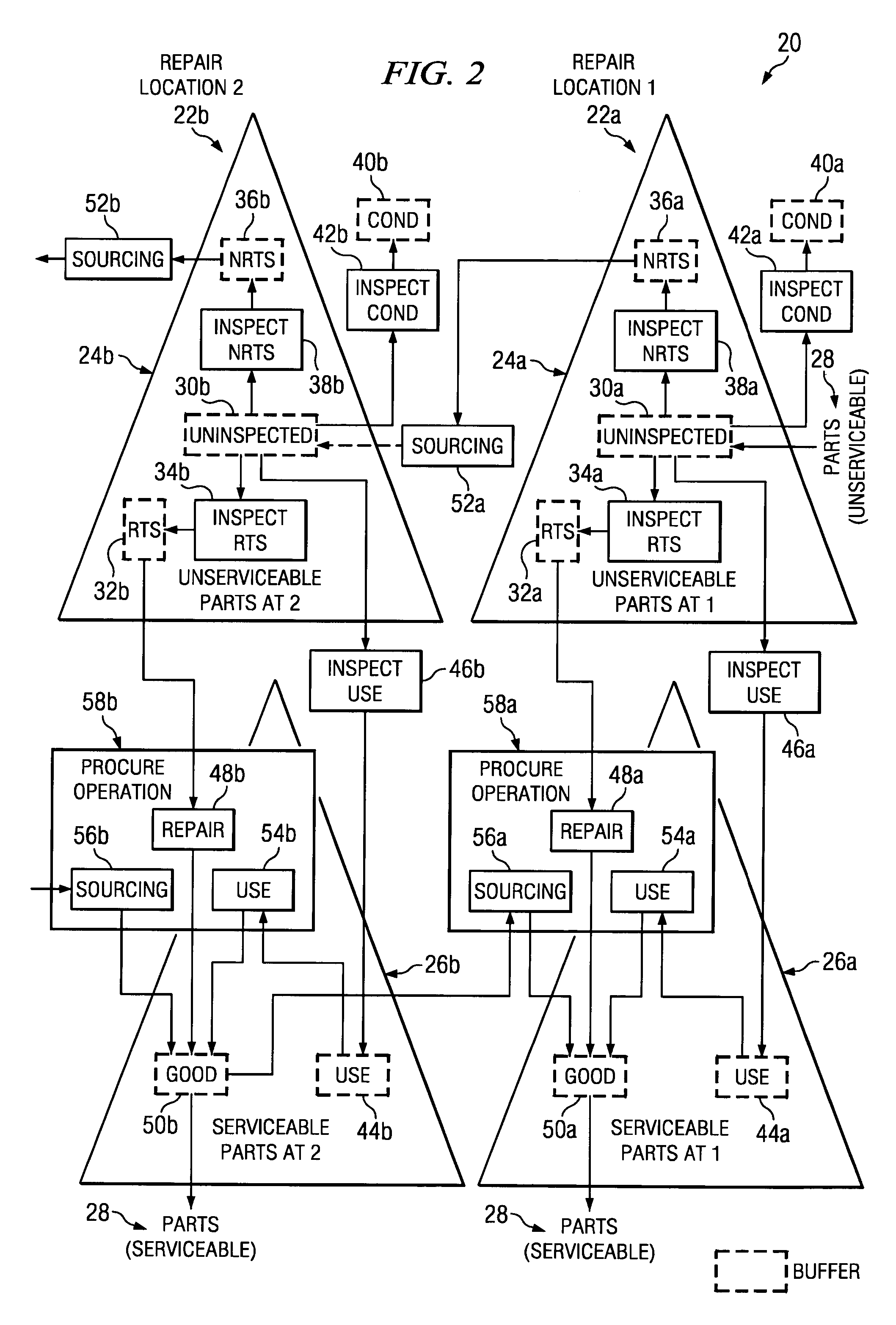

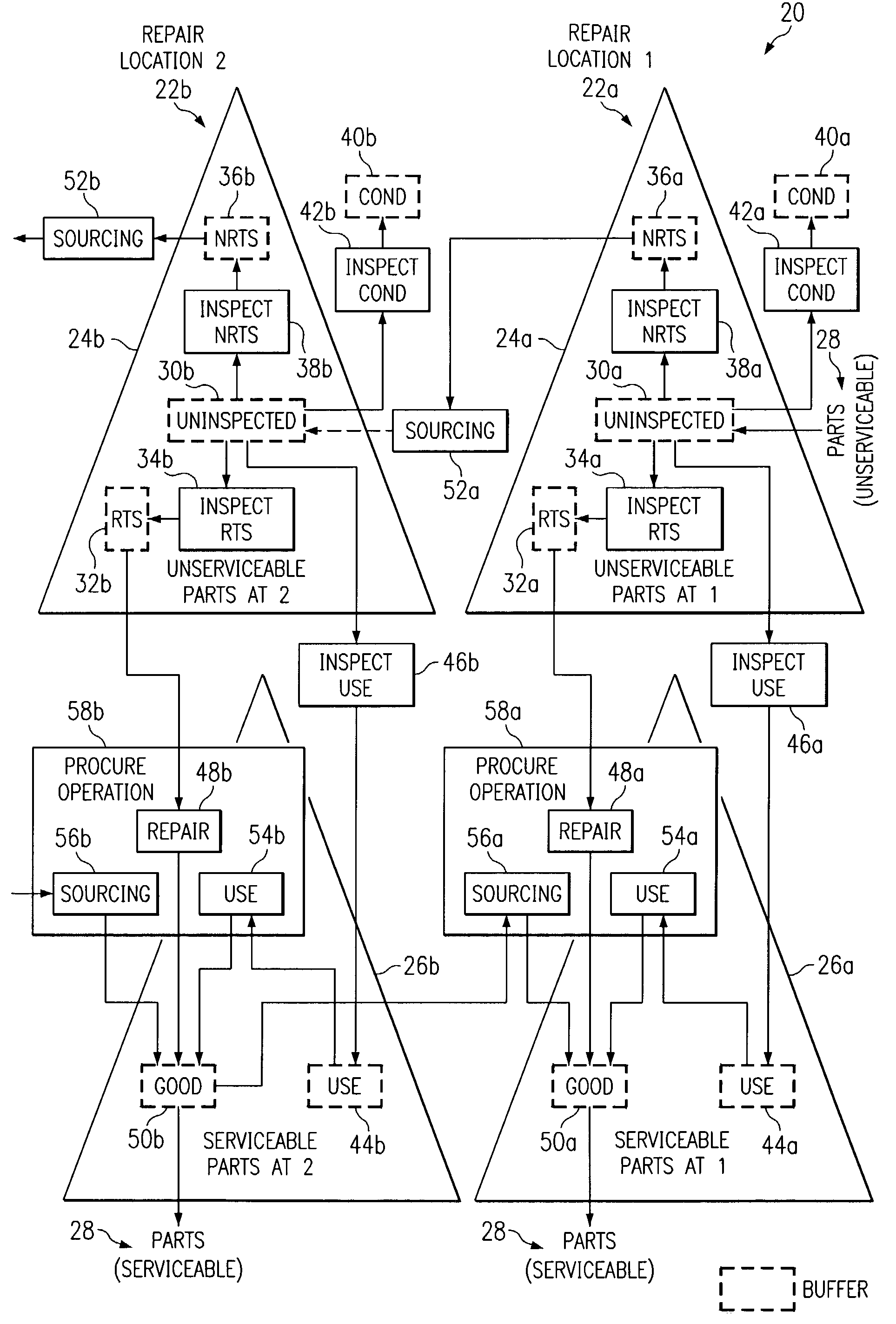

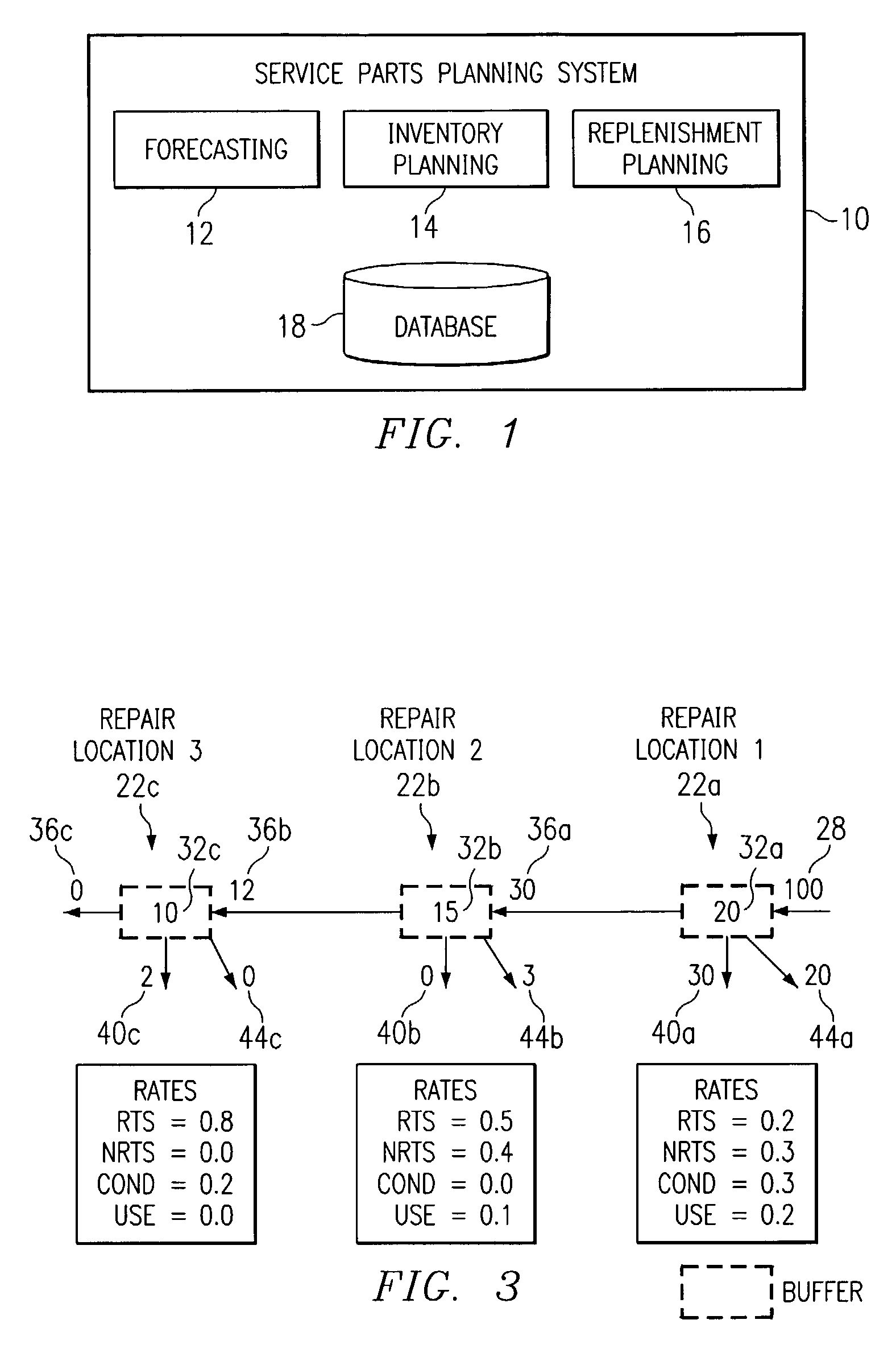

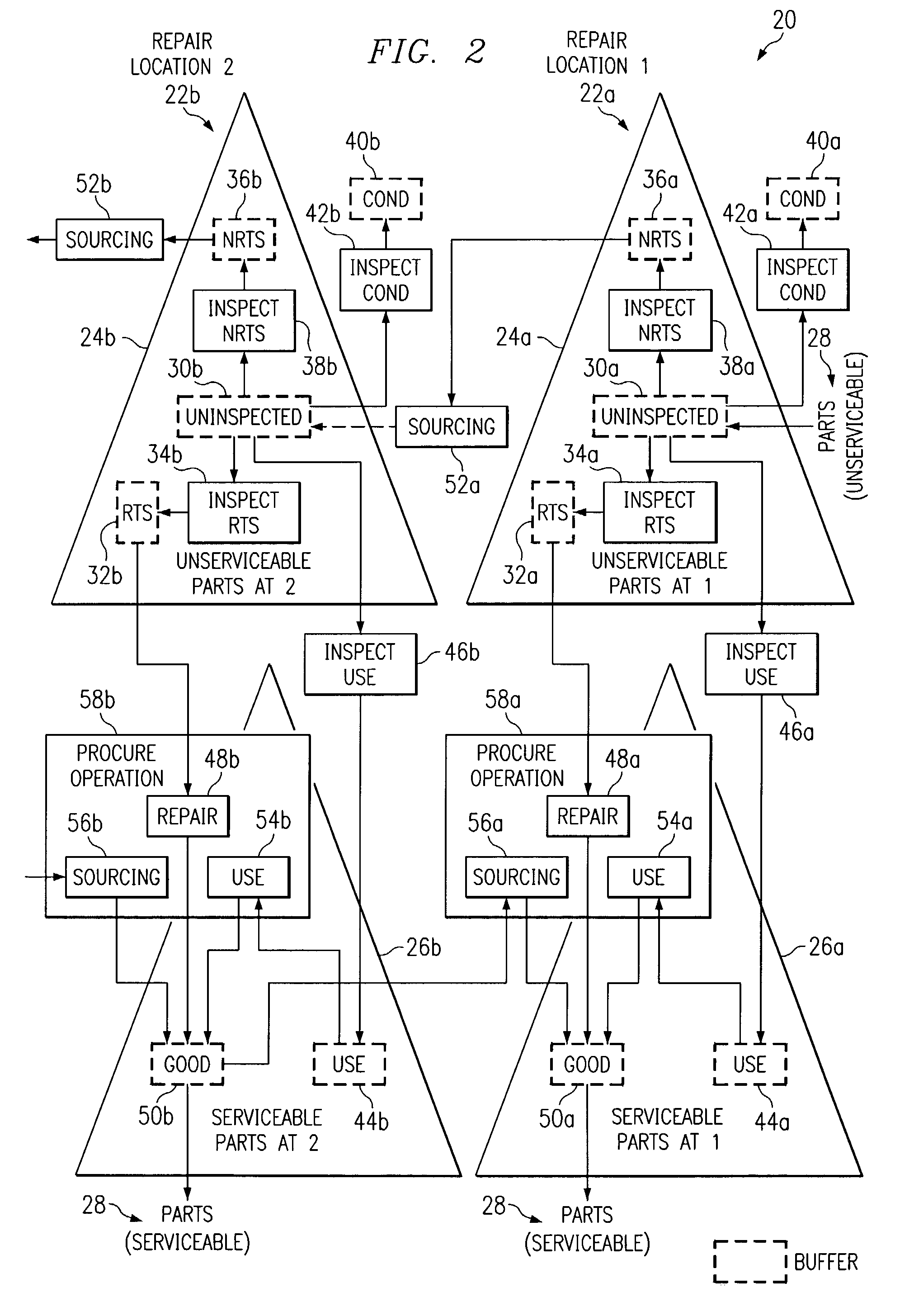

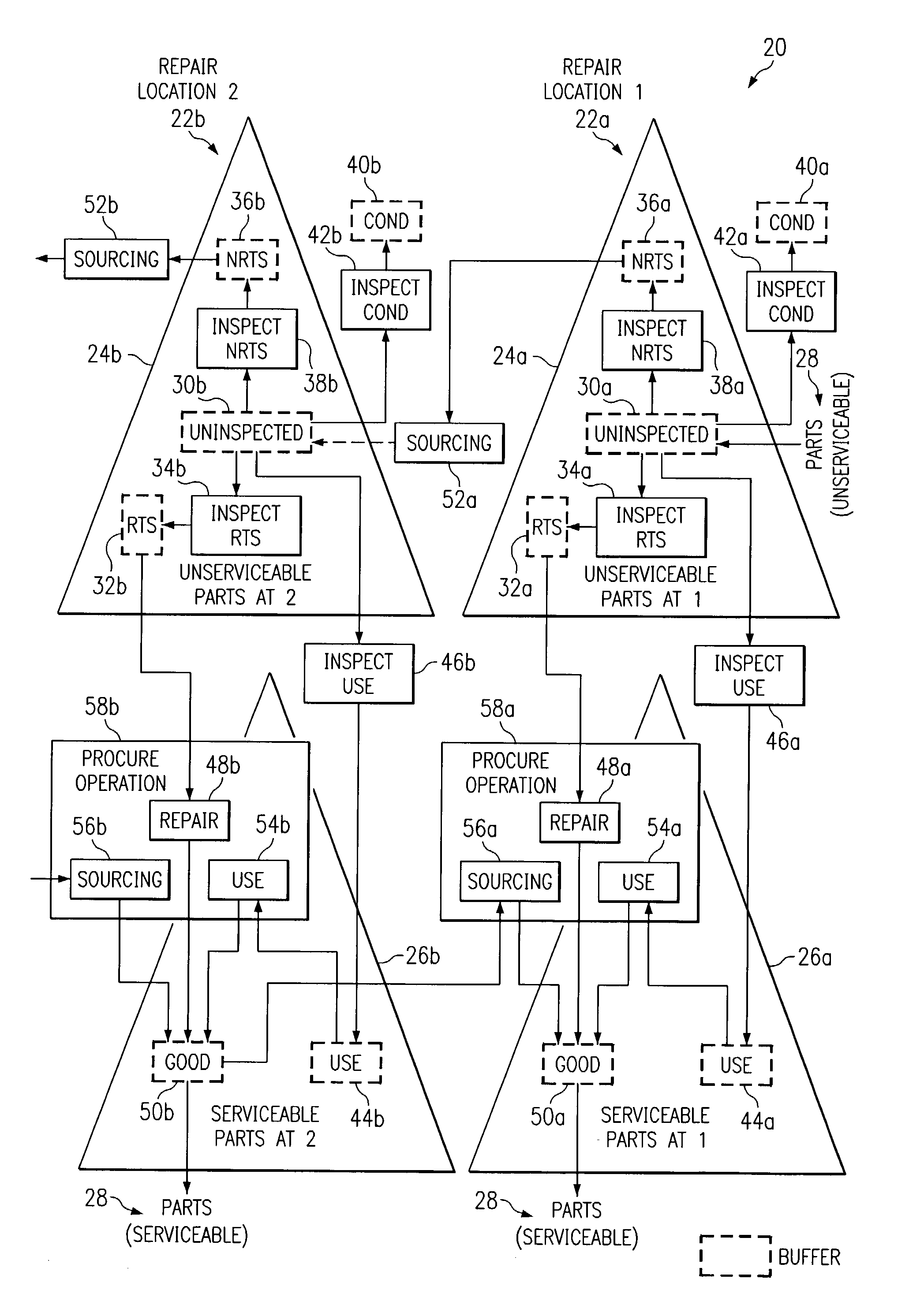

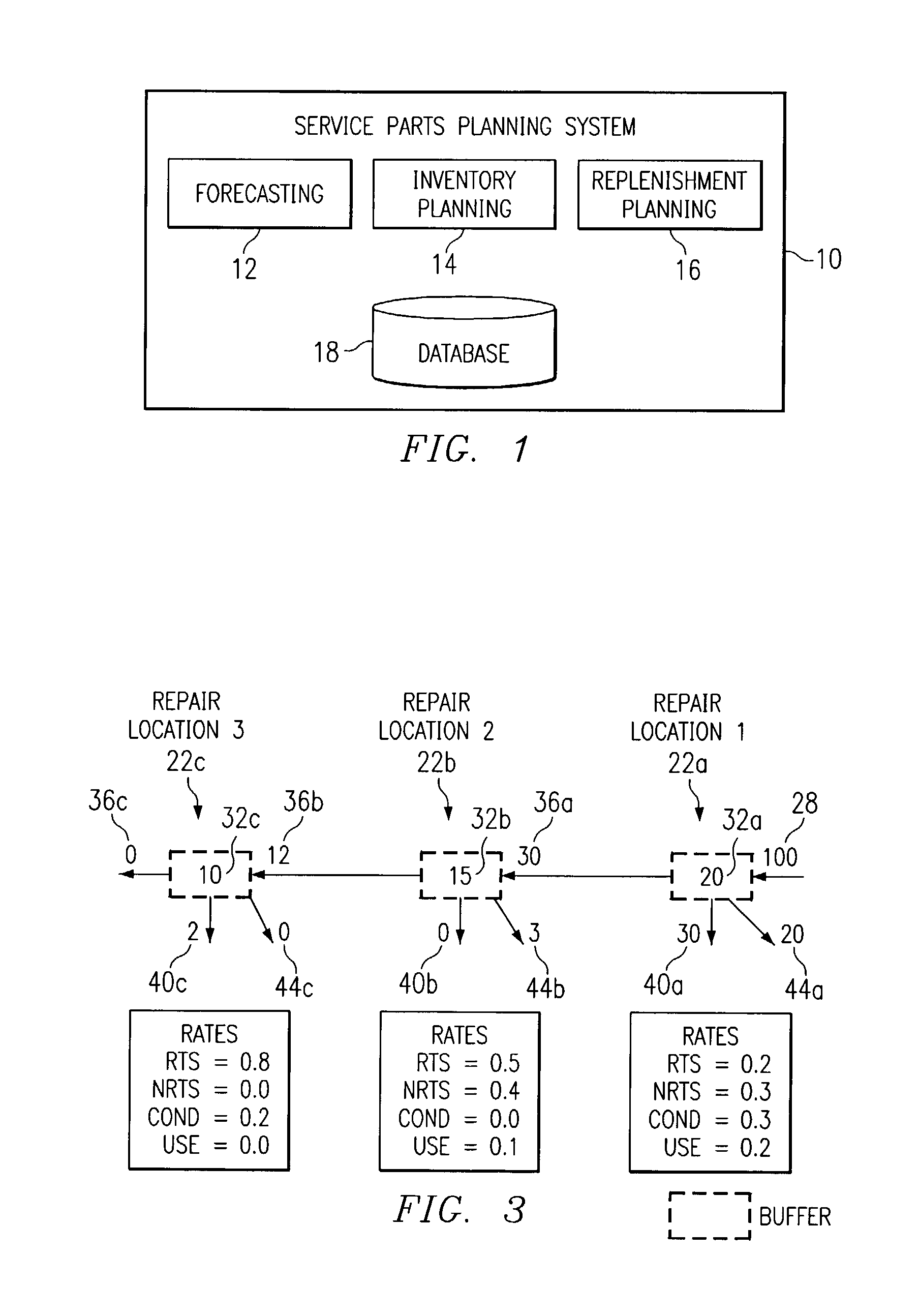

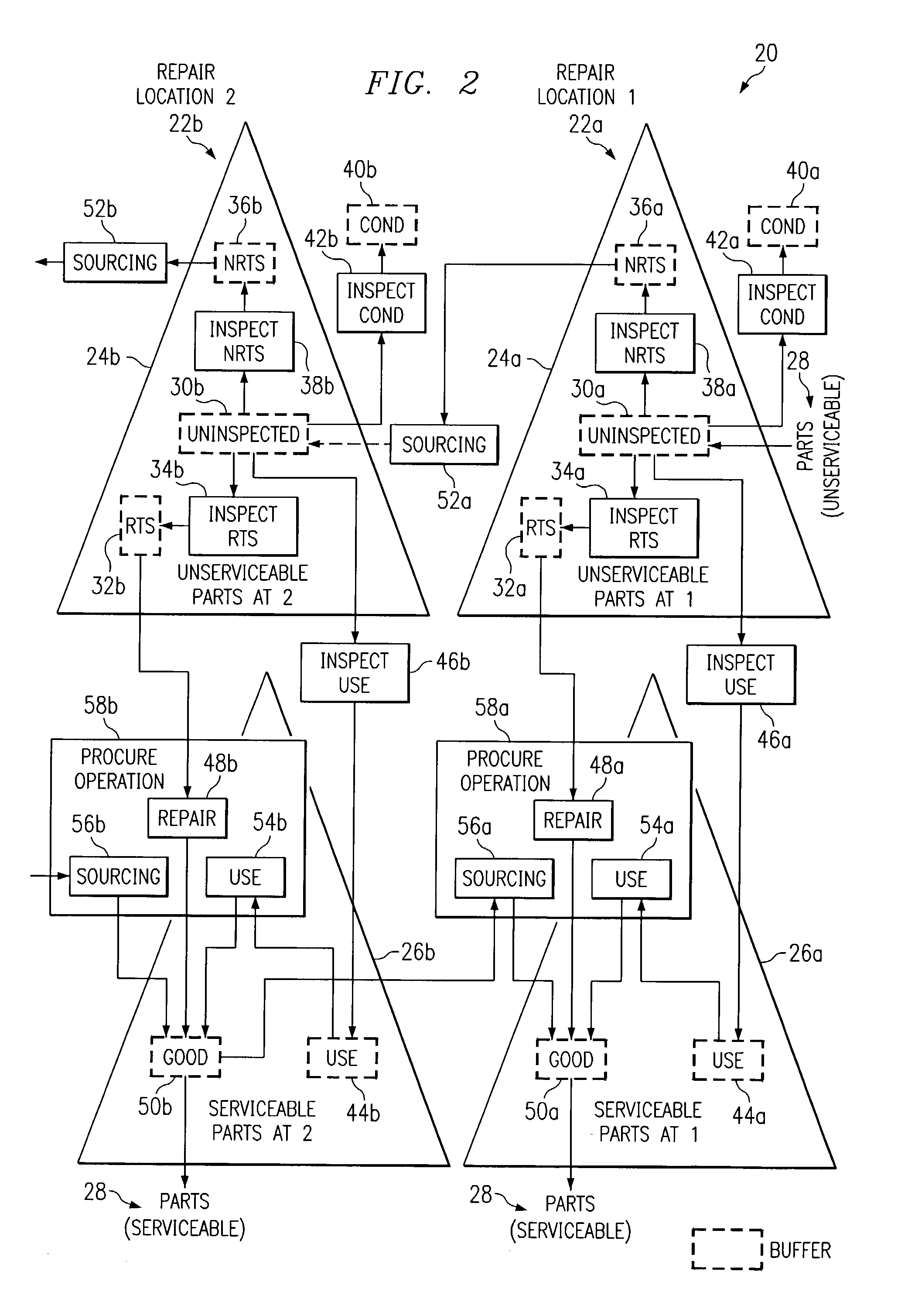

Push planning for unserviceable parts to facilitate repair planning in a repair network

ActiveUS7277862B1Disadvantages can be reduced eliminatedIncrease supplyMultiprogramming arrangementsComputation using non-denominational number representationMaintenance planningRepair time

In one embodiment, a method for repair planning for a location in a repair network includes modeling: (1) an uninspected buffer for parts received but not yet inspected at the location; (2) a first buffer for parts inspected at the location and repairable at the location; (3) a second buffer for parts inspected at the location and not repairable at the location; (4) a third buffer for parts inspected at the location and not repairable at any location in the repair network; and (5) a fourth buffer for parts inspected at the location and serviceable without repair. The parts in the uninspected buffer are assigned to the first, second, third, and fourth buffers at corresponding rates according to an inspection operation. One or more operation plans are generated to push parts out of the uninspected buffer to the first, second, third, and fourth buffers according to the corresponding rates, a part pushed out being available within the first, second, third, or fourth buffer only after a predetermined disposition time has elapsed. An operation plan is generated to push parts out of the second buffer to one or more upstream locations, a part pushed out being available at an upstream location only after a predetermined move lead time has elapsed. For each part pushed out of the uninspected buffer to the first or second buffer, the earliest time at which repair can begin for the part is estimated, this earliest repair time determining the earliest time at which, after the part has been repaired to make it serviceable, the part can be available to satisfy a demand at the location.

Owner:BLUE YONDER GRP INC

Pull planning for unserviceable parts in connection with on-demand repair planning

InactiveUS20050091070A1Disadvantages can be reduced eliminatedMinimize undesirable costResourcesSpecial data processing applicationsMaintenance planningStart time

In one embodiment, planning repairs in response to demand in a multi-level repair network includes accessing a forecasted demand for serviceable parts at a repair location and, for each inspected unserviceable part at the location that is not repairable at the location: (1) planning a move of the part to an upstream repair location such that the part can be available for repair at the upstream location at an estimated earliest time; (2) estimating a latest time at which a repair of the part can begin at the upstream location to help satisfy the forecasted demand, according to the forecasted demand and the estimated earliest time, and planning a repair at the upstream location at the estimated latest time; and (3) re-planning the move, according to the start time of the repair, by modifying a move delivery time according to a repair start time and modifying a move start time according to the modified delivery time. The re-planned move start time is an estimated latest time at which the part can be moved to the upstream location for repair to help satisfy the forecasted demand.

Owner:BLUE YONDER GRP INC

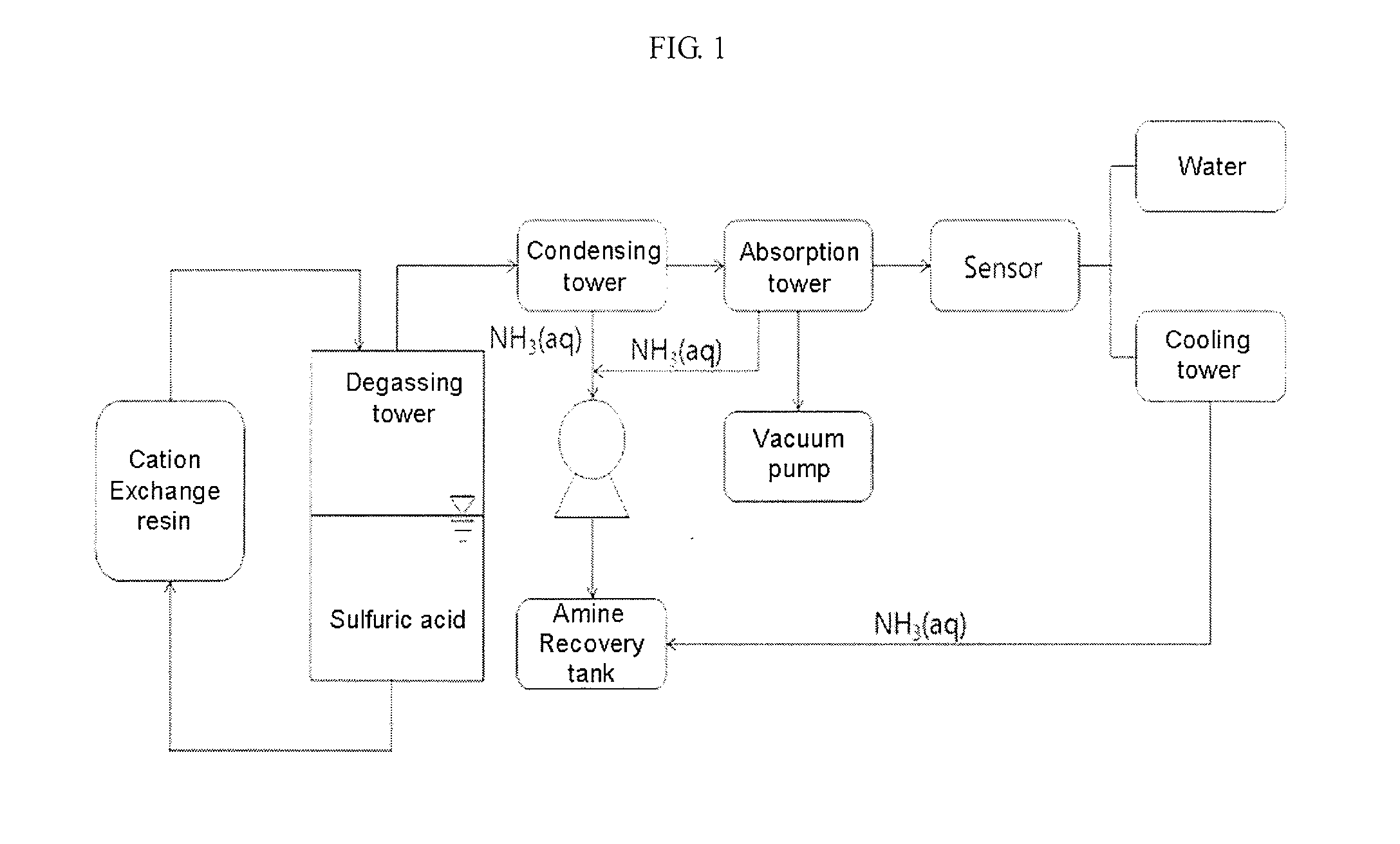

Method and apparatus for recovery of amine from amine-containing waste water and regeneration of cation exchange resin

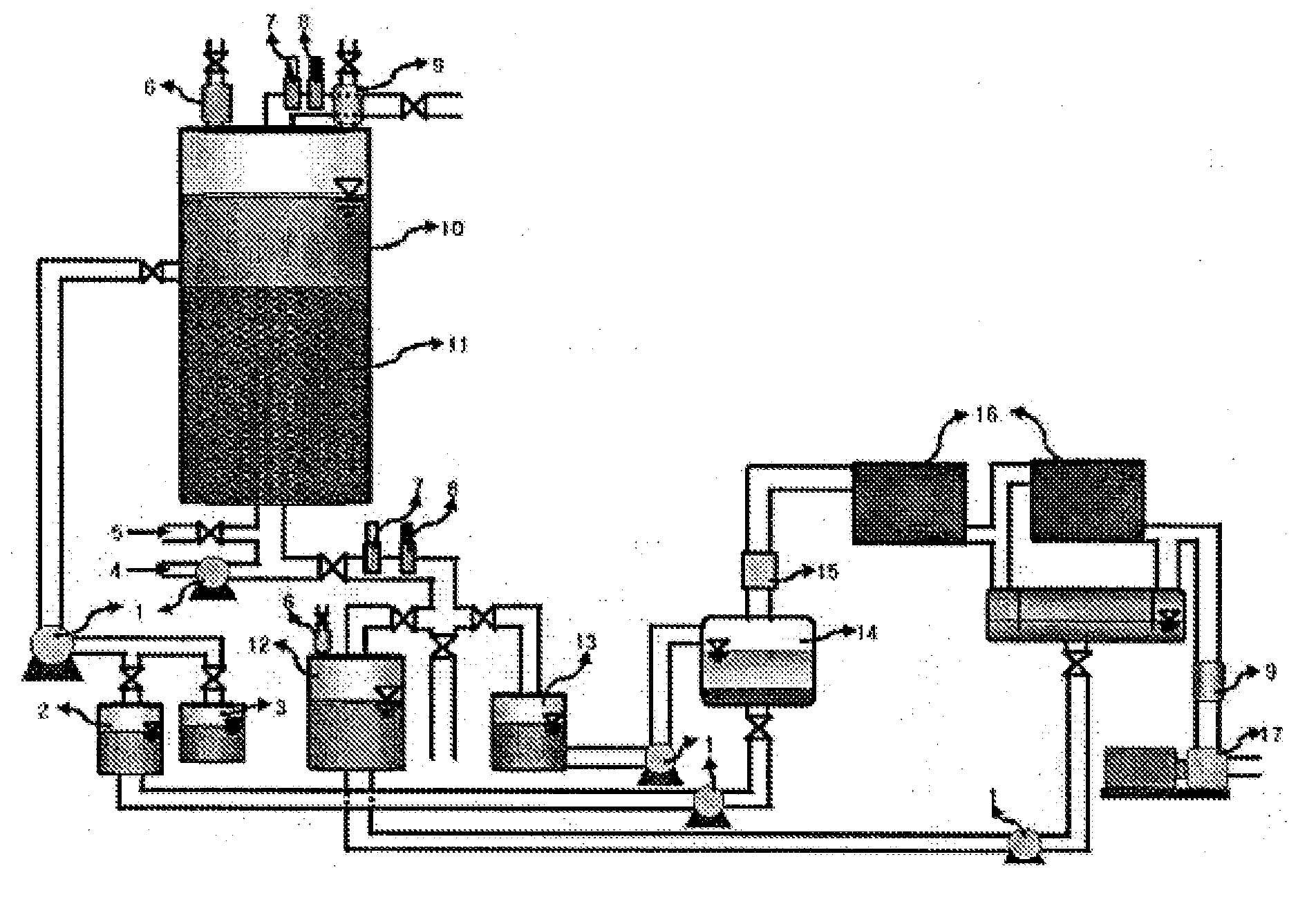

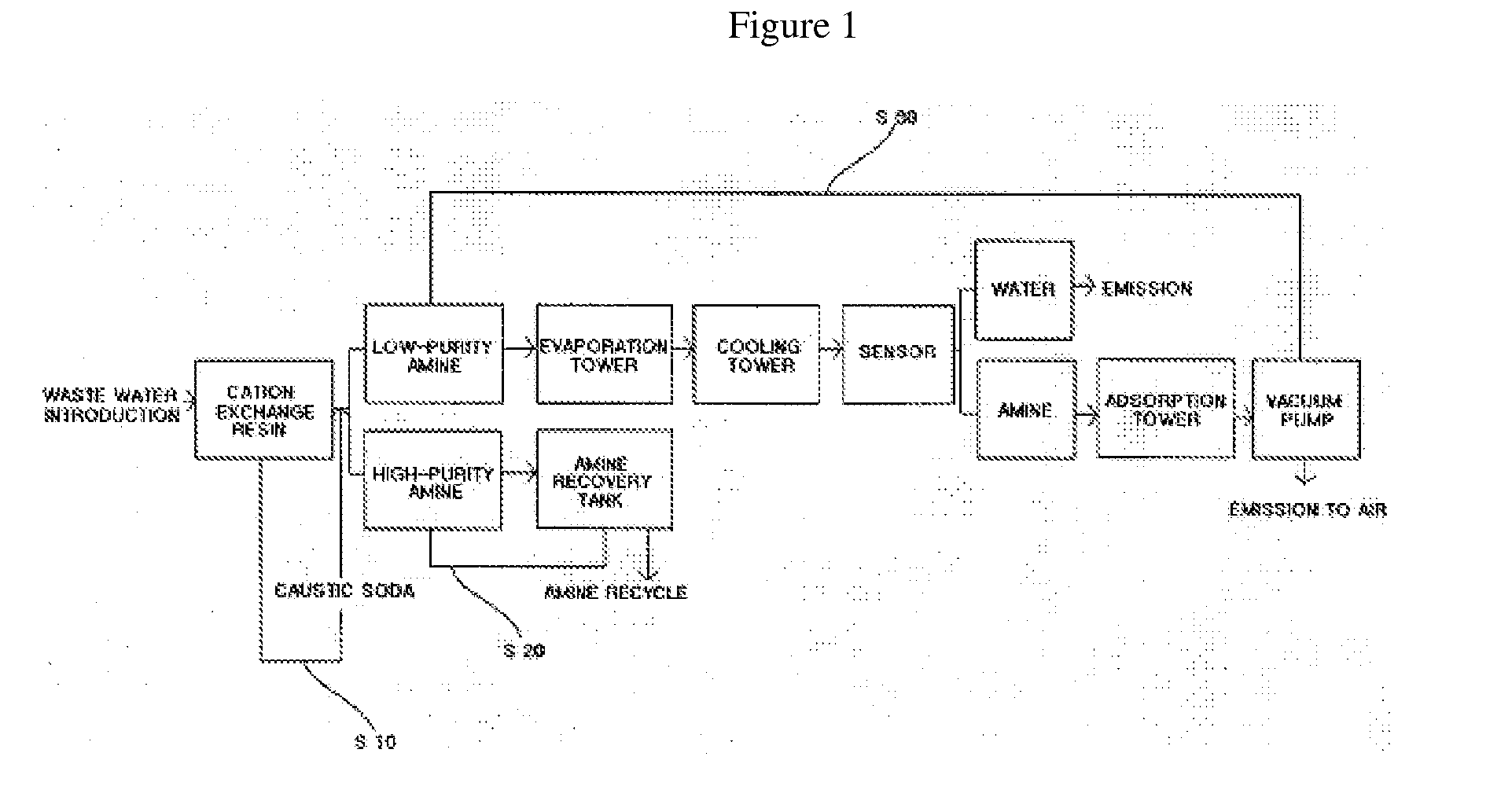

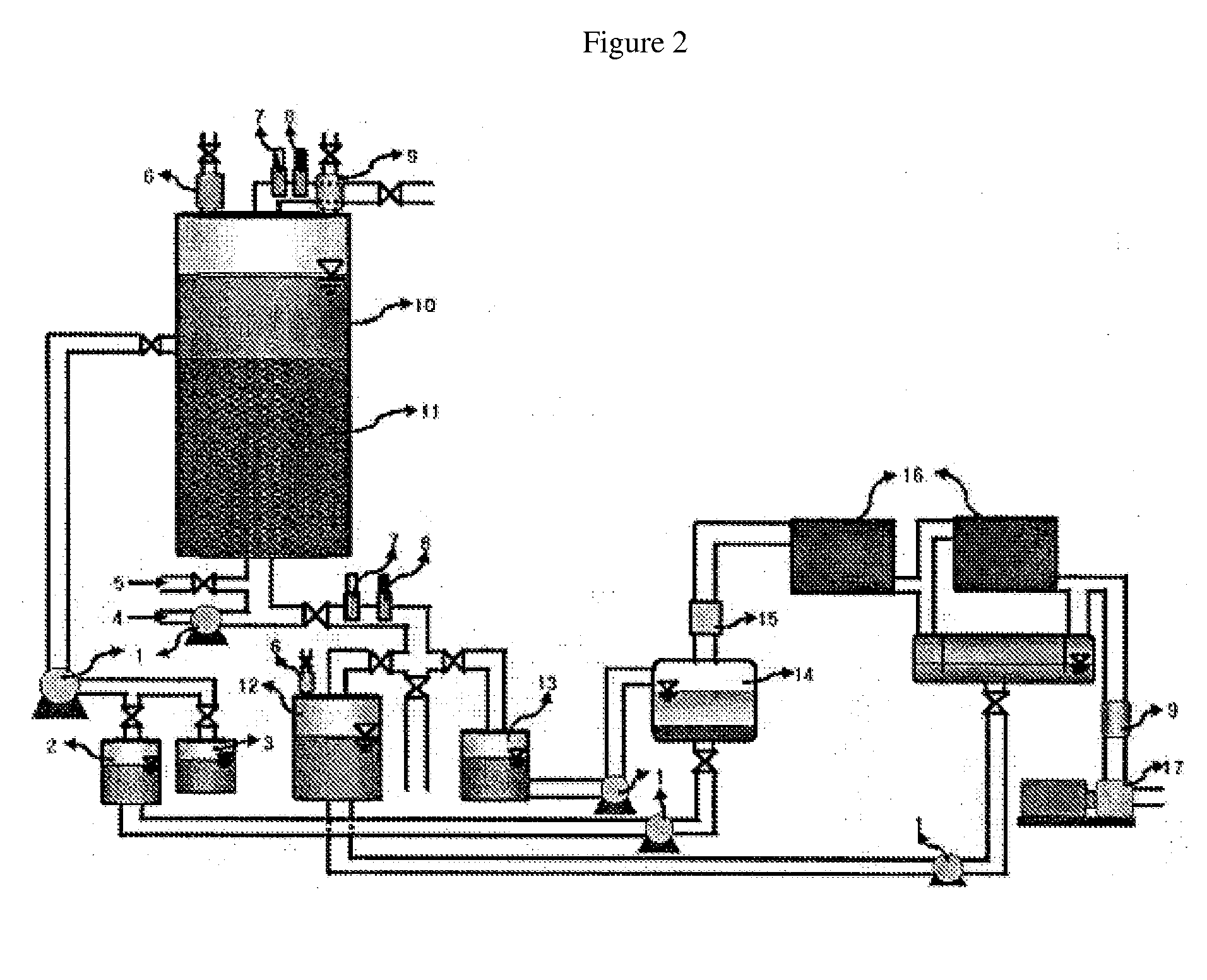

ActiveUS20120029233A1High nitrogen contentImproved cost-efficiencyAmino compound purification/separationWater treatment parameter controlPower stationCooling tower

Provided is an apparatus for recovering amines from amine-containing waste water generated in power stations, etc., and regenerating a cation exchange resin. The apparatus includes: a cation exchange resin layer capturing amines from amine-containing waste water and eluting the amines therefrom; a degassing tower degassing the eluted amines; a vacuum pump connected to the degassing tower; and a condensation and cooling tower condensing the degassed amines at a temperature of −33° C. or lower, wherein the amines captured in the cation exchange resin layer are eluted by injecting a strong acidic solution, while the resin is regenerated, and the amines eluted by the strong acidic solution is subjected to vacuum degassing and then recovered. Provided also is a method for recovering amines and regenerating a cation exchange resin using the apparatus. The apparatus and method for recovering amines and regenerating a cation exchange resin improve the quality of effluent water from power stations, etc., and increase the cost-efficiency through the recycle of amines.

Owner:SOONCHUNYANG UNIV IND ACAD COOP FOUND

On-demand repair planning

InactiveUS7620561B1Disadvantages can be reduced eliminatedIncrease supplyError detection/correctionResourcesMaintenance planningProgram planning

Owner:BLUE YONDER GRP INC

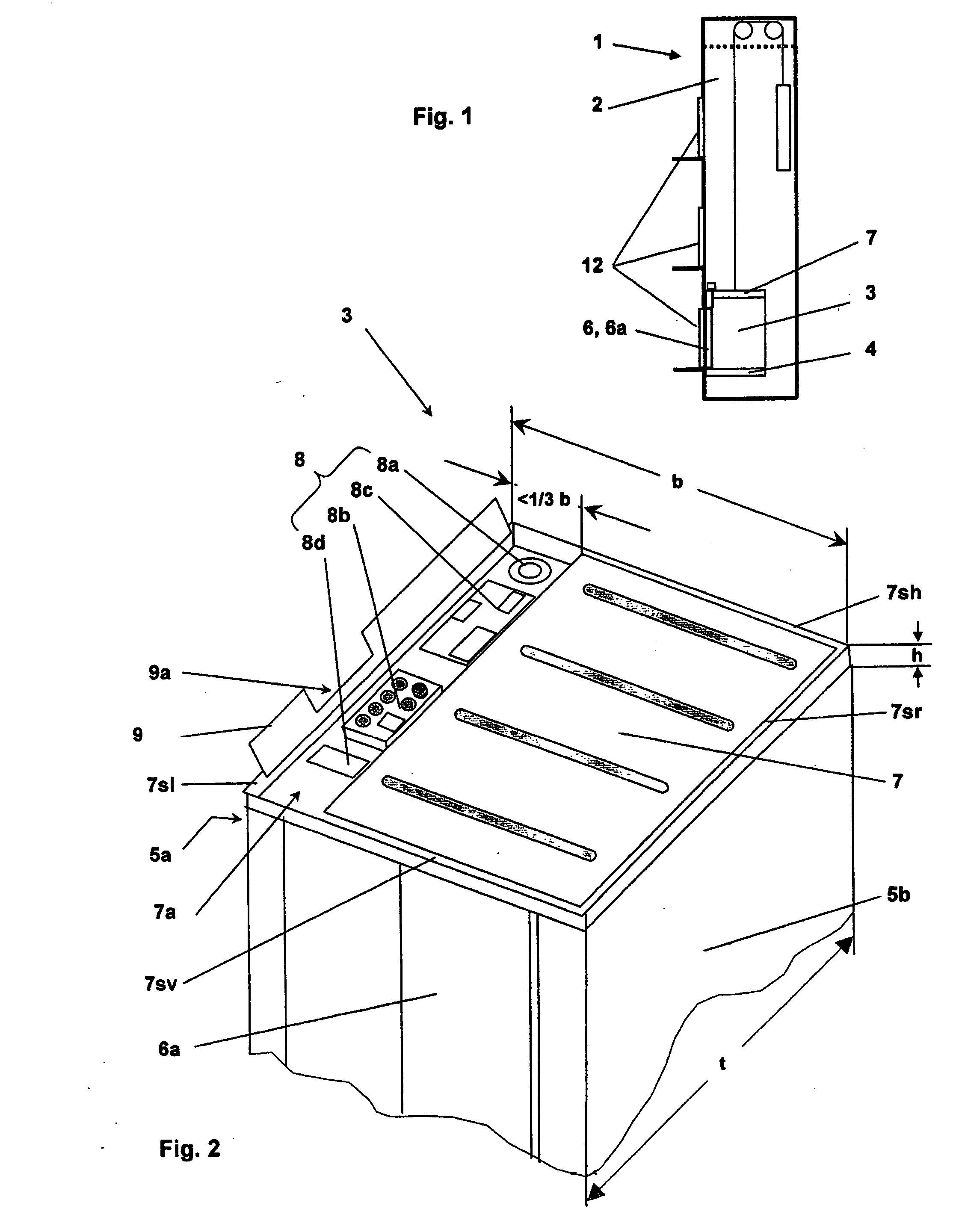

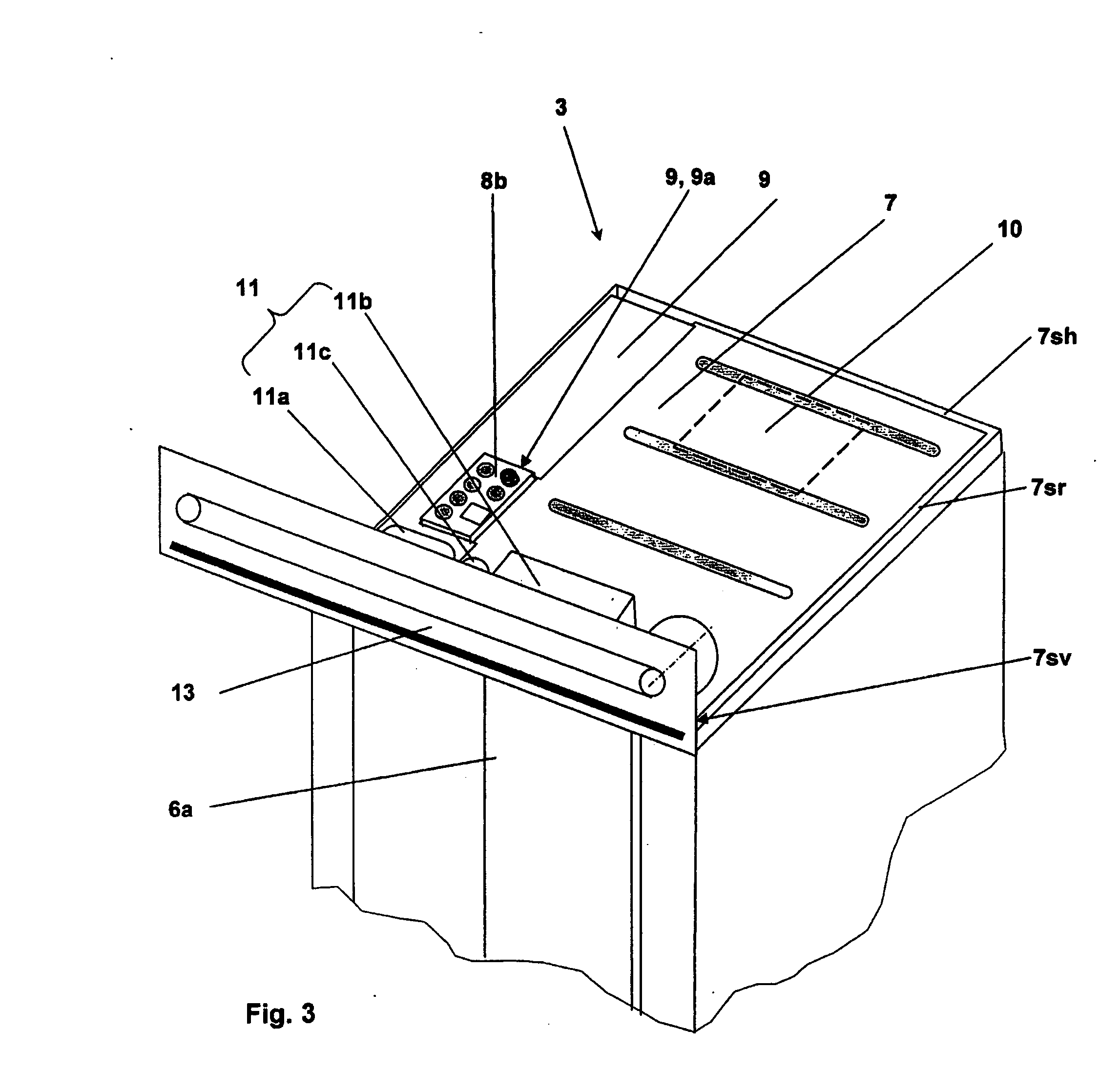

Elevator car with car electrical system integrated in the car roof and method of mounting an elevator installation

Owner:INVENTIO AG

Fat/meat grading method and system

ActiveUS8820534B2Quality improvementImprove consistencyMeat packaging/handling/transportingSortingSimulation

Owner:MAREL HF

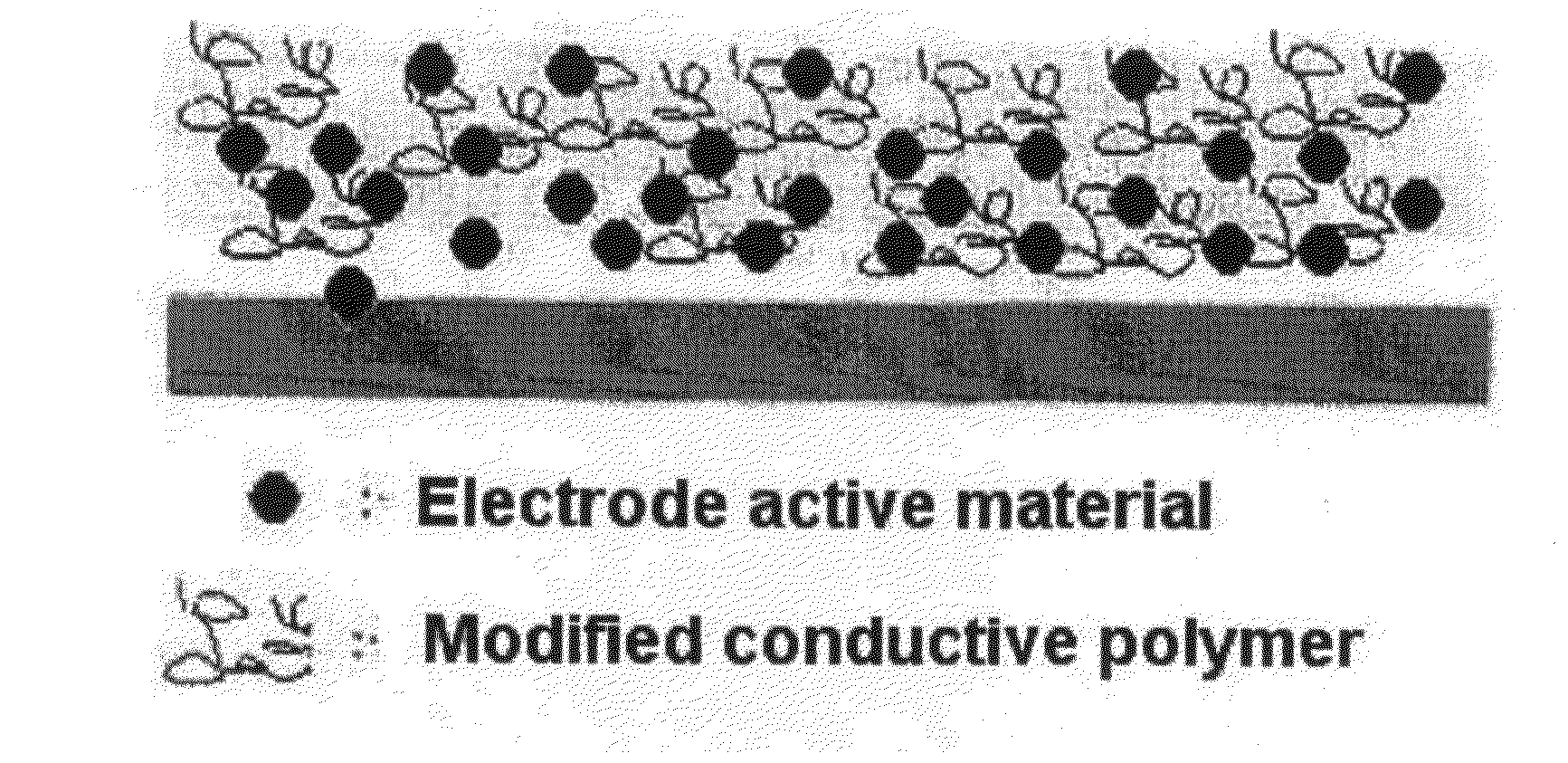

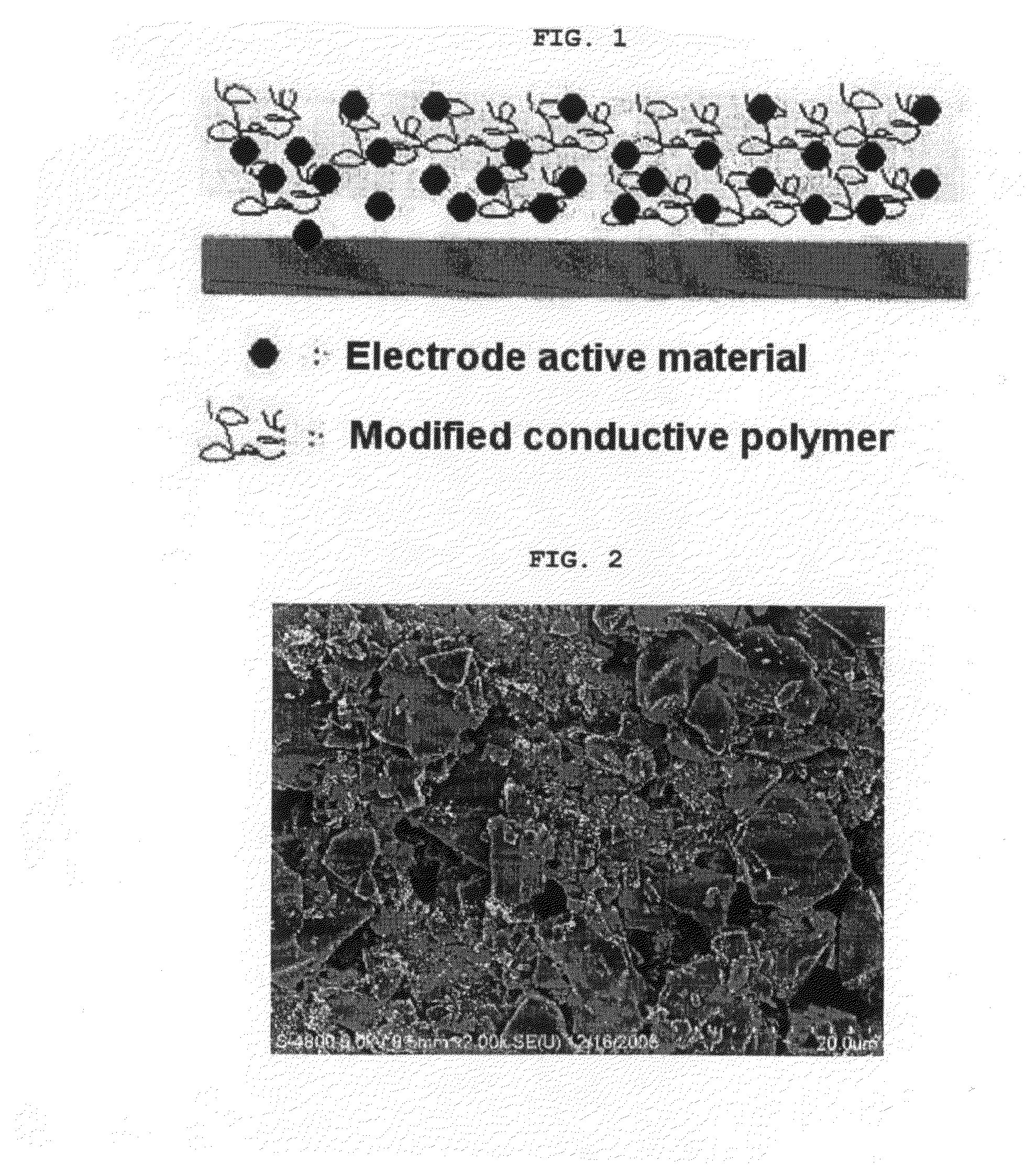

Highly electron conductive polymer and electrochemical energy storage device with high capacity and high power using the same

InactiveUS20100151319A1Lower resistanceImprove electronic conductivityElectrolytic capacitorsConductive materialDopantConductive polymer

Disclosed is a method for preparing a highly electron conductive polymer, the method comprising a step of doping a conductive polymer with a dopant capable of introducing movable charge carriers into the repeating units of the polymer, wherein a voltage higher than a conduction band of the polymer is applied to the polymer while the polymer is doped with the dopant, so as to modify electron conductivity of the conductive polymer. A highly electron conductive polymer obtained by the method, an electrode comprising the highly electron conductive polymer, and an electrochemical device including the electrode arc also disclosed. The novel doping method for improving the electron conductivity of a conductive polymer can provide a conductive polymer with a conductivity comparable to the conductivity of a conventional conductive agent.

Owner:LG CHEM LTD

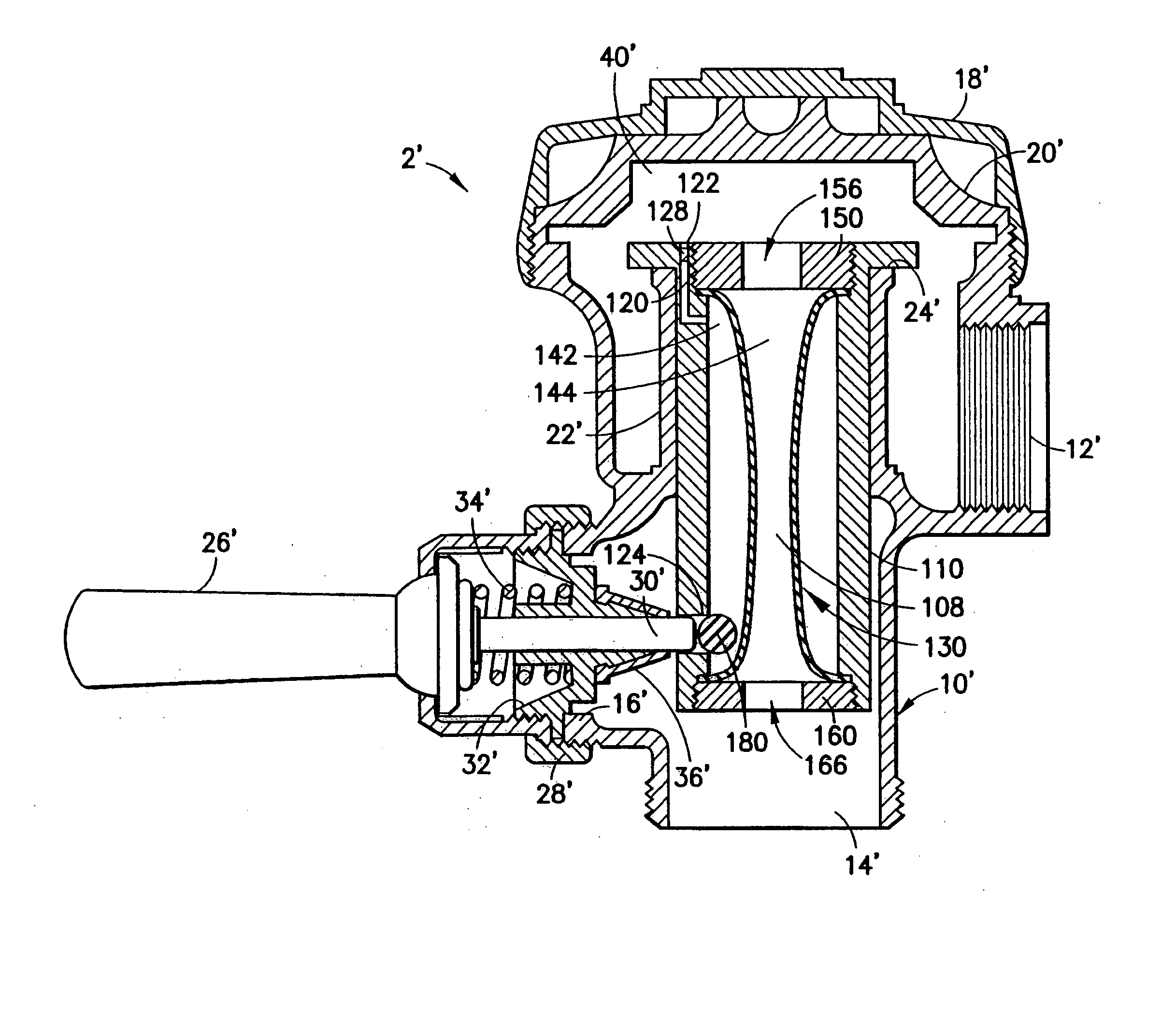

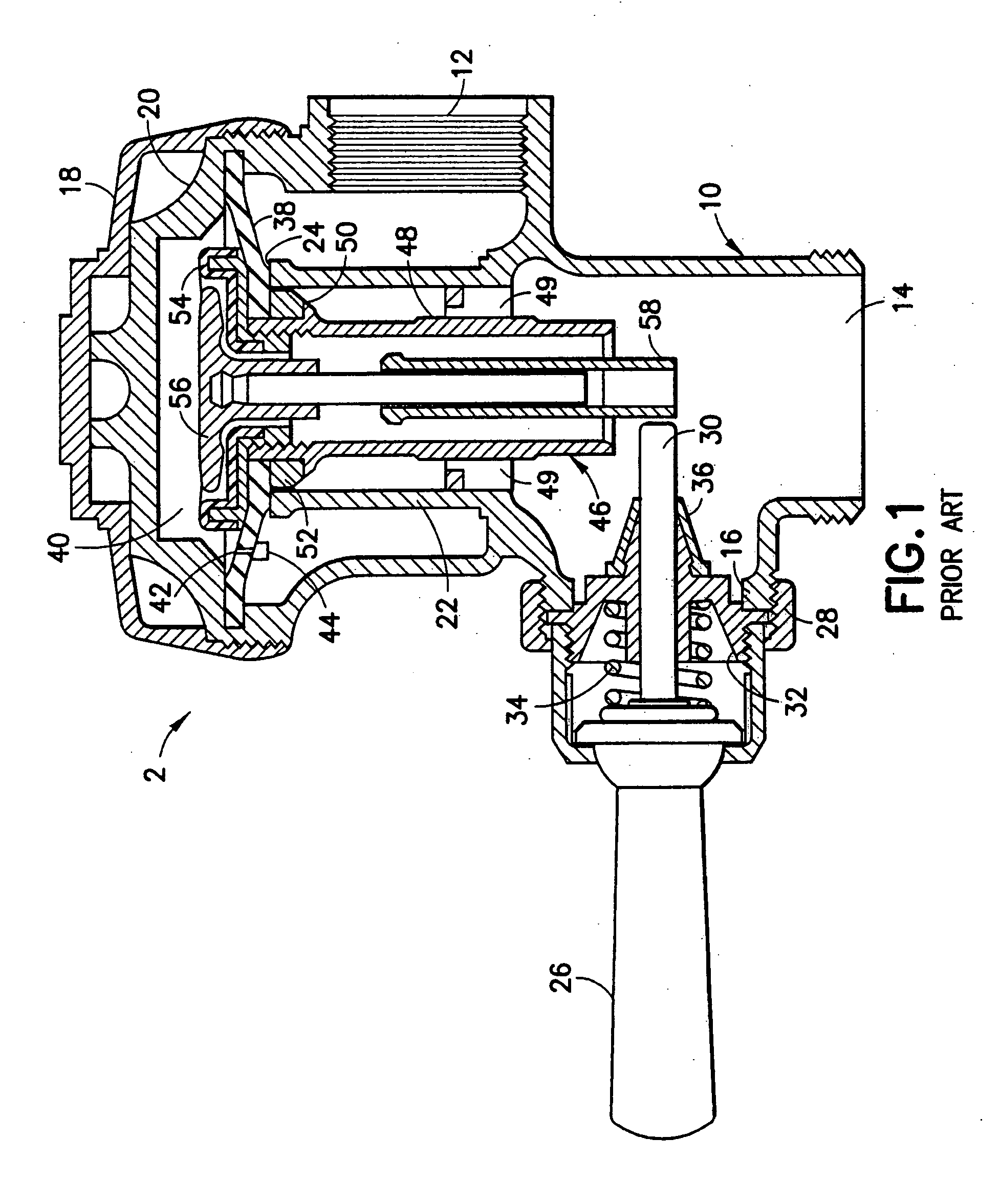

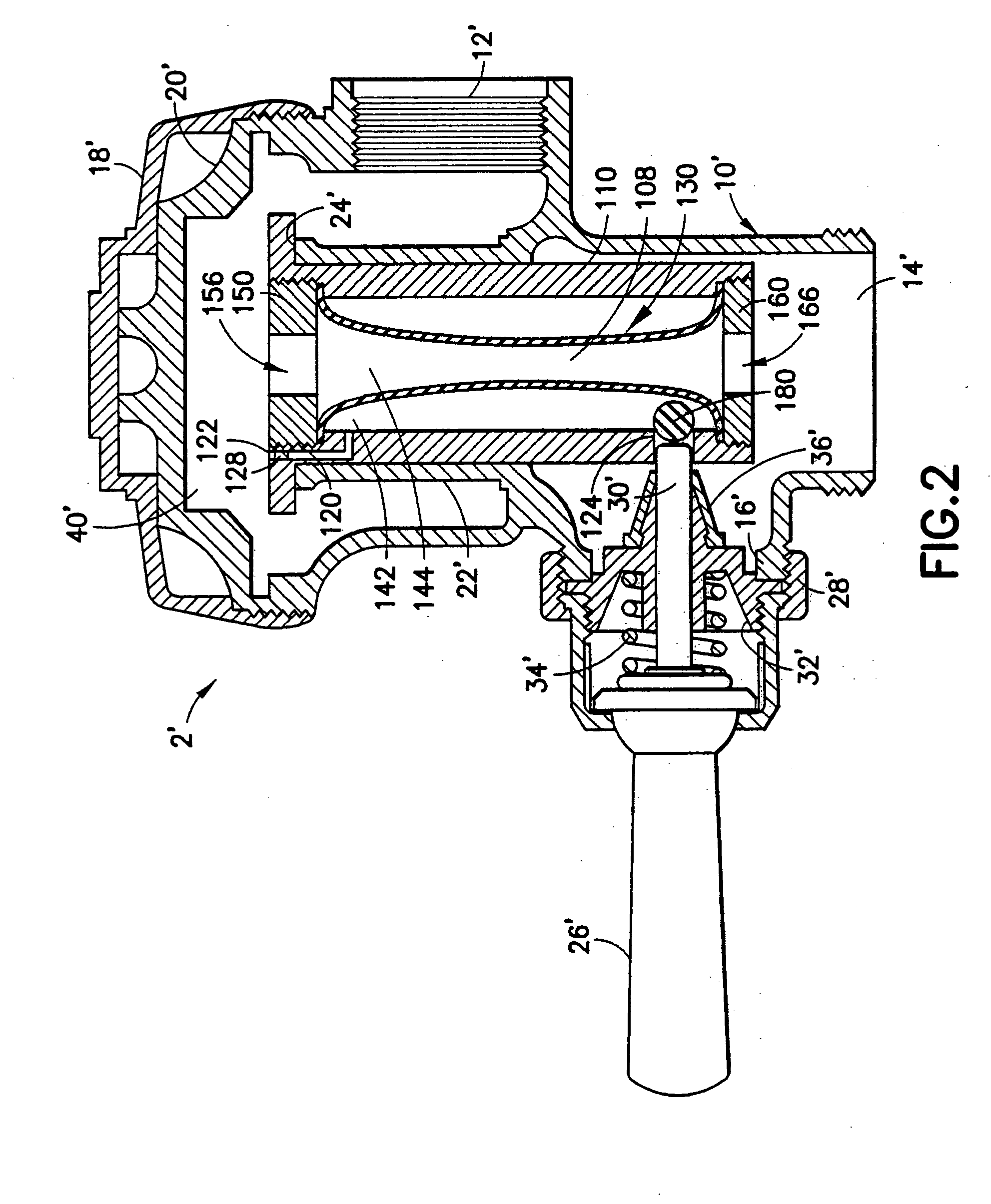

Pinch valve element for plumbing fixture flush valve

ActiveUS20050067590A1Reduce failure rateImproved cost efficiencyDiaphragm valvesOperating means/releasing devices for valvesPinch valveDiaphragm valve

The present invention discloses a pinch valve for replacing a diaphragm valve in a plumbing fixture. The plumbing fixture includes an inlet chamber defining a fluid inlet and in fluid communication with an inside chamber defining a fluid outlet. The pinch valve includes a cartridge member with a fluid inlet opening, a fluid outlet opening and a cartridge chamber defined by a cartridge chamber wall and in fluid communication with the fluid inlet opening and the fluid outlet opening. A flexible sealing member is positioned at least partially within the cartridge chamber and includes a wall with an inner surface defining an inner chamber and an outer surface defining an outer chamber between the outer surface of the flexible sealing member wall and the cartridge chamber wall. The inlet chamber of the plumbing fixture is in fluid communication with the inner chamber and the outer chamber.

Owner:SDB IP HLDG

Method and arrangement for receiving an optical input signal and transmitting an optical output signal

ActiveUS20120155879A1Large electric bandwidthHigh optical extinction ratioWavelength-division multiplex systemsElectromagnetic transmittersTransceiverEngineering

The present invention relates to a transceiver unit in a PON, Passive Optical Network, for receiving an optical input signal and transmitting an amplitude modulated optical output signal. Further, the present invention relates to a method in a transceiver unit for receiving an optical input signal and transmitting an amplitude modulated optical output signal.

Owner:TELEFON AB LM ERICSSON (PUBL)

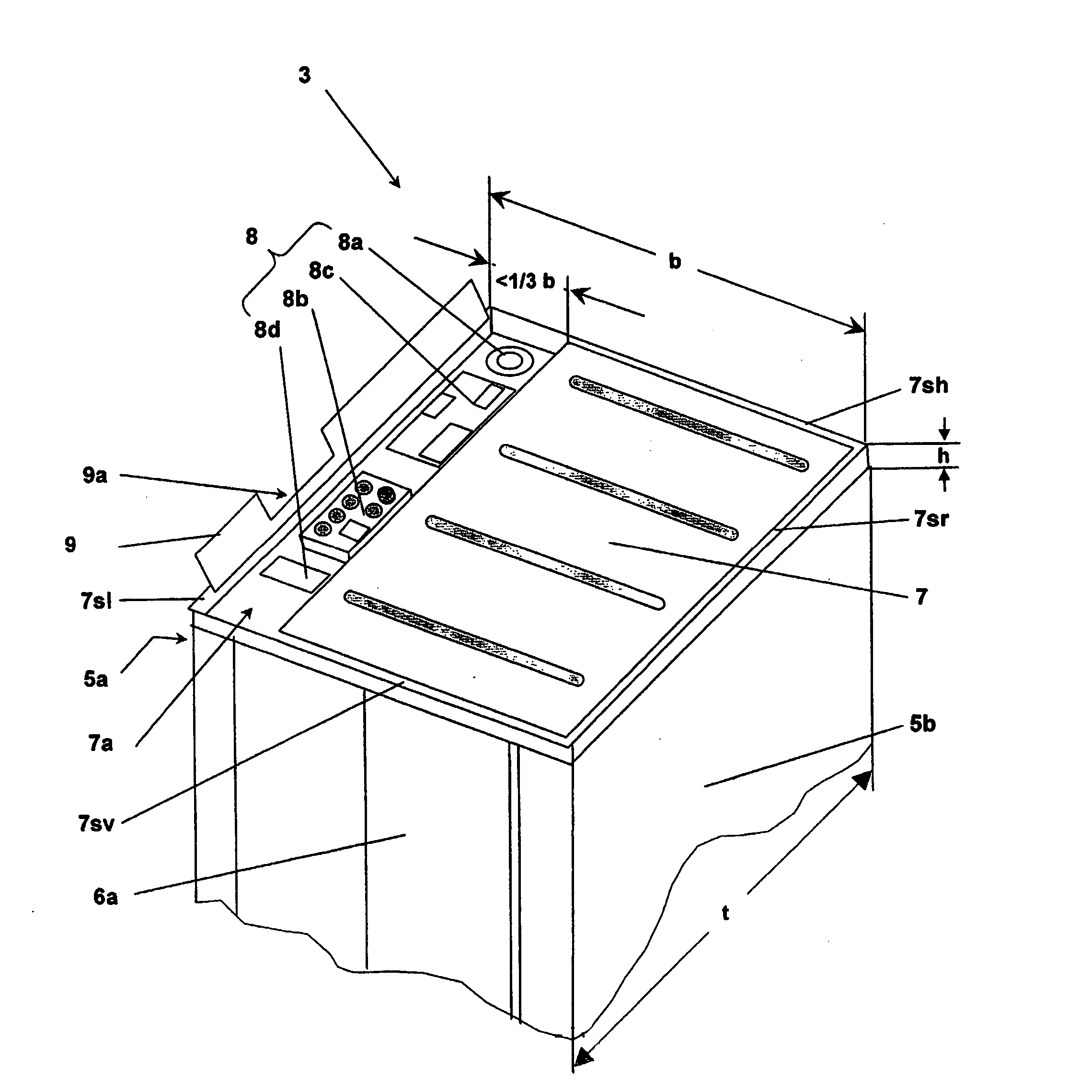

Elevator car with car electrical system integrated in the car roof and method of mounting an elevator installation

A portion of an elevator car electrical system, such as car computer, terminals, communication apparatus, etc., is mounted in an apparatus space integrated into a car roof. The apparatus space is arranged along a car roof edge and utilizes a constructional height required for stiffening the car roof. The portion of the car electrical system is accessible by a moveable cover for service. When closed, the cover forms a standing surface which can be used for servicing in the elevator shaft.

Owner:INVENTIO AG

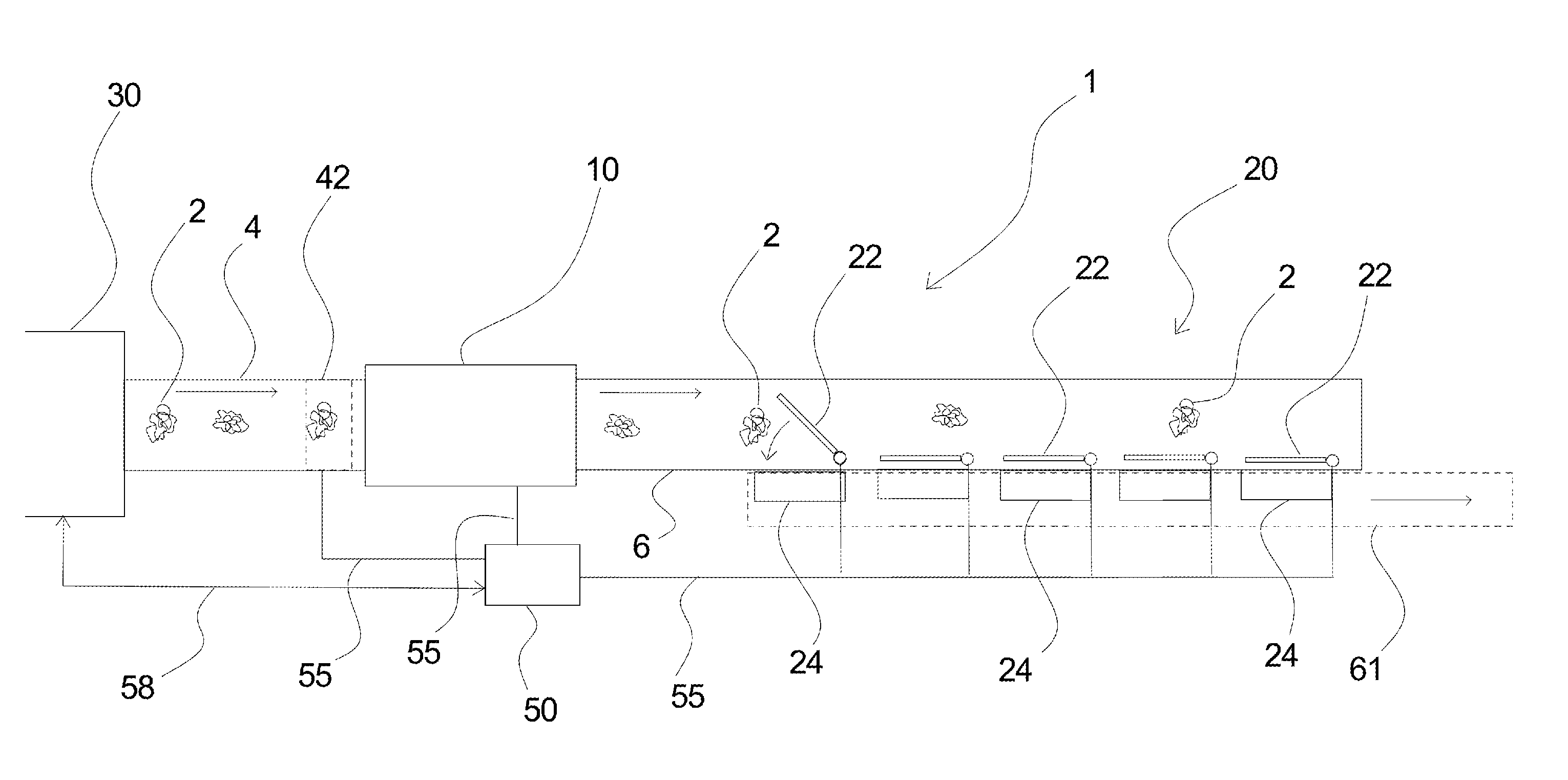

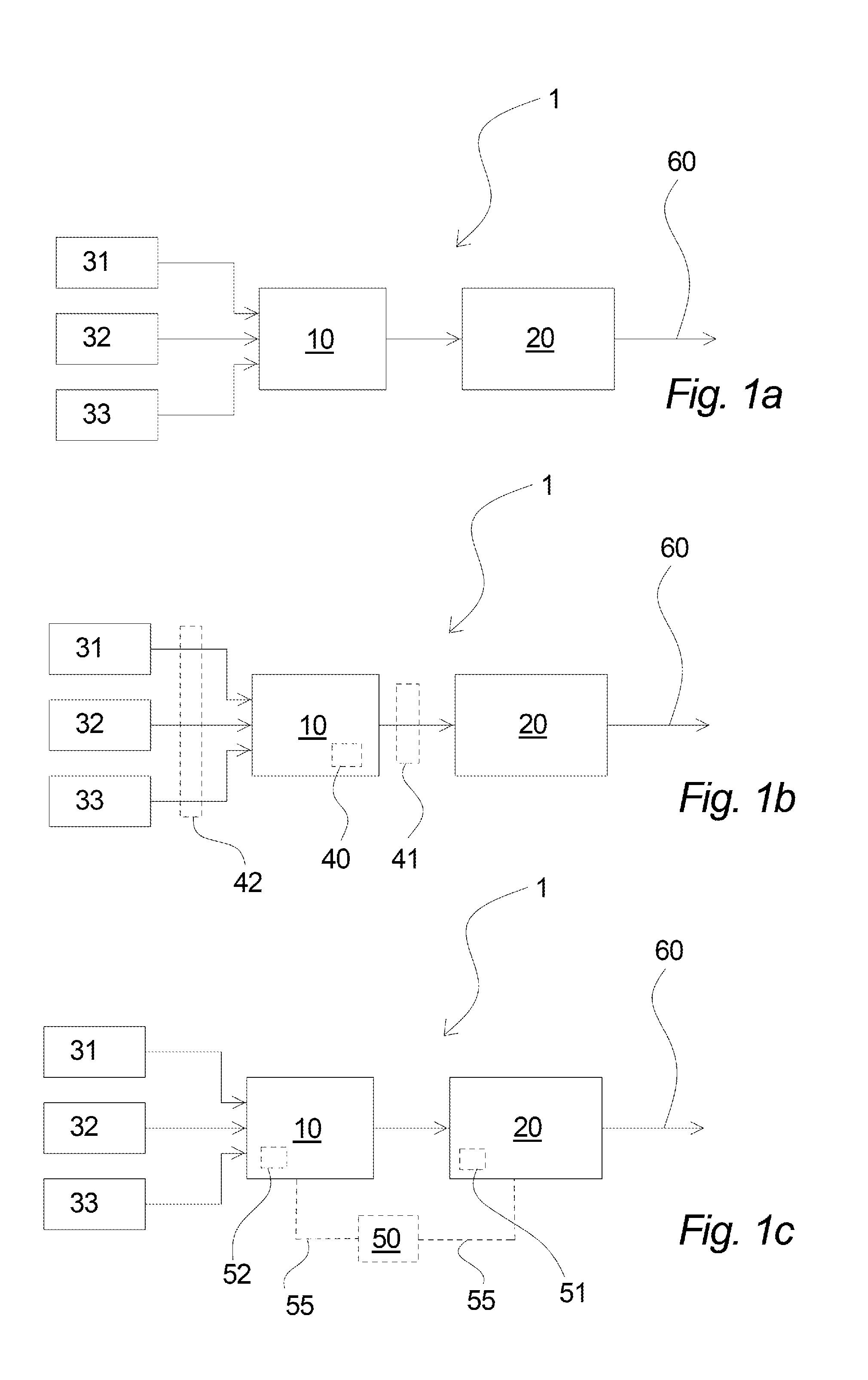

Fat/meat grading method and system

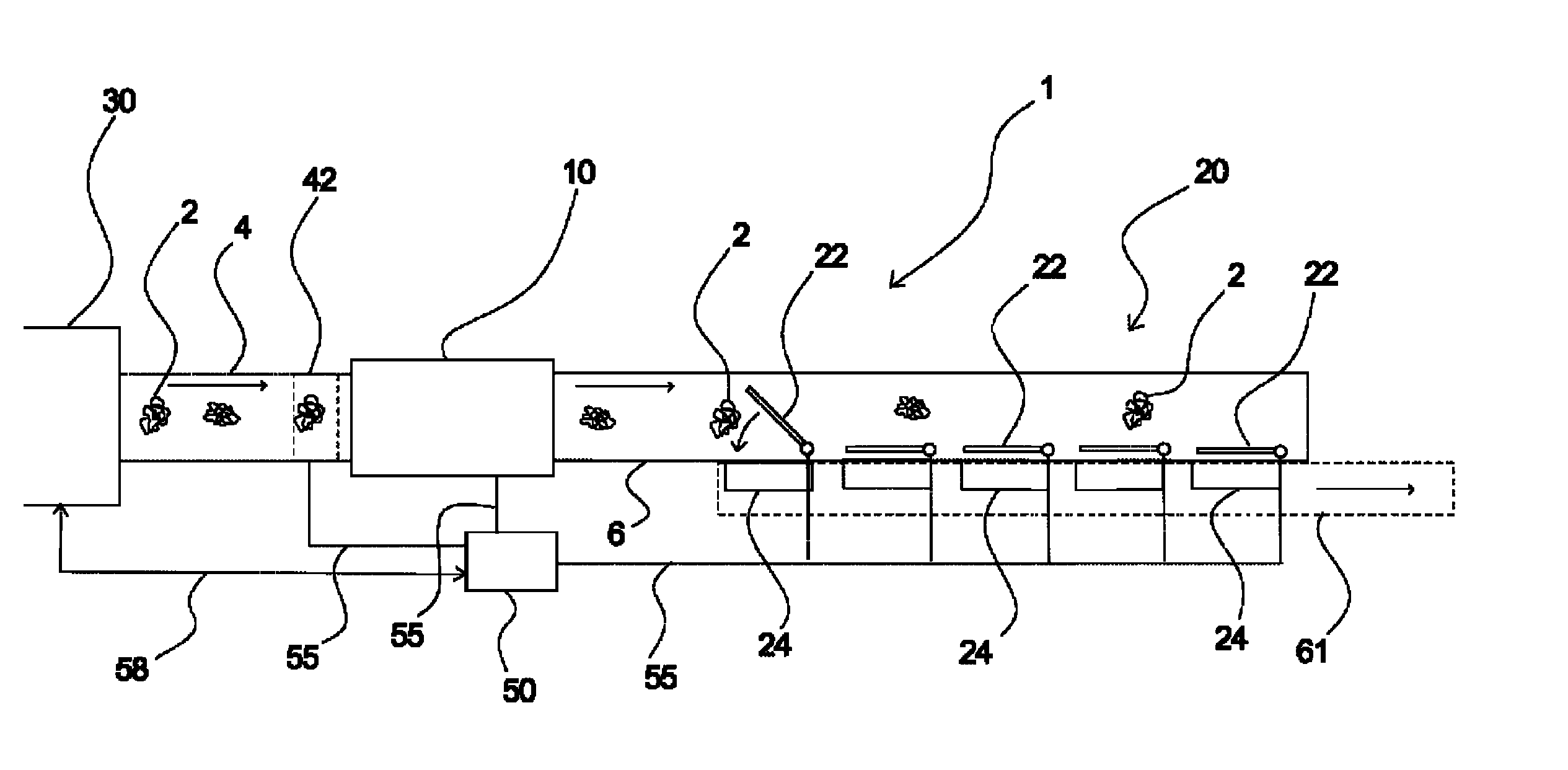

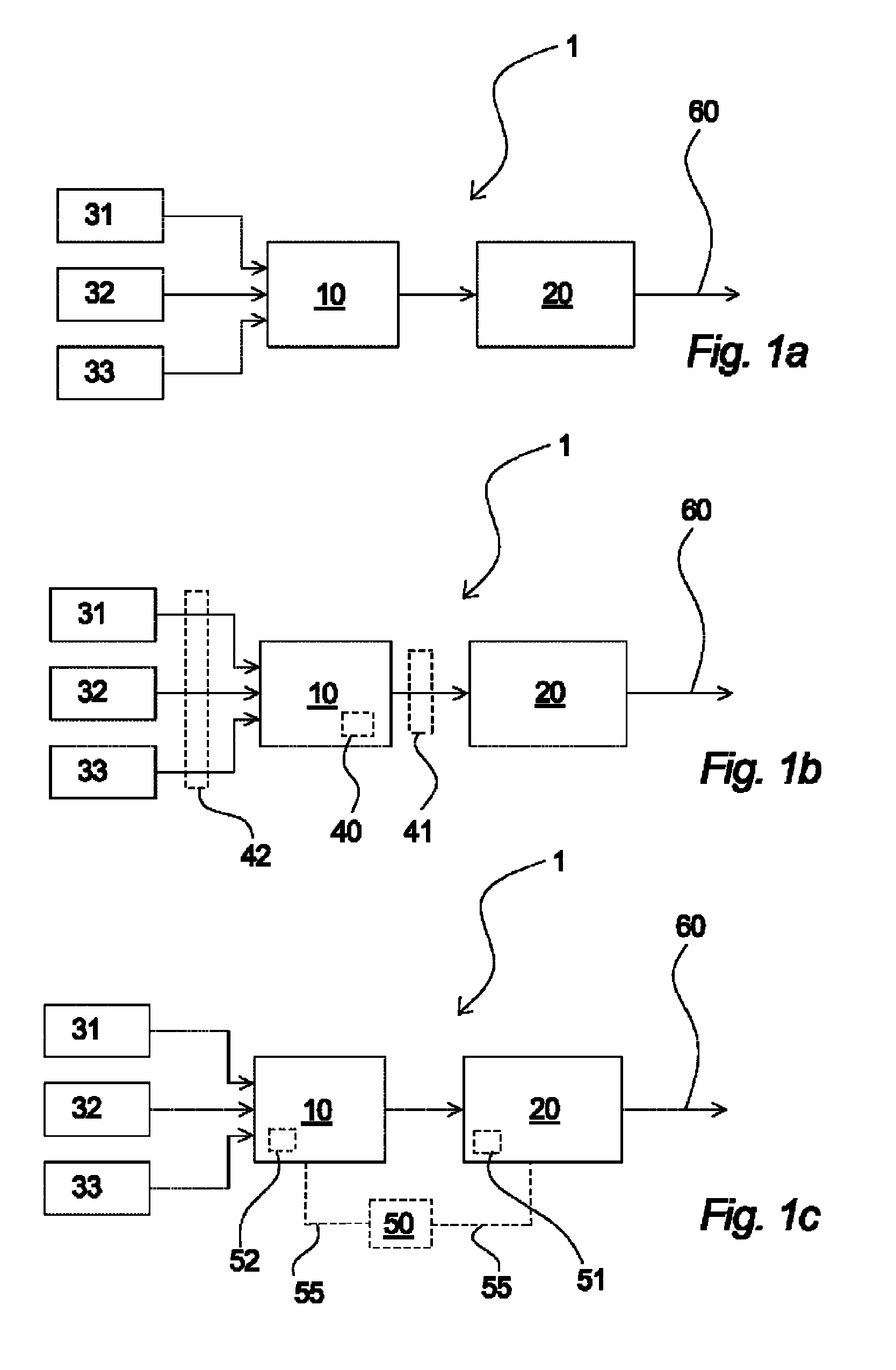

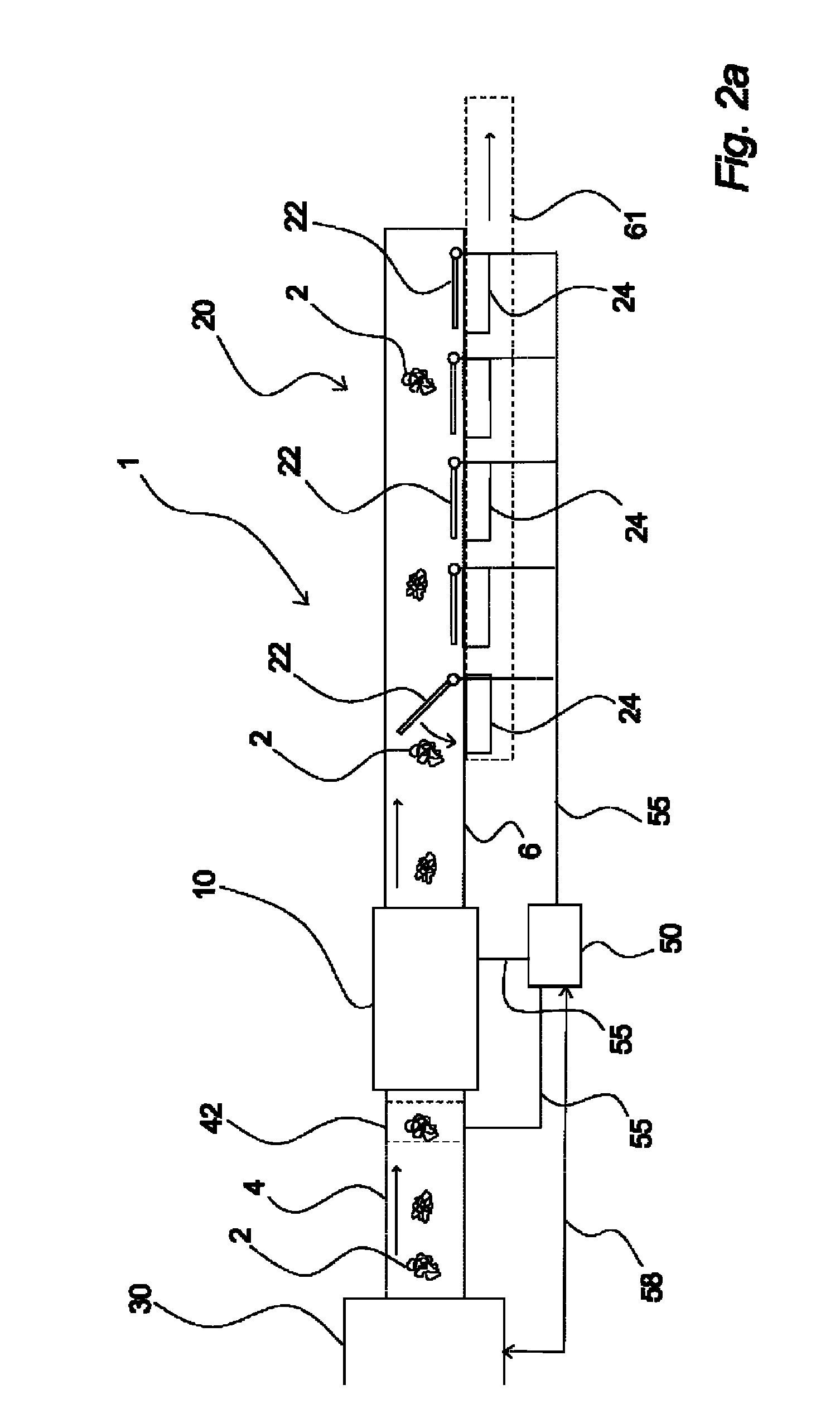

ActiveUS20130199971A1High degree of automationQuality improvementMeat packaging/handling/transportingSortingSimulationTotal fat

Method and system for processing of meat trim products, where trim products are supplied as a sequence of collections of trim (COTs), each collection of trim (COT) comprising a plurality of trim products, wherebya fat / meat relationship for a collection of trim (COT) is measured,a collection of trim (COT) is transferred to a selected station by a separator, controlled by a controller, and wherebya batch is completed at a selected station on the basis of data for said fat / meat relationship, said batch comprising one or more collections of trim (COTs) and fulfilling a predetermined criterion regarding a total fat / meat relationship.

Owner:MAREL HF

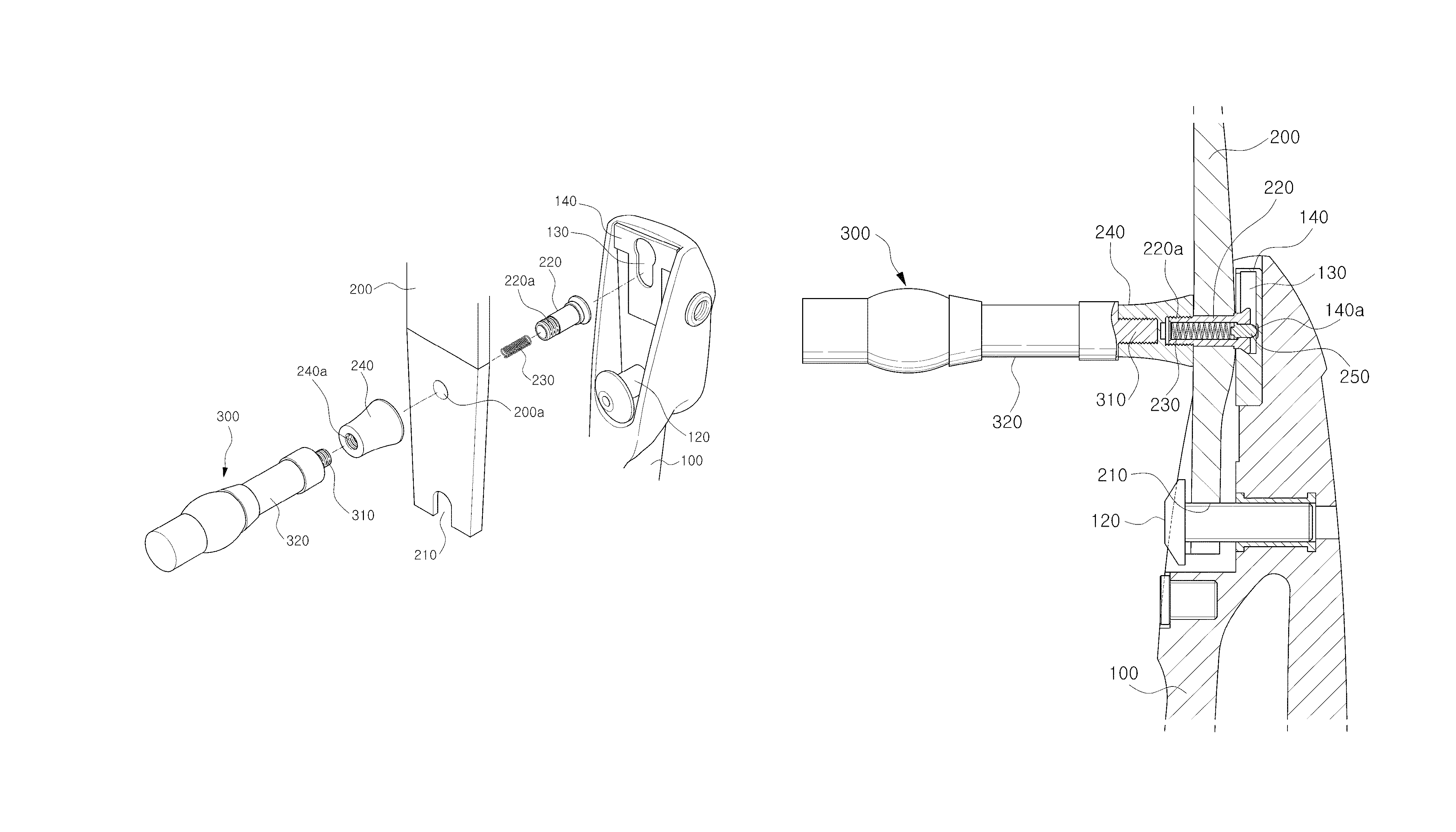

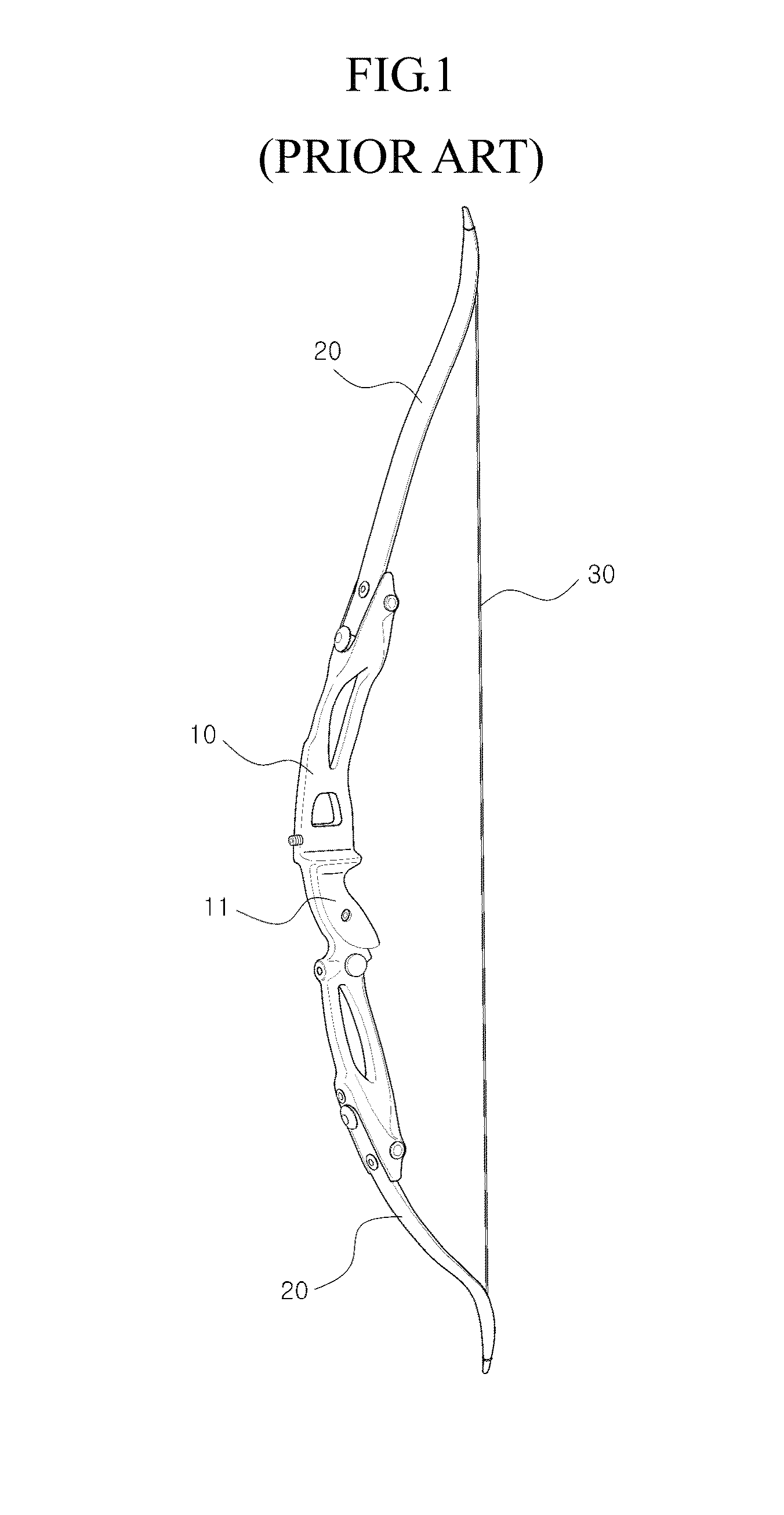

Recurved bow with improved vibration damping function

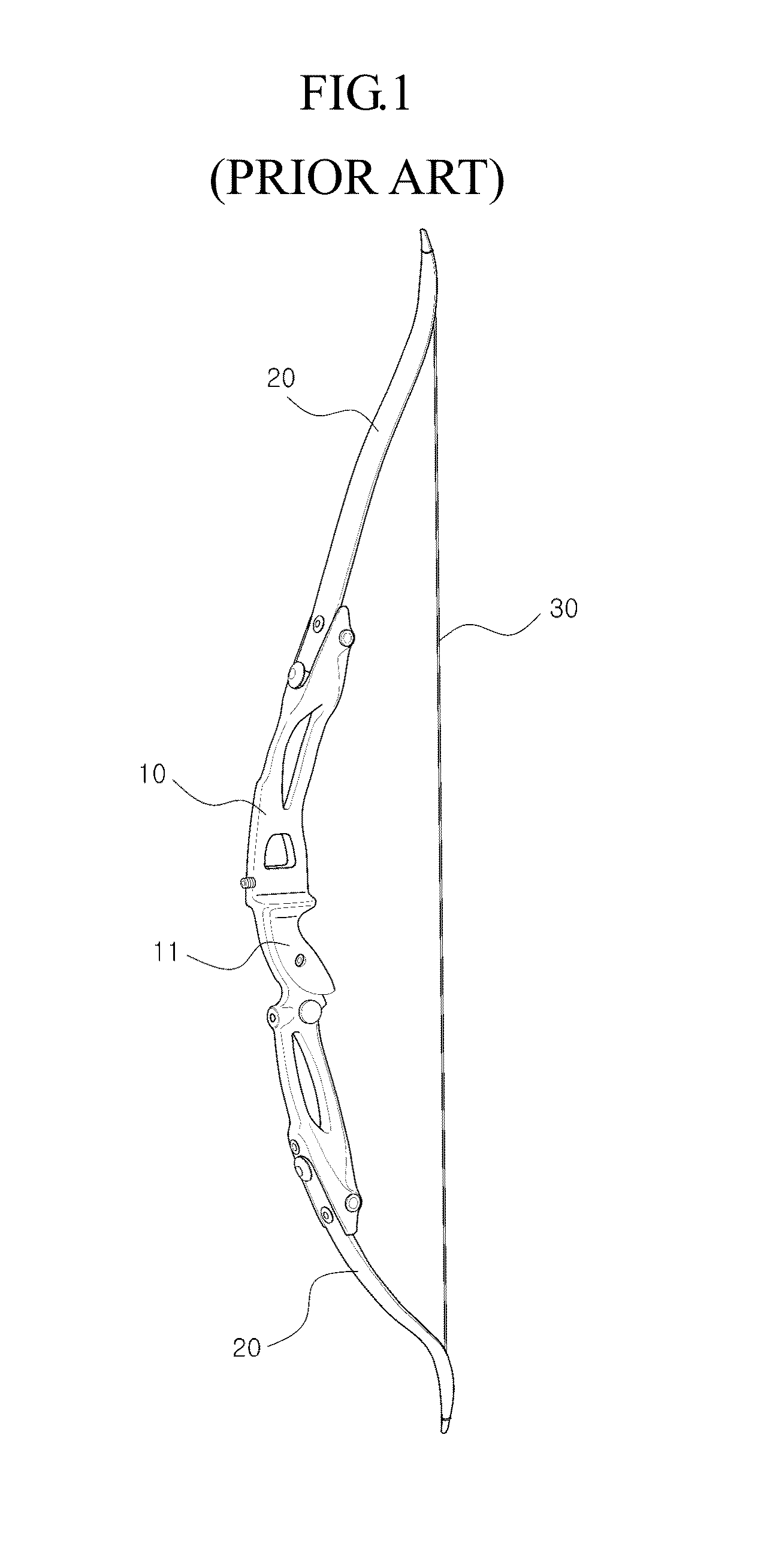

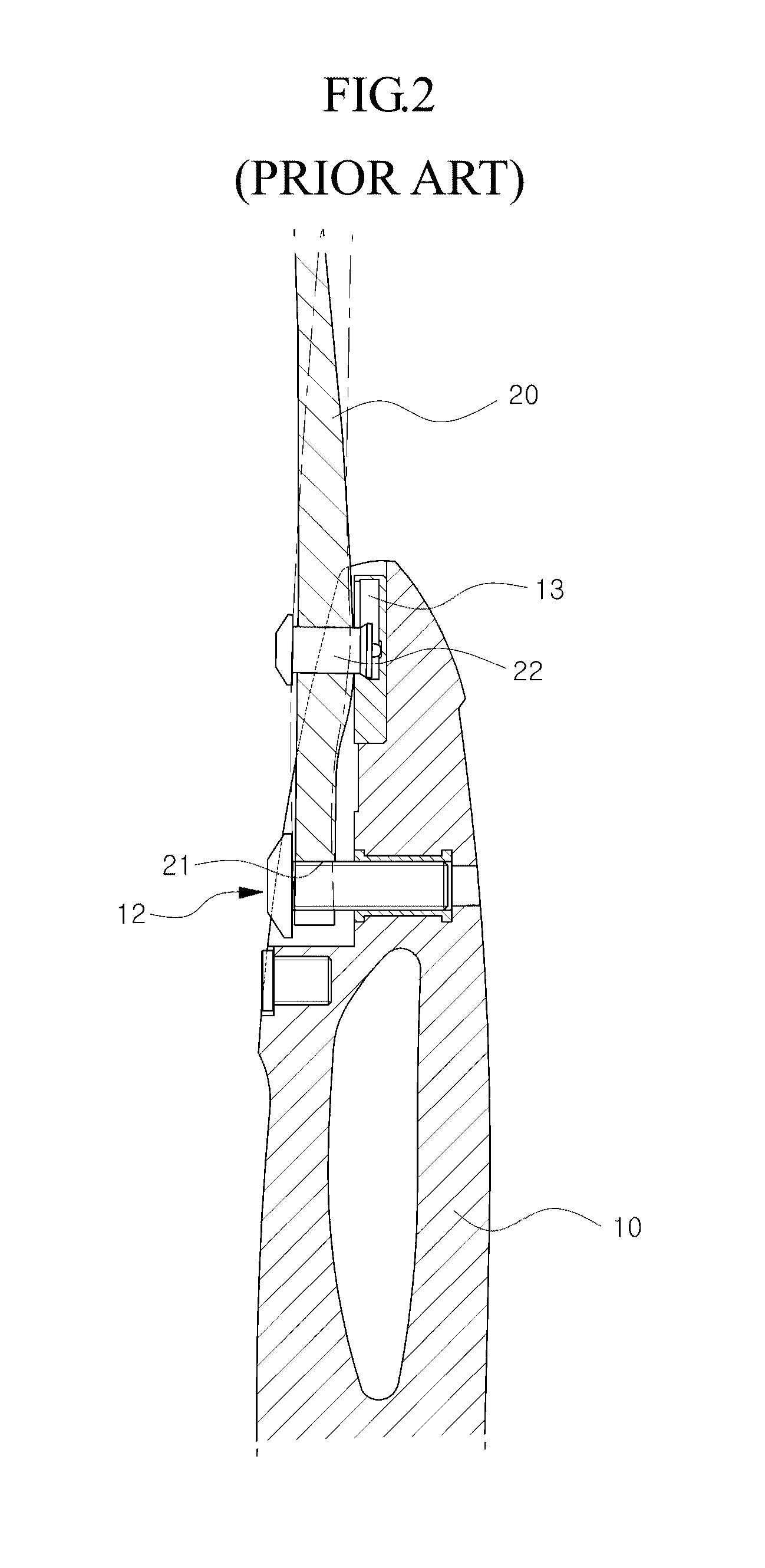

InactiveUS20160209158A1Improve accuracyRapid vibrationBows/crossbowsEngineeringMechanical engineering

Provided is a recurved bow including: a handle; a pair of limbs coupled at both ends of the handle; and a bowstring, wherein a projecting coupling member is provided in front of each of the limbs, and is extended forwardly from each of the limbs, and has a coupling portion in the front thereof, and is coupled with a coupling pin of a rear side of each of the limbs, and wherein a damper member is provided in which the damper member comprises a corresponding coupler that is coupled with the coupling portion formed in front of each of the projecting coupling member, and a damper coupled with the front of the corresponding coupler, to thereby rapidly damp vibrations generated in one end of each of the limbs to thus enhance a vibration damping function.

Owner:WIN & WIN

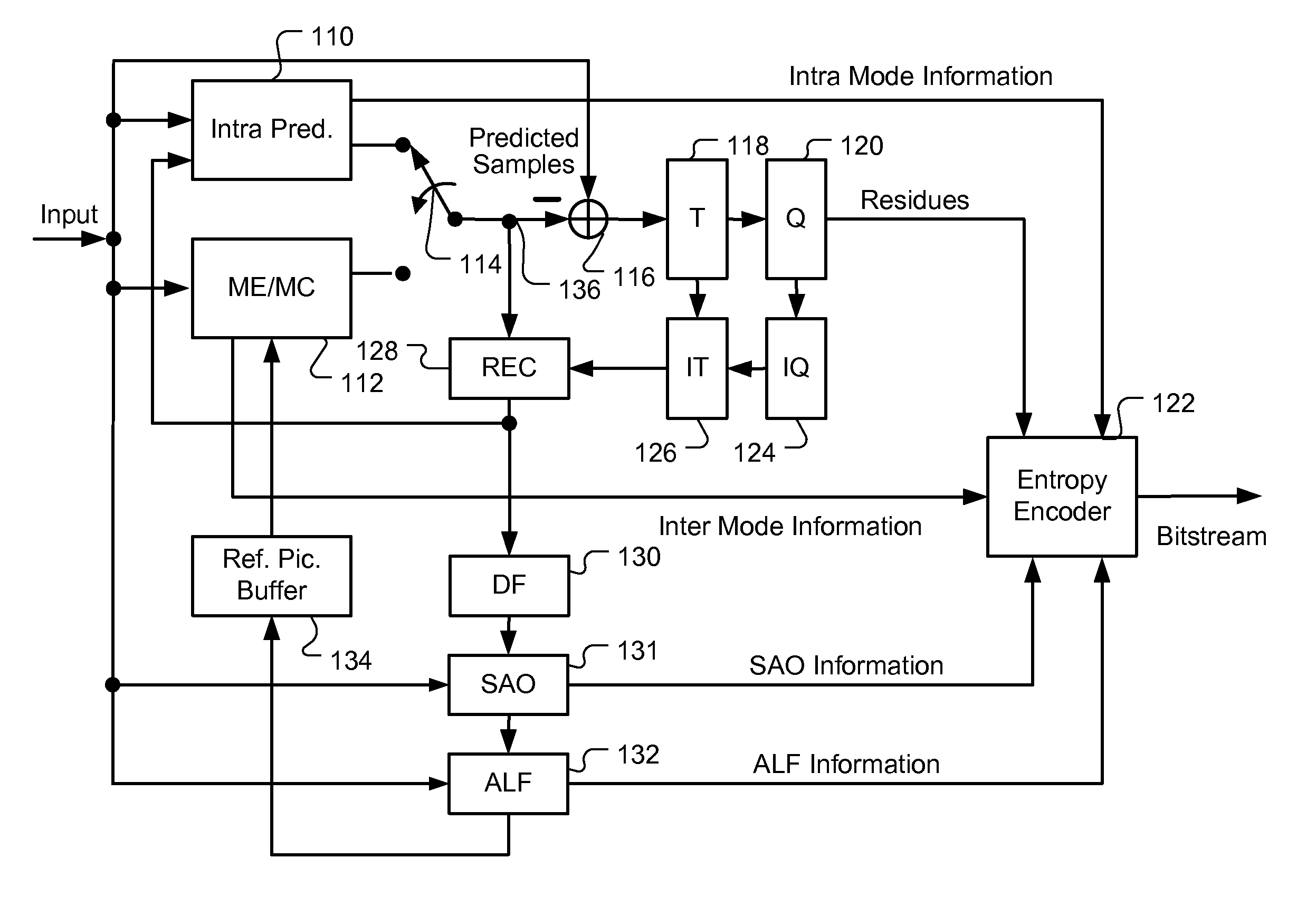

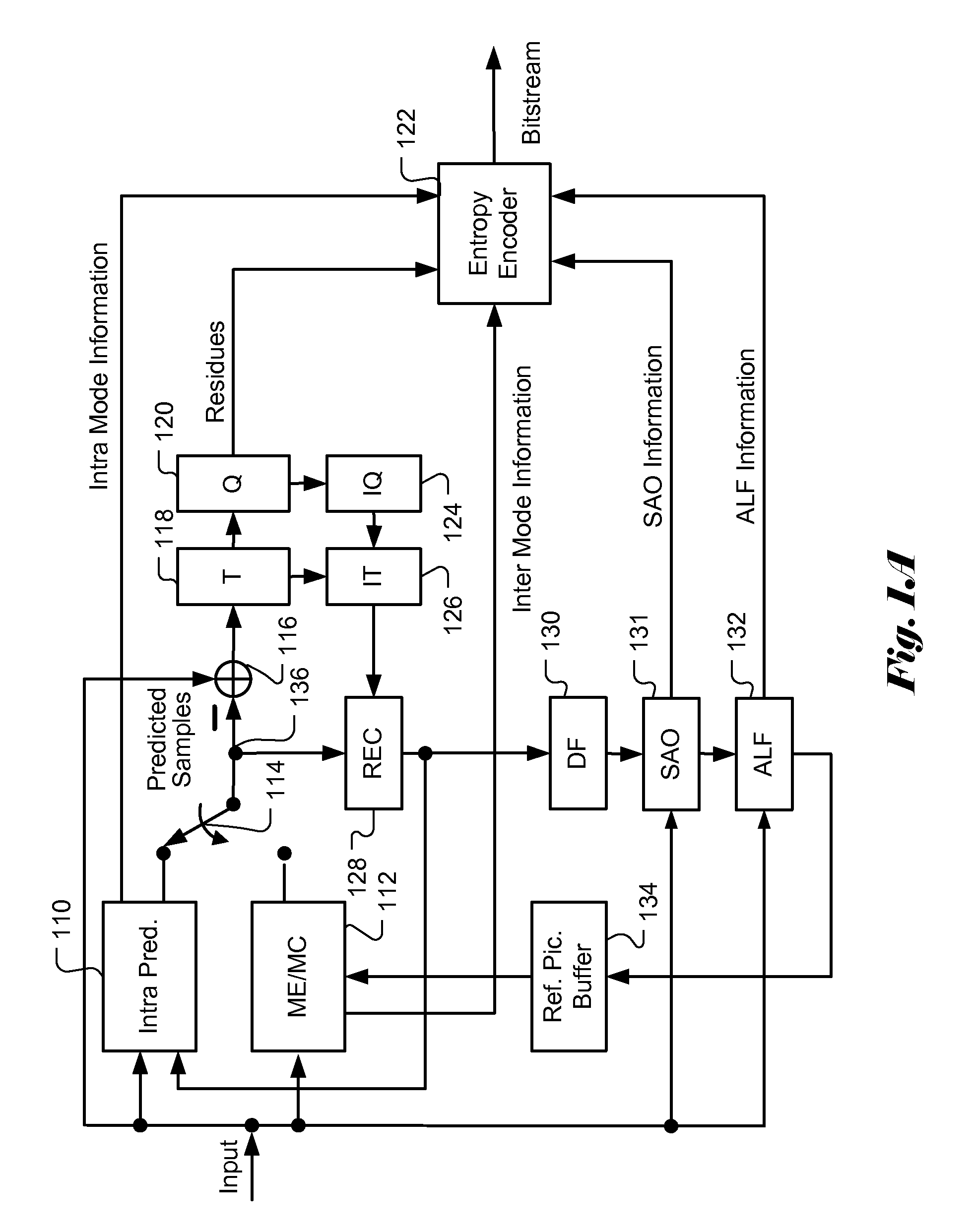

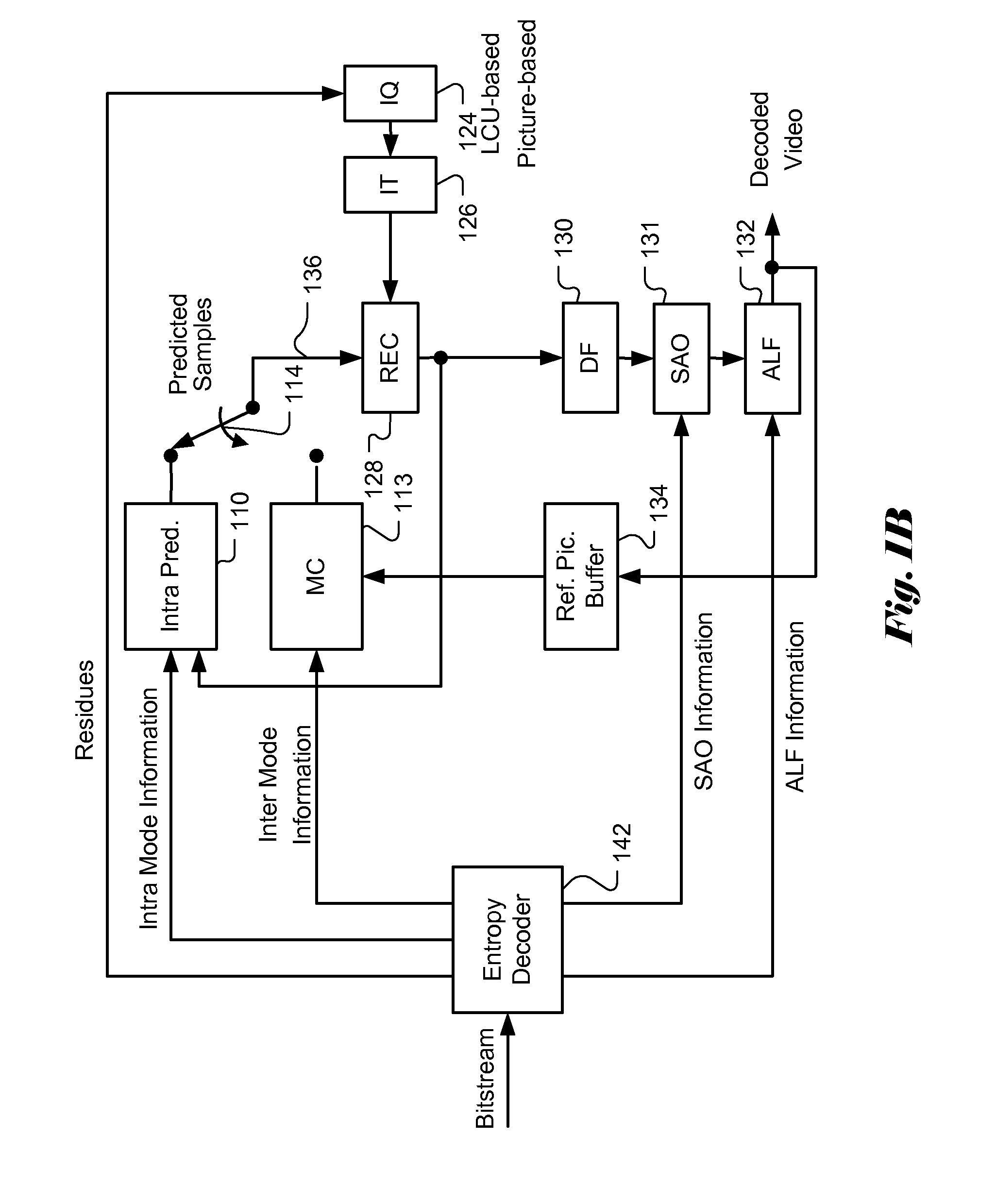

Method and Apparatus for Video Processing Incorporating Deblocking and Sample Adaptive Offset

ActiveUS20140036992A1Reduce processing latencyImproved cost-efficiencyColor television with pulse code modulationColor television with bandwidth reductionComputational scienceStart time

A method and apparatus for applying DF processing and SAO processing to reconstructed video data are disclosed. The DF processing is applied to a current access element of reconstructed video data to generate DF output data and the deblocking status is determined while applying the DF processing. Status-dependent SAO processing is applied to one or more pixels of the DF output data according to the deblocking status. The status-dependent SAO processing comprises SAO processing, partial SAO processing, and no SAO processing. The SAO starting time for SAO processing is between the DF-output starting time and ending time for the current block. The DF starting time of a next block can be earlier than the SAO ending time of the current block by a period oft, where t is smaller than time difference between the DF-output starting time and the DF starting time of the next block.

Owner:MEDIATEK INC

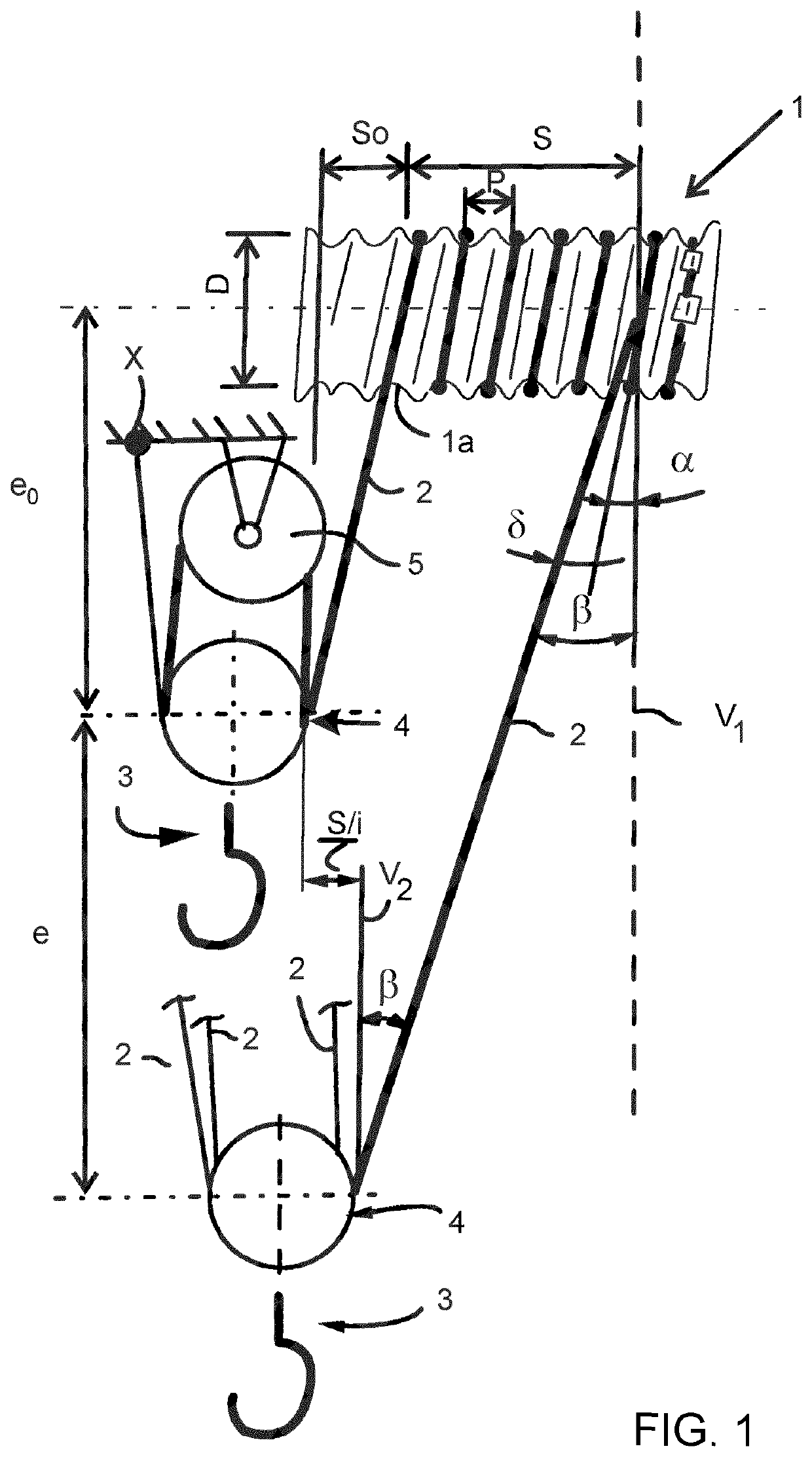

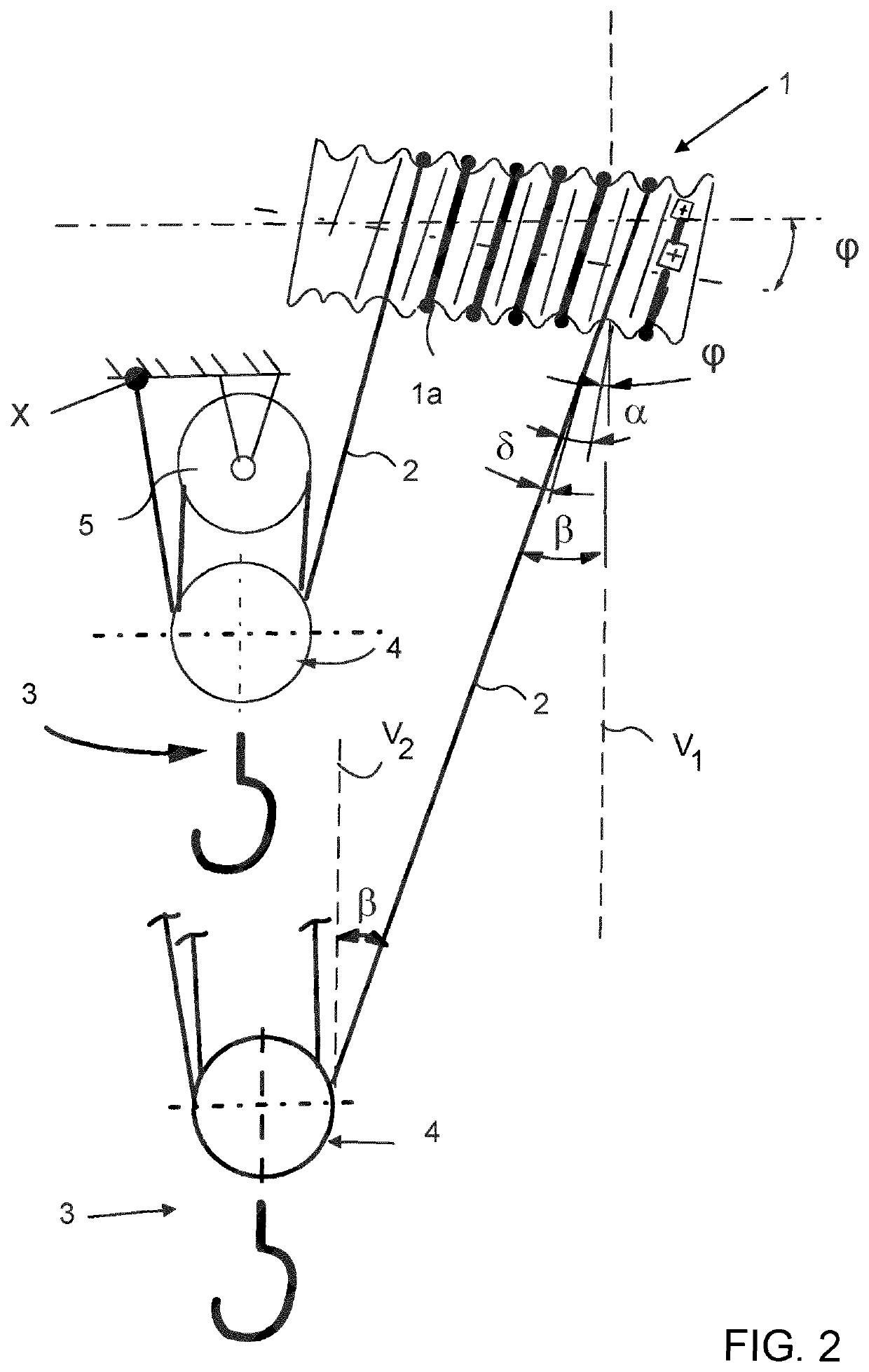

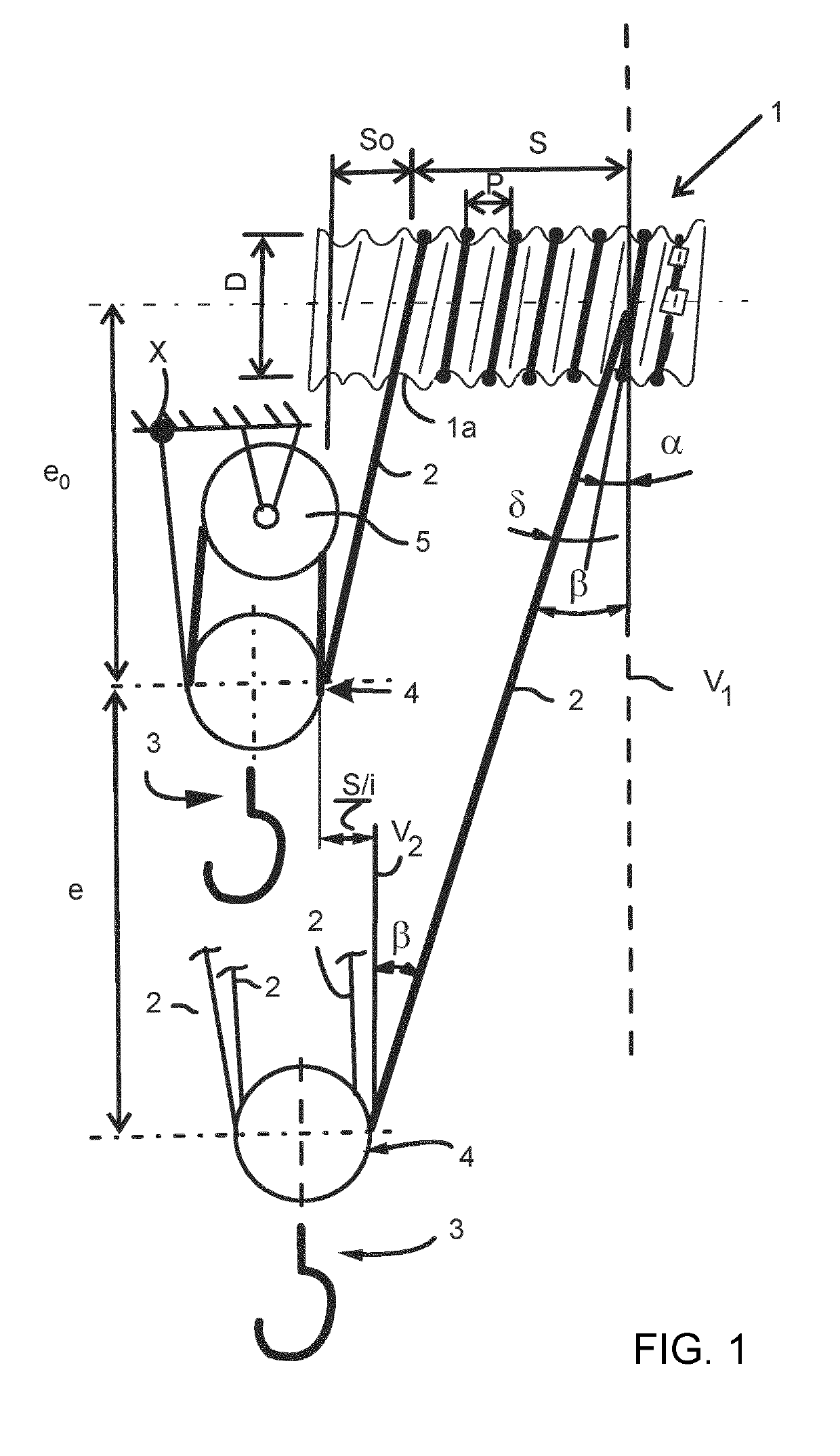

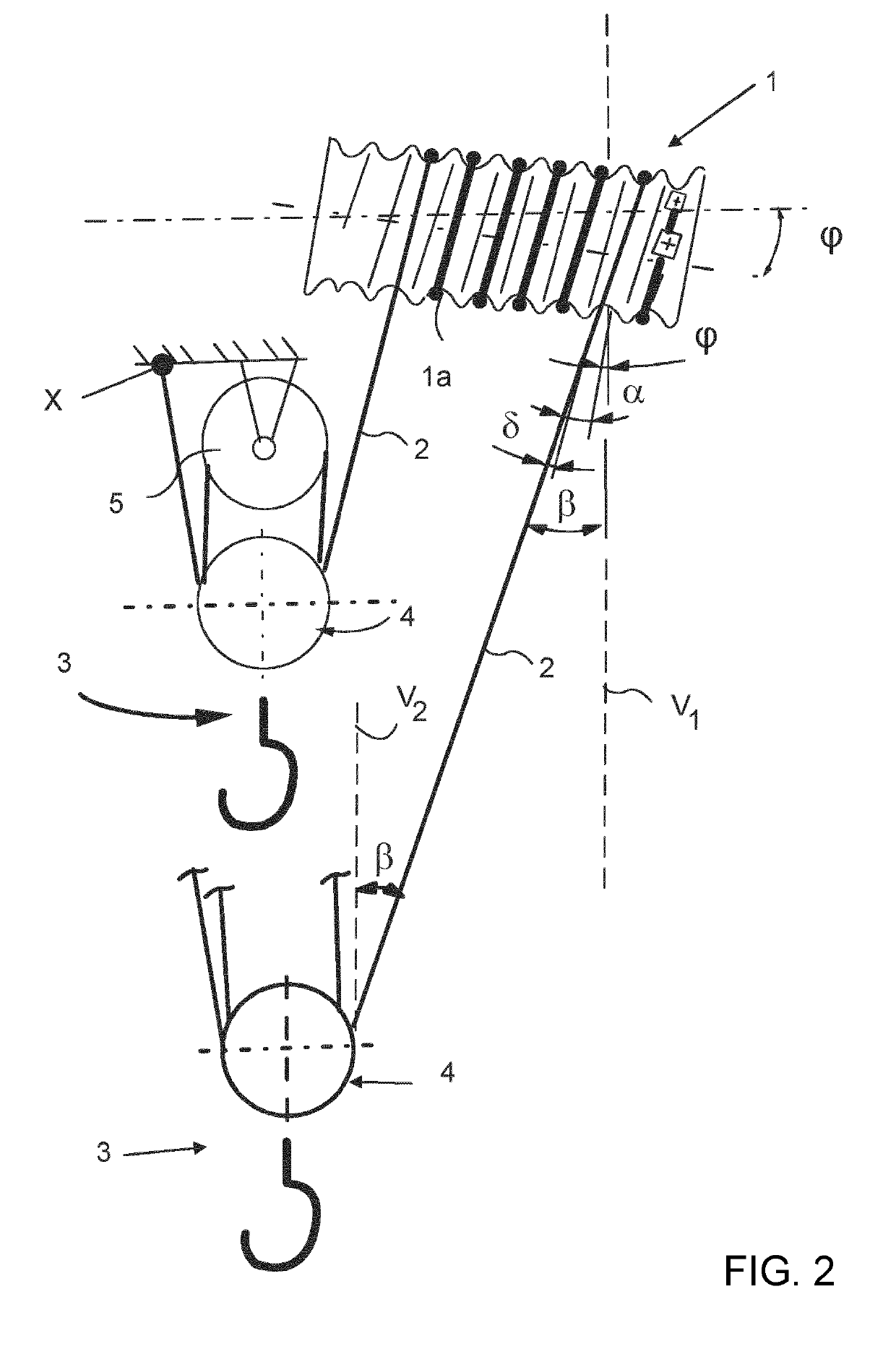

Hoisting arrangement of rope hoist

ActiveUS10926982B2Eliminate riskShort lifePortable liftingWinding mechanismsClassical mechanicsHoist device

A hoisting arrangement of a rope hoist includes a hoisting rope, a rope drum with one rope groove for the hoisting rope, and a hoisting member for hoisting a load. The hoisting member includes a rope pulley arrangement for the hoisting rope. The hoisting rope is routed from the rope drum via at least the hoisting member's rope pulley arrangement to a fixed attachment point on the rope hoist. The rope drum is tilted in relation to the horizontal plane in a manner where the first end of the rope drum, towards which the hoisting rope is wound in the hoisting member's upper position, is higher than the rope drum's second end, towards which the hoisting rope is unwound in the hoisting member's lower position.

Owner:KONECRANES GLOBAL

Method for Recovering Amine From Amine-Containing Waste Water

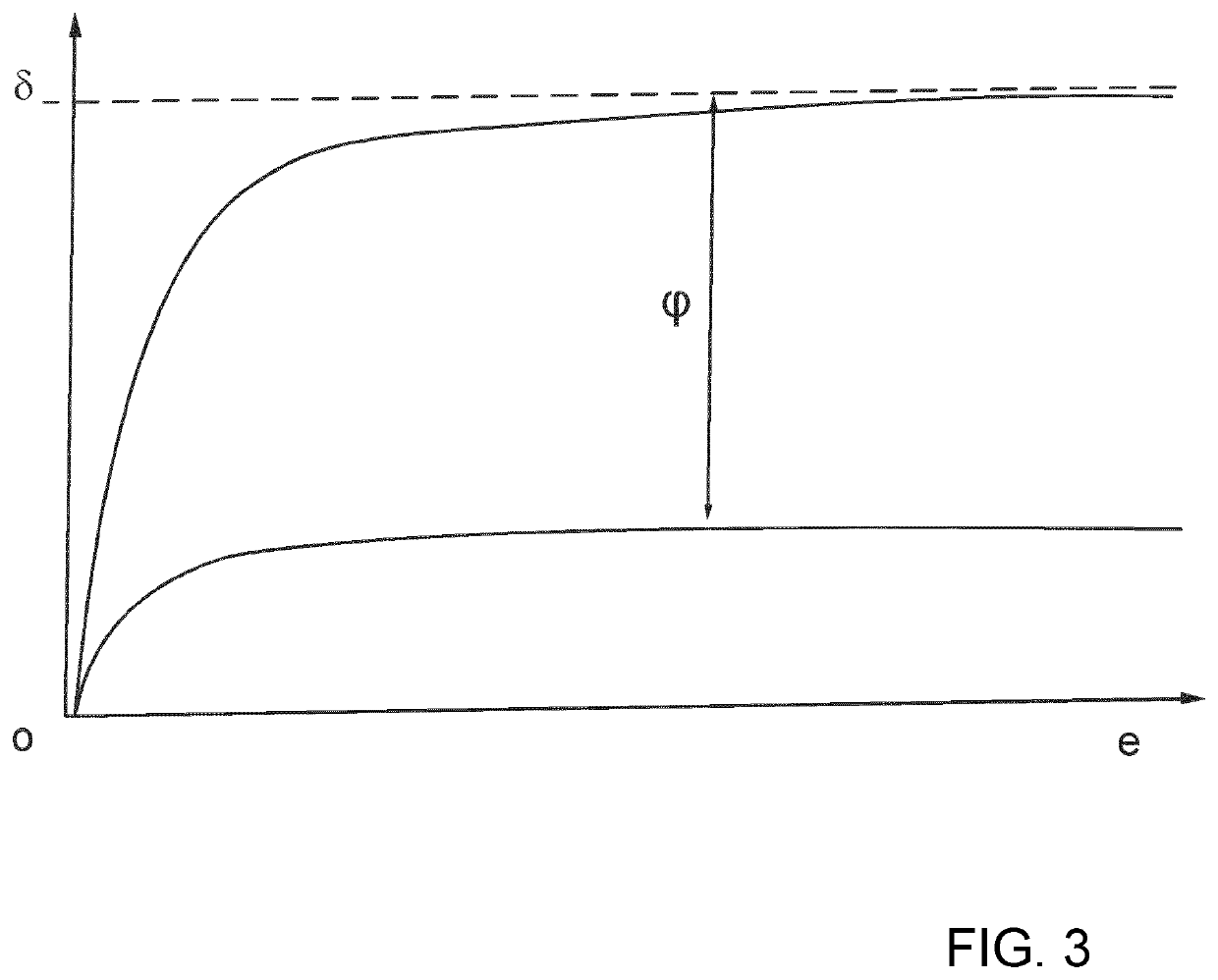

ActiveUS20110100917A1Improved cost-efficiencyAvoid loopsIon-exchanger regenerationDistillation regulation/controlWater useHigh concentration

Provided is a method for recovering high-concentration and high-purity amine from amine-containing waste water generated from nuclear power plants and thermal power plants. The method includes: capturing amine and concentrating waste water using a cation exchange resin; separating amine from the concentrated amine-containing waste water; and carrying out further separation of amine via distillation. The method may be applied to treat amine, which causes an increase in biochemical oxygen demand (BOD) and total nitrogen concentration, drastically at the time of its generation from waste water of nuclear power plants and thermal power plants. In this manner, the method may prevent an increase in load of existing waste water treating plants and avoid a need for modifying the equipment in the existing plants. In addition, the method disclosed herein may allow recovery and reutilization of amine, injected continuously to prevent corrosion of water / vapor circulation systems of nuclear power plants and thermal power plants, thereby improving the cost-efficiency in such power plants.

Owner:SOONCHUNYANG UNIV IND ACAD COOP FOUND

Hoisting arrangement of rope hoist

ActiveUS20190135595A1Eliminate riskReduced service lifePortable liftingWinding mechanismsIndustrial engineeringPulley

A hoisting arrangement of a rope hoist includes a hoisting rope, a rope drum with one rope groove for the hoisting rope, and a hoisting member for hoisting a load. The hoisting member includes a rope pulley arrangement for the hoisting rope. The hoisting rope is routed from the rope drum via at least the hoisting member's rope pulley arrangement to a fixed attachment point on the rope hoist. The rope drum is tilted in relation to the horizontal plane in a manner where the first end of the rope drum, towards which the hoisting rope is wound in the hoisting member's upper position, is higher than the rope drum's second end, towards which the hoisting rope is unwound in the hoisting member's lower position.

Owner:KONECRANES GLOBAL

Method of precious metal recovery

InactiveUS7846234B2Reduce in quantitySpeed up the processSolvent extractionGold compoundsMetal chlorideSource material

The proposed invention relates to methods of precious metal recovery and may be applied to the recovery of precious metals from various types of mineral raw source materials containing chlorides of alkali and earth metals, e.g. collective concentrate produced from clay-salt residue of potassium production, or marker clays, etc. This method includes chlorinating roasting of the collective concentrate produced during enrichment of the material with residual chlorides content of 7-13%, or natural concentrate with up to 15% chlorides content. Thereafter, the cinder is leached by an aqua-regia solution, the precious metals are recovered from the pulp via of sorption, chlorinating roasting is held at 600-700° C., the precious metals are leached from the cinder using diluted solution of aqua-regia, and then via sorption. The process is cost-efficient due to the use of chlorinating agent, reduction of the process steps number, decreasing of the roasting temperature, and the leaching by diluted acid.

Owner:SINEGRIBOV VIKTOR ANDREEVICH +5

Recurved bow with improved vibration damping function

Provided is a recurved bow including: a handle; a pair of limbs coupled at both ends of the handle; and a bowstring, wherein a projecting coupling member is provided in front of each of the limbs, and is extended forwardly from each of the limbs, and has a coupling portion in the front thereof, and is coupled with a coupling pin of a rear side of each of the limbs, and wherein a damper member is provided in which the damper member comprises a corresponding coupler that is coupled with the coupling portion formed in front of each of the projecting coupling member, and a damper coupled with the front of the corresponding coupler, to thereby rapidly damp vibrations generated in one end of each of the limbs to thus enhance a vibration damping function.

Owner:WIN & WIN

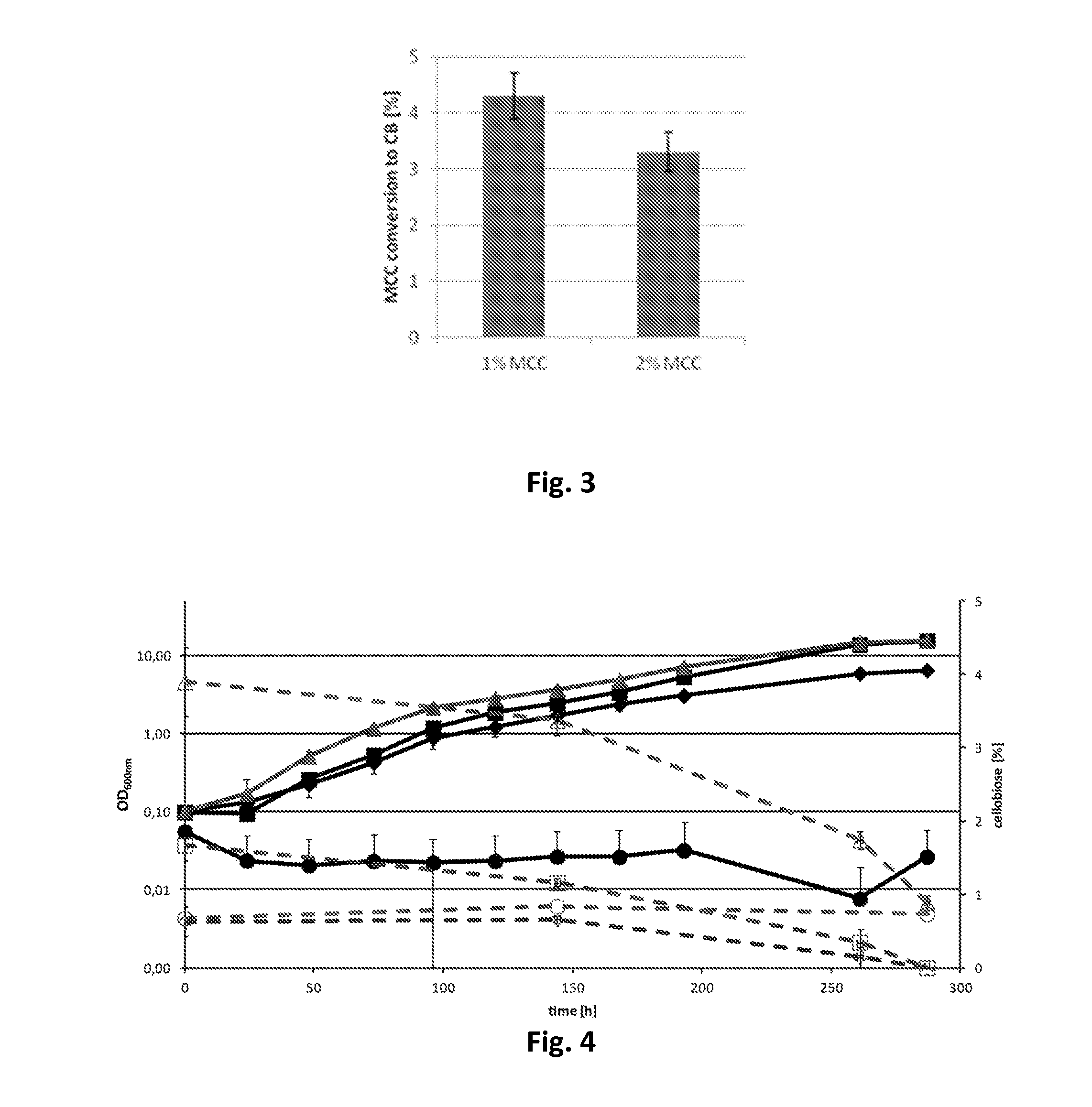

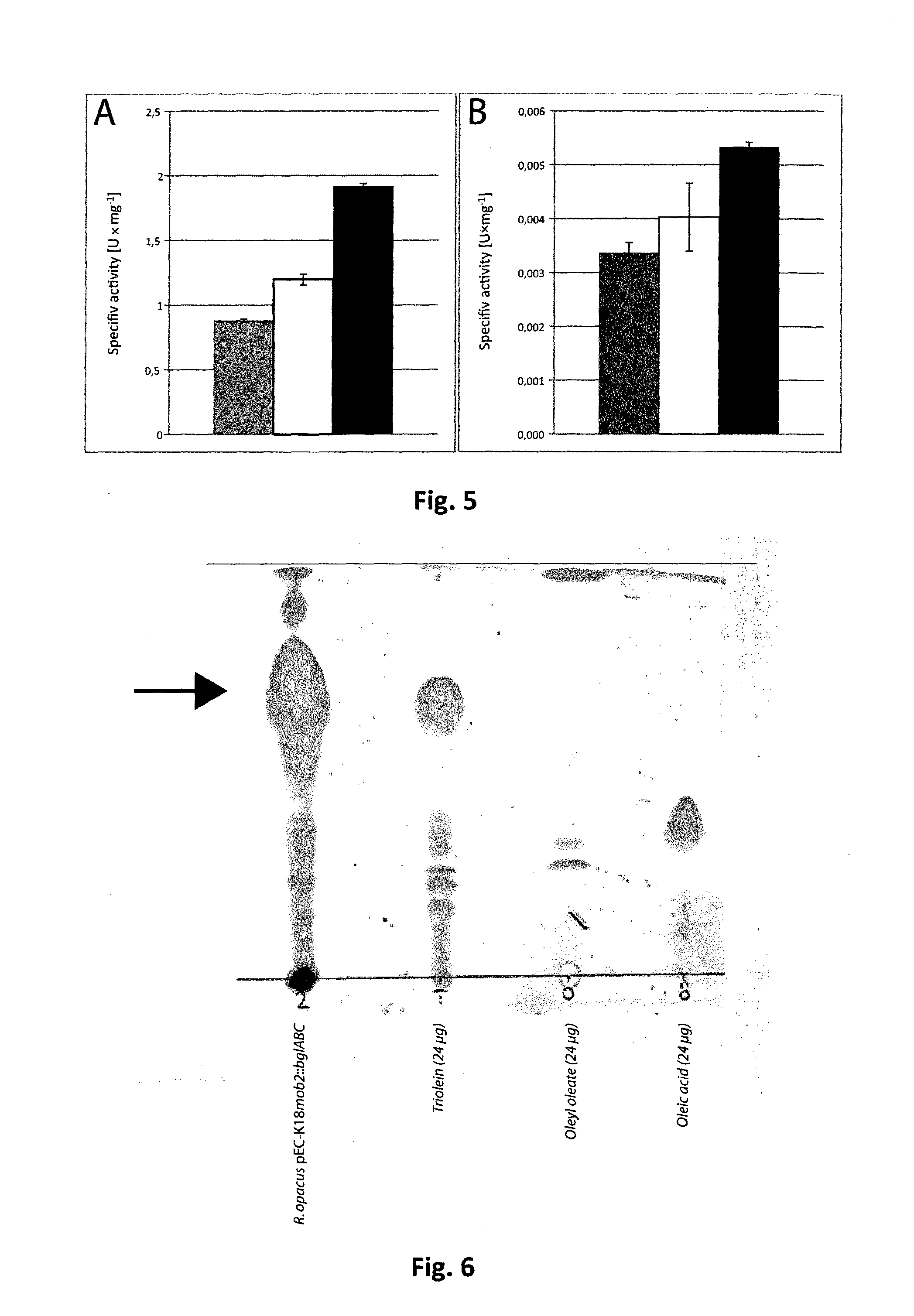

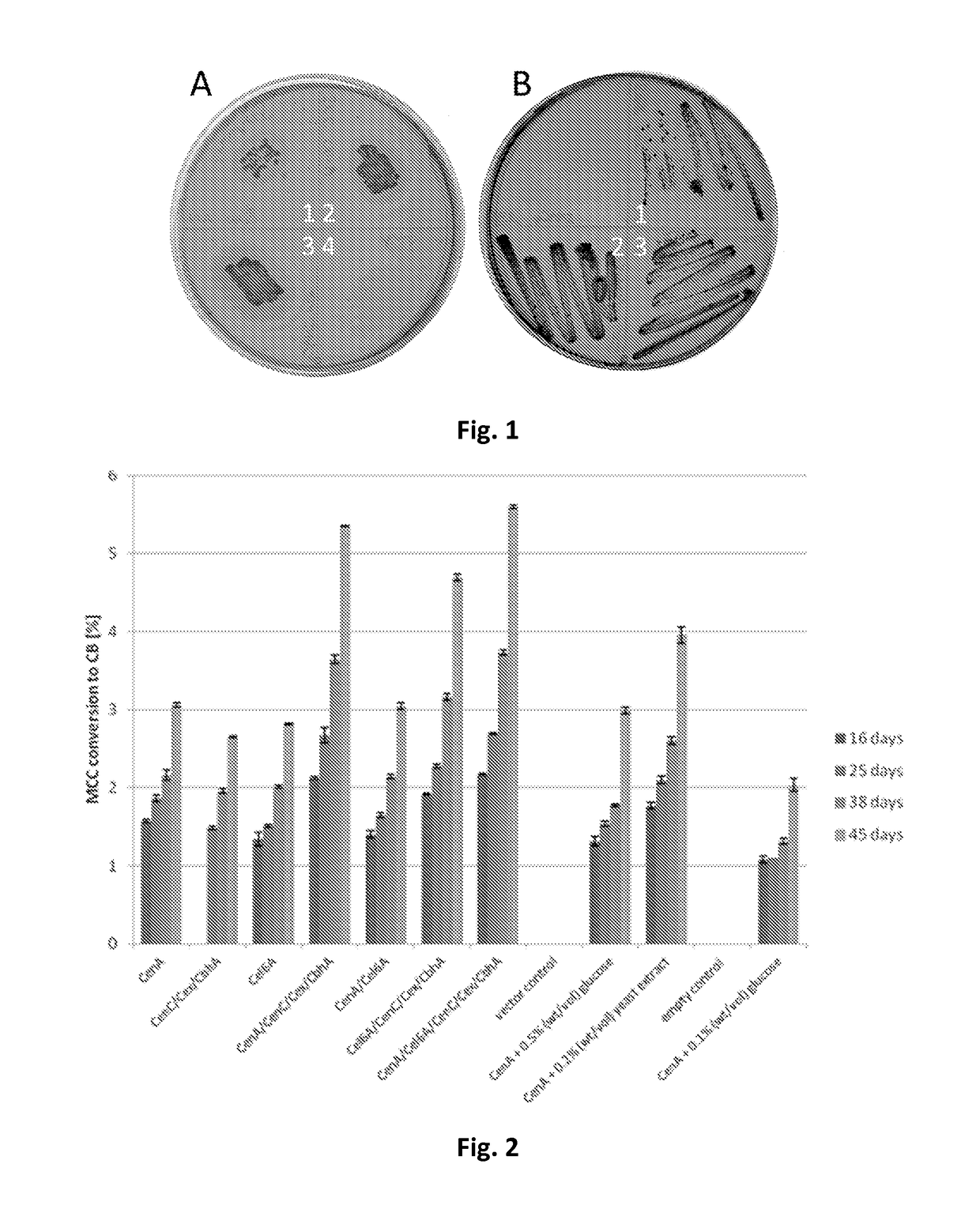

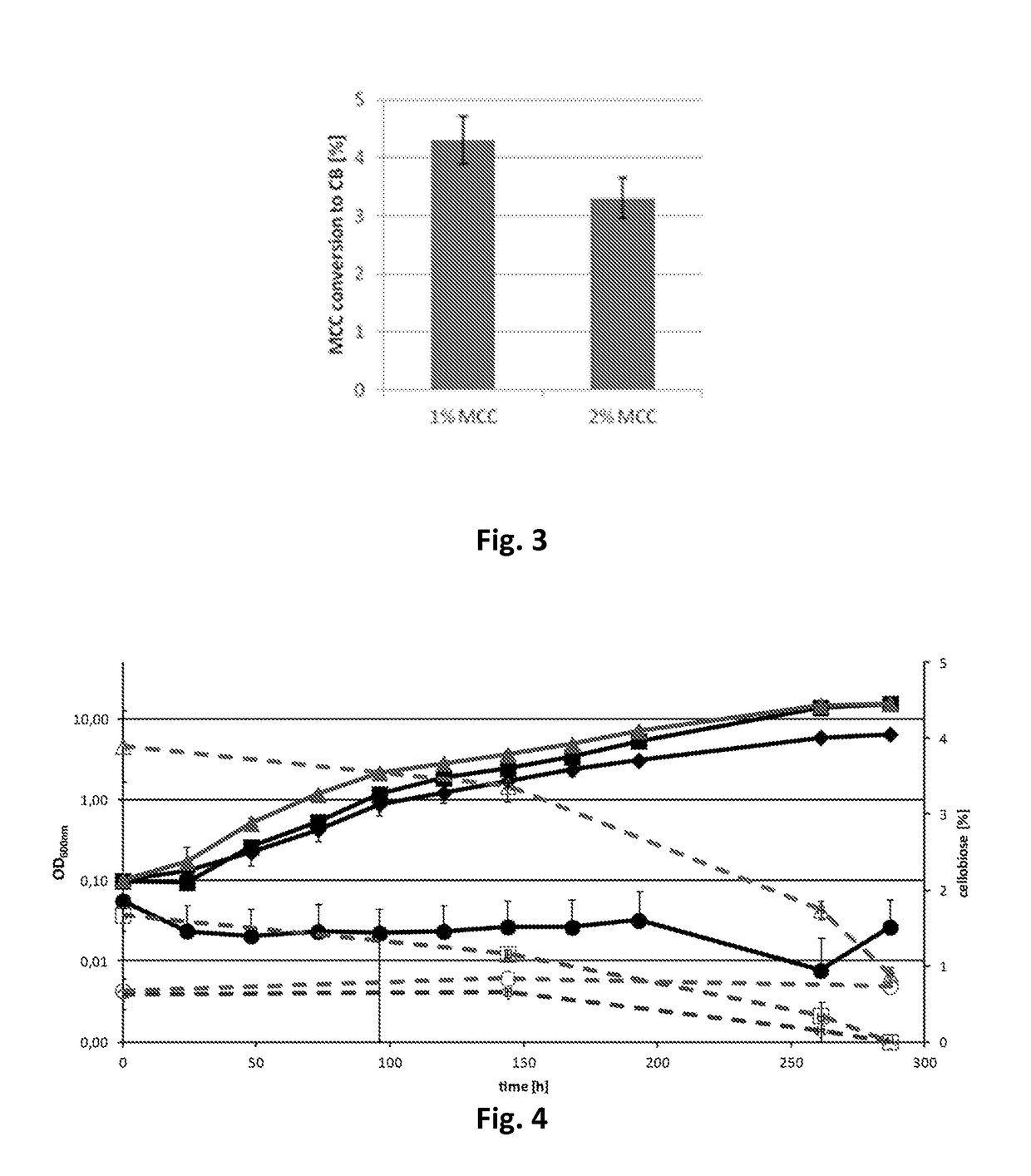

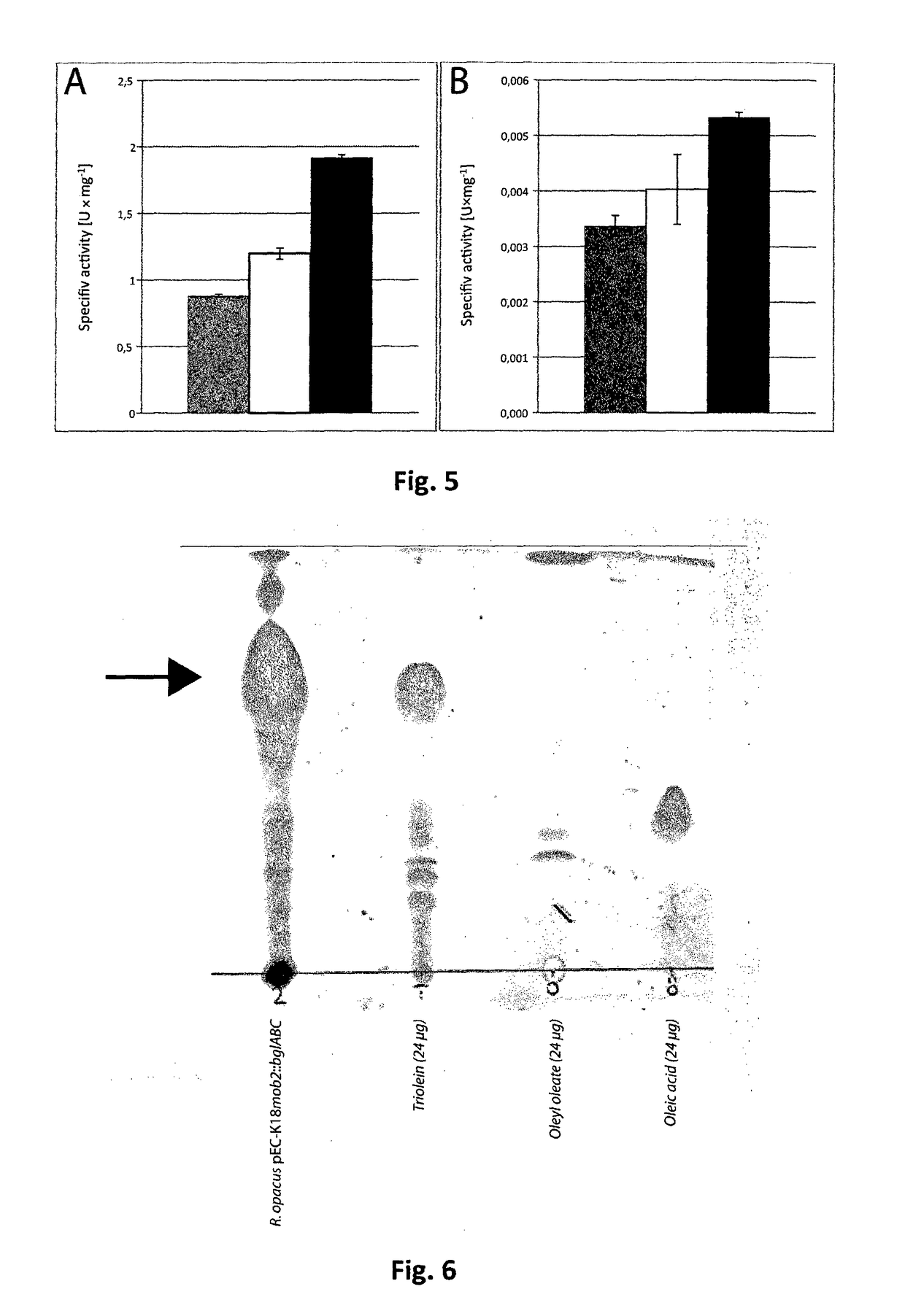

Oleaginous Bacterial Cells and Methods for Producing Lipids

This invention relates to cells and methods for producing lipids using cellulosic carbon source. More specifically the invention relates to oleaginous bacterial cells, wherein genes encoding at least one cellulolytic activity has been introduced. This invention also relates to methods for lipid production by cultivating an oleaginous bacterial strain or strains capable of expressing one or more cellulolytic activity.

Owner:NESTE OIL OY

Methods for drug delivery comprising unfolding and folding proteins and peptide nanoparticles

InactiveUS9066870B2Reduce the amount requiredImproved cost-efficiencyBiocidePowder deliveryNanoparticleActive agent

The present invention provides preparation methods of protein nanoparticles for in vivo delivery of pharmacologically active agents, wherein said methods are to encase pharmaceutically active agents into proteins or peptides to form nanoparticles by unfolding the protein, and subsequently refolding or assembling the protein to produce a pharmacologically active agent encased within a protein nanoparticle.

Owner:NANJING UNIV +1

Method of precious metal recovery

InactiveUS20110088512A1High power inputCost-efficient and complete recoveryProcess efficiency improvementSource materialPotassium

The proposed methods of precious metal recovery and may be applied to the recovery of precious metals from various types of mineral raw source materials containing organic compounds of precious metals and chlorides of alkali and earth metals, e.g. collective concentrate produced from clay-salt residue of potassium production, or marker clays, etc. This method includes chlorinating roasting of the collective concentrate produced during enrichment of the material with residual chlorides, or natural concentrate with up to 15% chlorides content. Thereafter, the cinder is leached by an aqua-regia solution, the precious metals are recovered from the pulp via of sorption, chlorinating roasting is held at 600-700° C., the precious metals are leached from the cinder using diluted solution of aqua-regia, and then via sorption. The process is cost-efficient due to the use of chlorinating agent, reduction of the process steps number, decreasing of the roasting temperature, and the leaching by diluted acid.

Owner:SINEGRIBOV VIKTOR ANDREEVICH +6

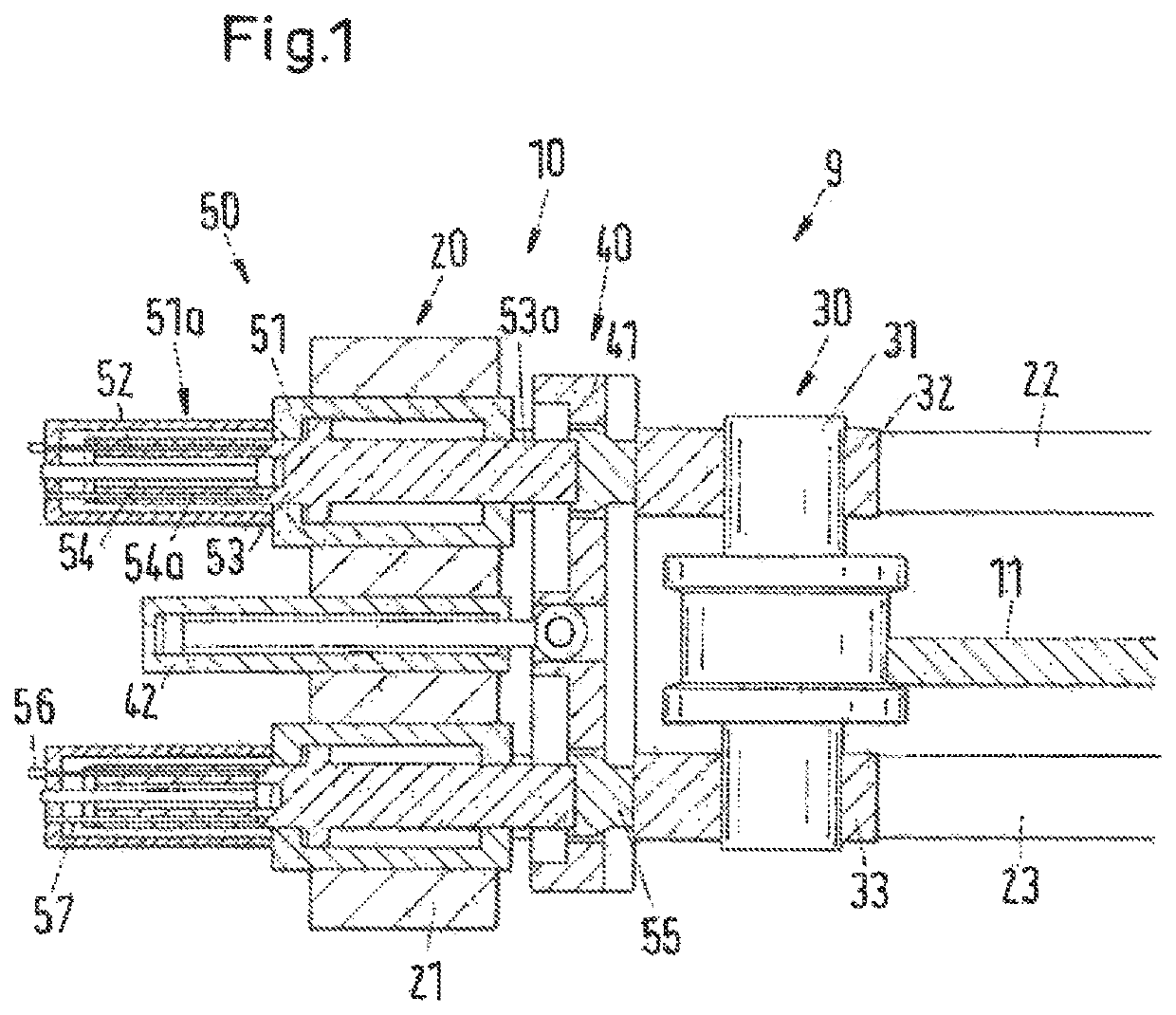

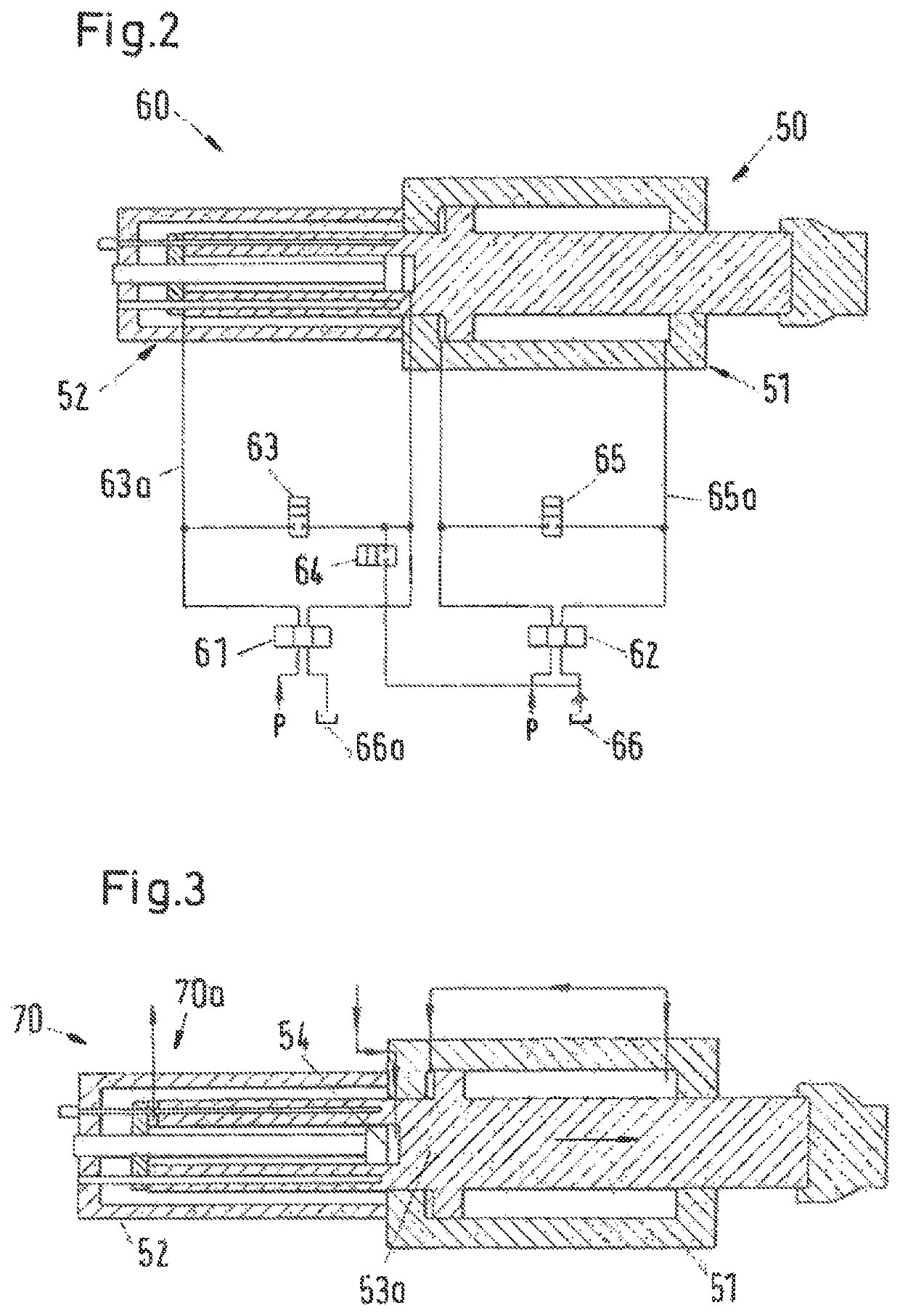

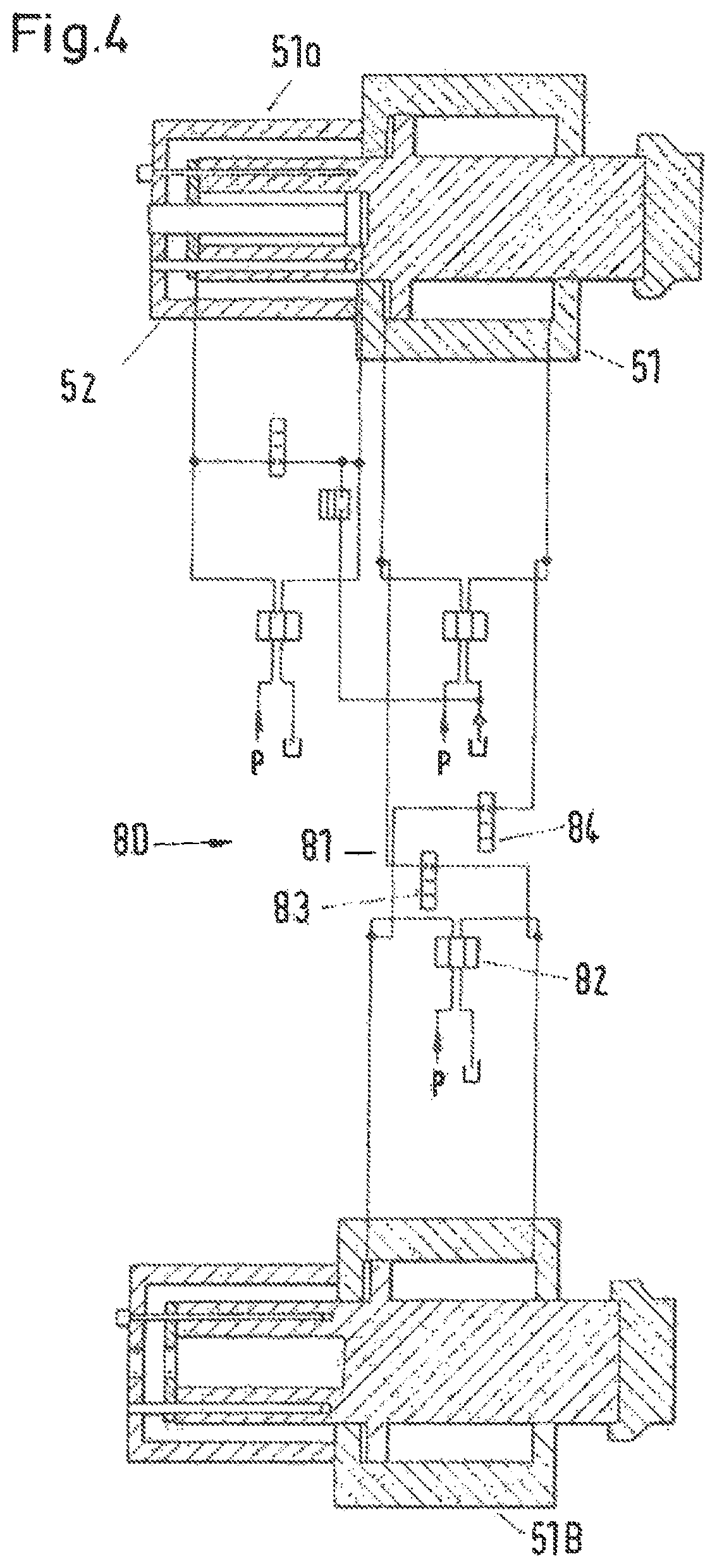

Quick-action adjustment for adjusting cylinder in edging stands

ActiveUS11117173B2Improved cost-efficiencyEasy to adjustRoll force/gap control deviceMetal rolling stand detailsClassical mechanicsControl theory

An adjusting cylinder quick-action adjustment for a long, rapid stroke movement in an edging stand which includes an edger upright, adjustment system, balancing system and edging roll sets, comprises a piston which acts via edging roll chocks of at least one edging roll for adjustment against the rolling stock. The adjustment of the edging roll can be actuated on each side hydraulically by a fluid. The adjusting cylinder quick-action adjustment is mounted in the edger upright and exerts the force required for the edging process. The adjusting cylinder quick-action adjustment includes on each side of the edging upright at least one double cylinder which has two cylinders coupled to one another and is separately controllable and configured for rapid adjustment and for control adjustment of the edging roll.

Owner:SMS GRP GMBH

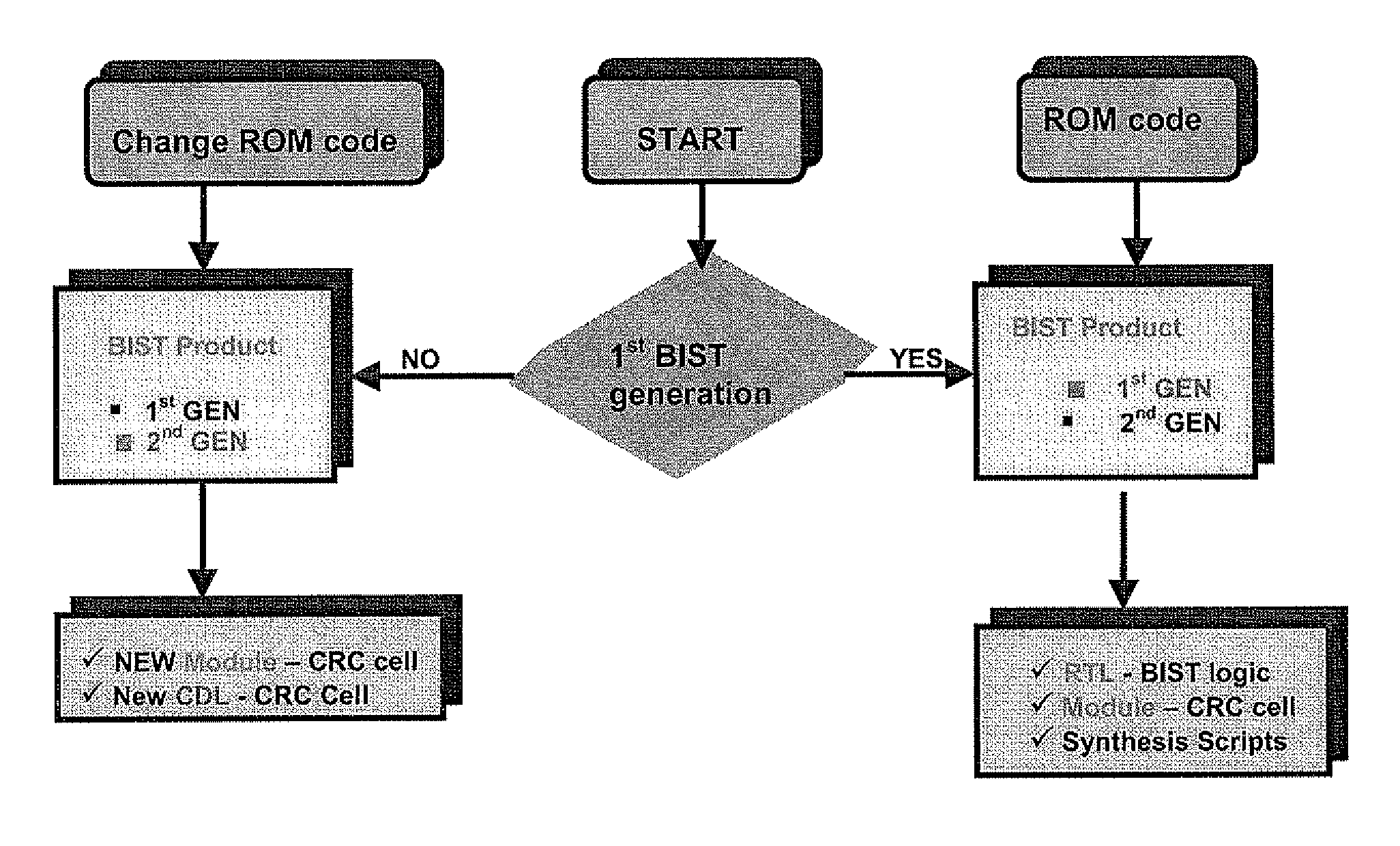

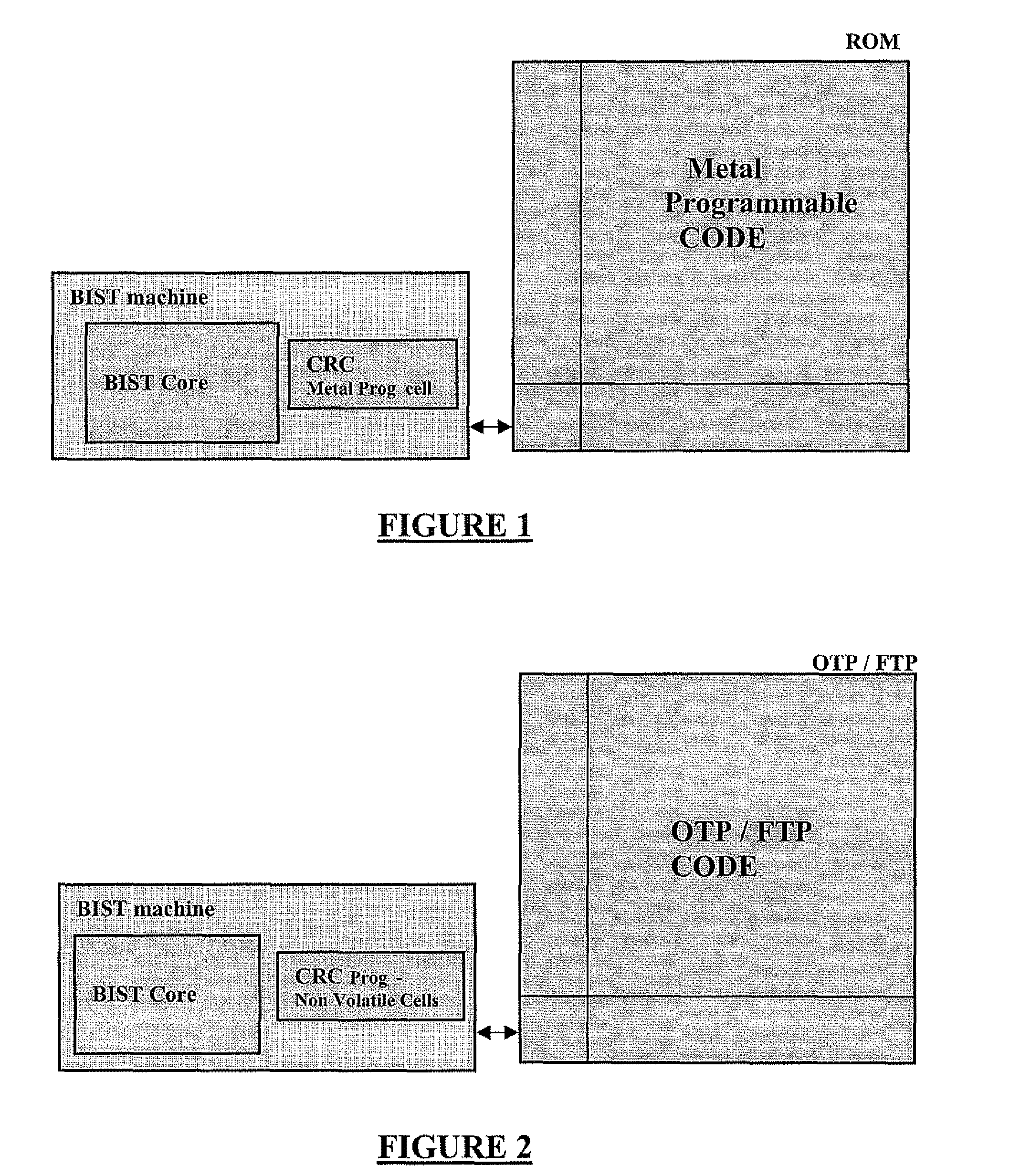

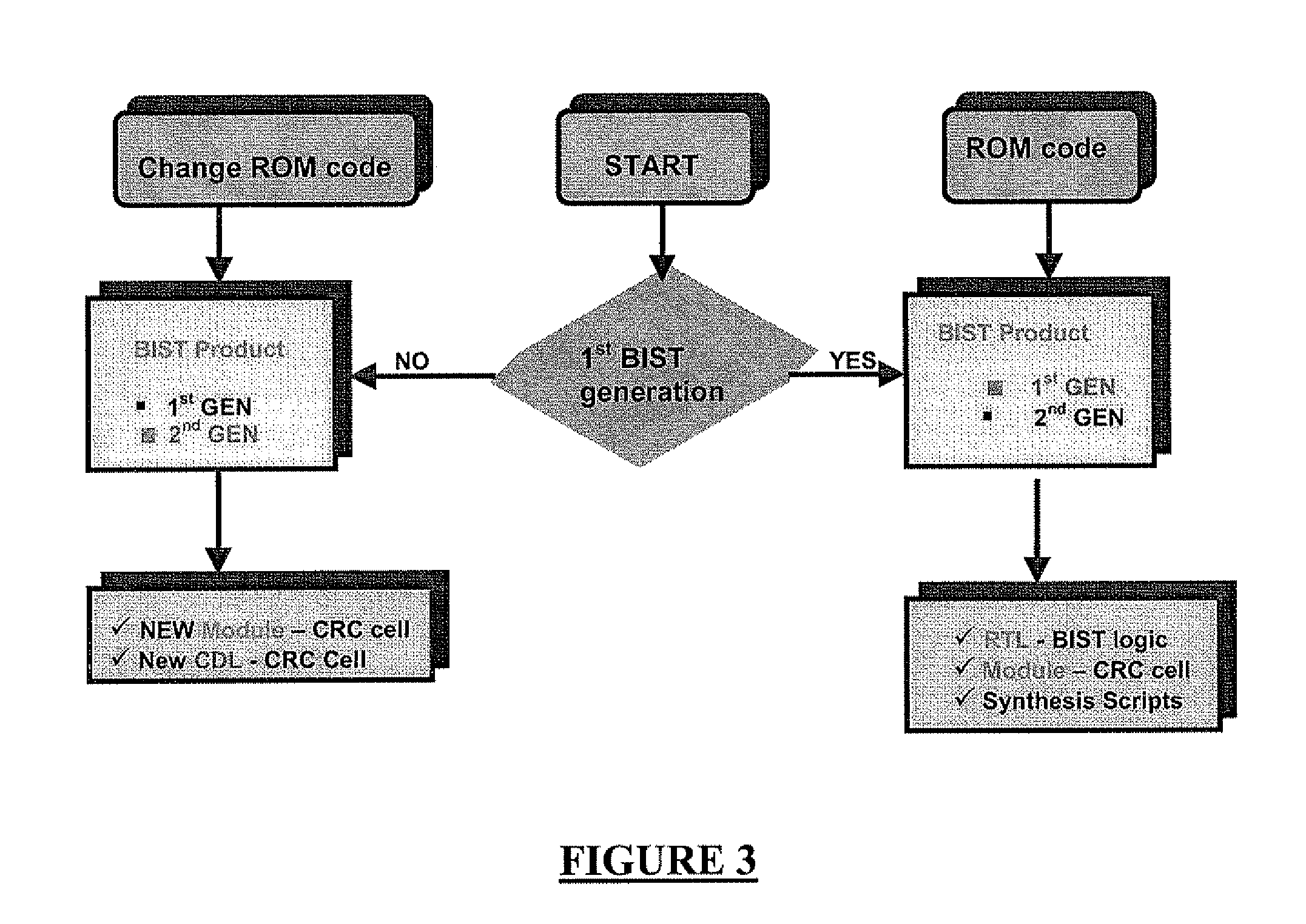

Process and system for the verification of correct functioning of an on-chip memory

ActiveUS8161327B2Improved cost-efficiencyLow costElectronic circuit testingError detection/correctionBuilt-in self-testRead-only memory

A method is for making an integrated circuit with built-in self-test. The method includes forming at least one nonvolatile read only memory (ROM) to store ROM code and forming a logic self-test circuit to verify a correct functioning of the at least one nonvolatile ROM. Moreover, the method includes defining, in the logic self-test circuit, a logic self-test core to process the ROM code and to generate a flag based upon a control signature and defining, in the logic self-test circuit, a nonvolatile storage block, coupled to the logic self-test core, to store the control signature. Furthermore, the method includes writing the ROM code to the at least one nonvolatile ROM and writing the control signature to the nonvolatile storage block, during a same fabrication step.

Owner:STMICROELECTRONICS SRL

Oleaginous bacterial cells and methods for producing lipids

Owner:NESTE OIL OY

Method of improving the coercivity of Nd—Fe—B magnets

ActiveUS11114237B2Increase in coercivityImproved cost-efficiencyMagnetic materialsPermanent magnet manufactureRare-earth elementMaterials science

A method of improving coercivity of an Nd—Fe—B magnet includes a first step of providing an Nd—Fe—B magnet having a first surface and a second surface. Next, a first solidified film of at least one pure heavy rare earth element is formed and attached to the first surface of the Nd—Fe—B magnet to prevent a reduction in corrosion resistance caused by oxygen and fluorine and hydrogen. After forming the first solidified film, the Nd—Fe—B magnet is subjected a diffusion treatment in a vacuum or an inert atmosphere. After the diffusion treatment, the Nd—Fe—B magnet is subjected to an aging treatment in the vacuum or the inert atmosphere.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

Pull planning for serviceable parts to facilitate on-demand repair planning

ActiveUS8117059B1Disadvantages can be reduced eliminatedIncrease supplyResourcesCommerceMaintenance planningOn demand

Owner:BLUE YONDER GRP INC

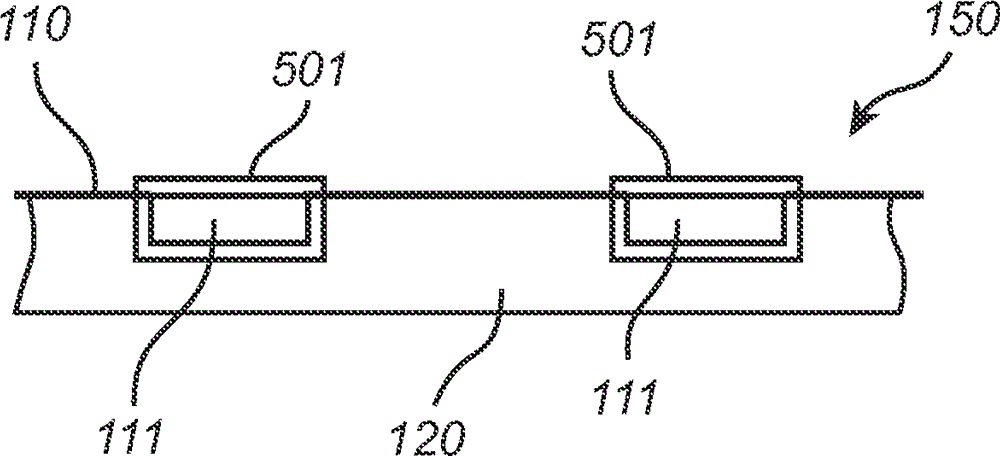

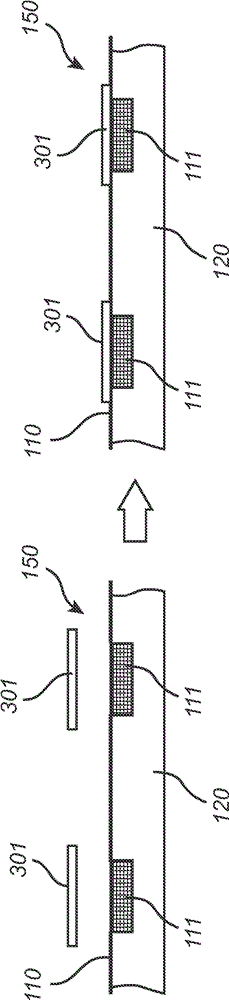

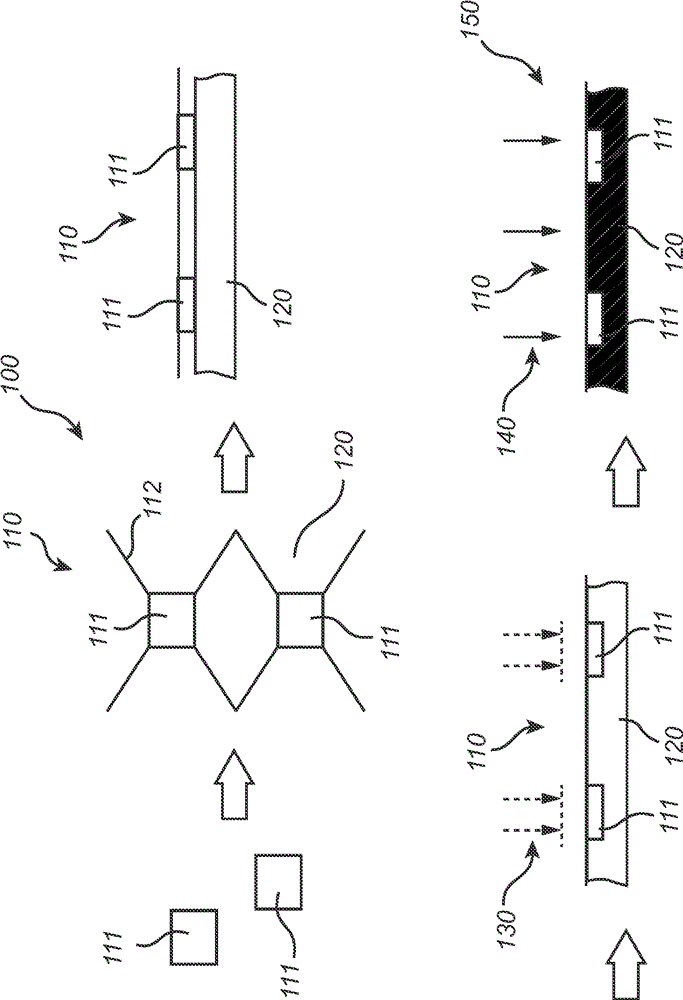

Lighting module and method of manufacturing a lighting module

ActiveCN104160522ASave materialLow costLaser detailsElectric circuit arrangementsElectricityEffect light

A lighting module (150) and a method (100) of manufacturing a lighting module, wherein the method comprises the steps of providing a heat sink material (120) in a fluid state and providing a light-source assembly (110) comprising a plurality of light sources (111) being electrically connected to a carrier (112), wherein each of the light sources has a light-emitting surface (113). The method further comprises the steps of embedding (130) the light-source assembly into the heat sink material such that the carrier and a part of each of the light sources are covered by the heat sink material while the light-emitting surface of each of the light sources is uncovered by the heat sink material, and solidifying (140) the heat sink material.

Owner:SIGNIFY HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com