Pixel structure and method for manufacturing pixel structure

A pixel structure and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of increasing storage capacitors, display aperture ratio limitations, and difficulty in taking into account high-quality display aperture ratios, etc., and achieves a simple manufacturing method , The effect of high display aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

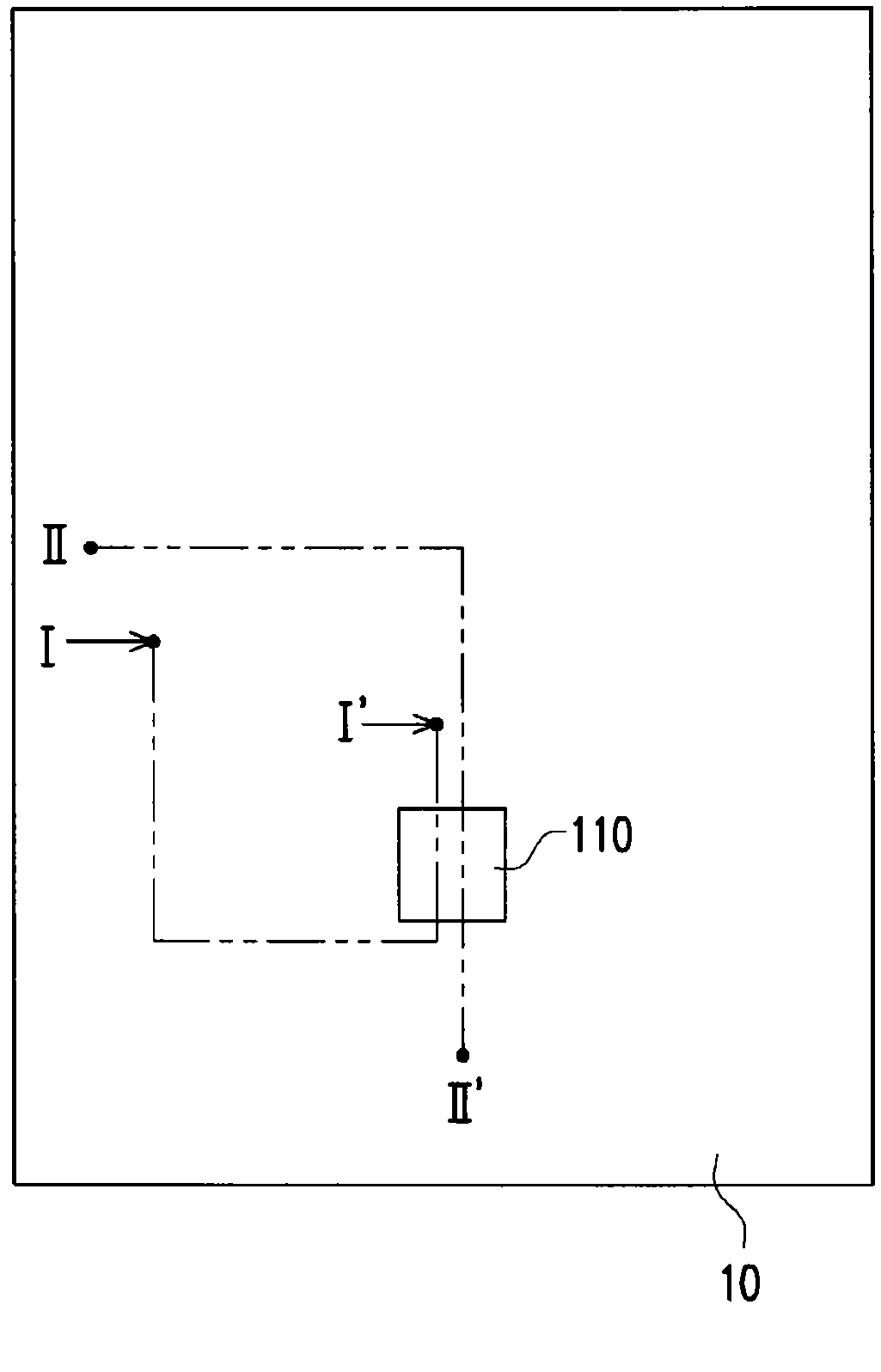

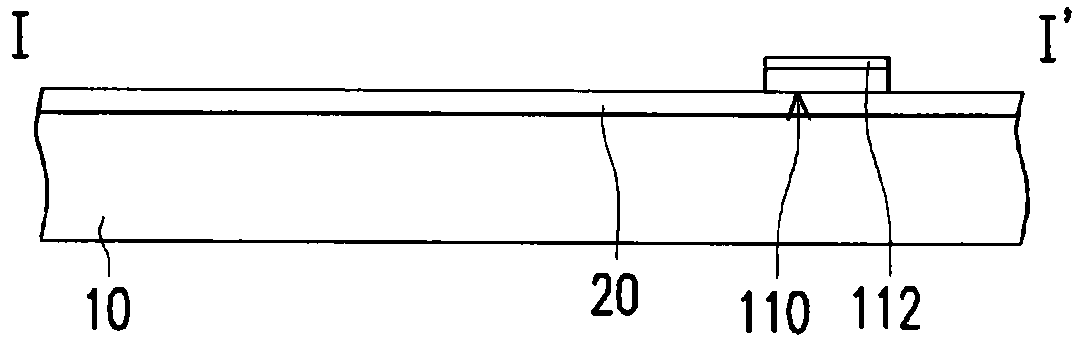

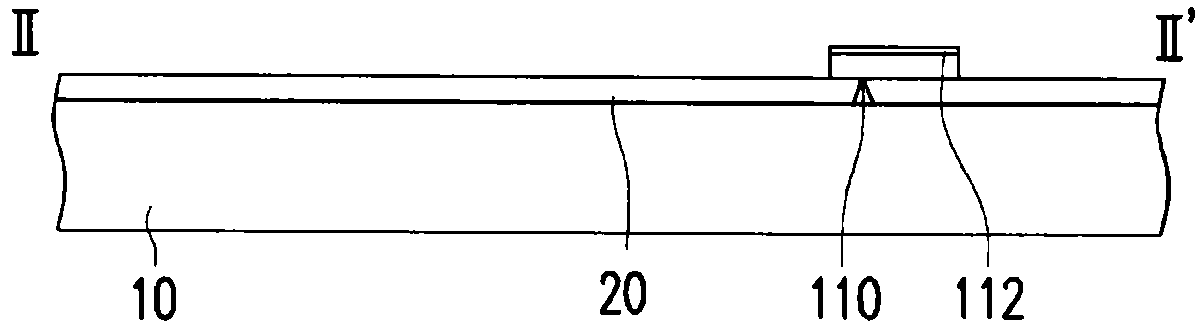

[0059] Figure 1A Shown is a schematic top view of the first photomask manufacturing process in a method for manufacturing a pixel structure according to an embodiment of the present invention, and Figure 1B versus Figure 1C Respectively along Figure 1A The section line I-I' and the section line II-II' show the section. Please also refer to Figure 1A , 1B versus Figure 1C The manufacturing method of this embodiment is, for example, first forming a channel layer 110 on the substrate 10. The channel layer 110 can be manufactured using a first photomask manufacturing process. That is, the specific implementation of this step is, for example, first performing deposition manufacturing processes such as physical vapor deposition, chemical vapor deposition, and sputtering to form an entire layer of semiconductor material on the substrate 10. Next, a lithographic etching manufacturing process is performed through a first photomask (not shown) to pattern the entire layer of semiconduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com