Unpowered gas centrifugal dehumidifying and demisting device

A demisting device and technology of power gas, applied in separation method, dispersed particle separation, chemical instrument and method, etc., can solve the problems of complicated operation, high energy consumption, poor dehumidification and demisting effect of oxygen-rich, etc. Low resistance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

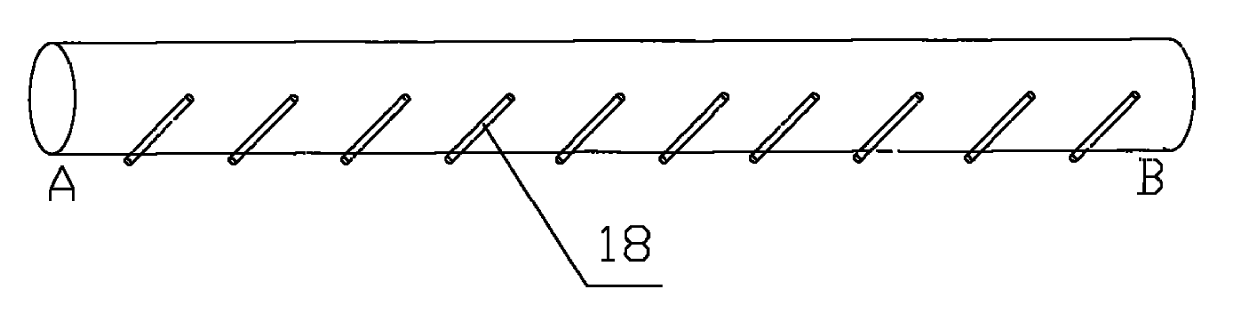

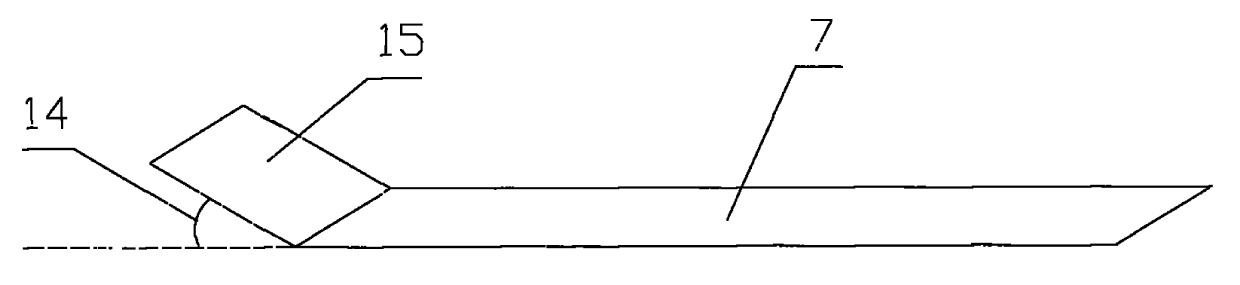

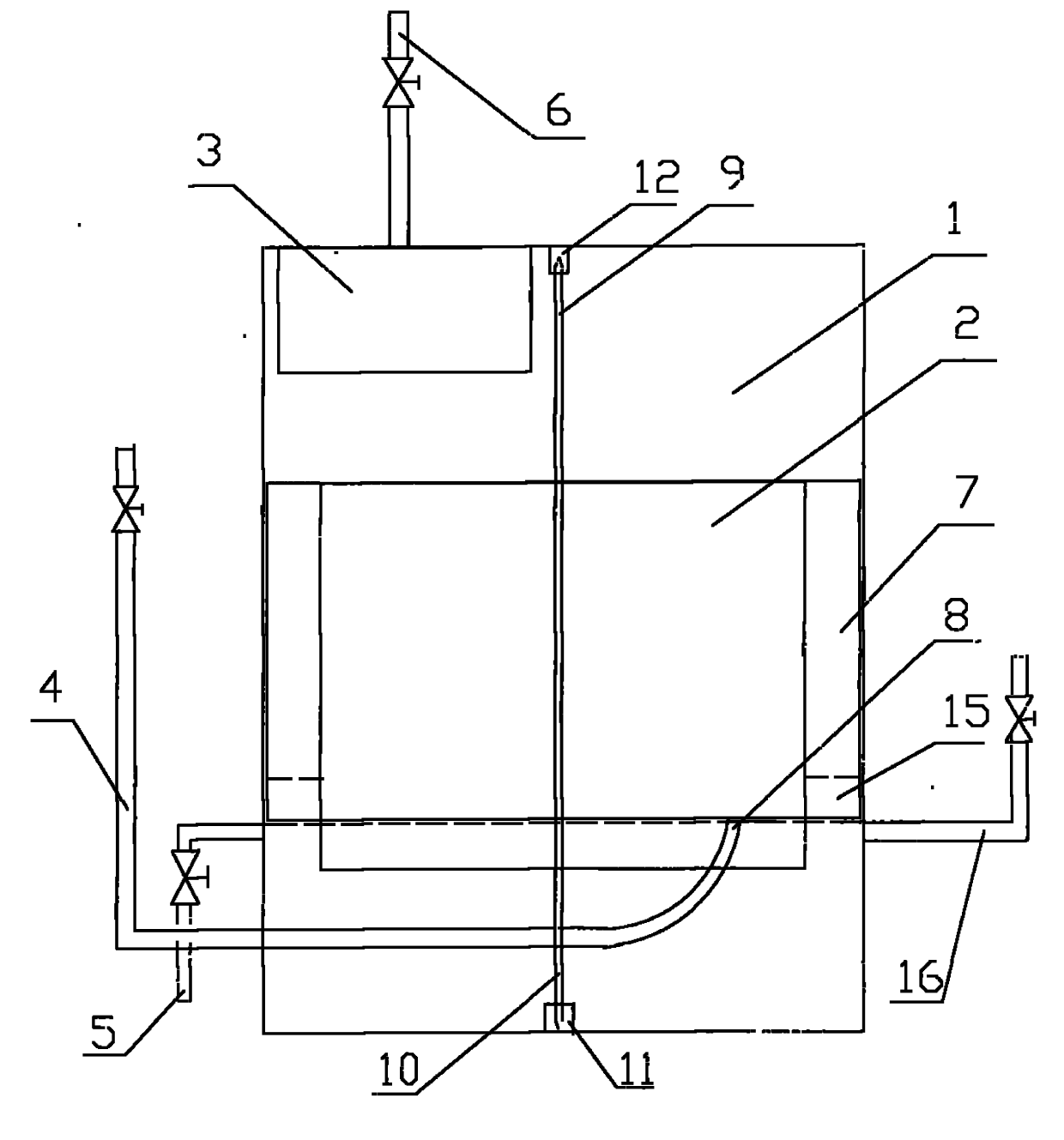

[0019] Below in conjunction with accompanying drawing, the present invention is further described:

[0020] exist Figure 1~5 In the embodiment, the non-powered gas centrifugal dehumidification and demisting device includes a normal pressure gas dehumidification tank 1, and a completely sealed floating tank 2 floating in the dehumidification tank 1 and capable of horizontal rotation is installed in the dehumidification tank 1 , the upper part of the floating tank 2 is flat, and the lower part can be flat or inverted conical; the upper and lower centers of the floating tank 2 are welded with an upright central shaft, and the upper central shaft 9 gaps are sleeved in the upper cover of the dehumidification tank 1 The upper bearing 12 installed in the center can rotate freely; the lower central shaft 10 is sleeved in the lower bearing 11 installed in the center on the lower bottom surface of the dehumidification tank 1, and can rotate freely; the outer wall of the floating tank 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com