Baffle type cyclone demister

A technology of demisters and baffles, which is applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of difficult small-diameter droplets, effective removal, etc., and achieve the overall simplification of the device and the small space occupied , the effect of low height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

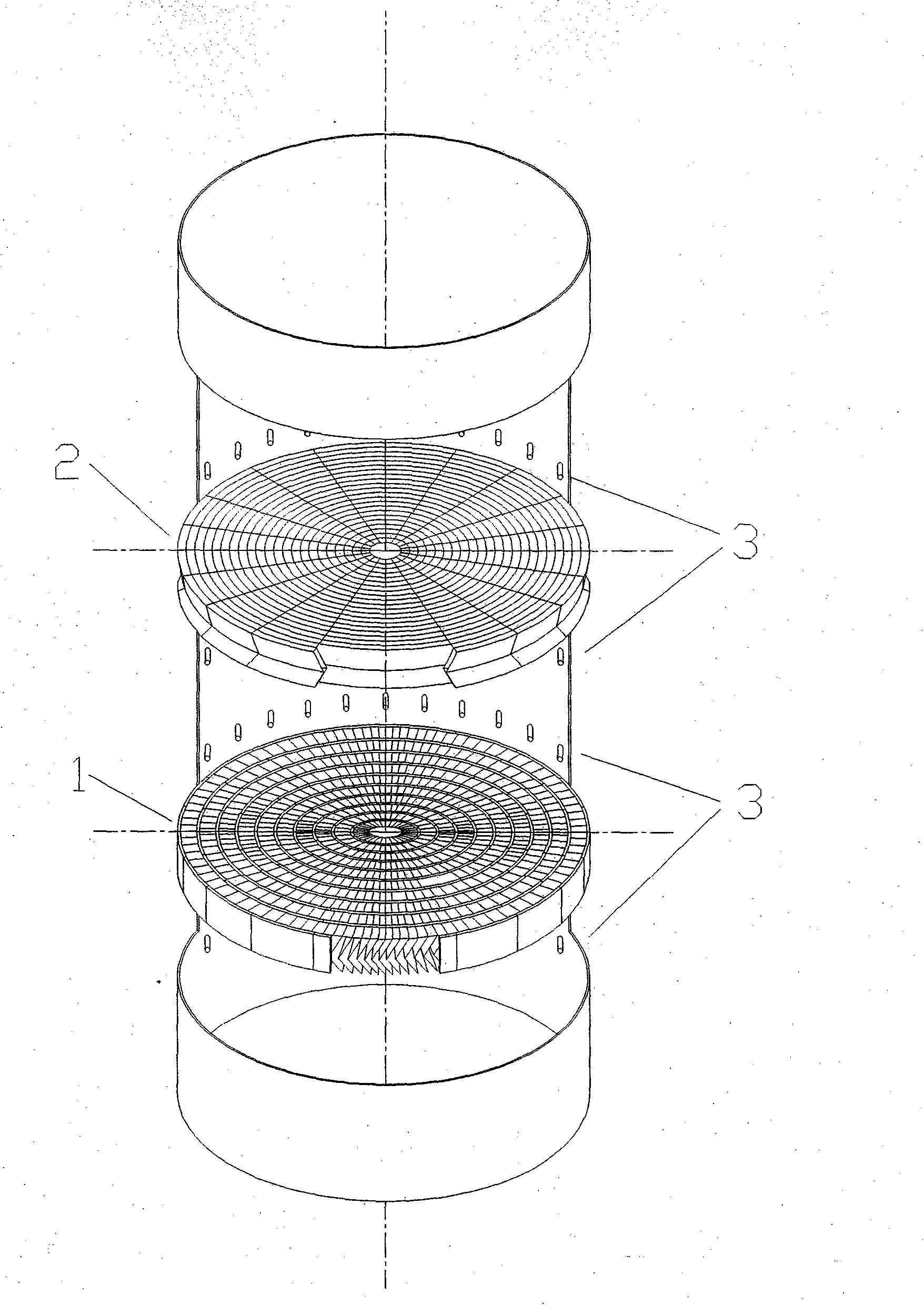

[0032] The present invention is applied in the wet flue gas desulfurization process to remove mist droplets in the flue gas after desulfurization: the designed demist device and wet flue gas desulfurization equipment are set as an integral desulfurization system, which is arranged above the desulfurization tower. The diameter of the tower is 12m, the total height of the defogging section is 4.0m, and the average rising velocity of the flue gas in the tower is 5m / s.

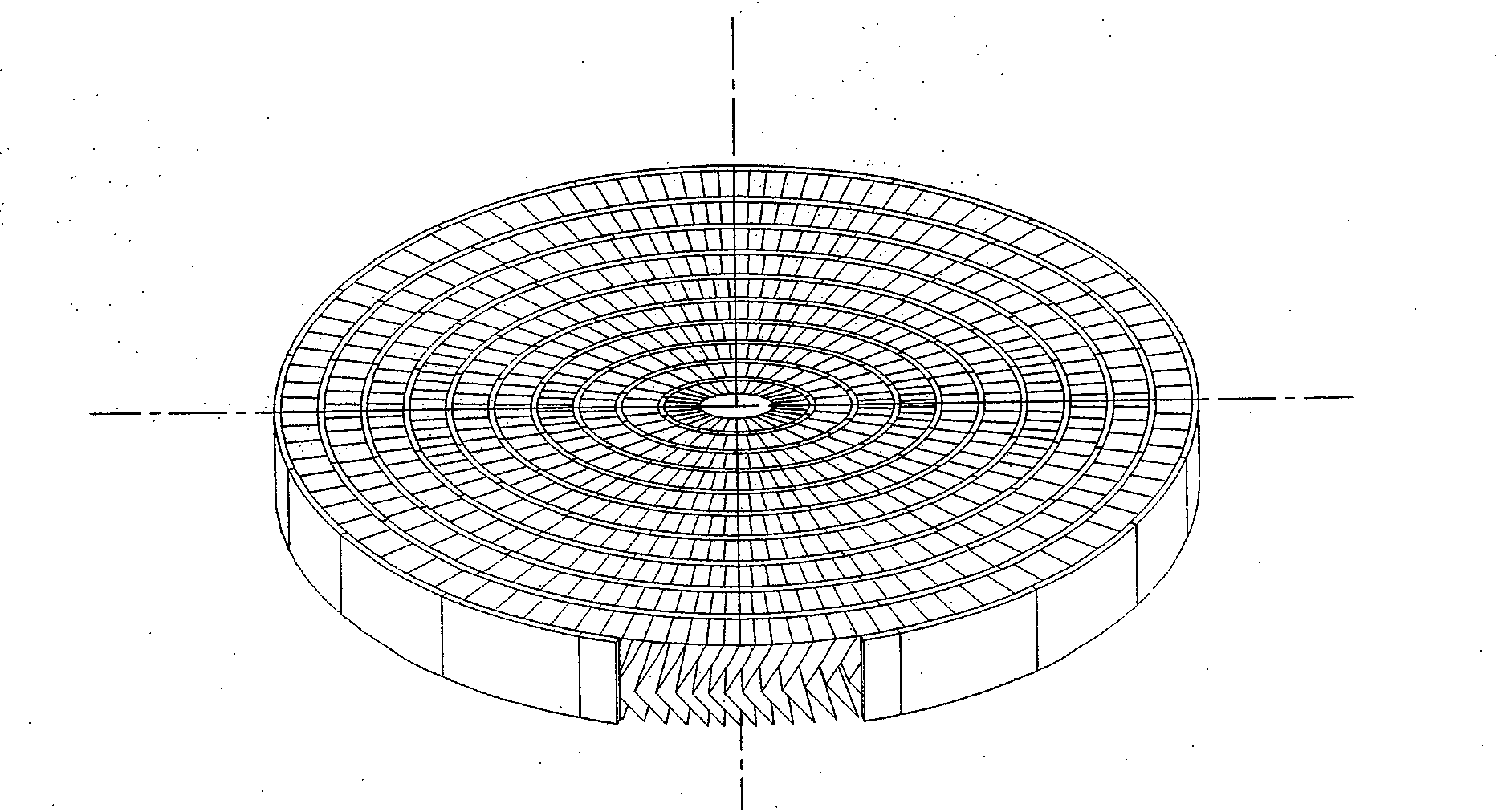

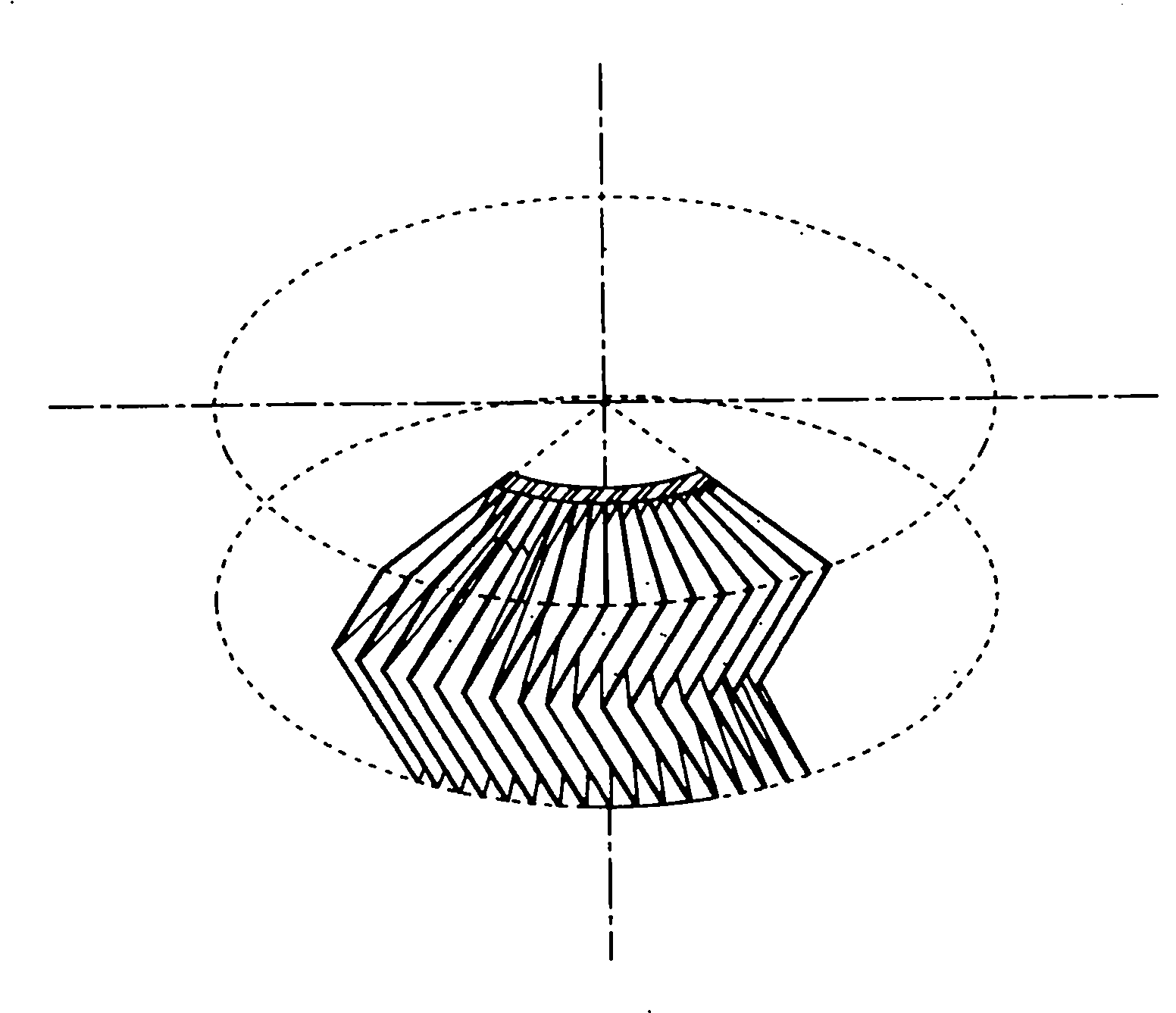

[0033] The flue gas containing mist drops first passes through the first stage demister from bottom to top. The first-stage flap-type defogging blades are arranged side by side with each other, the blade spacing is 40mm, the blade height is 350mm, and the blade angle is 75°, and they are arranged to form a ring shape. become a group of leaves. There are 7 sets of ring-shaped blades in the first-stage demister, each with a width of 750mm. The cylindrical area with a diameter of 1500mm in the middle is set as a bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com