Electric wire routing structure

A technology for electric wires and protective components, which is applied in the field of wire layout structure of protective components, can solve the problems of increased workload, increased number of parts, and increased transportation efficiency, so as to reduce the workload of assembly, reduce the number of parts, and improve transportation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

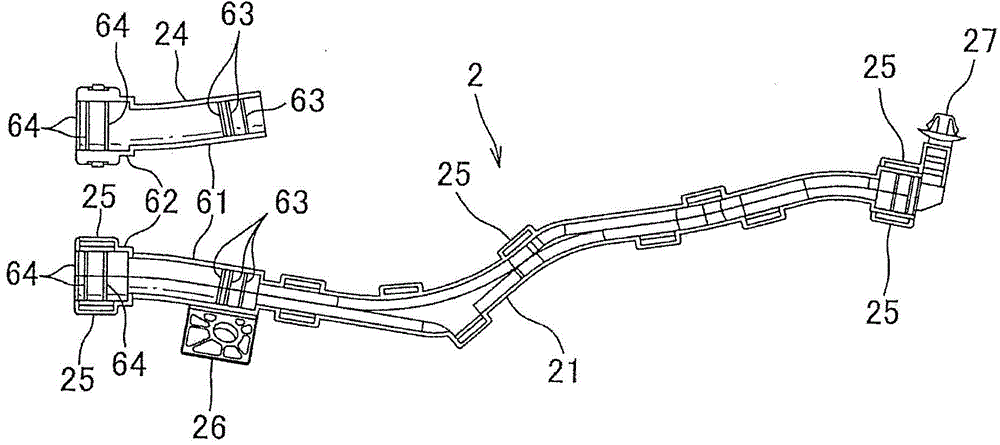

[0042] will now refer to Figure 1A to Figure 5B A wire routing structure according to an embodiment of the present invention will be described. The electric wire routing structure of this embodiment is used as a structure that is used in, for example, a vehicle, particularly an electric vehicle running with the driving force of an electric motor or a vehicle running with both the driving force of the engine and the electric motor. In a hybrid car, it is connected between the battery and the inverter and between the inverter and the electric motor. The electric wire routing structure is configured to have electric wires W connected to electric devices and an outer member 1 serving as a protective portion covering and protecting the electric wires W, wherein the electric wires W covered with the outer member 1 are laid longitudinally, for example, on the underfloor of the vehicle. extend. The electric wire W connects, for example, a battery installed in a trunk room on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com