Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Improve installation rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

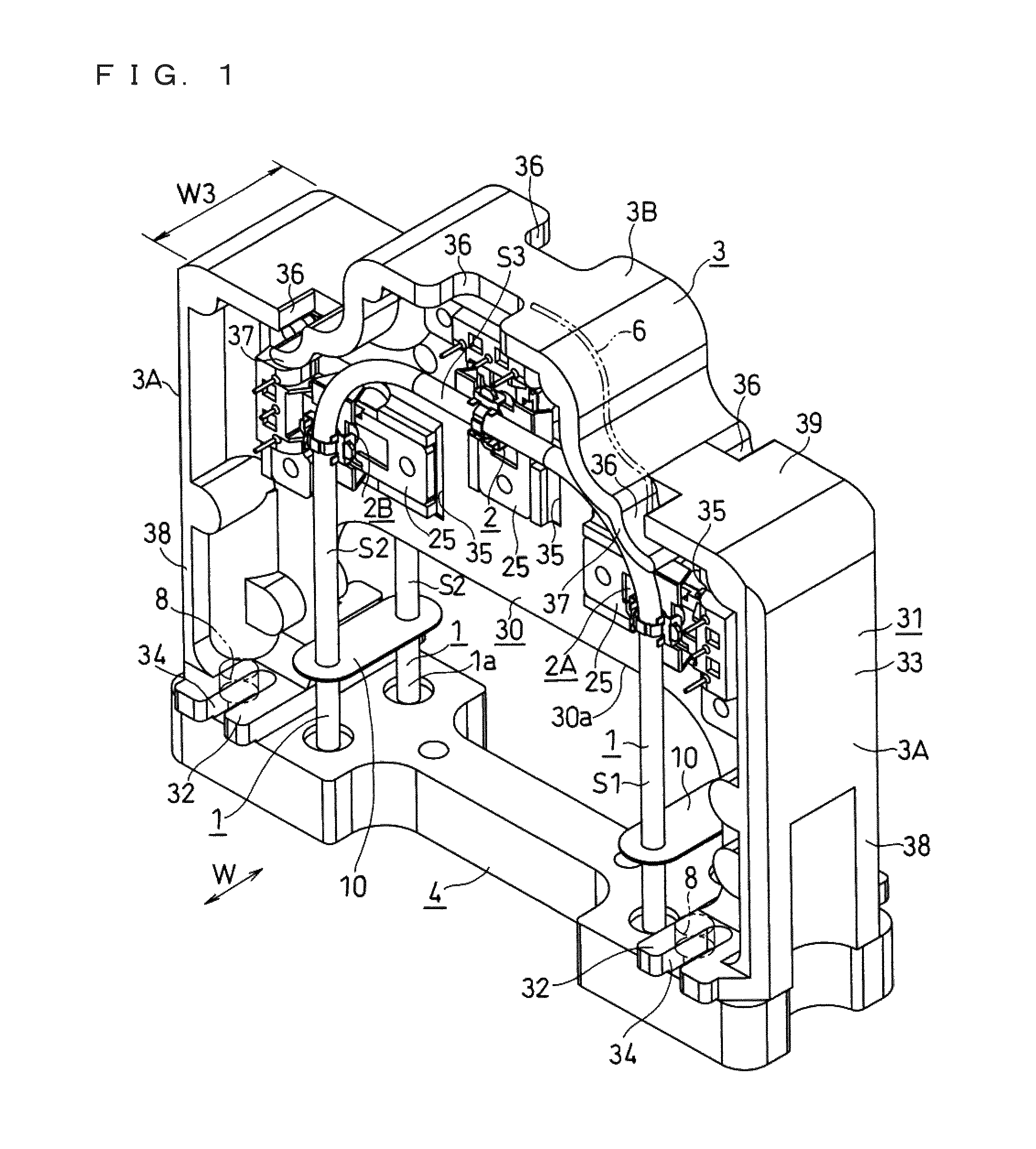

Flowmeter

InactiveUS20100005906A1Reduce thicknessSmall distanceDirect mass flowmetersMechanical engineeringEngineering

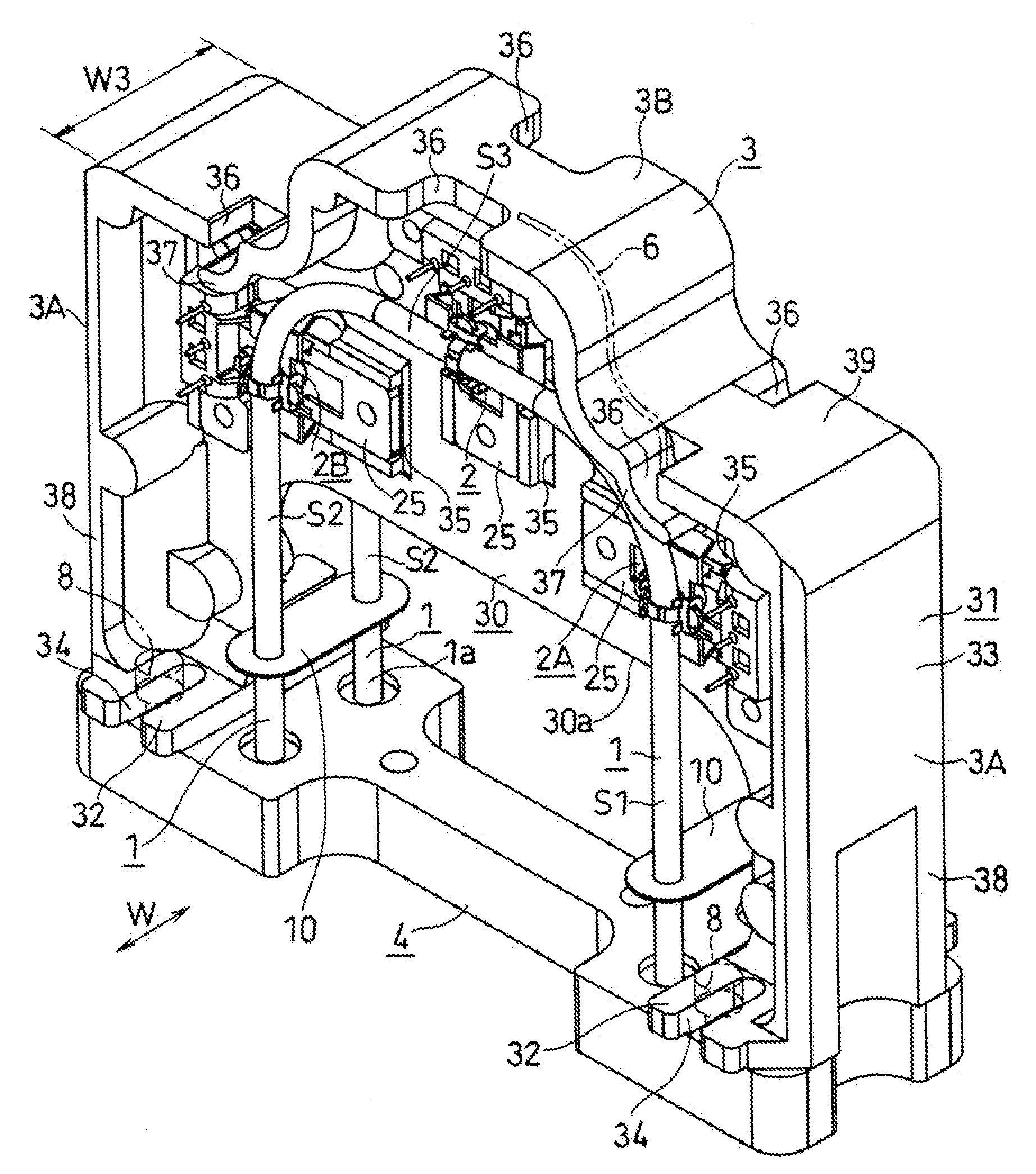

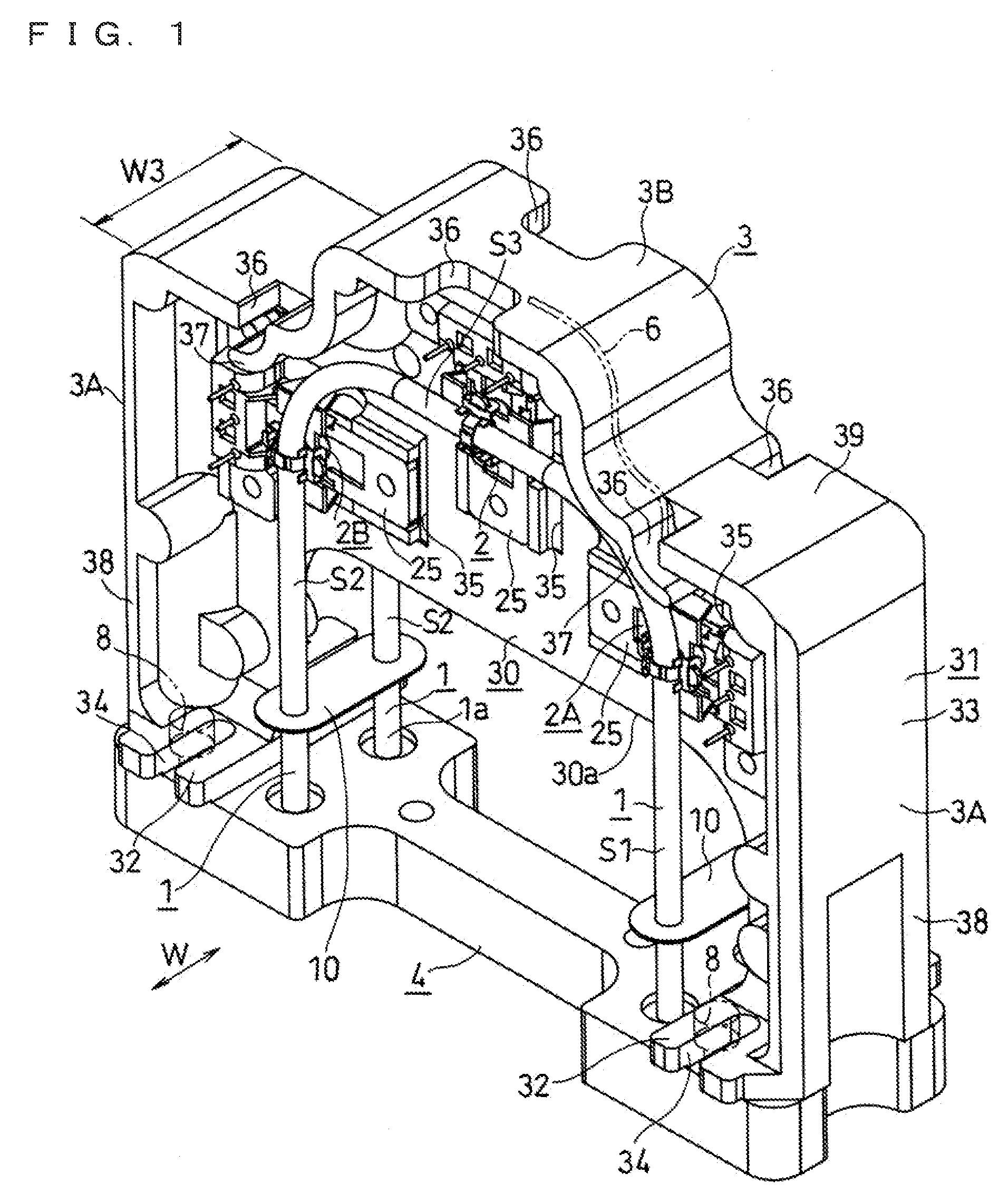

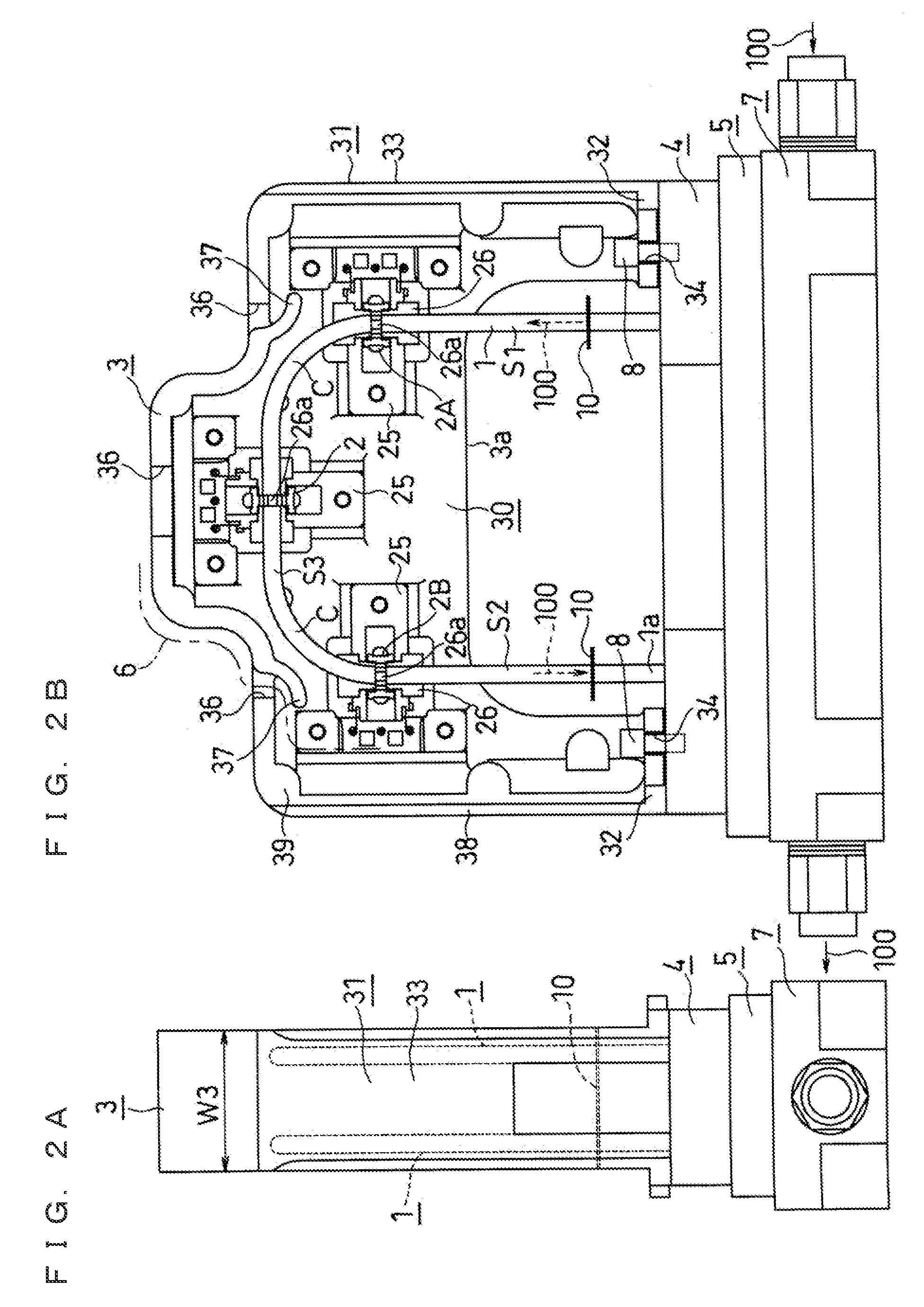

A flow meter of Coriolis type includes a supporting base that supports a pair of fluid pipes in a manner capable of being vibrated, and a frame fixed to the supporting base. The frame is integrally formed with a mounting portion disposed between the fluid pipes and having a thickness that does not interfere with the fluid pipes, a reinforcing portion disposed at the outer circumference of the mounting portion and enhancing the rigidity of the mounting portion, and a fixing portion for being fixed to the supporting base. The reinforcing portion has an outer wall portion that protrudes at least to one side of the thickness direction of the mounting portion, and substantially continuously surrounds the outer circumference of the fluid pipes. Penetrating portions for disposing the coils corresponding to respective magnetic substances mounted on the fluid pipe are formed in the mounting portion.

Owner:KEYENCE

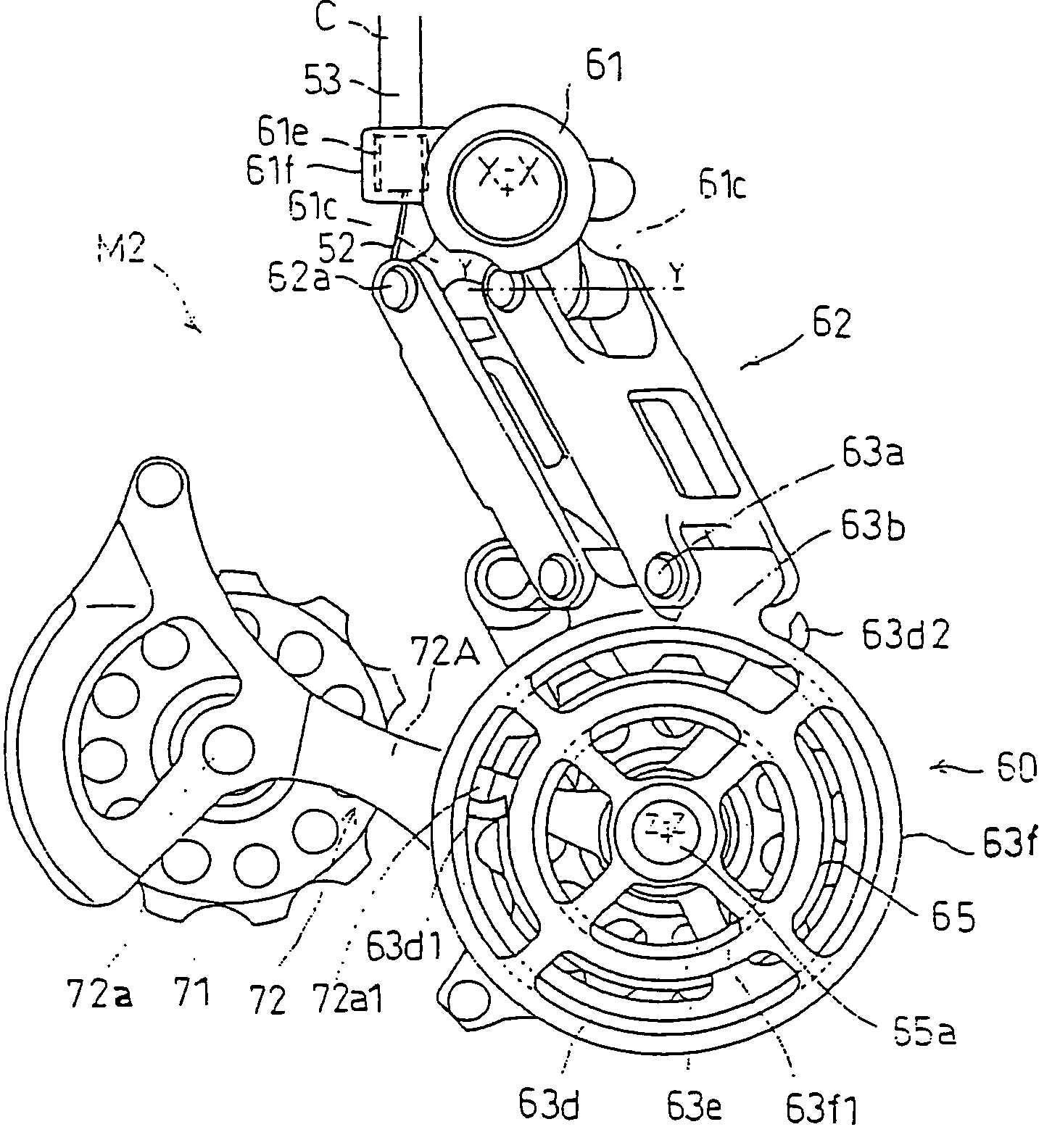

Structure of transmission for bicycle

InactiveUS20050176537A1Improve structureSimple structureWheel based transmissionChain/belt transmissionAbutmentMechanical engineering

To achieve downsizing and weight reduction of a derailleur shaft and the mounting structure thereof and to improve the rigidity of the derailleur shaft without increasing the thickness thereof more than necessary. A transmission case is divided into left and right halves, and the left and right halves are provided with bosses therein having holes opposing each other. The bosses are brought into abutment with each other and united by fitting tightening bolts to the holes of the bosses and tightening the same. A sleeve-shaped derailleur shaft is fitted on the outer periphery of the bosses to support and mount the derailleur shaft. The derailleur shaft includes a hole at the shaft end thereof. A mounting position of the derailleur shaft is achieved by a pin inserted into the hole and a hole provided on one of the cases.

Owner:HONDA MOTOR CO LTD

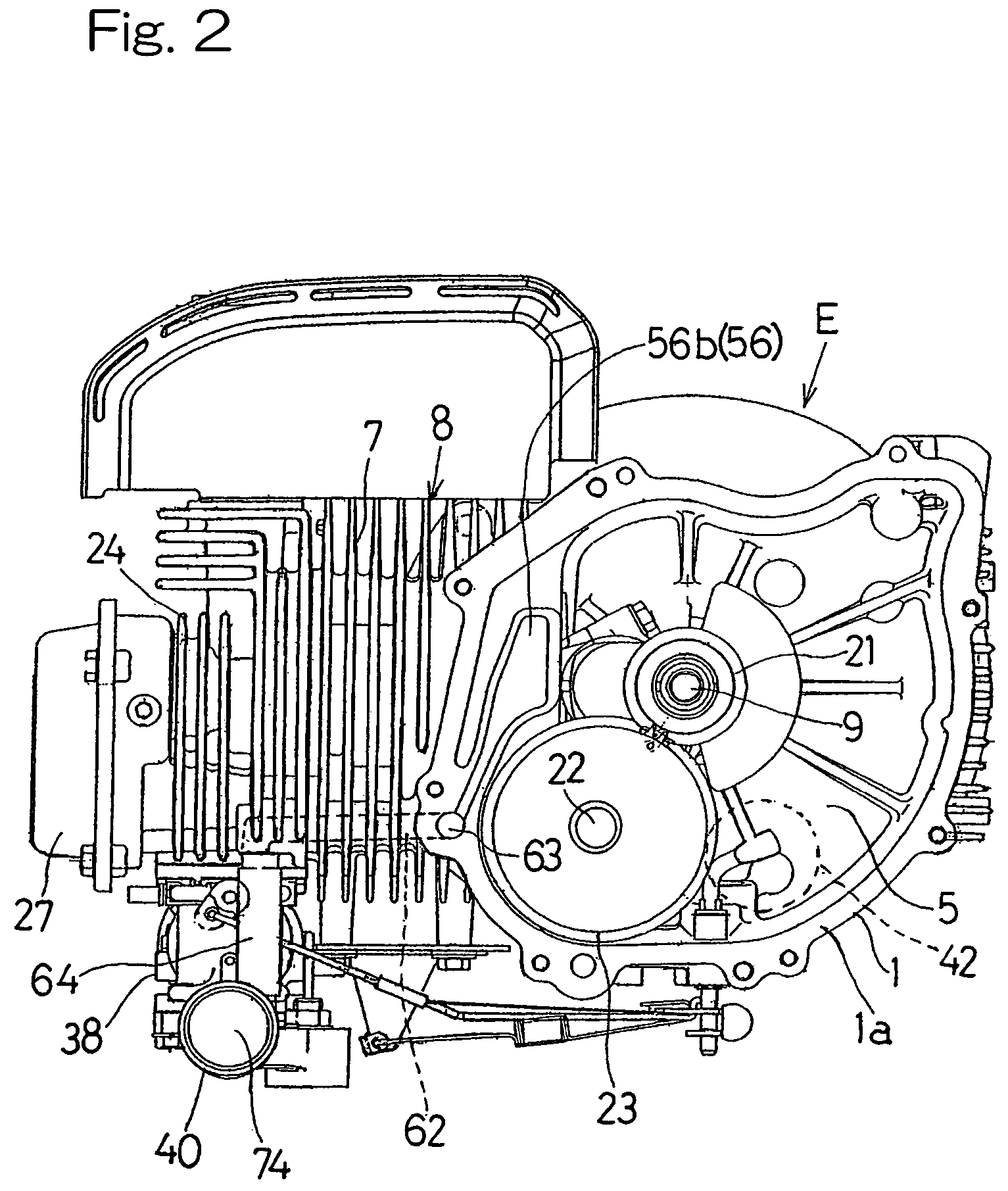

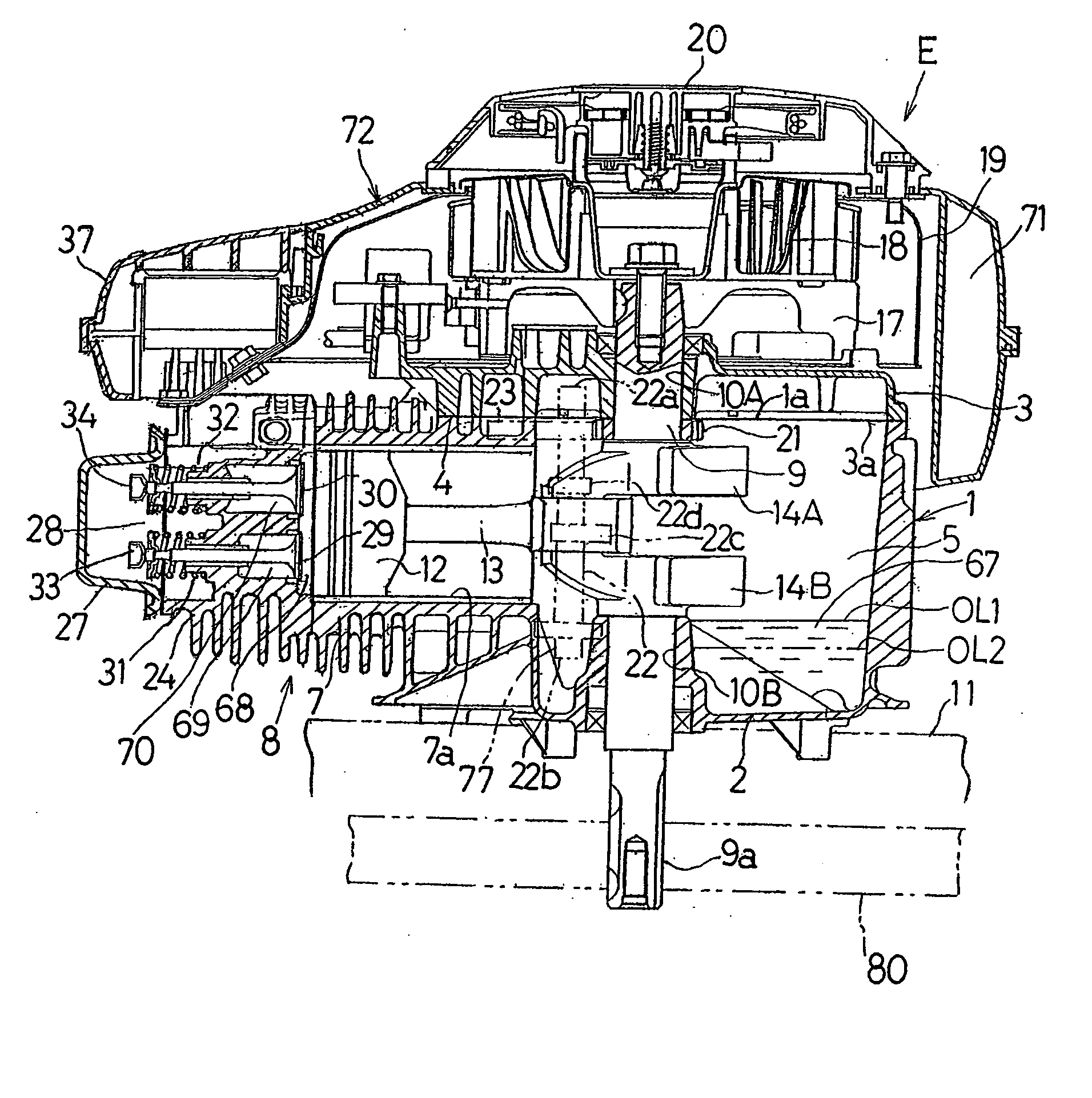

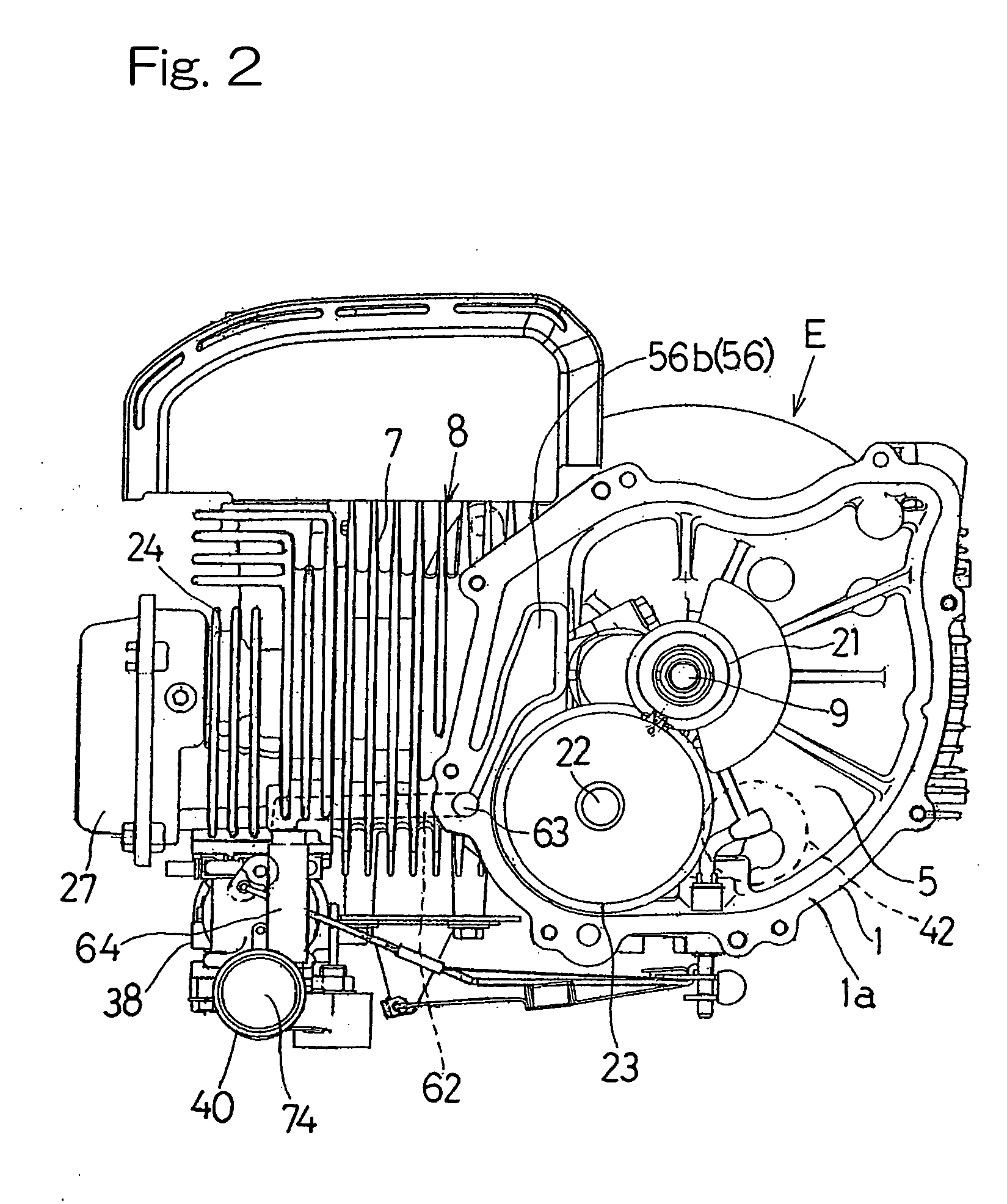

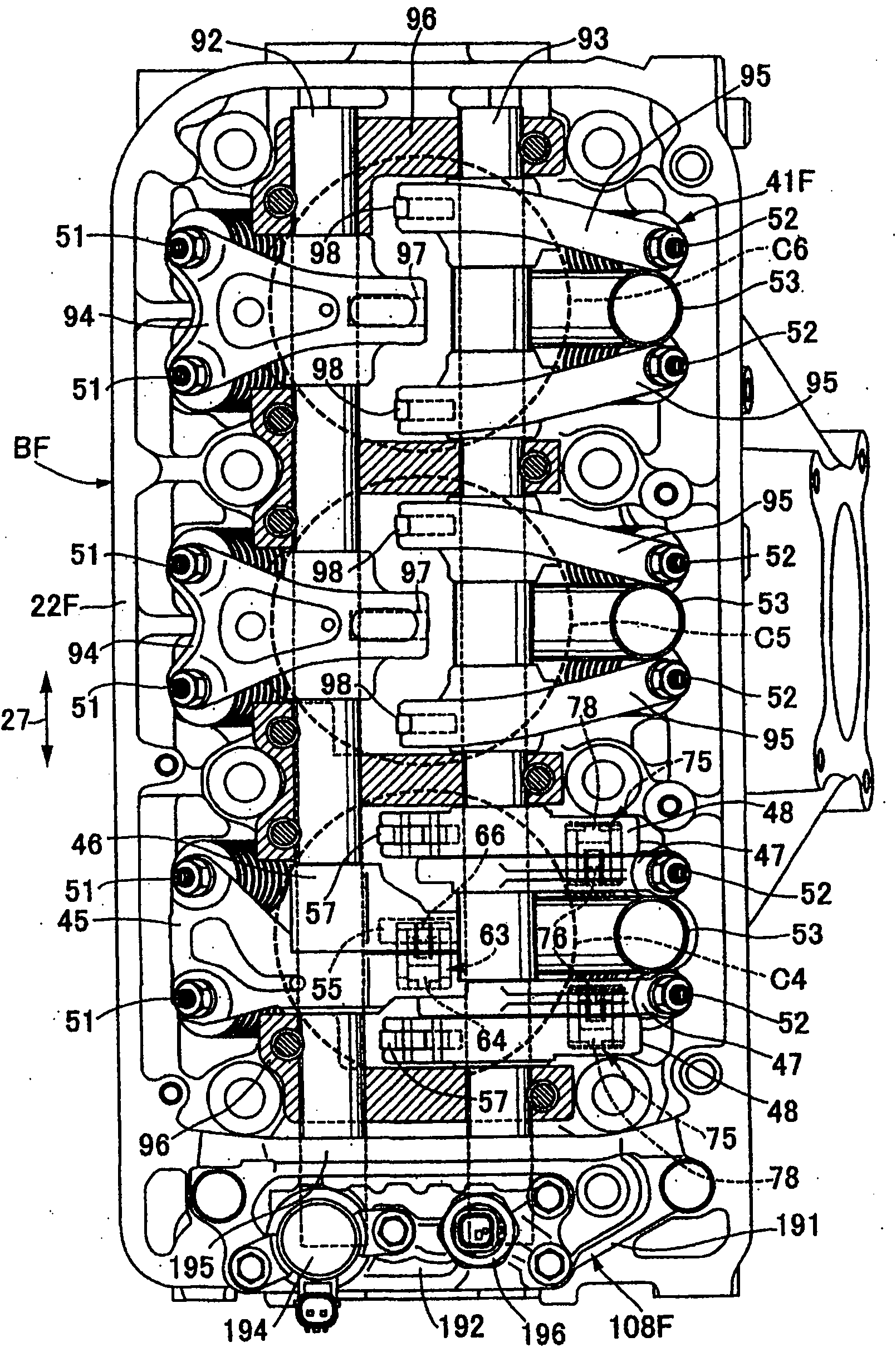

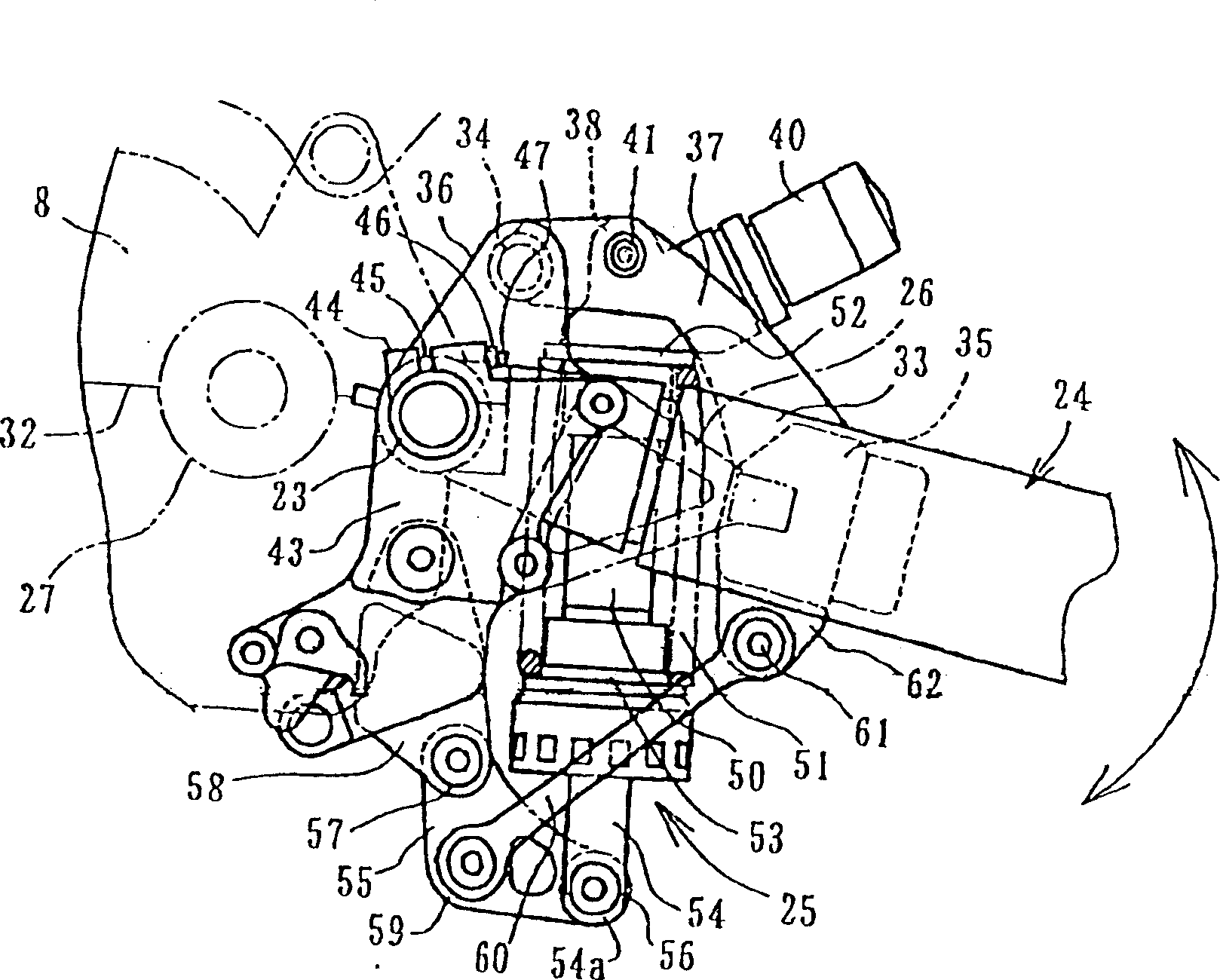

Combustion engine of vertical shaft type

ActiveUS7201132B2Improve installation rigidityEasy maintenanceCasingsCylinder headsCombustionCrankcase

Owner:KAWASAKI MOTORS LTD

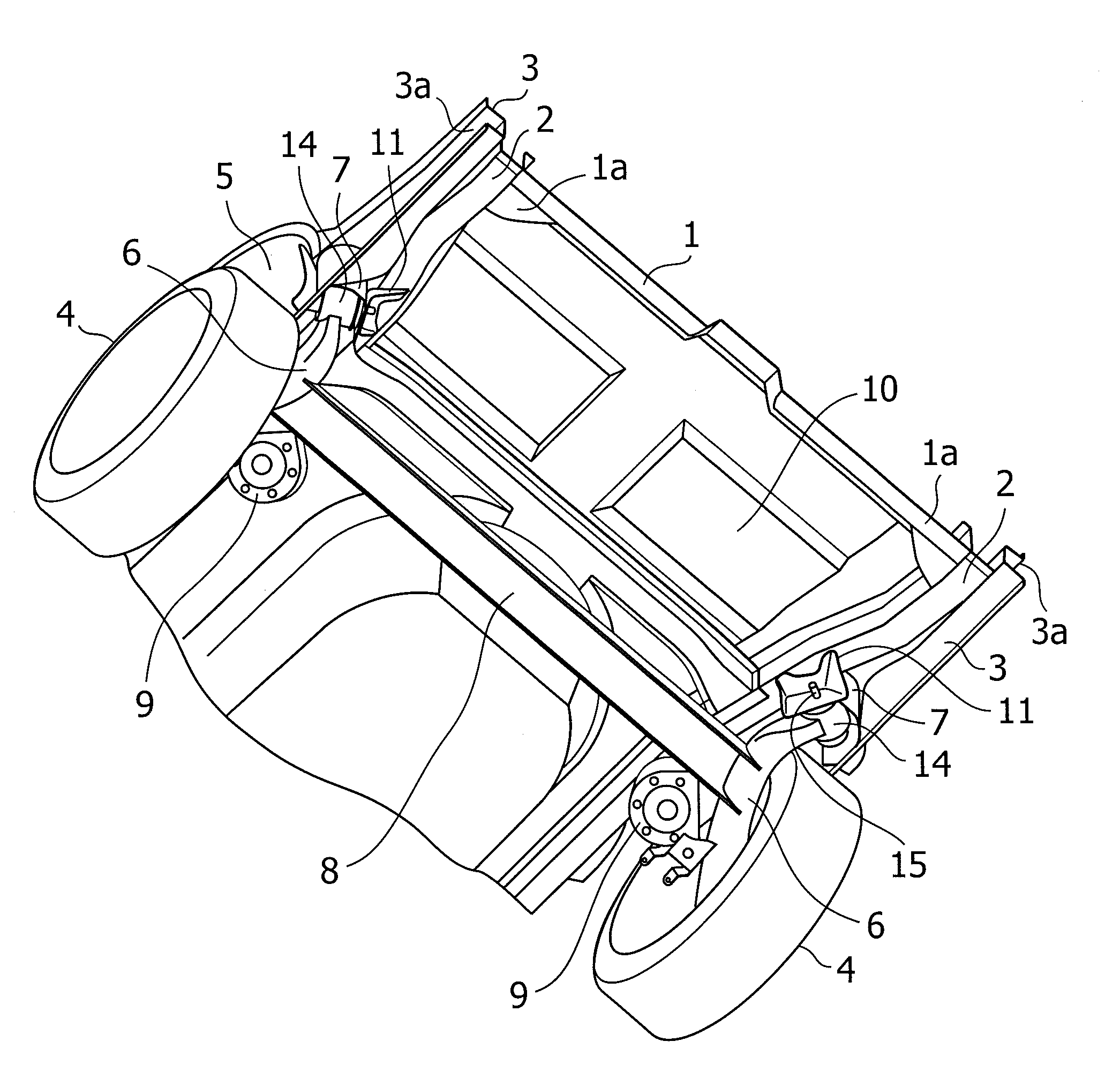

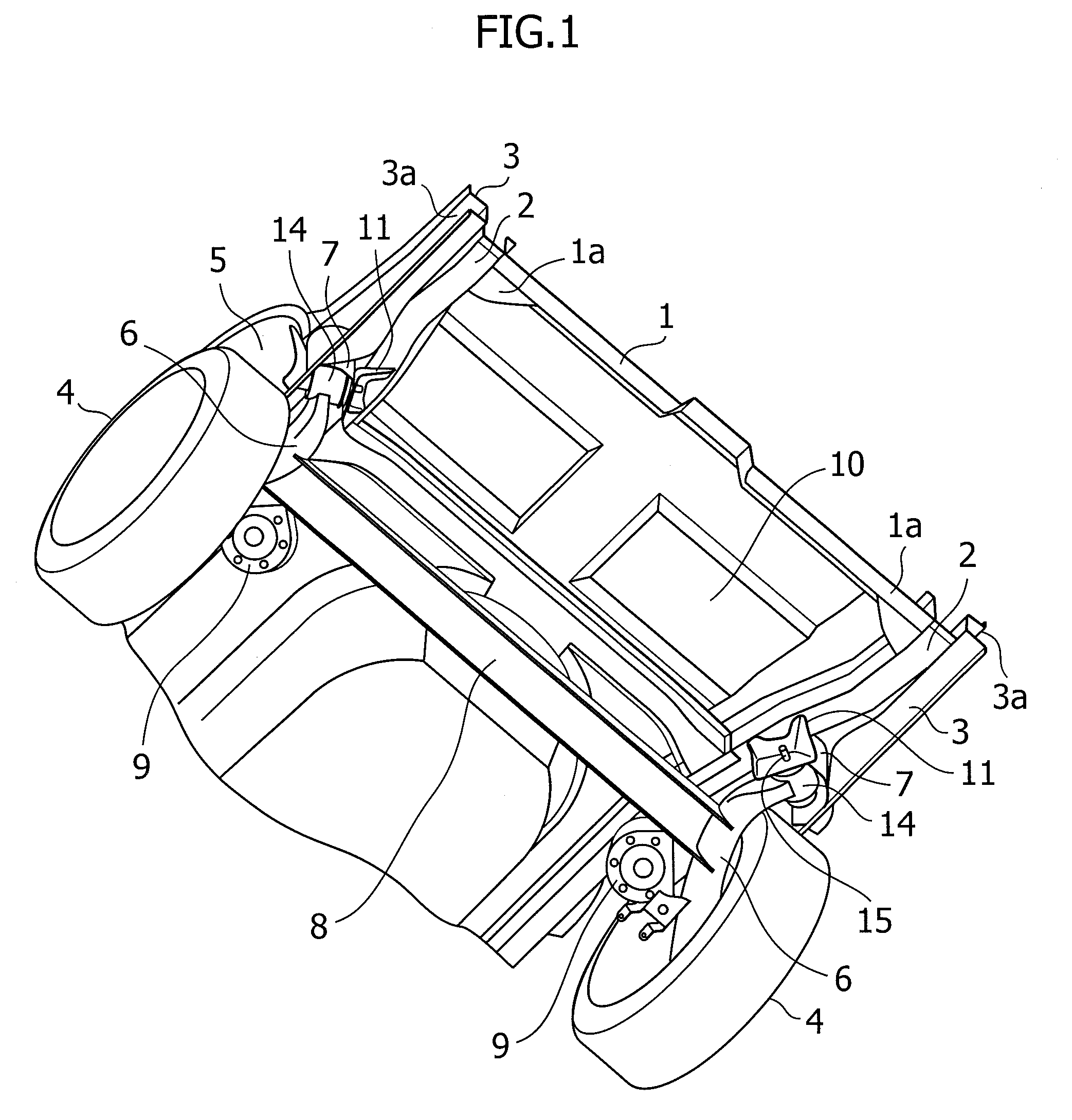

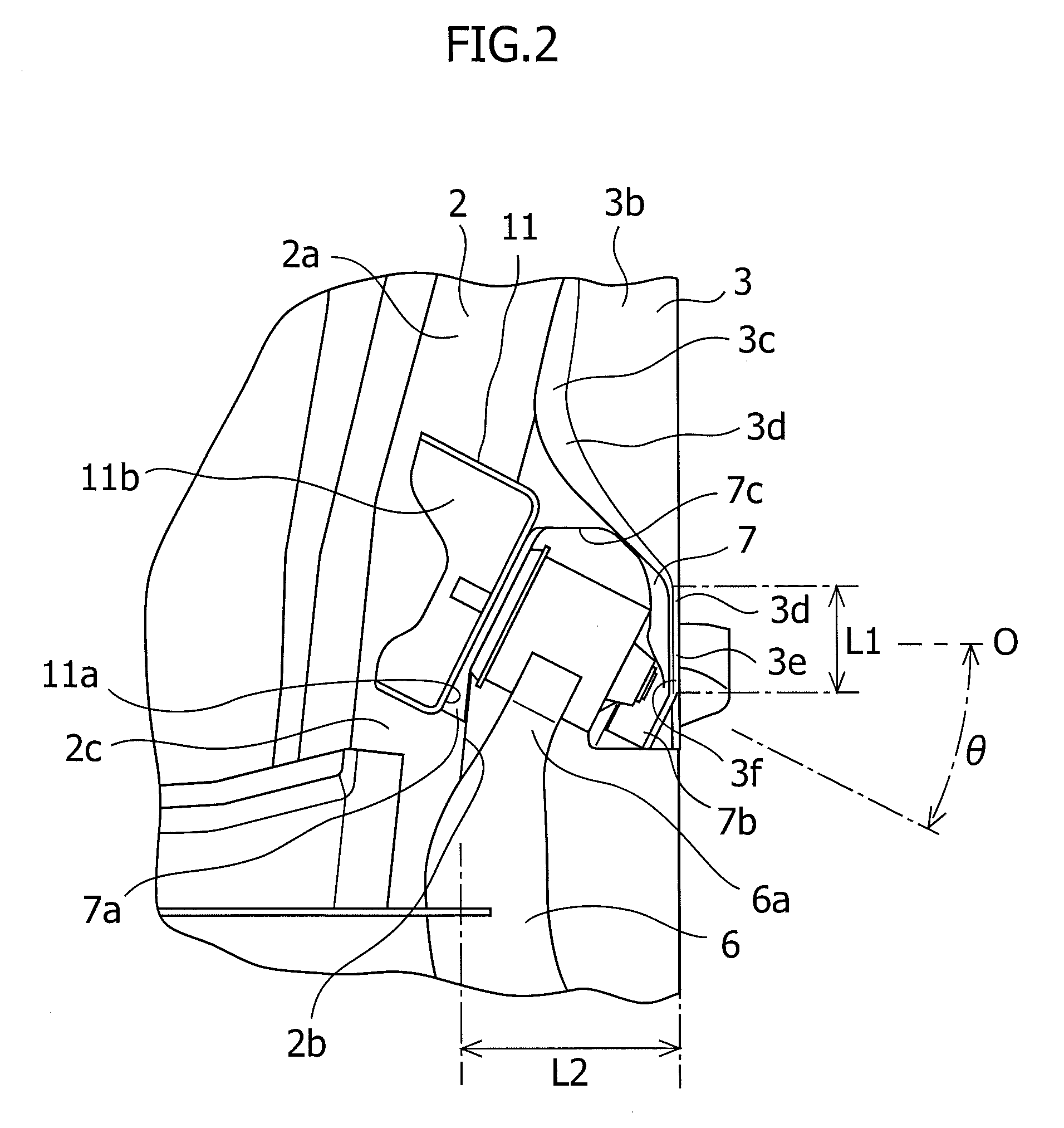

Combustion engine of vertical shaft type

ActiveUS20050229893A1Improve installation rigidityEasy maintenanceCasingsLubrication of auxillariesCombustionEngineering

To provide an internal combustion engine of a vertical shaft type, in which leakage of an oil from a crankcase and an oil pan is effectively prevented, which has high mounting rigidity relative to a working machine and, also, which is capable of being easily serviced, the combustion engine includes a vertically extending crankshaft (9) having a pair of upper and lower crank webs (14A and 14B), a crankcase (1) accommodating the crankshaft (9) and including an oil pan (2), and a crankcase cover (3) mounted on an upper surface (1a) of the crankcase (1) to cover the crankcase (1). The upper surface (1a) of the crankcase (1) is positioned above the upper crank web (14A).

Owner:KAWASAKI MOTORS LTD

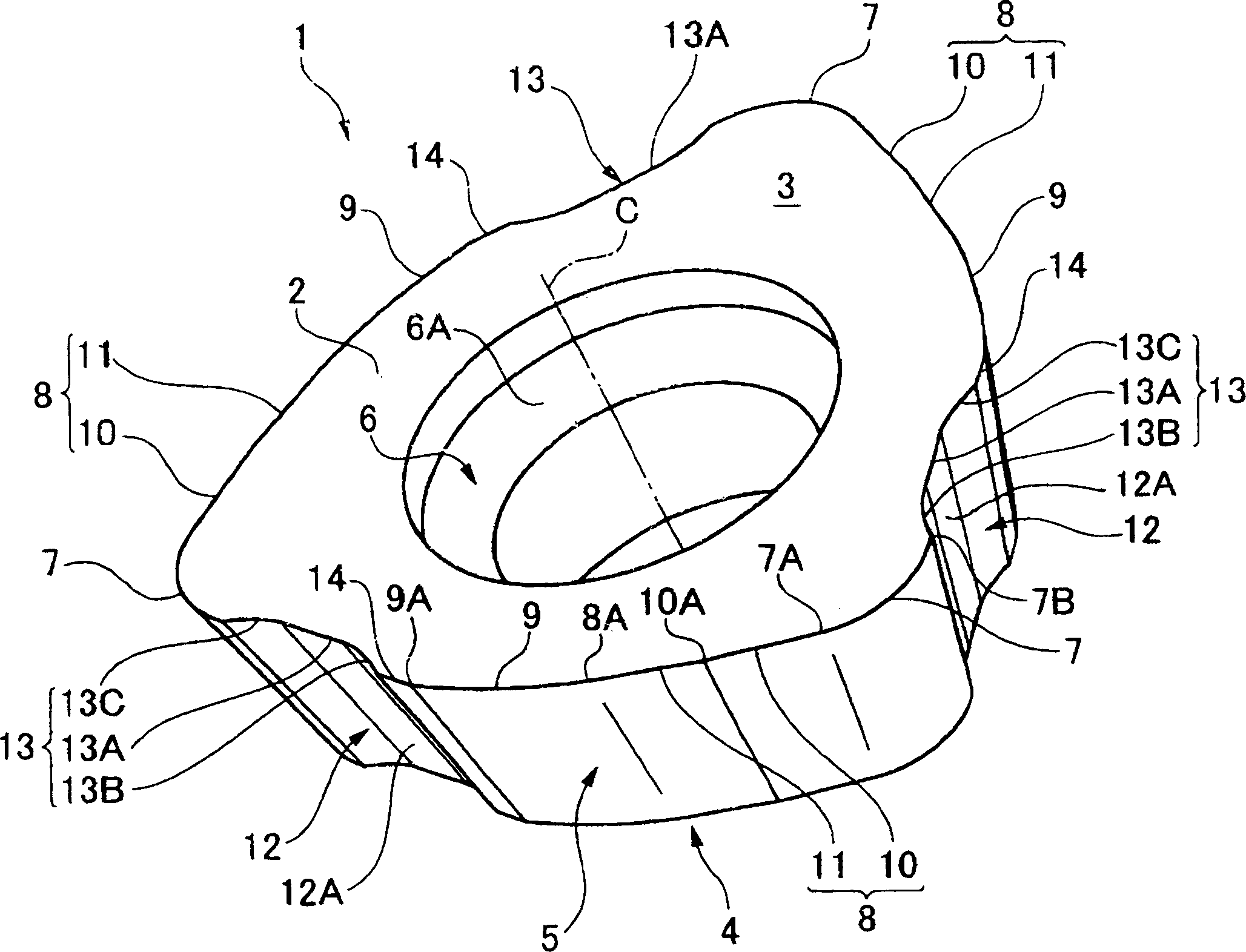

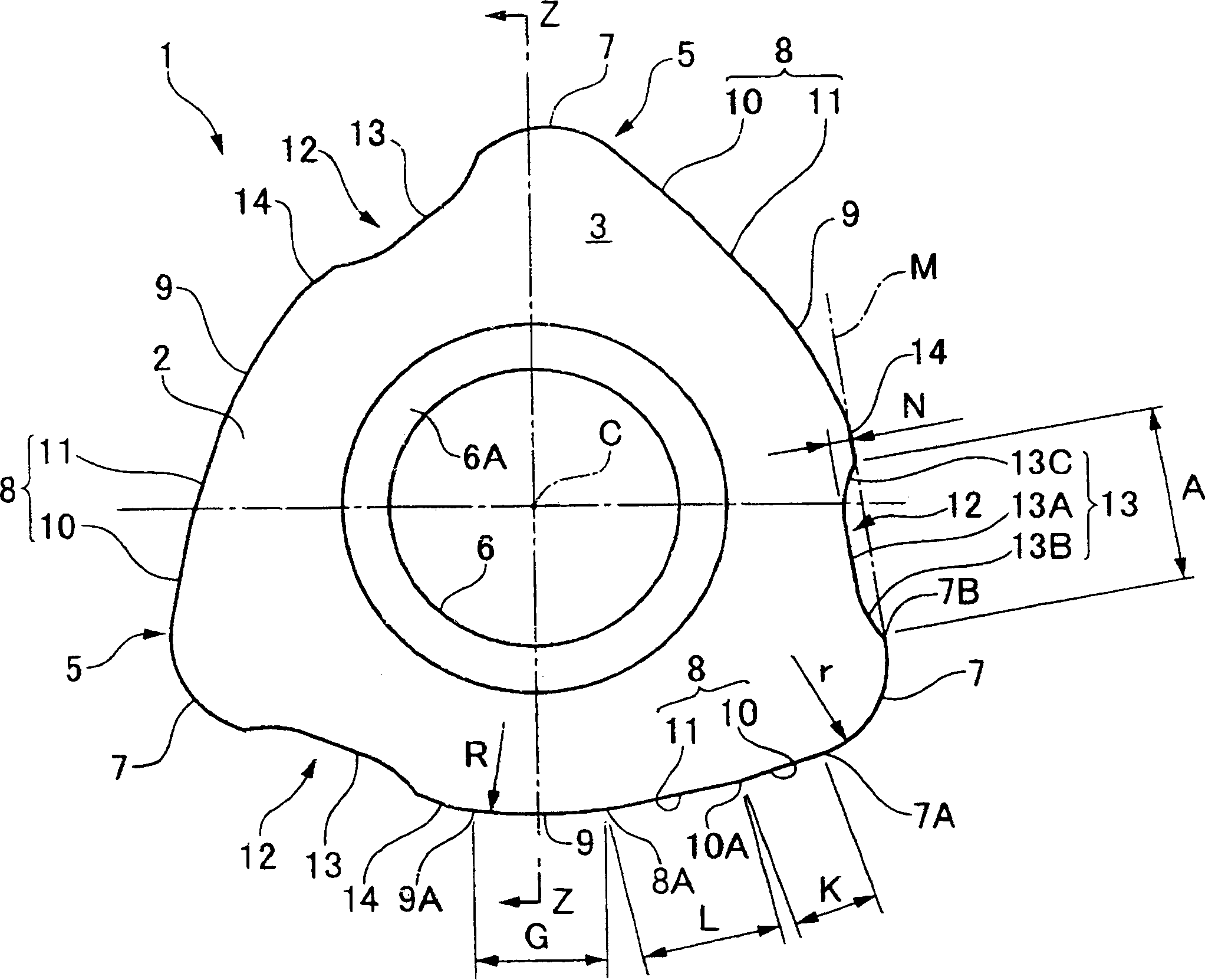

Multiple-cutting-edge cutter-bit and multiple-cutting-edge cutter-bit type cutting tool

InactiveCN1445038AAvoid breakingImprove qualityMilling cuttersTurning toolsStructural engineeringKnife blades

A throwaway insert (1) comprises an insert body (2) formed in a polygonal shape, a cutting face (3) formed by a polygonal face of the insert body (2), a corner cutting edge (7) which is formed in a curved shape at a corner of the cutting face (3), a major cutting edge (8) which is formed along a side edge of the cutting face (3) that is connected to a first end (7A) of the corner cutting edge (7), and a concave portion (13) which is formed, in another side edge of the cutting face (3) that is connected to a second end (7B) of the corner cutting edge (7), so as to be adjacent to the second end (7B) of the corner cutting edge (7), and so as to be made concave toward the inside of the cutting face (3) from a tangent (M) of the corner cutting edge (7) drawn at the second end (7B) of the corner cutting edge (7). By using the throwaway insert (1), cut chips are prevented from being packed in a gap between the throwaway insert (1) and a surface (V) being machined, and the fixing rigidity of the throwaway insert (1) is increased.

Owner:MITSUBISHI MATERIALS CORP

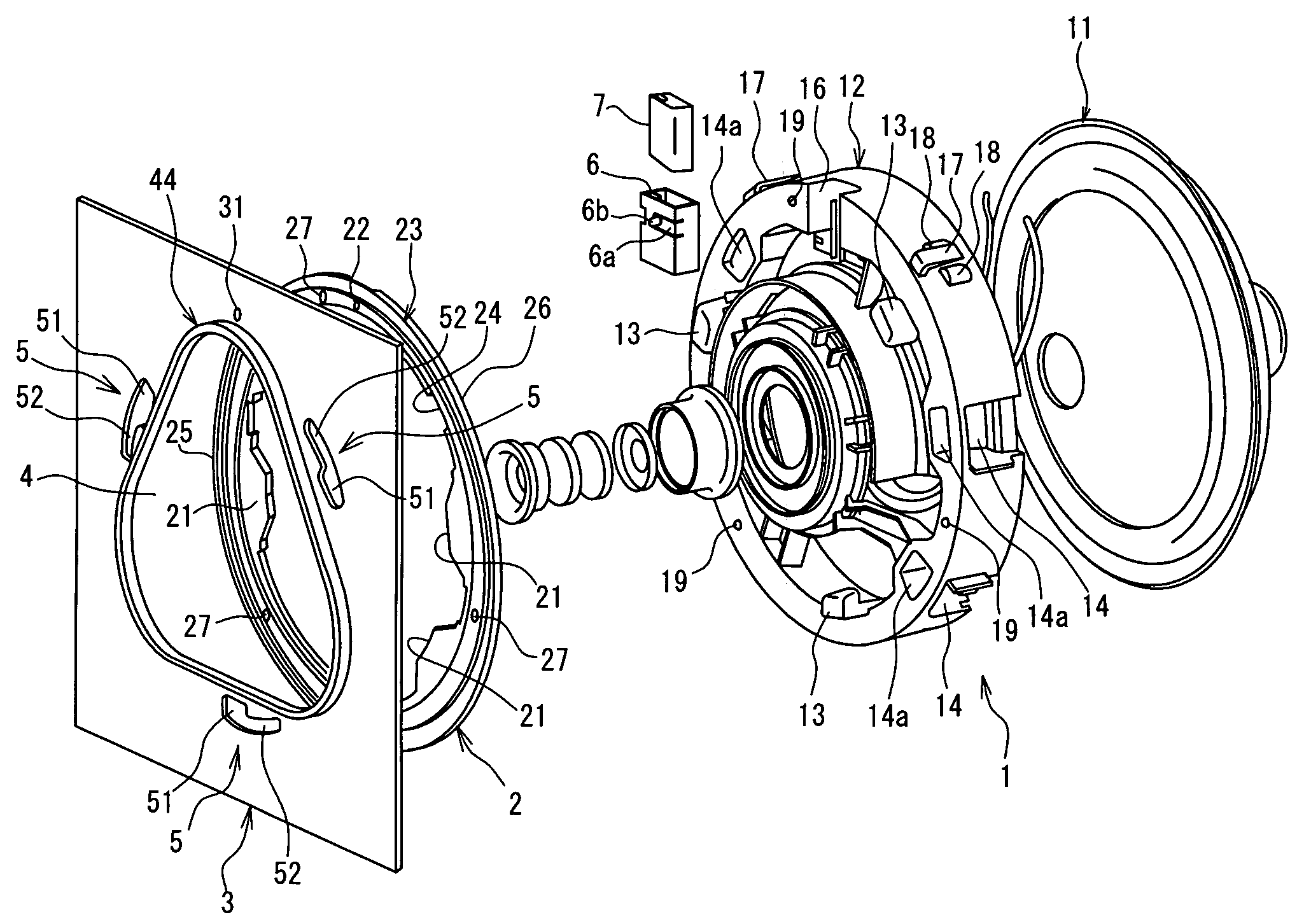

Speaker for vehicle and mounting structure of the speaker

ActiveUS7177438B2Improve installation efficiencyImprove acoustic propertiesPiezoelectric/electrostrictive microphonesLoudspeaker transducer fixingEngineeringLoudspeaker

The present invention relates to a speaker for a vehicle and an installation structure therefor, and it is an object of the invention to enhance the speaker installation rigidity without impairing the acoustic characteristic of the speaker. The speaker installation structure comprises a speaker unit (1) for holding a speaker body (11) and having a plurality of claws (13) and a panel member (3) having an opening (4) and a plurality of slits (5). For the installation of the speaker unit (1), the plurality of claws (13) are inserted into the plurality of slits (5), respectively, and the speaker unit (1) is rotated in its circumferential direction. The opening (4) is made to be smaller than the diameter of a speaker housing (12) and to have at least three linear portions (41). Each of the slits (5) is formed outside the three linear portions (41) and inside an outer circumference of the speaker housing (12).

Owner:MITSUBISHI MOTORS CORP

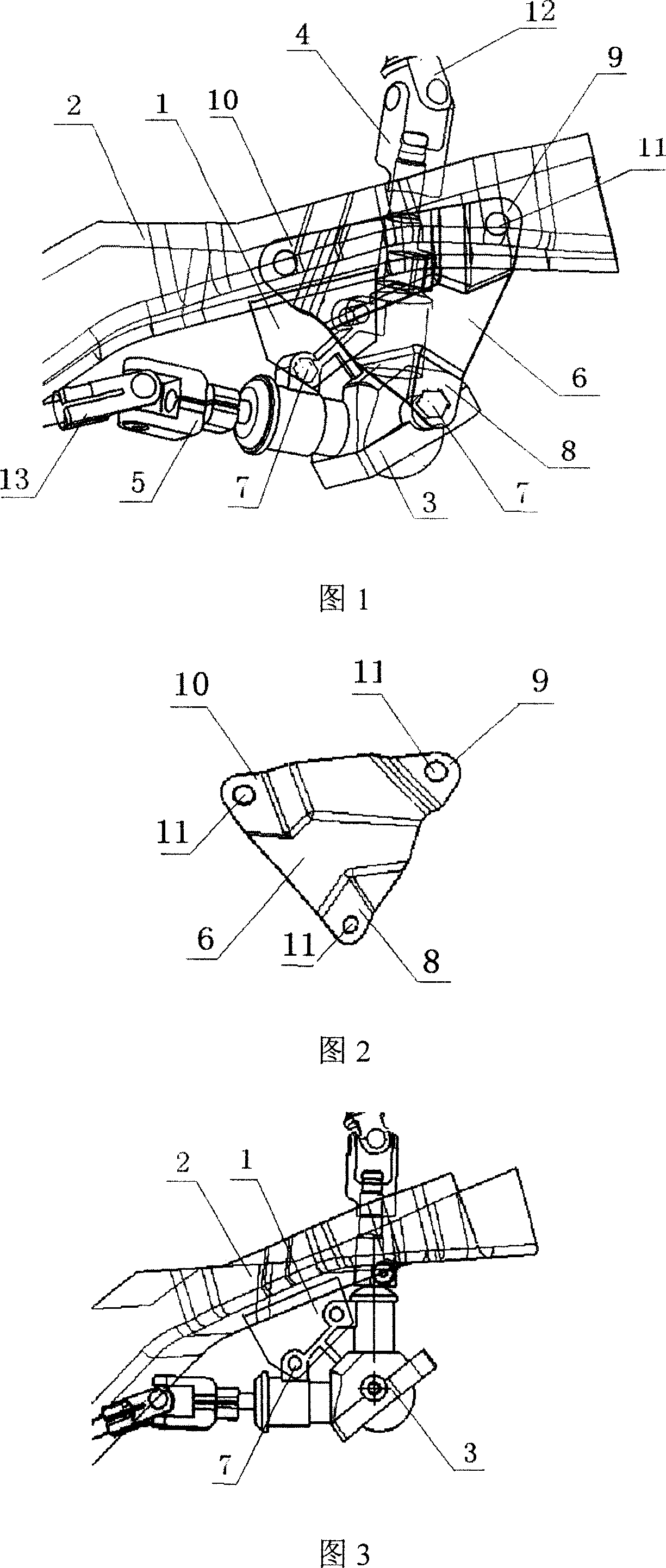

Vehicle door mirror mounting structure

InactiveCN101578200AImprove observation effectImprove installation rigidityDoorsOptical viewingEngineeringWing mirror

Owner:HONDA MOTOR CO LTD

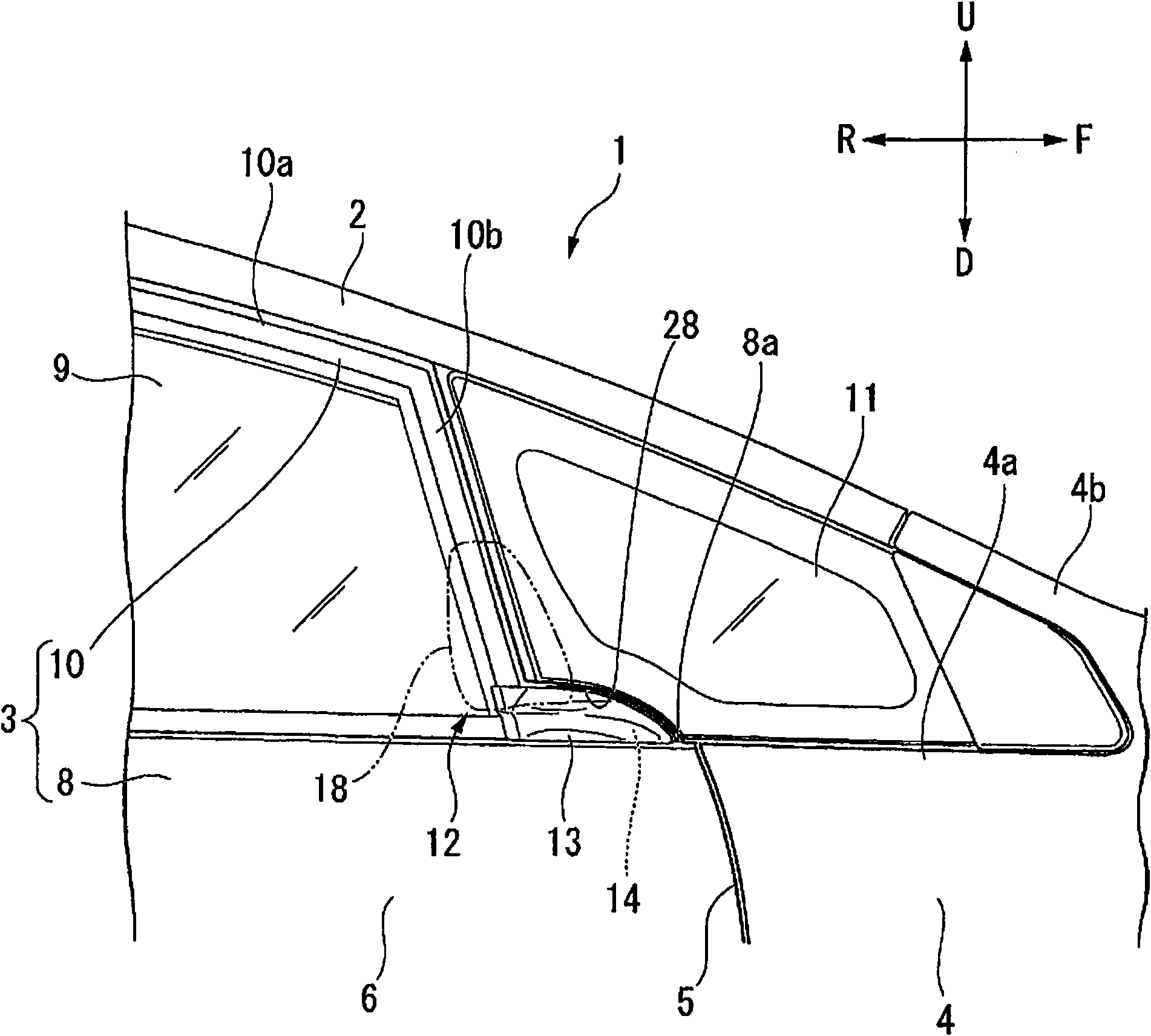

Weather strip and mounting structure thereof

InactiveUS20060000148A1Easy to assembleImprove sealingVehicle sealing arrangementsSealing arrangementsMechanical engineering

A weather strip adapted to be mounted on a door of a vehicle: the weather strip has a mount base part including an interior-side engagement portion and an exterior-side engagement portion which are engageable with a pair of engagement recesses provided on a mount portion of a door. A neck portion extends from the interior-side engagement portion. A hollow seal part includes a bottom wall portion extending from the neck portion substantially linearly and substantially in parallel with the interior-side engagement portion of the mount base part. A predetermined space is formed between the bottom wall portion and the interior-side engagement portion. A seal wall is provided on a side of the bottom wall portion which is opposite to a surface of the bottom wall portion facing the interior-side engagement portion.

Owner:TOYODA GOSEI CO LTD

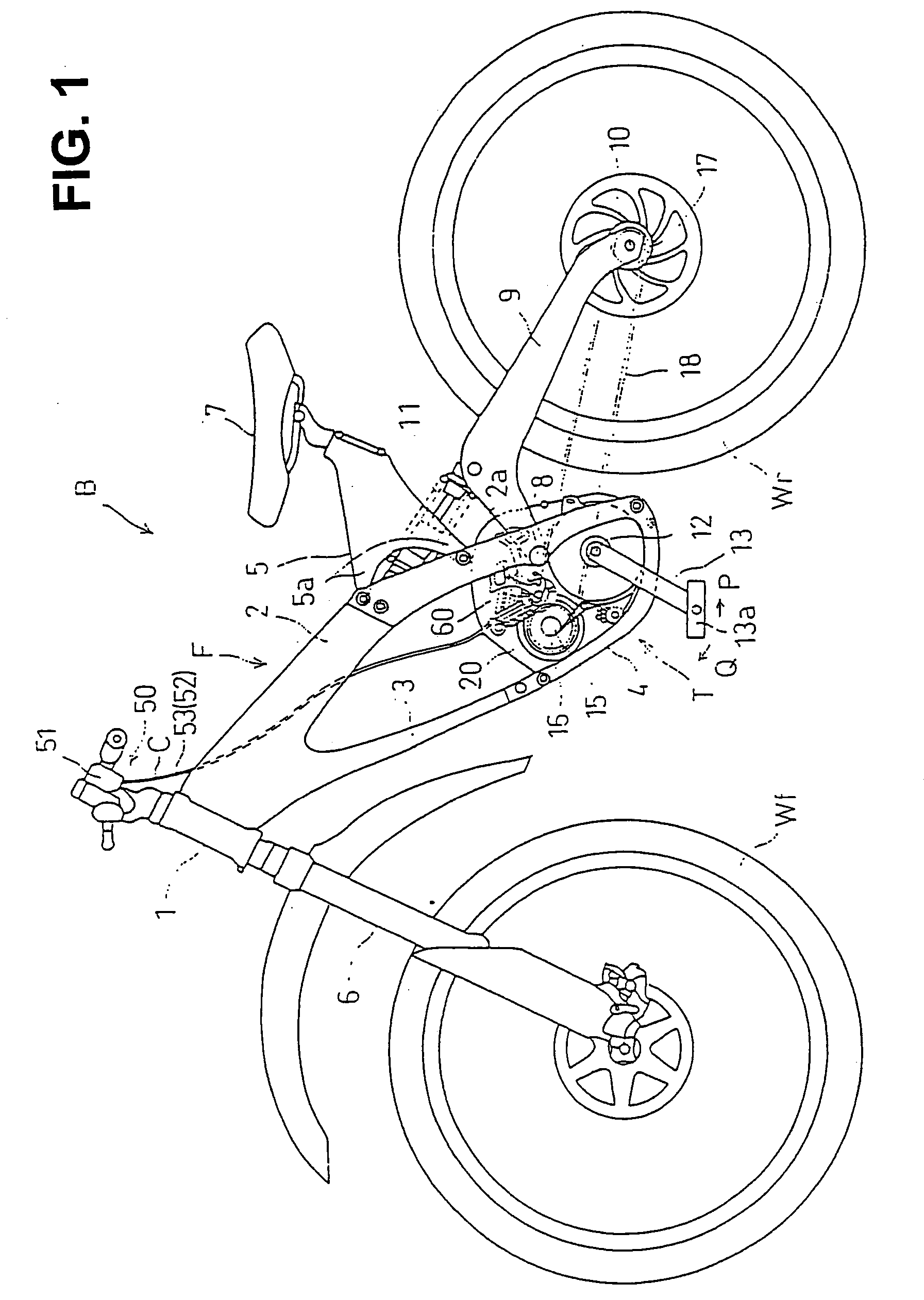

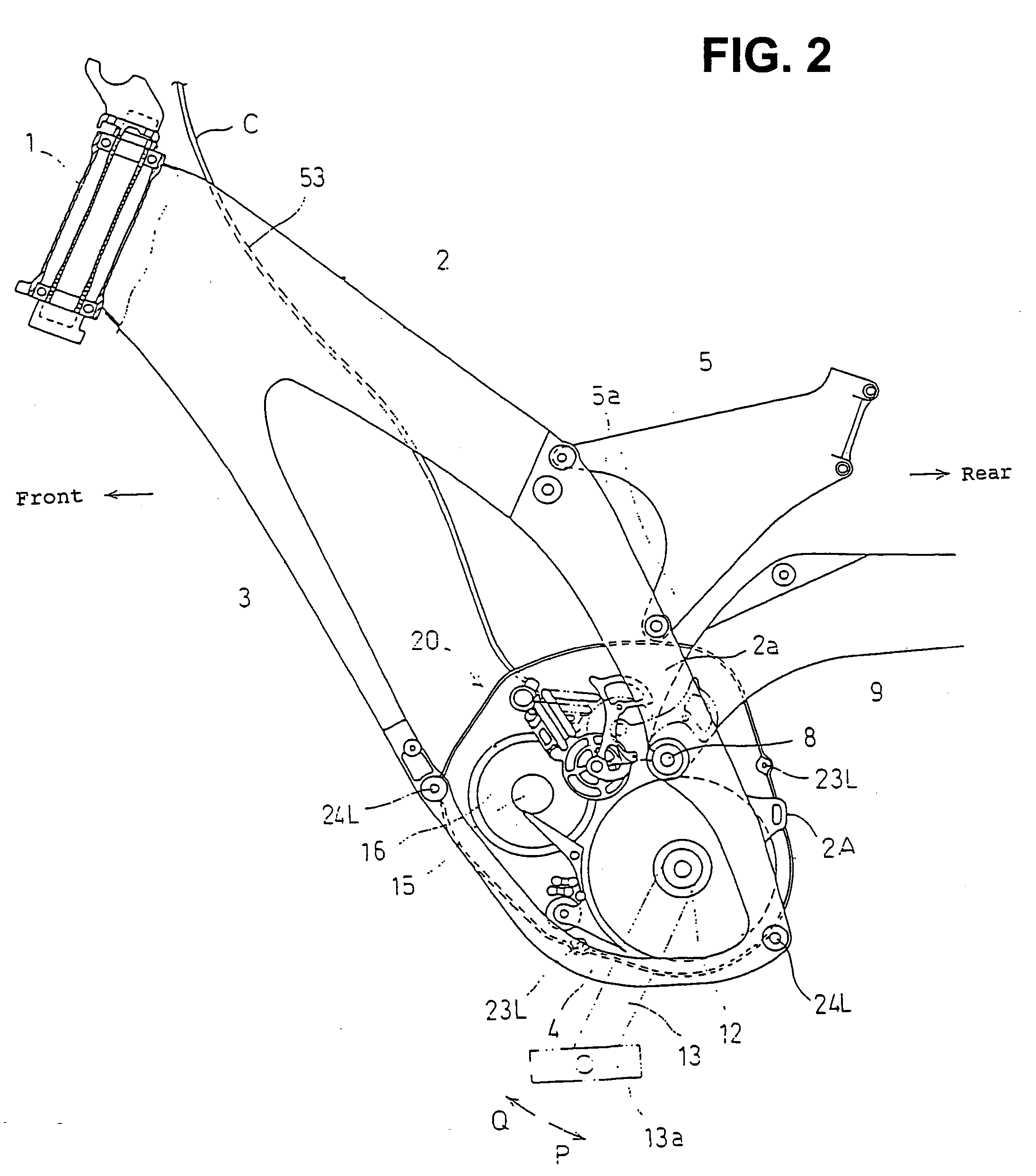

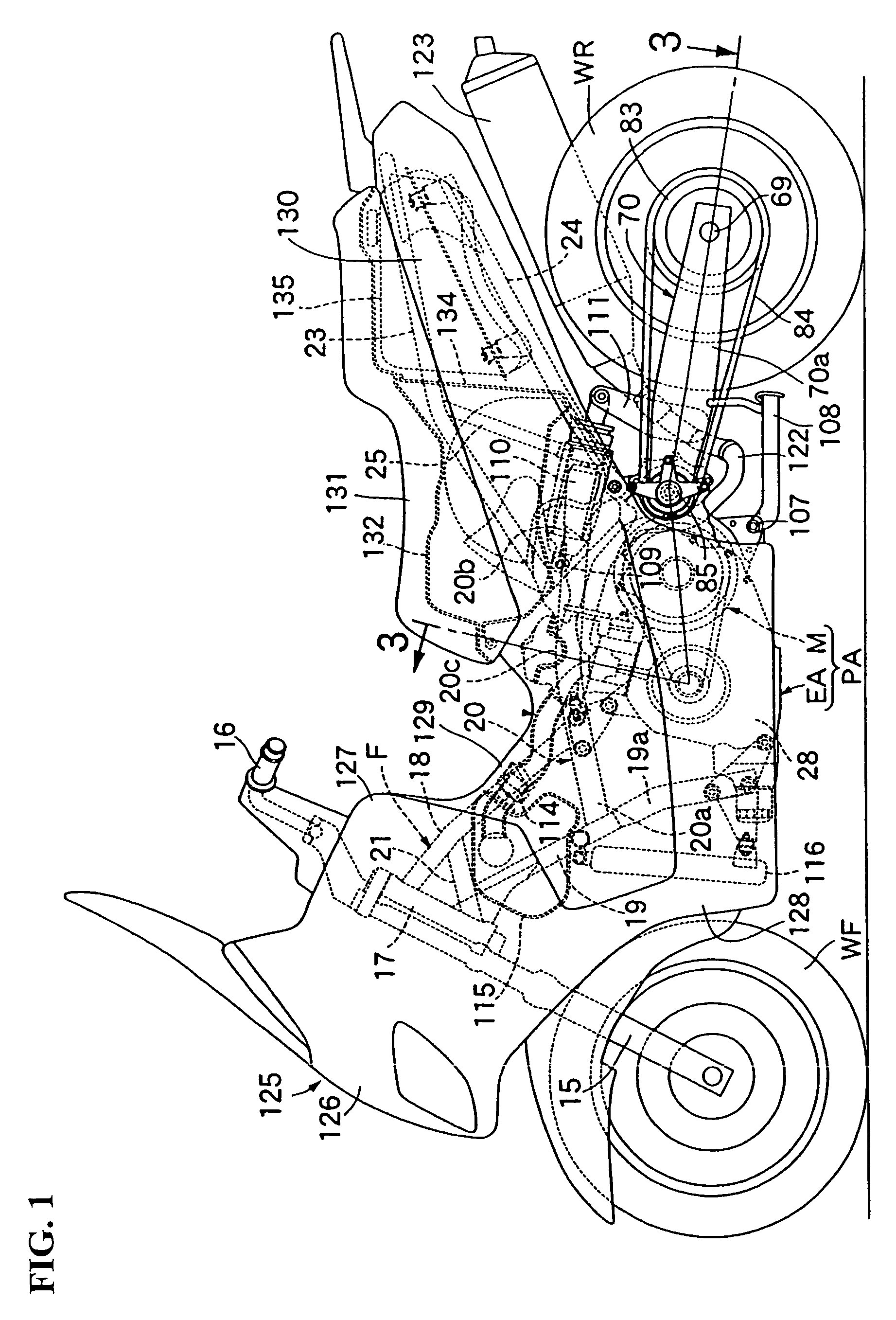

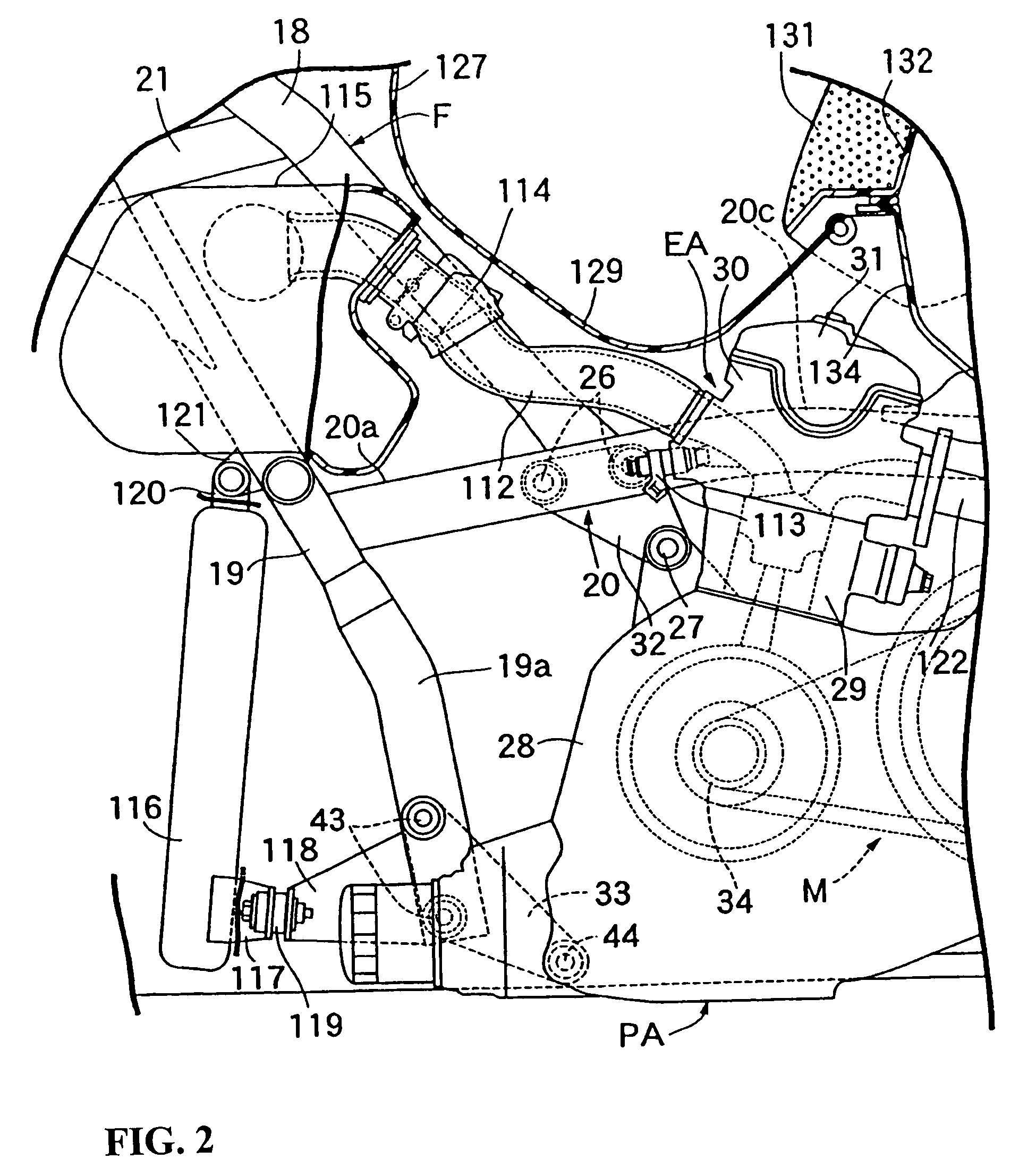

Swing arm support structure in a motorcycle, and motorcycle incorporating same

InactiveUS7527119B2Easy to ensure rigidity and strengthImprove rigidityPassenger cyclesChildren cyclesEngineeringPower unit

Owner:HONDA MOTOR CO LTD

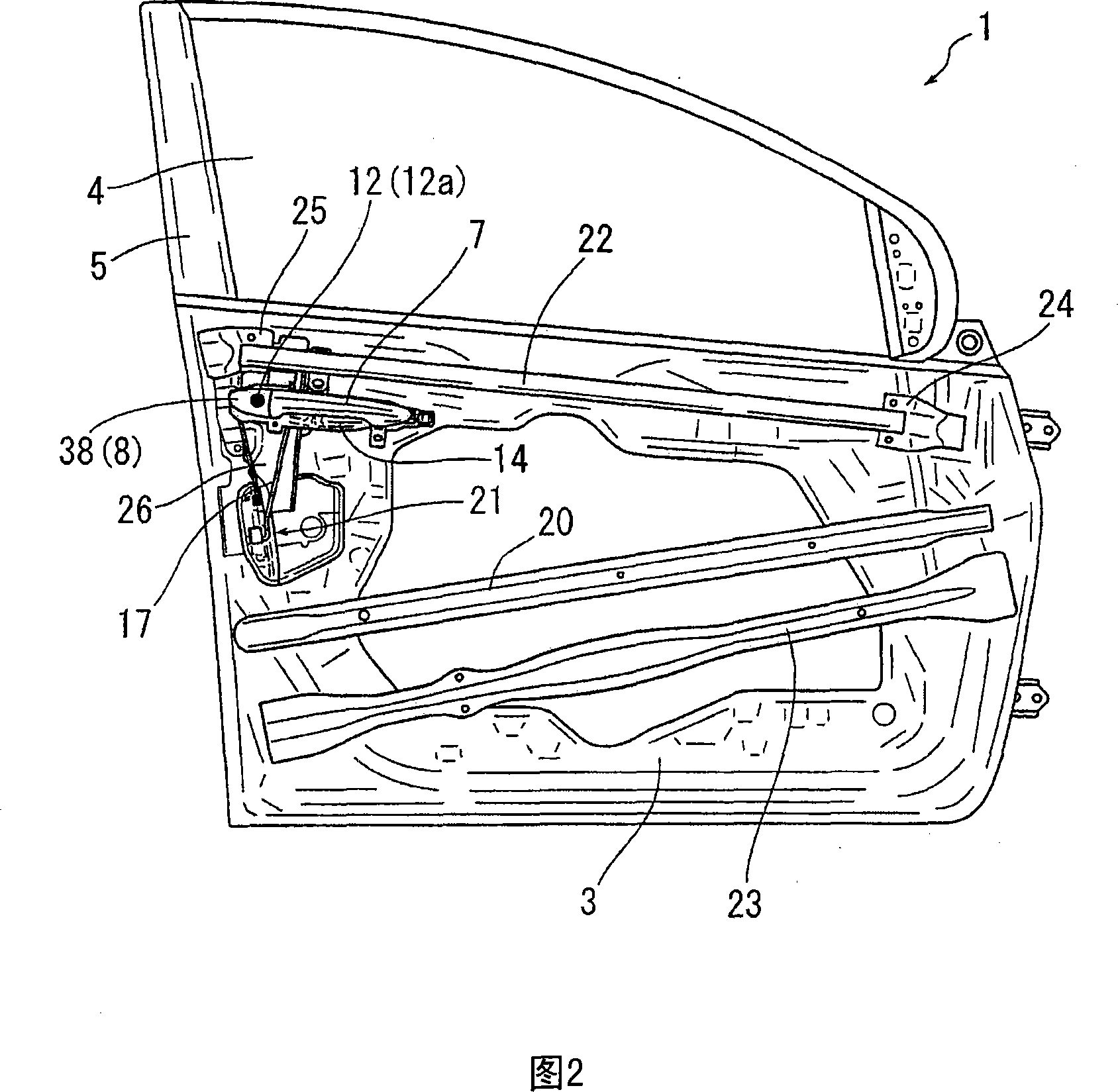

Door structure of automotive vehicle

InactiveCN101240683AImprove installation rigidityBurglar prevention lockingDoor/window applicationsEngineeringCar door

A handle knob 7 to conduct an opening / closing operation of a front door 1 is provided on an outer-face side of an outer panel 2 , and a handle base 14 to pivotally support the handle knob 7 is provided on an inner-face side of the outer panel 2 . A beltline reinforcement 22 to reinforce an beltline portion of the outer panel 2 is provided on the inner-face side of the outer panel 2 . The handle base 14 is connected to the beltline reinforcement 22 via an connecting portion 28. Thereby, the support rigidity of the handle base 14 can be increased, thereby properly preventing the handle base 14 from moving by an improper access.

Owner:MAZDA MOTOR CORP

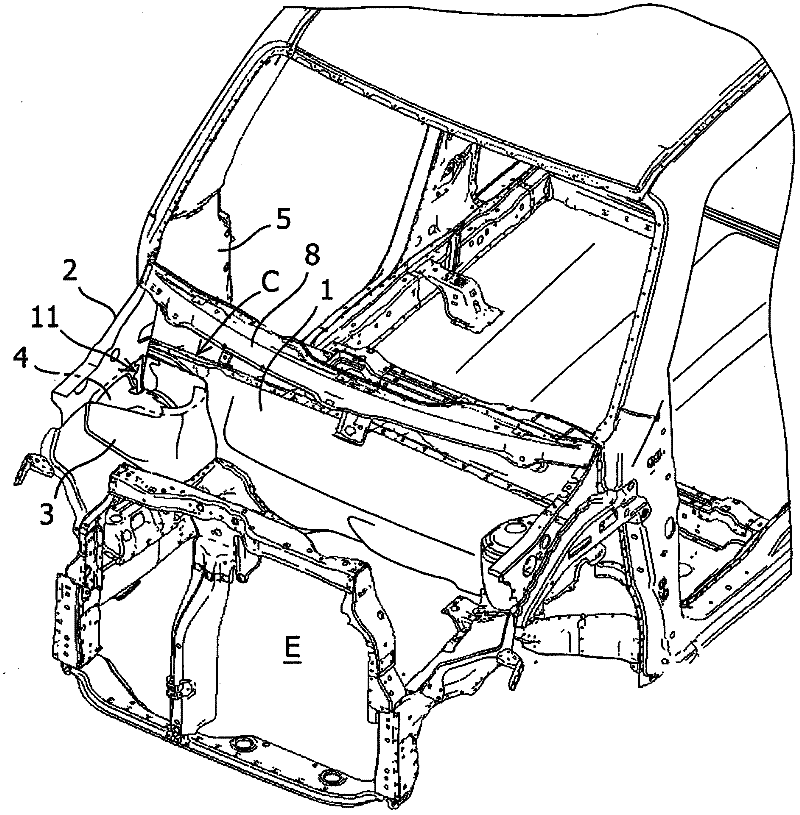

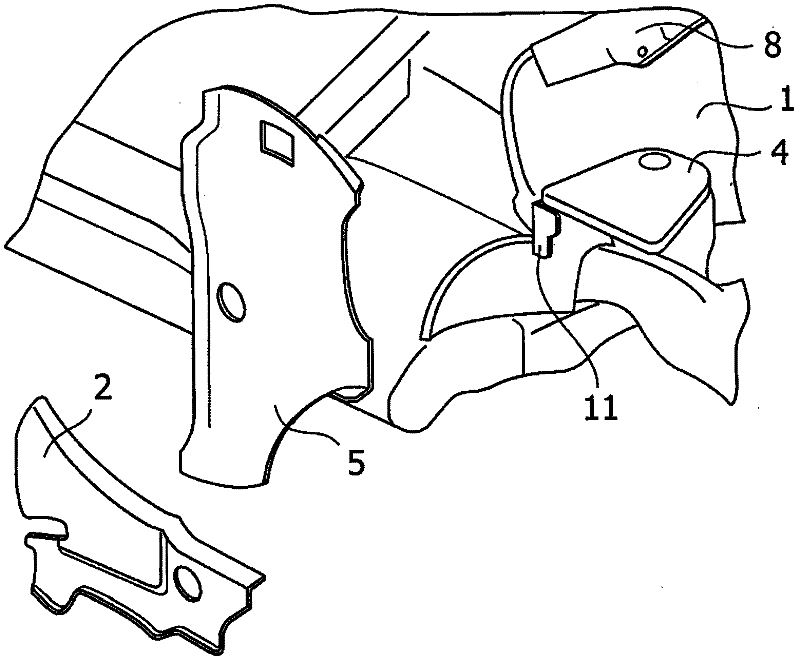

Reinforcing structure for front portion of vehicle

InactiveCN102464027AEfficient receptionReduce vibration transmissionSuperstructure subunitsNeck sidesMechanical engineering

Provided is a reinforcing structure for the front portion of a vehicle. The reinforcing structure comprises a mud blocking plate (3), an upper suspension carriage (4) and protruding edges (4b, 4c). The mud blocking plate is arranged on the corner portion (C) of an engine room (E) formed by a front enclosing plate (1) and a vehicle neck side plate (2). The upper suspension carriage is arranged on the upper portion of the mud blocking plate (3) and the vehicle neck side plate (2). The protruding edges are respectively arranged on the rear edge and the side edge of the upper suspension carriage (4). The upper suspension carriage (4) is jointed to the front enclosing plate (1) and the vehicle neck side plate (2) via the protruding edges. A reinforcing element (11) is disposed on the corner portion (C), is jointed to the front enclosing plate (1) and the vehicle neck side plate (2), and is L-shaped from the above of the vehicle. The rear part of the upper portion of the reinforcing element (11) and the upper suspension carriage (4) are jointed together to the front enclosing plate (1), and the side of the upper portion of the reinforcing element (11) and the upper suspension carriage (4) are jointed together to the vehicle neck side plate (2).

Owner:SUZUKI MOTOR CO LTD

Structure of transmission for bicycle

InactiveUS7744498B2Simple structureImprove rigidityWheel based transmissionChain/belt transmissionAbutmentEngineering

To achieve downsizing and weight reduction of a derailleur shaft and the mounting structure thereof and to improve the rigidity of the derailleur shaft without increasing the thickness thereof more than necessary. A transmission case is divided into left and right halves, and the left and right halves are provided with bosses therein having holes opposing each other. The bosses are brought into abutment with each other and united by fitting tightening bolts to the holes of the bosses and tightening the same. A sleeve-shaped derailleur shaft is fitted on the outer periphery of the bosses to support and mount the derailleur shaft. The derailleur shaft includes a hole at the shaft end thereof. A mounting position of the derailleur shaft is achieved by a pin inserted into the hole and a hole provided on one of the cases.

Owner:HONDA MOTOR CO LTD

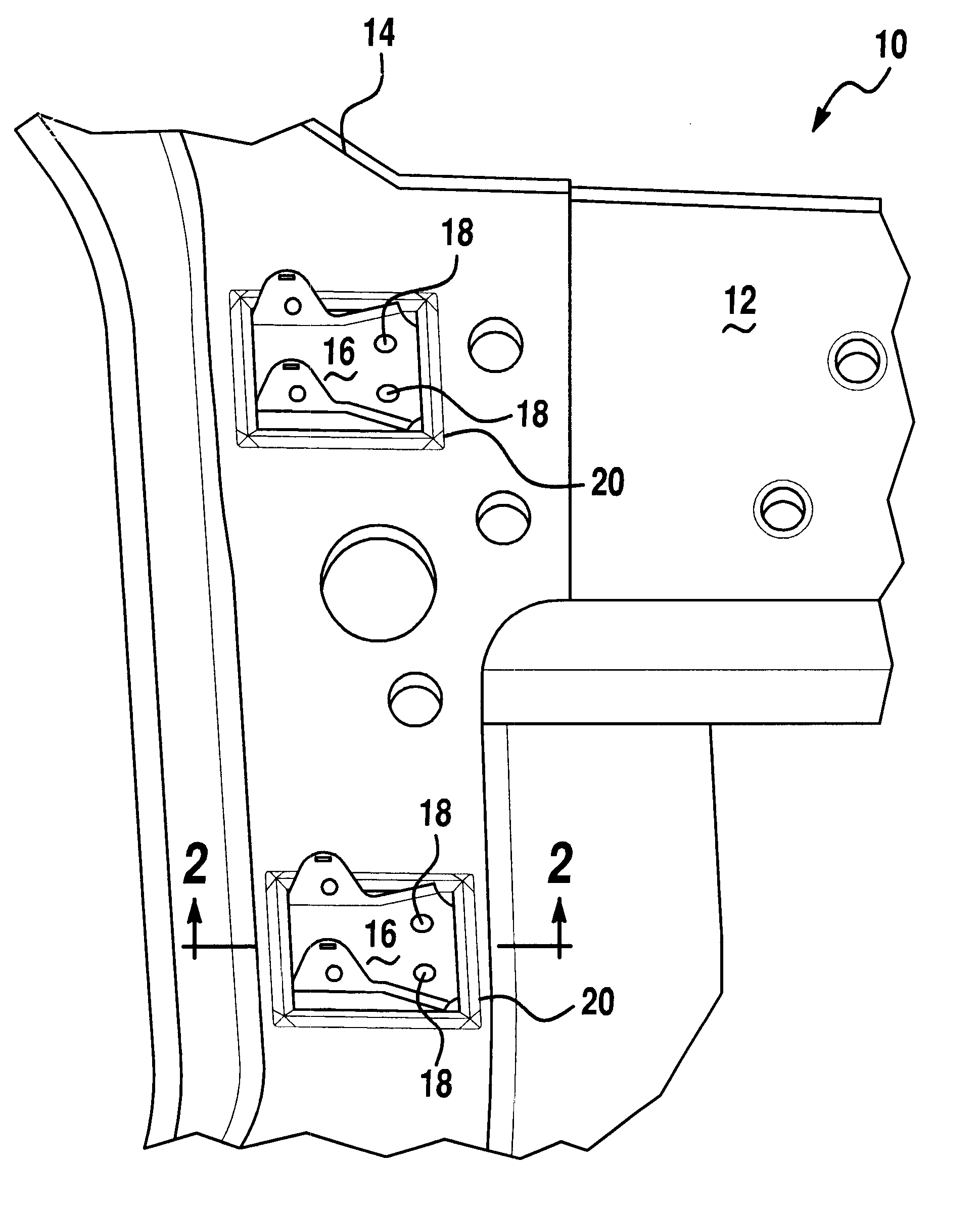

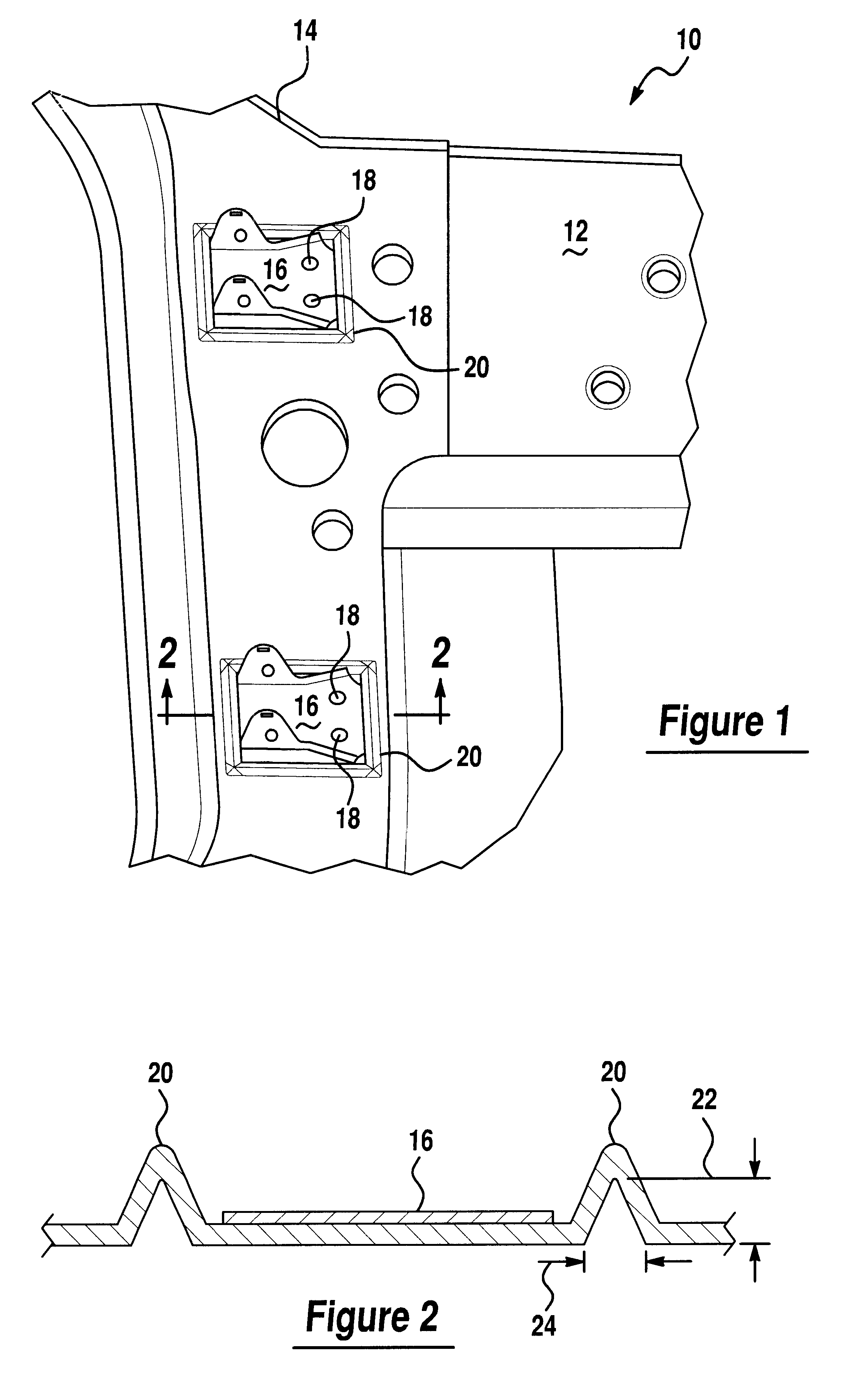

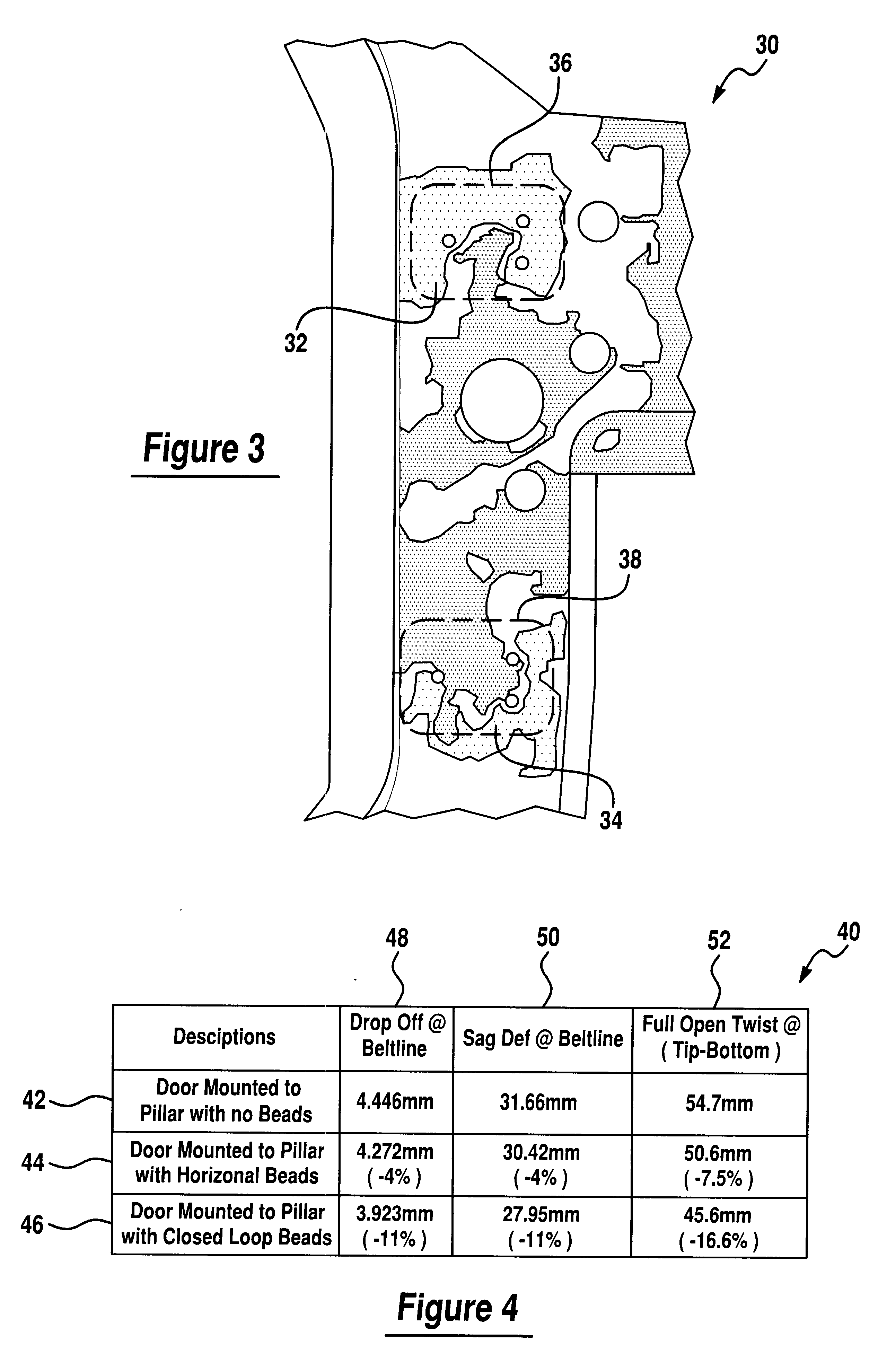

Mounting structure with improved stiffness characteristics

InactiveUS6439653B1Good stiffness characteristicsCertain performanceVehicle seatsWing accessoriesClosed loopCar door

Owner:FORD GLOBAL TECH LLC

Trailing arm mounting structure

InactiveUS8590910B2Reduce stiffnessAvoid displacementUnderstructuresInterconnection systemsTrailing armEngineering

A trailing arm mounting structure is capable of size reduction as well as weight saving of a trailing arm bracket while ensuring mounting rigidity. In the trailing arm mounting structure, a clearance is formed between an outer sidewall of a side member and an inner sidewall of an extended portion of a side sill. In addition, an inner sidewall of a mounting bracket for a trailing arm is attached to an outer sidewall of the side member while the mounting bracket for the trailing arm is disposed in the clearance. An outer sidewall of the mounting bracket for the trailing arm is attached to the inner sidewall of the extended portion of the side sill, and a base end portion of the trailing arm is supported between the inner sidewall and the outer sidewall of the mounting bracket for the trailing arm.

Owner:SUZUKI MOTOR CORP

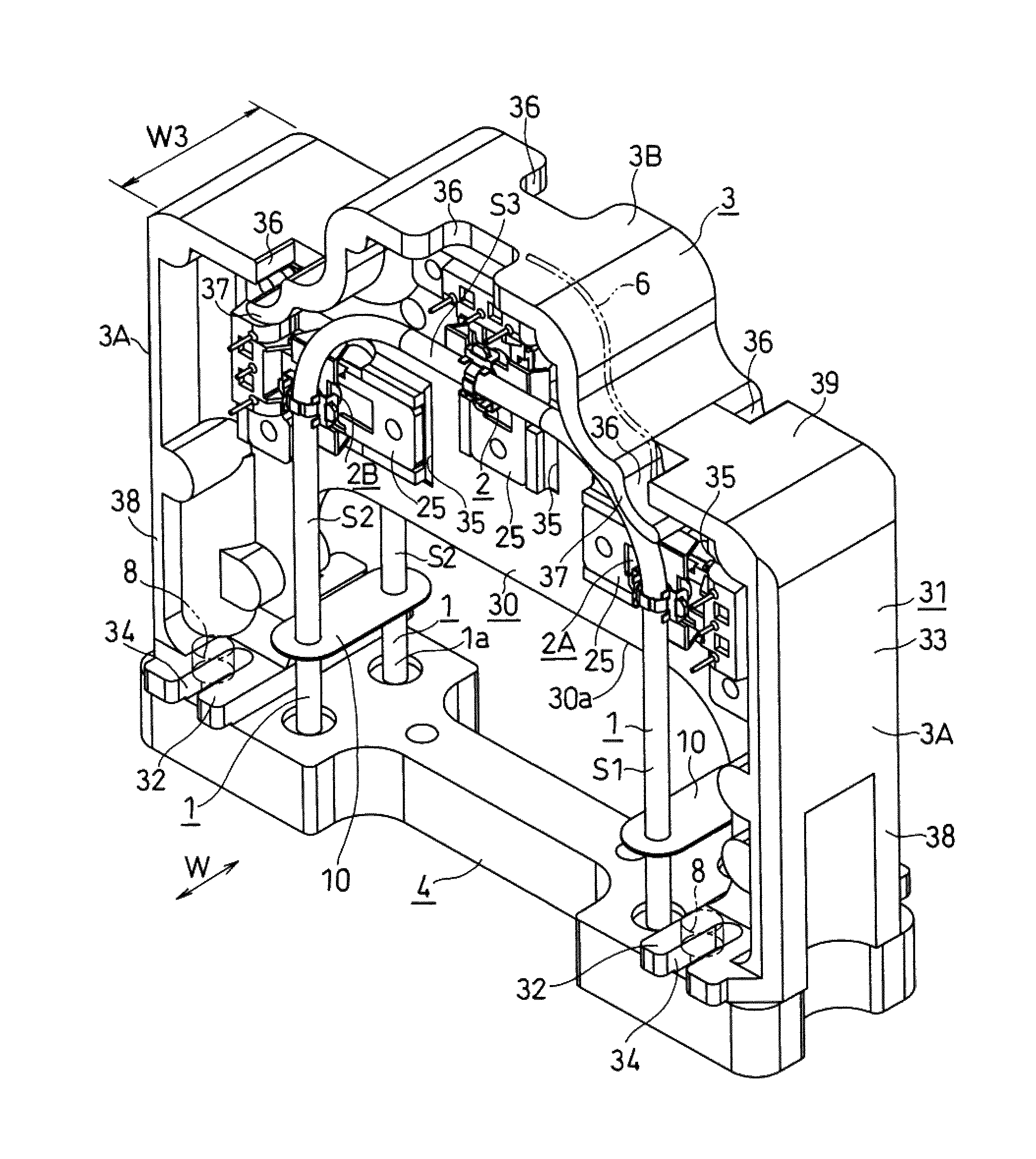

Flowmeter

InactiveUS8096192B2Reduce thicknessSmall distanceDirect mass flowmetersEngineeringMechanical engineering

A flowmeter of Coriolis type includes a supporting base that supports a pair of fluid pipes in a manner capable of being vibrated, and a frame fixed to the supporting base. The frame is integrally formed with a mounting portion disposed between the fluid pipes and having a thickness that does not interfere with the fluid pipes, a reinforcing portion disposed at the outer circumference of the mounting portion and enhancing the rigidity of the mounting portion, and a fixing portion for being fixed to the supporting base. The reinforcing portion has an outer wall portion that protrudes at least to one side of the thickness direction of the mounting portion, and substantially continuously surrounds the outer circumference of the fluid pipes. Penetrating portions for disposing the coils corresponding to respective magnetic substances mounted on the fluid pipe are formed in the mounting portion.

Owner:KEYENCE

Device for improving vehicle behavior when steering

InactiveCN102858587AImprove installation rigidityIncreased vibration damping forceSpeed controllerPropulsion using ac induction motorsVehicle behaviorMotor torque

The drive torque of a motor for driving a vehicle wheel, as shown in (a), during the period between the start of steering t1 and an instant t2 when a prescribed interval TM1s has passed, is controlled so as to be a value which is temporarily increased from the intended motor torque by just the amount indicated by the solid line waveform in (a); and during the period between t2 and an instant t4 when a prescribed interval TM2s has passed, the drive torque of a motor for driving a vehicle wheel is controlled so as to be a value which is temporarily decreased from the intended motor torque by just the amount indicated by the solid line waveform in (a). In the t1 - t2 interval (initial stage) of (c), the turning moment becomes large according to the difference between the turning moment of the turning direction of the outer wheel Mout and the turning moment (restoring moment) of the turning direction of the inner wheel Min. The increment in the yaw rate promptly rises in the initial stage of the instant t1 - t2 as indicated by a solid line in (b), in accordance with the increase in the apparent lateral force caused by the increase in the turning moment, thus the yaw rate is caused to rise without delay, and thereby it is possible to greatly improve the steering response (initial turning characteristics) of the vehicle.

Owner:NISSAN MOTOR CO LTD

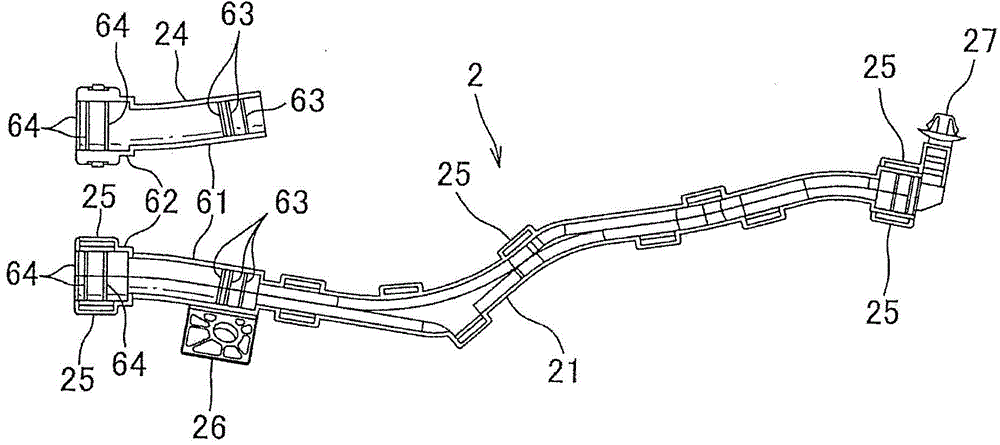

Electric wire routing structure

ActiveCN104584351AImprove installation rigidityReduce vibrationElectrical apparatusElectric/fluid circuitEngineeringElectrical wiring

Provided is an electric wire routing structure which increases rigidity of mounting to a vehicle, etc., to suppress vibration, and which can increase conveyance efficiency and assembling workability. An exterior member (1) is provided with a stiff first protector (2) provided on one side in the longitudinal direction of a wire (W), a stiff second protector (3) provided on the other side thereof, an inside corrugated tube (4) which covers the outside of the wire (W) across the first protector (2) and the second protector (3), and an outside corrugated tube (5) which covers the outside of the inside corrugated tube (4). One end (41, 51) of the inside corrugated tube (4) and the outside corrugated tube (5) is fixed to the first protector (2); the other end (42) of the inside corrugated tube (4) is fixed to the second protector (3) and the other end (52) of the outside corrugated tube (5) is supported to allow sliding in the longitudinal direction relative to the second protector (3).

Owner:YAZAKI CORP +1

Vehicle body front structure

ActiveUS20200101852A1Minimize front overhang lengthImprove installation rigidityVehicle connectorsCharging stationsMechanical engineeringElectrical and Electronics engineering

Owner:HONDA MOTOR CO LTD

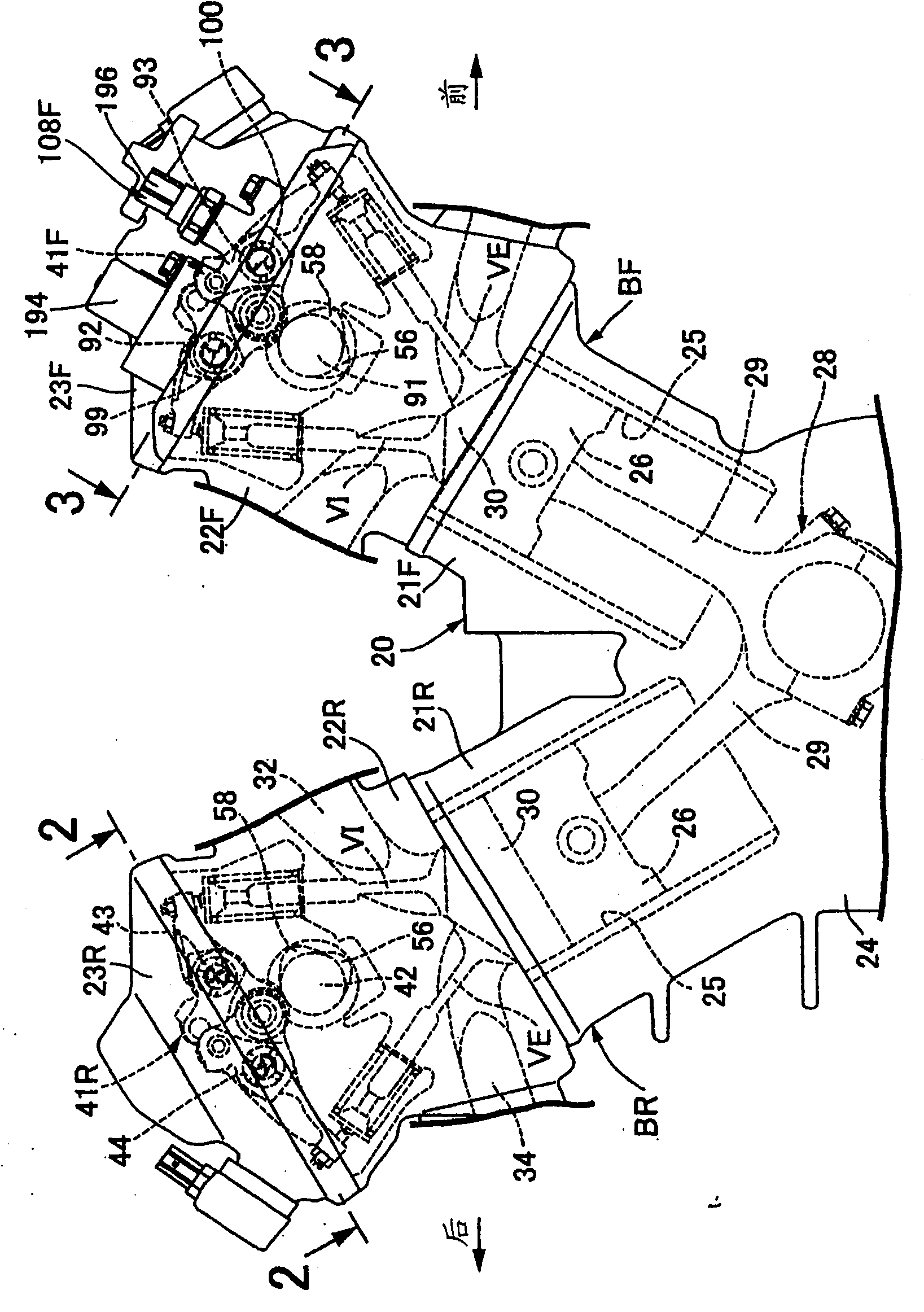

Valve gear control device for internal combustion engine

InactiveCN101779010AImprove sealingImprove installation rigidityValve arrangementsCasingsSpool valveHydraulic control unit

A valve gear control device for an internal combustion engine is adapted such that hydraulic pressure control means controls hydraulic pressure applied to a valve operation mode change mechanism. The hydraulic pressure control means has a holder mounted on a cylinder head, a spool valve formed by slidably installing a spool valve body in a valve body, and electromagnetic on-off valves for controlling hydraulic pressure in a pilot hydraulic pressure chamber. The holder (109) is constructed by integrally interconnecting a to-be-received section (109a) and a projection section (109b) by a connection section (109c). The to-be-received section (109a) is received between the head cover and the cylinder head (22R). The projection section (109b) projects outward from the cylinder head (22R) and the head cover and having the electromagnetic on-off valves (113, 114) mounted on the projection section (109b). A seal surface (116) between the connection section (109c) and the head cover is formed on the connection section (109c), and the valve body (110) is provided contiguous to the to-be-received section (109a) so as to be received between the head cover and the cylinder head (22R). This enhances sealing characteristics between the holder and the head cover.

Owner:HONDA MOTOR CO LTD

Steering mechanism of motor vehicle

InactiveCN100999222AImprove installation accuracyImprove installation rigiditySteering gearsUniversal jointMotor vehicle part

The present invention relates to a motor-vehicle steering mechanism. It includes an angle change-over device connected with vehicle body by means of mounting supporting frame, the input end of said angle change-over device is connected with input universal joint, its output end is connected with output universal joint. It is characterized by that between the described angle change-over device and vehicle body a fixed supporting frame is set, said fixed supporting frame is respectively connected with the described angle change-over device and symmetrical surface of said vehicle body by means of screw bolts. Besides, said invention also provides its working principle and concrete operation method.

Owner:CHERY AUTOMOBILE CO LTD

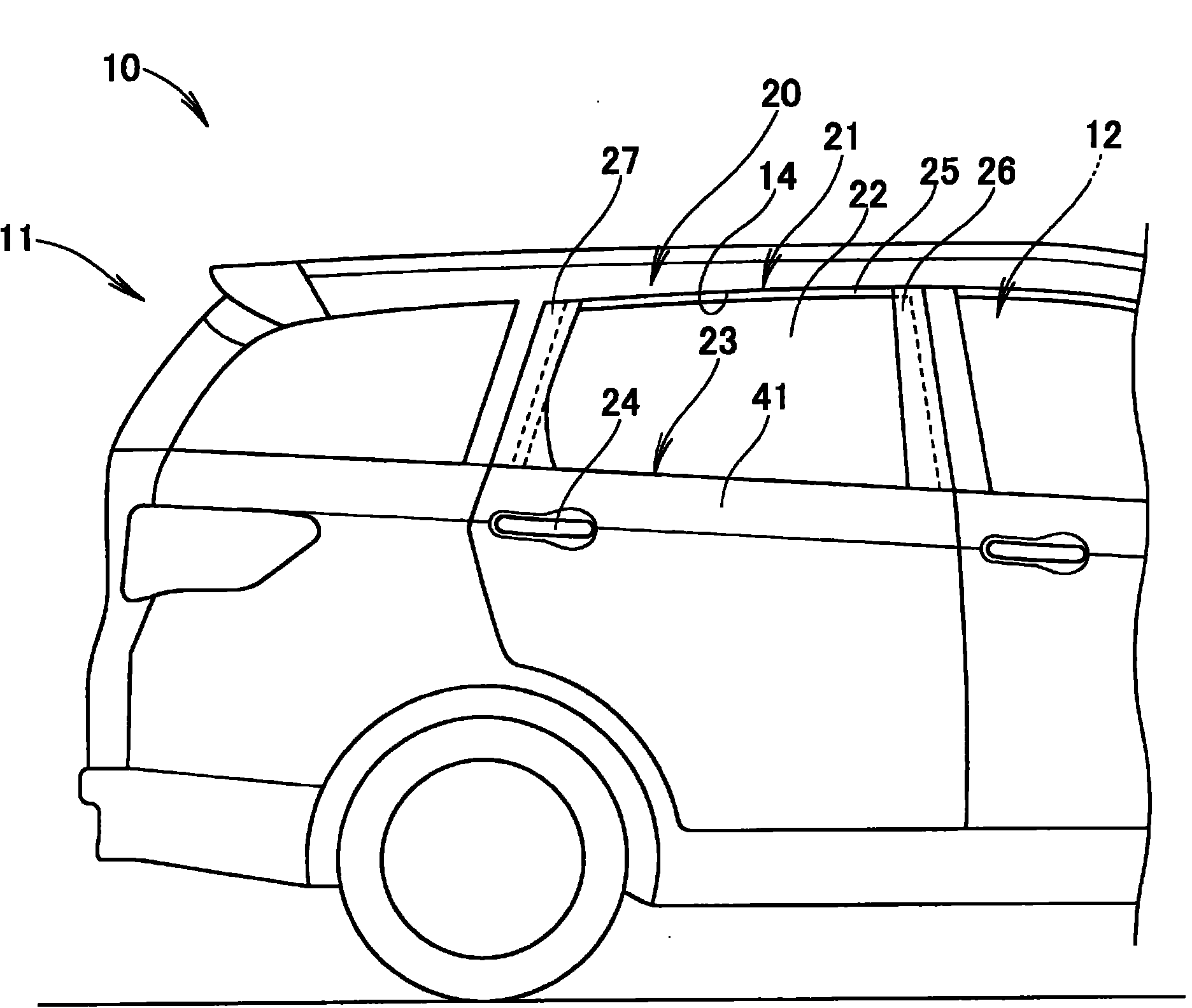

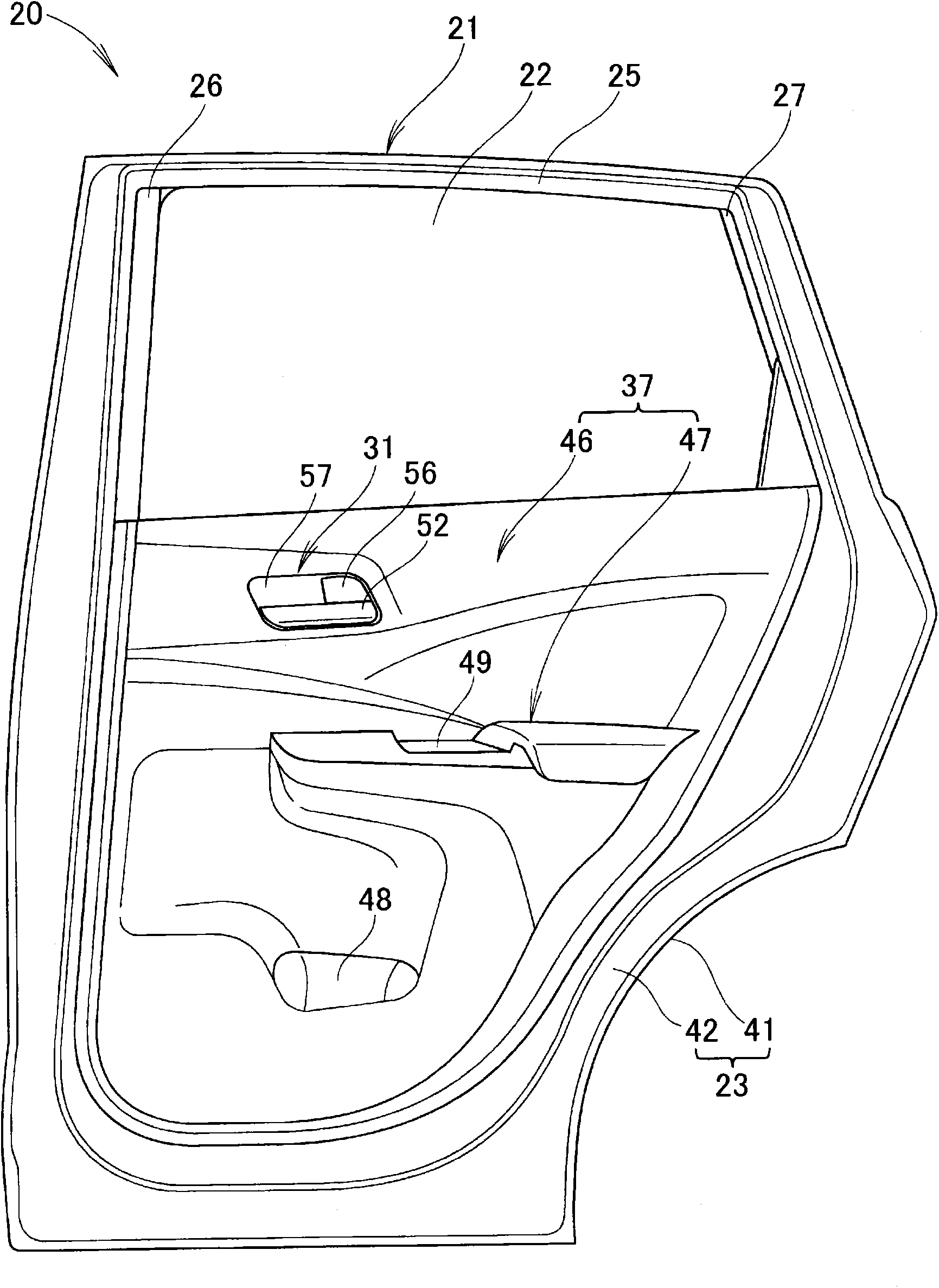

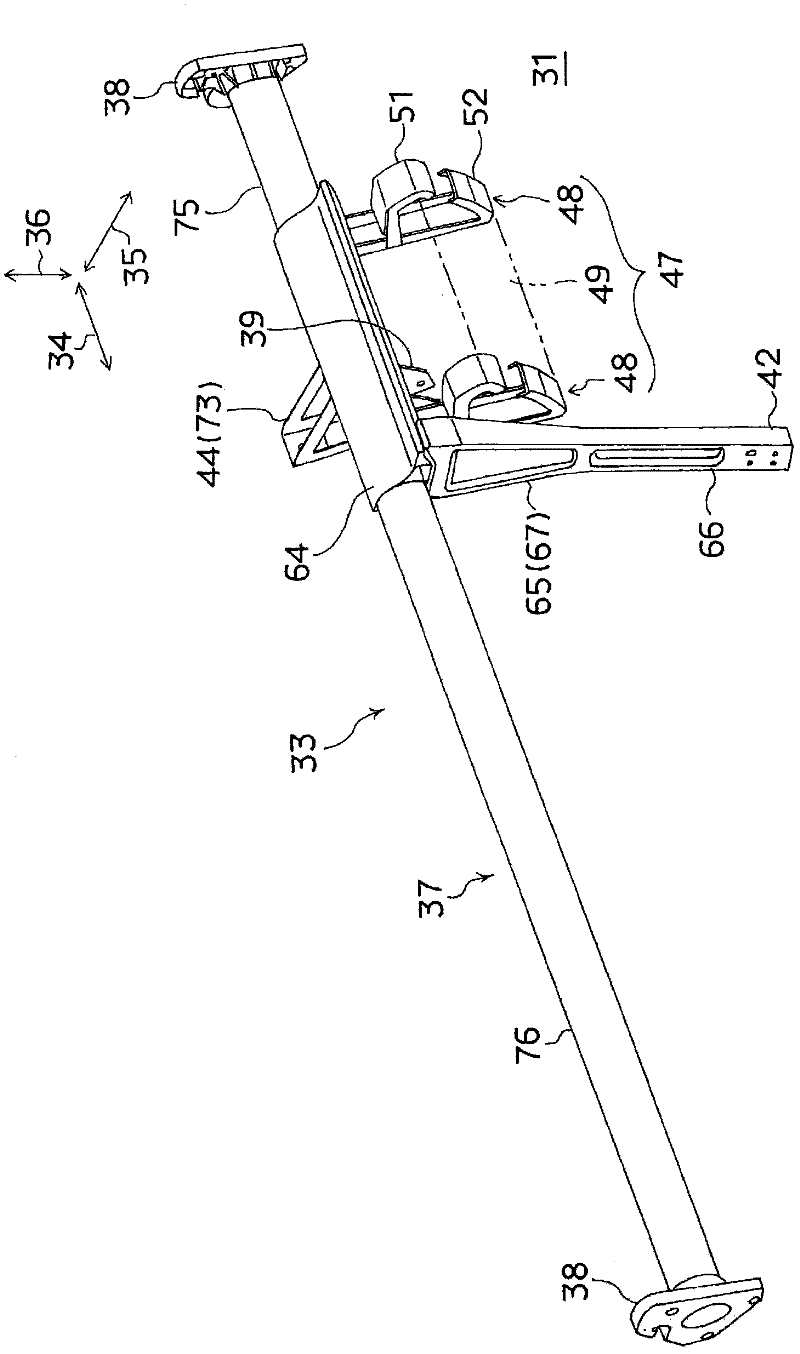

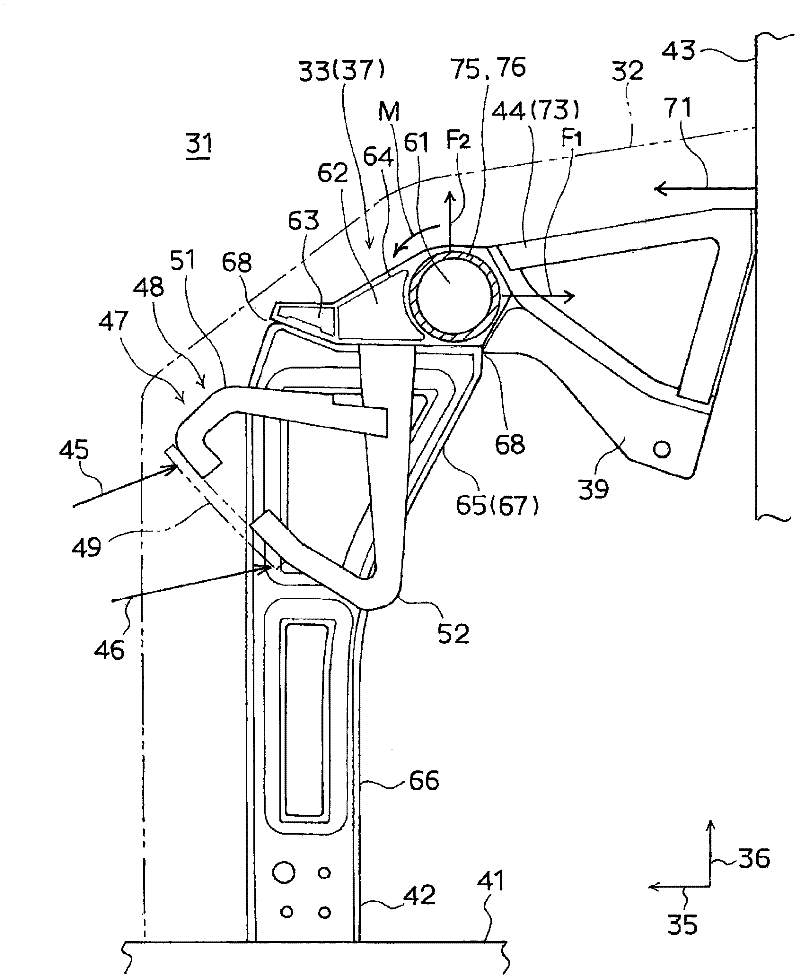

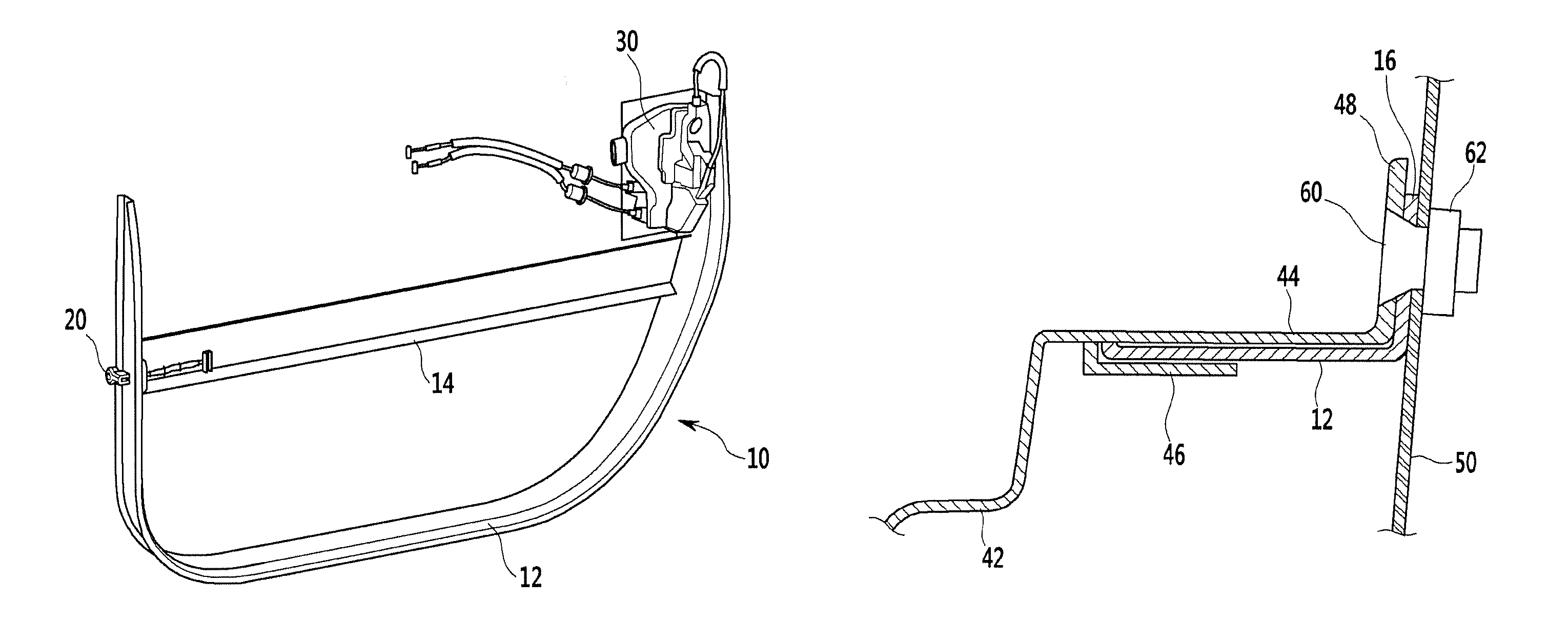

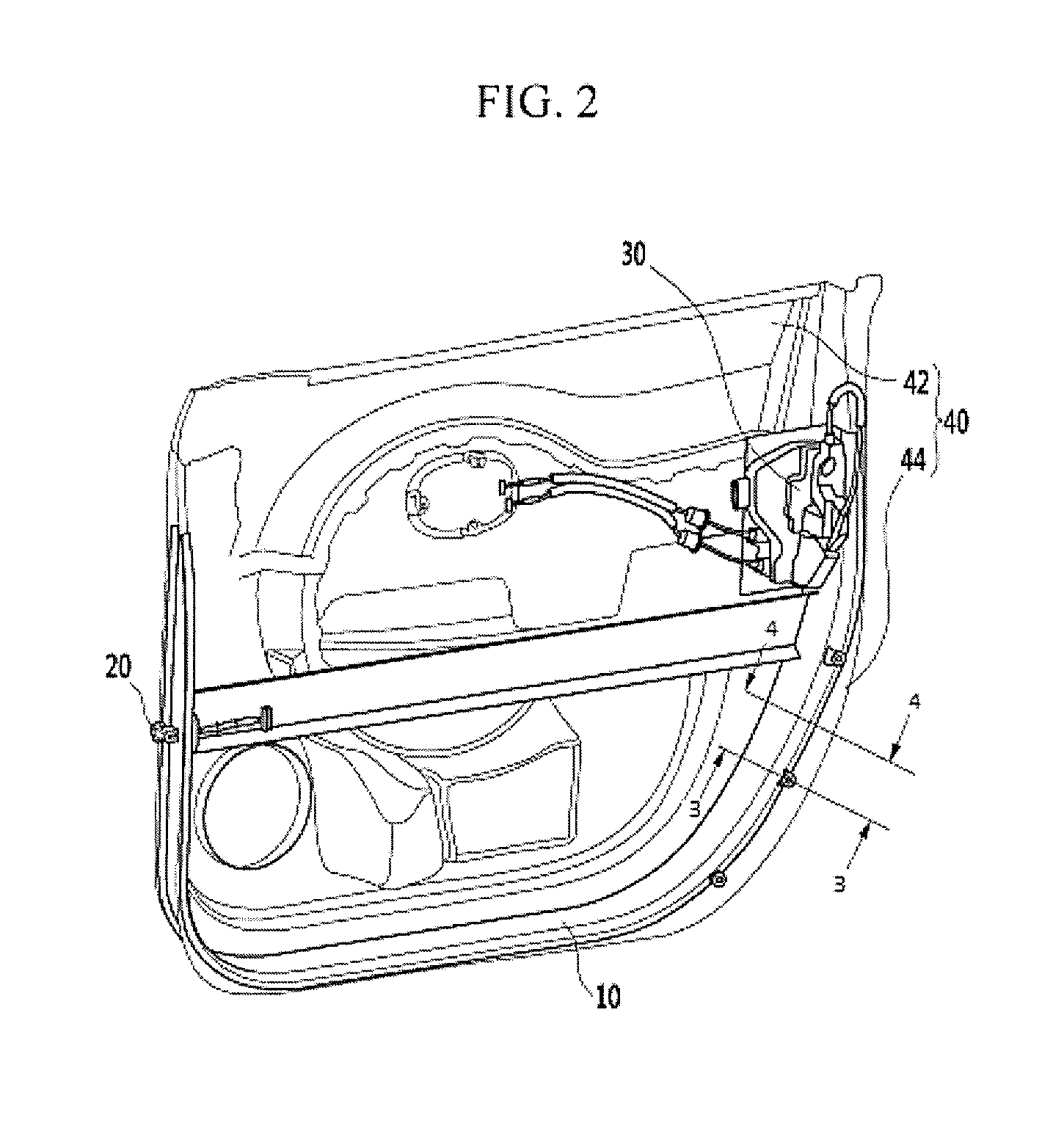

Door device for vehicle

ActiveCN103459735AEasy to operateOmit confirmation workVehicle locksWing handlesElectrical and Electronics engineeringCar door

A door device for a vehicle includes: a cable (35) for connecting a handle device (31), which is mounted to the door panel (23) of the door body (21) covering a door opening (14) of the vehicle body (11) in an openable and closable manner, and a lock unit (32), with which the door body (21) is engaged. A cable holding member (58) mounted to the handle device (31) is displaced between an engagement position (A1) at which the cable holding member (58) engages with the cable (35) and a non-engagement position (A2) at which the cable holding member (58) does not engage with the cable (35). An interference section (44) is provided to the door panel (23). The interference section (44) is configured in such a manner that, in a state in which the handle device (31) is mounted to the door panel (23), the interference section (44) interferes with the cable holding member (58) located at the non-engagement position (A2) and does not interfere with the cable holding member (58) located at the engagement position (A1).

Owner:HONDA MOTOR CO LTD

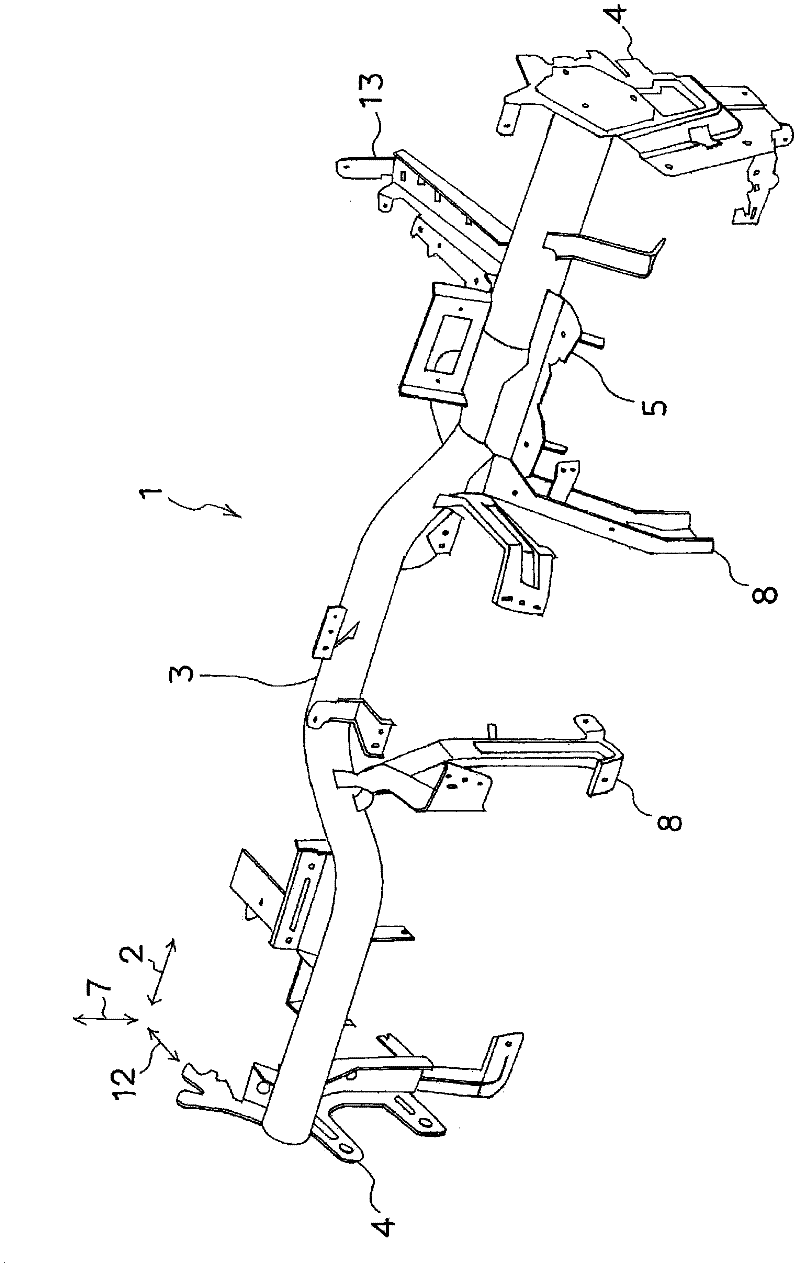

High-strength member structure for auto bodies

InactiveCN102224060AAvoid mobilityAvoid bendingUnderstructuresSuperstructure subunitsKnee protectorEngineering

To improve the strength and rigidity of the main body of high-strength members for auto bodies, the high-strength member structure for auto bodies is provided with an auto body high-strength member main body (37) that is provided at the front of the cabin (31) of the vehicle and extends essentially in the direction of the car width, a high-rigidity structural part (64) that is provided at least in the middle of said auto body high-strength member main body (37) and has multiple closed cross-sections in the fore-aft direction of said vehicle, a stay (42) that is attached to said high-rigidity structural part (64) and supports said auto body high-strength member main body (37) in the vertical direction, a post bracket (44) that is attached to said high-rigidity structural part (64) and supports said auto body high-strength member main body (37) in the fore-aft direction of the vehicle, and a knee protector (47) that is attached to said high-rigidity structural part (64) and can accept the passengers' knees to absorb an input load to the knees when a sudden input load acts in the fore-aft direction of the vehicle.

Owner:CALSONIC KANSEI CORP

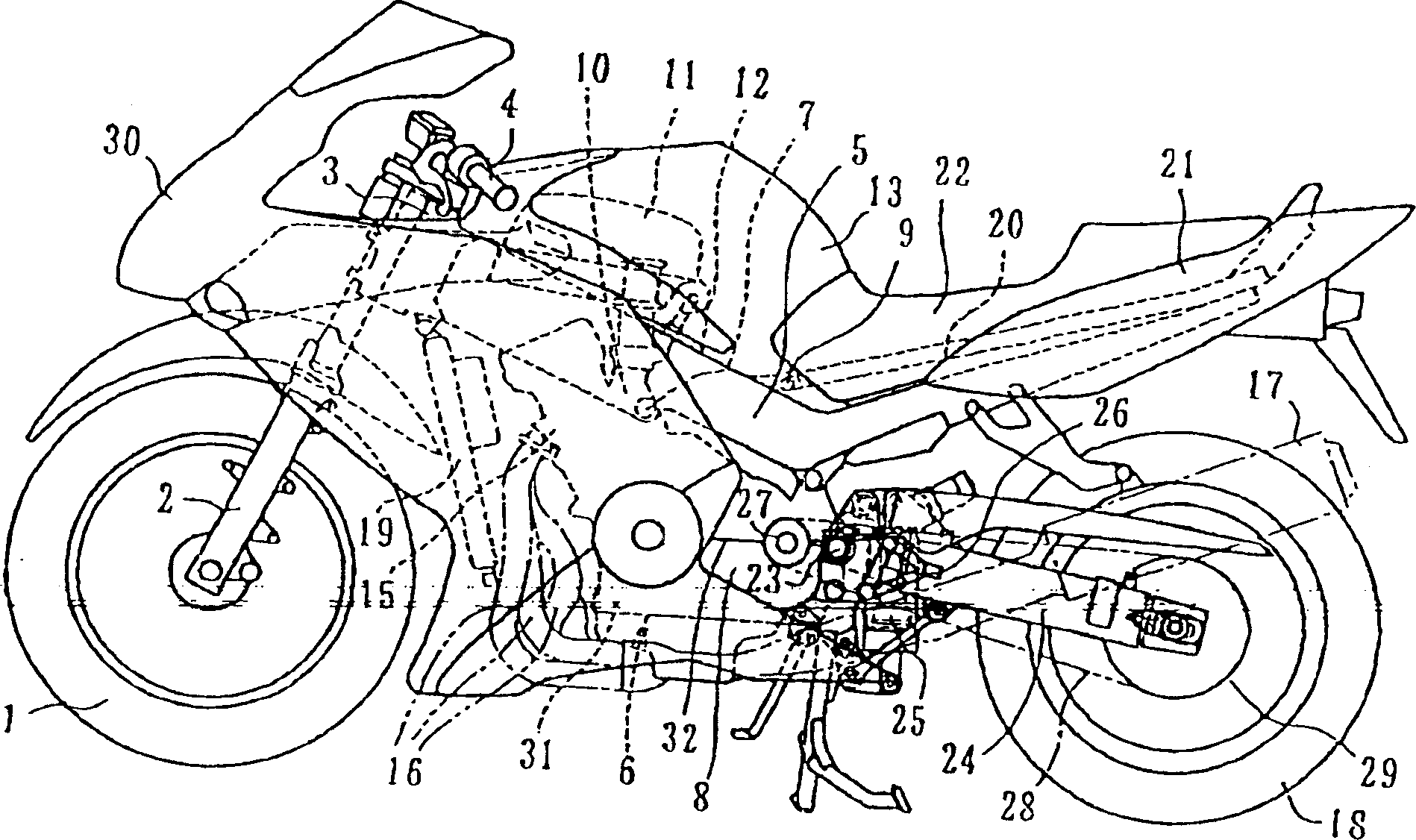

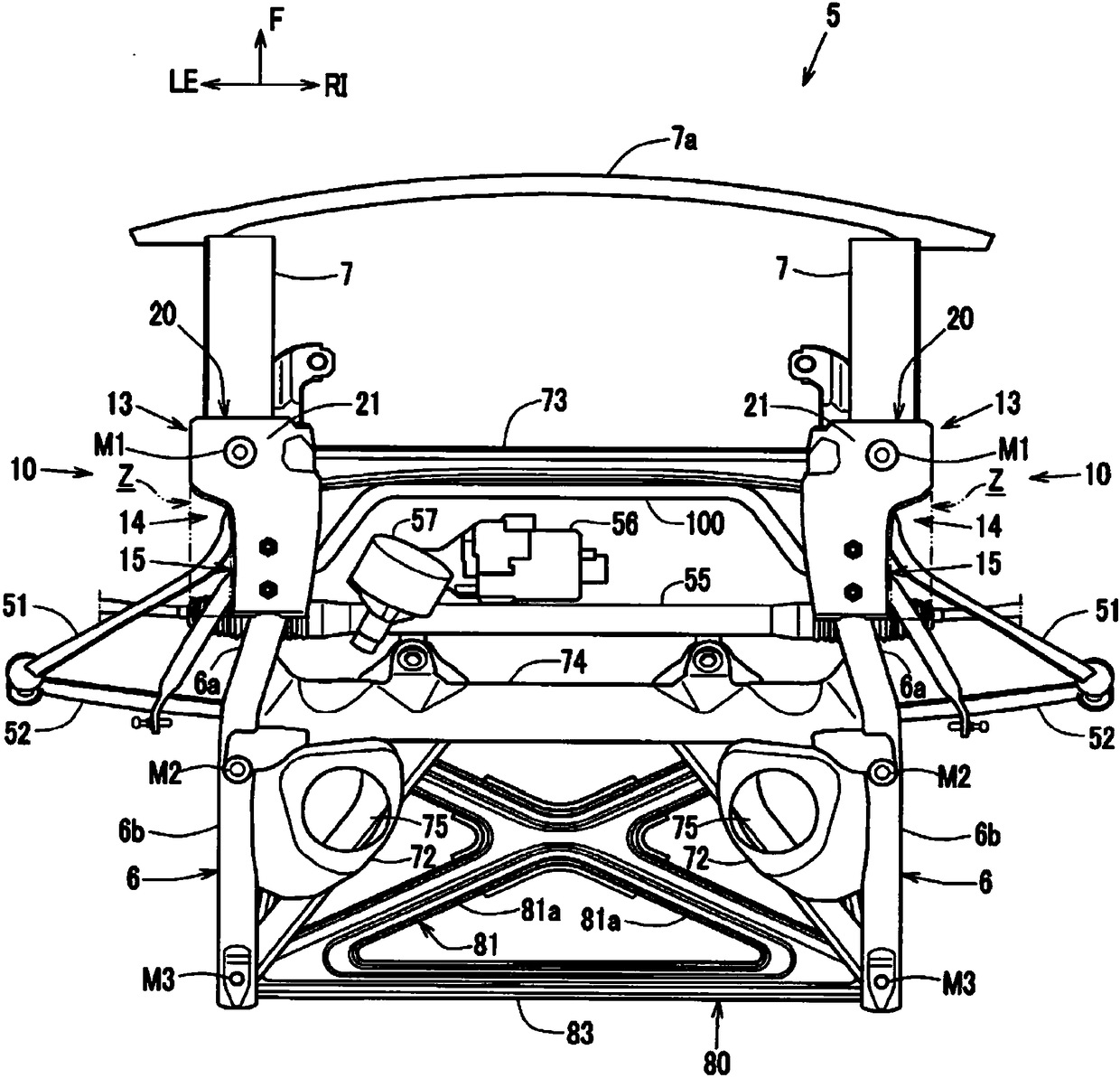

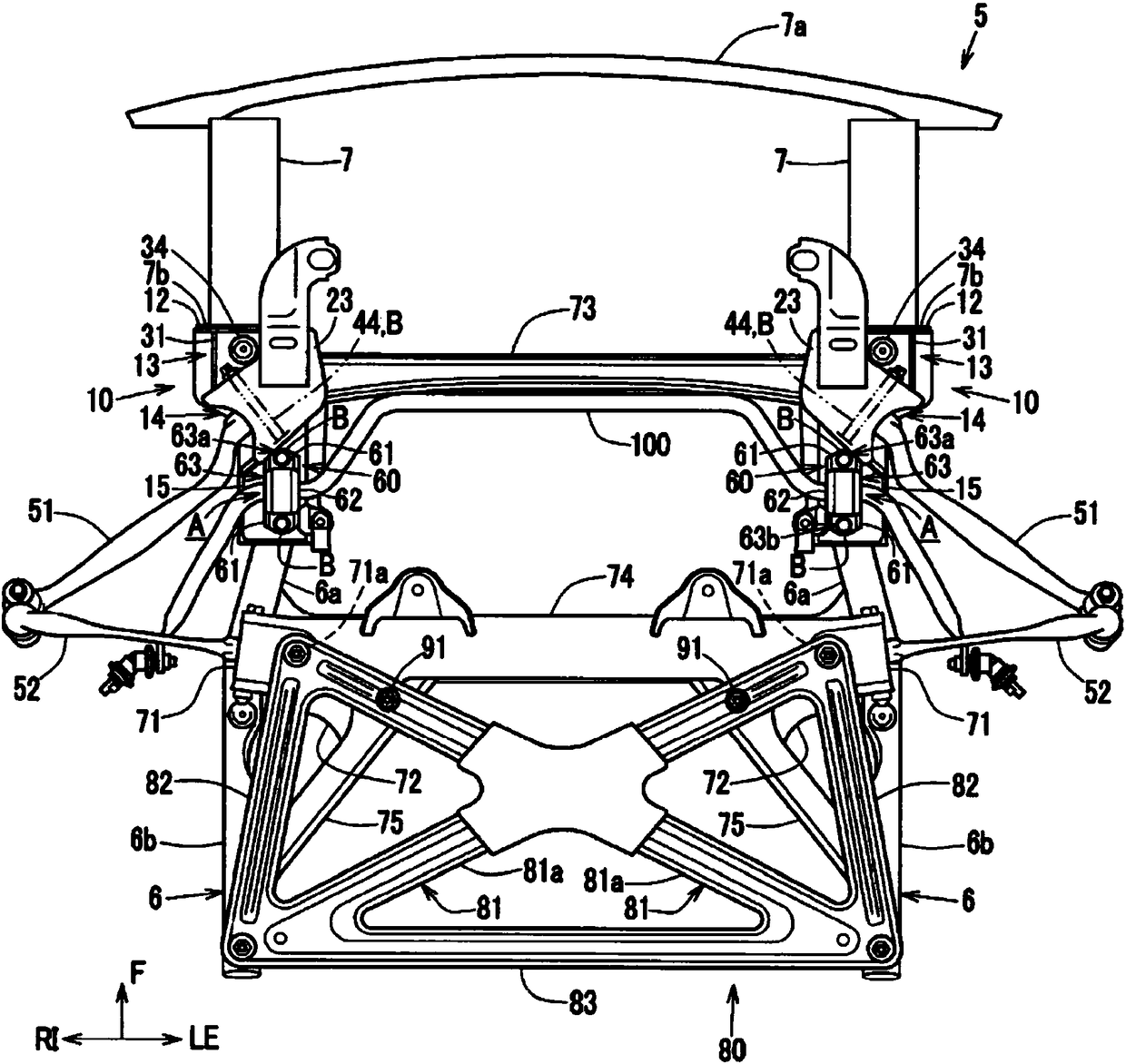

Structure for installing a rear cushion

A structure for installing a rear cushion in a motorcycle having a hydraulic shock absorber with a subsidiary cylinder used as the suspension device. The swing arm includes a pair of left and right arm portions, the respective front portions being coupled with a first cross member and a second cross member. A pair of cushion brackets extend in the back-and-forth direction with the upper portion of the rear cushion sandwiched therebetween. The front and rear ends of the cushion brackets are coupled to the first and second cross members, thereby supporting the cushion brackets at both ends. An upper portion of the rear cushion fits within a space enclosed by the first and the second cross members, and the left and right cushion brackets, and is coupled to the intermediate portion of the left and right cushion brackets.

Owner:HONDA MOTOR CO LTD

Electric control box structure for space vehicle and assembly method thereof

PendingCN108901171AIncrease usageImprove installation rigidityClamping/extracting meansEngineeringElectric control

The invention provides an electric control box structure for a space vehicle and an assembly method thereof. The structure comprises a base and a steamer machine case, wherein the steamer machine casecomprises an upper layer steamer machine case and lower layer steamer machine case; the base comprises a bottom plate and a side plate; the side plate is arranged around the bottom plate so as to form a splicing structure; an electronic element and PCBs are arranged in the splicing structure; a horizontal framework structure is arranged inside the splicing structure; the horizontal framework structure is used for installing the electronic device and the PCBs; the lower layer steamer machine case is arranged on the splicing structure in the horizontal direction; the upper layer steamer machinecase is arranged on the lower layer steamer machine case in the horizontal direction; the PCBs are respectively arranged in the lower layer steamer machine case and the upper layer steamer machine case. By using the scheme, the space utilization rate of the existing electric control box installation and design structure can be improved, so that the problem of space waste inside the machine case is solved. By using the technical scheme provided by the invention, the structure is compact and reasonable; the assembly and the dismounting are convenient; the shielding performance is good; the costis relatively low.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Front sub-frame structure

InactiveCN108349537AImprove support rigidityImprove installation rigidityUnderstructuresBumpersVehicle frameWeight transfer

In order to increase tension rod support rigidity and sub crush can attachment rigidity, while forming a front sub-frame front section using a plate material, the present invention has a configurationwhereby: a sub crush can attachment section (12) and a tension rod support section (14) are provided in a front section of a front sub frame (5); a front-side vehicle body attachment section (13) isprovided between both; a suspension cross member (73) is provided in the front-side vehicle body attachment section (13) and the tension rod support section (14); the front-side vehicle body attachment section (13) comprises a sub crush can weight transfer member (30); and an upper surface section (21) of the front-side vehicle body attachment section (13) and a partition (33) in the sub crush canweight transfer member (30) extend in the vehicle front / rear direction, separated from each other.

Owner:MAZDA MOTOR CORP

Engine supporting structure for working vehicle

InactiveUS8985261B2Improve installation rigidityDistribute pressureElectric propulsion mountingGas pressure propulsion mountingEngineeringEngine mount

It is an object of the present invention to provide an engine supporting structure for a working vehicle that can realize the simplification of manufacturing processes and the reduction of costs. With respect to an engine supporting structure for a working vehicle (backhoe) that includes an engine and a plurality of engine mounts to support the engine, the engine supporting structure includes one piece of mount plate to support the plurality of engine mounts, wherein the mount plate is supported by a stand having a skin-stressed sheet-metal body construction, surrounding with beams welded to the left and right end portions of the mount plate, and with beams welded to the anterior and posterior end portions of the mount plate.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Resin molded article and molding method thereof

ActiveUS7976928B2Improve rigidityImprove installation rigidityLayered productsThin material handlingShell moldingEngineering

An annular mount base 11 continuously protruded from one face of a panel main body 3 and surrounding a through hole 9 has a dual structure of an inner mount base portion 17 and an outer mount base portion 19 which are joined to each other by four parts of a joint mount base portion 21. A skin layer 23 is formed at the surface of a door inner panel 1. An expanded layer 25 with a large number of pores is formed inside the panel main body 3. The mount base 11 and a part of the panel main body 3 between the inner mount base portion 17 and the outer mount base portion 19 are formed of a solid layer 27 having no expanded layer 25. Whereby, a lightweight resin molded article including a high-rigidity mount base is provided.

Owner:DAIKYONISHIKAWA CORP

Vehicle door structure

ActiveUS9555695B2Improve installation rigidityIncrease stiffnessSuperstructure subunitsDoorsCar doorEngineering

Owner:HYUNDAI MOTOR CO LTD

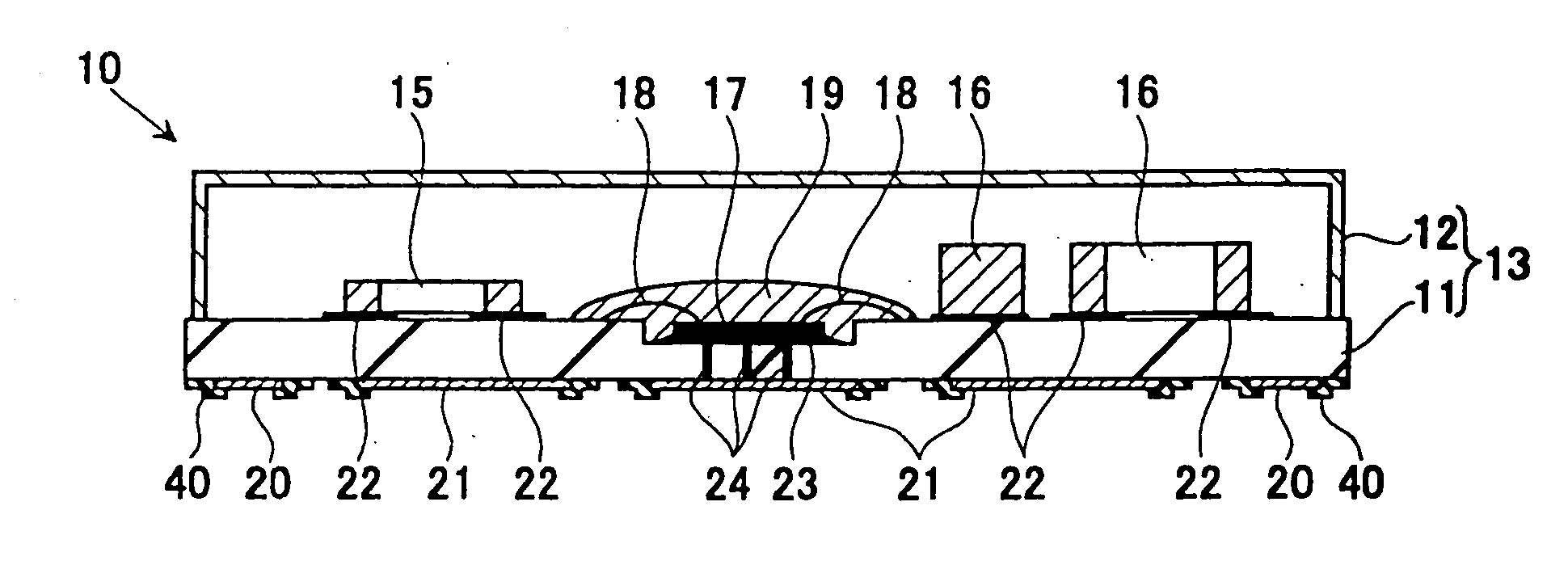

Hybrid integrated circuit device, and method for fabricating the same, and electronic device

InactiveUS20060091526A1Improve installation rigidityComfortable communicationPrinted circuit assemblingGain controlTectorial membraneMicrometer

A hybrid integrated circuit device having high mount reliability comprises a module substrate which is a ceramic wiring substrate, a plurality of electronic component parts laid out on the main surface of the module substrate, a plurality of electrode terminals laid out on the rear surface of the module substrate, and a cap which is fixed to the module substrate to cover the main surface of the module substrate. The electrode terminals include a plurality of electrode terminals which are aligned along the edges of the module substrate and power voltage supply terminals which are located inner than these electrode terminals. The electrode terminals aligned along the substrate edges are coated, at least in their portions close to the substrate edge, with a protection film having a thickness of several tens micrometers or less. Connection reinforcing terminals consist of a plurality of divided terminals which are independent of each other, and are ground terminals.

Owner:RENESAS ELECTRONICS CORP

Vehicle lateral rod mounting apparatus

InactiveCN1126670CImprove layout freedomImprove installation rigidityInterconnection systemsResilient suspensionsCross pinEngineering

The invention provides a cross bar installation structure, which structure comprises: a pin insertion hole in the side wall of a spring plate; a cross pin with a longitudinal end of the cross bar and a The horizontal pin fixed installation part in the parallel, fixedly installed on the tubular part of axle housing, the side wall part of spring plate and the horizontal pin bracket on the horizontal pin fixed installation part. The structure can improve the installation rigidity of the cross pin, increase the installation rigidity of the cross pin in the lateral direction of the vehicle, increase the degree of freedom in arrangement of the cross bar, reduce cost and save space, and improve the accuracy of the installation position of the cross pin.

Owner:SUZUKI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com