Multiple-cutting-edge cutter-bit and multiple-cutting-edge cutter-bit type cutting tool

A cutting tool and blade technology, applied in the field of multi-edged blades, can solve problems such as blade damage, blade offset, damage to the processing surface, etc., to achieve the effects of preventing precision, stable and smooth cutting, and improving installation rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

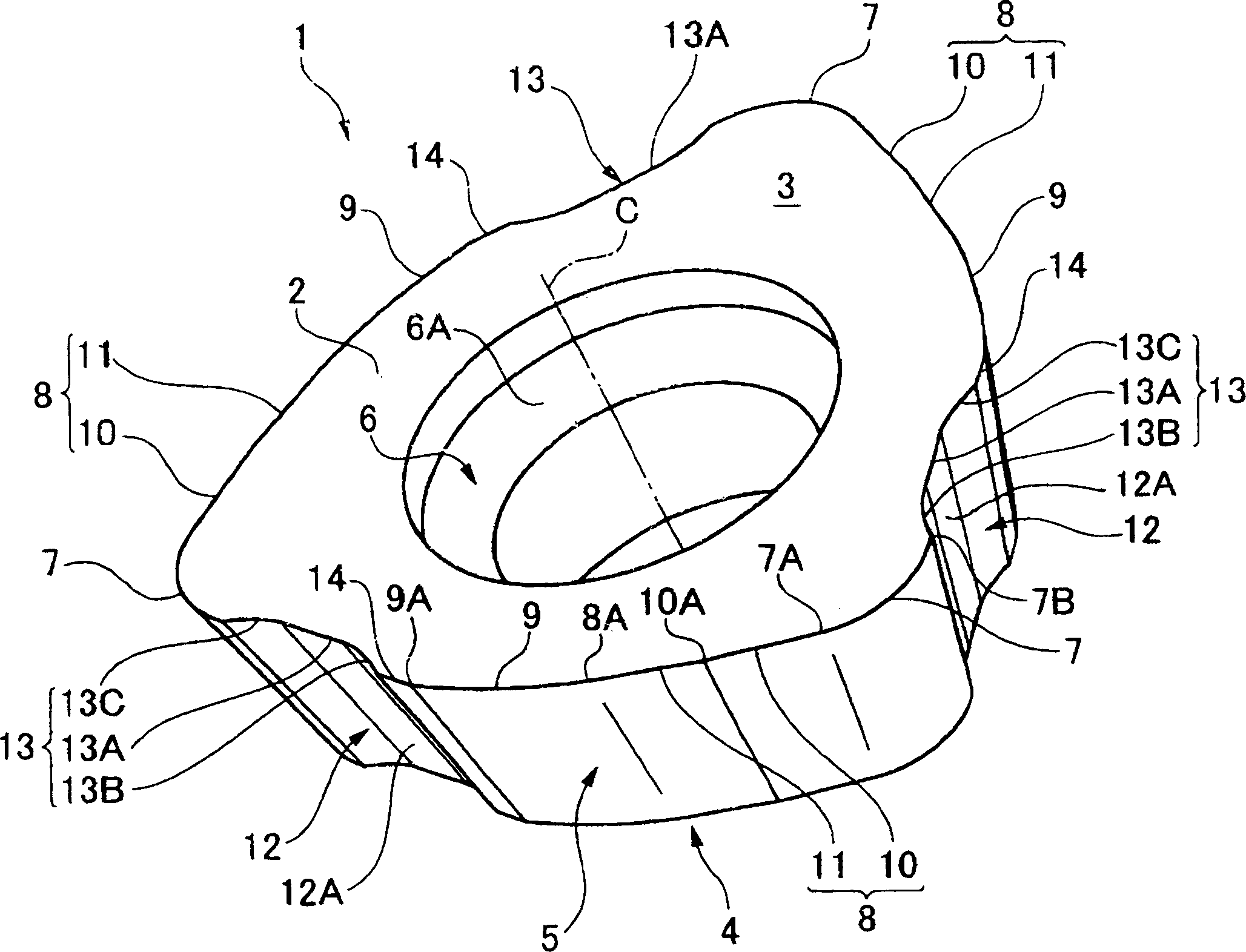

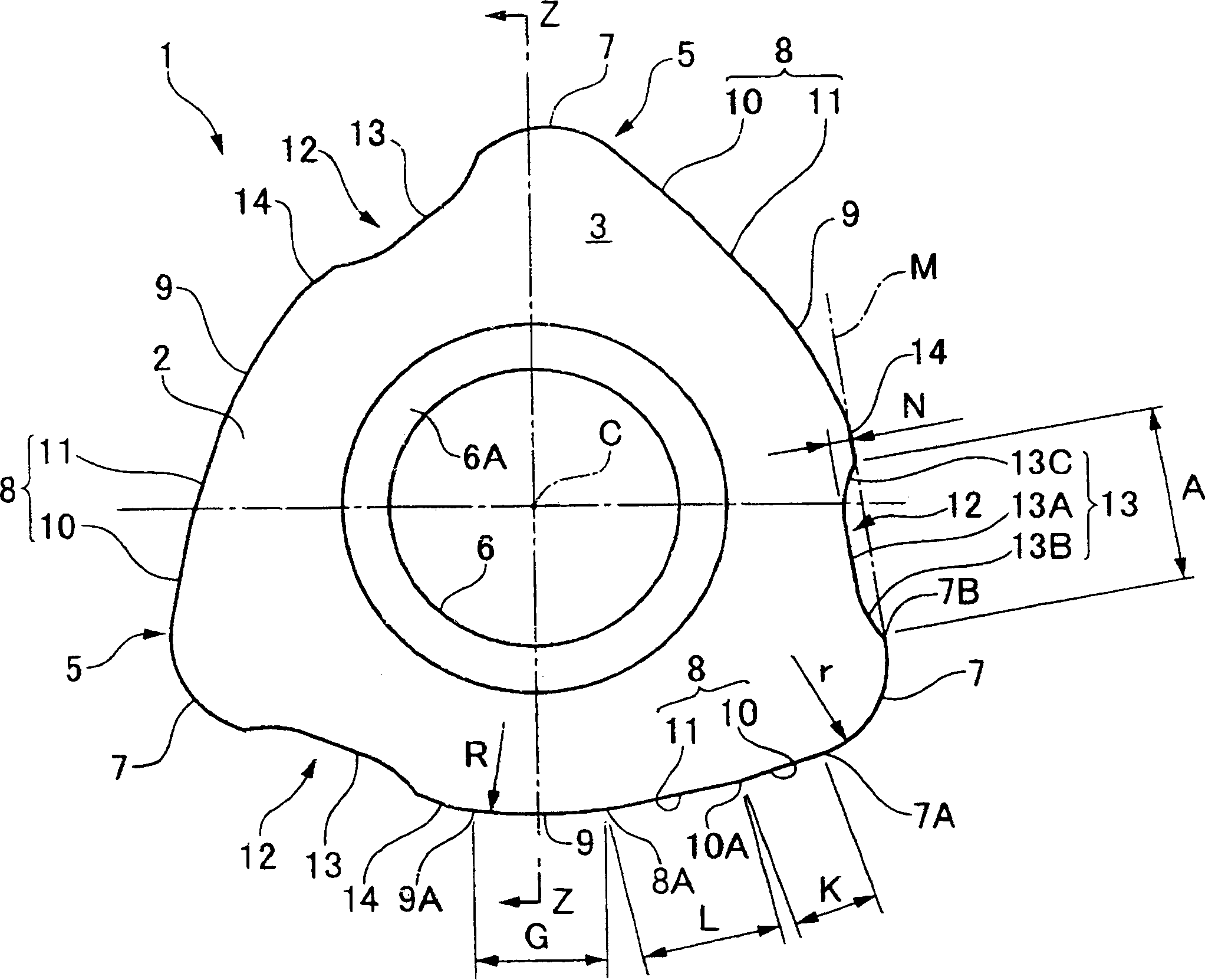

[0027] Figure 1 to Figure 4 It is a figure which shows the blade 1 of 1st Embodiment of this invention. The blade 1 of this embodiment forms its blade main body 2 with hard materials such as cemented carbide alloys, and its profile is a roughly equilateral triangle (more specifically, a hexagonal) plate shape, constituting one face of a roughly equilateral triangle as the front The rake face 3 and the other face serve as a support face 4 parallel to the rake face. In addition, a relief face 5 is formed on the sides around the rake face 3 and the support face 4. Cutting edges are formed on intersecting ridgeline portions of the rake face 3 , that is, edge portions of the rake face 3 . In addition, the insert 1 of the present embodiment is a positive insert with an edge bevel on the relief surface 5 by intersecting the rake surface 3 and the relief surface 5 via cutting edges to form an acute angle. In other words, the support surface 4 is formed into a similar shape that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com