Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

204results about How to "Improve defogging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

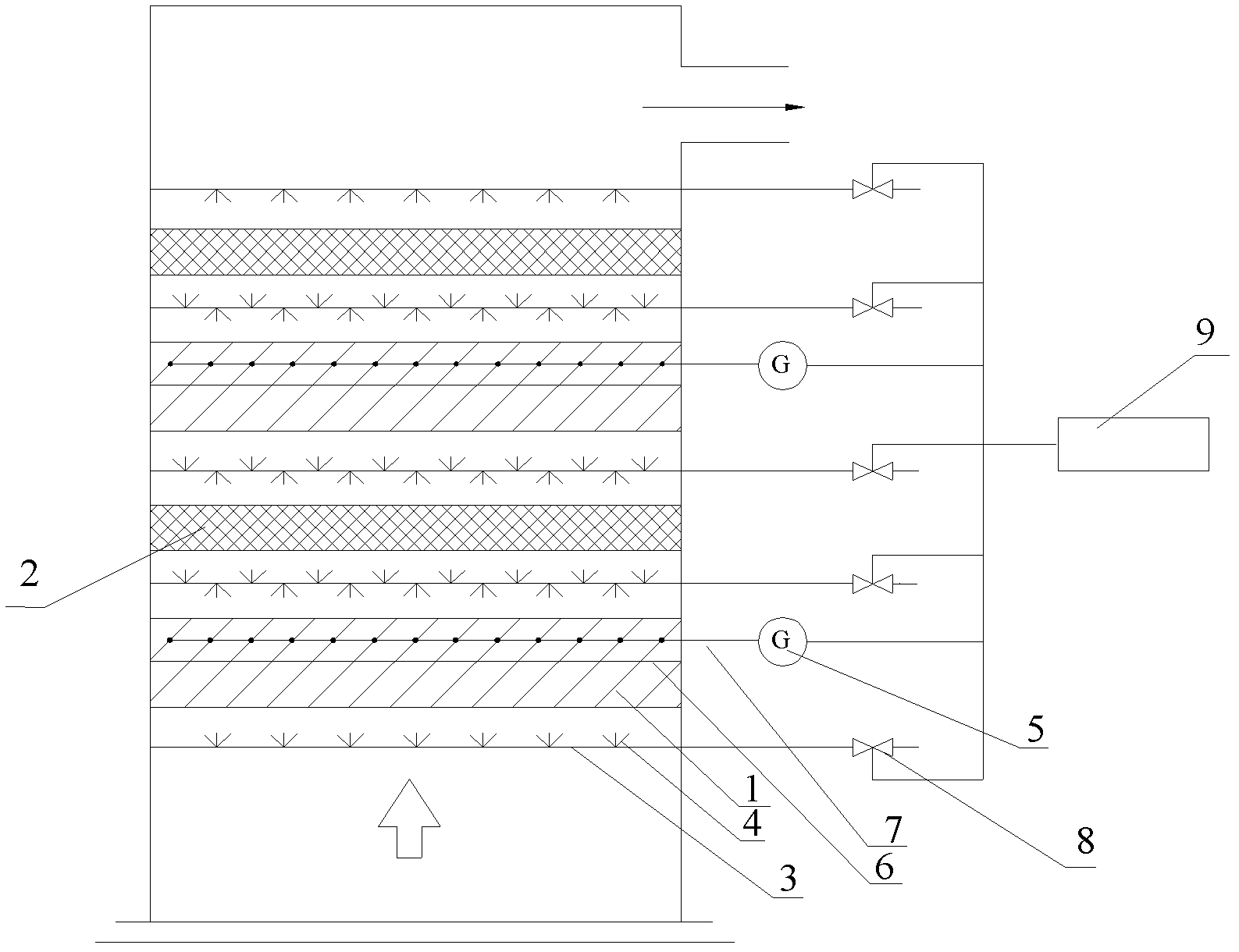

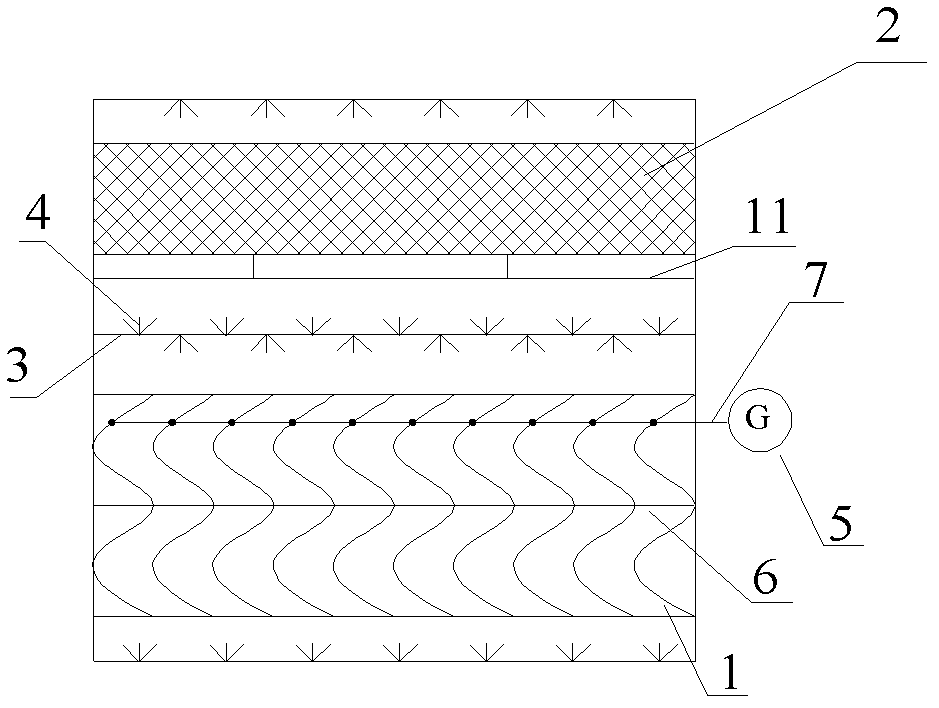

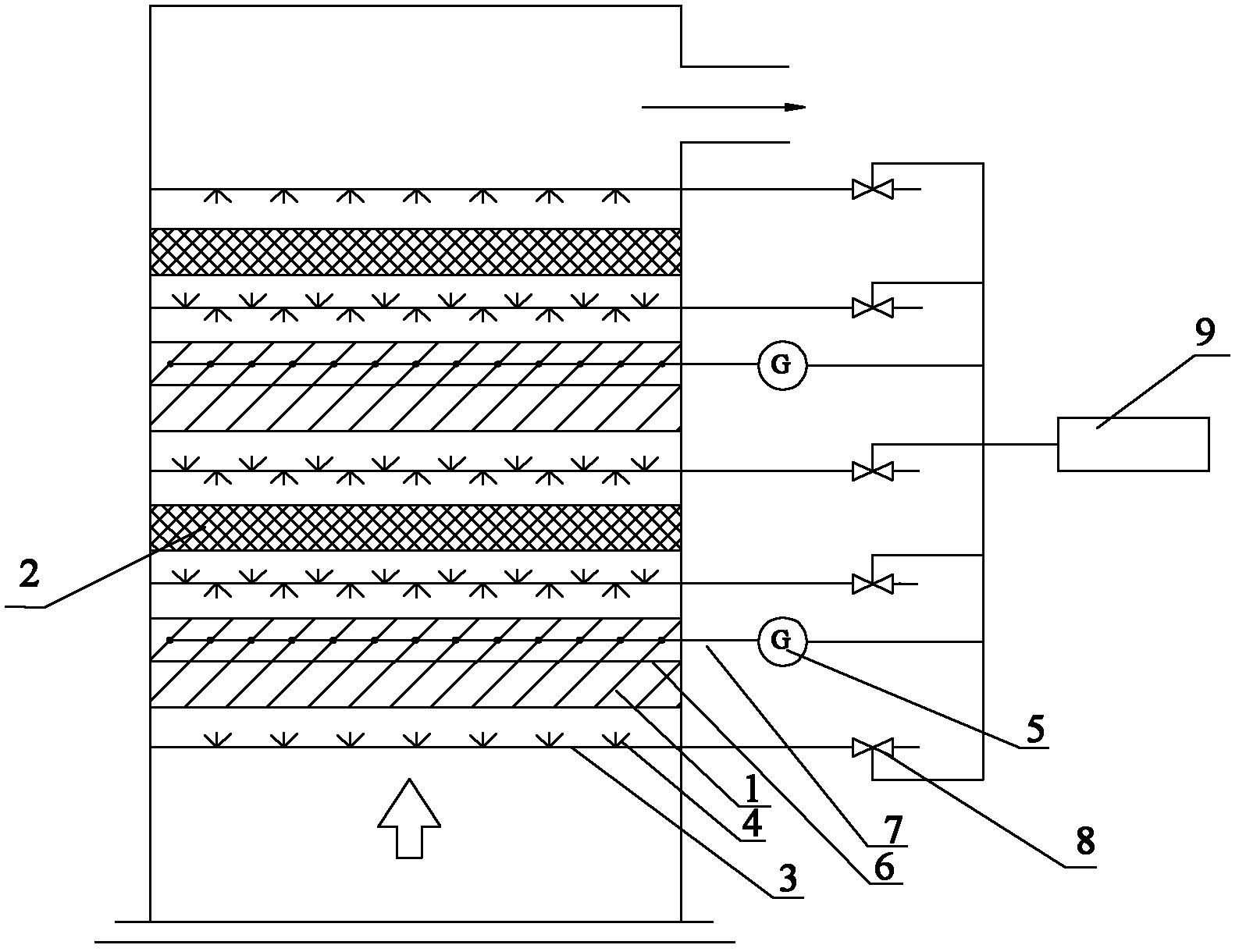

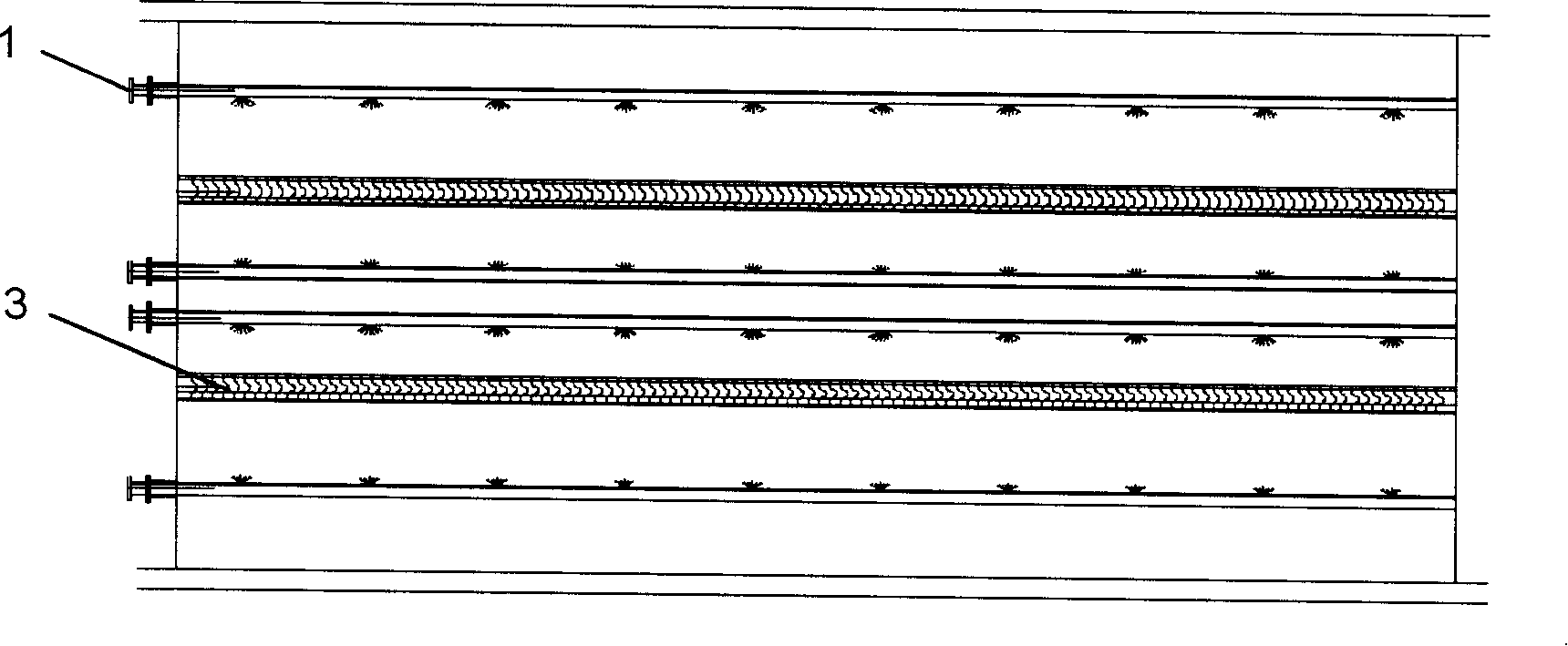

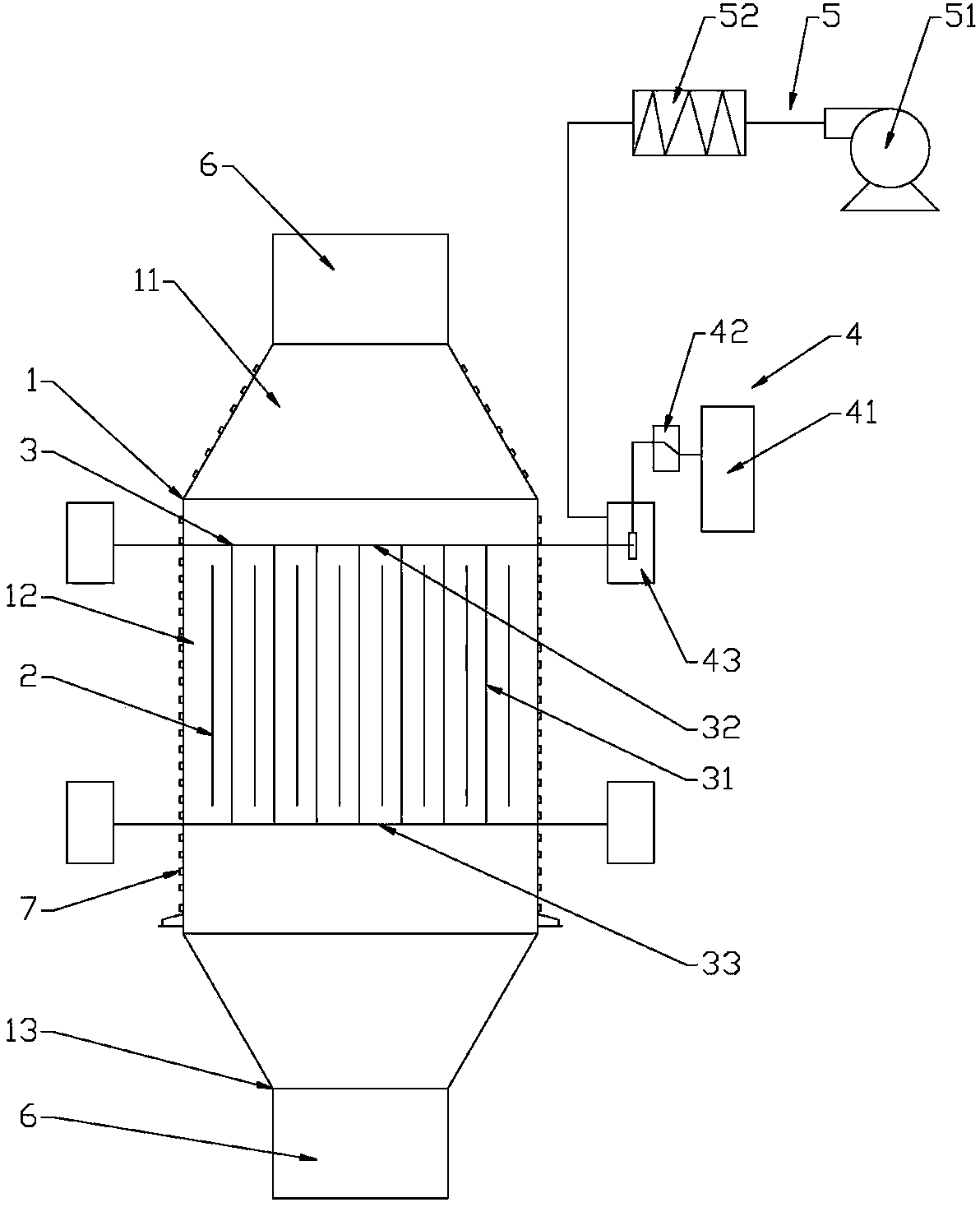

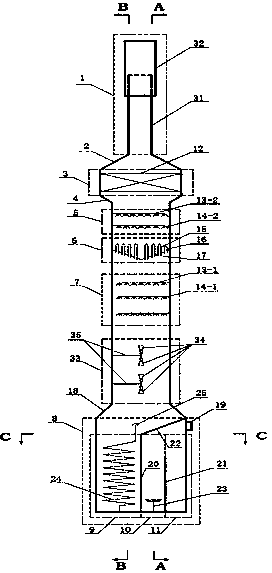

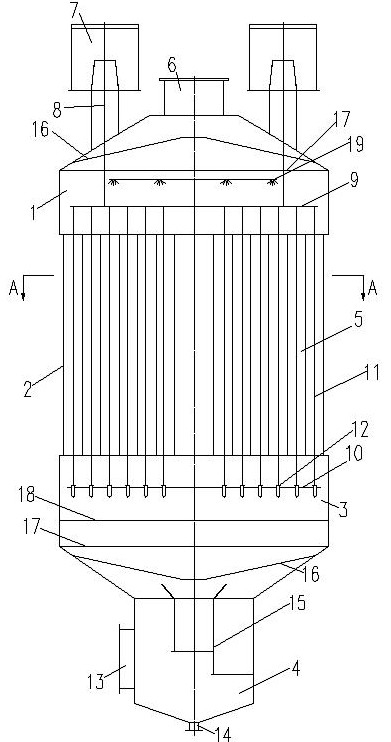

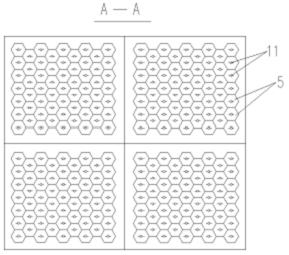

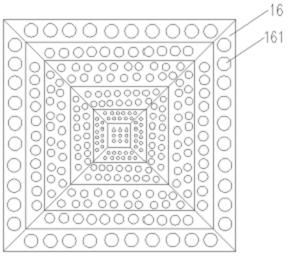

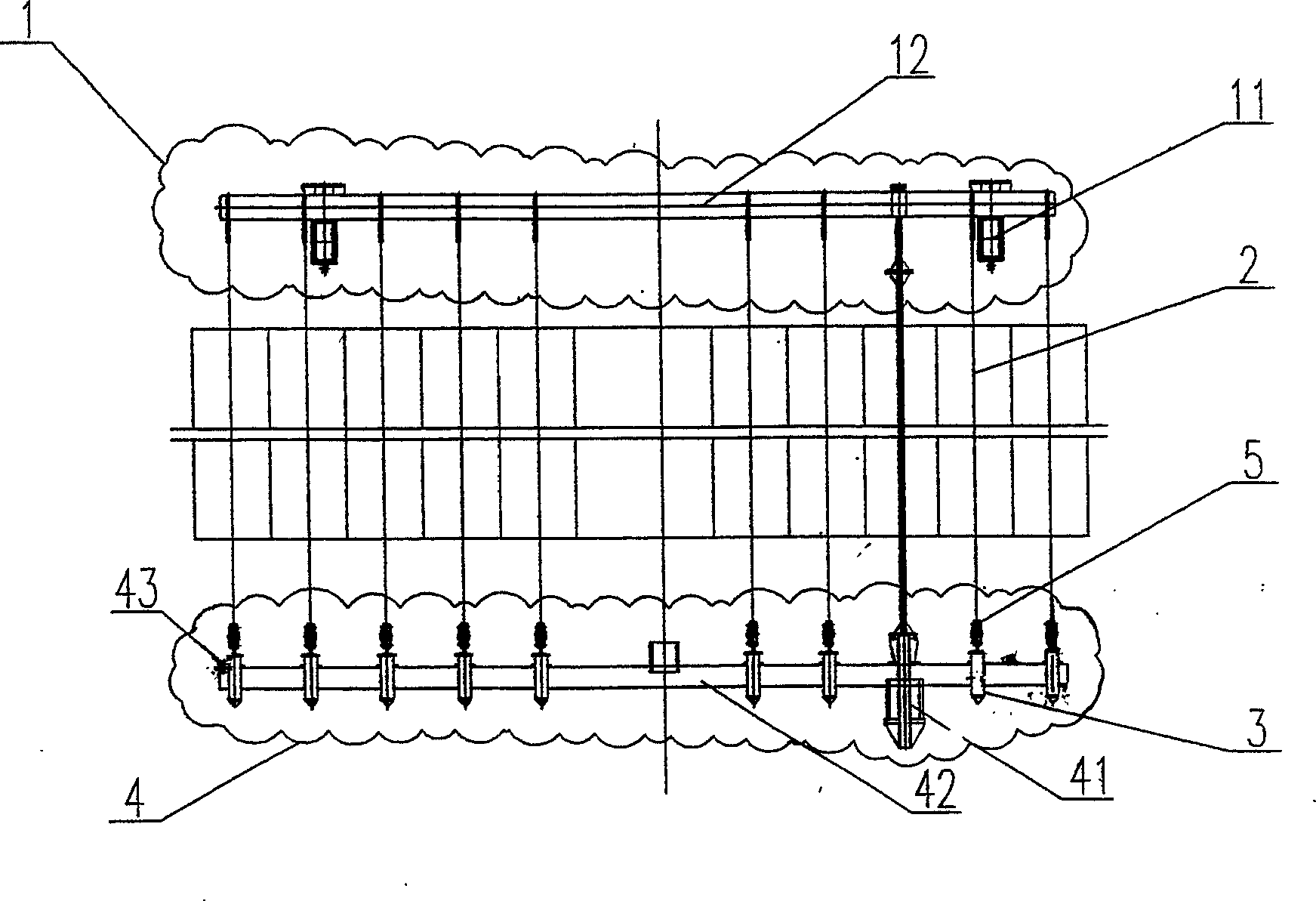

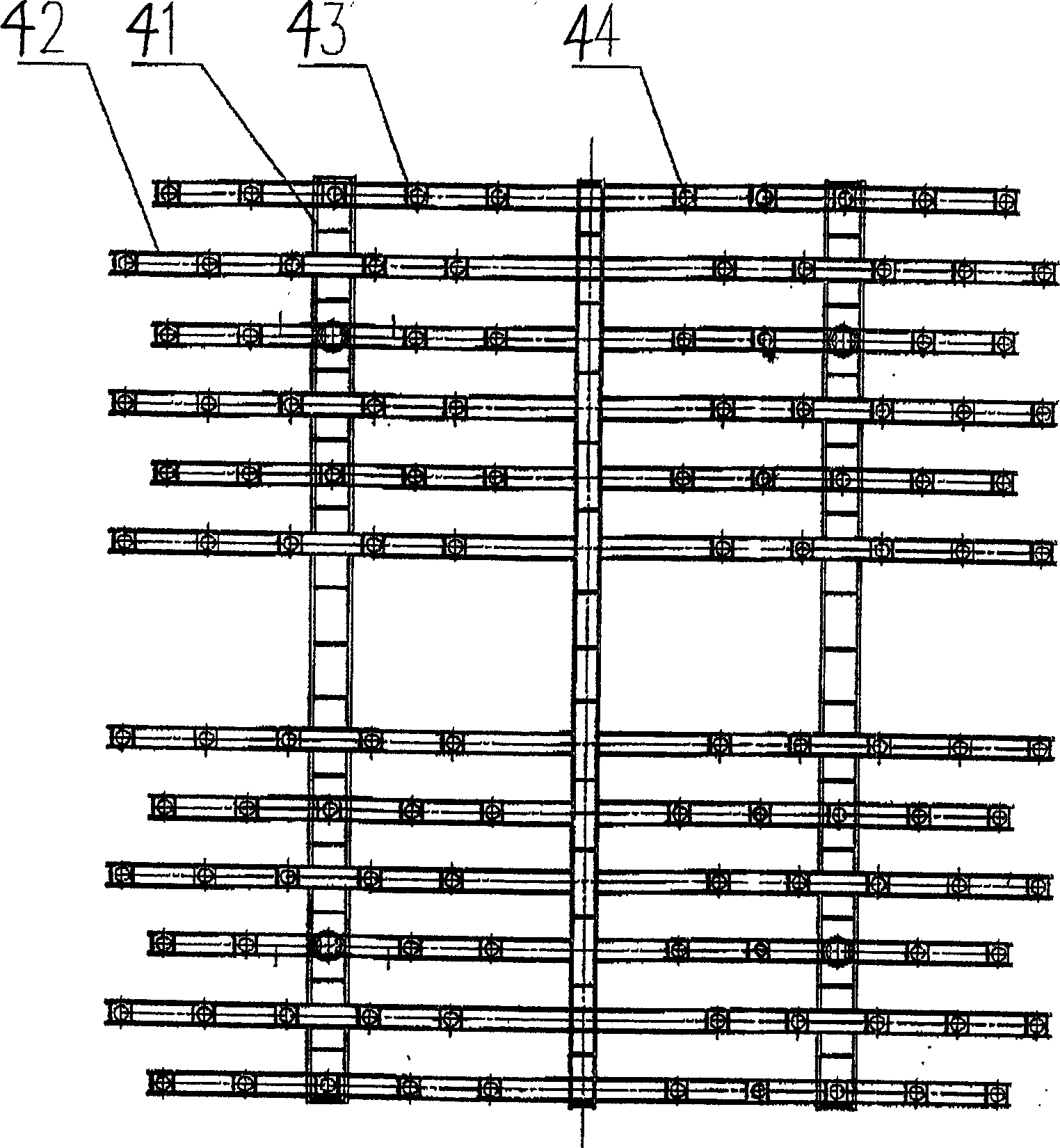

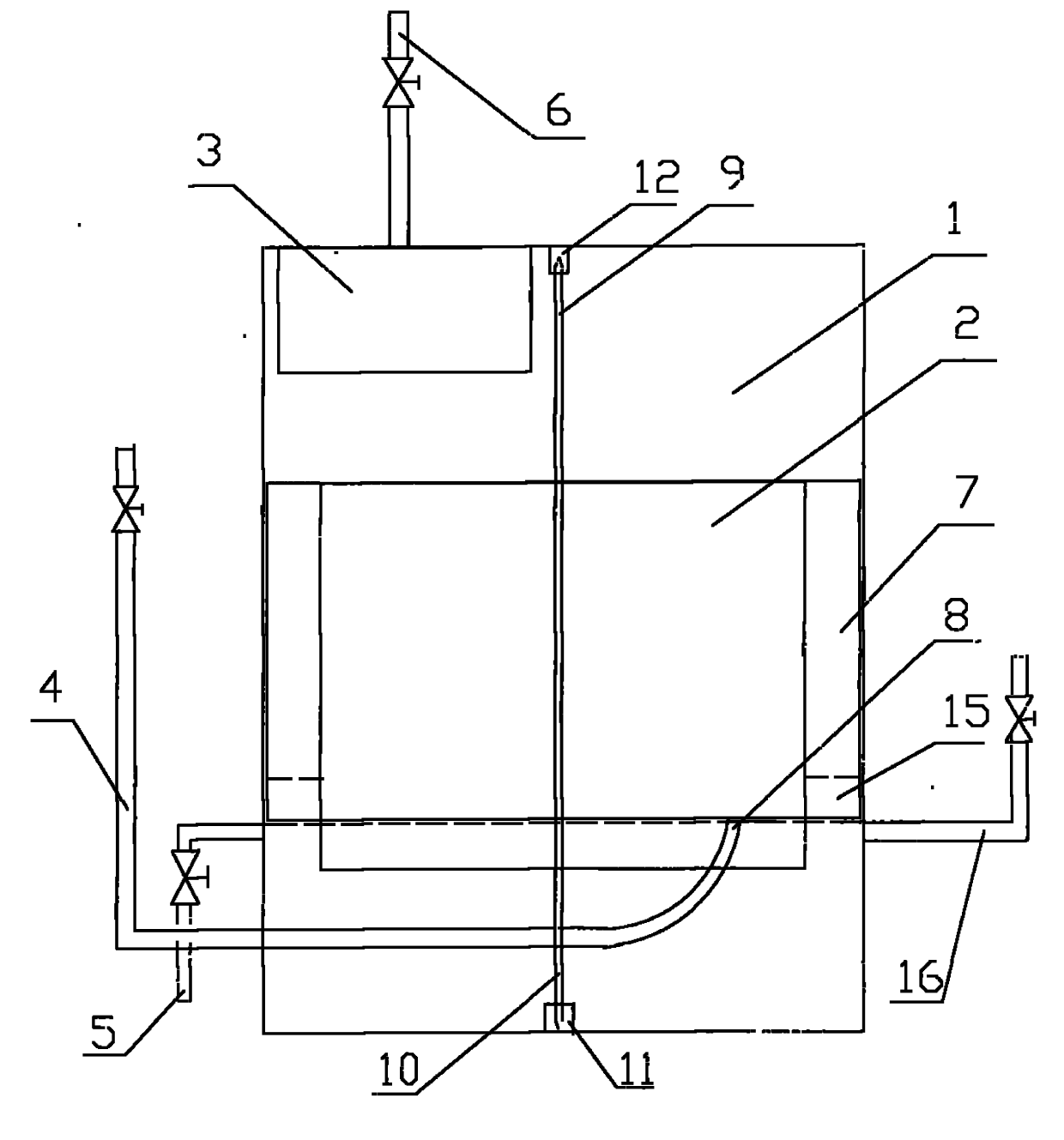

Intelligent anti-blocking demister used for wet flue gas desulfurization

ActiveCN102423597ARealize fine defoggingReduce cleaning blind spotsCombination devicesControl systemFlue gas

The invention discloses an intelligent anti-blocking demister used for wet flue gas desulfurization. The intelligent anti-blocking demister comprises a demister body, at least a first order demisting system is provided in the demister body, the demisting system is connected with a PLC control system; the demisting system comprises a first flushing layer, a swing type baffle demisting layer, a second flushing layer, a silk screen demisting layer and a third flushing layer which are successively arranged in an ascending order. The swing type baffle demisting layer is capable of removing liquid drops with large diameter, realizing crude demisting and decontamination, increasing the flushing coverage rate of a nozzle, minimizing the flushing blind area and effectively solving the problems of fouling and blocking of the demister; the silk screen demister is capable of removing the droplets with small diameter in flue gas after performing crude demisting to realize fine demisting. The demister has the advantages of high demisting efficiency, safe and stable operation, uses intelligent control and is capable of effectively preventing the generation of fouling and blocking. The intelligent anti-blocking demister can be widely used in flue gas desulphurization demisting systems of industries like electric power, petrochemistry, metallurgy and cement.

Owner:SOUTH CHINA UNIV OF TECH

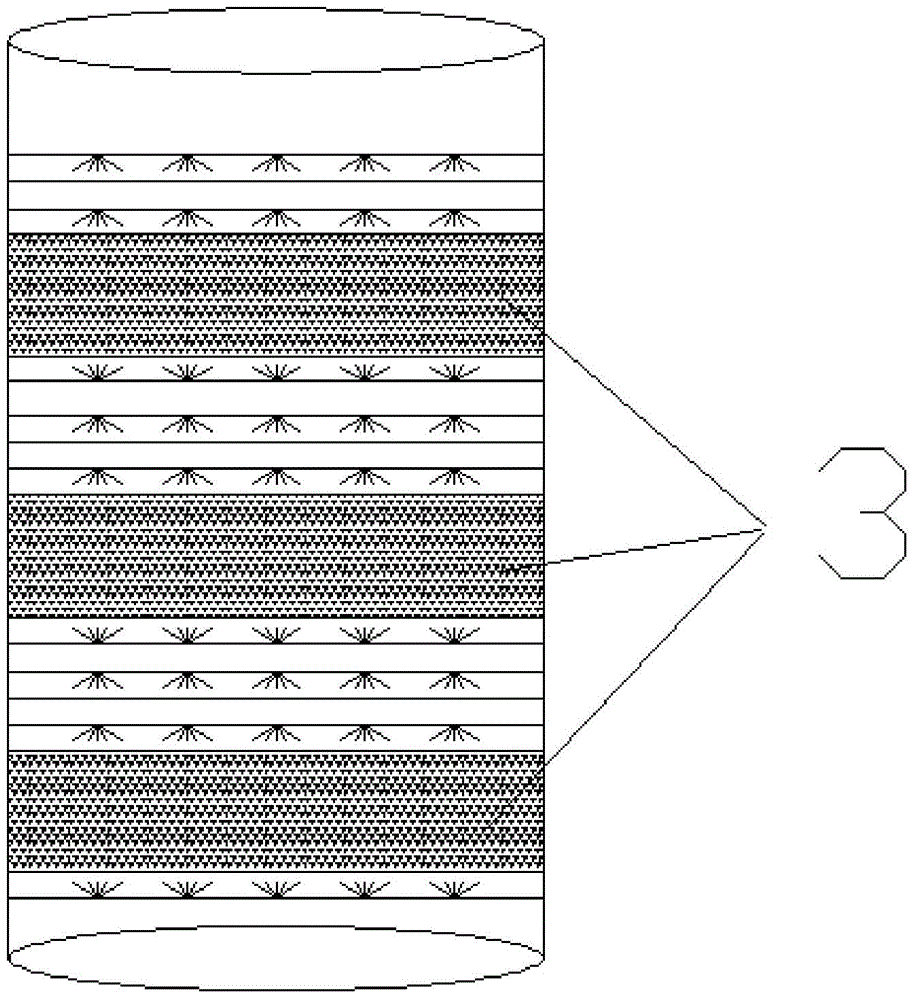

Straight cylinder-shaped flow baffling type demister

ActiveCN104606963AEfficient removalAchieve separationDispersed particle separationChemical industryTower

The present invention discloses a straight cylinder-shaped flow baffling type demister, which comprises a plurality of demisting assemblies, wherein each demisting assembly comprises a gas rising pipe and a straight cylinder, the straight cylinder is arranged on the outer side of the gas rising pipe and is at the same axis line as the gas rising pipe, the gas rising pipe is fixed on a tower disk, the top portion of the gas rising pipe is provided with a sealing cover plate, the circumference of the gas rising pipe is provided with a plurality of seams, and the gas rising pipe circumference close to each seam is provided with tangential diversion wings. According to the straight cylinder-shaped flow baffling type demister, the separation of the liquid droplet and the gas is achieved through the multiple flow baffling during the fluid flowing process; and the straight cylinder-shaped flow baffling type demister has characteristics of simple structure, easy installation and effective gas-liquid separation achieving, and is suitable for the gas-liquid separation process in the fields of chemical industry, environmental protection, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

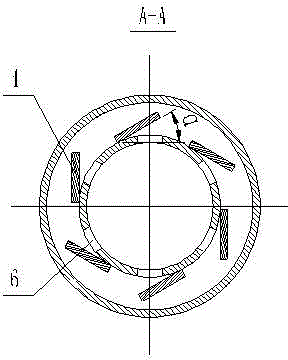

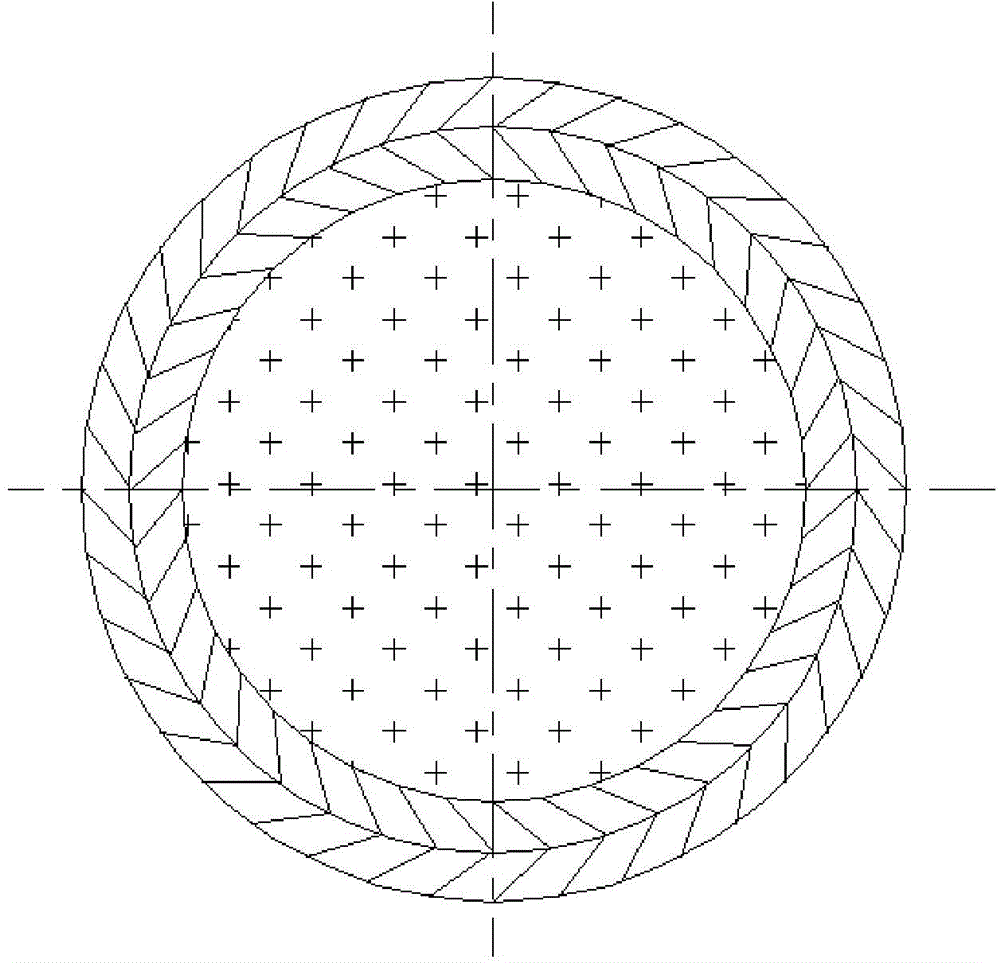

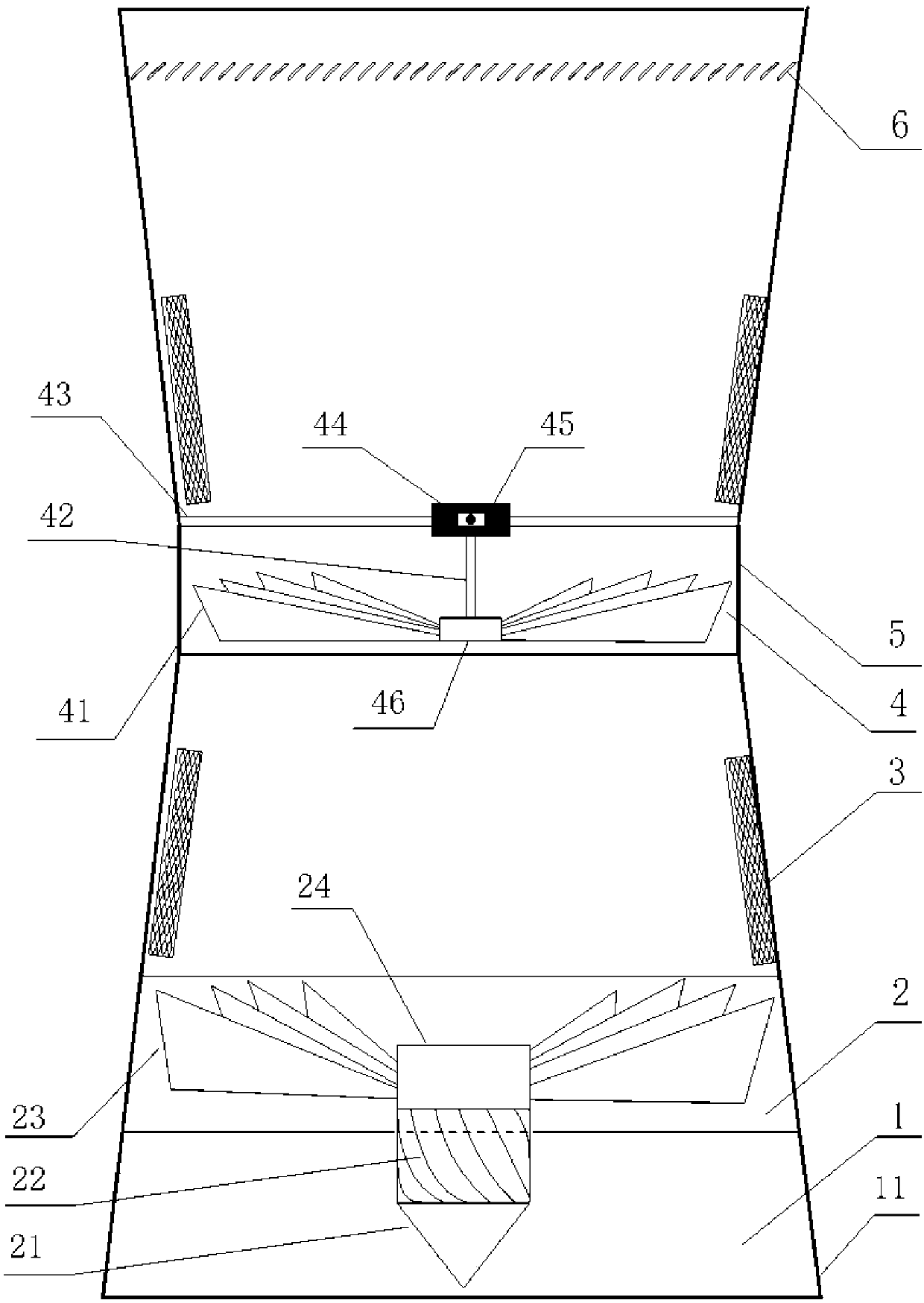

Baffle type cyclone demister

InactiveCN101791505AImprove defogging efficiencyThe overall simplicity of the deviceDispersed particle separationConcentric ringAirflow

The invention provides a baffle type demisting device combining inertial separation and cyclone centrifugal separation and a method thereof. The method is as follows: the demisting device is designed as a two-level demister, and when airflow passes through a channel arranged between demisting blades of a first-level baffle on the base layer, mist drops impact the blades under the inertia effect due to flow line deflection, thereby realizing capture of large-diameter droplets. In addition, the outlet section of the baffle is arranged obliquely and faces one rotating direction, thereby achieving the functions of both demisting and diversion, so that the airflow can rise in a rotating way when passing through the first-level blades. The channel of a second-level demister is of deflection type in the vertical direction and is of a concentric ring shape in the horizontal direction, so that when rotating airflow passes through the demisting channel on the layer, smaller mist drops can be further removed under the combined effect of the baffle inertia separation and the rotating centrifugal separation, thereby making the whole demister achieve the effect of completely demisting.

Owner:SOUTHEAST UNIV

Indoor air static electricity purification device

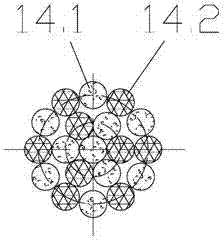

InactiveCN103615767AImprove adsorption capacityImprove dust removal effectLighting and heating apparatusExternal electric electrostatic seperatorImpellerCoupling

The invention relates to an indoor air static electricity purification device which solves the problems that an existing purification device is single in function, high in device investment and poor in effect of catching fine particles. According to the technical scheme, the indoor air static electricity purification device comprises a barrel and a motor, and further comprises at least one layer of static electricity assembly driven by the motor; each static electricity assembly comprises an insulation coupler and an electrified shaft; a conductive disc is arranged in the axial direction of each electrified shaft and is evenly provided with a plurality of sets of combined electrode wires; one end of each combined electrode wire is connected to the corresponding conductive disc, and the other end of each combined electrode wire is a free end; each combined electrode wire is formed by bundling up a plurality of braided wires and metal conductive wires after the braided wires and the metal conductive wires are distributed in a staggered mode; the lower end of the electrified shaft of the static electricity assembly at the lowest layer is connected with an air induction impeller located at the position of the barrel center axis of the lower section of the barrel. The indoor air static electricity purification device is extremely simple in structure, easy and convenient to operate, low in resistance, high in efficiency, small in occupied space, resistant to corrosion, free of scaling and blocking, light in weight, little in energy consumption and low in cost, and has the functions of dust removal, sterilization and defogging.

Owner:WUHAN WUTUO TECH +1

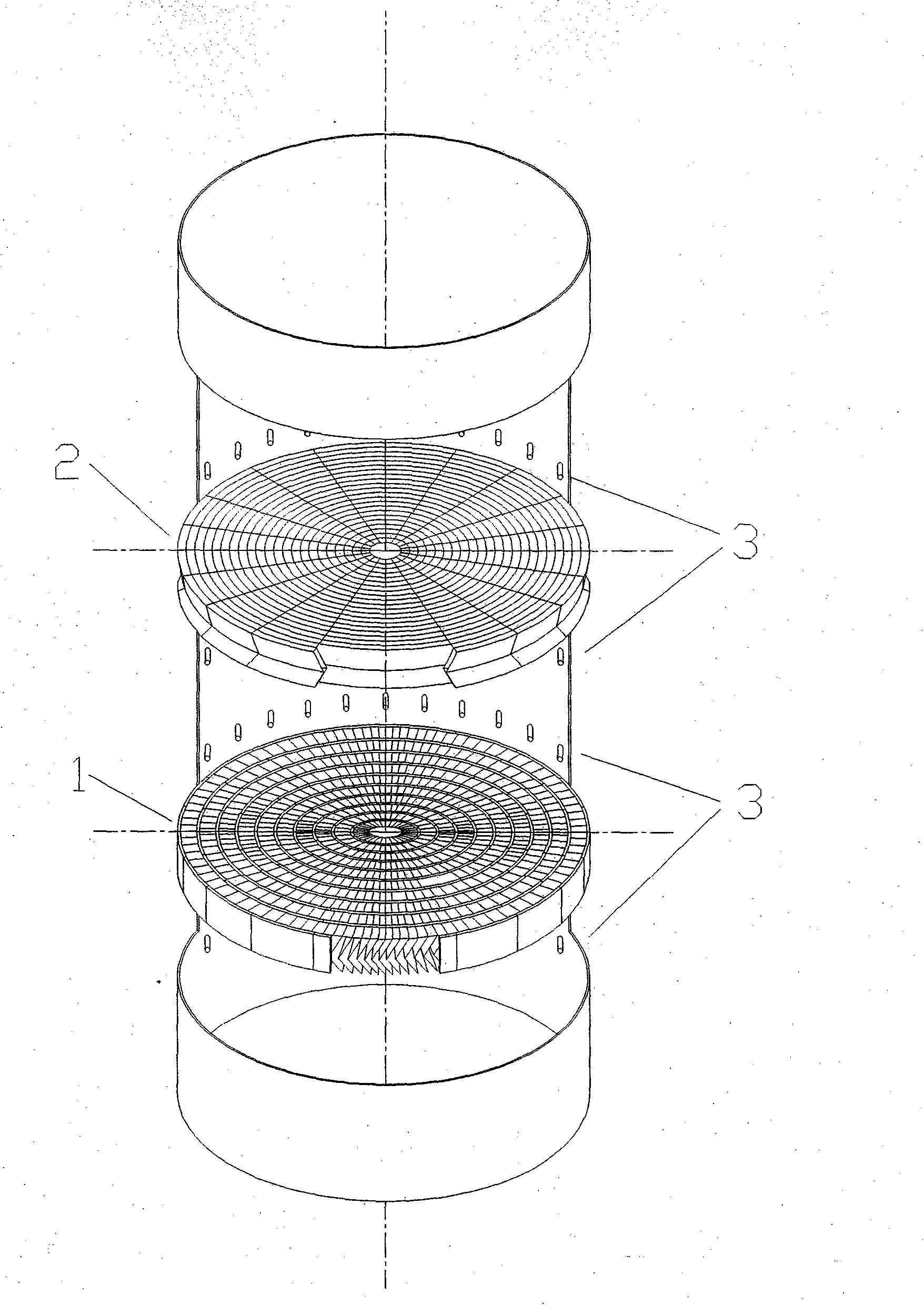

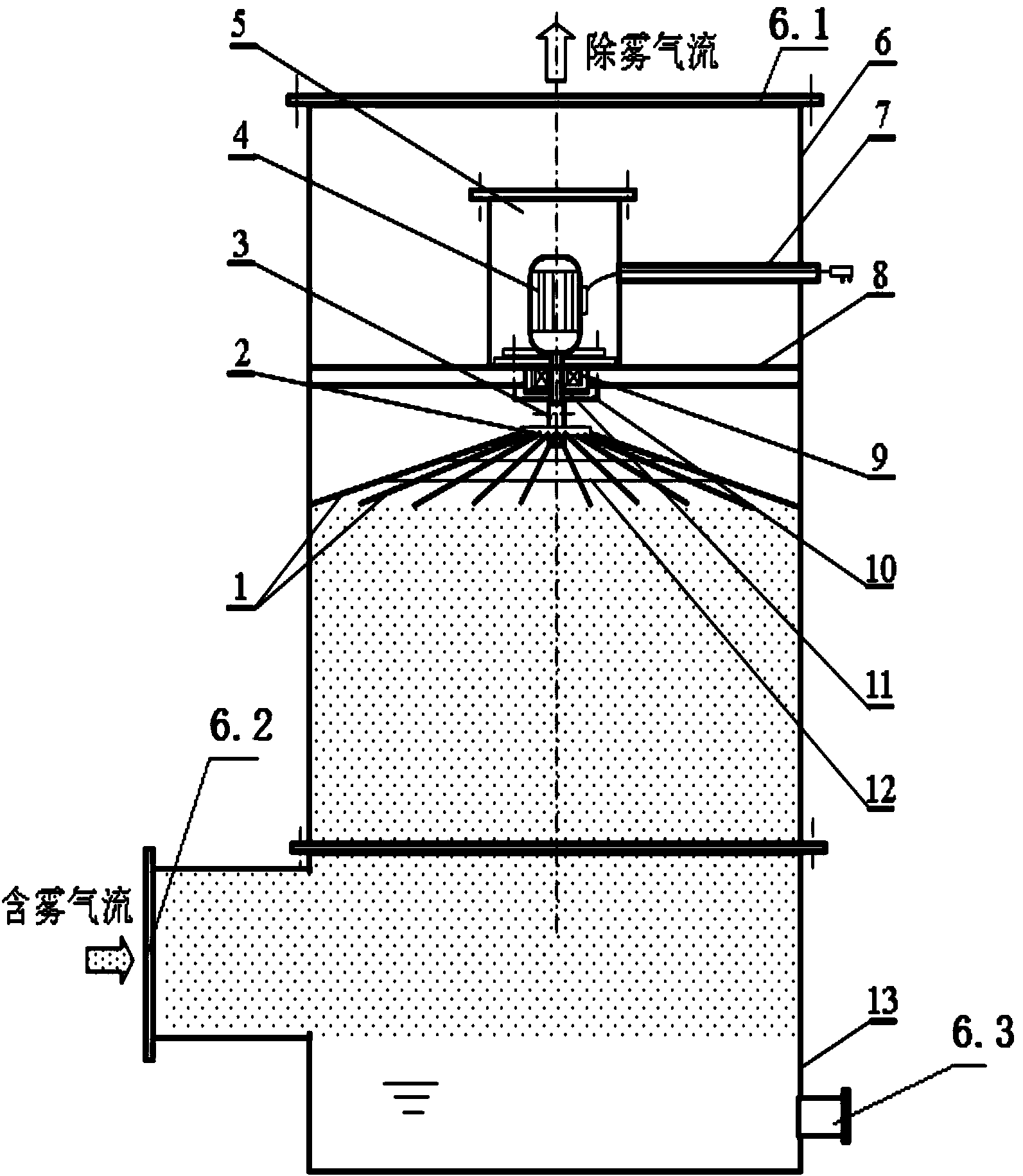

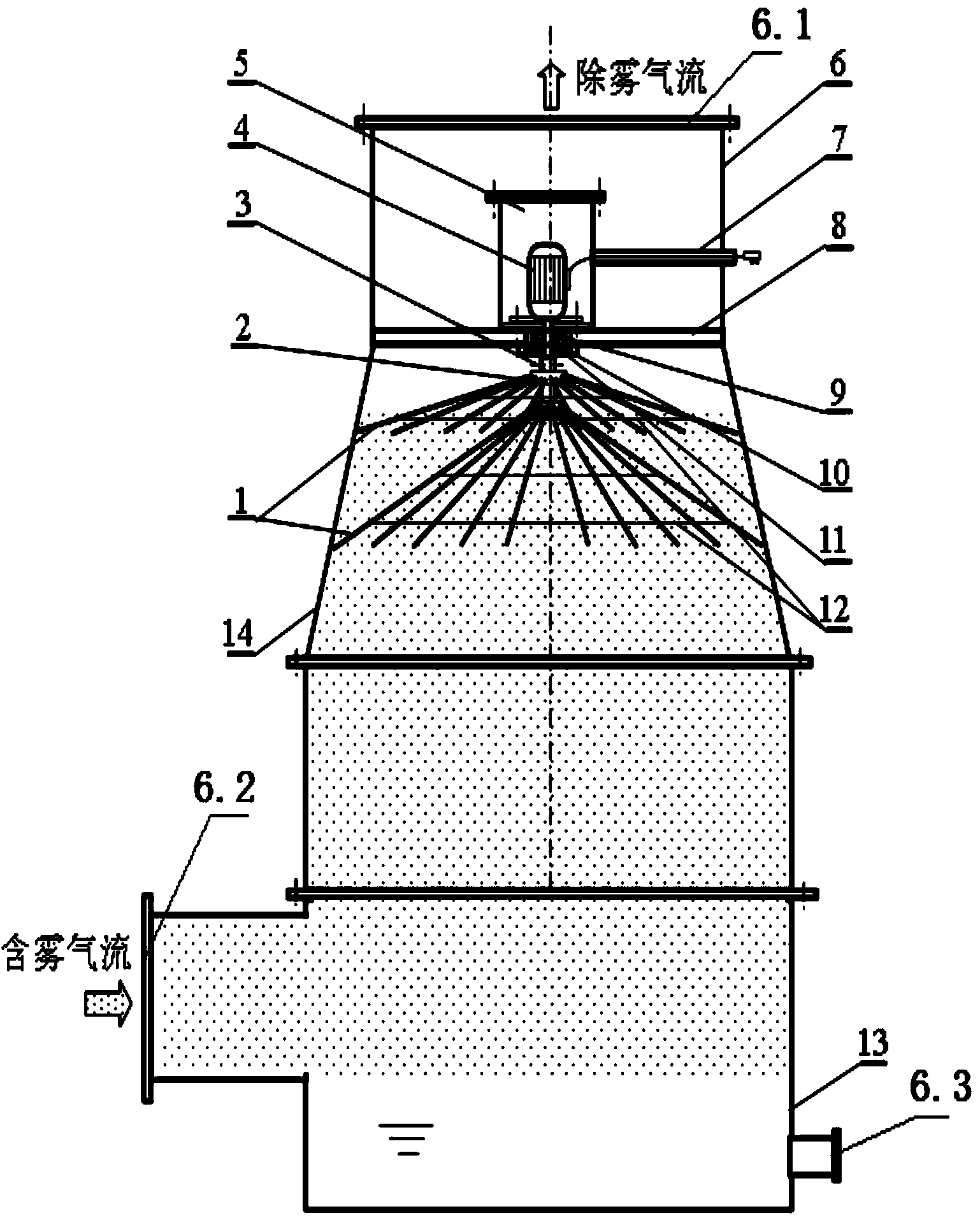

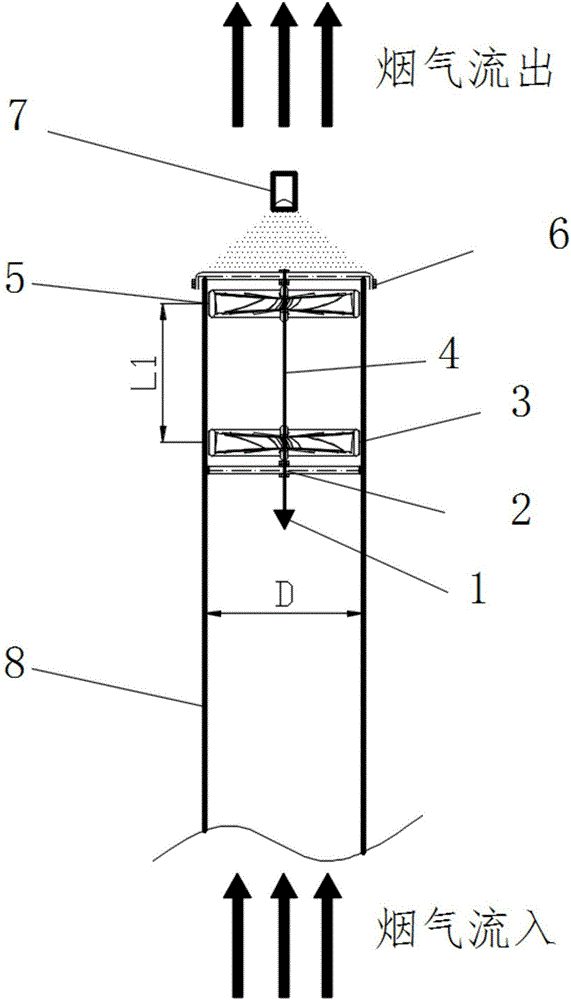

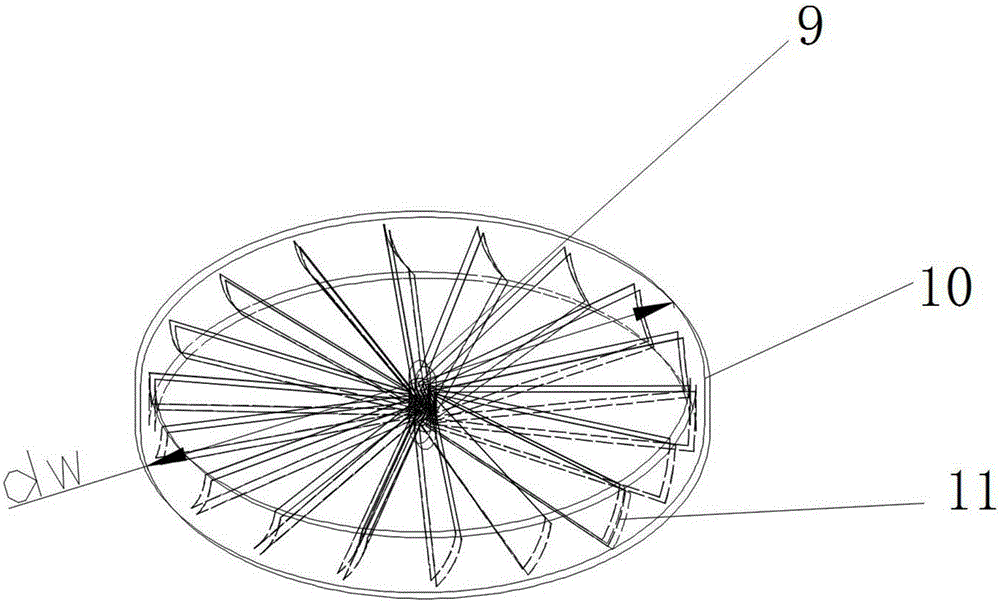

Flexible fiber spiral line demisting device

InactiveCN103657266AAvoid the problem of secondary sheddingStrong turbulent diffusion effectDispersed particle separationFlue gasEngineering

The invention relates to a flexible fiber spiral line demisting device, which solves the problems that the existing demising device has low demisting efficiency, the filter type demister is easy to block and the static demister is high in cost and large in occupied area and is corroded and scaled. According to the technical scheme, the flexible fiber spiral line demisting device comprises a gas inlet, a gas outlet and an exhaust cylinder of a liquid discharge pipe, wherein a motor is arranged on the vertical center line of the upper section of the exhaust cylinder; a rotating shaft of the motor is sleeved with a shaft sleeve; at least one layer of disc is arranged in the axis direction of the shaft sleeve; flexible fiber spiral lines are arranged on the disc; the flexible fiber spiral lines comprise a plurality of warps; one end of each warp is connected to the disc uniformly and the other end of each warp is a free end. The flexible fiber spiral line demisting device has the advantages of low resistance, high efficiency, no occupied area, no corrosion, no scaling and blockage, large flue gas treatment quantity, simple structure, light weight, low energy consumption and low cost.

Owner:JIANGHAN UNIVERSITY +2

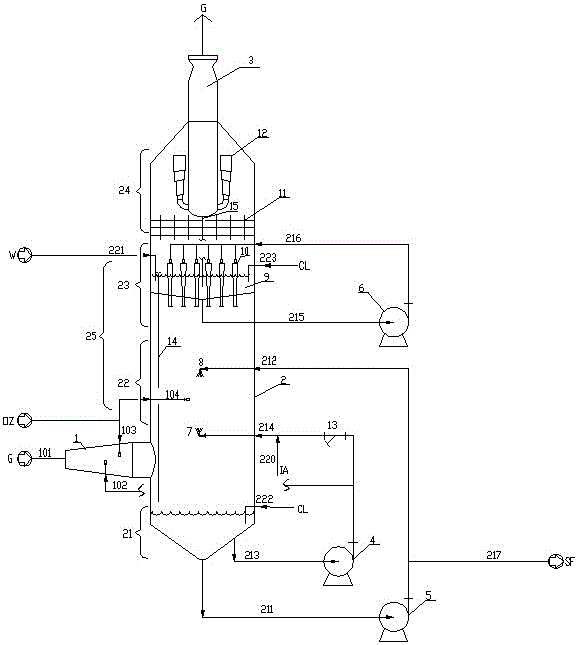

Flue gas desulfurization dust and mist removal method

InactiveCN105013311AReduce material requirementsLow investment costCombination devicesCycloneFlue gas

The present invention provides a flue gas desulfurization dust and mist removal method, a desulfurization medium is an alkaline liquid; a desulfurization tower bottom zone liquid enters respectively from absorption reaction zone bottom and upper parts into a desulfurization tower, a circulating fluid entering from the bottom part is atomized into small liquid drops, parallelly flows with fuel gas, and meanwhile complete sulphide absorption reaction with the countercurrent circulating liquid; by use of alkaline liquid small liquid drop parallel flow capture and venturi particle capture two-level dust removal, and arrangement of surface coalescing and multi-stage cyclone for mist removal, flue gas purification can be achieved.

Owner:QINGDAO JINGRUN PETROCHEM ENG

Deep dedusting and defogging device

ActiveCN105854425AIncrease flow rateIncrease centrifugal forceDispersed particle separationDual actionFlue gas

The invention relates to a deep dedusting and defogging device which comprises flow guide cylinders arranged in an absorption tower, wherein airflow passages are formed in the flow guide cylinders; spiral passages communicated with the airflow passages are further formed above the air flow passages; outlets of the spiral passages are inclined; the cylinder walls of the flow guide cylinders are higher than the outlets of the spiral passages, and volume-enlarged chambers with openings are formed in the position above the spiral passages. According to the device, the spiral passages are additionally formed in the position above the airflow passages, and in a rising process of flue gas, the effect of absorbing dust and removing liquid drops is achieved by virtue of continuous rotation and collision movement between water drops in the flue gas, the water drops and the dust as well as the water drops and the walls of the passage walls under double actions of centrifugal force and inertial collision, so that defogging and dedusting efficiency is effectively improved; in the volume-enlarged chamber, the speed of the flue gas is reduced, the separated liquid drops fall, and the liquid drops are discharged through the downward passages separated from the flue gas, so that secondary carrying is prevented.

Owner:TIANJIN XIANGYUANXI ENVIRONMENTAL PROTECTION EQUIP CO LTD +1

Defroster

InactiveCN101209387AIncrease contact areaImprove defogging efficiencyDispersed particle separationBiochemical engineeringDefogger

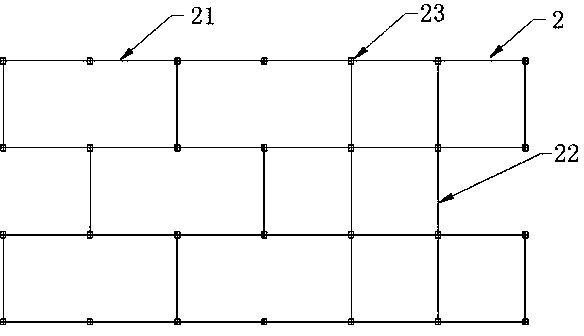

The invention provides a defogger which comprises a cleaning unit which is used for cleaning the defogger, a defogging unit which is used for separating air and liquid, a fixing unit which is used for fixing the defogging unit, wherein, the defogging unit is an array or a plurality of arrays of blades, and the blade takes an annular shape. The defogger of the invention reduces secondary entrainment and improves defogging efficiency; meanwhile, the defogger has simple structure and convenient installation, maintenance and operation.

Owner:SHANGHAI HUOLIN ENG PLASTICS

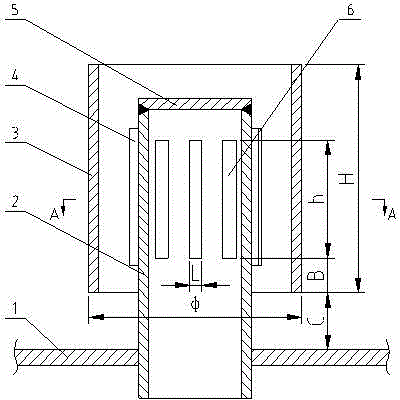

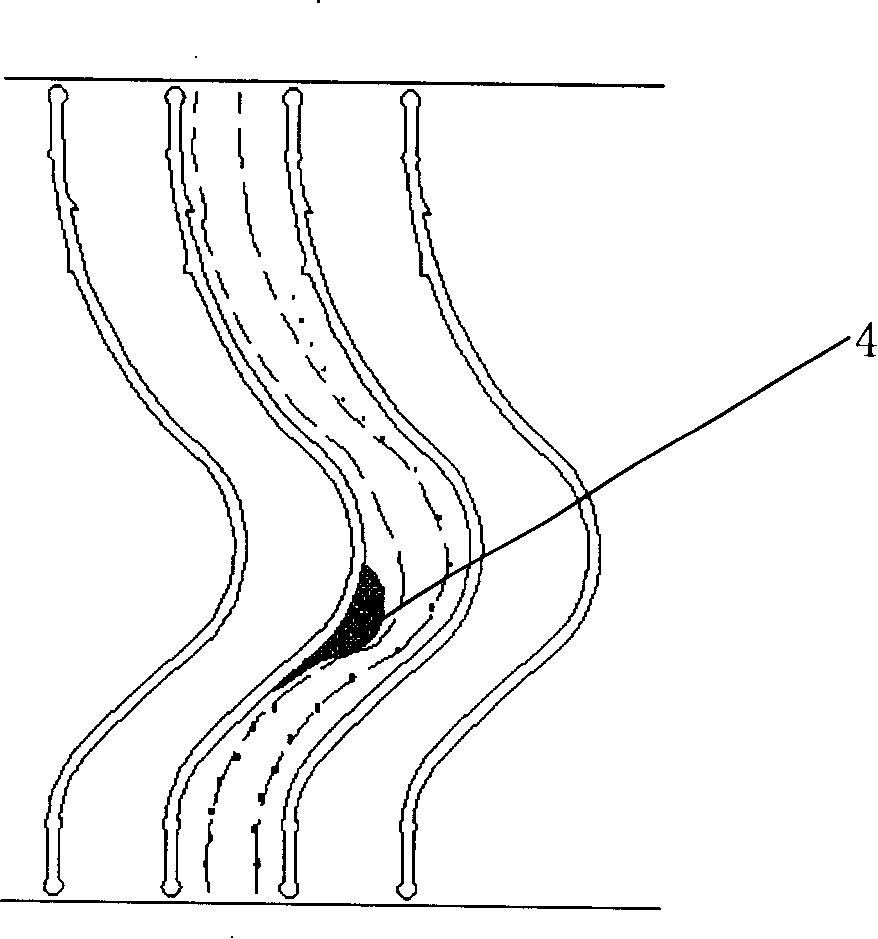

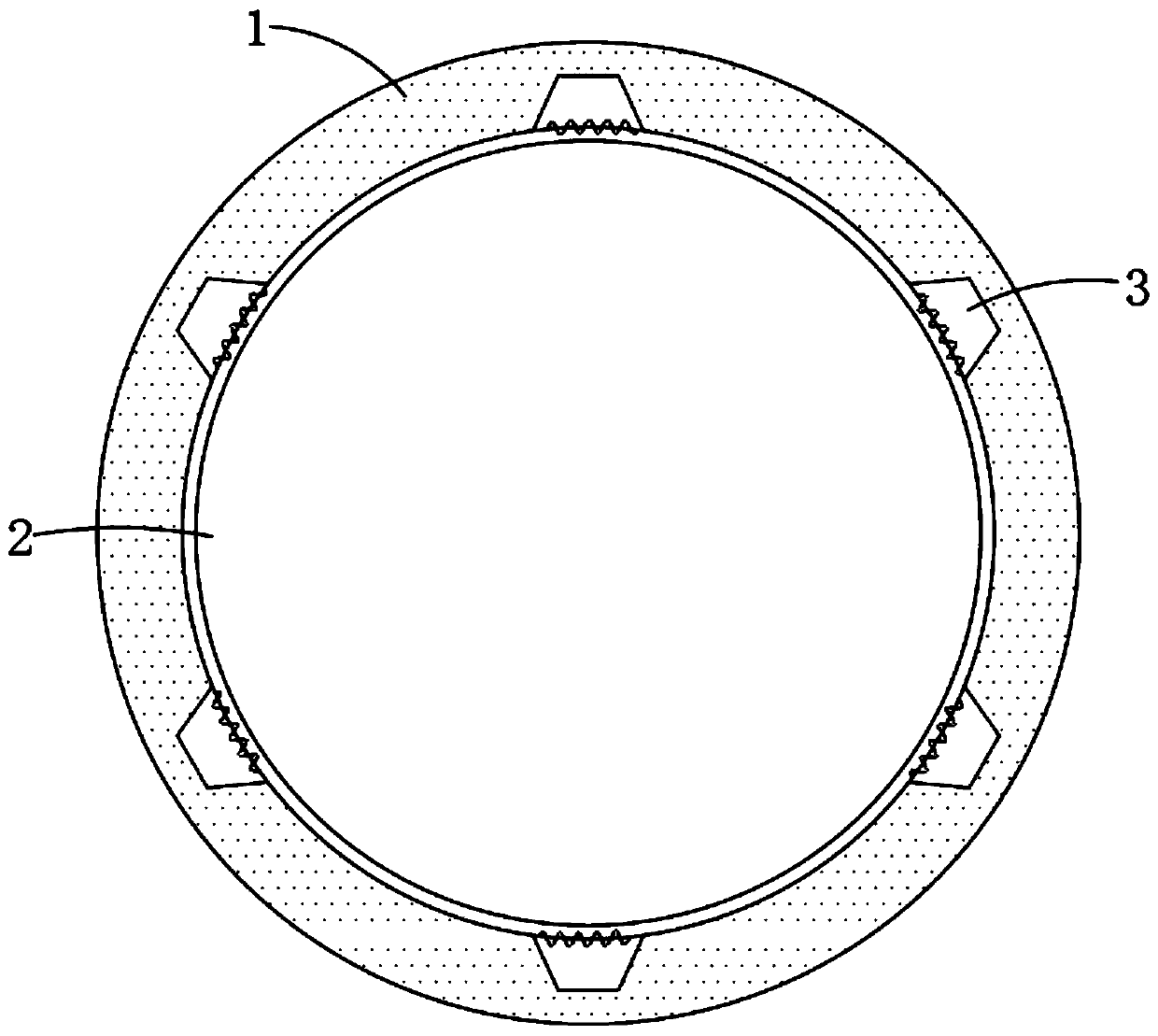

Cathode wire for wet electrostatic dust collector

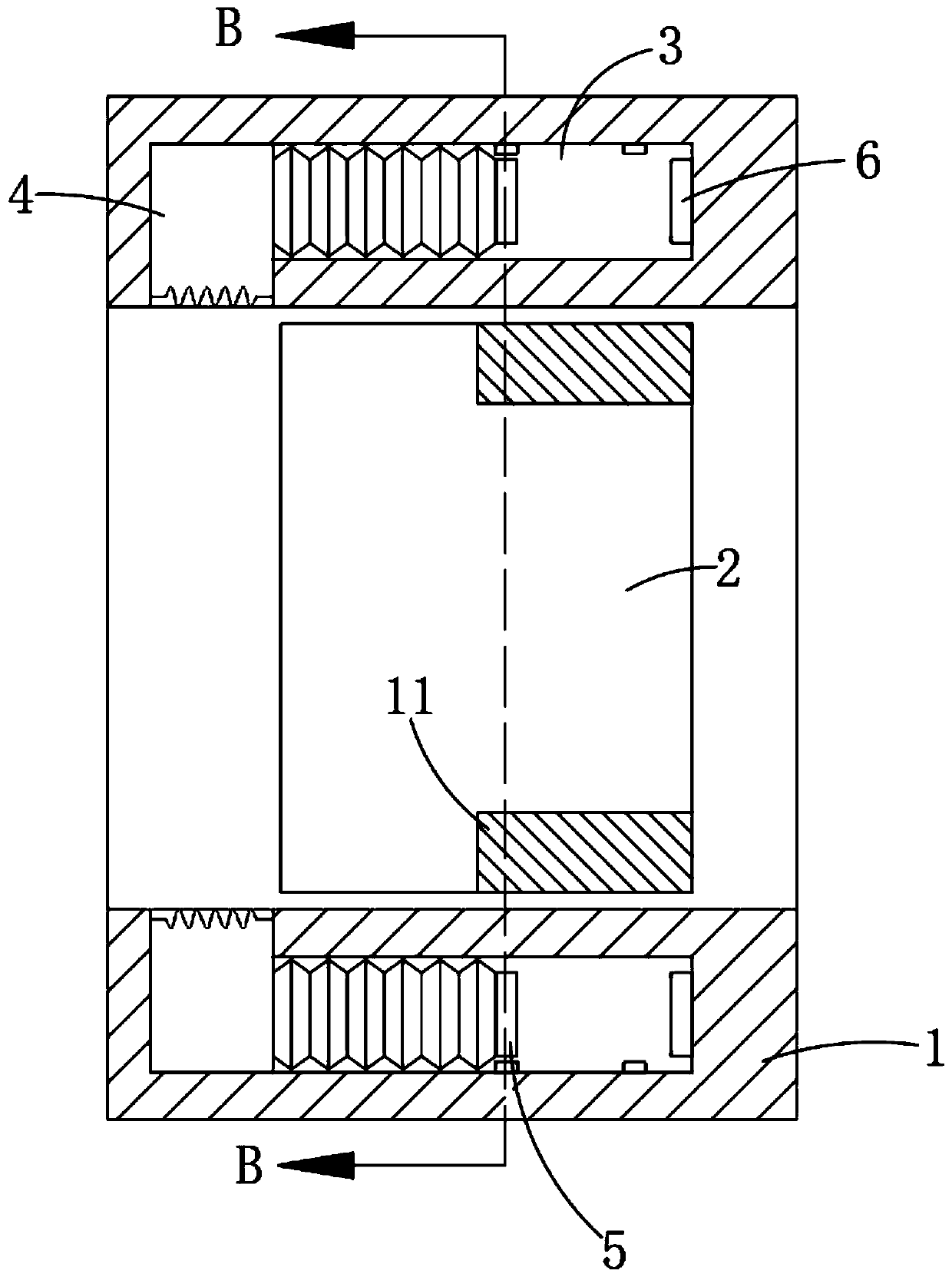

InactiveCN103801458AWith discharge functionSimple structureExternal electric electrostatic seperatorElectrode constructionsElectrical field strengthEngineering

The invention discloses a cathode wire for a wet electrostatic dust collector. The cathode wire comprises a cathode rod (1), and is characterized in that bur rings (2) are arranged on the cathode rod (1); the discharging points of the bur rings (2) are of sharp-pointed annular or polygonal structures; connecting pieces (4) are arranged at the two ends of the cathode rod (1) respectively, so that the cathode wire is fixed on a cathode frame through the connecting pieces (4). The bur ring type cathode wire is simple in structure and easy to manufacture and mount; the discharging points of the bur rings form the sharp-pointed annular or polygonal structures, so that the bur rings have a discharging function in each direction, and the number of discharging points can be set according to needs; the wet electrostatic dust collector with the cathode wire has the characteristics of low critical coronal voltage, high electric field intensity and uniform electric field distribution, the problem of corona dead zones of a conventional wet electrostatic dust collector is well solved, and the dust collection and defogging efficiency of the wet electrostatic dust collector is further improved.

Owner:双盾环境科技有限公司

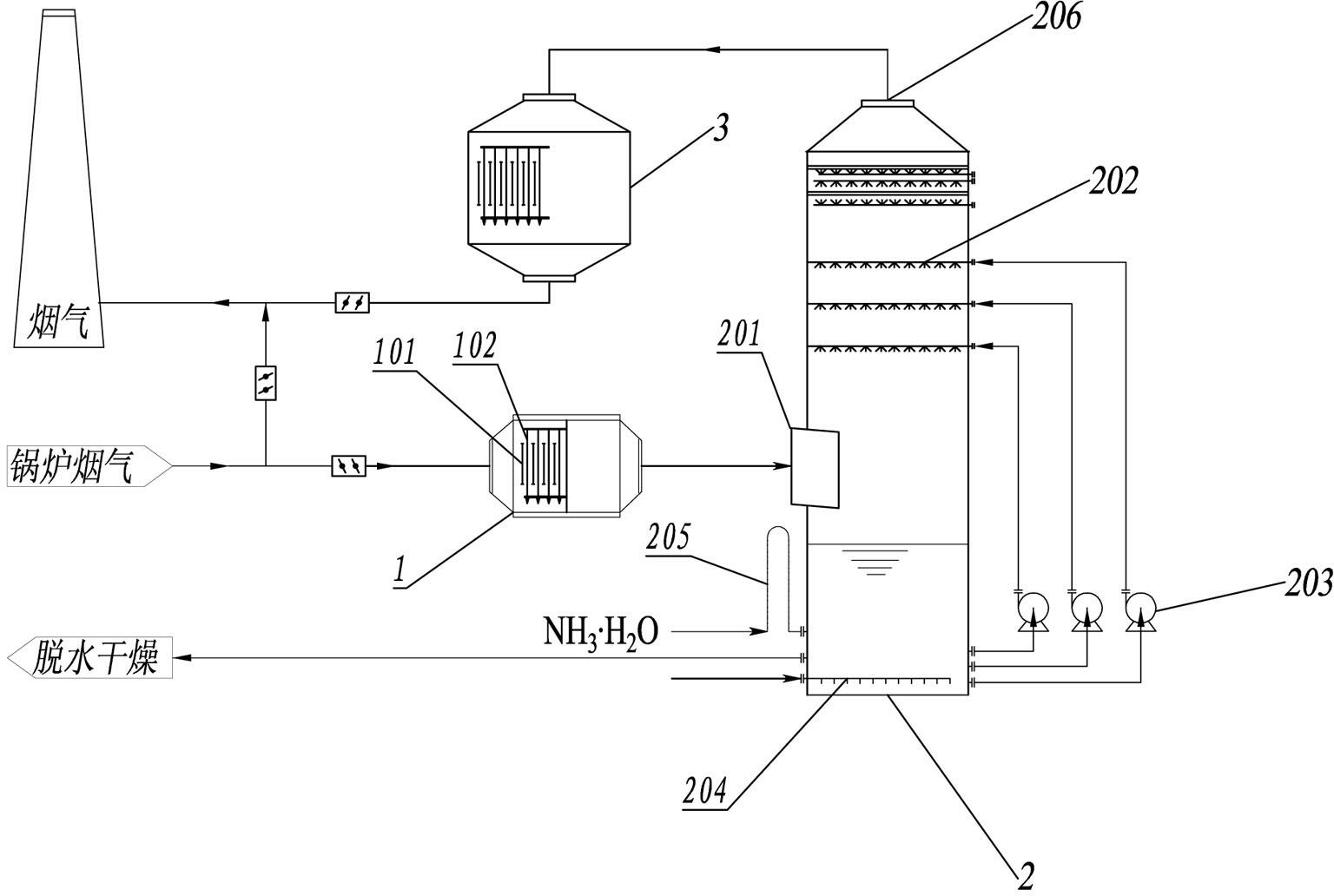

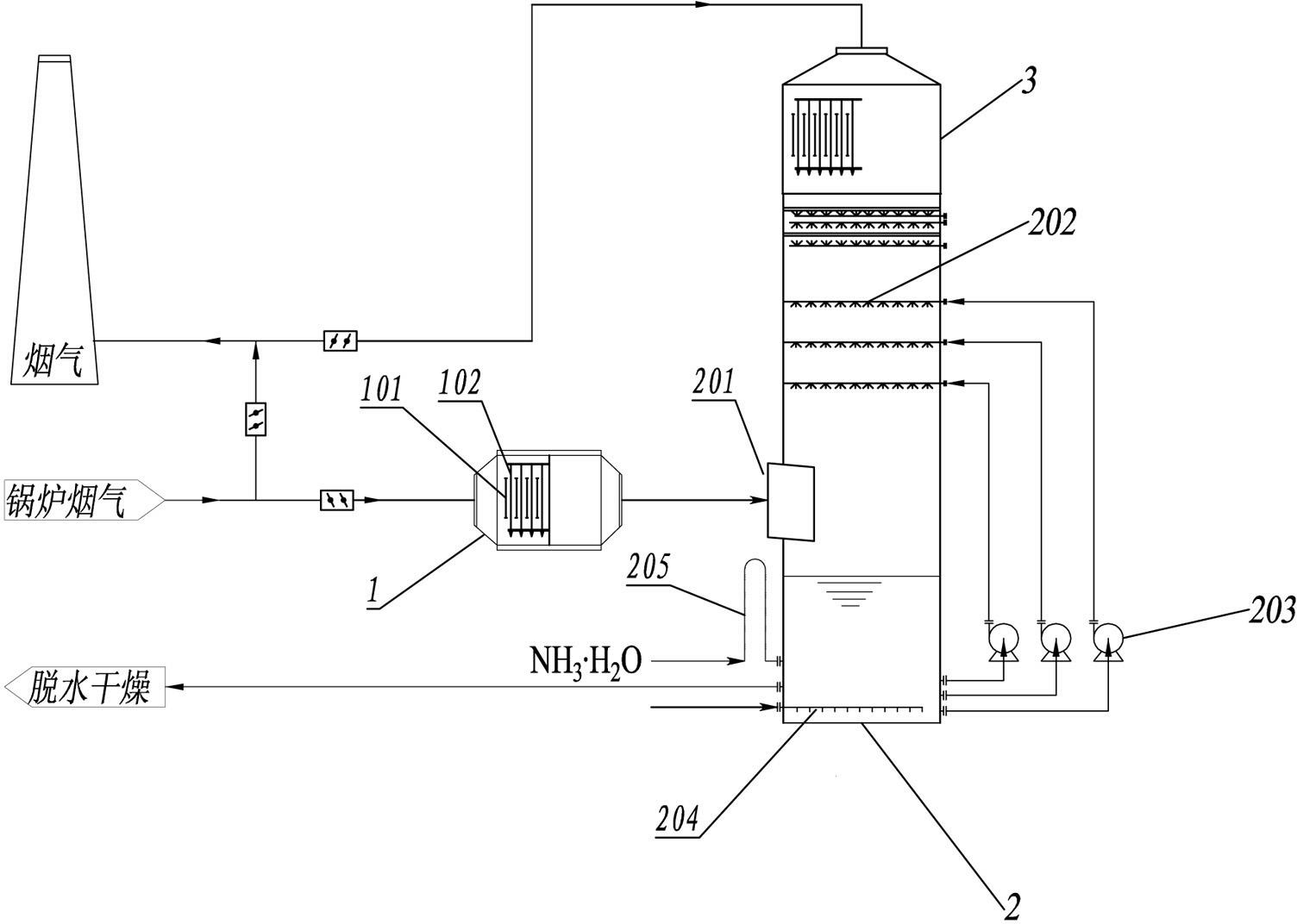

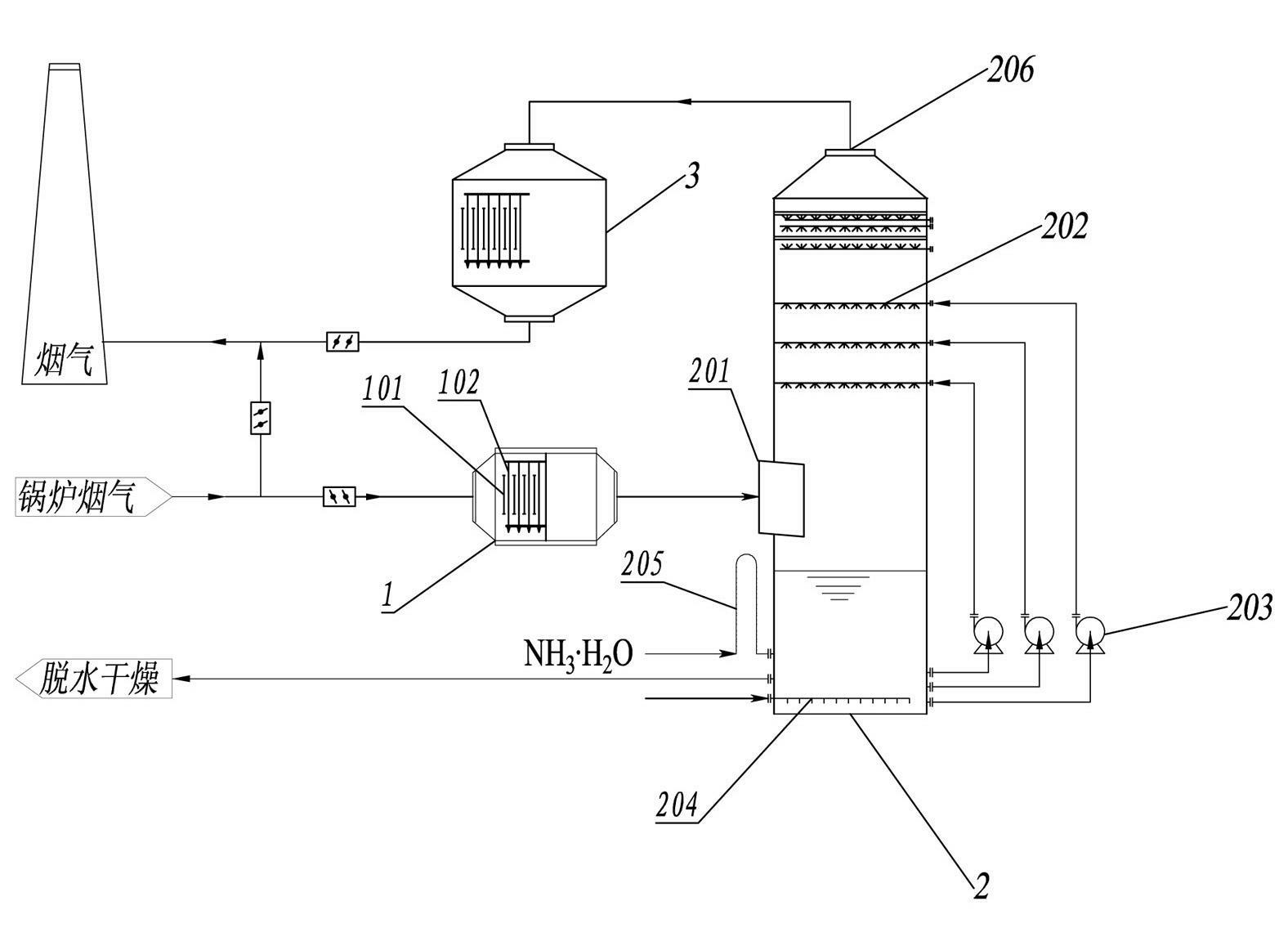

Streamer discharge ammonia flue gas desulfurization, denitrification and fog removal integrated method

InactiveCN102274680AIncrease added valueImprove defogging efficiencyDispersed particle separationAmmonium salt fertilisersFlueDemister

The invention discloses an integrated method for flue gas desulfurization, denitrification and demisting by streamer discharge ammonia method, which comprises the following steps: 1) boiler flue gas containing sulfur dioxide and nitrogen oxides is sent to streamer discharge denitrification reactor after dedusting; 2) The flue gas after the streamer discharge denitrification reactor enters the desulfurization tower and is discharged from the top outlet of the desulfurization tower; 3) The flue gas from the top outlet of the desulfurization tower is demisted and purified by the electric demister and sent to the chimney for discharge. The method of the present invention simultaneously desulfurizes and denitrates, has high demisting efficiency, effectively suppresses ammonia escape, eliminates ammonium salt entrainment, reduces ammonia loss, reduces exhaust smoke turbidity at the outlet, reduces corrosion to tail flue and chimney, and produces nitrogen fertilizer by-product.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

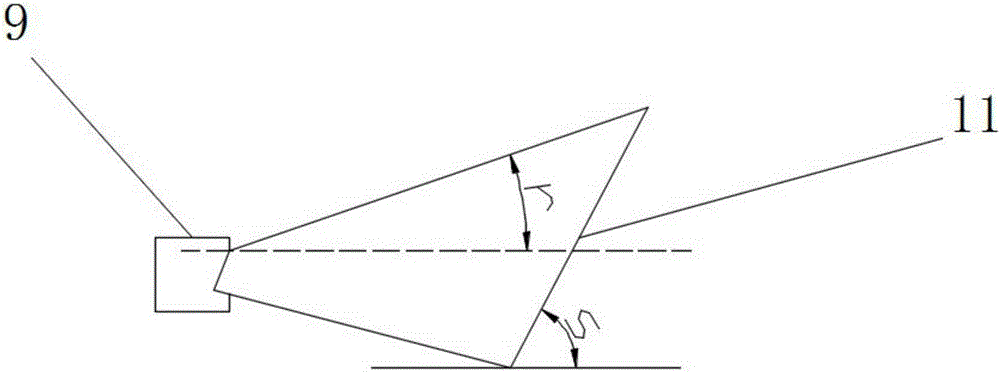

Anti-fog camera

ActiveCN110677572AAvoid affecting monitoring clarityIncrease the defogging areaTelevision system detailsColor television detailsAnti-fogElectromagnet

The invention discloses an anti-fog camera which comprises a lens barrel, a lens is embedded in the lens barrel; a plurality of strip-shaped grooves are formed in the side wall of the lens barrel at equal intervals in the circumferential direction of the lens barrel; a plurality of wedge-shaped air outlets communicated with the strip-shaped groove are formed in the side wall of the lens barrel; apower generation assembly formed by connecting a plurality of thermoelectric power generation pieces in series is embedded in the lens barrel, an electric heating wire electrically connected with thepower generation assembly is embedded in each wedge-shaped air outlet, a telescopic air bag is fixedly connected to the inner wall of the strip-shaped groove, and a driving device for driving the telescopic air bag to stretch out and draw back is installed in the strip-shaped groove. The electromagnet drives the telescopic air bag to stretch back and forth to blow out high-speed air to the lens, the blown-out air can rapidly evaporate water mist on the lens after being heated by the electric heating wire, and the situation that monitoring definition is affected due to the fact that water mistis condensed on the lens of the camera for a long time is avoided.

Owner:SHENZHEN FSAN INTELLIGENT TECH

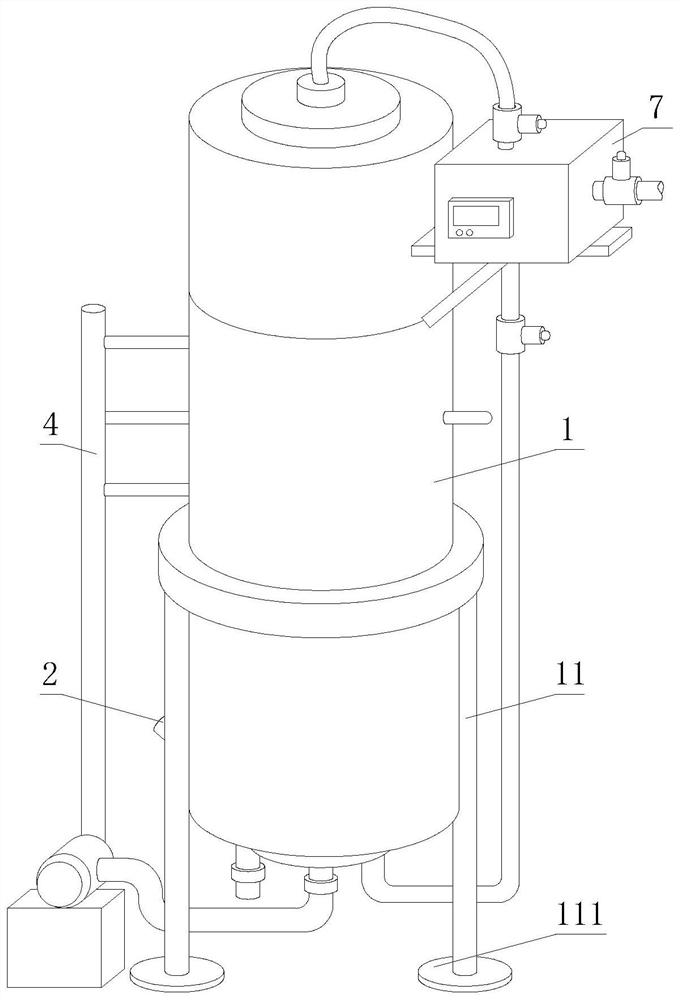

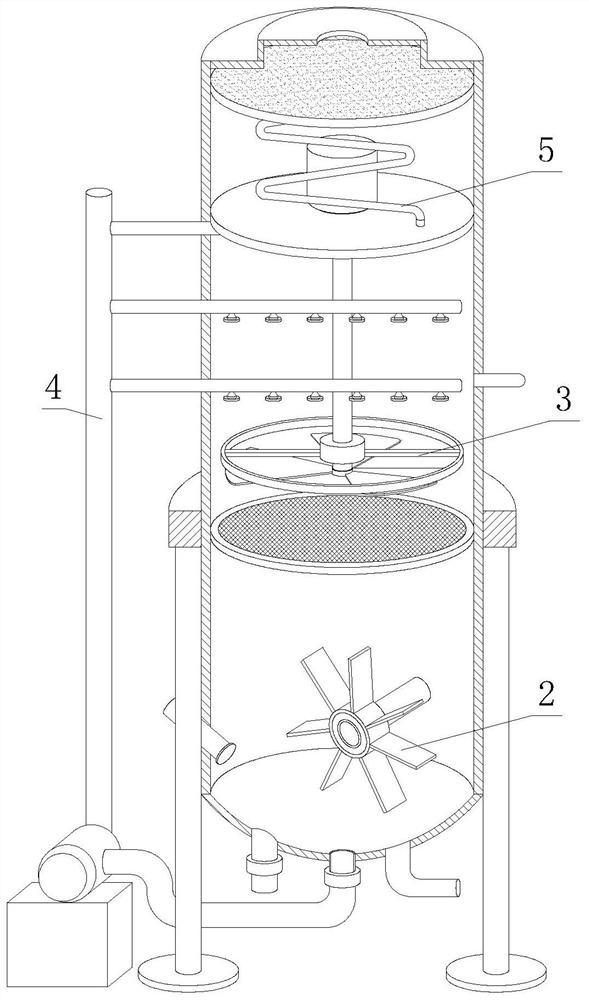

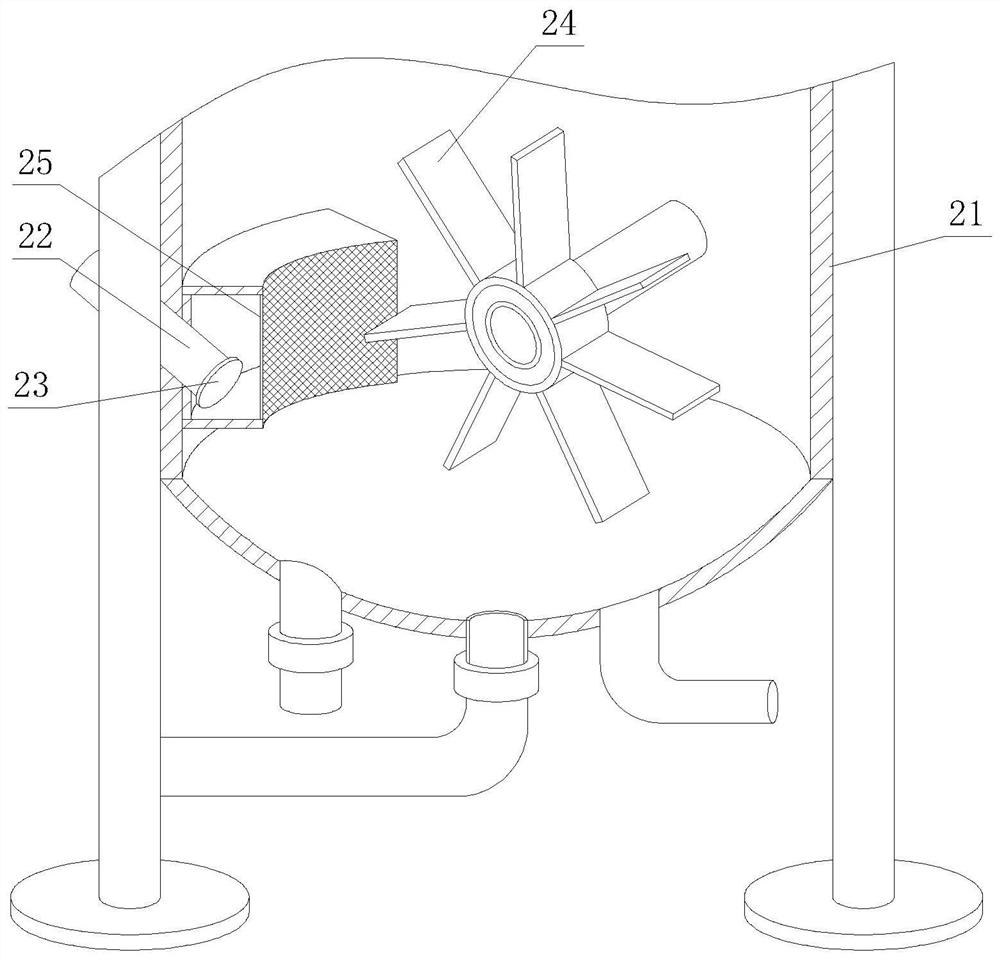

Wet desulphurization and dust removal equipment for industrial waste gas and use method thereof

InactiveCN112933903AIncrease contact areaImprove reaction efficiencyCombination devicesIndustrial wasteCondensed water

The invention discloses wet desulphurization and dust removal equipment for industrial waste gas and a use method thereof, and belongs to the technical field of industrial waste gas desulfurization. The equipment includes an outer cylinder, wherein a support is fixedly mounted below the outer side of the outer cylinder, and supporting legs are fixed below the support. According to the equipment and the use method thereof, the contact area with limestone water is increased, the reaction efficiency is improved, internal water backflow is prevented, the situation that gas rises too fast and cannot make contact with a spraying device is prevented, the contact time is prolonged, the treatment efficiency is improved, and the limestone water sprayed out of a spray head makes full contact with the gas, thus improving the desulphurization effect, forming a wet desulphurization cycle, increasing the utilization efficiency, reducing the waste of resources, preventing condensate water residues inside, avoiding secondary pollution caused by long-time residues, improving the condensation conveying efficiency, strictly controlling the gas emission quality, protecting the environment from being polluted, improving the desulphurization quality, reducing the waste of heat energy and increasing the treatment benefits.

Owner:LIAONING INST OF SCI & TECH

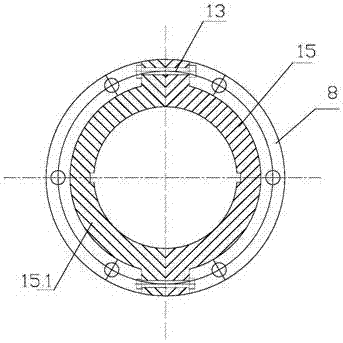

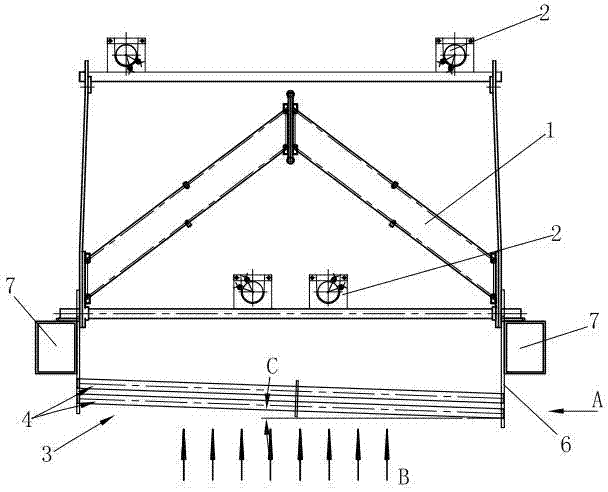

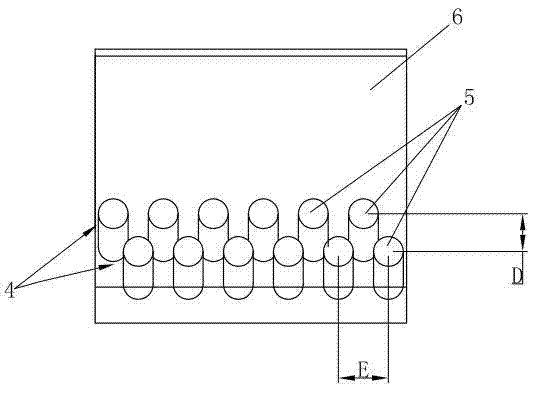

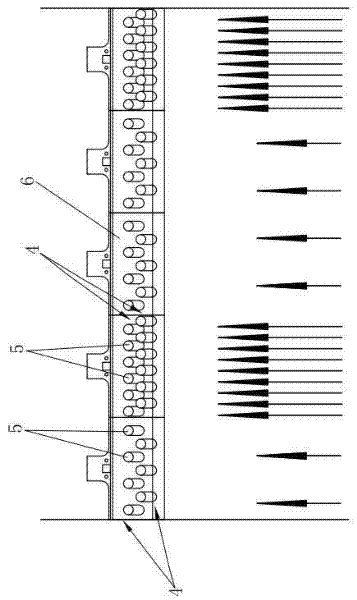

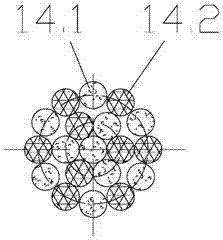

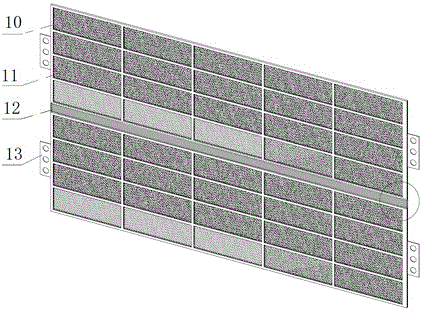

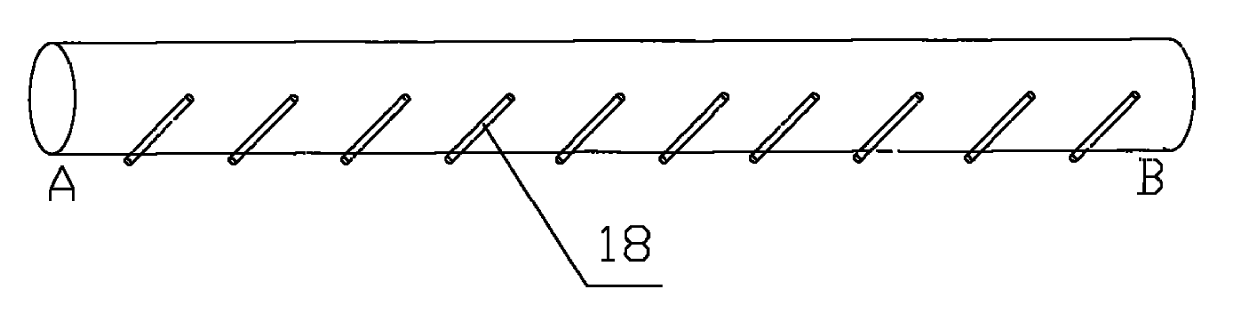

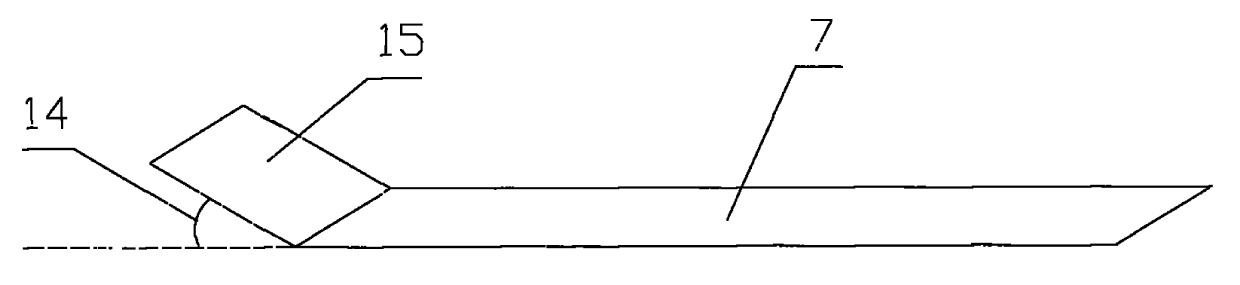

Defogging device for absorption tower

InactiveCN102527193AReduce processingImprove defogging efficiencyDispersed particle separationEngineeringTower

The invention relates to a defogging device for an absorption tower. The defogging device comprises at least one of a flat plate defogger, a ridge defogger or a diamond defogger, and is characterized in that a pre-defogger is arranged at the upstream position relative to the defogger in the flow direction of smoke gas and comprises at least two layers of pipe rows which are arranged in parallel, wherein the pipe rows consists of circular pipes which are arranged in parallel; the circular pipes in the two adjacent layers of pipe rows are arranged in a staggered mode; and the circular pipes in the pipe rows of the pre-defogger are tilted relative to a horizontal plane. According to the defogging device, the pre-defogger is arranged in front of the defogger, part of fog drips in the smoke gas is removed, the treatment capacity of the defogger in the rear is relieved, and smoke gas flow fields in a flue are distributed uniformly by arranging intervals of the pipe rows and intervals of the circular pipes reasonably, so that the defogging efficiency is improved, and the phenomena of carrying and gypsum rain are avoided; and aggregated water drops can be discharged quickly along the circular pipes, so that the water drops which are dripped directly are prevented from being winded up again by the smoke gas or blocking the flowing of the smoke gas.

Owner:江苏德克环保设备有限公司

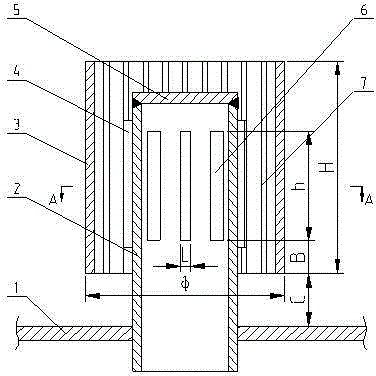

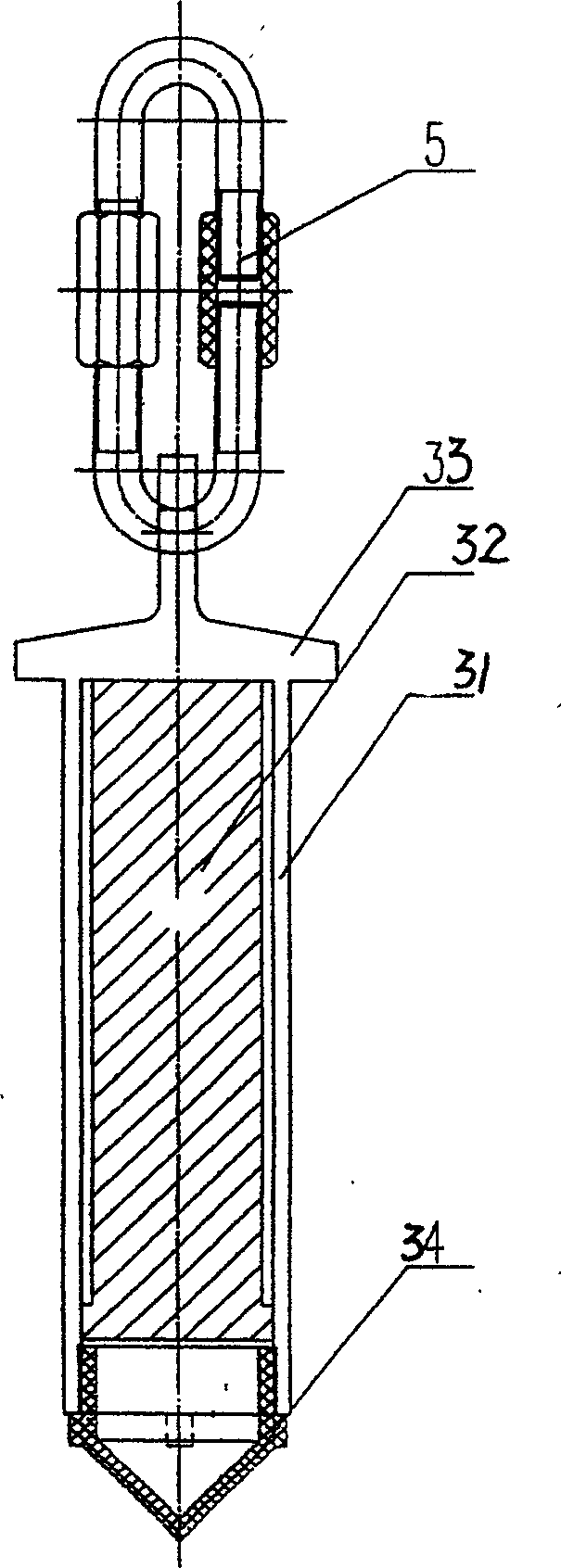

Efficient tubular plate vertical current wet-type electrostatic dust collector

InactiveCN103817005AEasy to driveImprove dust removal efficiencyExternal electric electrostatic seperatorElectric supply techniquesEngineeringHigh pressure

The invention discloses an efficient tubular plate vertical current wet-type electrostatic dust collector. The efficient tubular plate vertical current wet-type electrostatic dust collector comprises a shell (1), wherein an anode dust collecting mechanism (2) arranged vertically is arranged in the shell (1) and adopts a tubular plate structure formed by dust collecting boards; a vertically arranged cathode wire (31) with discharge points is arranged between the tubular plates of the anode dust collecting mechanism (2); the upper end of the cathode wire (31) is fixed on a cathode girder (32) above the cathode wire (31); the lower end of the cathode wire (31) is fixed on a tension frame (33) blow the cathode wire (31); the cathode girder (32) is connected with a high voltage power supply system (4) through conductive wires; a cathode system is formed by the cathode girder (32), the cathode wire (31) and the tension frame (33). As an electrostatic field formed by the tubular plate anode dust collecting mechanism and the cathode wires, effectively solves the problem of difficult removing of PM2.5 tiny particles, acid mist, liquid drops, aerosol, heavy metals and the like from the smoke, and the efficient tubular plate vertical current wet-type electrostatic dust collector is widely used.

Owner:双盾环境科技有限公司

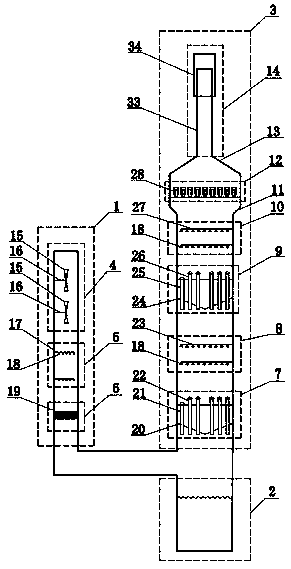

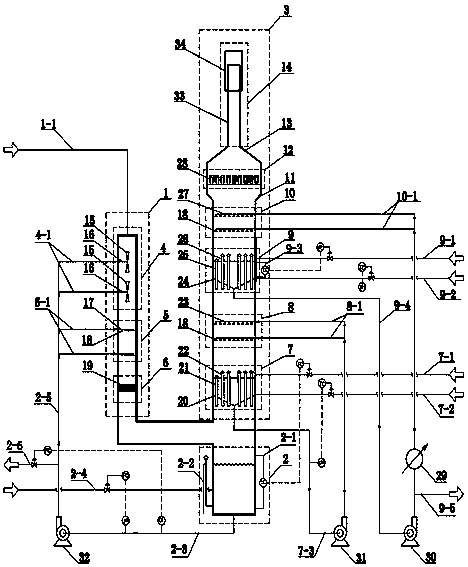

Flue gas desulfurization and regeneration integral tower and flue gas desulfurization method

ActiveCN110559804AAchieve recyclingReduce moisture contentGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a flue gas desulfurization and regeneration integral tower and a flue gas desulfurization method. The flue gas desulfurization and regeneration integral tower comprises a fluegas discharge zone, a demisting zone, a secondary spraying zone, a liquid holding groove zone, a primary spraying zone, a quenching cooling zone and an absorbed liquid regeneration zone, wherein the absorbed liquid regeneration zone is divided into a preheating zone, a steam stripping zone and a liquid collection ozone from left to right in sequence by using a vertical partition plate I, a partition plate II and a partition plate III; the preheating zone communicates with the primary spraying zone; the preheating zone communicates with the steam stripping zone through an opening in the bottomof the partition plate I; the height of the partition plate II is lower than that of the partition plate I; the steam stripping zone communicates with the liquid collection zone through a space at theupper part of the partition plate II; at the tops of the steam stripping zone and the liquid collection zone, the steam stripping zone and the liquid collection zone are completely partitioned from the spraying zone through the partition plate III; a heat exchange tube group is arranged in the preheating zone; a flue gas is fed into a tower through the heat exchange tube pipe; and an outer sleeveis arranged at the top of a chimney arranged in the flue gas discharge zone. The tower is capable of achieving SO2 recycling and deep demisting in the flue gas, is short in process course, simple inequipment and low in operation cost, and has wide application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

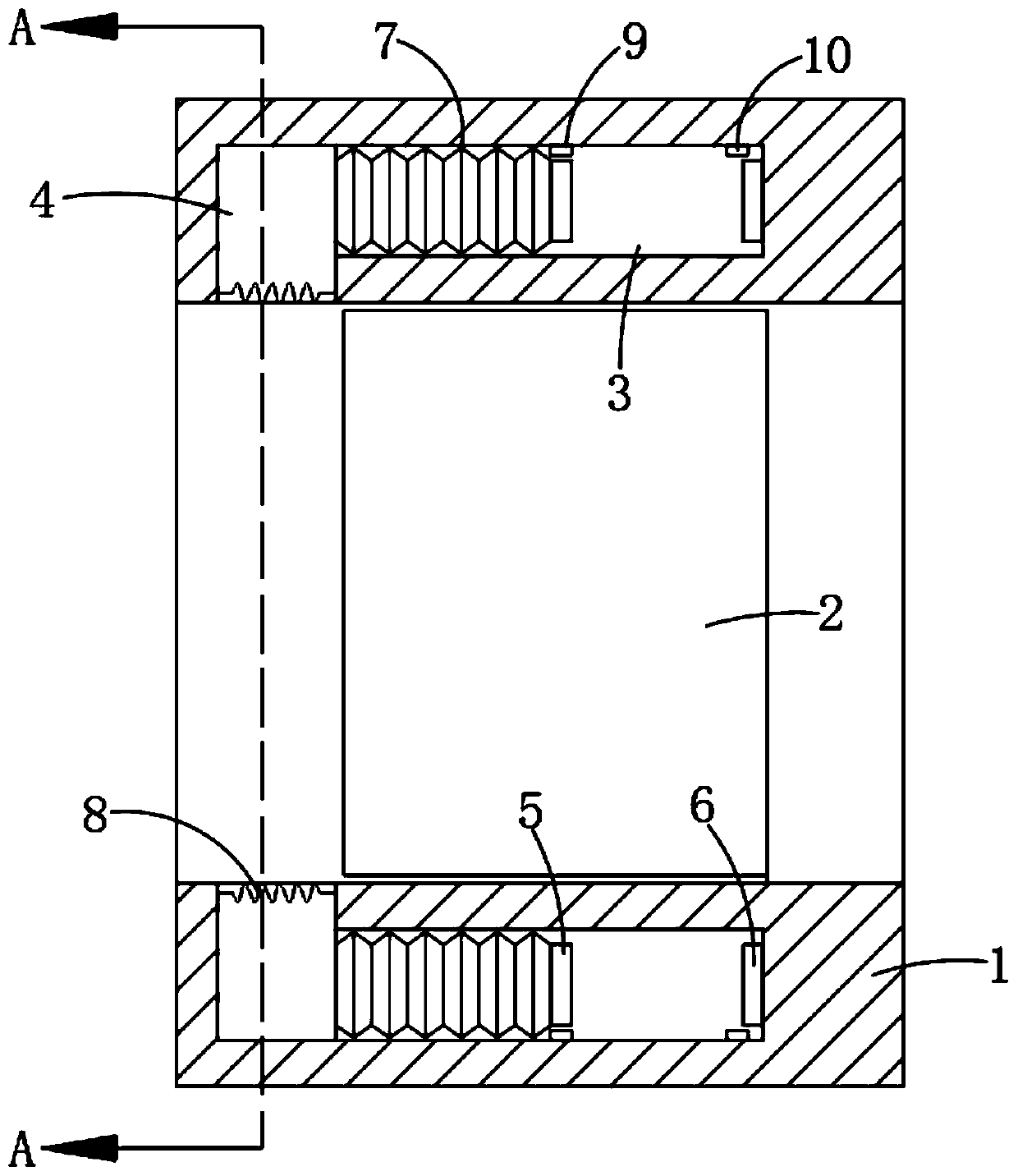

Improved electroconductive glass fiber reinforced plastic electric demister

ActiveCN102626672AReduce shakingImprove defogging efficiencyExternal electric electrostatic seperatorElectrode constructionsL-shellElectric field

The invention discloses an improved electroconductive glass fiber reinforced plastic electric demister. One side in the lower shell, corresponding to an air inlet flange, is provided with a forced air flow guiding and distributing plate, a middle shell below a lower cathode bearing framework is internally provided with a forced air distributing plate, an adjustable air distributing plate and an air rectifying and distributing plate from bottom to top in sequence, an upper shell is internally provided with an adjustable air distributing plate and a forced air distributing plate from bottom to top, the forced air distributing plates in the upper shell and the middle shell are both arranged in a prism frustum body of each of the upper shell and the lower shell, and by means of arranging the forced air guiding and distributing plate in the lower shell, arranging three layers of air flow distributing plates, namely the forced air distributing plate, the adjustable air distributing plate and the air rectifying and distributing plate, in the middle shell, and arranging the adjustable air distributing plate and the forced air distributing plate in the upper shell, air flows passing in and out of an electric field are made uniform, so that the shakes of a cathode system are reduced and the demist efficiency of the electric demister is increased.

Owner:双盾环境科技有限公司

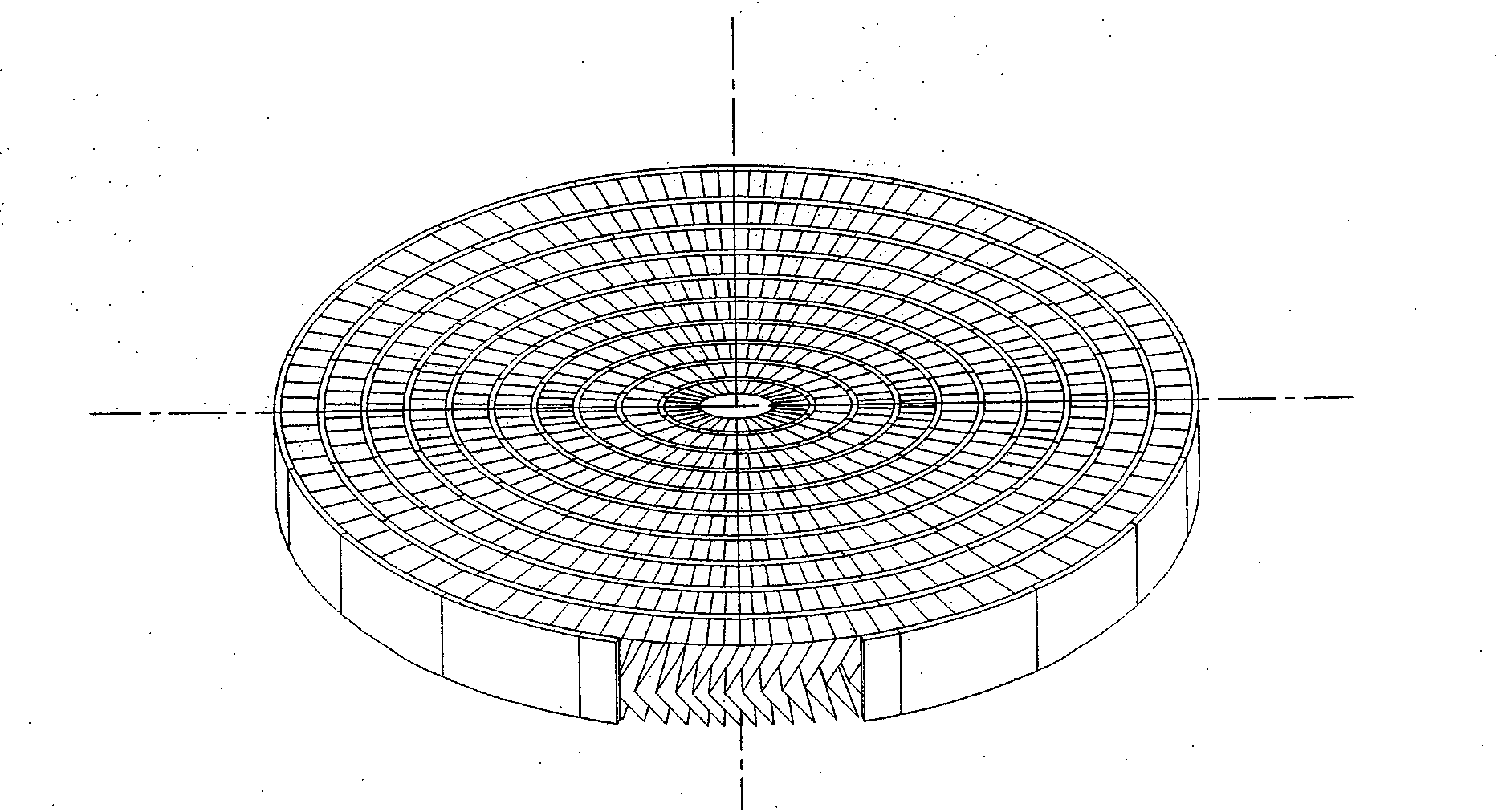

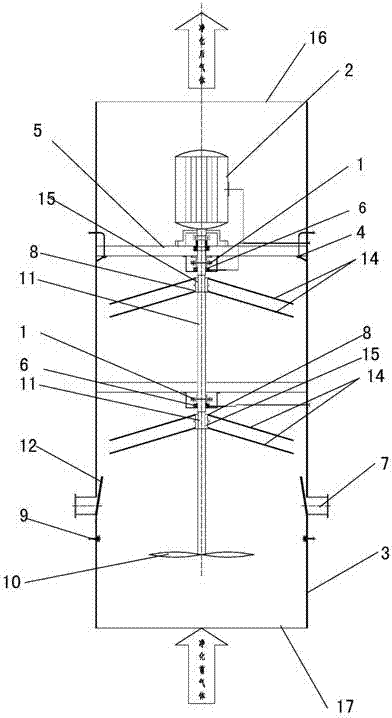

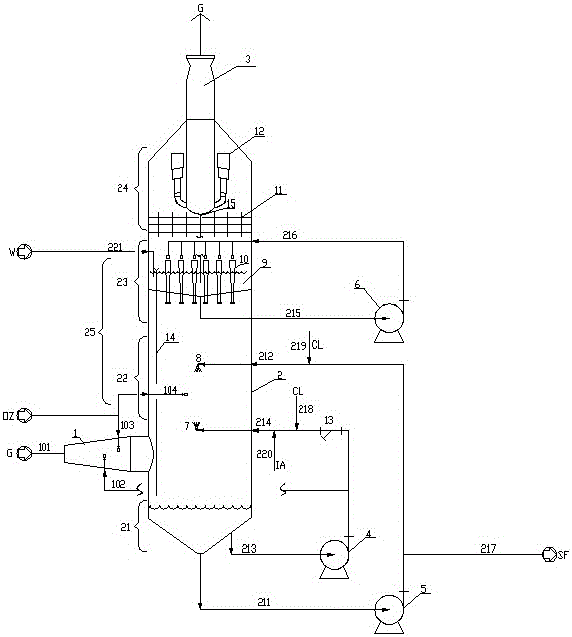

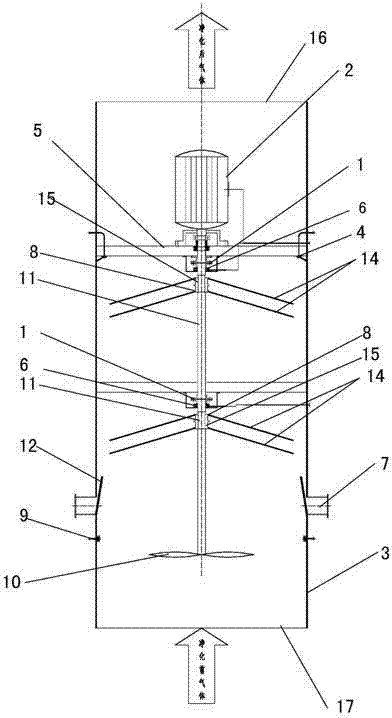

Gas static purification method based on rotary polar lines

InactiveCN103639046ASimple structureReduce resistanceLighting and heating apparatusDeodrantsPurification methodsSpray nozzle

The invention discloses a gas static purification method based on rotary polar lines and solves the problems of an existing purification method that the effect is single, the capturing effect on fine particulate matters is poor, the energy consumption is high and the like. According to the technical scheme, the gas static purification method comprises a gas inlet for leading gas into the bottom of a barrel; the gas which is conveyed to the gas inlet from a water inlet nozzle on a barrel wall is sprayed and humidified and then flows from bottom to top; the plurality of combined rotary polar lines which rotate around the central axis of the barrel and have negative-high-voltage static electricity can form an umbrella-shaped static layer with the negative-high-voltage static electricity in a corresponding barrel area; when the humidified gas penetrates through the layer, bacteria are killed and fog drops and the fine particulate matters are thrown to the inner wall of the barrel; the purified gas penetrating through the umbrella-shaped static electricity layer is raised to a gas outlet to be exhausted. The gas static purification method based on the rotary polar lines is simple in method, simple and convenient to operate, low in resistance, high in efficiency, small in occupied area, corrosion-resisting, light in weight, small in energy consumption and low in cost; the gas static purification method has no scaling and blocking and has the effects of removing dust, sterilizing and defogging.

Owner:WUHAN WUTUO TECH +2

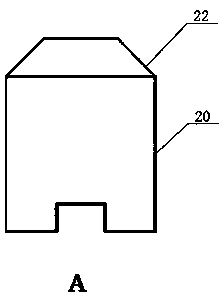

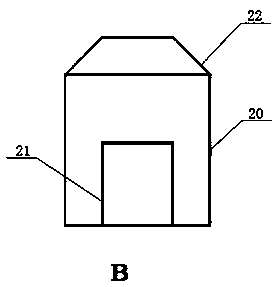

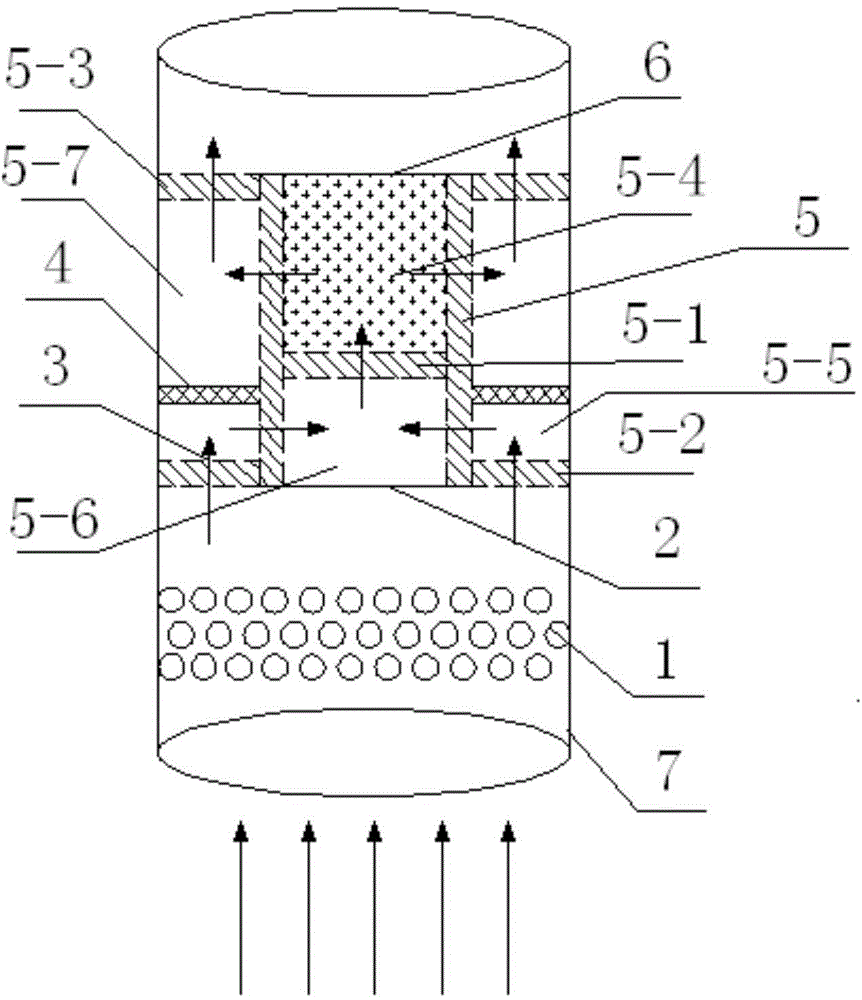

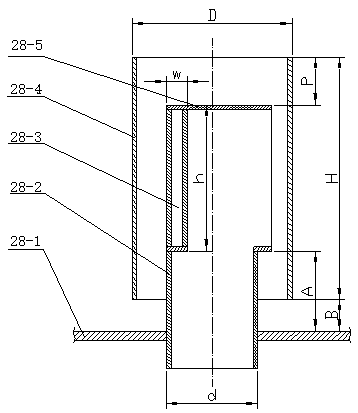

High-efficiency multistage demister

The invention discloses a high-efficiency multistage demister. The high-efficiency multistage demister comprises a plurality of demisting components; each demisting component comprises a gas riser pipe and an outer barrel; the outer barrel is arranged on the outer side of the gas riser pipe and located on the same axis as the gas riser pipe; the inner surface of the outer barrel is provided with spiral fins; the gas riser pipe is fixed on a tray; the top of the gas riser pipe is provided with a sealing cover; and a rectifying passage is arranged on the circumference of the gas riser pipe. Thedemister of the invention realizes the separation of droplets from gas by rectification, acceleration and scraping effect in the flowing process of fluids. The demister of the invention has the advantages of simple structure, convenient installation and small possibility of scale formation, and can effectively realize gas-liquid separation and reduce entrainment of mist.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multichannel-type composite demister and demisting method

ActiveCN104815501ADisadvantages of changing single-stage defoggingInsufficient changeCombination devicesFilling materialsMechanical engineering

The invention discloses a multichannel-type composite demister and a demisting method. The multichannel-type composite demister comprises a demister case and a cylindrical structure enclosed by a baffle plate and arranged in the demister case with axial direction, the inner part of the cylindrical structure is divided into a filling material chamber and an intermediate rectification chamber; a second baffle plate and a third baffle plate are arranged between an upper end of the cylindrical structure and the demister case as well as a lower end of the cylindrical structure demister case; a support plate is arranged between central section of the outer wall of the cylindrical structure and the demister case, a bottom circulation chamber is formed by a cavity defined by the second baffle plate and the support plate, a top circulation chamber is formed by a cavity defined by the support plate and the third baffle plate; air flow is introduced into the bottom circulation chamber, an intermediate rectification chamber, a filling material chamber and the top circulation chamber from the bottom of the demister case in order, and is discharged from the top of the demister case. By employing a composite demisting effect with combination of multichannel separating, baffle plate inertia separating and filling material separating, little liquid drop can be removed, so that the demister can better solve the raining or gypsum rain phenomenon of a chimney.

Owner:SOUTH CHINA UNIV OF TECH

Cathode system for electric demisting device with conductive fiberglass reinforced plastic

ActiveCN1827224AAvoid Galvanic CorrosionFirmly connectedElectrode constructionsCompound (substance)Electrochemistry

The cathode system of conductive glass steel electric defroster can be used in the device for removing acid mist in the process that purifying the mercurial smoke in acid industry, belonging to the electric defroster area. The invention is formed by a cathode support beam, a cathode wire, a weight, and a lower cathode frame; wherein, the upper end of cathode wire is hanged on the cathode support beam, which is characterized in that the weight that connecting the lower end of cathode wire is formed by a sealed plastic outer cylinder and a inner lead weight; the lower cathode frame is formed by main beam and branch beam that made from plastic or glass steel; the branch beam has a hole adjusting plate; the weight outer cylinder is through the hole of said adjusting plate. In said system, lead weight inside the weight and the cathode wire are separated to effectively avoid the electric chemical erosion between them, and prolong the service life of cathode wire; the lower cathode frame has simple structure, high strength, and its hole adjusting plate make the position and distance adjustment of cathode wire easy; each cathode wire can be independently adjusted according to the shape of anode tube, with controllable size accuracy, lower weight, and easy installment; the electric field inside the conductive glass steel electric defroster is stable, with long service life, high defrosting efficiency and the acid mist outlet is not more than 3mg / NM3.

Owner:双盾环境科技有限公司

High-efficiency defogging device

ActiveCN108499227ASimple structureSmall pressure dropDispersed particle separationProduct gasEngineering

The invention discloses a high-efficiency defogging device. The high-efficiency defogging device comprises a plurality of parallel defogging components; each defogging component comprises a gas riserpipe and an outer barrel; the outer barrel is arranged on the outer side of the gas riser pipe and located on the same axis as the gas riser pipe; the gas riser pipe is axially divided into an upper part and a lower part, the upper part is a gas riser pipe I, the lower part is a gas riser pipe II, the gas riser pipe II is fixed on a tray, and the gas riser pipe I and the gas riser pipe II are connected with each other by a bearing; the top of the gas riser pipe I is provided with an upper capping plate; the gas riser pipe I is circumferentially provided with a plurality of slits; and vanes arecircumferentially arranged on the gas riser pipe I at positions close to the slits. The high-efficiency defogging device of the invention realizes the separation of droplets from gas by multiple baffling, acceleration and scraping effect in the flowing process of fluids. The high-efficiency defogging device of the invention has the advantages of simple structure, small pressure drop, small possibility of scale formation, convenient installation, reduced mist entrainment and capacity of effectively realizing gas-liquid separation, and is especially applicable to occasions with large gas flow fluctuations.

Owner:CHINA PETROLEUM & CHEM CORP +1

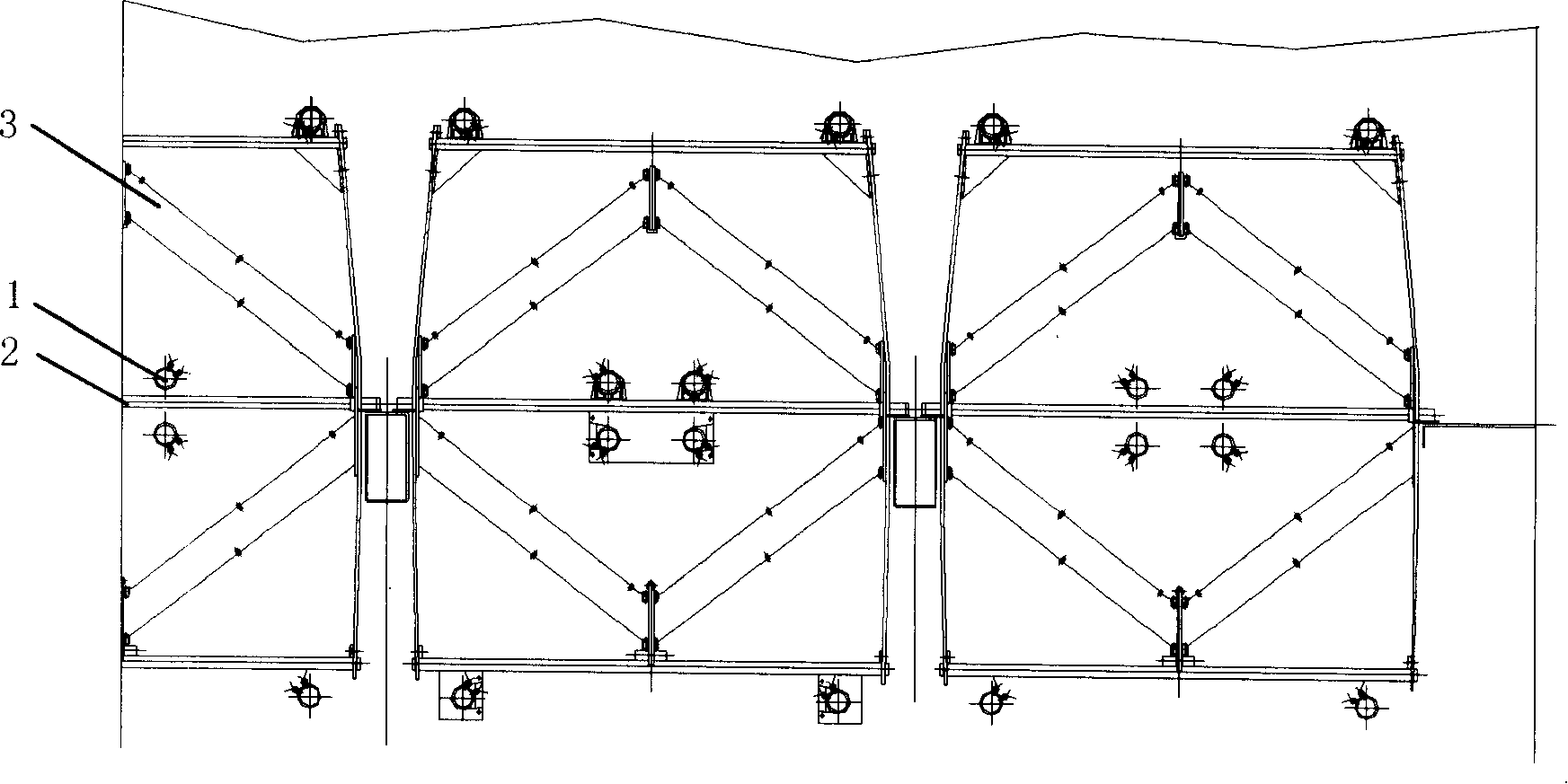

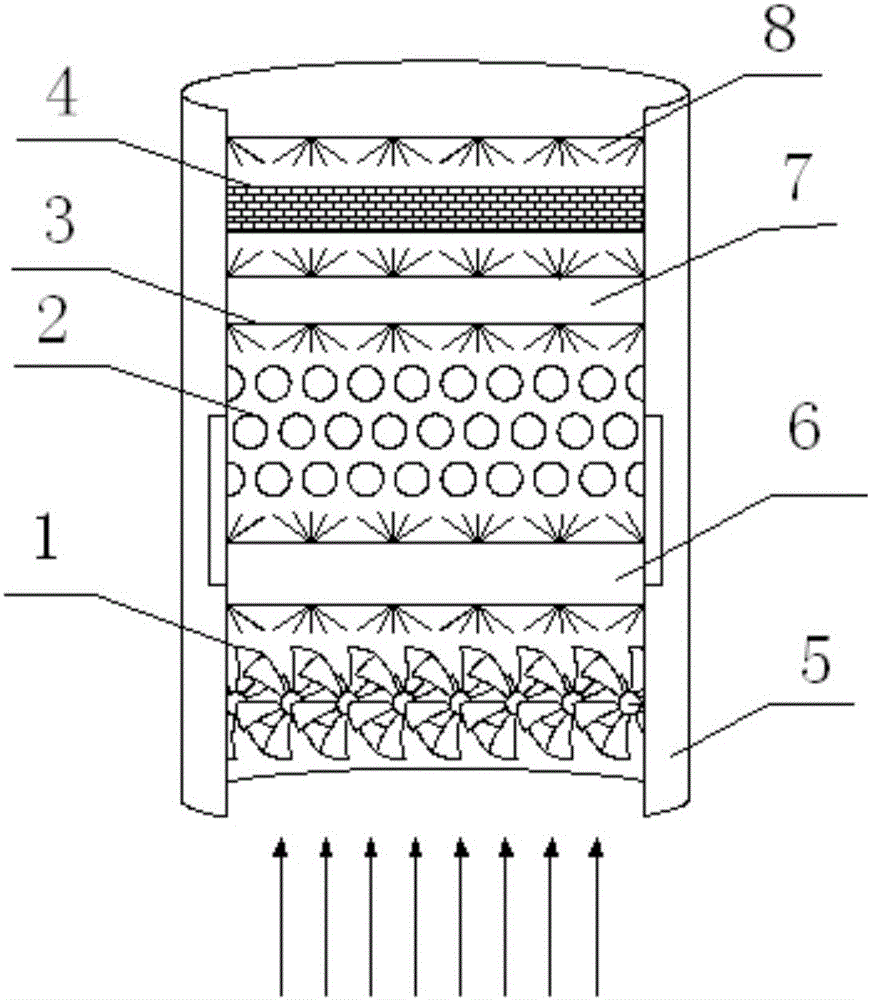

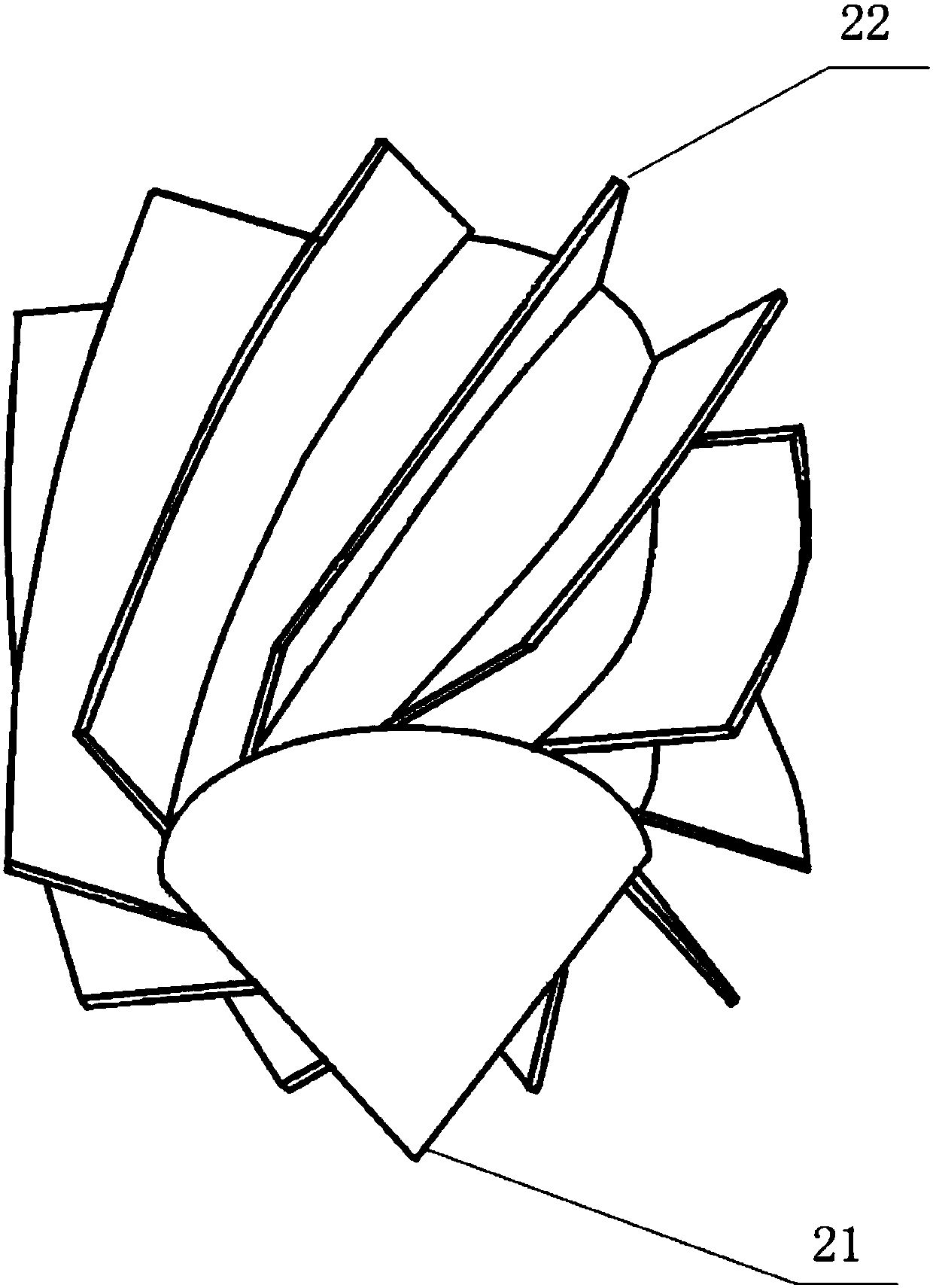

Windmill-tubular condensing-type demister and demisting method thereof

ActiveCN105032087ADrop carrying dropletAbility to drop solid particlesCombination devicesDrop impactCarrying capacity

The invention discloses a windmill-tubular condensing-type demister and a demisting method thereof. In a shell body, a windmill array demisting layer, a heat exchange tube array demisting layer and a wire mesh demisting layer which are successively arranged from bottom to top at intervals. The windmill array demisting layer is formed by connecting a plurality of windmills to form a row, wherein the inclining direction is same as the rotation direction of blades in each windmills. The wire mesh demisting layer is formed by wires in an interweaving manner. When air flows into the windmill array, the flow line of air is deflected so that large-diameter drops impact the blades in each windmills under the effects of inertia and are trapped in a large quantity, when the air flows on the surface of the heat exchange tubes in which cooling water flows, the temperature of air is reduced and the carried mist is condensed into hyper-saturated drops, and further the carrying capacity of air is reduced. By means of wire mesh demisting, the carrying amount of mist in flue gas is further reduced. In addition, by means of the free rotation of the windmill, the demister is free of washing dead corner, thereby solving the problem that a conventional demister is liable to be blocked. The demister is less in investment, is low in operation and maintenance cost, and is reduced in generation of gypsum rain in chimney in wet desulphurization.

Owner:SOUTH CHINA UNIV OF TECH

Flue gas dedusting and desulfurizing tower and flue gas dedusting and desulfurizing method

ActiveCN108686490ARealize rapid cooling and coolingReduce the burden onGas treatmentUsing liquid separation agentQuenchingProcess engineering

The invention discloses a flue gas dedusting and desulfurizing tower and a flue gas dedusting and desulfurizing method. The flue gas dusting and desulfurizing tower comprises a pretreatment unit, an advanced treatment unit and a tower bottom liquid tank area, and the pretreatment unit is communicated with the advanced treatment unit by a flue gas pipeline. The pretreatment unit sequentially comprises a quenching and spraying area, a first-stage spraying area and a Venturi grating washing area from top to bottom; and the advanced treatment unit sequentially comprises a middle liquid tank area,a second-stage spraying area, an upper liquid tank area, a third-stage spraying area, a demisting area and a flue gas discharging area from bottom to top. The white smoke phenomenon of wet desulfurization is eliminated, so the white smoke phenomenon of a smoke discharging opening is significantly reduced; and the triple functions of flue gas dedusting, desulfurizing and advanced demisting are achieved in the tower, and all functional areas cooperate with each other and promote each other, so the occupied area of the tower is greatly reduced, and the cost for construction and reconstruction ofthe tower is significantly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self-adaptation type floating ball demister and demisting method thereof

The present invention discloses a self-adaptation type floating ball demister and a demisting method thereof. According to the self-adaptation type floating ball demister, multiple layer floating ball demisting units are arranged in the demister housing, the floating ball demisting units are separated through sieve plates, gas flow enters the demister housing from the bottom portion of the demister housing and then enters the floating ball demisting unit through the sieve plate, the accumulated floating balls in the floating ball demisting units present the floating state under the gas flow effect while the rising gas flow contacts the floating balls being in the floating state, the gas flow direction produces deflection under the effects of inertia and baffling flow, the liquid droplets and the solid particles carried in the gas flow are continuously adsorbed and aggregated by the surface of the floating balls, and the liquid droplet-removed and solid particle-removed gas flow is discharged from the top portion of the demister so as to complete the self-adaptation type demisting. According to the present invention, the floating ball adopts the polymer hollow small ball, characteristics of equipment investment reducing, demisting efficiency improving, clogging resistance, easy rinsing, strong working condition adaptability, less investment, and low operation and maintenance cost are provided, and the generation of the wet method desulfurization chimney gypsum rain is effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH

Double-cyclone dust-removing and demisting device

The invention provides a double-cyclone dust-removing and demisting device. The double-cyclone dust-removing and demisting device comprises a cyclone cylinder with a venturi tube shape, a primary cyclone unit and a secondary cyclone unit, wherein the middle part of the cyclone cylinder is a throat pipe; the primary cyclone unit is coaxially arranged at a bottom gas inlet in the cyclone cylinder; the secondary cyclone unit is coaxially arranged in the throat pipe; the secondary cyclone unit comprises a driven free type impeller arranged in the throat pipe. The double-cyclone dust-removing and demisting device provided by the invention is simple in structure and high in reliability; various manners including bent curved surface separation, inertial separation, centrifugal separation and thelike are combined to treatment flue gas for a plurality of times; small-grain dust and fog drops with the size of 5mu m or lower can be efficiently removed and a demisting effect of a desulfurizationtower is increased; the resistance loss also can be reduced, and the investment cost and the operation cost of the desulfurization tower are reduced; the double-cyclone dust-removing and demisting device provided by the invention can be applied to the wet type desulfurization tower.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Demister

InactiveCN107803069AHarm reductionTo achieve the effect of defoggingDispersed particle separationEngineeringTower

The invention discloses a demister. The demister comprises several parallel demisting assemblies, each demisting assembly comprises a gas rising pipe and an outer cylinder, the outer cylinder is arranged on the outer side of the gas rising pipe and is at the same axis line as the gas rising pipe, the gas rising pipe is fixed on a tower disk, the top portion of the gas rising pipe is provided witha sealing cover plate, the circumference of the gas rising pipe is provided with several rectification channels, the rectification channels are horizontally embedded along a tangent direction of an outer wall of the gas rising pipe, a sidewall I of the rectification channels close to one side of the outer cylinder, the other sidewall II is intersectant to the wall of the gas rising pipe, and the rotation direction of the rectification channels is same; the top of the rectification channel is leveled with the sealing cover plate, and the bottom is intersectant to the wall of the gas rising pipe. The demister can realize separation of liquid drops and gas through rectification, acceleration and surface scraping effect of fluid during a flowing process, The demister has the advantages of simple structure, convenient installation, and difficult fouling, and reduces mist entrainment, and can effectively realize gas-liquid separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

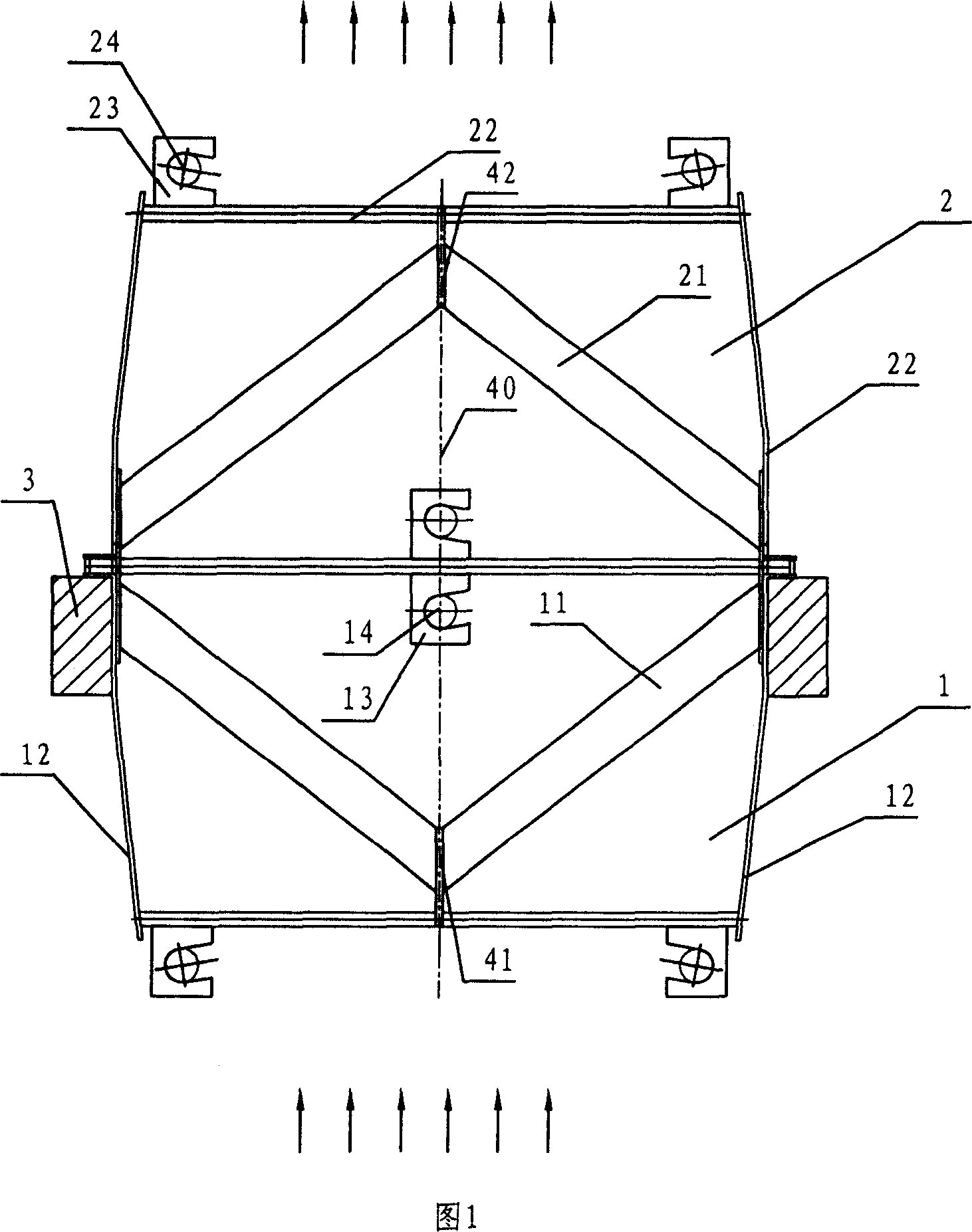

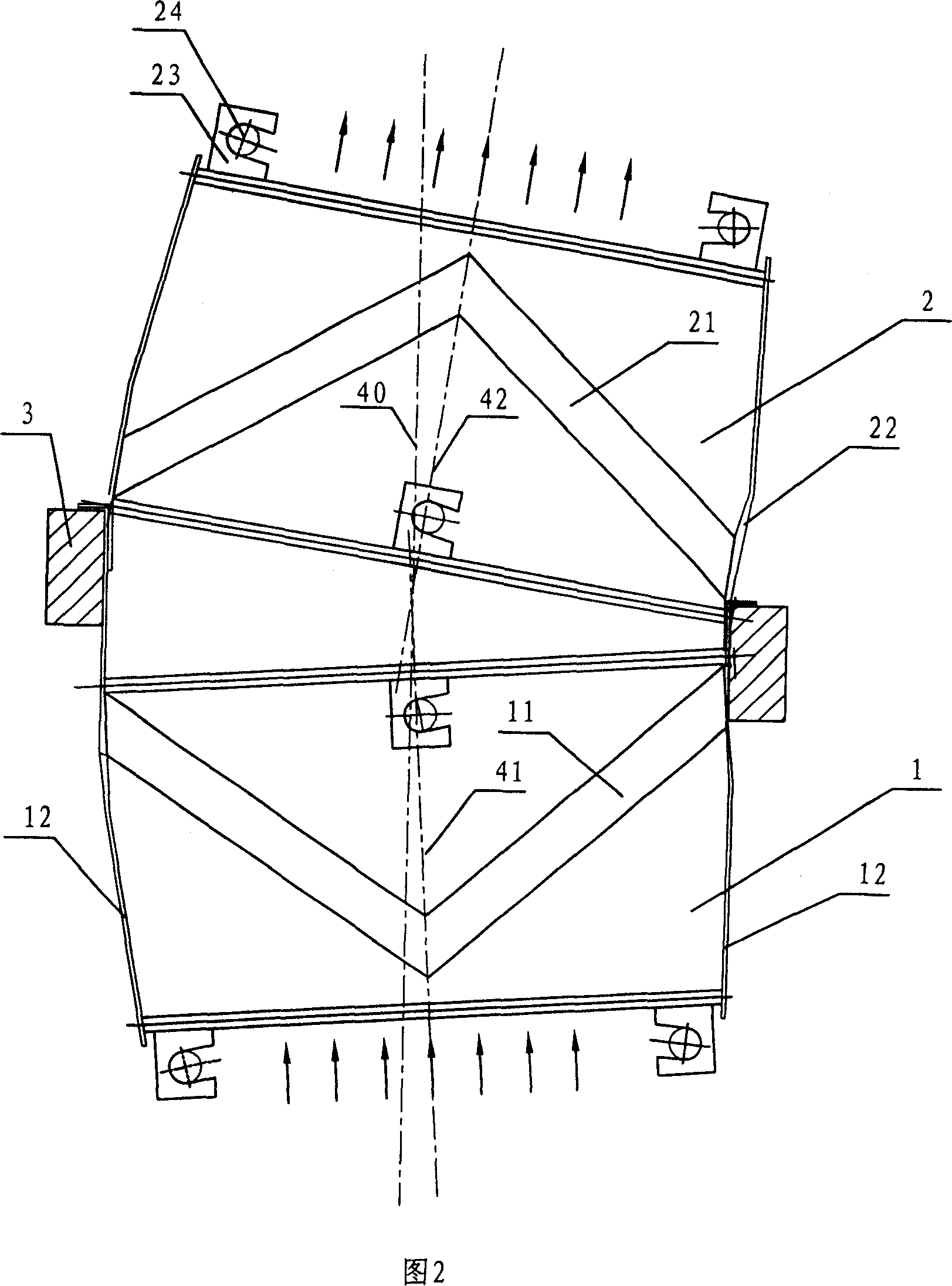

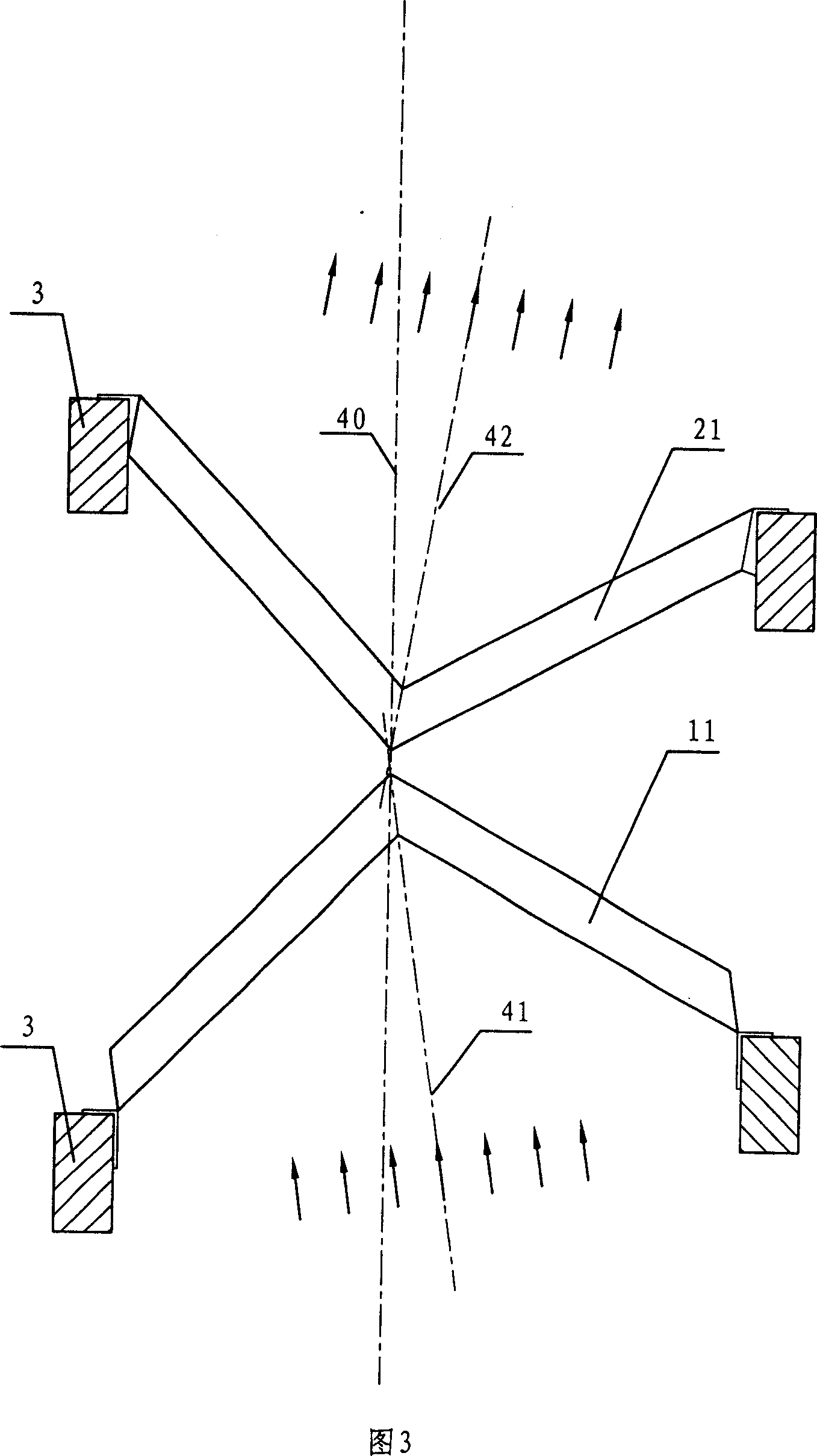

Wave baffle type mist eliminator

InactiveCN101007229AImprove the overall effectImprove defogging efficiencyDispersed particle separationEngineeringSmoke

The invention discloses a demister, it includes the first order demister (1), the second order demister (2), and the support beams (3) supporting these two demisters and washing water system. The first order demister (1) and the second order demister (2) are combined by certain number of the first order demister components (11) and the second order demister component (21) which section is similar with V-shape in rows and one by one, the central line (41) of the first order demister components (11) is coincidence with downstream gas velocity direction of the demister components. The invention enables the thruflow gas amounts of two sidewall demister vane channel s of V-shaped demister components are equivalent to avoid secondary entrained catalyst loss and poor demisting capacity and improve the demisting capacity of demister.

Owner:CHANGZHOU 3C HAIPENG ENVIRONMENTAL EQUIP

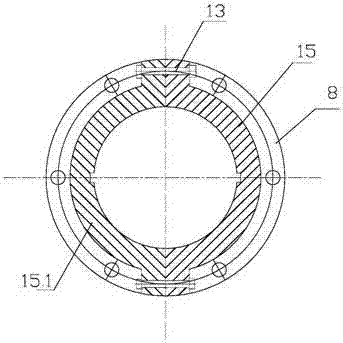

Demisting and dedusting device for wet chimney of coal-fired power plant

InactiveCN105194934AImprove defogging efficiencySmall running resistanceDispersed particle separationEngineeringEddy current

The invention discloses a demisting and dedusting device for a wet chimney of a coal-fired power plant. The demisting and dedusting device comprises, from bottom to top, a gravity hammer, a lower supporting structure, an eddy current distributor, a connecting rod, an eddy current demister, an upper supporting structure and a nozzle, wherein the eddy current distributor is composed of a group of concentric blades and is fixed on the lower supporting structure through bolts, and the lower supporting structure is fixed below the connecting rod through bolts; the eddy current demister is located above the eddy current distributor and is fixed below the lower supporting structure through bolts; the eddy current demister is also composed of a group of concentric blades which are oppositely arranged relative to the blades of the eddy current distributor, so the rotation directions of air flows formed by the blades of the eddy current demister and the eddy current distributor are opposite; and the connecting rod is fixed below the upper supporting structure through bolts, and the upper supporting structure is fixed on the top of the inner wall of the chimney through a detachable fixing device. The demisting and dedusting device has the following beneficial effects: high demisting efficiency, small operation resistance, small flow obstruction effect on flue gas, low energy consumption, convenience in installation and easiness in operation and maintenance.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

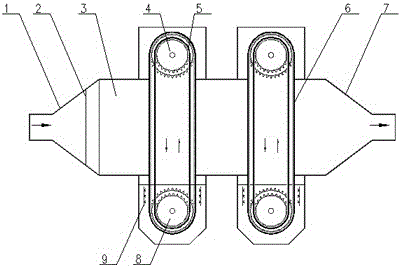

Deep fog and dust removal apparatus

InactiveCN105664629ARealize dynamic dust and fog removalReduce resistanceCombination devicesFlue gasGas passing

The invention discloses a deep fog and dust removal apparatus including a gas inlet smoke box, a rotary filter bed for blocking and adsorbing fog drops and smoke dust in the gas inlet smoke box, a gas outlet smoke box for receiving the gas passing through the rotary filter bed, and a water cleaning assembly, in which one end of the filter bed is immersed for cleaning the rotary filter bed. The deep fog and dust removal apparatus is used for flue gas emission treatment after wet desulfurization, can remove ultrafine fog drops and dust being not less than 3 [mu]m, and is more than 90% in fog removal efficiency.

Owner:GUODIAN NANJING AUTOMATION

Unpowered gas centrifugal dehumidifying and demisting device

InactiveCN101766936AImprove cooling effectHigh dehumidificationDispersed particle separationEngineeringWater level

The invention discloses an unpowered gas centrifugal dehumidifying and demisting device which comprises a dehumidifying pot and a floating pot, wherein, a plurality of clapboards are evenly distributed on the outer wall of the floating pot and have 60-90 degrees of inclination angle relative to the floating pot; a small clearance is left between each clapboard and the inner surface of the dehumidifying pot; an air inlet pipe is arranged at the outside lower part of the dehumidifying pot, wriggling up obliquely along the inside edge of the dehumidifying pot after going into the humidifying pot and extending to the other side of the dehumidifying pot and in the same level as a drainpipe outlet to form a port; the port is opened upward with 45 degrees relative to the horizontal tangent direction of the inner diameter of the dehumidifying pot, the center of the port is positioned in the middle of the joint part of the clapboards and the water surface; a plurality of short pipes with small inner diameter are arranged in the middle parts beside the immerged part of the air inlet pipe in the dehumidifying pot and are communicated with the air inlet pipe; a dry gas outlet is arranged right above the drainpipe. The floating pot is driven to rotate by the wet gas with only few kilopascals of pressure to make the wet gas be dehydrated among the clapboards. The invention has the advantages of good cooling and dehumidifying effect for wet gas, and unnecessary additional power for centrifugal dehumidification.

Owner:魏伯卿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com