Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve the display aperture ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

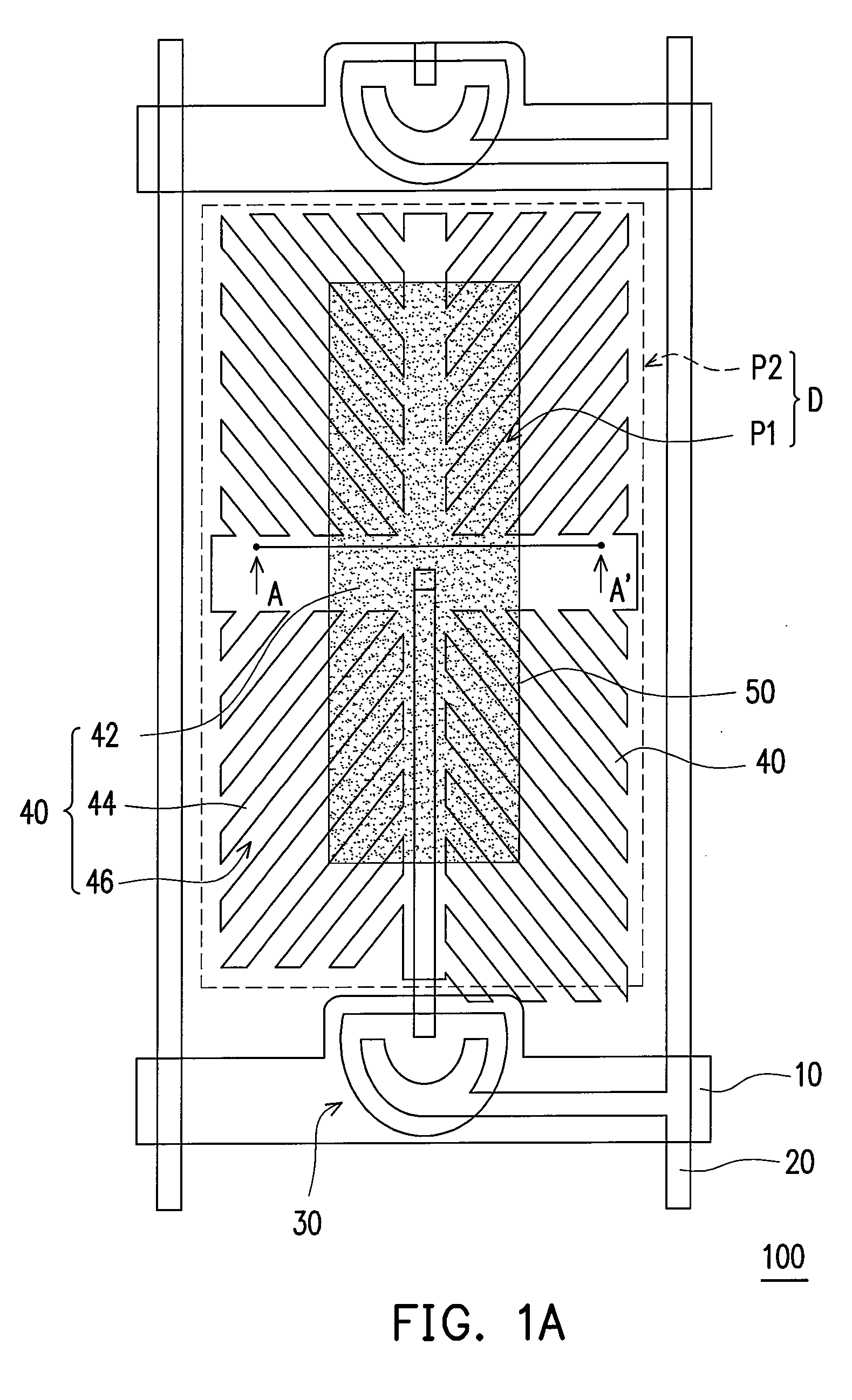

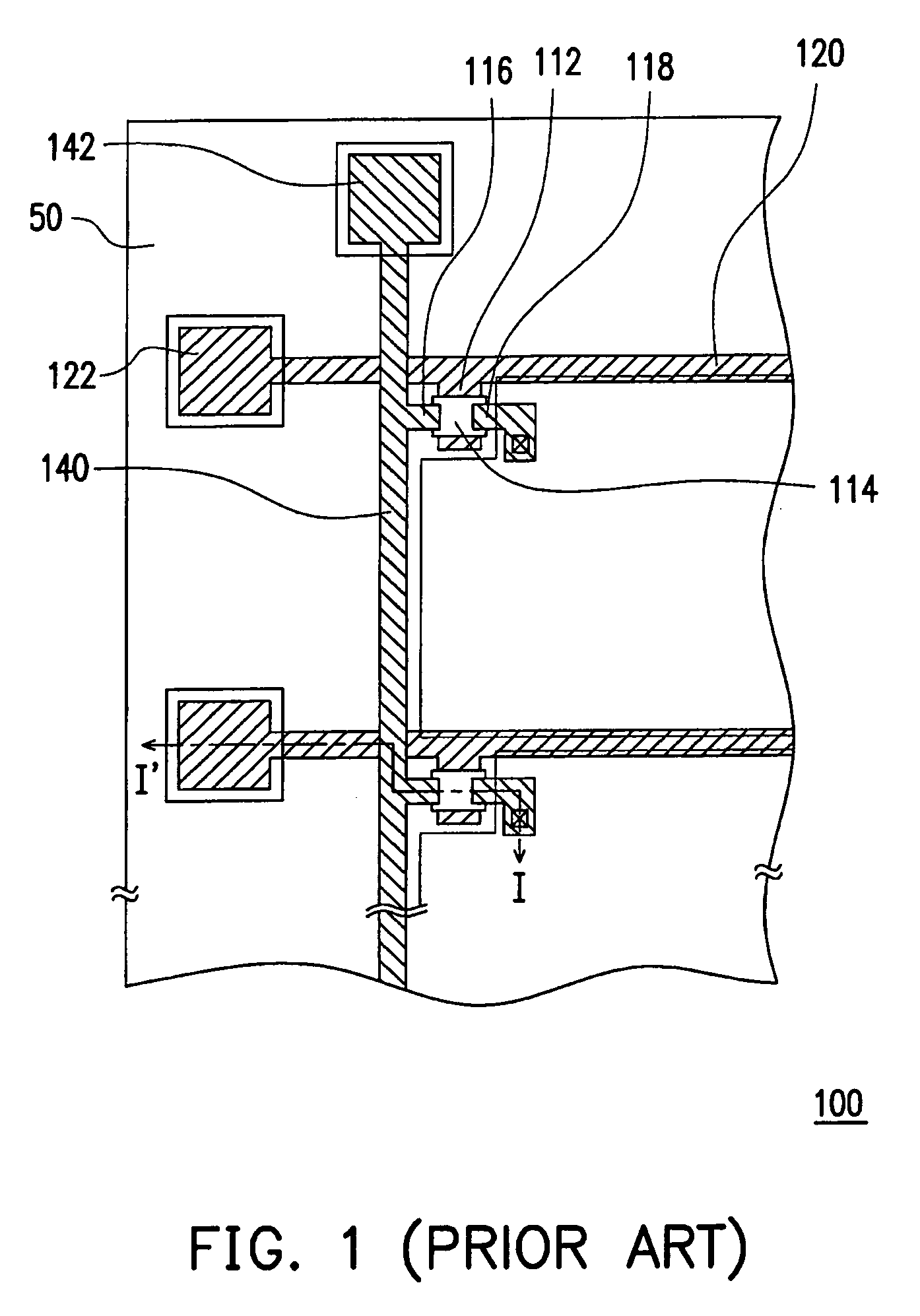

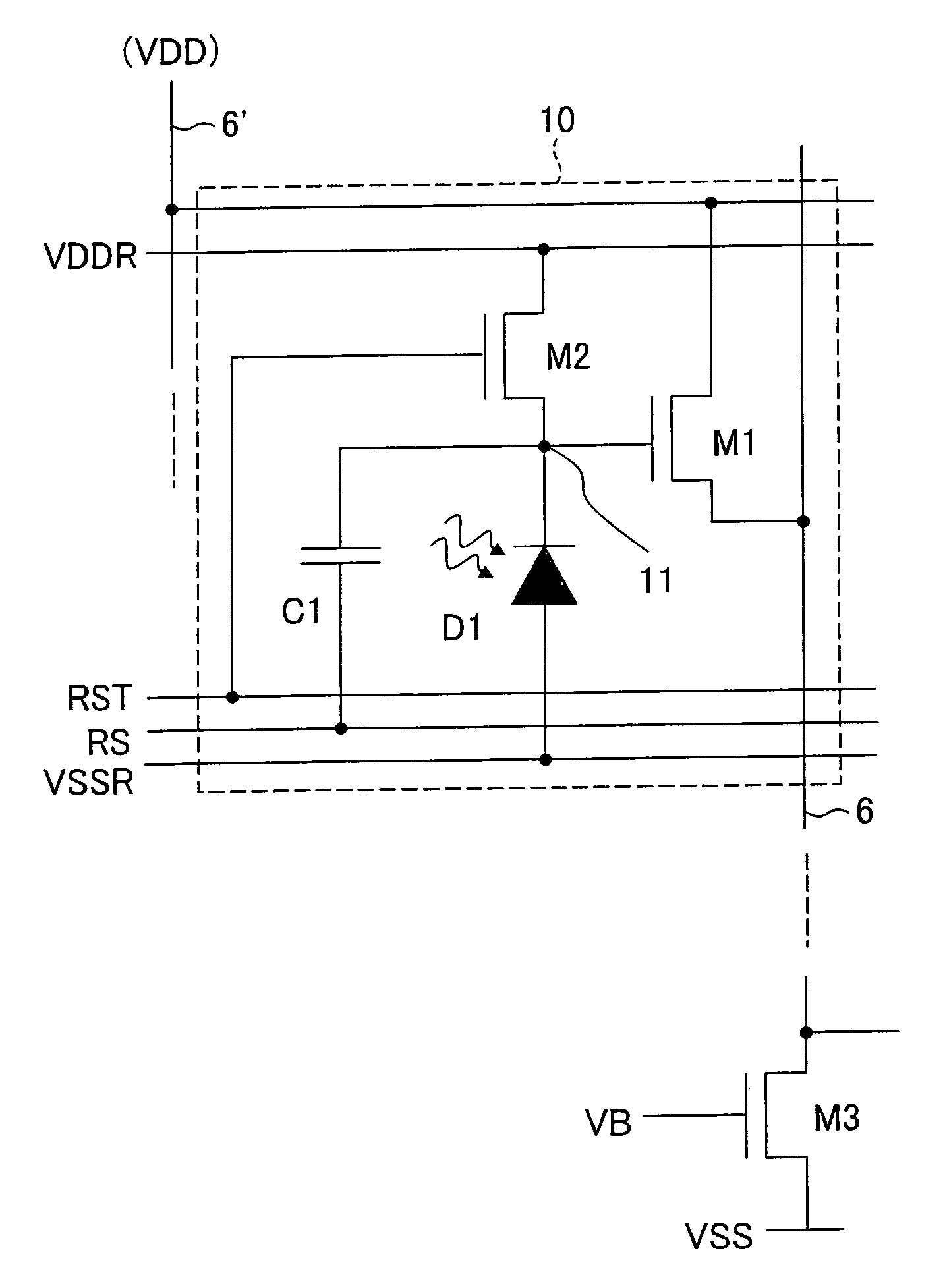

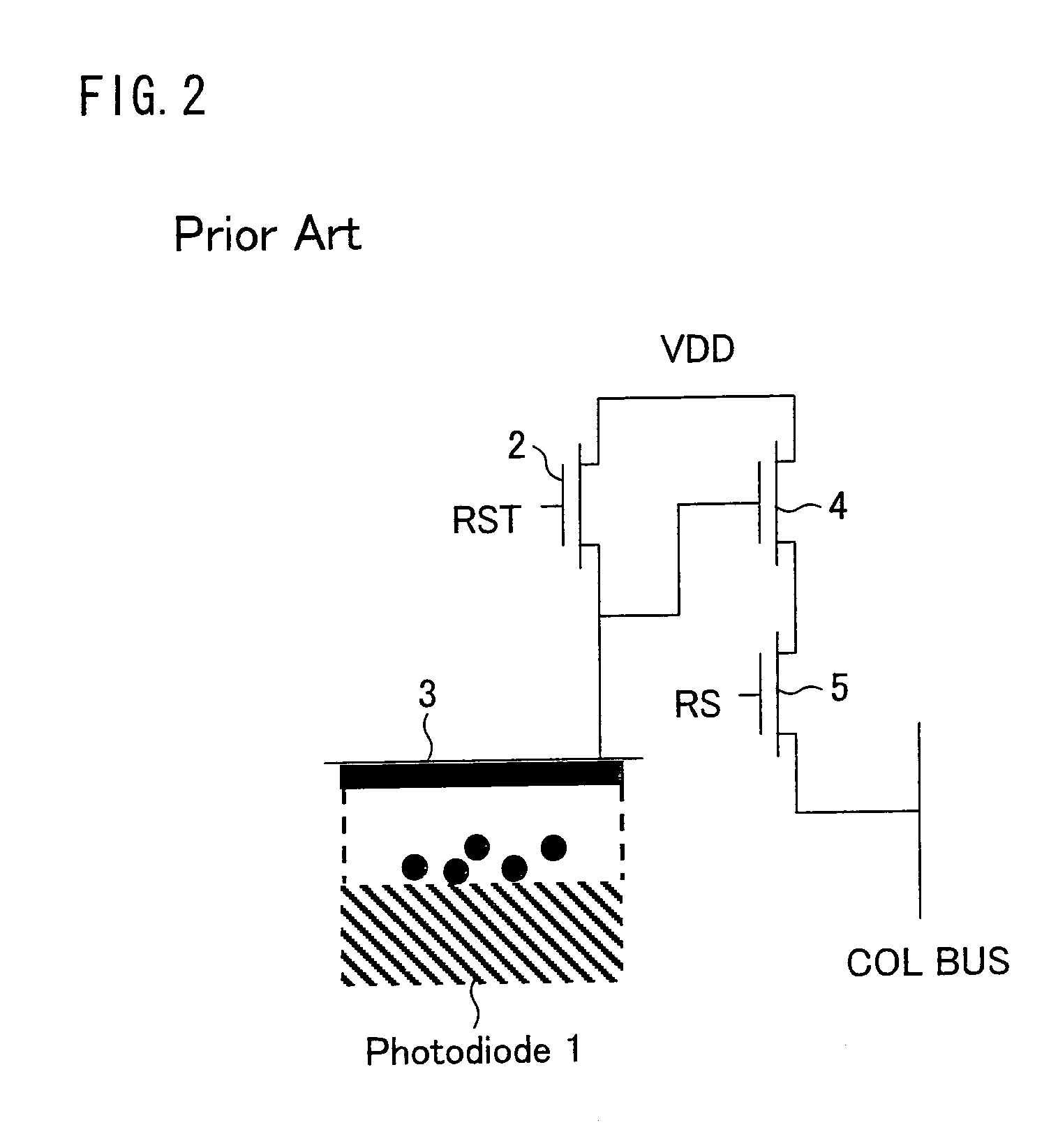

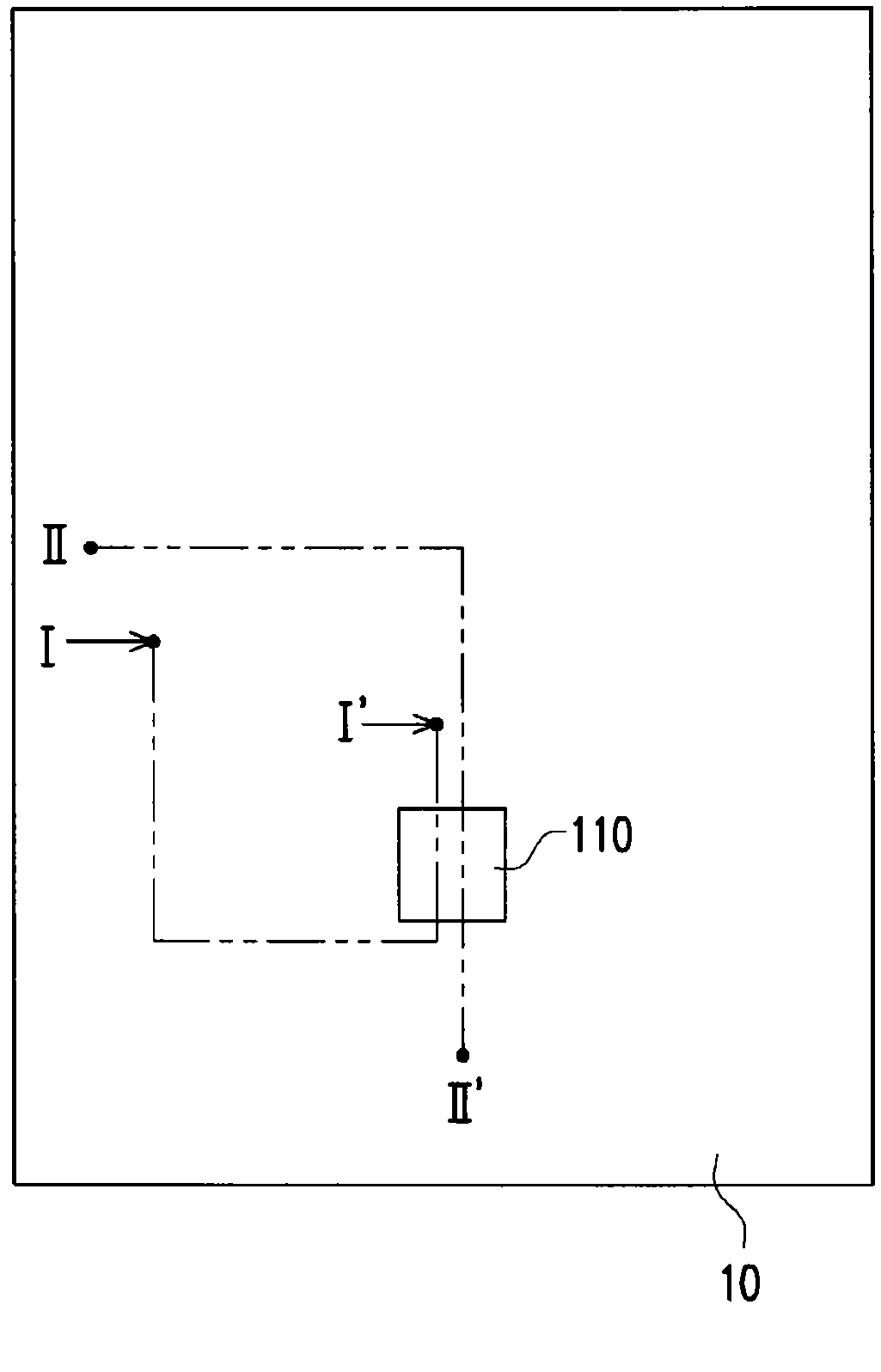

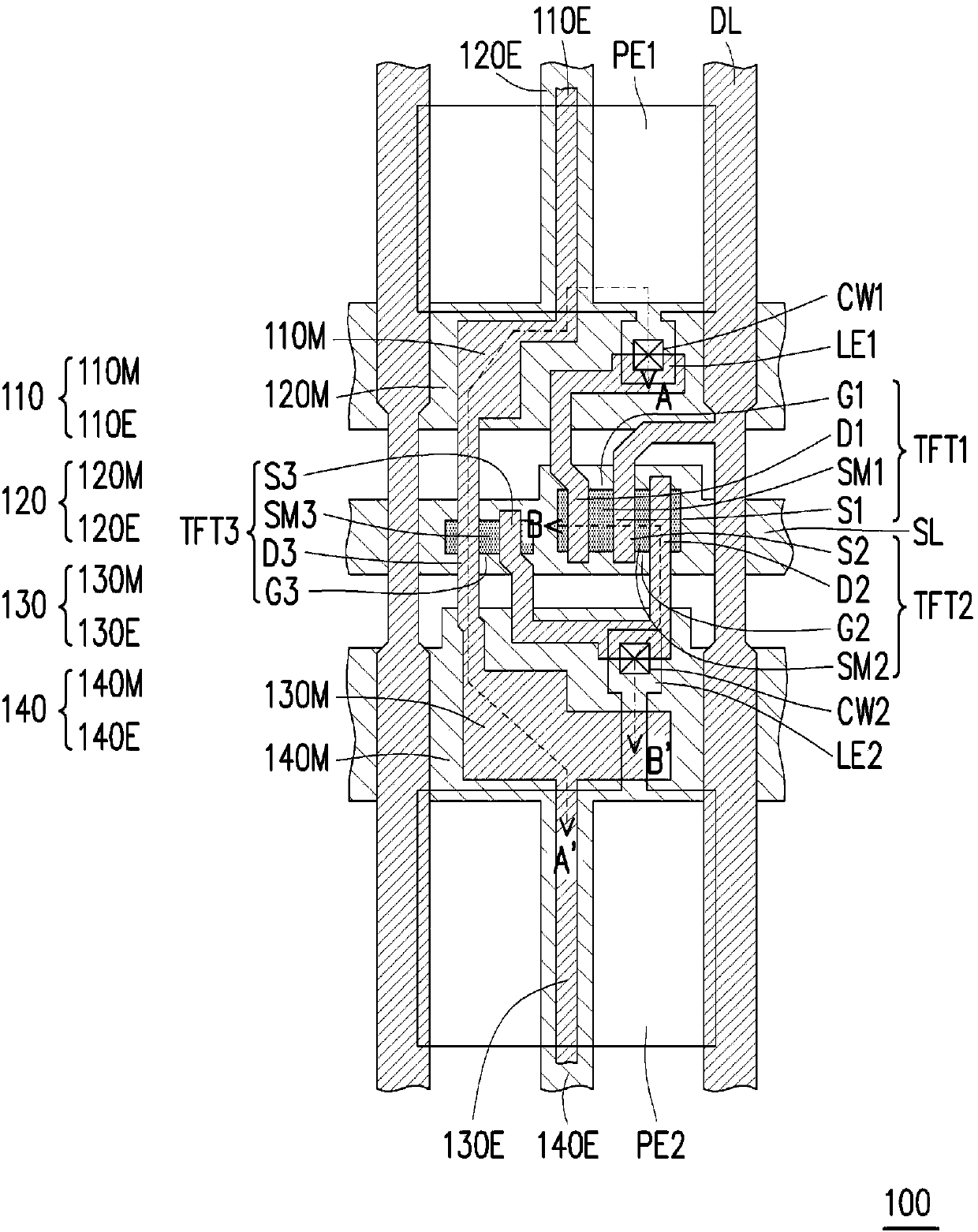

Combined image sensor and display device

ActiveUS20100231562A1Reduce the valueImprove the display aperture ratioTelevision system detailsTelevision system scanning detailsDisplay devicePhotodiode

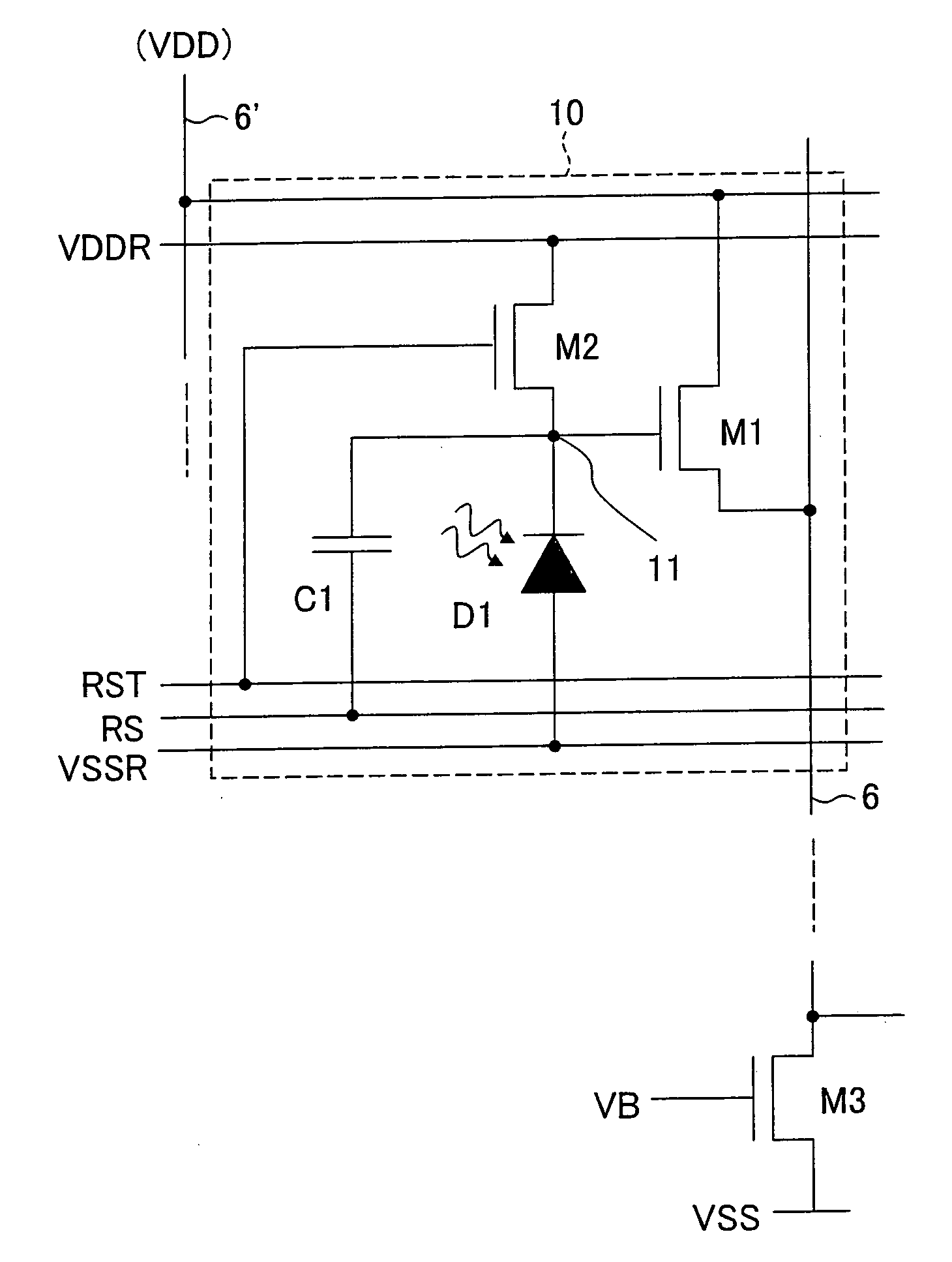

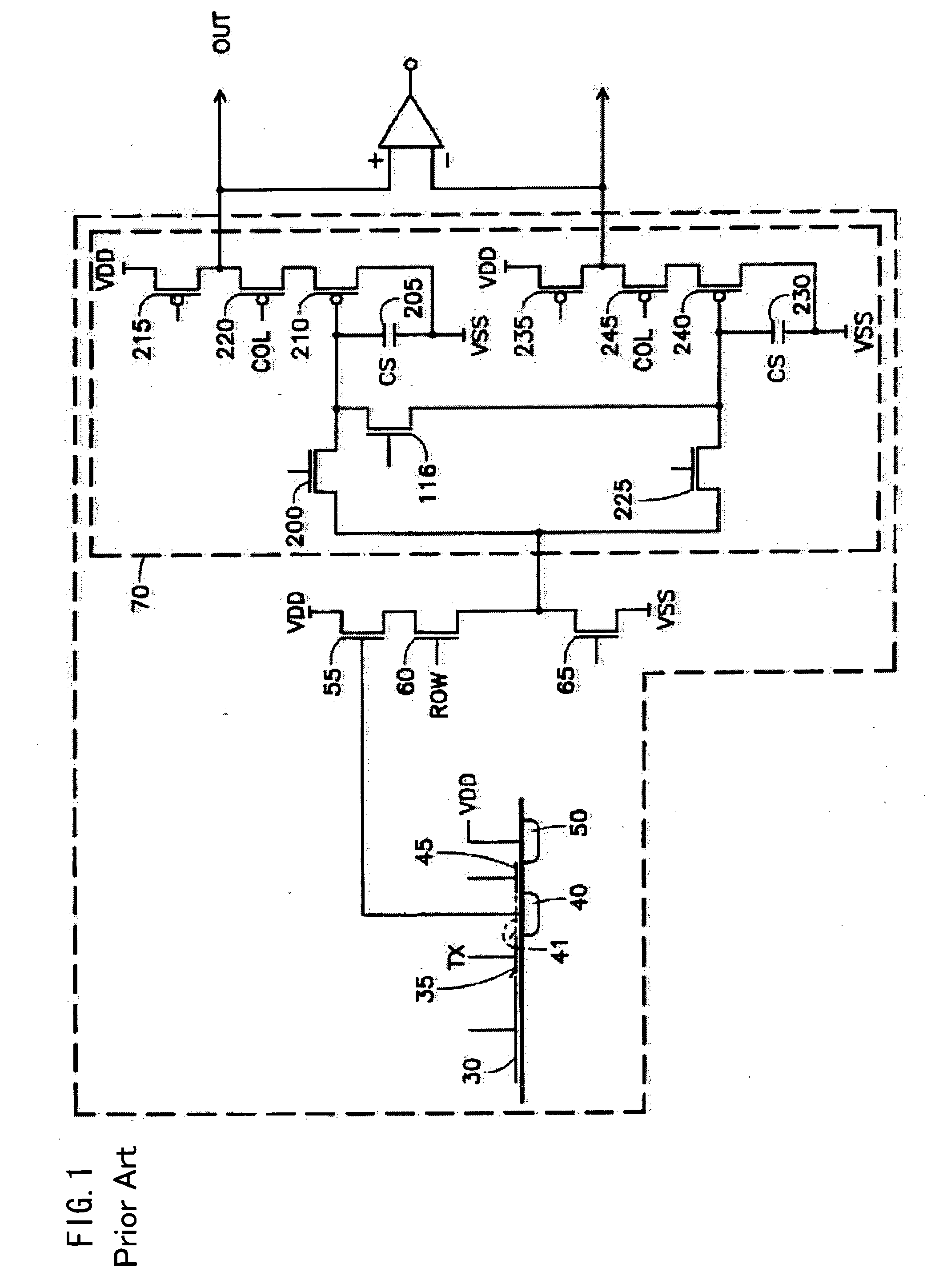

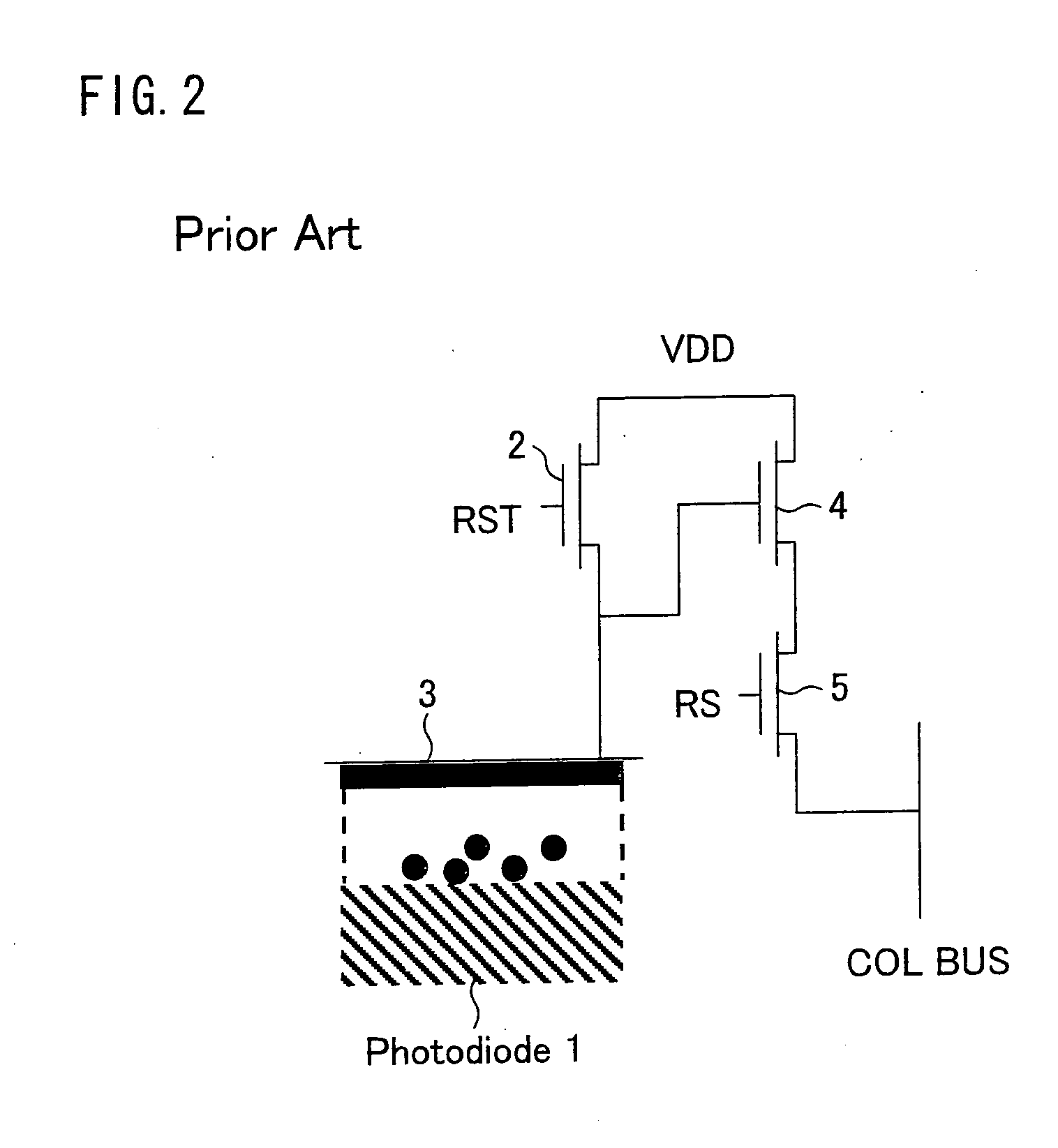

A combined image sensor and display device comprises an array of device elements (18), each of which comprises a display pixel (M4, C2, CLC). The display pixels have data inputs connected to column data lines (SL, 6,6′). The array includes sensor elements (10), each comprising a transistor (M1), an integrating capacitor (C1) and a photodiode (D1) connected together to an integrating node (11). The transistor (M1) is connected between column data lines (6,6′). The capacitor (C1) is connected to a control input (RS) which receives a first voltage during a sensing phase for switching off the transistor (M1) and a second voltage during a reading phase for enabling the transistor (M1).

Owner:SHARP KK

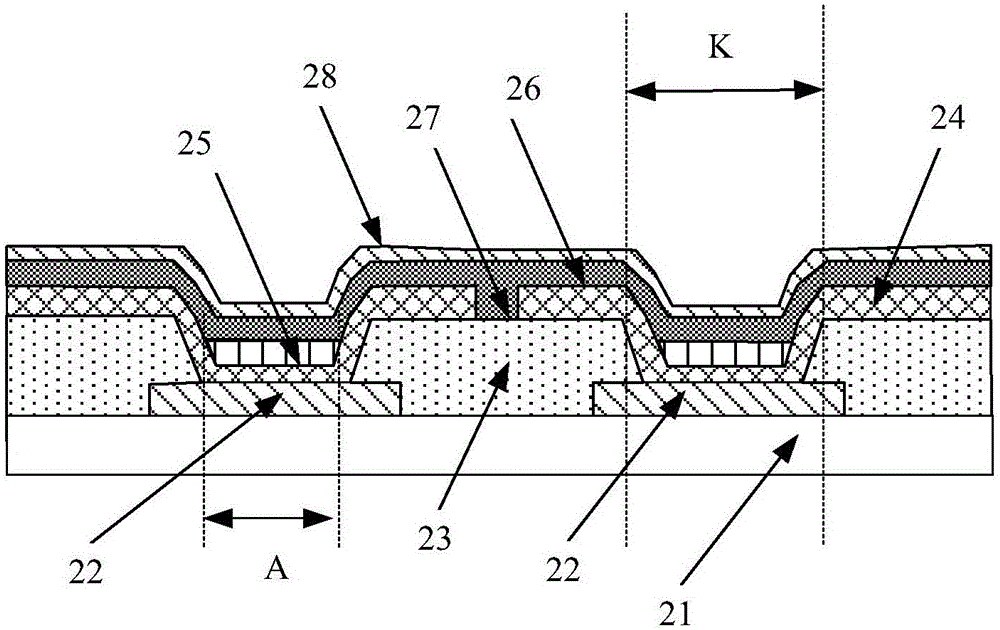

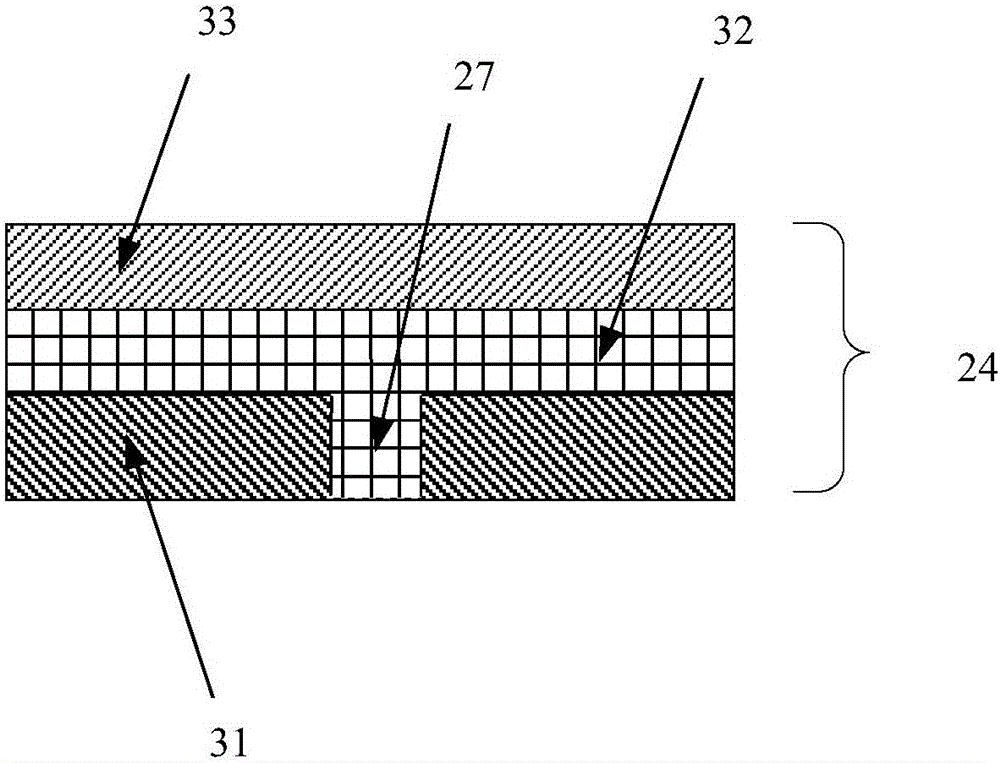

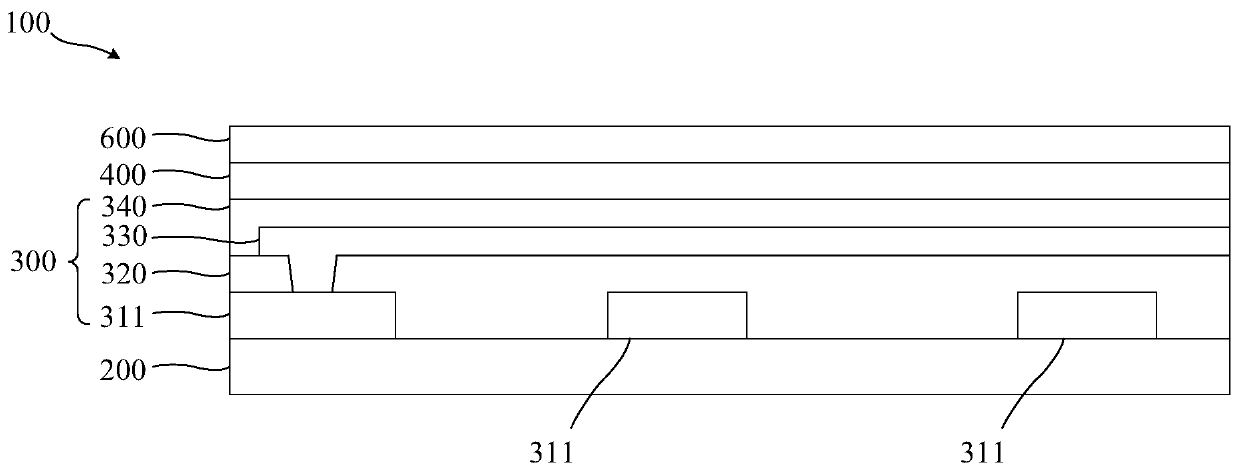

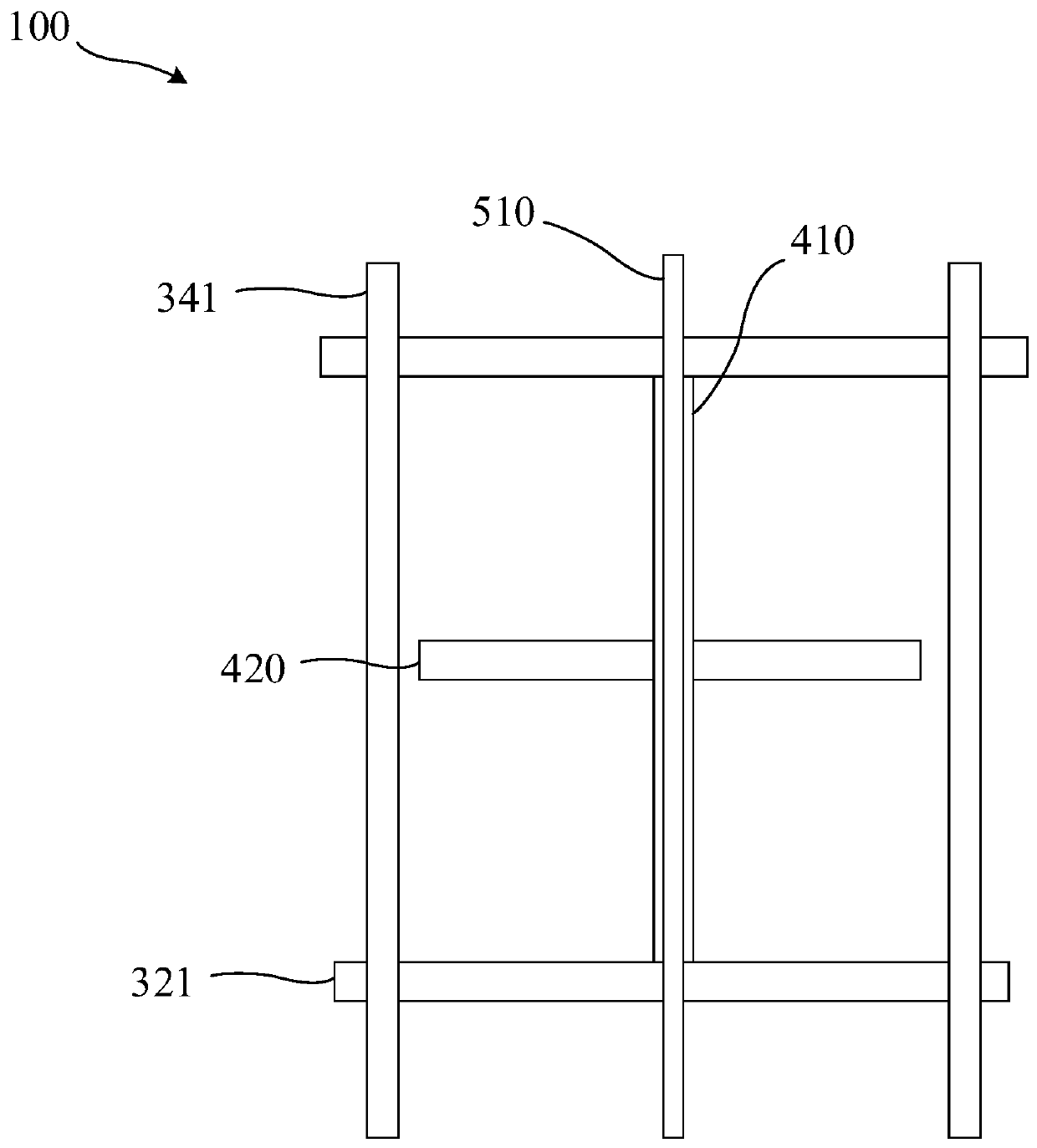

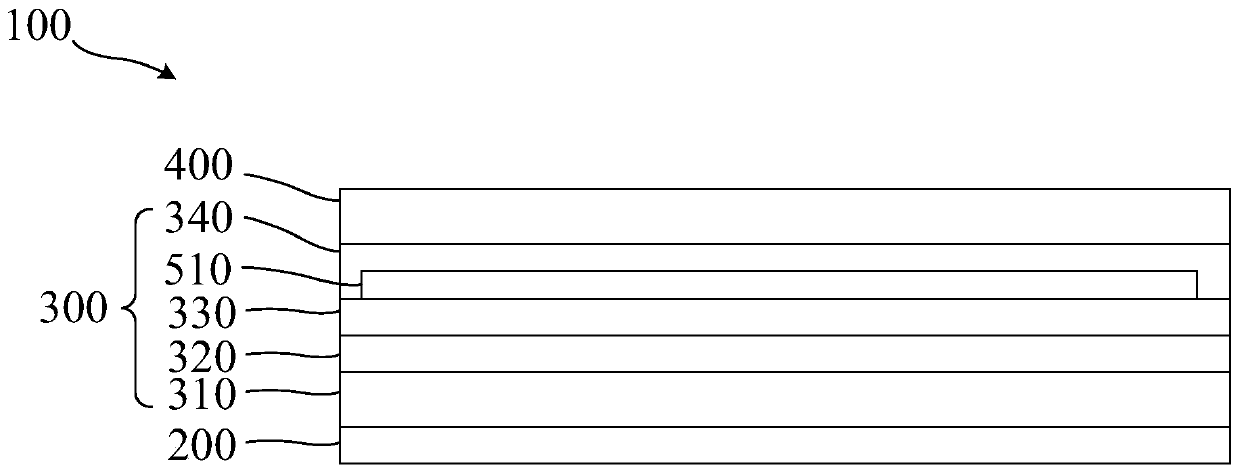

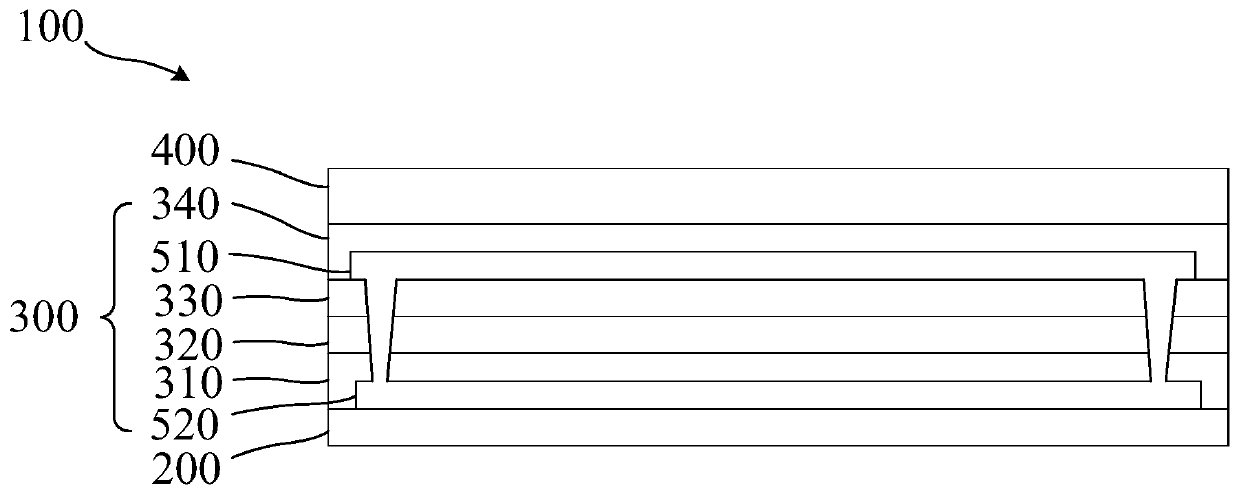

Display panel, manufacturing method and electronic equipment

ActiveCN105895664AGuaranteed image display effectHigh-resolutionSolid-state devicesSemiconductor devicesOptoelectronicsElectron

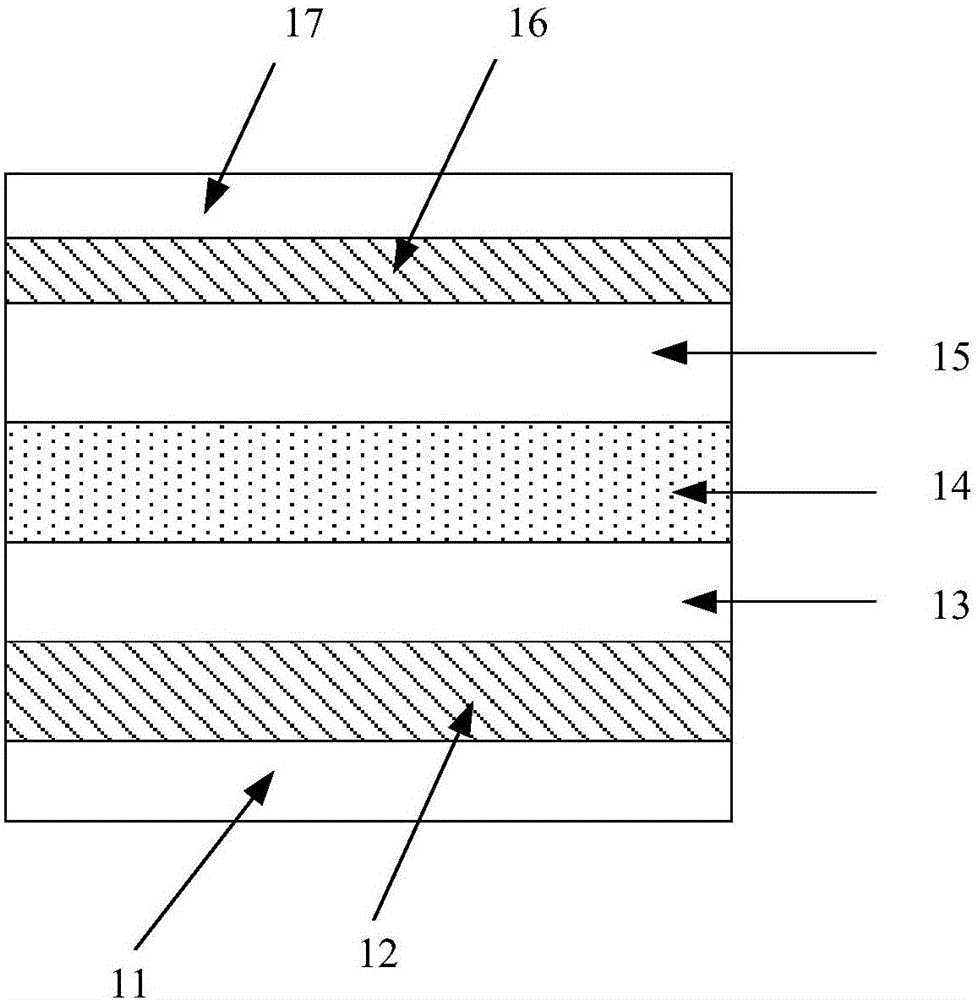

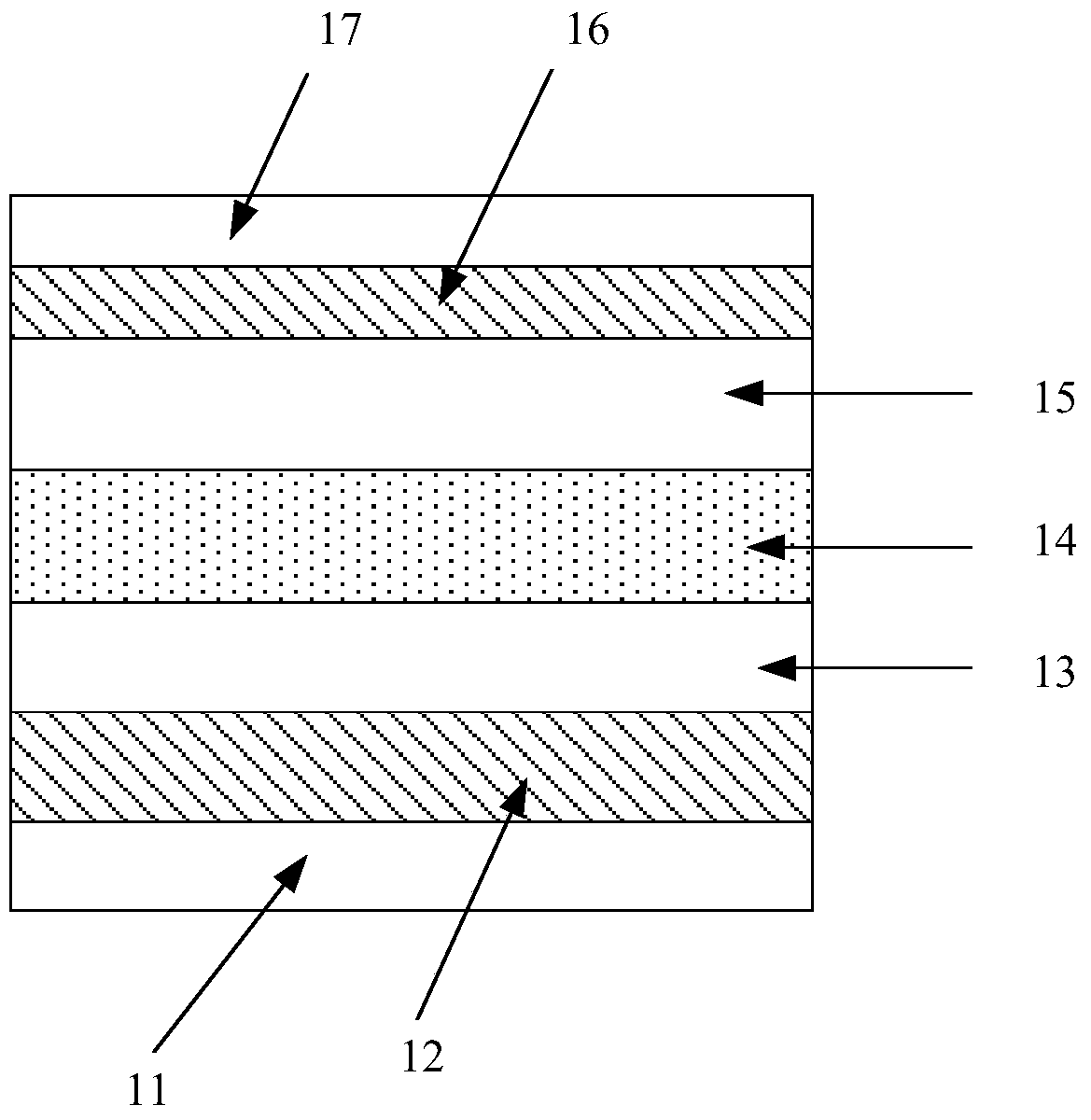

The invention discloses a display panel, a manufacturing method and electronic equipment. The display panel comprises a substrate, a positive electrode layer and a pixel definition layer, a first common layer, a luminous layer and a negative electrode layer, wherein the positive electrode layer and the pixel definition layer are positioned on the same side of the substrate; the positive electrode layer comprises multiple positive electrodes in array configuration; each positive electrode comprises a first electrode part; the pixel definition layer comprises multiple pixel openings which are in one-to-one correspondence with the positive electrodes and are used for exposing the first electrode parts; the first common layer is positioned on one side, deviating from the substrate, of the pixel definition layer and the positive electrodes; the first common layer comprises at least one preset sub functional layer; the corresponding preset sub functional layer has a partition structure; the luminous layer is arranged on the surface of the first common layer; the luminous layer comprises multiple luminous units which are in one-to-one correspondence with the pixel openings; the luminous units are positioned in the corresponding pixel units, and the first electrode parts are fully covered with the luminous units; and the negative electrode layer is positioned on one side, deviating from the substrate, of the luminous layer. Due to the partition structure, the display panel can prevent electric leakage.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Liquid crystal display panel

InactiveUS20110102698A1Increase contrastImprove display qualityNon-linear opticsInput/output processes for data processingLiquid-crystal displayEngineering

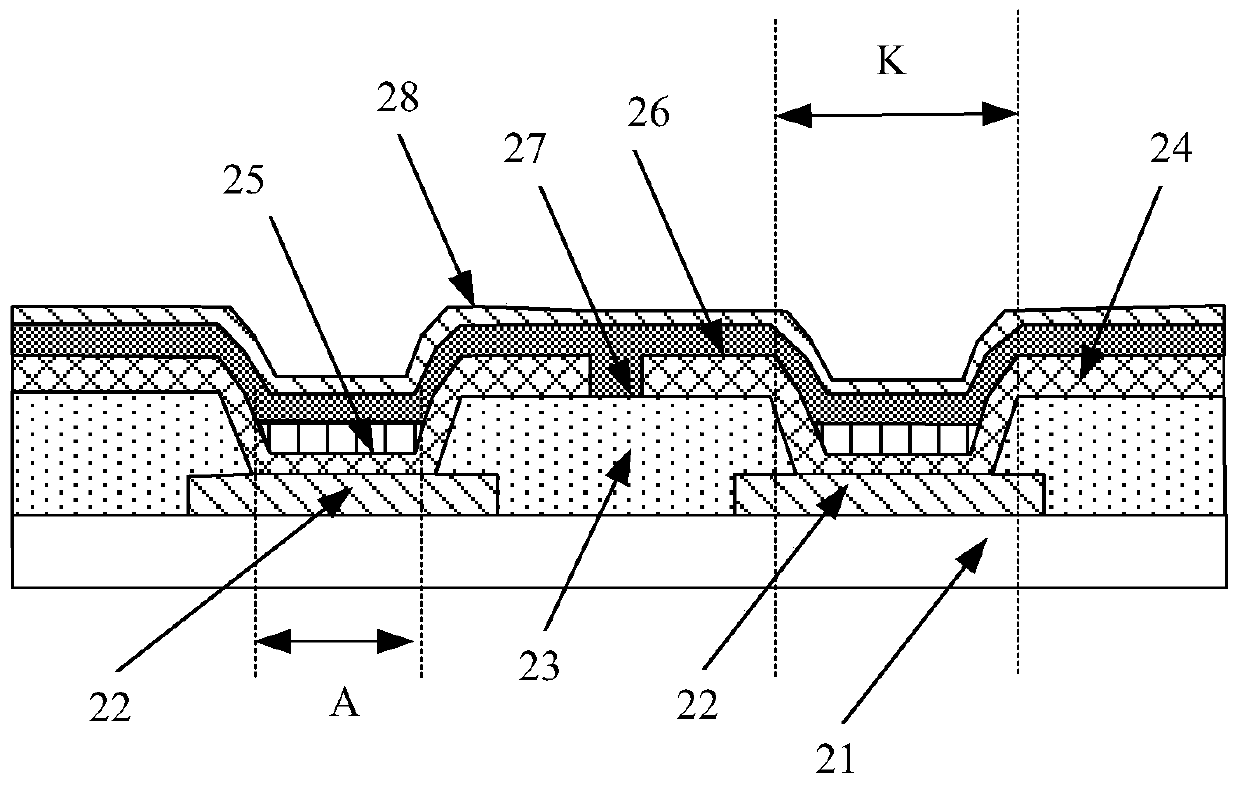

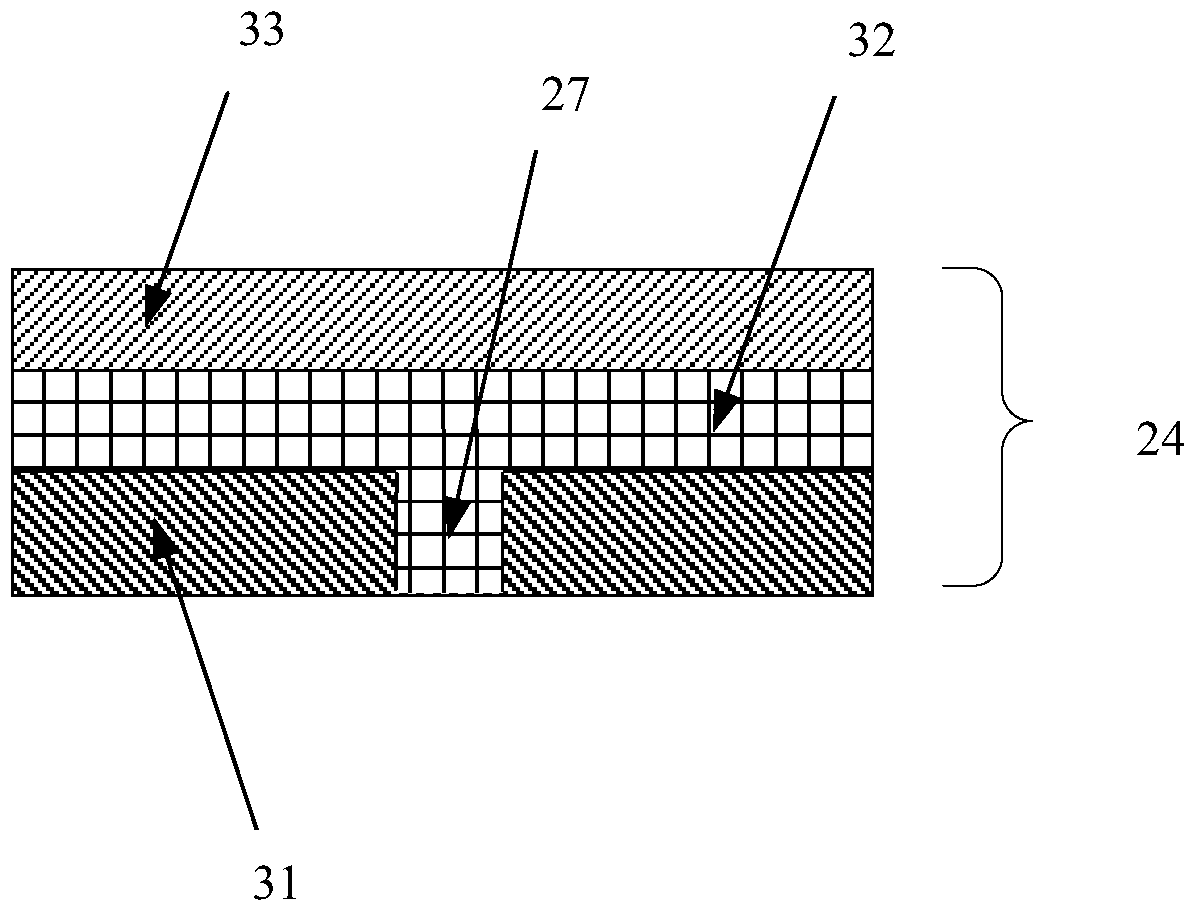

A liquid crystal display panel including an active device matrix substrate, an opposite substrate, and a liquid crystal layer is provided. The active device matrix substrate includes a first substrate, an active, device array, a padding device, first connecting electrodes, and shielding electrodes. The padding device is disposed on active devices and data lines of the active device array. The first connecting electrodes are located above the active devices and electrically connected to the active devices. The shielding electrodes are located above the data lines and electrically connected to a common voltage. The opposite substrate includes a second substrate, first electrodes, an insulating layer, second electrodes having slits and opposite to the first electrodes, spacers corresponding to the active devices, and second connecting electrodes covering the spacers to directly contact with the first connecting electrodes and electrically connected to the first electrodes or the second electrodes.

Owner:WINTEK CORP

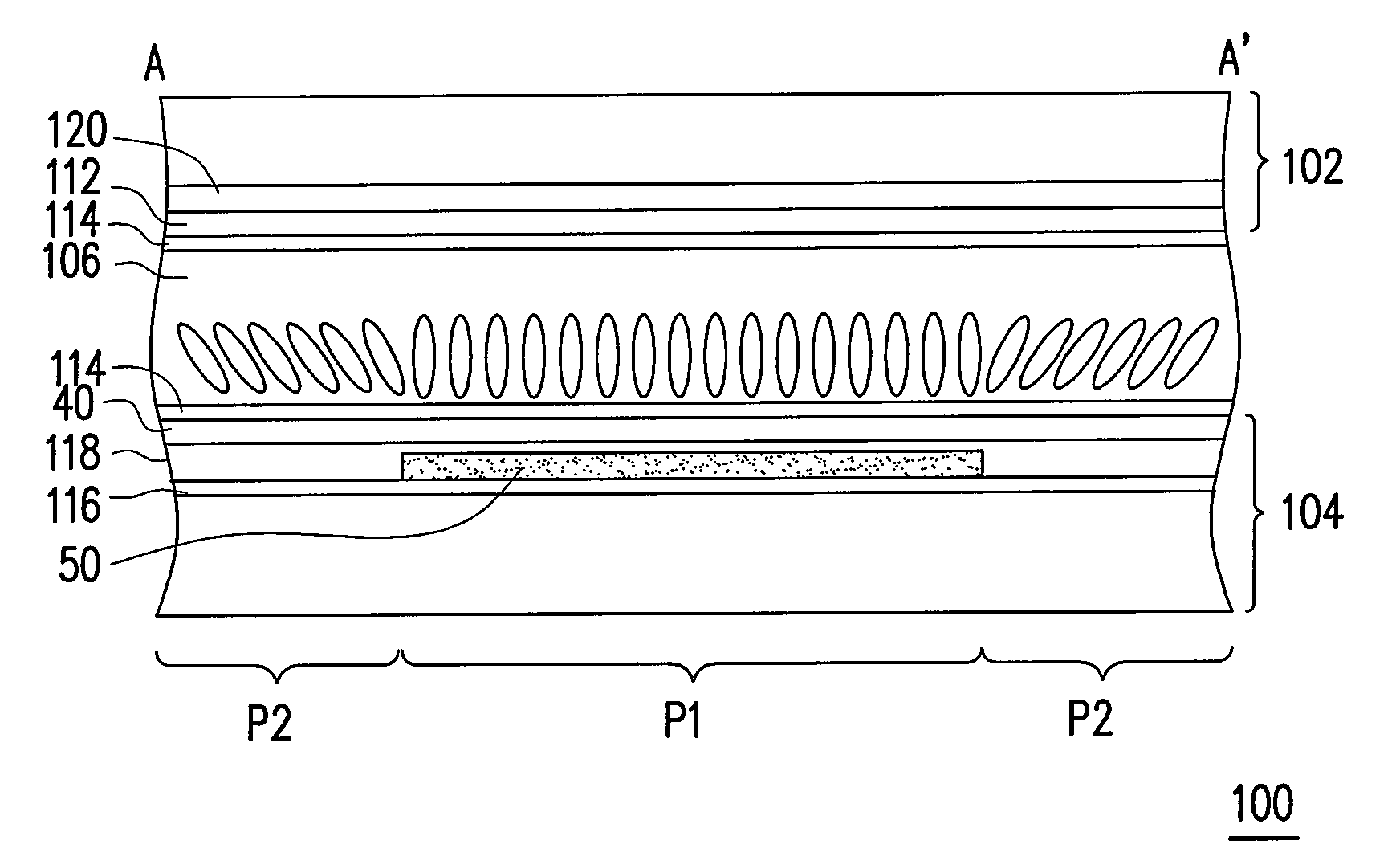

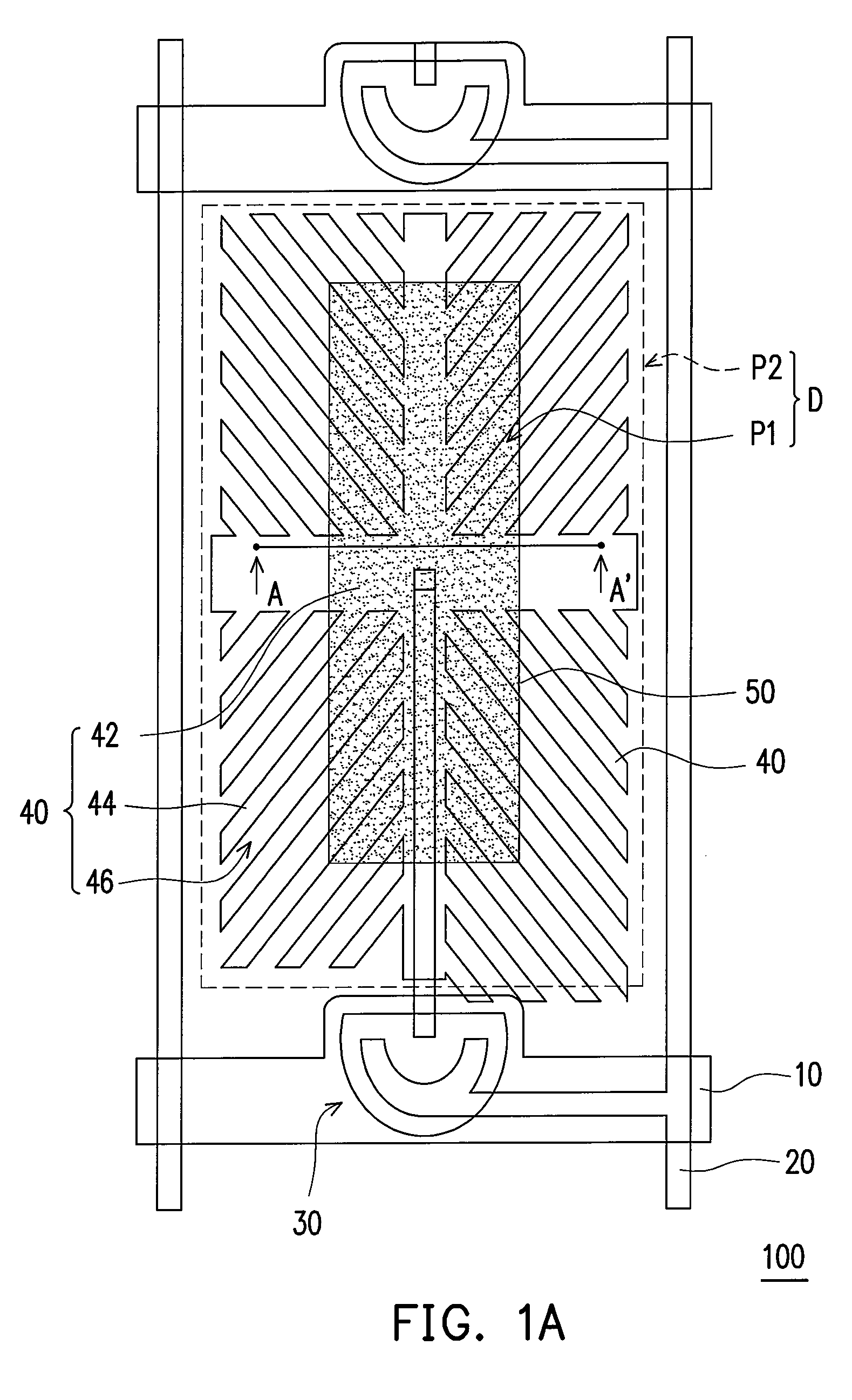

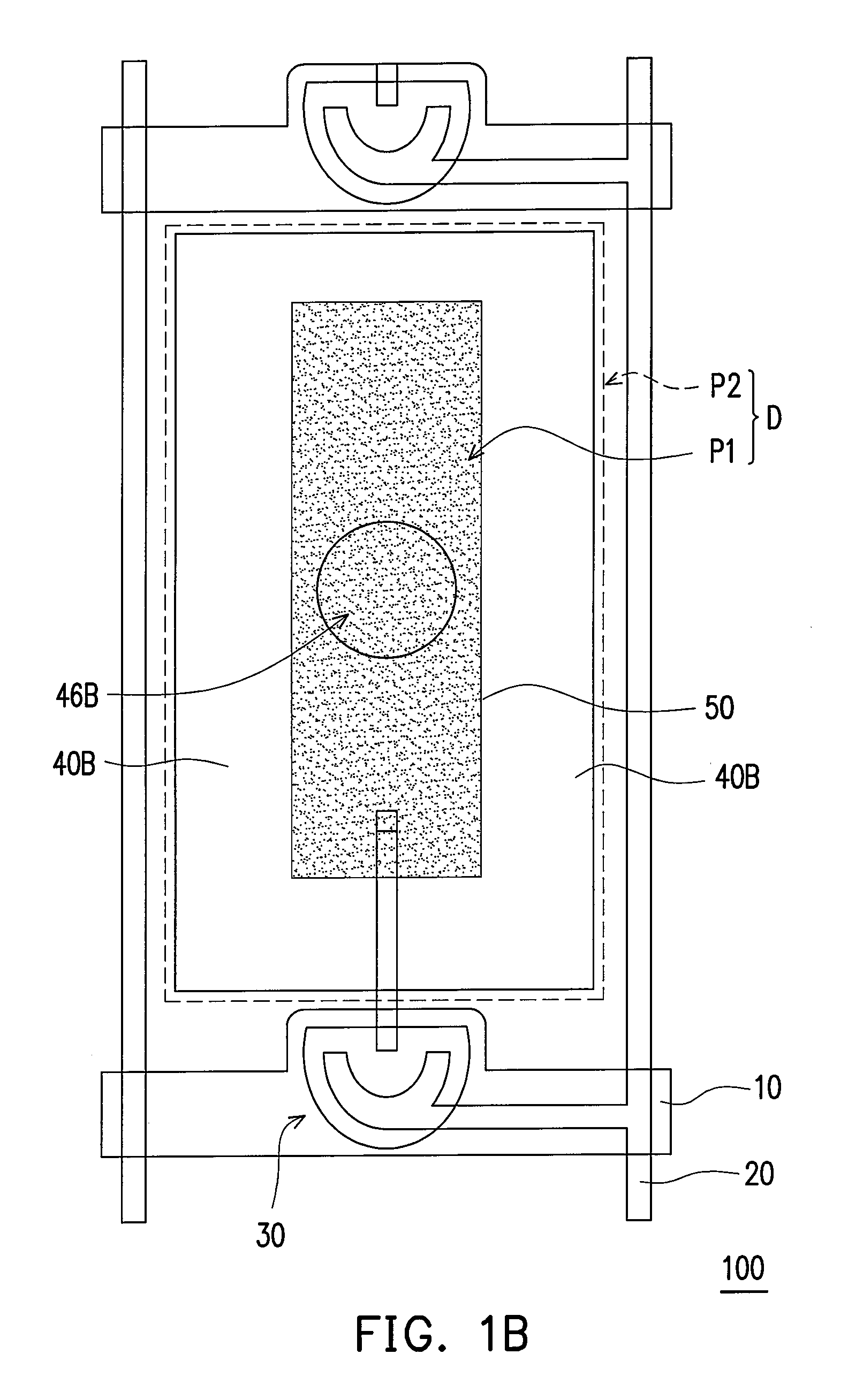

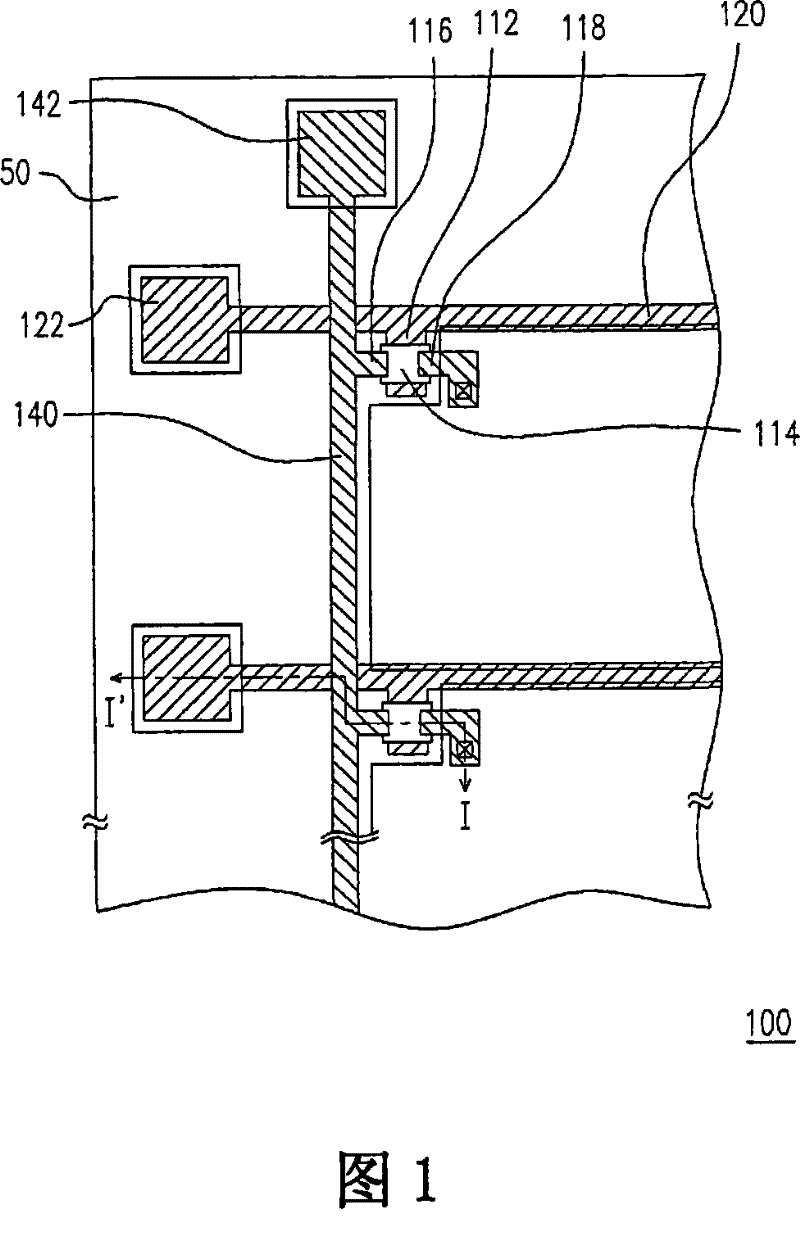

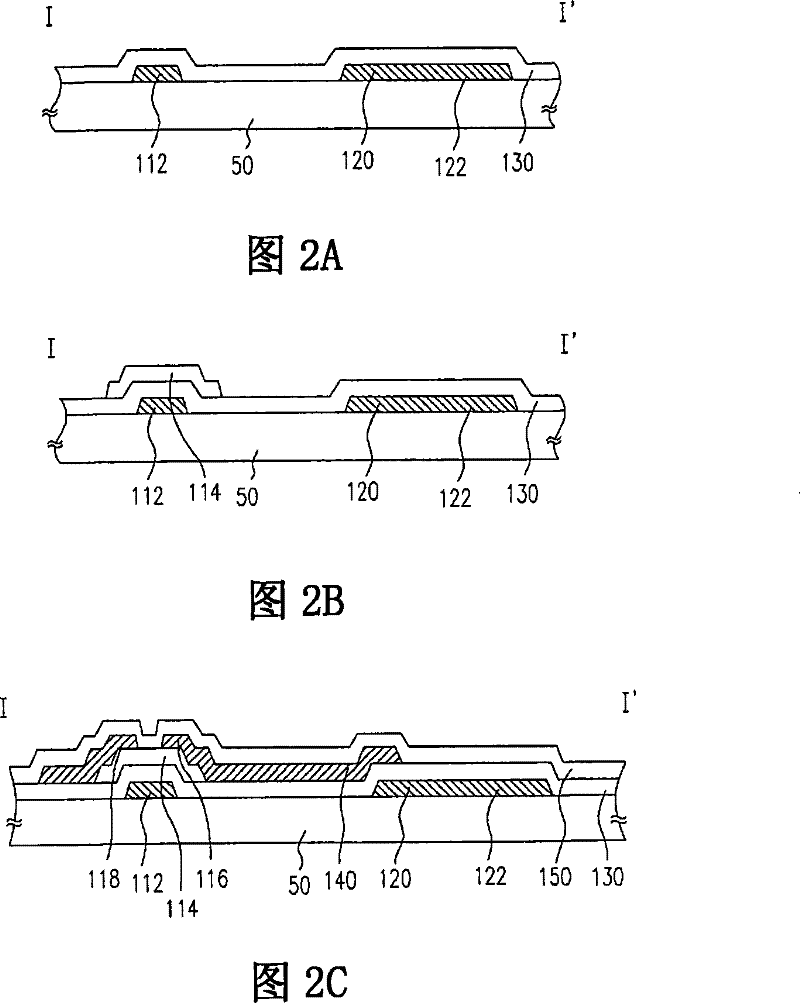

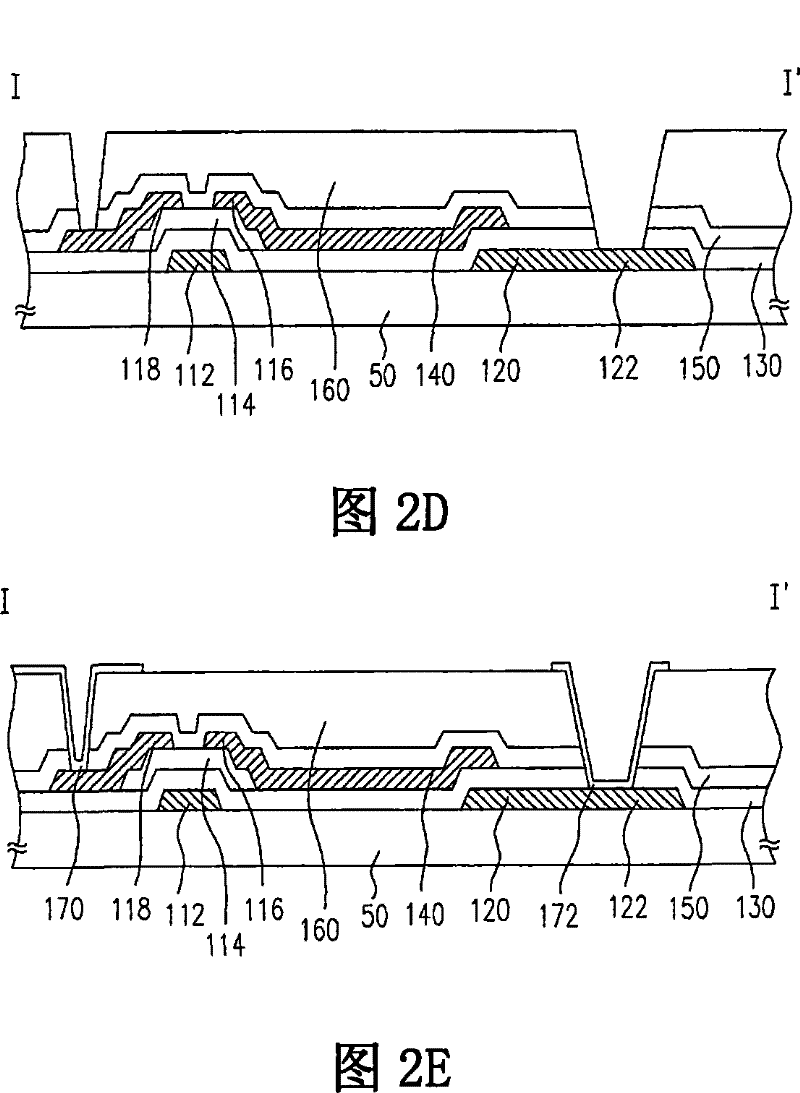

Pixel unit, liquid crystal display panel, electro-optical apparatus, and methods for manufacturing the same

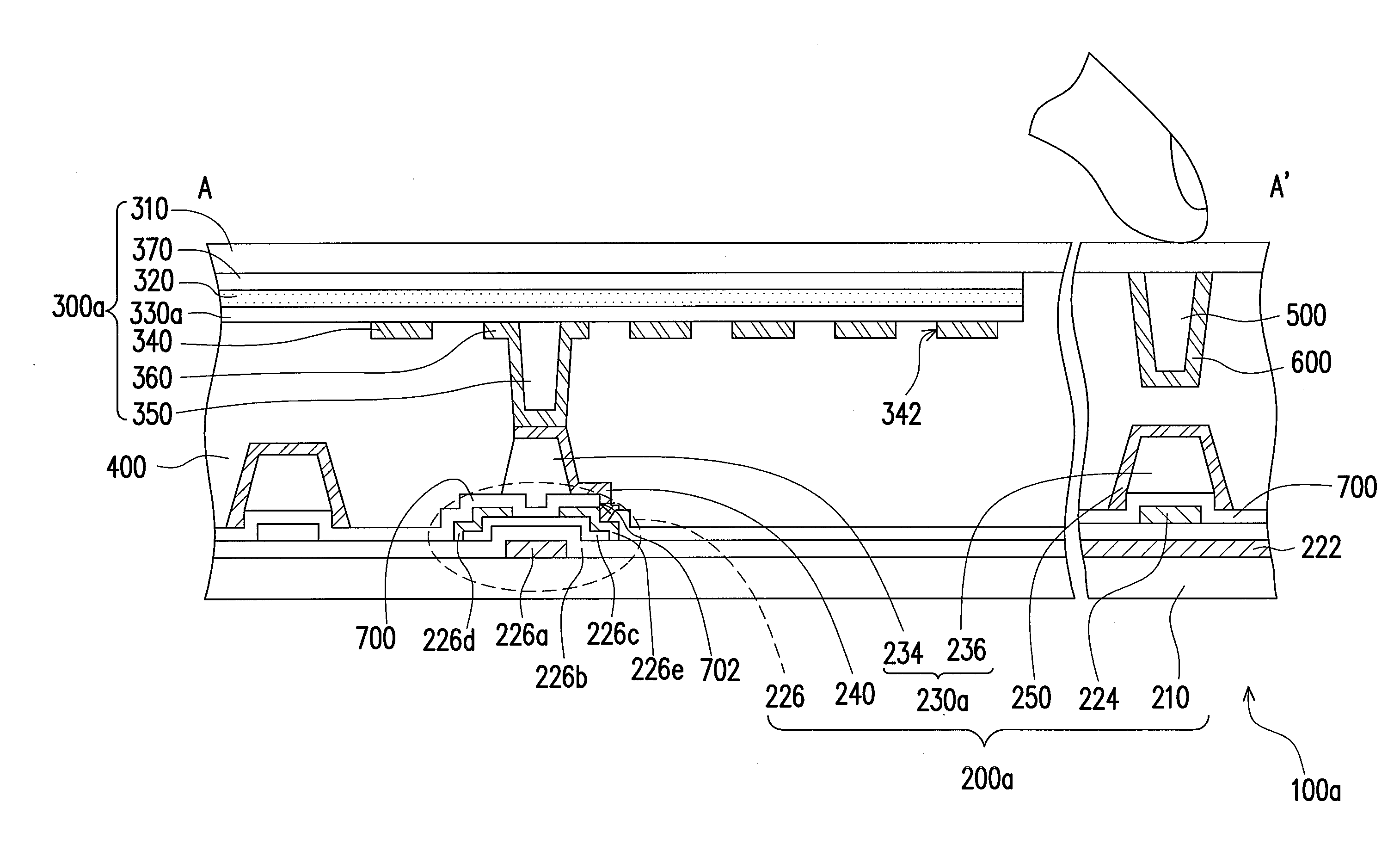

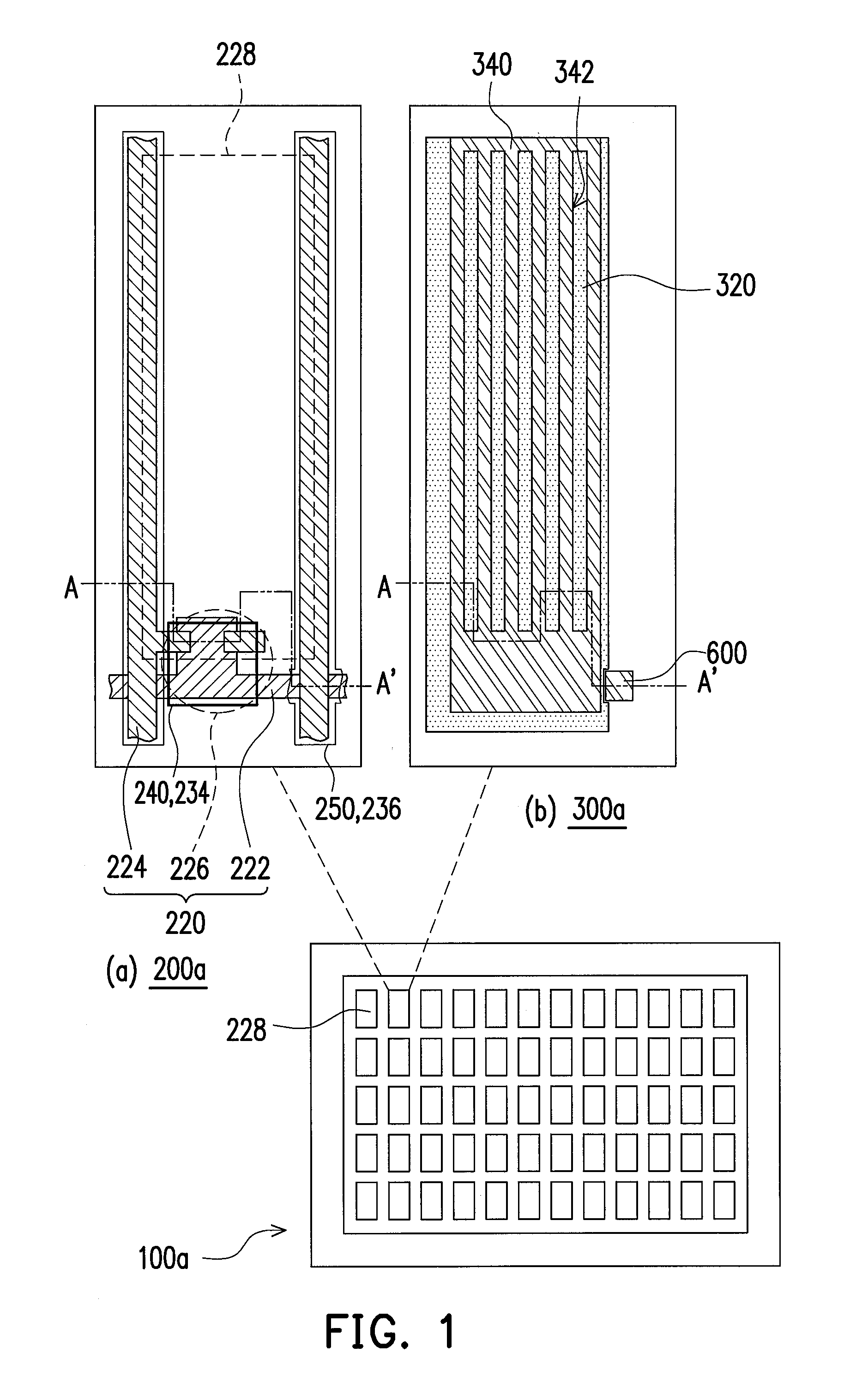

ActiveUS20090213307A1Improve display qualitySimple designVacuum evaporation coatingSputtering coatingUltraviolet lightsElectro-optics

A pixel unit having a display area is provided. The pixel unit includes a first substrate, a second substrate, a liquid crystal layer, and at least one ultraviolet light (UV) absorption pattern. The second substrate is disposed in parallel to the first substrate, and the liquid crystal layer is disposed between the first substrate and the second substrate. The UV absorption pattern is disposed between the first substrate and the second substrate. A part of the display area overlaps the UV absorption pattern to define at least one first alignment area, while the part of the display area which does not overlap the UV absorption pattern defines at least one second alignment area. The liquid crystal molecules of the liquid crystal layer present different pre-tilt angles in the first alignment area and the second alignment area.

Owner:AU OPTRONICS CORP

Liquid crystal display panel comprising first connecting electrodes disposed on a padding device and electrically connected to active devices and to second connecting electrodes

InactiveUS8421978B2Increase contrastImprove display qualityNon-linear opticsInput/output processes for data processingElectricityLiquid-crystal display

A liquid crystal display panel including an active device matrix substrate, an opposite substrate, and a liquid crystal layer is provided. The active device matrix substrate includes a first substrate, an active device array, a padding device, first connecting electrodes, and shielding electrodes. The padding device is disposed on active devices and data lines of the active device array. The first connecting electrodes are located above the active devices and electrically connected to the active devices. The shielding electrodes are located above the data lines and electrically connected to a common voltage. The opposite substrate includes a second substrate, first electrodes, an insulating layer, second electrodes having slits and opposite to the first electrodes, spacers corresponding to the active devices, and second connecting electrodes covering the spacers to directly contact with the first connecting electrodes and electrically connected to the first electrodes or the second electrodes.

Owner:WINTEK CORP

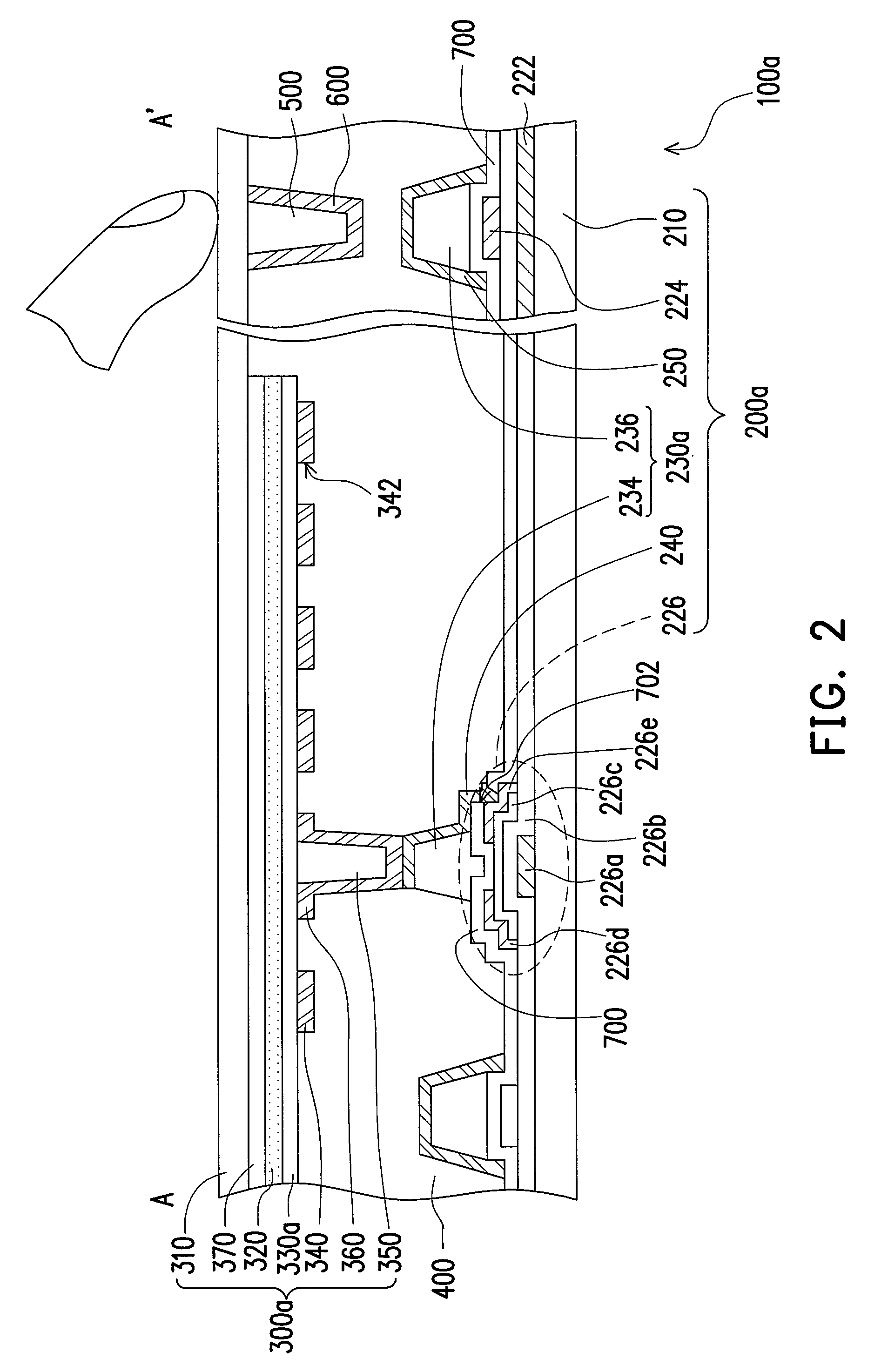

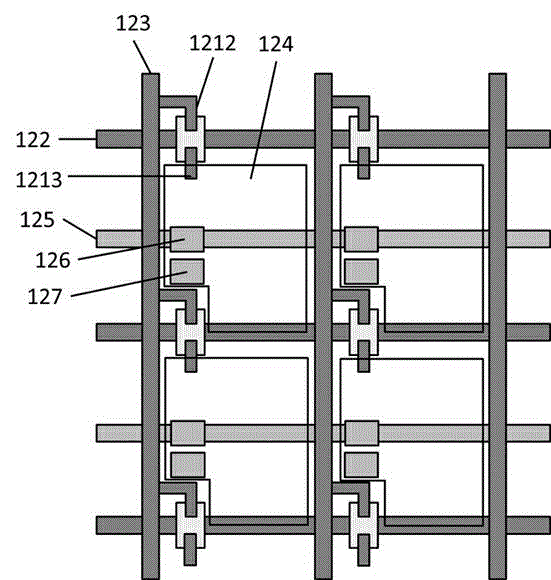

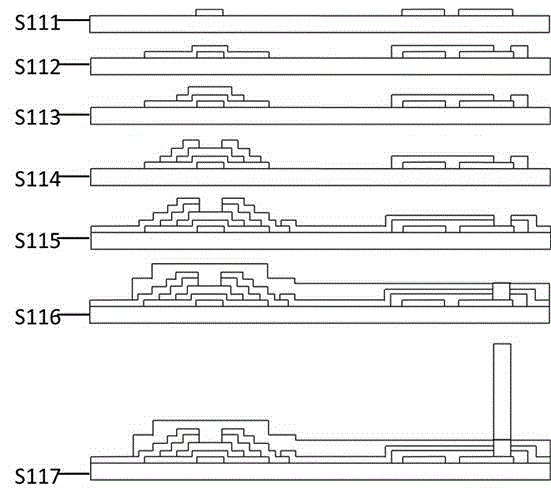

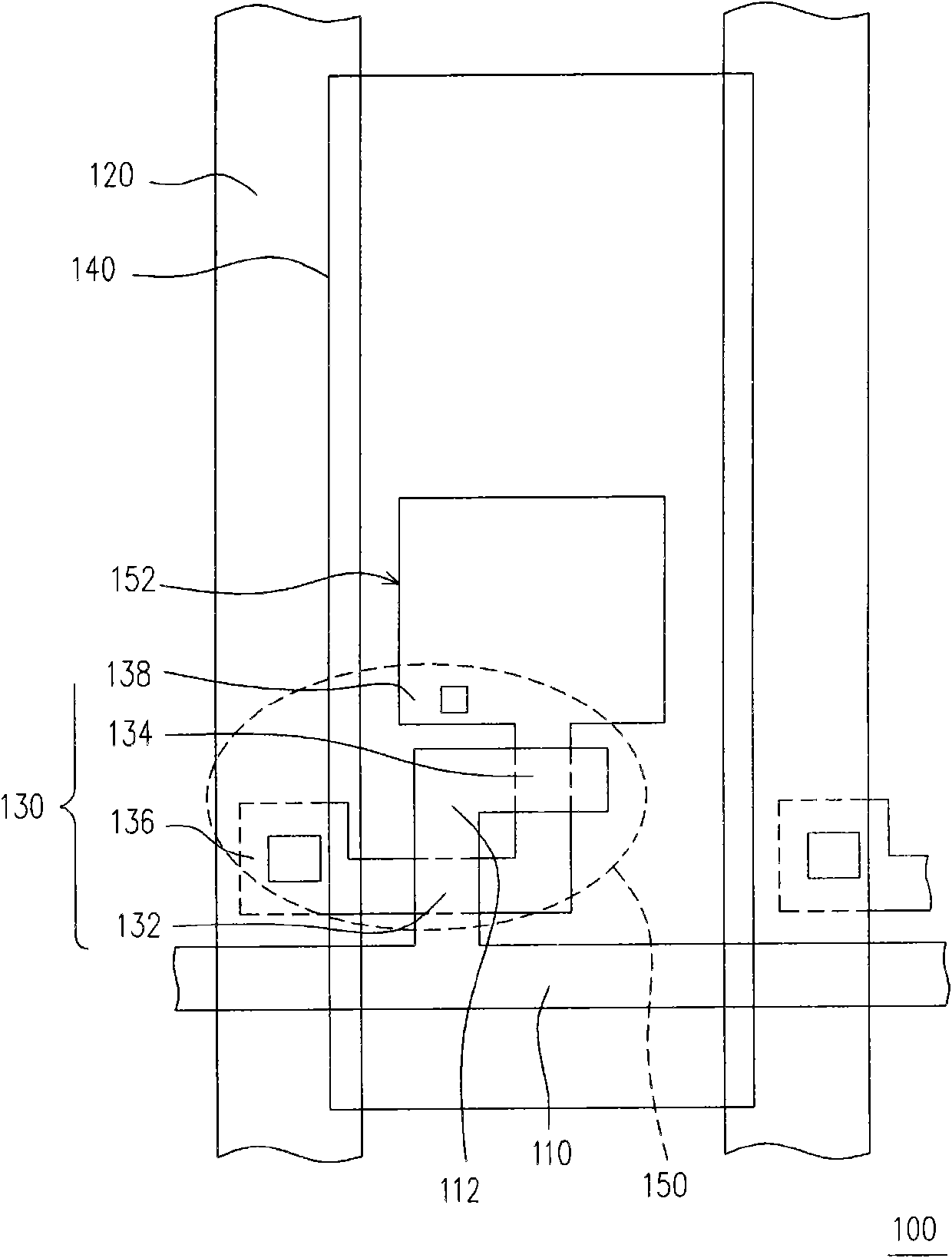

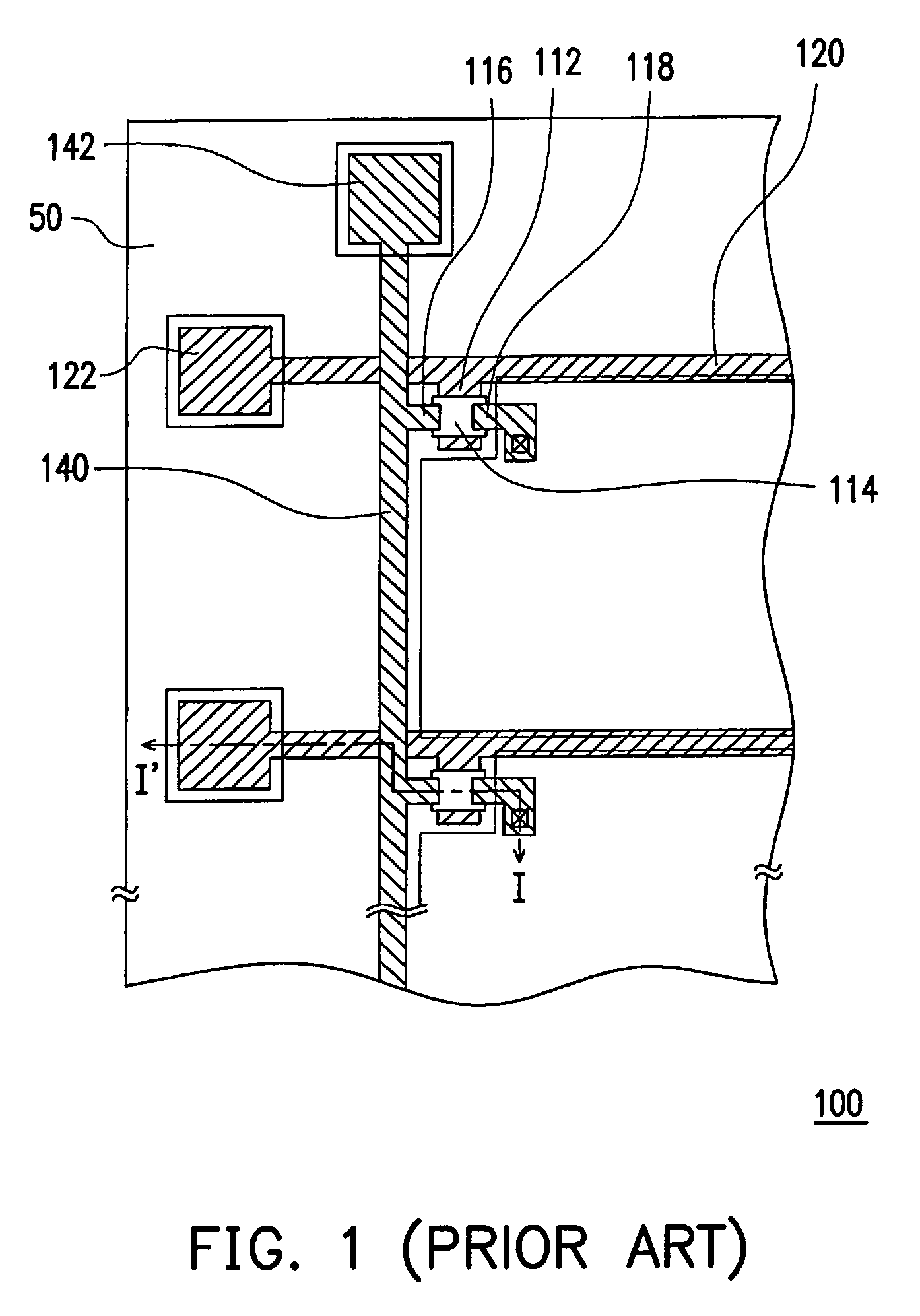

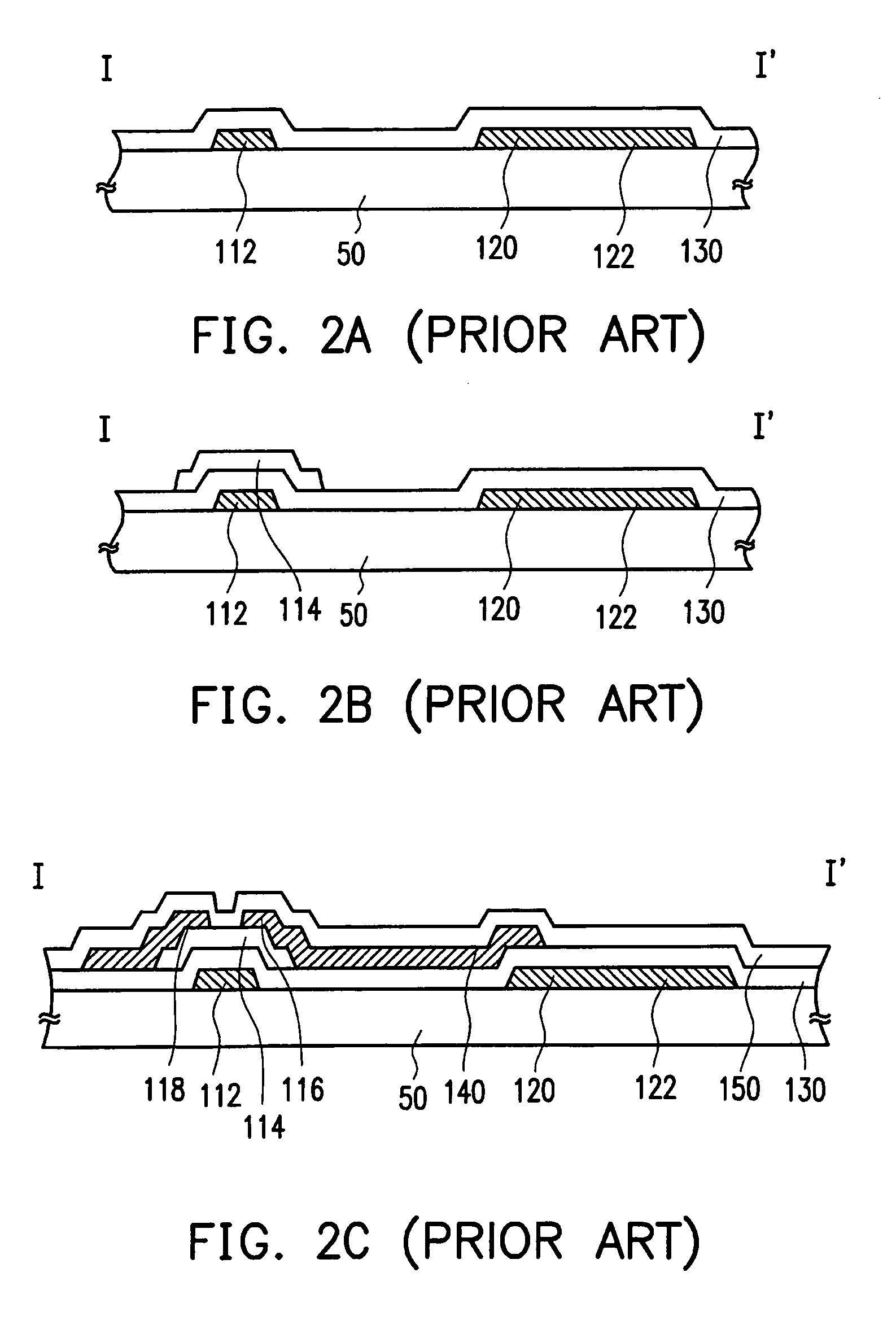

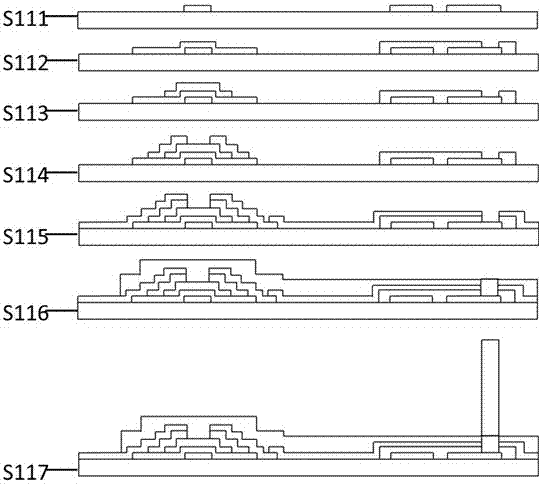

Active matrix array structure and manufacturing mehtod thereof

ActiveUS20090173943A1Improve the display aperture ratioReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorActive matrix

An active matrix array structure, disposed on a substrate, includes a first patterned conductive layer, a patterned gate insulating layer, a patterned semiconductor layer, a second patterned conductive layer, a patterned overcoat layer and a transparent conductive layer. The patterned gate insulating layer has first openings that expose a part of the first patterned conductive layer. The patterned semiconductor layer is disposed on the patterned gate insulating layer. The second patterned conductive layer is disposed on the patterned semiconductor layer. The patterned overcoat layer has second openings that expose a part of the first patterned conductive layer and a part of the second patterned conductive layer. The transparent conductive layer is completely disposed on the substrate. The transparent conductive layer disposed in the first openings and the second openings is broken off at a position that is in between the substrate and the patterned overcoat layer.

Owner:AU OPTRONICS CORP

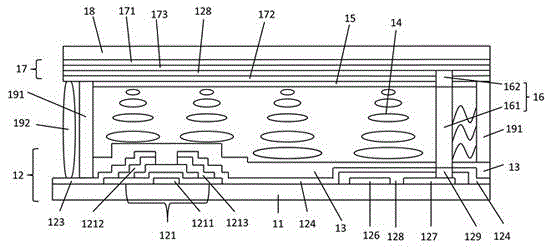

Integrated touch function display screen and manufacture method thereof

ActiveCN104407726AImprove the display aperture ratioSave production raw material costNon-linear opticsInput/output processes for data processingColor gelEngineering

The invention relates to an integrated touch function display screen and a manufacture method thereof. The integrated touch function display screen is characterized by comprising a first substrate, a thin film transistor, a first alignment layer, a liquid crystal molecular layer, a second alignment layer, a plurality of isolation columns, a colorful optical filter layer and a second substrate. The display screen can be manufactured by adopting traditional processes and also can be manufactured by adopting 3D technology, and a touch and display function can be realized if the integrated touch function display screen is provided with a driving and processing assembly. The isolation columns of the invention realizes an isolating and supporting function, and meanwhile, a lead on the second substrate can be connected to the first substrate; and a touch unit is arranged below the display screen to effectively increase a display opening rate. Meanwhile, parts of the processes adopt a 3D printing technology, and the manufacture method is greatly simplified when the manufacture method is compared with a traditional method, multiple complex processes, such as exposure, development, etching and the like, in the traditional processes can be omitted, and production raw materials and the manufacture cost are saved and lowered.

Owner:FUZHOU UNIV

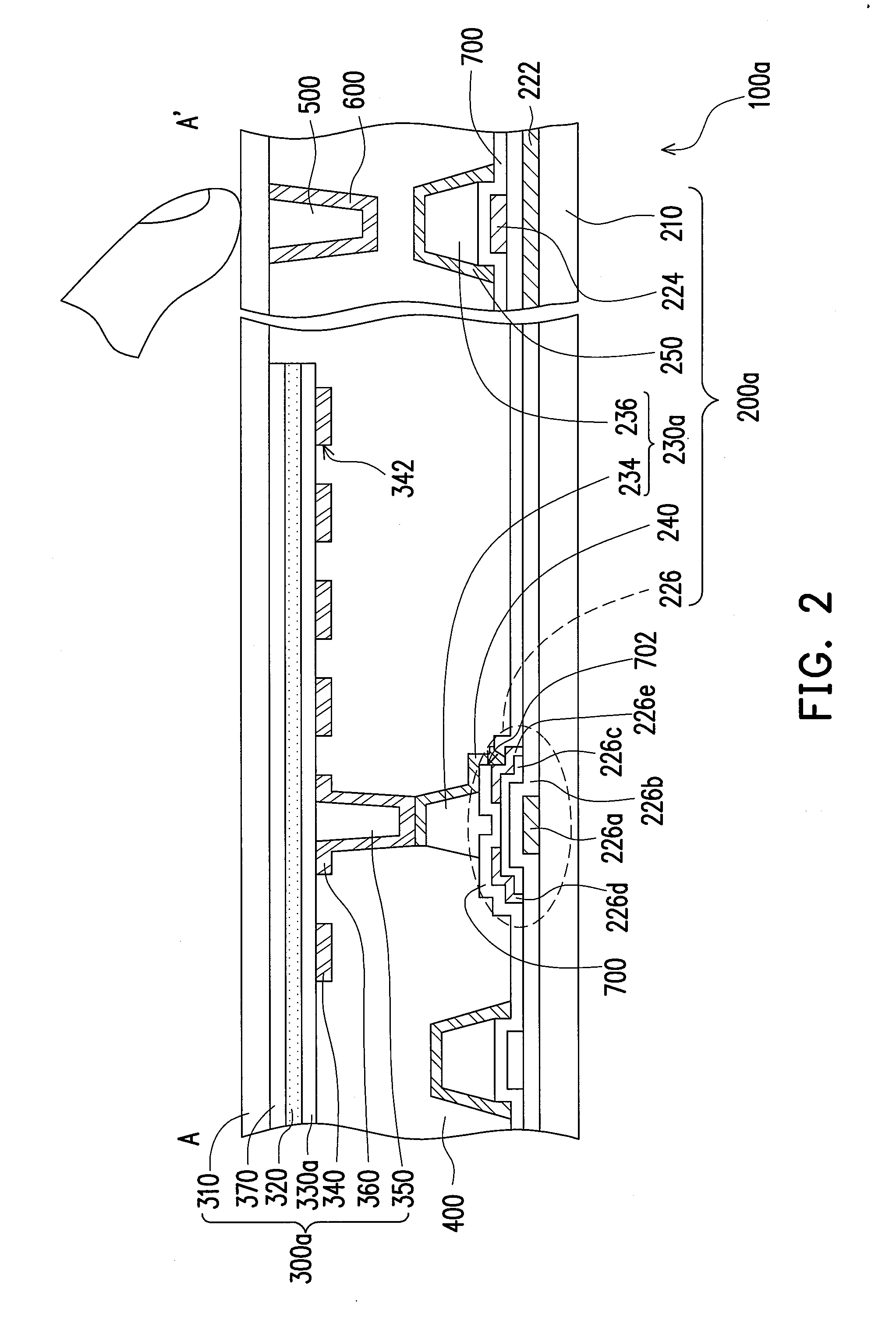

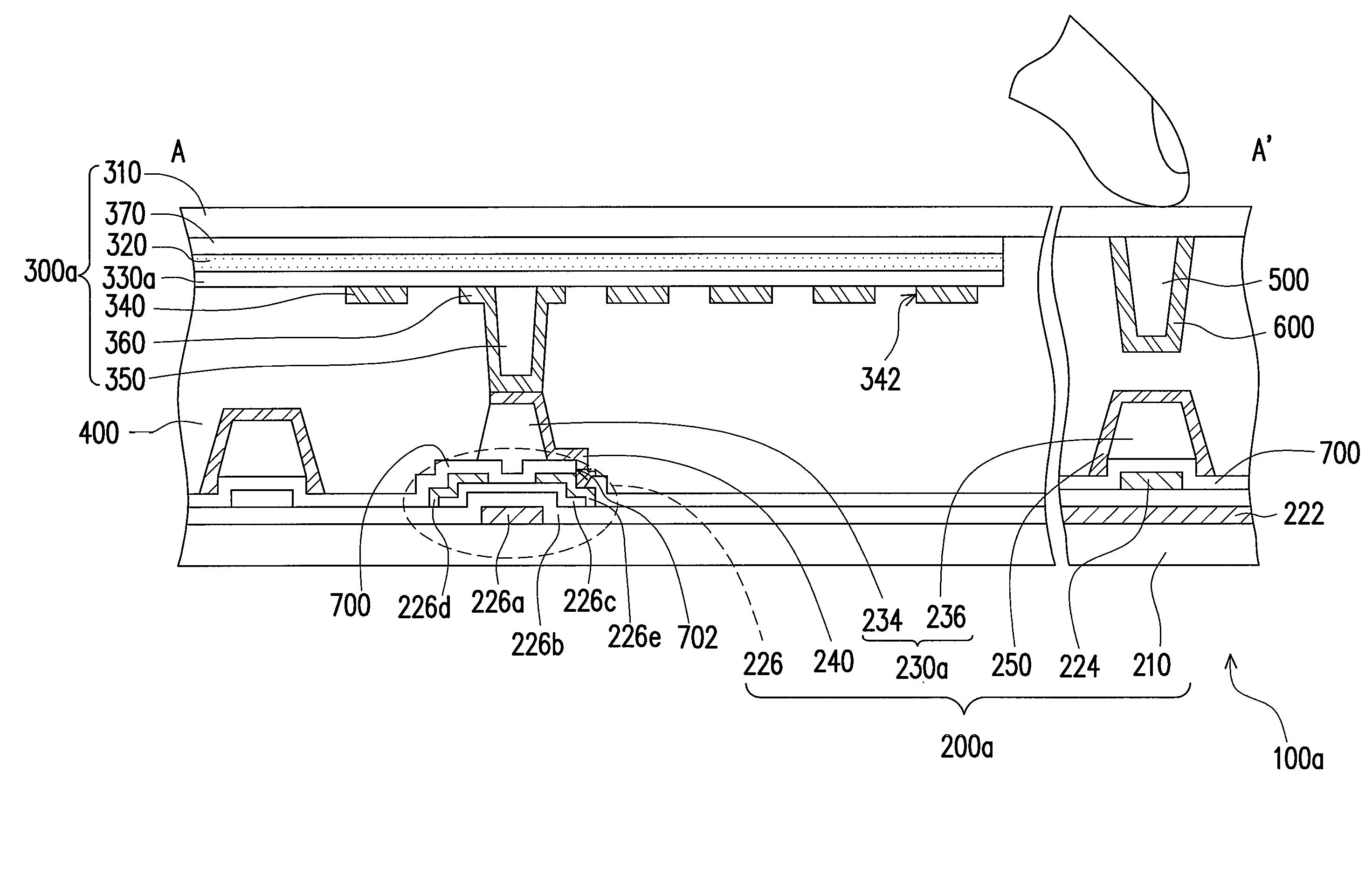

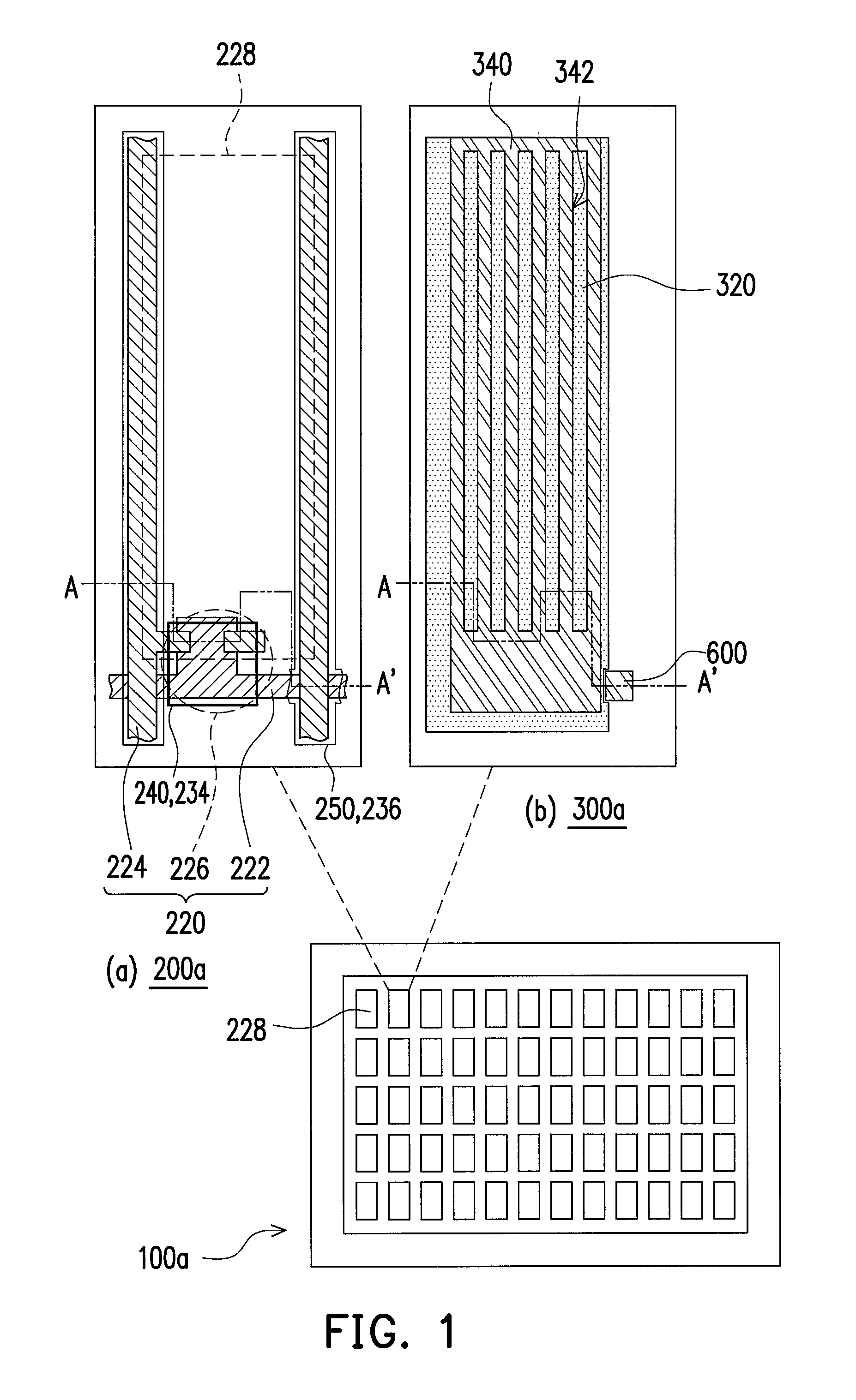

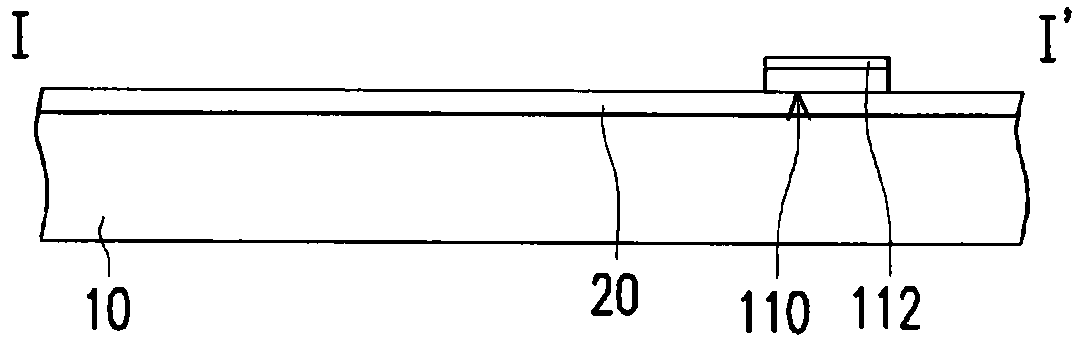

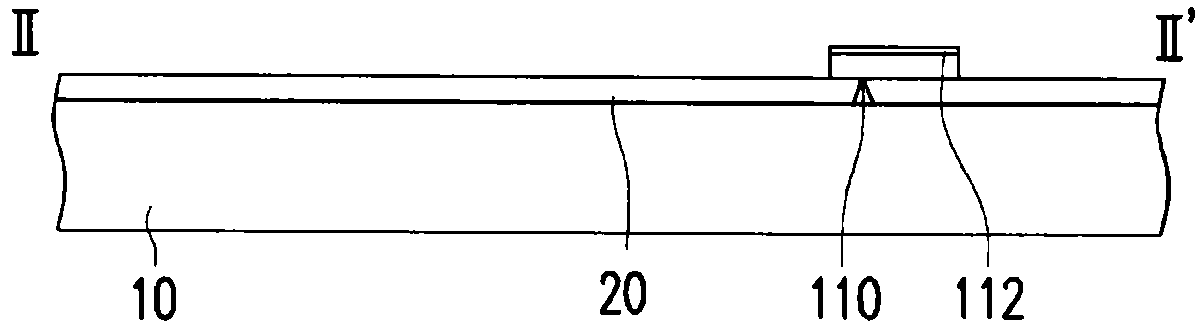

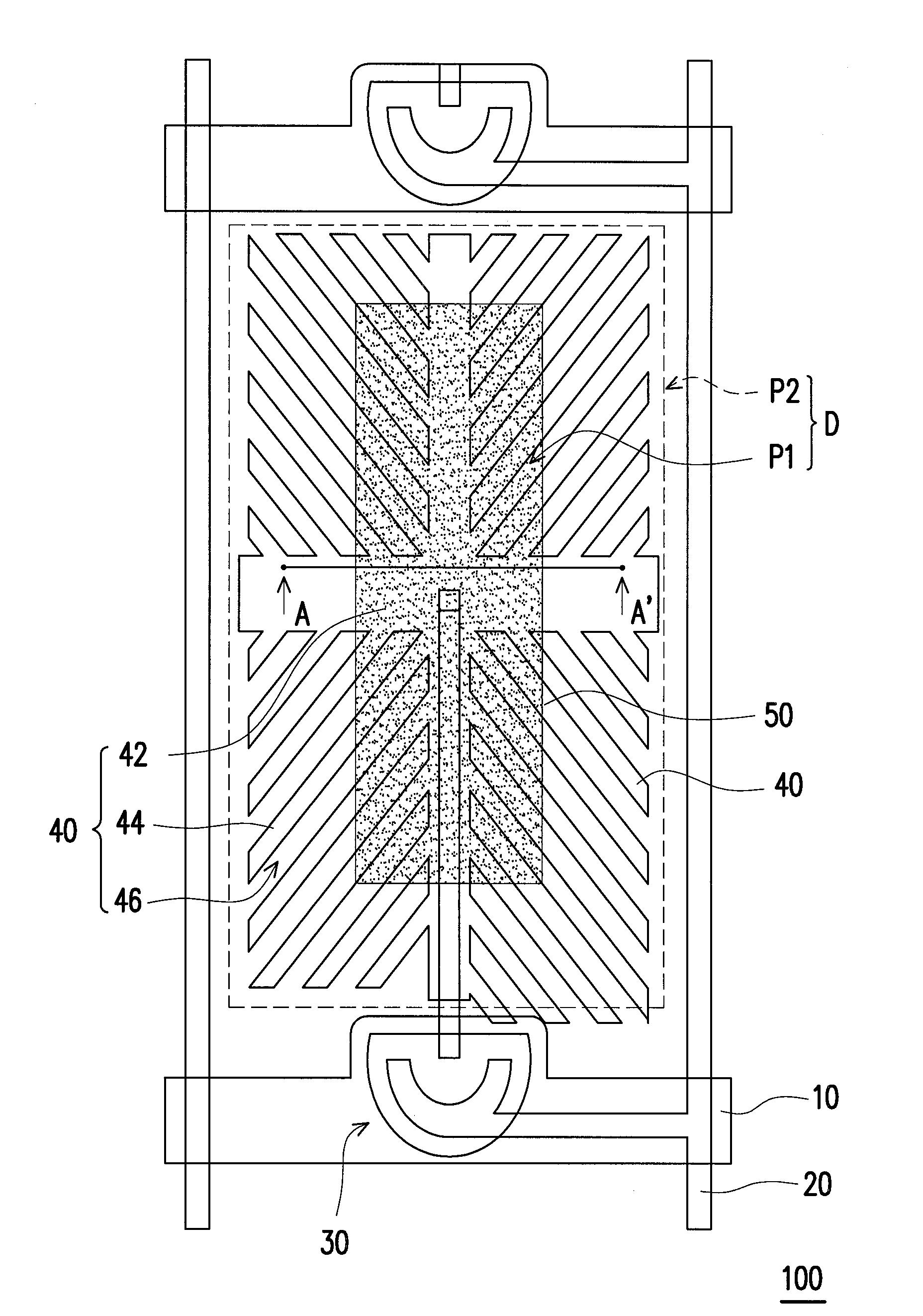

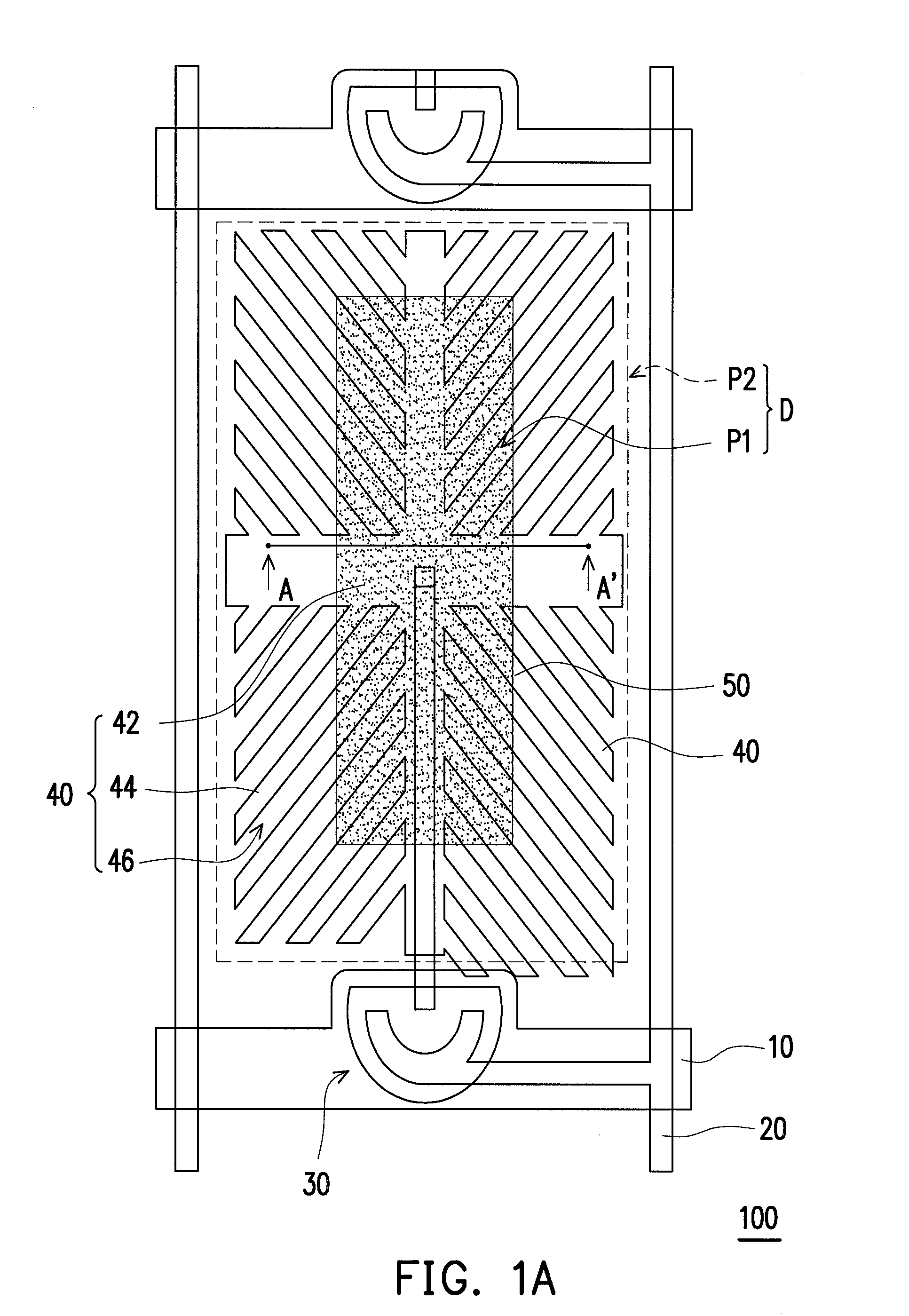

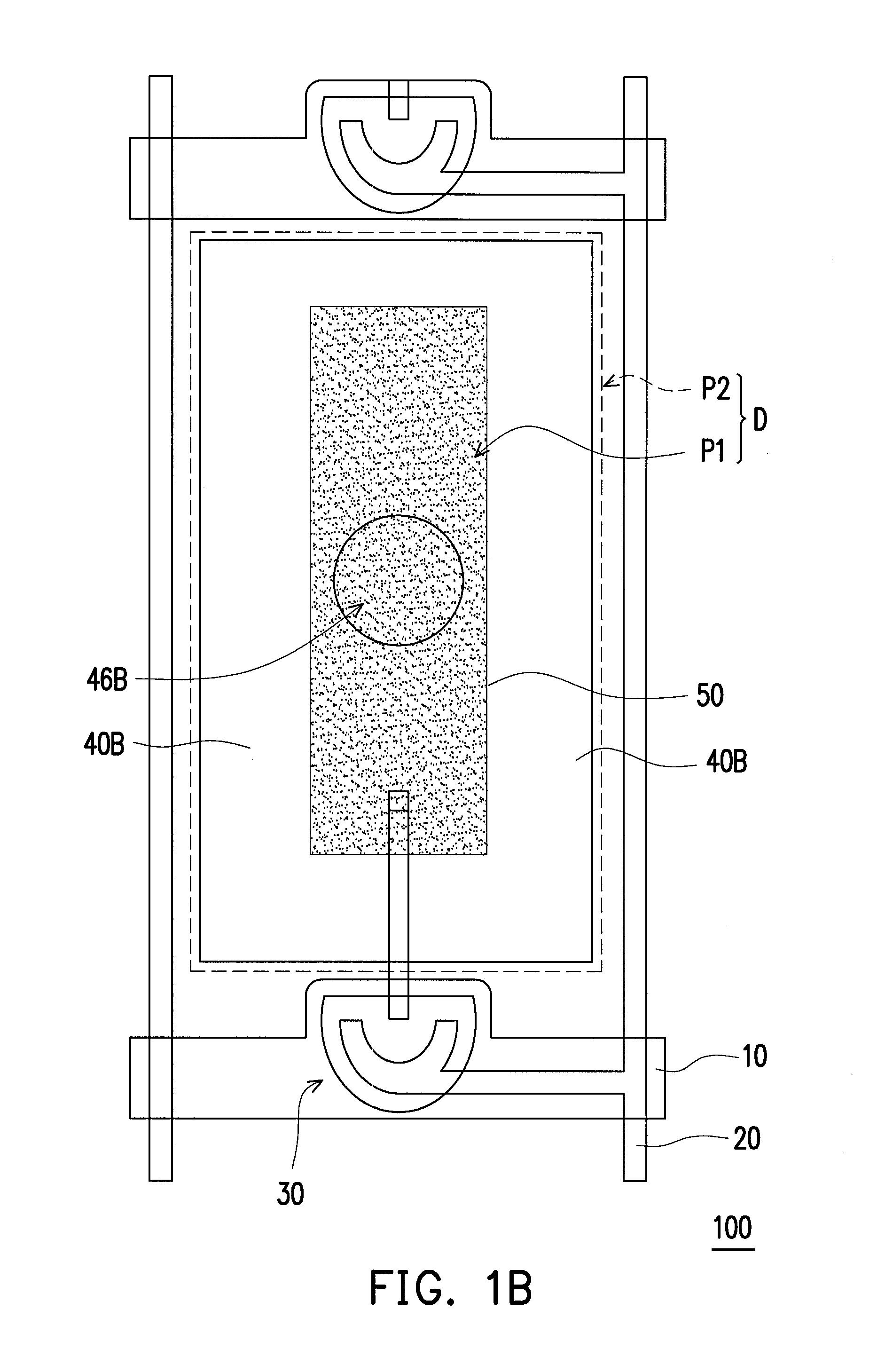

Combined image sensor and display device

ActiveUS8139055B2Reduce the valueImprove the display aperture ratioTelevision system detailsTelevision system scanning detailsDisplay devicePhotodiode

A combined image sensor and display device comprises an array of device elements (18), each of which comprises a display pixel (M4, C2, CLC). The display pixels have data inputs connected to column data lines (SL, 6,6′). The array includes sensor elements (10), each comprising a transistor (M1), an integrating capacitor (C1) and a photodiode (D1) connected together to an integrating node (11). The transistor (M1) is connected between column data lines (6,6′). The capacitor (C1) is connected to a control input (RS) which receives a first voltage during a sensing phase for switching off the transistor (M1) and a second voltage during a reading phase for enabling the transistor (M1).

Owner:SHARP KK

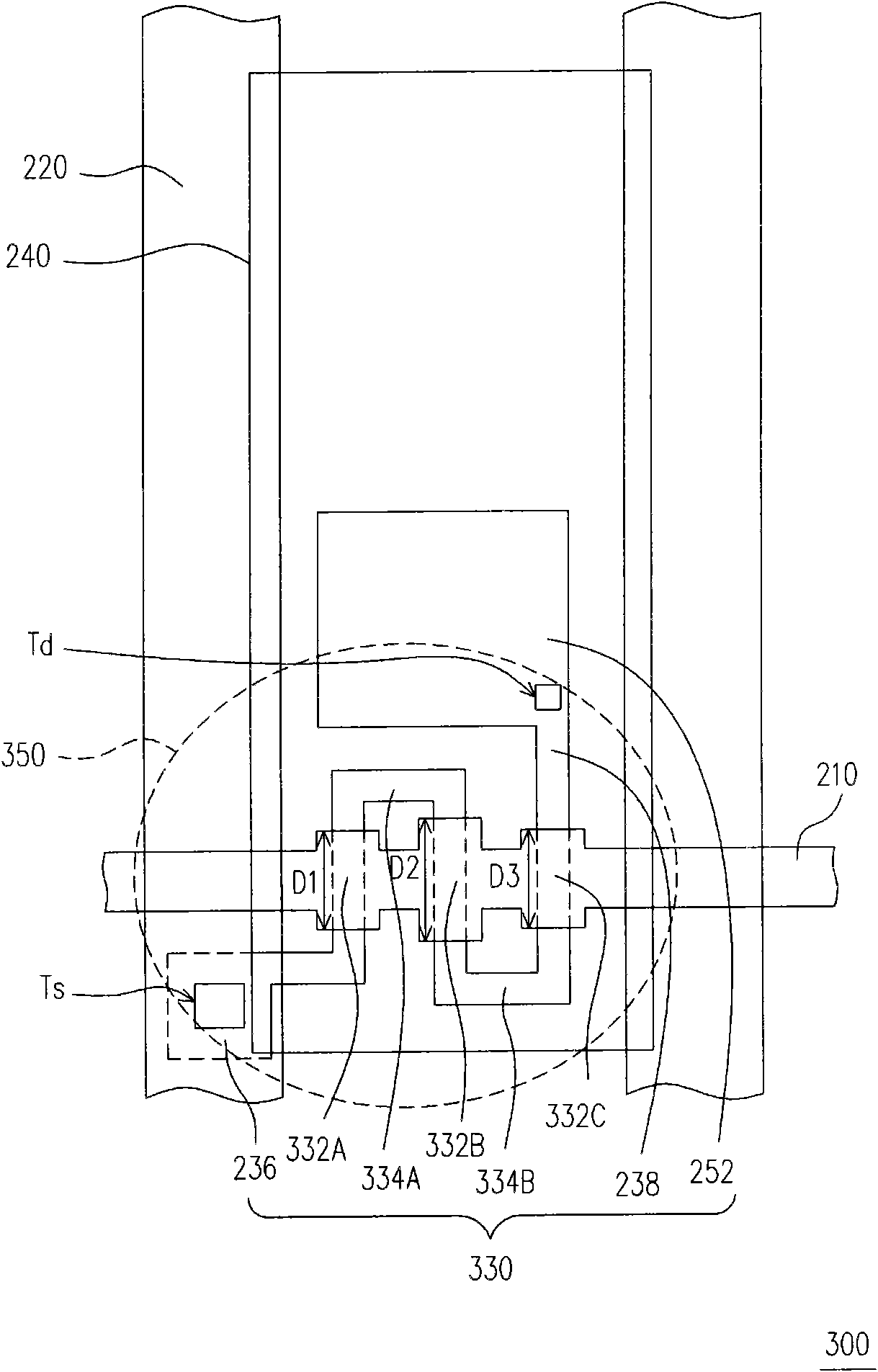

Pixel structure

ActiveCN101950746AReduce leakage currentImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesScan lineSemiconductor

The invention discloses a pixel structure which comprises a scanning line, a data line, a semiconductor pattern, a source region, a drain region and a pixel electrode, wherein the scanning line is provided with a branch; the data line and the scan line are arranged in a staggered mode; the branch is positioned below the data line and overlaps the data line; the semiconductor pattern comprises at least two channel regions positioned below the scanning line, at least one doped region connected between every two channel regions; the pixel electrode is electrically connected with the drain region; the source region is connected between one channel region and the data line; and the drain region is connected between the other channel region and the pixel electrode. By utilizing the changes of the semiconductor pattern, the semiconductor pattern and the scanning line are intersected in at least two regions, thereby being beneficial to reducing the drain current of the polysilicon thin film transistor.

Owner:AU OPTRONICS CORP

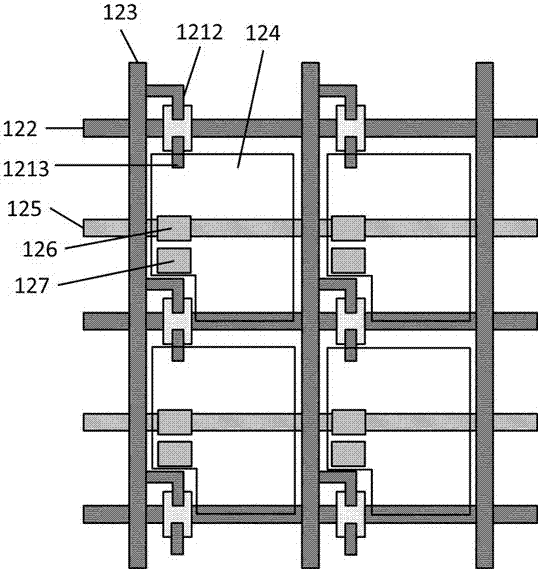

Pixel structure and method for manufacturing pixel structure

ActiveCN102436104ASimple manufacturing methodIncreased configuration areaSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceScan line

The invention provides a pixel structure and a method for manufacturing the same. The pixel structure comprises a channel layer, a first patterned metal layer, a first insulating layer, a second patterned metal layer, a second insulating layer and a pixel electrode, which are sequentially formed. The first patterned metal layer comprises a data line, a source electrode and a drain electrode. The first insulating layer is provided with a first opening so as to expose the drain electrode. The second patterned metal layer comprises a scan line and a capacitor electrode. The capacitor electrode comprises a first part overlapped with the data line. The second insulating layer is provided with a second opening communicated with the first opening so as to expose the drain electrode. The pixel electrode is connected with the drain electrode through the second opening and the first opening and is at least overlapped with the first part of the capacitor electrode.

Owner:AU OPTRONICS (KUNSHAN) CO LTD

Methods for manufacturing pixel unit, liquid crystal display panel, and electro-optical apparatus

ActiveUS20110212393A1Simple designResolution problemLiquid crystal compositionsVacuum evaporation coatingUltraviolet lightsElectro-optics

A pixel unit having a display area is provided. The pixel unit includes a first substrate, a second substrate, a liquid crystal layer, and at least one ultraviolet light (UV) absorption pattern. The second substrate is disposed in parallel to the first substrate, and the liquid crystal layer is disposed between the first substrate and the second substrate. The UV absorption pattern is disposed between the first substrate and the second substrate. A part of the display area overlaps the UV absorption pattern to define at least one first alignment area, while the part of the display area which does not overlap the UV absorption pattern defines at least one second alignment area. The liquid crystal molecules of the liquid crystal layer present different pre-tilt angles in the first alignment area and the second alignment area.

Owner:AU OPTRONICS CORP

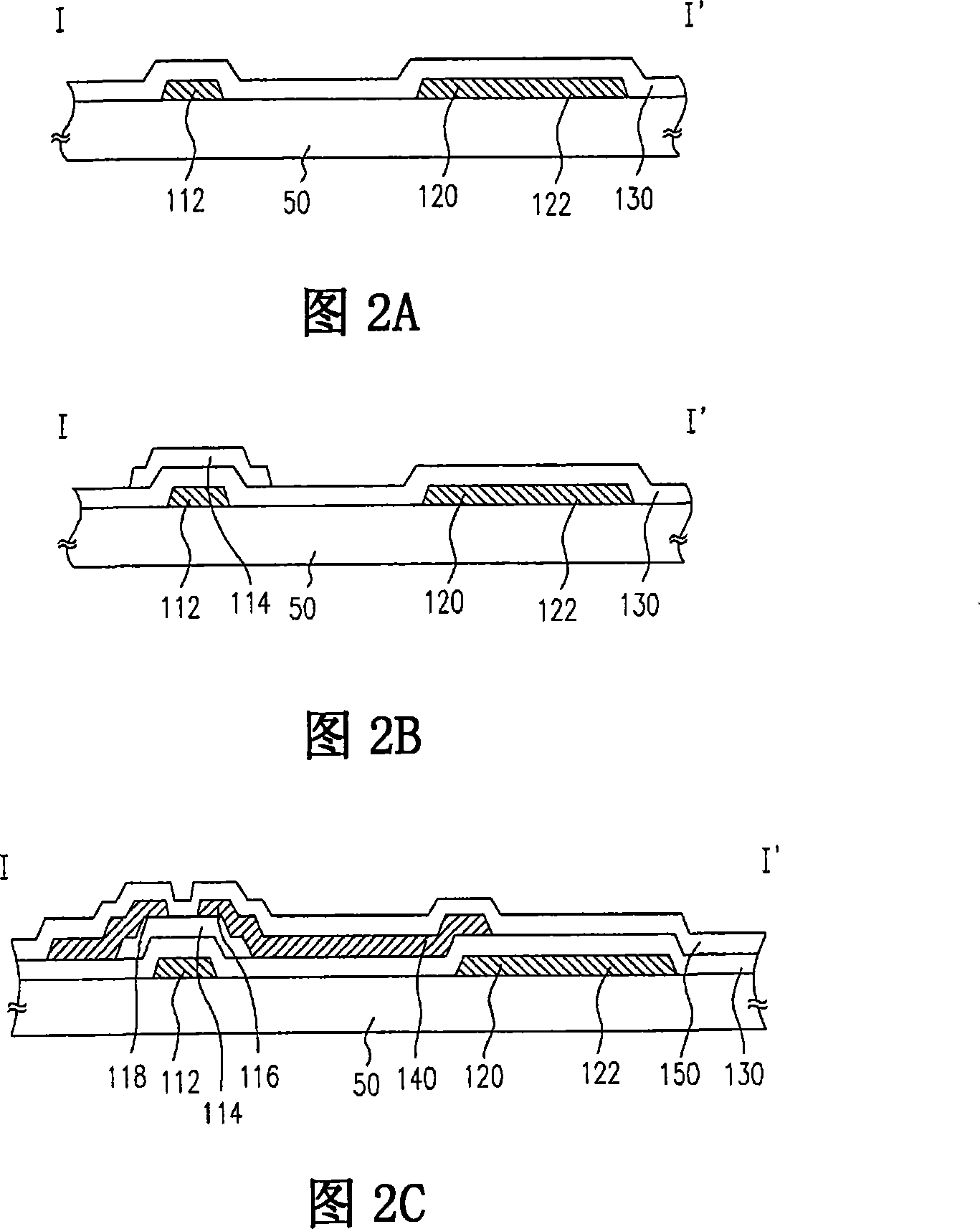

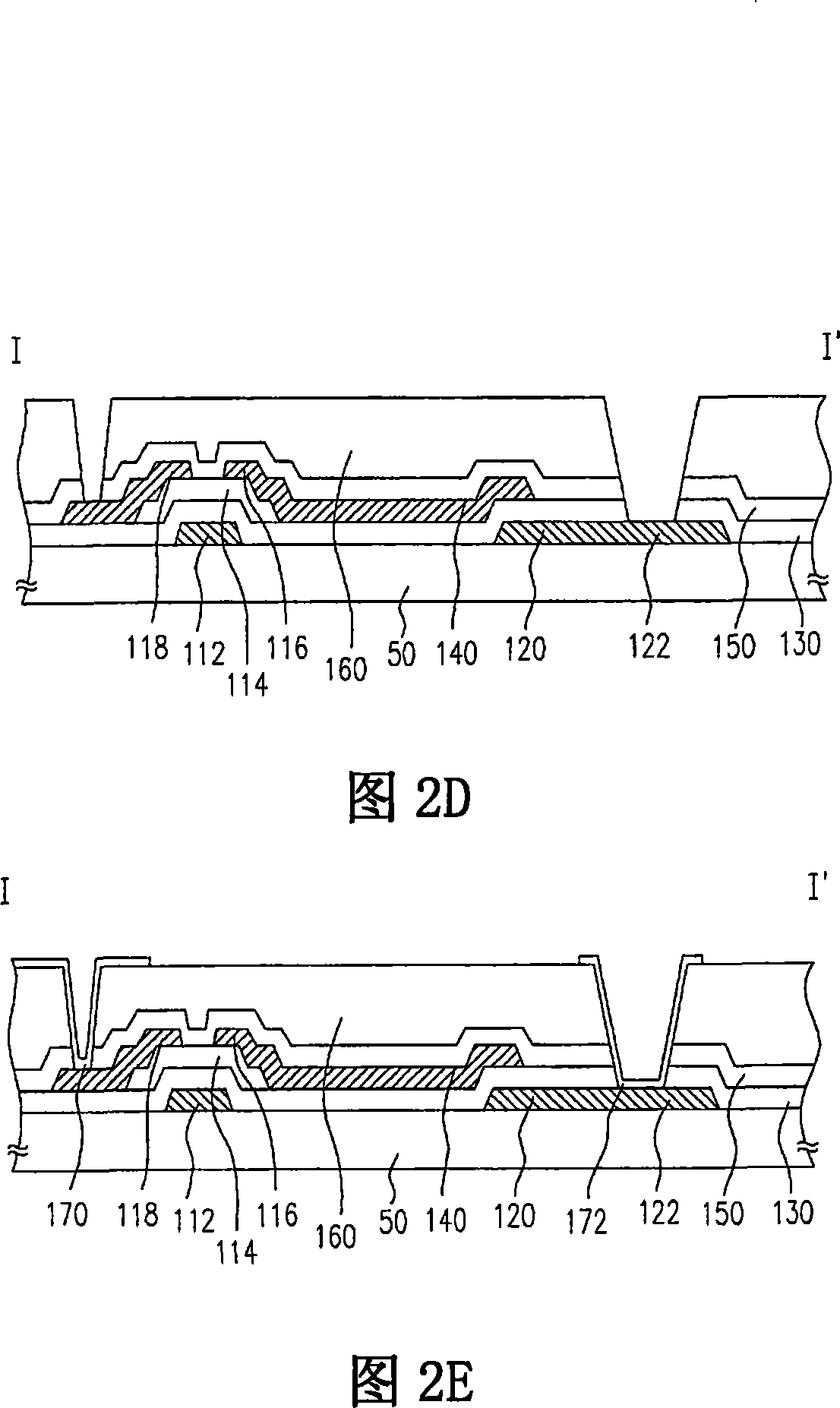

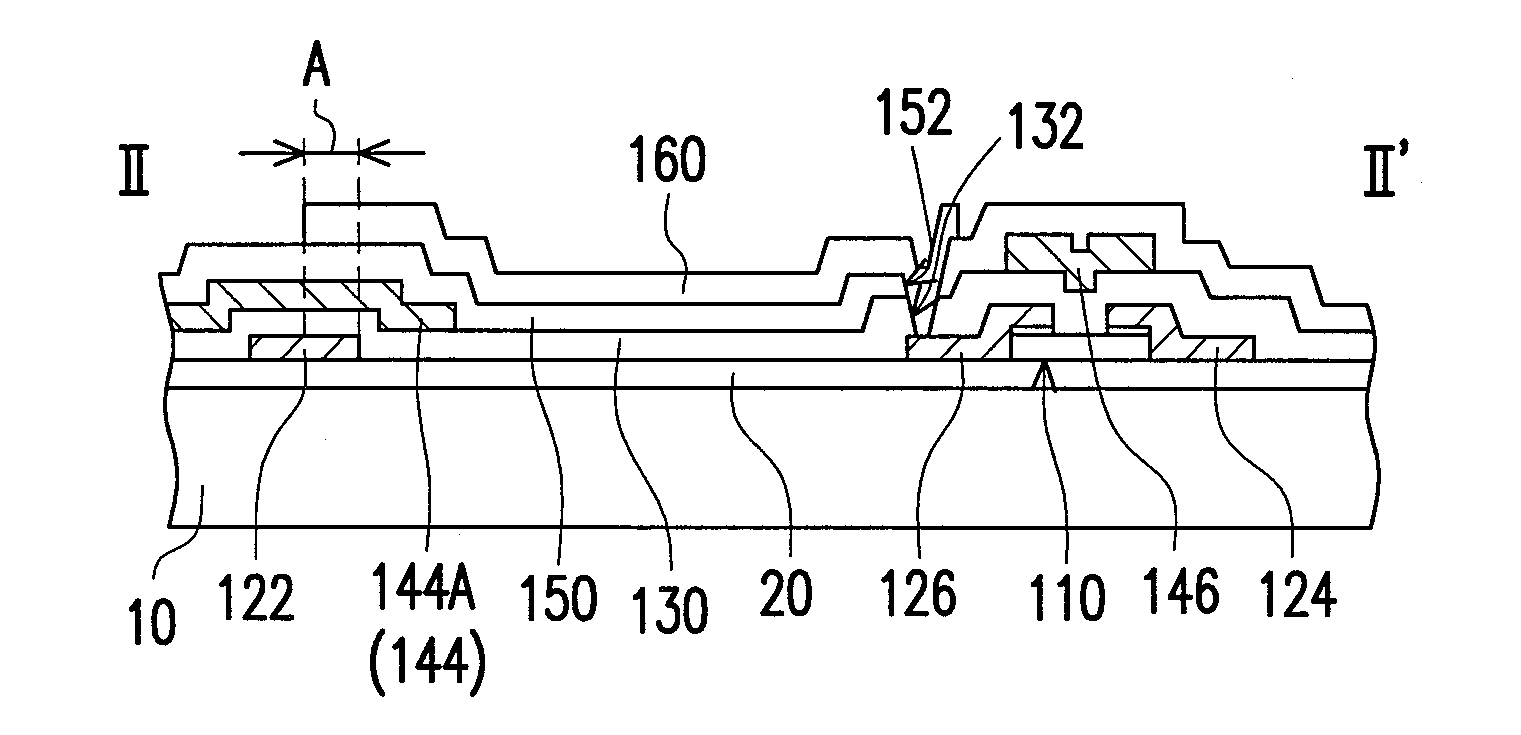

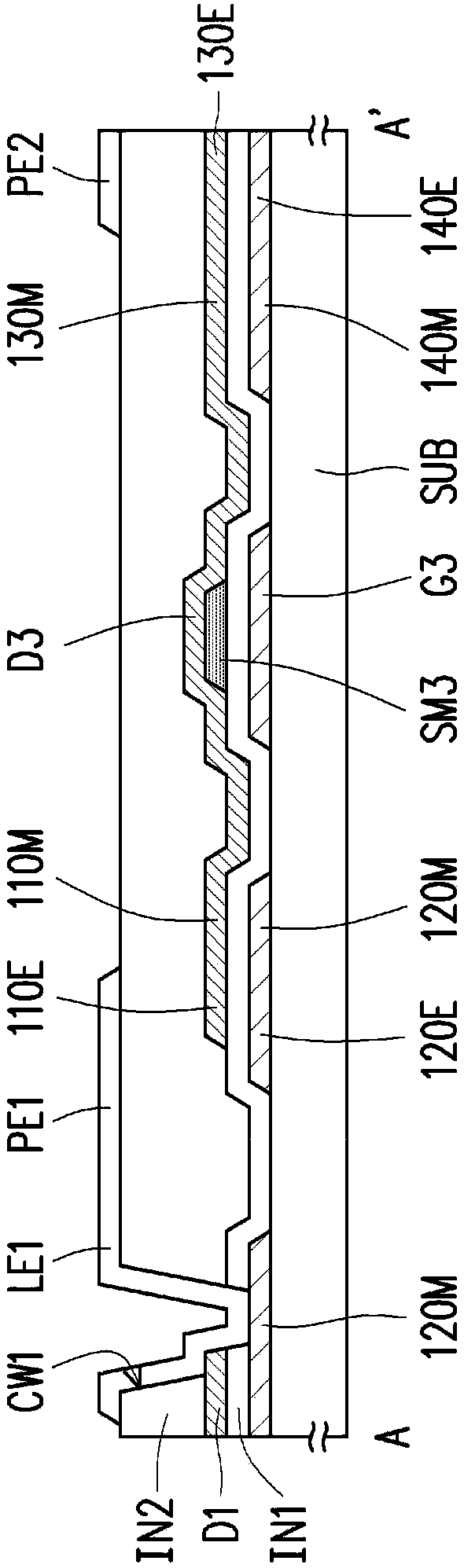

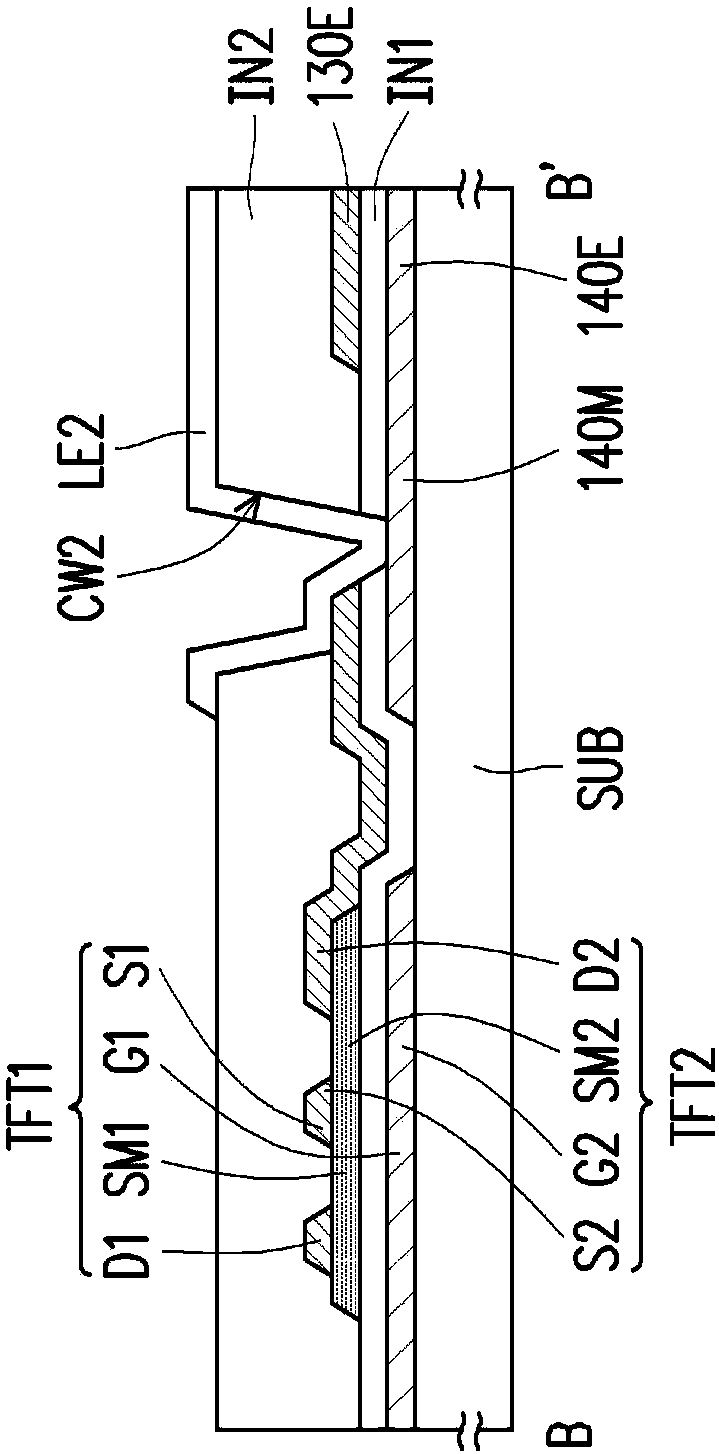

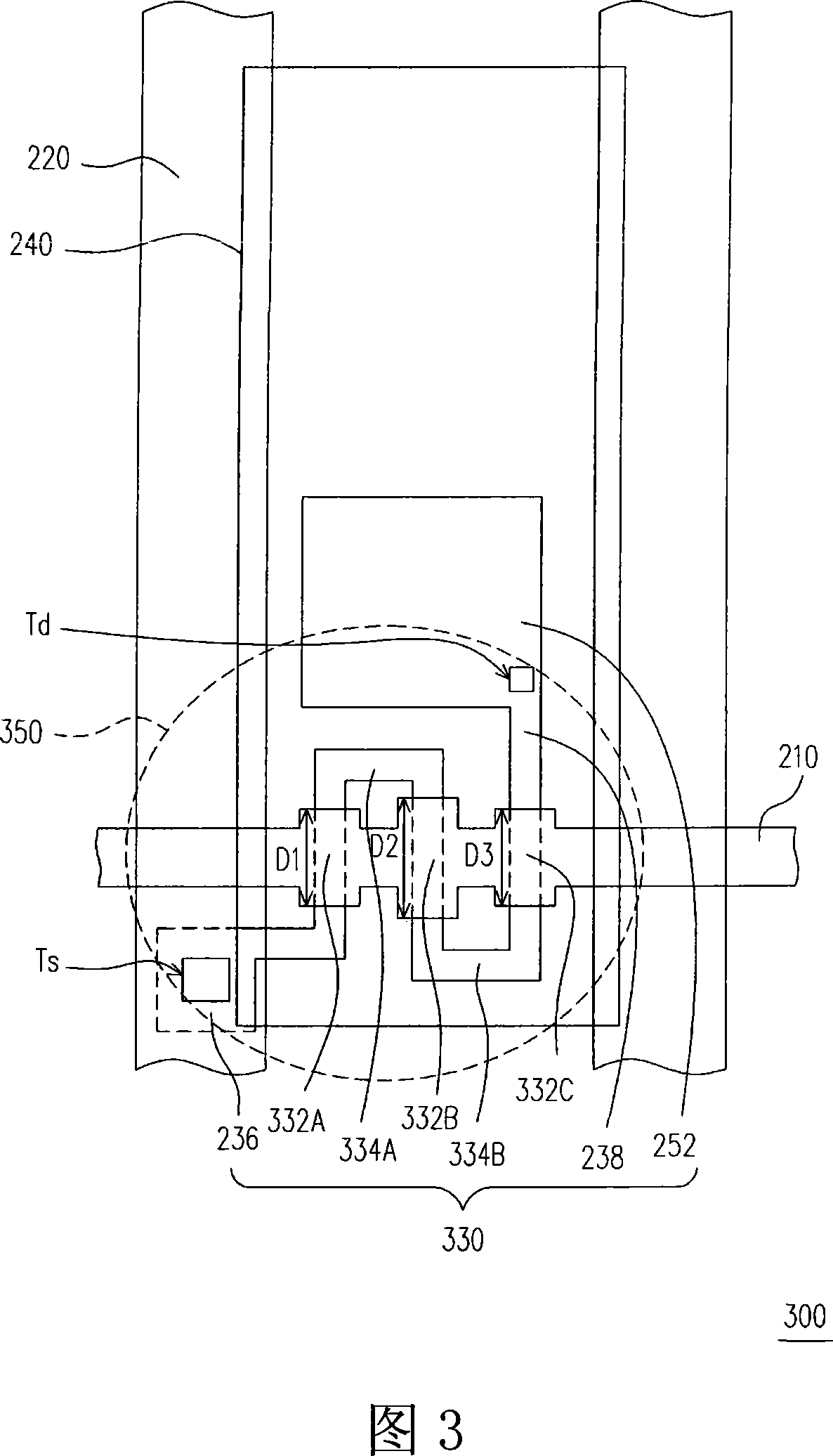

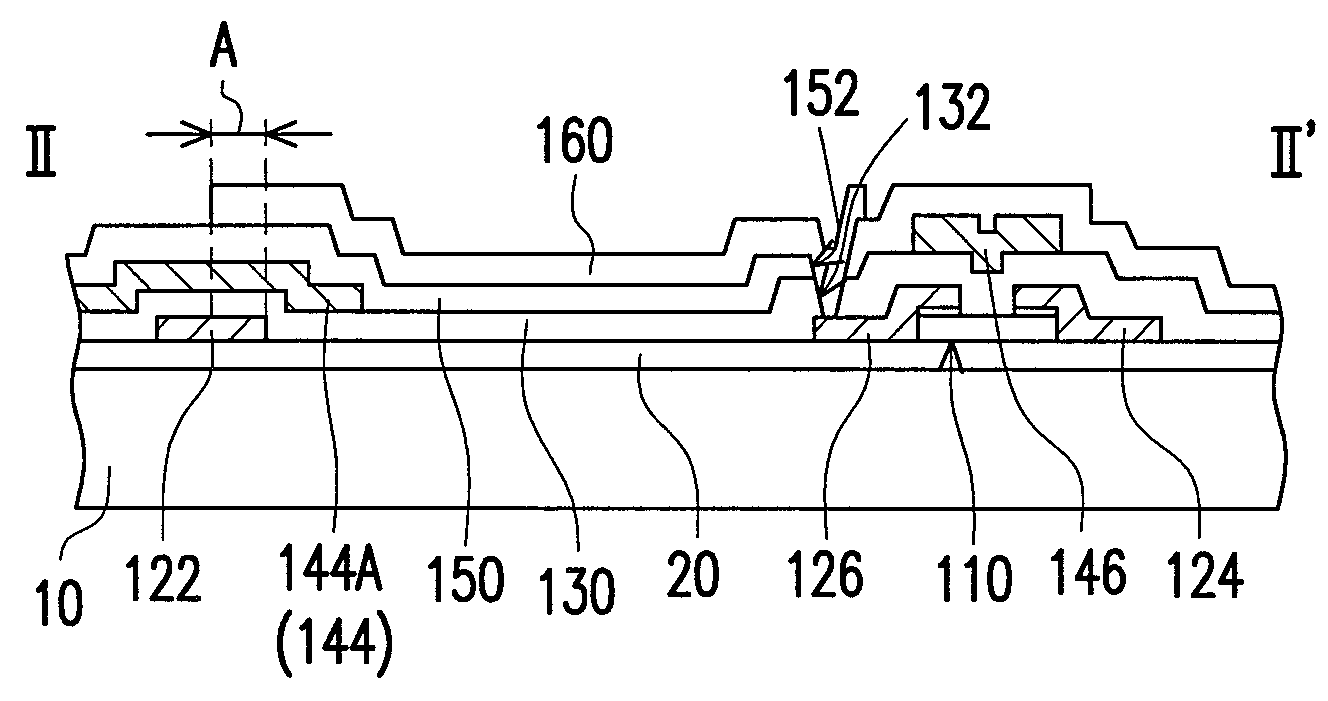

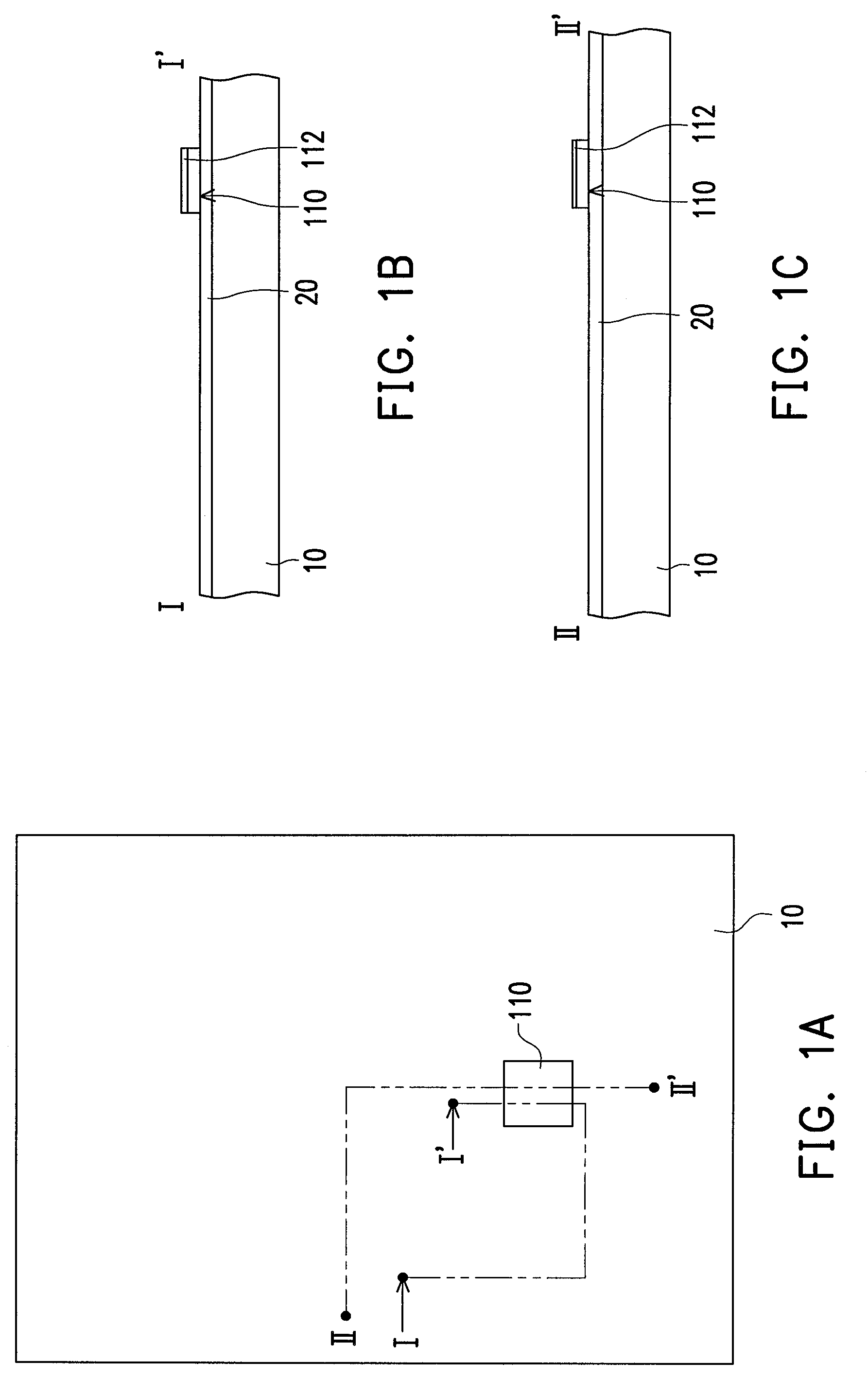

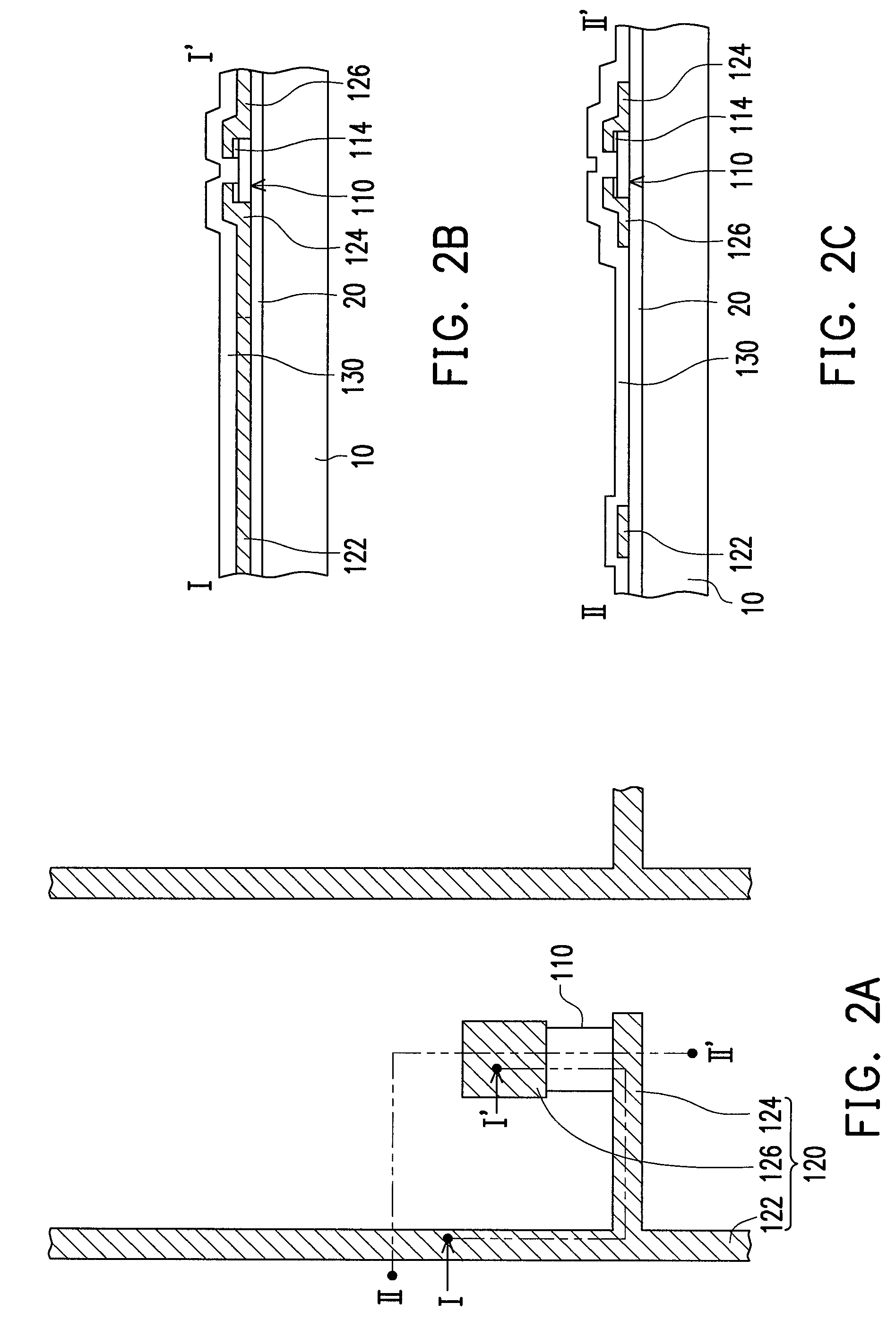

An active member array structure and the corresponding manufacturing method

ActiveCN101217153AImprove the display aperture ratioReduce stray capacitanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

The invention relates to an active element array structure, which is arranged on a base plate, the invention includes a first patterning conductor layer, a patterning grid insulation layer, a patterning semiconductor layer, a second patterning conductor layer, a patterning flat layer and a transparent conductive layer. The patterning grid insulation layer is provided with a first opening to expose part of the first patterning conductor layer. The patterning semiconductor layer is arranged on the patterning grid insulation layer. The second patterning conductor layer is arranged on the patterning semiconductor layer. The patterning flat layer is provided with a second opening to expose part of the first patterning conductor layer and part of the second patterning conductor layer. The transparent conductive layer is comprehensively arranged on the base plate. Part of the transparent conductive layer which is arranged in the first opening and the second opening is disconnected between the base plate and the patterning flat layer. The active element array structure of the invention can be applied in a liquid crystal display panel to enhance the display opening rate of the liquid display crystal panel. The invention also provides a manufacturing method of the active element array structure, which can reduce needed processing cost during the manufacture of the active element array structure.

Owner:AU OPTRONICS CORP

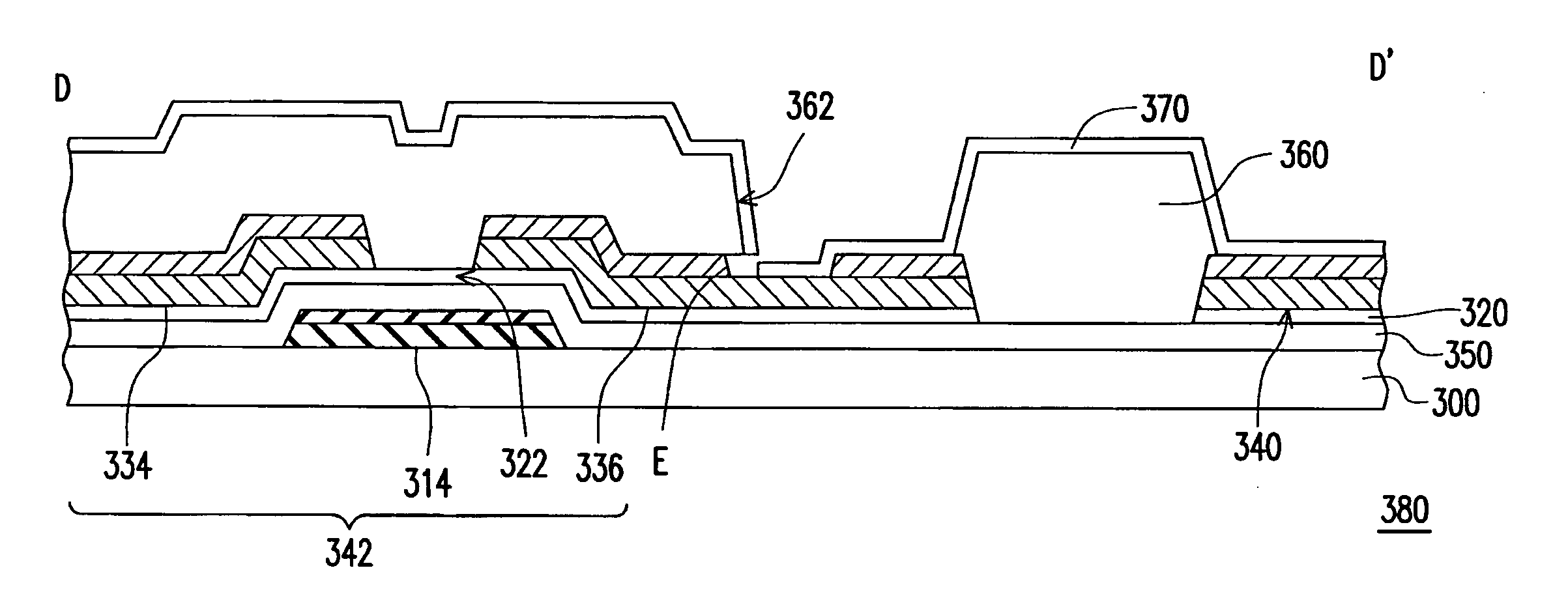

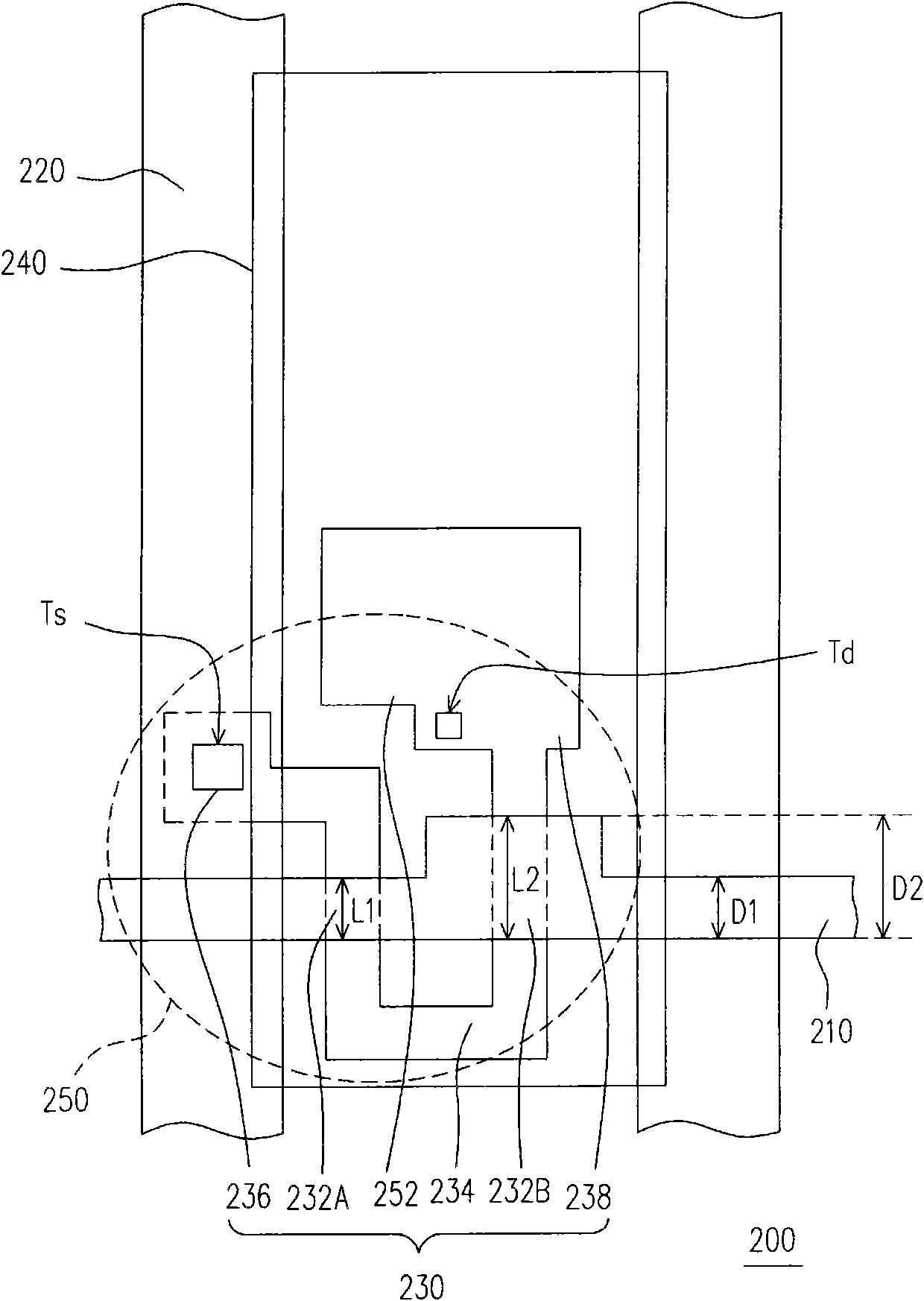

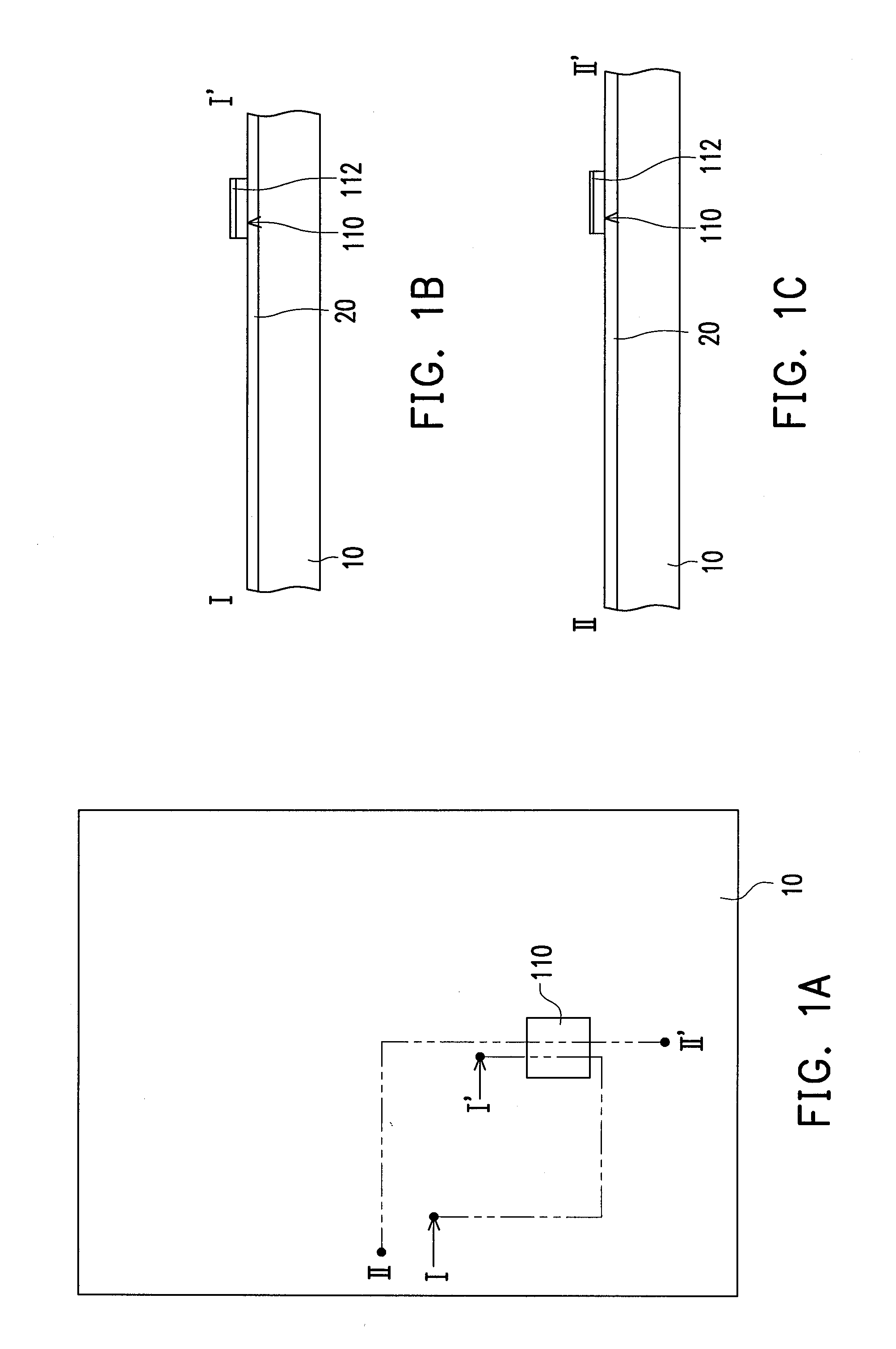

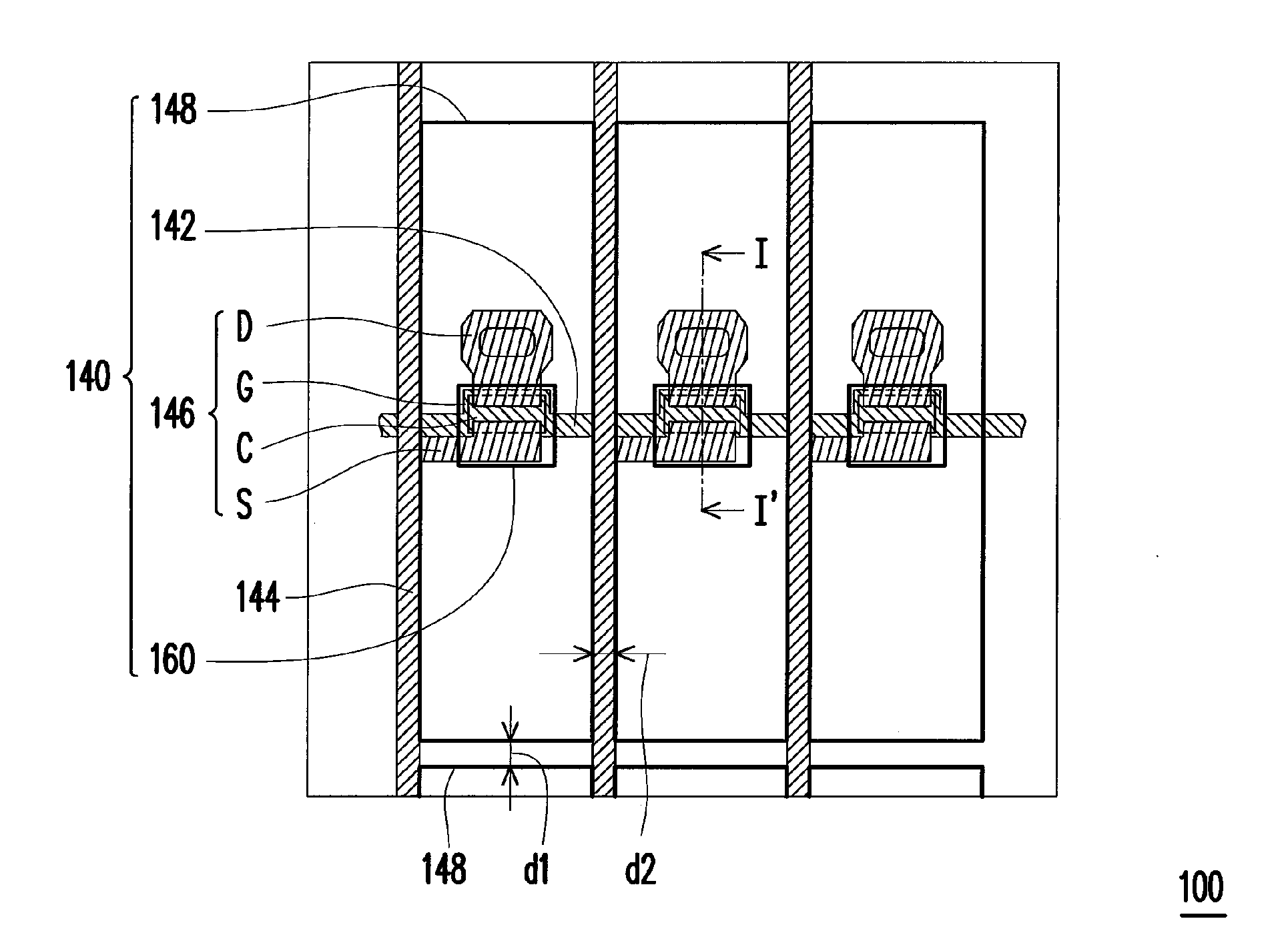

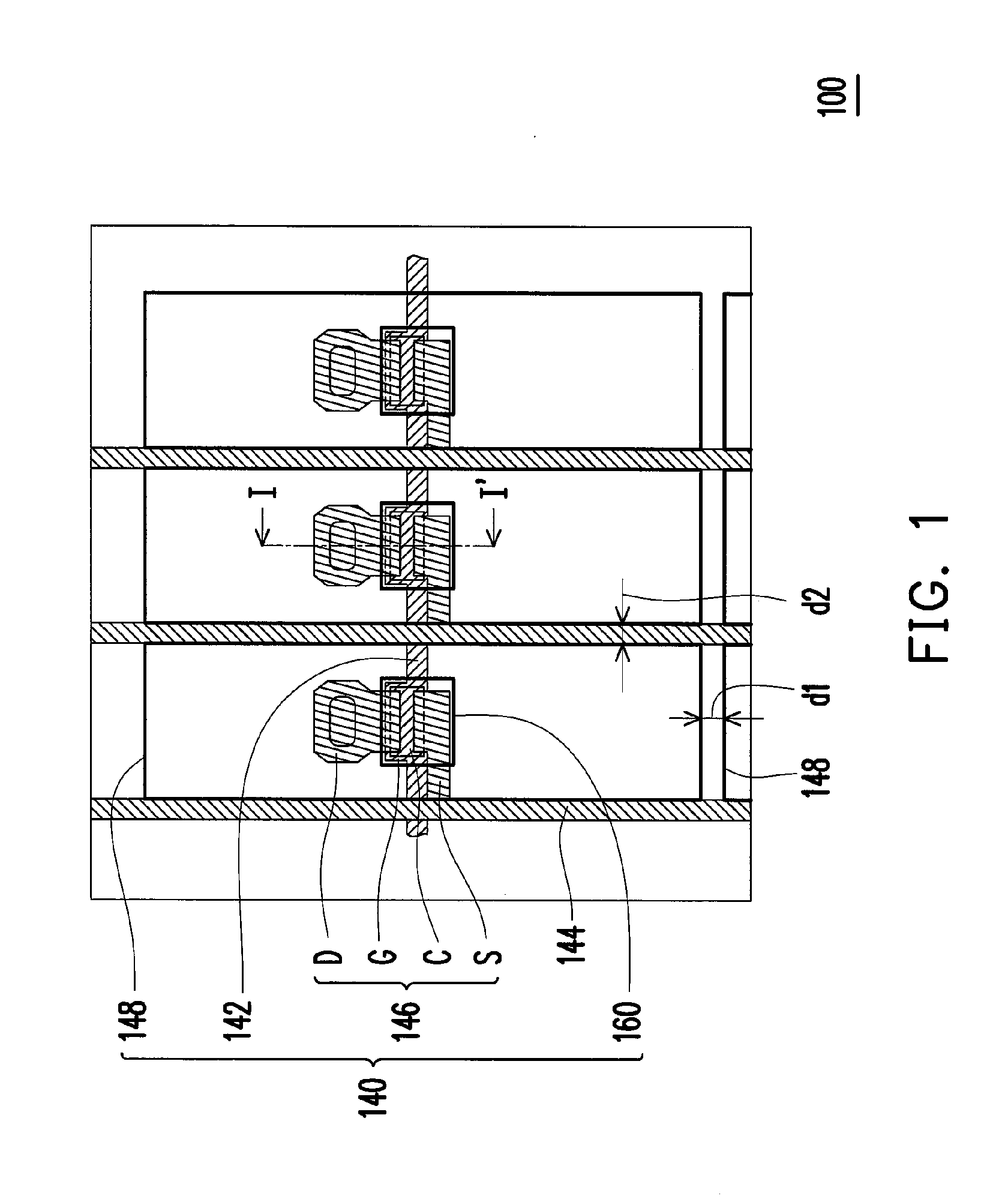

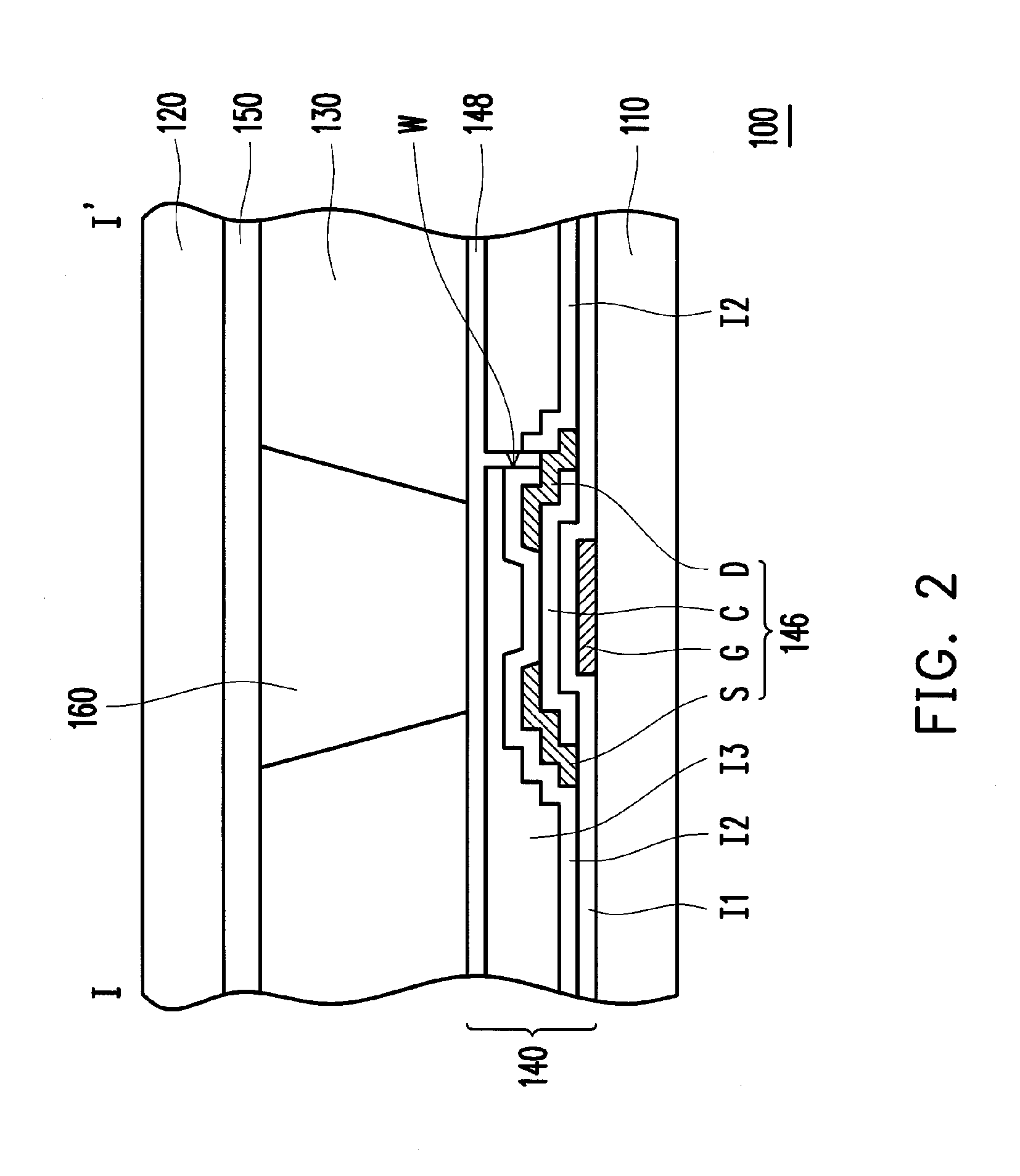

Pixel structure and fabrication method of pixel structure

ActiveUS20130119386A1Sufficient storage capacitanceImprove the display aperture ratioTransistorSolid-state devicesInsulation layerScan line

A pixel structure and its fabrication method are provided. The pixel structure includes a channel layer, a first patterned metal layer, a first insulation layer, a second patterned metal layer, a second insulation layer, and a pixel electrode. The first patterned metal layer includes a data line, a source, and a drain. The first insulation layer has a first opening exposing the drain. The second patterned metal layer includes a scan line and a capacitor electrode. The capacitor electrode has at least one first portion overlapping the data line. The second insulation layer has a second opening communicating with the first opening to expose the drain. The pixel electrode is connected to the drain through the first opening and the second opening and at least overlaps the first portion of the capacitor electrode.

Owner:AU OPTRONICS CORP

Display panel

InactiveUS20120169576A1High aperture ratioDesirable efficiencyStatic indicating devicesNon-linear opticsCross overLiquid-crystal display

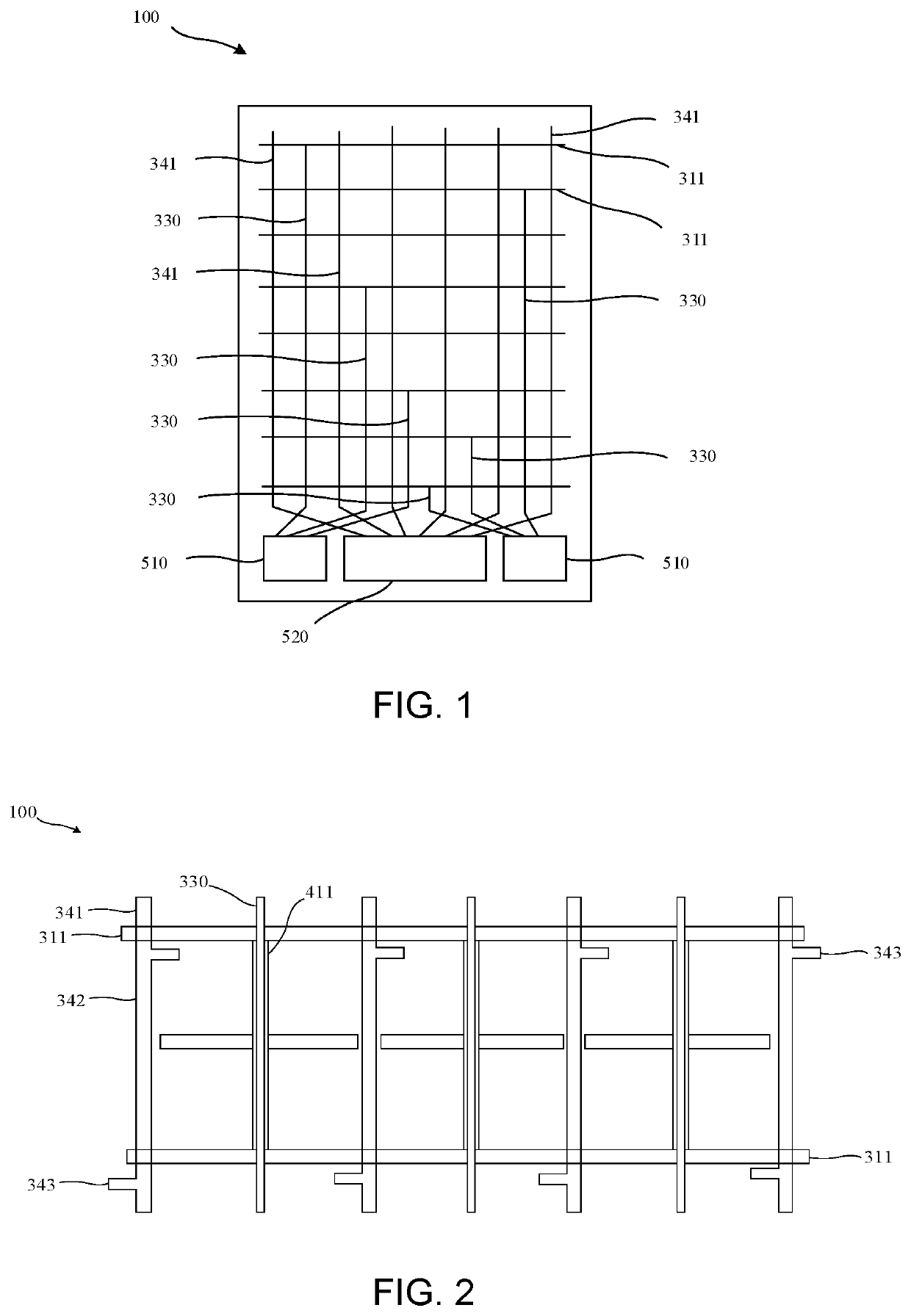

A display panel including a first substrate, a second substrate, a liquid crystal layer, a pixel structure array, a common electrode layer, and spacers is provided. The liquid crystal layer is disposed between the first substrate and the second substrate opposite thereto. The pixel structure array disposed on the first substrate is located between the liquid crystal layer and the first substrate and includes scan lines, data lines, active devices, and pixel electrodes. Each active device is connected to one scan line and one data line intersected therewith. Each pixel electrode crosses over one data line and one active device and is electrically connected to the corresponding one active device. The common electrode layer is disposed on the second substrate. The spacers disposed between the first substrate and the second substrate are located above the scan lines. The spacers are respectively located at centers of the pixel electrodes.

Owner:WINTEK CHINA TECH LTD +1

Pixel unit, liquid crystal display panel, electro-optical apparatus, and methods for manufacturing the same

ActiveUS7969535B2Simple designResolution problemVacuum evaporation coatingSemiconductor/solid-state device manufacturingUltraviolet lightsLiquid crystal molecule

A pixel unit having a display area is provided. The pixel unit includes a first substrate, a second substrate, a liquid crystal layer, and at least one ultraviolet light (UV) absorption pattern. The second substrate is disposed in parallel to the first substrate, and the liquid crystal layer is disposed between the first substrate and the second substrate. The UV absorption pattern is disposed between the first substrate and the second substrate. A part of the display area overlaps the UV absorption pattern to define at least one first alignment area, while the part of the display area which does not overlap the UV absorption pattern defines at least one second alignment area. The liquid crystal molecules of the liquid crystal layer present different pre-tilt angles in the first alignment area and the second alignment area.

Owner:AU OPTRONICS CORP

Pixel structure

ActiveCN107561805ATaking into account the display effectImprove color castNon-linear opticsCapacitanceEngineering

The present disclosure provides a pixel structure including a first active element, a first pixel electrode, a first capacitor electrode, a second capacitor electrode, a second active element, a second pixel electrode, a third capacitor electrode, a fourth capacitor electrode, and a third active element. The first pixel electrode is electrically connected to the first active element and partiallyoverlaps with the first capacitor electrode. The second capacitor electrode is electrically connected to the first active element and partially overlaps with the first capacitor electrode. The secondpixel electrode is electrically connected to the second active element and partially overlaps with the third capacitor electrode. The fourth capacitor electrode is electrically connected to the secondactive element and partially overlaps with the third capacitor electrode. The third active element and the second active element are electrically connected. The first capacitor electrode, the third active element, and the third capacitor electrode are electrically connected to each other. The pixel structure of the present invention can solve the problems of color cast and viewing angle problems,and simultaneously improve the display aperture ratio and the wide viewing angle display effect.

Owner:AU OPTRONICS CORP

Method of manufacturing active matrix array structure

ActiveUS7754547B2Improve the display aperture ratioReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixOptoelectronics

An active matrix array structure, disposed on a substrate, includes a first patterned conductive layer, a patterned gate insulating layer, a patterned semiconductor layer, a second patterned conductive layer, a patterned overcoat layer and a transparent conductive layer. The patterned gate insulating layer has first openings that expose a part of the first patterned conductive layer. The patterned semiconductor layer is disposed on the patterned gate insulating layer. The second patterned conductive layer is disposed on the patterned semiconductor layer. The patterned overcoat layer has second openings that expose a part of the first patterned conductive layer and a part of the second patterned conductive layer. The transparent conductive layer is completely disposed on the substrate. The transparent conductive layer disposed in the first openings and the second openings is broken off at a position that is in between the substrate and the patterned overcoat layer.

Owner:AU OPTRONICS CORP

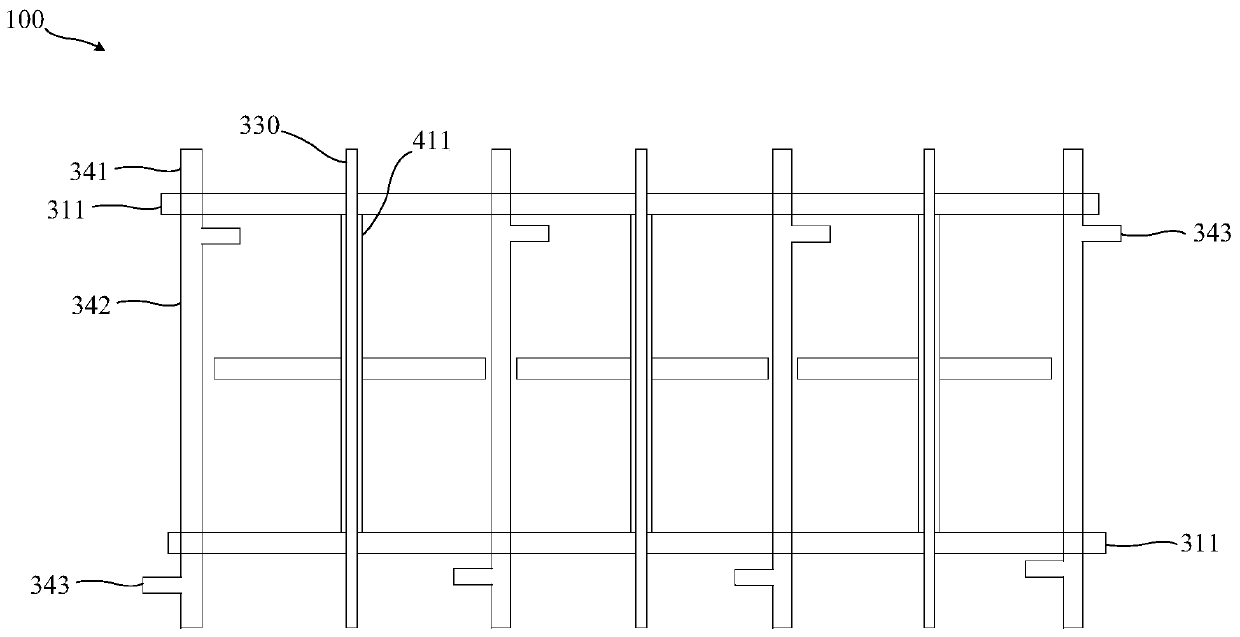

Display panel and display device

InactiveCN111258141AImprove the display aperture ratioReduce widthStatic indicating devicesSolid-state devicesScan lineDisplay device

The invention discloses a display panel and a display device. The display panel comprises a first substrate, a driving circuit layer located on the first substrate and a first common electrode layer located on the driving circuit layer. The display panel further comprises at least one scanning signal transmission line located between two adjacent data lines and parallel to the data lines, and theone scanning signal transmission line is electrically connected with a scanning line, wherein the scanning signal transmission line and the driving circuit layer are arranged on the same layer. According to the display panel, the scanning signal transmission lines are led to the bottom edge of the display panel through the display area of the display panel and arranged in a pixel unit, the widthsof other three frames of the display screen are reduced, the display aperture ratio of the display panel is increased, and the display effect is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

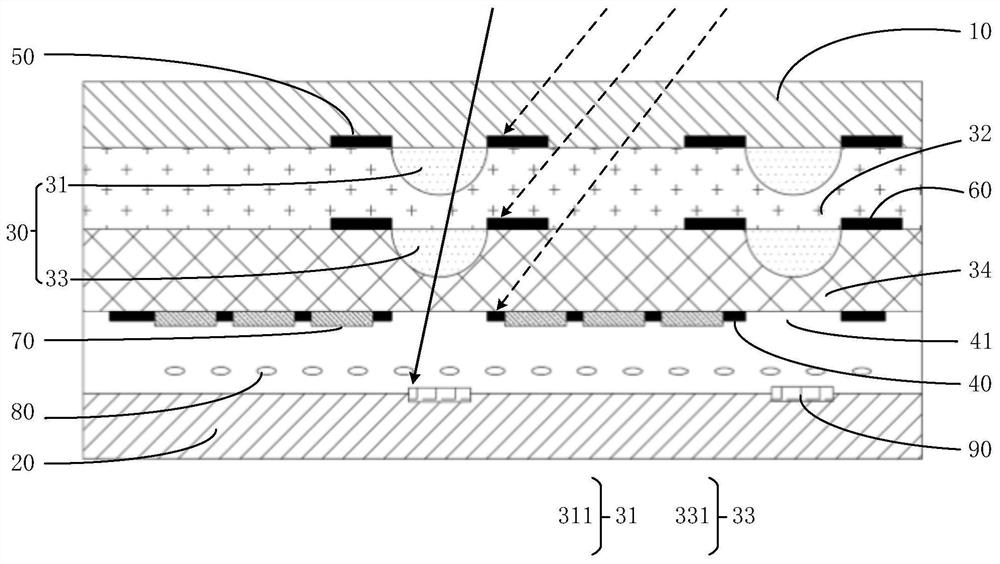

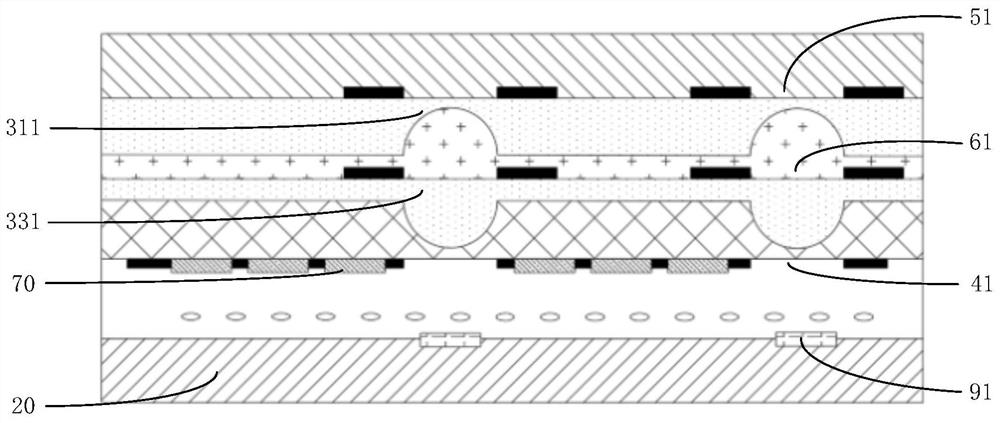

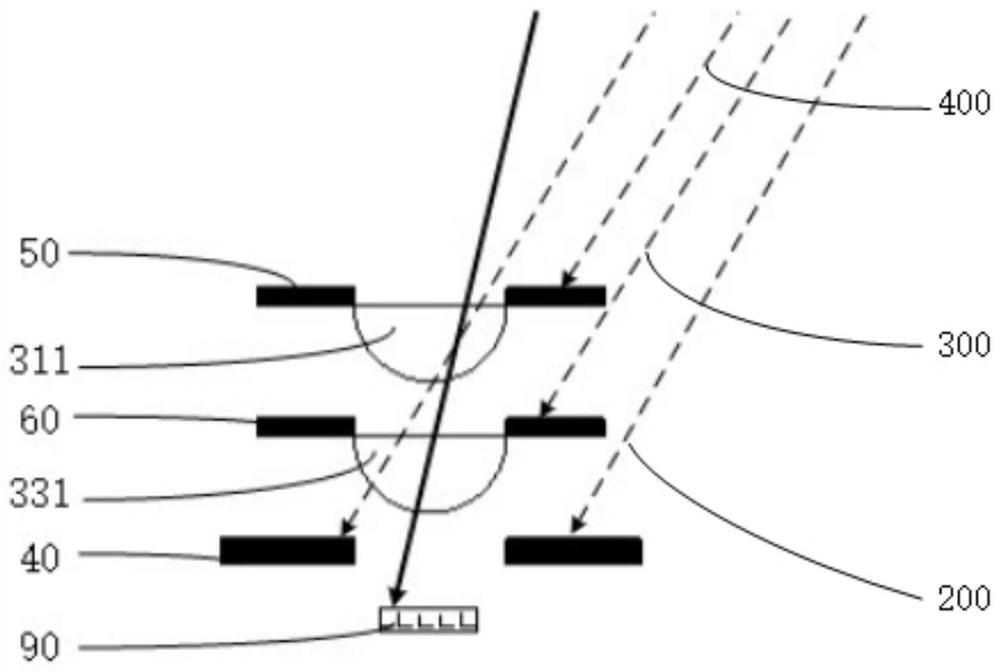

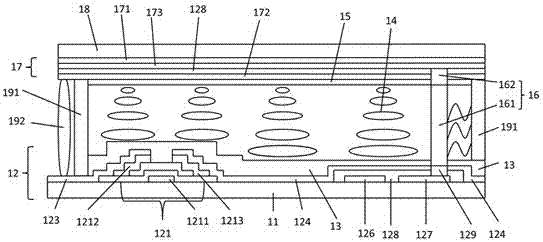

Liquid crystal display panel and display device

ActiveCN112882279AImprove the display aperture ratioAvoid mutual interferencePrint image acquisitionNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a liquid crystal display panel and a display device, and the liquid crystal display panel comprises a first black matrix which is provided with a plurality of first through holes; a first micro-lens array which comprises a plurality of first micro-lens units, a second micro-lens array which comprises a plurality of second micro-lens units, wherein the plurality of first micro-lens units and the plurality of second micro-lens units are arranged in a one-to-one correspondence manner; and a photosensitive sensor array which comprises a plurality of photosensitive sensors; wherein the plurality of second micro-lens units and the plurality of first through holes are arranged in a one-to-one correspondence manner, the plurality of first through holes and the plurality of photosensitive sensors are arranged in a one-to-one correspondence manner, and each first through hole, the orthographic projection of the second micro-lens unit arranged corresponding to the first through hole and the orthographic projection of the photosensitive sensor arranged corresponding to the first through hole on the array substrate are at least partially overlapped. According to the liquid crystal display panel provided by the invention, the area of fingerprint signals can be reduced through the combination of the double-layer lens, so that the area of an area for collecting the fingerprint signals is reduced, and the display aperture ratio is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Display panel and display device

InactiveCN111258144AImprove the display aperture ratioSolve the technical problem of low display aperture ratioNon-linear opticsCapacitanceDisplay device

The invention discloses a display panel and a display device. The display panel comprises a first substrate, a driving circuit layer located on the first substrate and a pixel electrode layer locatedon the driving circuit layer, wherein the pixel electrode layer comprises at least one first main electrode and at least one second main electrode; and the display panel further comprises a capacitorelectrode layer arranged on the same layer as the drive circuit layer, and the capacitor electrode layer and part of the pixel electrode layer form a storage capacitor. The capacitor electrode layer at least comprises a first capacitor unit, the orthographic projection of the first capacitor unit on the pixel electrode layer is located in the first main electrode or / and the second main electrode,and the first main electrode is perpendicular to the second main electrode. The orthographic projection of the capacitor electrode layer on the pixel electrode layer is located in the main electrode,so that the display aperture opening ratio is increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Pixel structure

ActiveCN101221960BReduce leakage currentImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor

Owner:AU OPTRONICS CORP

Pixel structure

ActiveCN101950746BReduce leakage currentImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorScan line

The invention discloses a pixel structure which comprises a scanning line, a data line, a semiconductor pattern, a source region, a drain region and a pixel electrode, wherein the scanning line is provided with a branch; the data line and the scan line are arranged in a staggered mode; the branch is positioned below the data line and overlaps the data line; the semiconductor pattern comprises at least two channel regions positioned below the scanning line, at least one doped region connected between every two channel regions; the pixel electrode is electrically connected with the drain region; the source region is connected between one channel region and the data line; and the drain region is connected between the other channel region and the pixel electrode. By utilizing the changes of the semiconductor pattern, the semiconductor pattern and the scanning line are intersected in at least two regions, thereby being beneficial to reducing the drain current of the polysilicon thin film transistor.

Owner:AU OPTRONICS CORP

An active member array structure and the corresponding manufacturing method

ActiveCN101217153BImprove the display aperture ratioReduce stray capacitanceSemiconductor/solid-state device detailsSolid-state devicesInsulation layerElectrical conductor

An active element array structure, which is arranged on a base plate, includes a first patterning conductor layer. A patterning grid insulation layer has first opening exposing part of the first patterning conductor layer. The first opening exposes an edge of a scanning pad. The first patterning conductor layer has an undercut effect side wall at the edge of the scanning pad. A patterning semiconductor layer is arranged on the patterning grid insulation layer. A second patterning conductor layer is arranged on the patterning semiconductor layer. A patterning flat layer has a second opening exposing part of the first patterning conductor layer and part of the second patterning conductor layer. A transparent conductive layer is comprehensively arranged on the base plate. Part of the transparent conductive layer which is arranged in the first opening and the second opening is disconnected between the base plate and the patterning flat layer. The active element array structure of the invention can be applied in a liquid crystal display panel to enhance the display opening rate of the liquid display crystal panel. The invention also provides a manufacturing method of the active element array structure, which can reduce needed processing cost during the manufacture of the active element array structure.

Owner:AU OPTRONICS CORP

Display panel, manufacturing method and electronic device

ActiveCN105895664BGuaranteed image display effectHigh-resolutionSolid-state devicesSemiconductor devicesEngineeringMaterials science

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

pixel structure

ActiveCN107561805BTaking into account the display effectImprove color castNon-linear opticsCapacitanceEngineering

A pixel structure including a first active device, a first pixel electrode, a first capacitor electrode, a second capacitor electrode, a second active device, a second pixel electrode, a third capacitor electrode, a fourth capacitor electrode, and a third active device is provided. The first pixel electrode is electrically connected to the first active device and overlaps the first capacitive electrode. The second capacitor electrode is electrically connected to the first active device and overlaps the first capacitor electrode. The second pixel electrode is electrically connected to the second active device and overlaps the third capacitive electrode. The fourth capacitor electrode is electrically connected to the second active device and overlaps the third capacitor electrode. The third active device is electrically connected to the second active device. The first capacitor electrode, the third active device, and the third capacitor electrode are electrically connected to each other.

Owner:AU OPTRONICS CORP

Display panel and display device

ActiveUS20220309986A1Reduce the ratioReduce widthStatic indicating devicesSolid-state devicesDisplay deviceHemt circuits

The present invention provides a display panel and a display device. The display panel comprises a first substrate, a driving circuit layer, a first common electrode layer, and at least one scanning signal transmission line located between two adjacent data lines and arranged in parallel with the data lines. The scanning signal transmission line and the driving circuit layer are arranged in a same layer. The present invention reduces widths of frames and increases display aperture ratio by directing the scanning signal transmission line to a bottom edge of the display panel and setting the scanning signal transmission line in pixel units.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH LTD

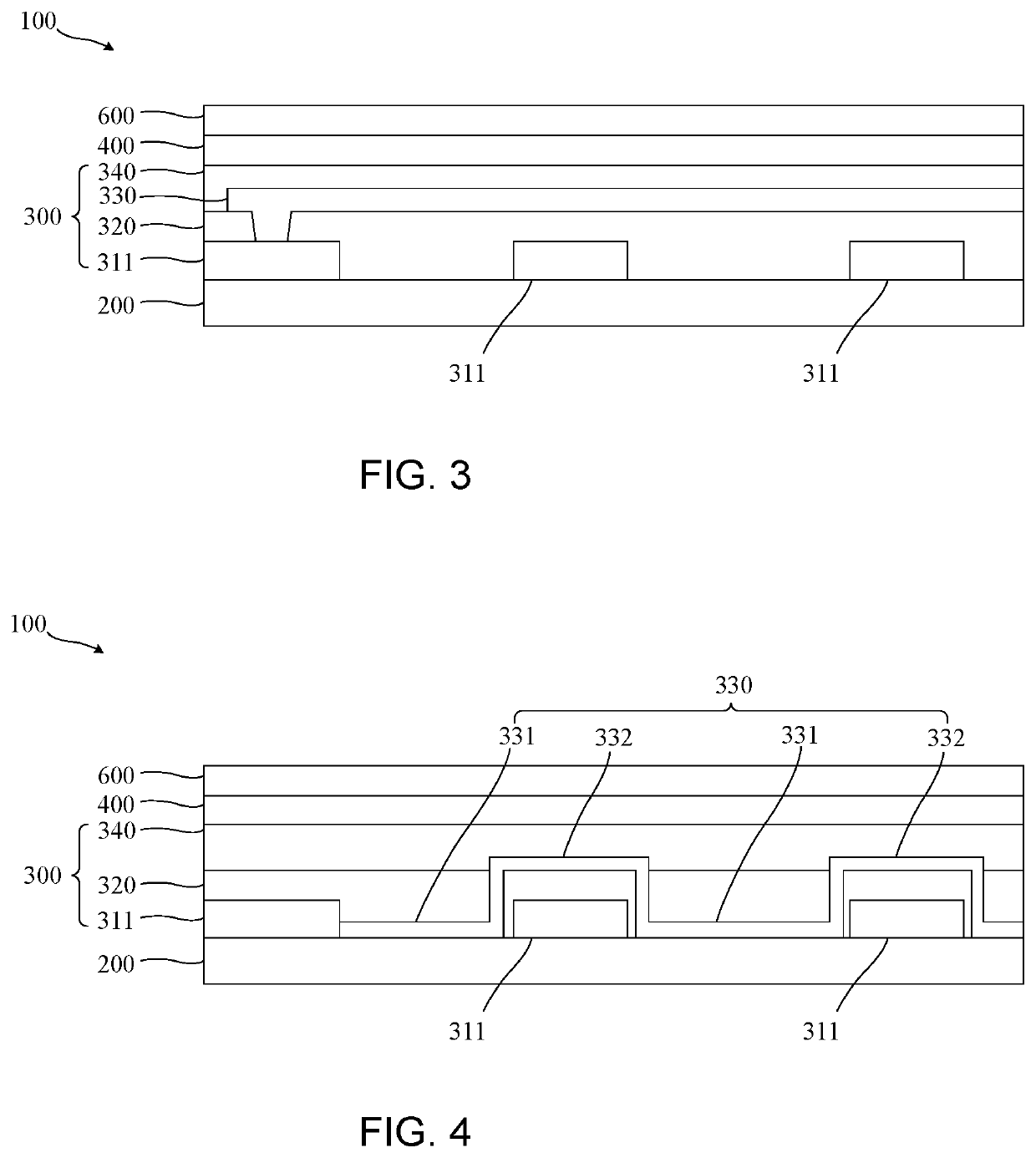

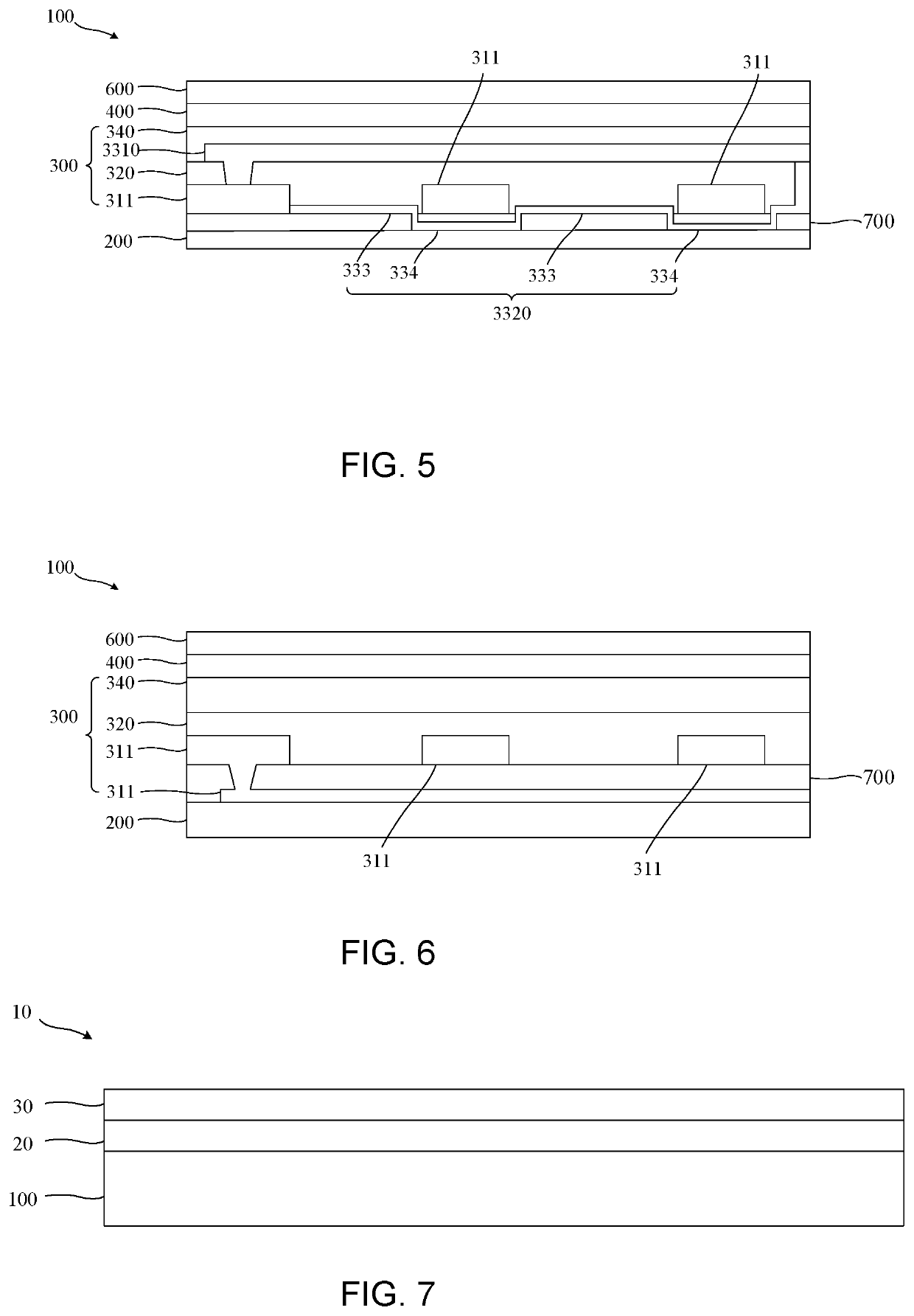

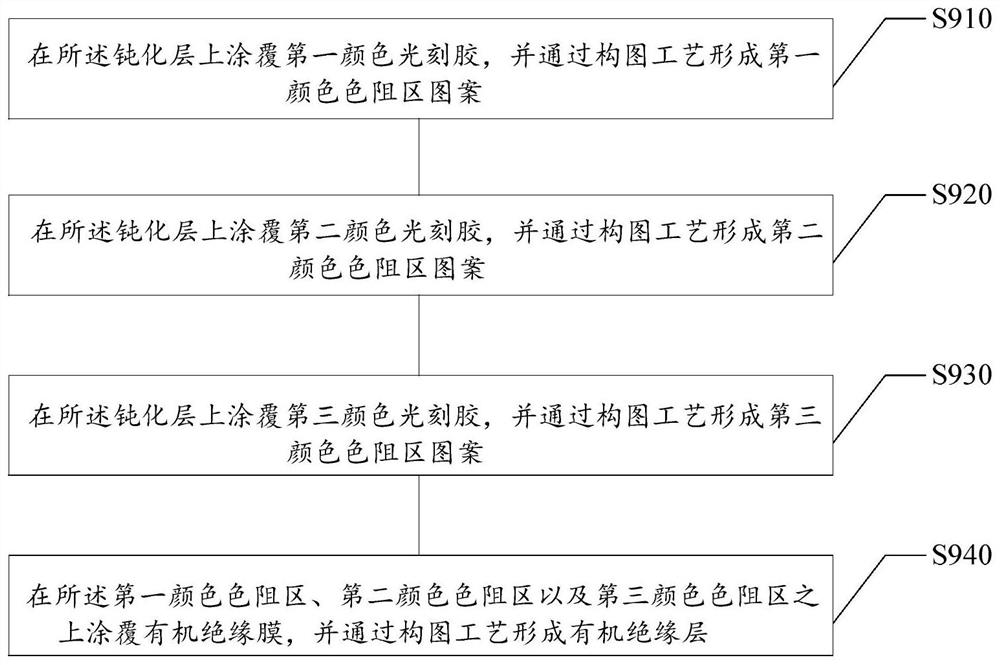

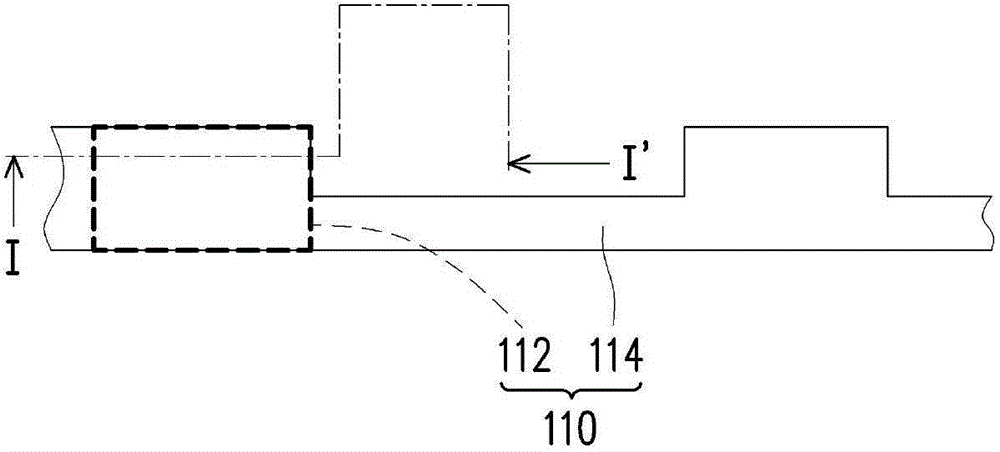

Display device, array substrate and method for manufacturing array substrate

ActiveCN107170754BSolve problems such as light leakageImprove the display aperture ratioSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayDisplay device

The disclosure relates to an array substrate, a manufacturing method thereof, and a display device, and relates to the technical field of liquid crystal display. The array substrate includes a base substrate, a thin film transistor layer on the base substrate, a passivation layer on the thin film transistor layer, a color resistance layer on the passivation layer, and a color resistance layer on the color resistance layer for An organic insulating layer that isolates the color resist layer. On the one hand, the present disclosure manufactures the color-resist layer in the array substrate, which can effectively solve the problems of light leakage caused by alignment deviation in the process of aligning liquid crystal display devices, thereby improving the display aperture ratio; on the other hand, the organic insulating layer is used as the The isolation layer of the color-resistive layer can improve the isolation effect, and can also avoid the formation of the isolation layer in the CVD chamber in the related art, thereby causing the diffusion of the color-resistor to contaminate the CVD chamber, thereby prolonging the maintenance period and reducing the maintenance cost.

Owner:BOE TECH GRP CO LTD

Pixel structure and manufacturing method of pixel structure

ActiveCN102856322BImprove the display aperture ratioEnough to store capacitanceTransistorSolid-state devicesCapacitanceDielectric

A pixel structure and a method of manufacturing a pixel structure are provided. The pixel structure includes an active device, a gate insulation layer, a dielectric insulation layer, a capacitance electrode, a protection layer and a pixel electrode. The active device includes a gate, a semiconductor channel layer, a source and a drain. The dielectric insulation layer covers the semiconductor channel layer. A dielectric index of the dielectric insulation layer is greater than a dielectric index of the gate insulation layer. The capacitance electrode is overlapped with the drain. The capacitance electrode, the drain and the dielectric insulation layer between the two constitute a storage capacitor structure. The protection layer is disposed on the dielectric insulation layer and the capacitance electrode is located between the protection layer and the dielectric insulation layer. The pixel electrode is disposed on the protection layer and connected to the drain of the active device.

Owner:AU OPTRONICS CORP

Pixel structure and fabrication method of pixel structure

ActiveUS8581256B2Sufficient storage capacitanceImprove the display aperture ratioTransistorSolid-state devicesInsulation layerScan line

A pixel structure and its fabrication method are provided. The pixel structure includes a channel layer, a first patterned metal layer, a first insulation layer, a second patterned metal layer, a second insulation layer, and a pixel electrode. The first patterned metal layer includes a data line, a source, and a drain. The first insulation layer has a first opening exposing the drain. The second patterned metal layer includes a scan line and a capacitor electrode. The capacitor electrode has at least one first portion overlapping the data line. The second insulation layer has a second opening communicating with the first opening to expose the drain. The pixel electrode is connected to the drain through the first opening and the second opening and at least overlaps the first portion of the capacitor electrode.

Owner:AU OPTRONICS CORP

A display with integrated touch function and its manufacturing method

ActiveCN104407726BImprove the display aperture ratioNon-linear opticsInput/output processes for data processingColor gelEngineering

The invention relates to an integrated touch function display screen and a manufacture method thereof. The integrated touch function display screen is characterized by comprising a first substrate, a thin film transistor, a first alignment layer, a liquid crystal molecular layer, a second alignment layer, a plurality of isolation columns, a colorful optical filter layer and a second substrate. The display screen can be manufactured by adopting traditional processes and also can be manufactured by adopting 3D technology, and a touch and display function can be realized if the integrated touch function display screen is provided with a driving and processing assembly. The isolation columns of the invention realizes an isolating and supporting function, and meanwhile, a lead on the second substrate can be connected to the first substrate; and a touch unit is arranged below the display screen to effectively increase a display opening rate. Meanwhile, parts of the processes adopt a 3D printing technology, and the manufacture method is greatly simplified when the manufacture method is compared with a traditional method, multiple complex processes, such as exposure, development, etching and the like, in the traditional processes can be omitted, and production raw materials and the manufacture cost are saved and lowered.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com