Door structure of automotive vehicle

A door and car technology, applied in the direction of doors, door leaves, vehicle locks, etc., can solve the problems of handle base movement, handle movement, illegal unlocking of doors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

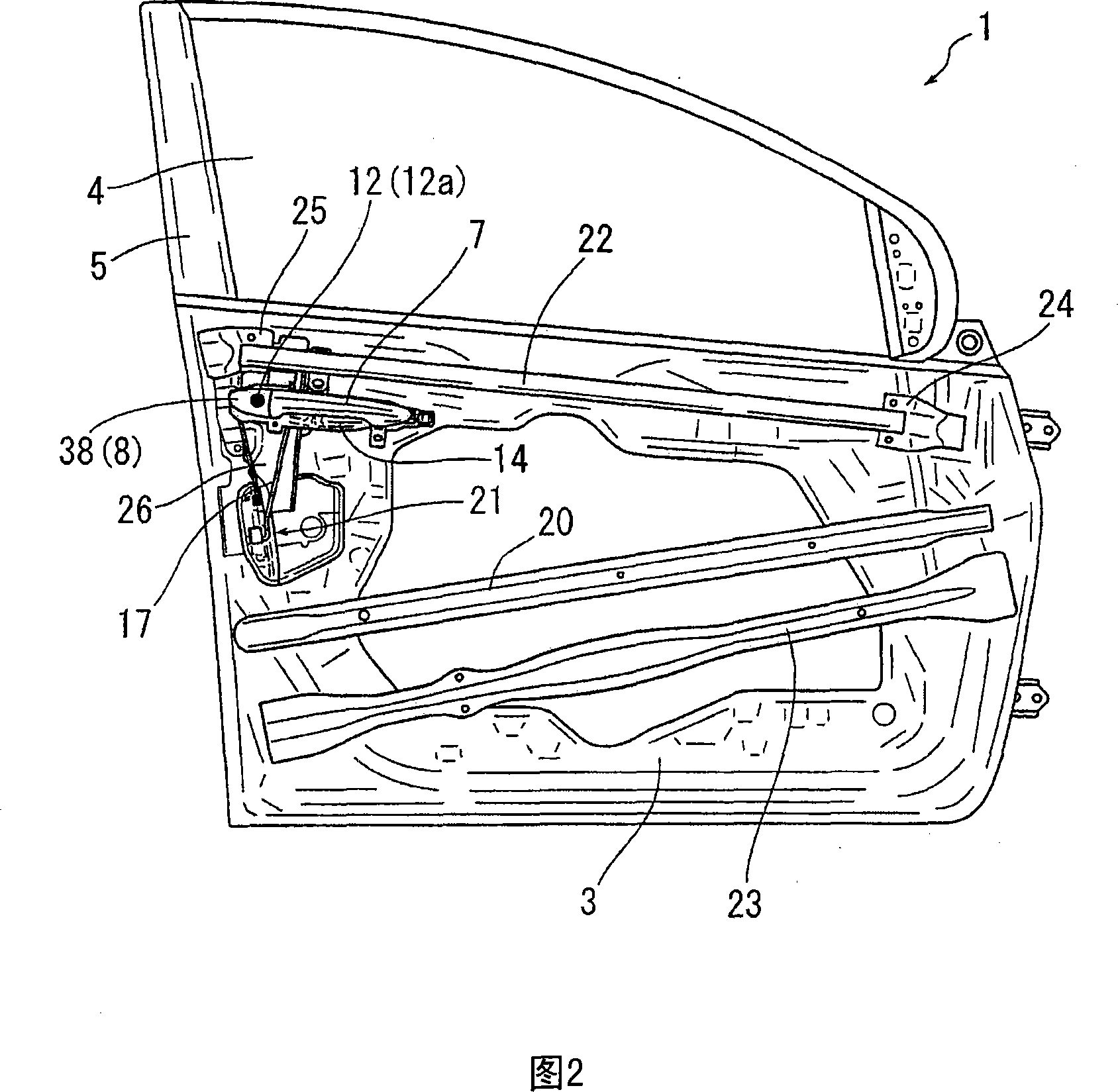

[0057] In FIGS. 1 and 2 , reference numeral 1 denotes a front door applied to a door structure according to an embodiment of the present invention. The front door 1 includes: a steel door outer panel (hereinafter referred to as the outer panel) 2; a steel door inner panel (hereinafter referred to as the inner panel) 3 arranged on the inner side of the door outer panel 2; A window frame 5 made of steel plate is provided on the upper part of the window glass 4 . In addition, FIG. 2 has shown the state which removed the said outer panel 2 in the state of FIG. 1. As shown in FIG.

[0058] The outer side of the above-mentioned outer panel 2, as shown in FIGS. 1 to 3 and FIG. 1, on the left end side), a handle 7 and a block (block) 8 are provided.

[0059] The handle 7 is used to open and close the front door 1 . The handle 7 extends in the front-rear direction (left-right direction in FIGS. 1 and 2 ) on the rear end side of the front door 1 . On the outer panel 2, in order to m...

no. 2 Embodiment approach

[0082]Fig. 11 shows a second embodiment. In this second embodiment, the mounting piece portion 30' and the mounting member 31' are expanded laterally (the front and rear direction of the vehicle body) compared to the above-mentioned first embodiment, and the upper end portion (second mounting portion) of the mounting piece portion 30' and the mounting member The lower ends of 31' are connected by two fastening members 32'. In addition, the lower end portion (first mounting portion) of the mounting piece portion 30' and the handle base 14 are connected by two fastening members 33'. With such a structure, the support rigidity of the above-mentioned handle base 14 can be further improved by the expanded mounting piece portion 30'.

[0083] Of course, in this structure, the above-mentioned mounting part 31' can also be omitted, and at least the above-mentioned body waistline reinforcement 22 and the above-mentioned handle base 14 are directly connected by the mounting piece part ...

no. 3 Embodiment approach

[0085] FIG. 12 is an external side view showing a door structure of an automobile, and a door 101 includes a door main body portion 102 and a door frame portion 103 .

[0086] The door body 102 is formed by joining a door outer panel 104 and a door inner panel 105 as a door panel, as shown in FIG. Inside the door (specifically, inside the door main body 102 ), as shown in FIG. 12 , there are provided a waistline reinforcement 106 and bumpers 107 and 108 extending in the vehicle front-rear direction.

[0087] The vehicle body waistline reinforcement 106 , as shown in FIG. 12 , is a reinforcement extending along the vehicle body waistline in the front and rear directions inside the door 101 . The body waistline reinforcement 106 is composed of a rigid pipe member, and is attached to the door inner panel 105 via brackets 109 and 110 provided at the front and rear.

[0088] In addition, among the above-mentioned upper and lower bumpers 107, 108, the upper bumper 107 is mainly use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com