Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Improve crimp quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

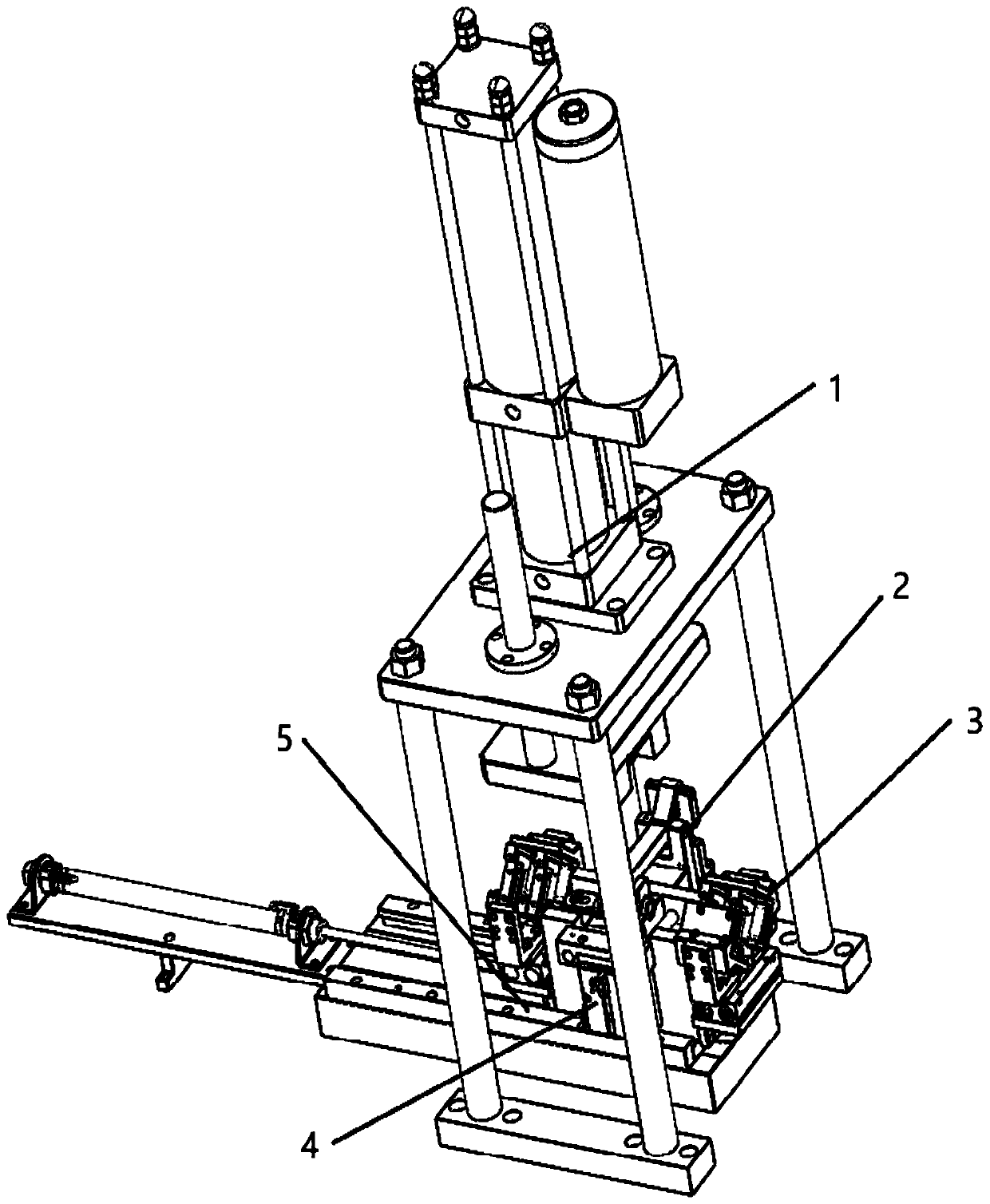

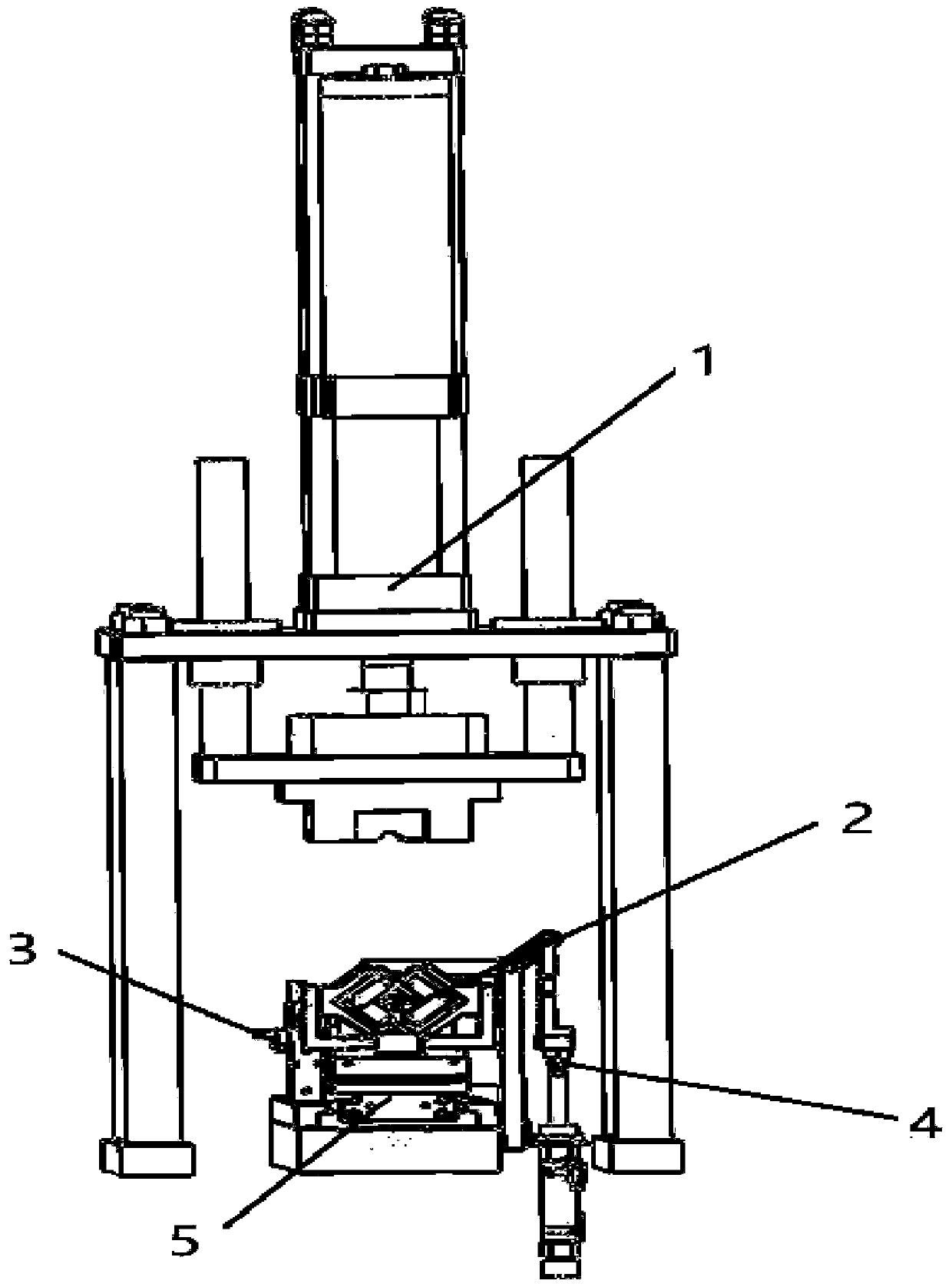

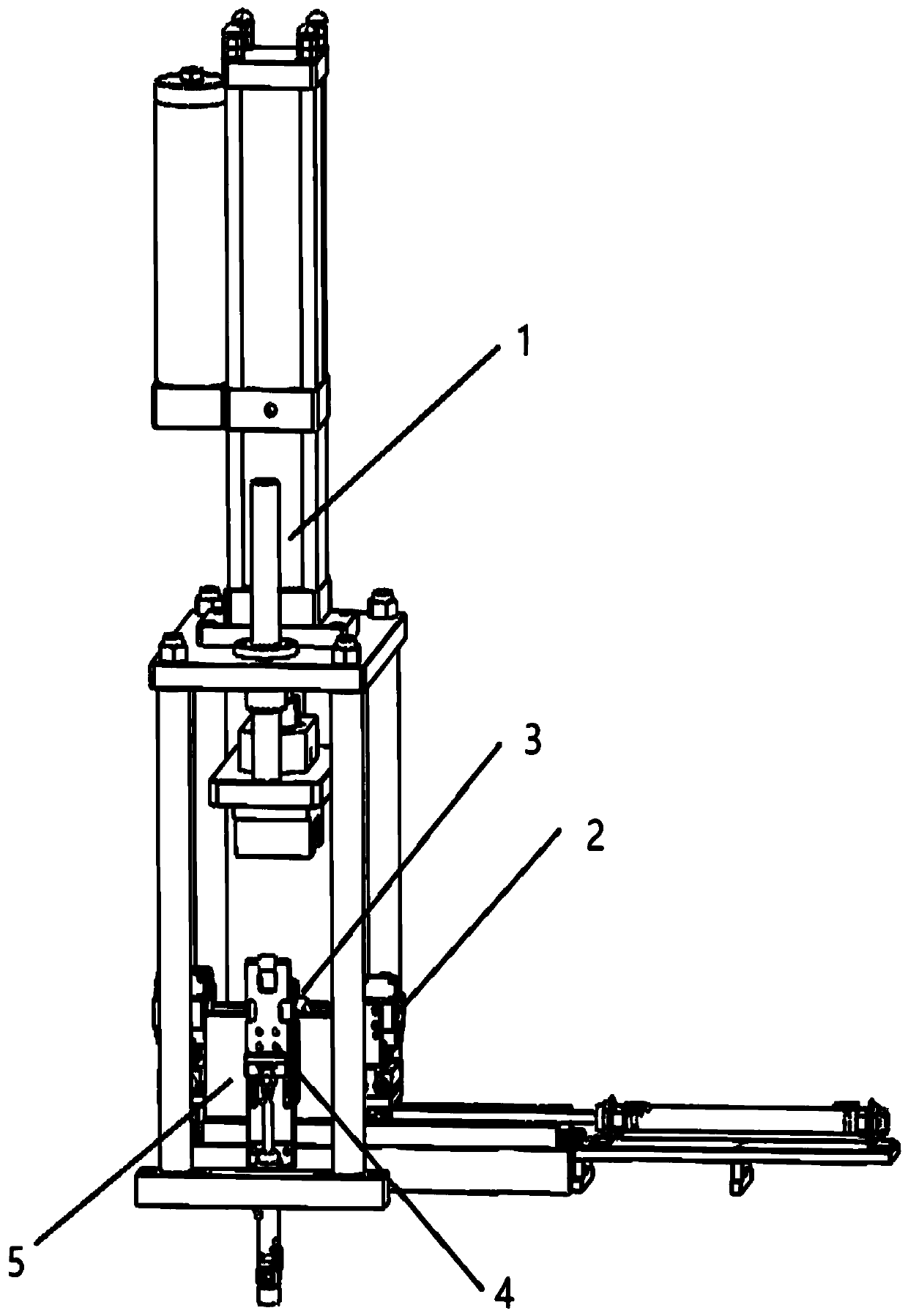

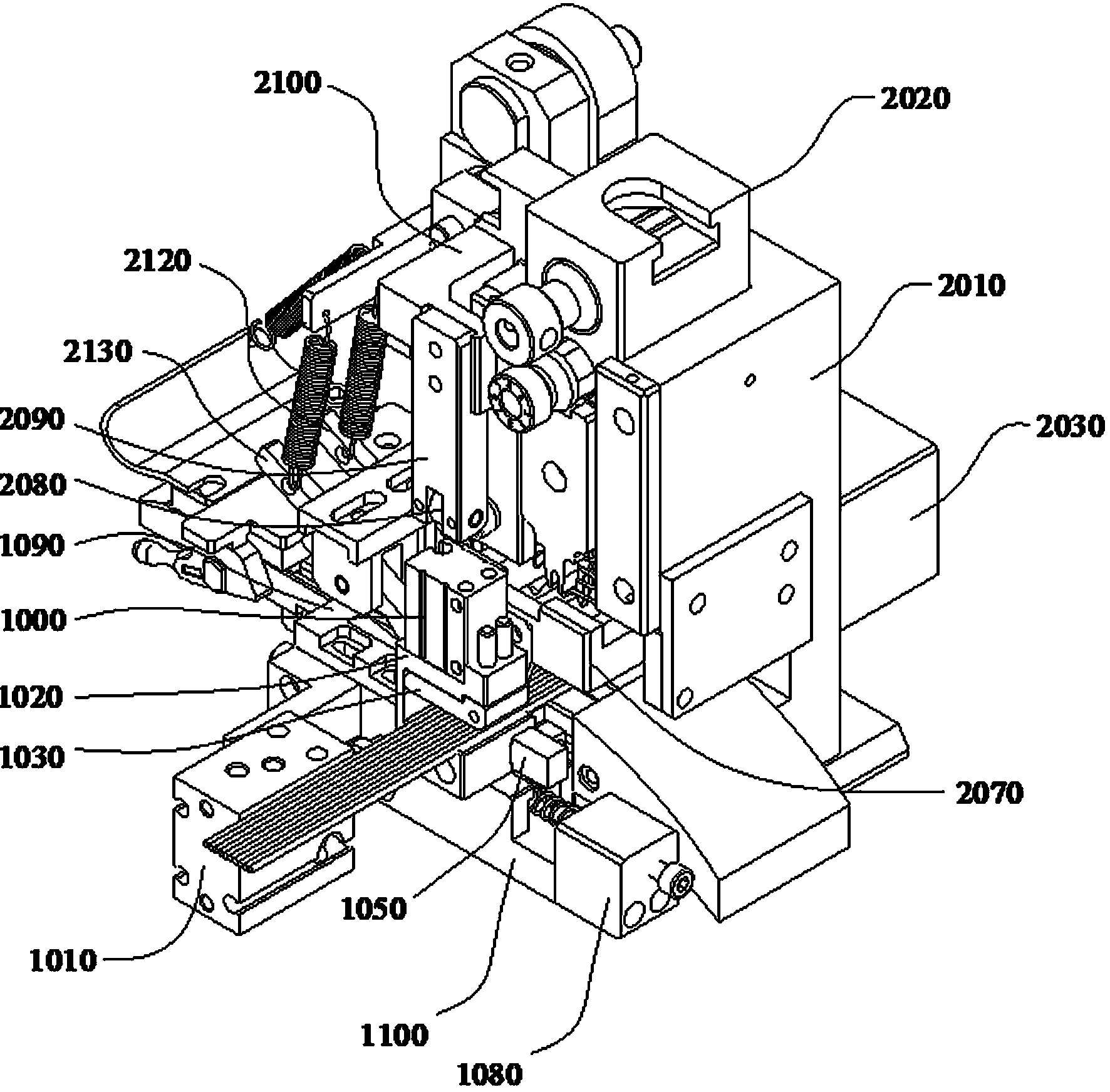

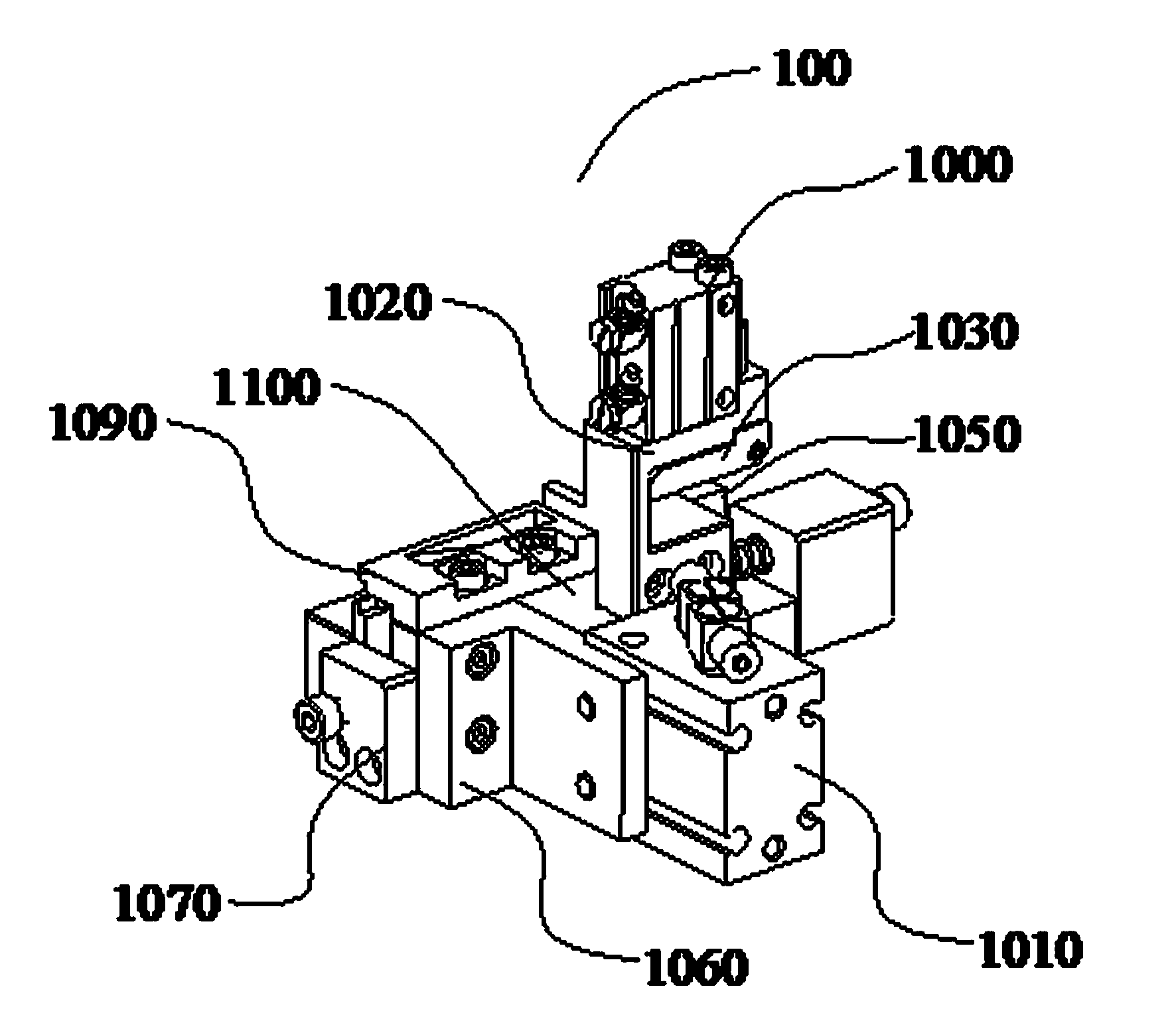

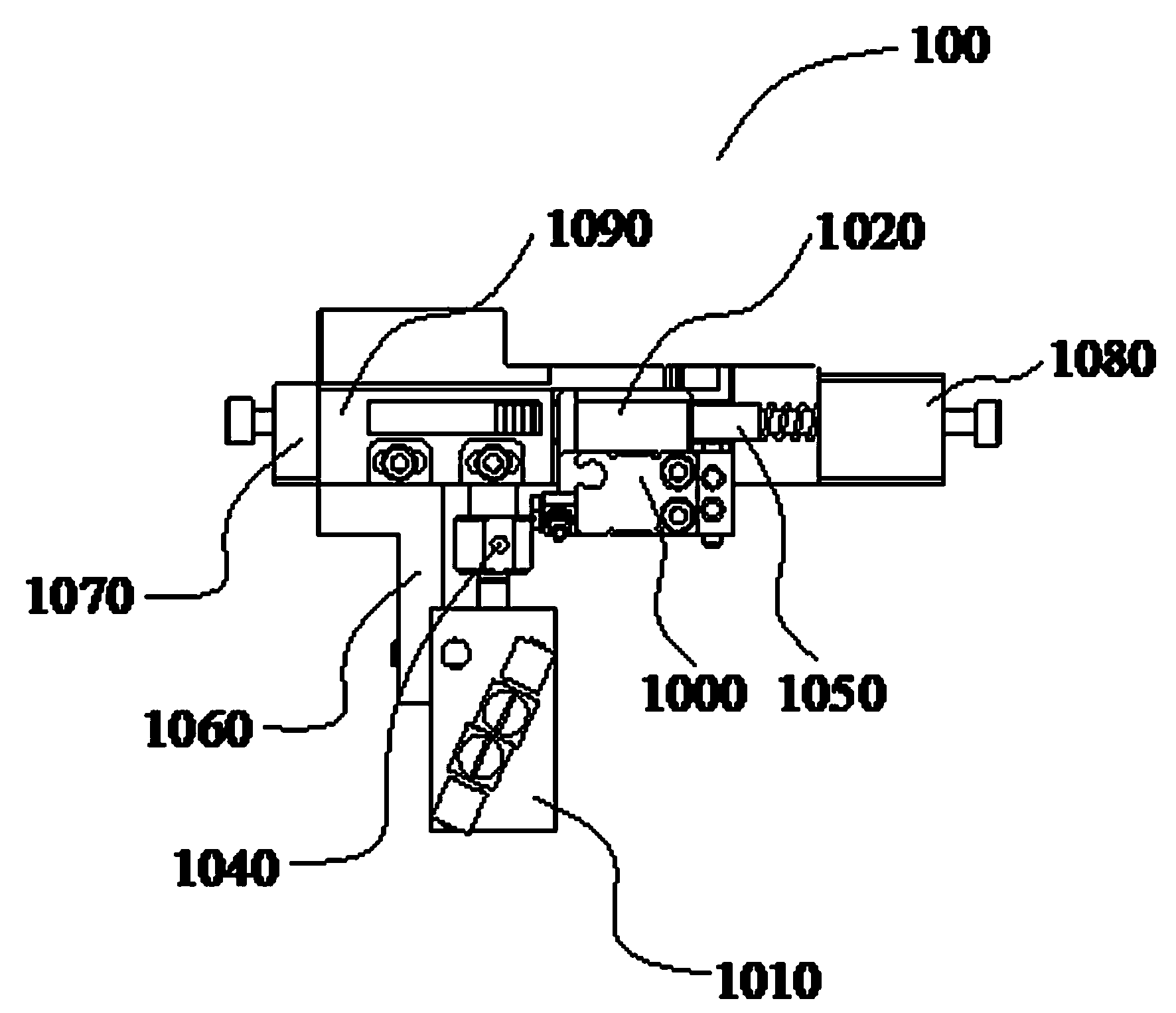

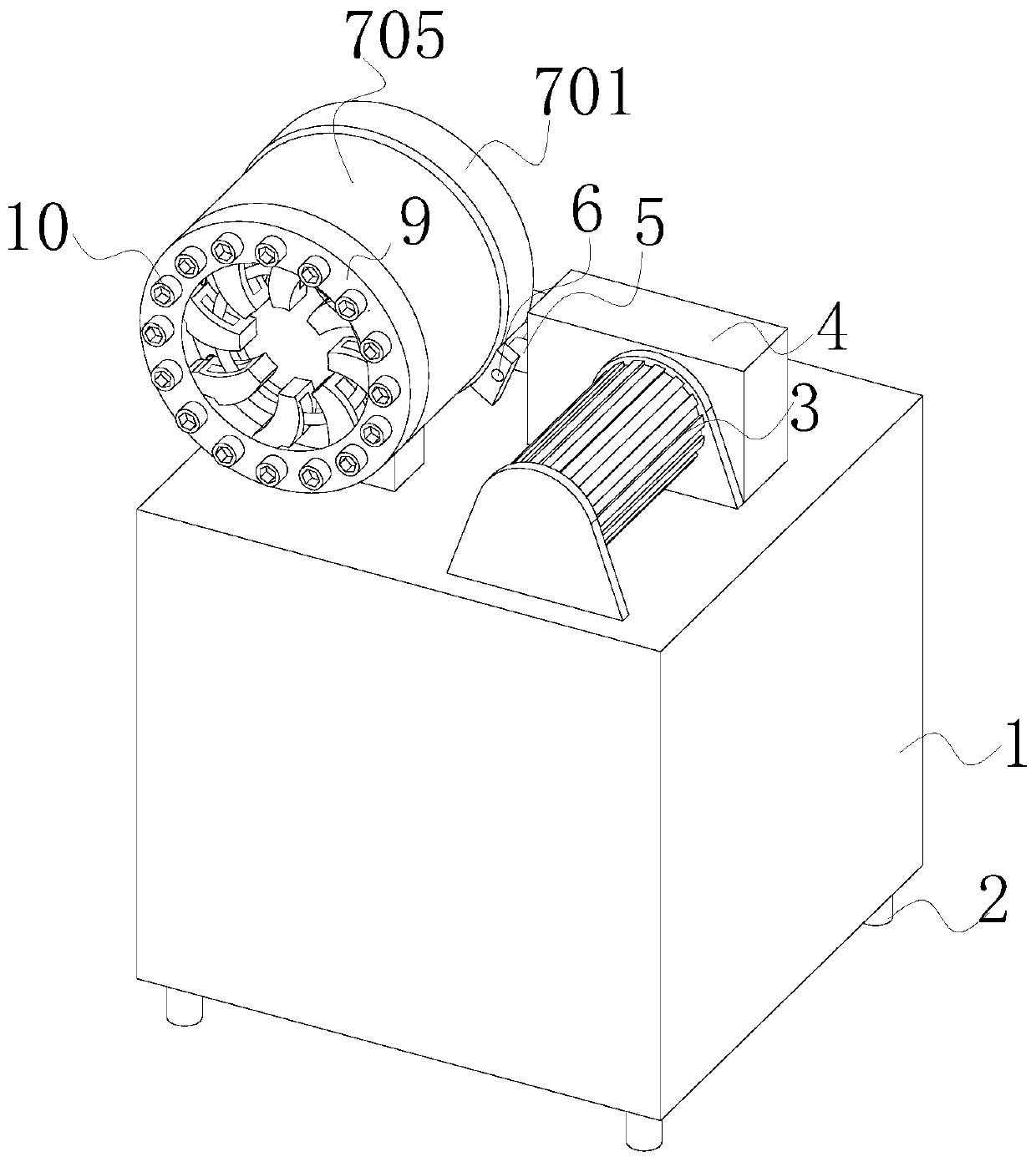

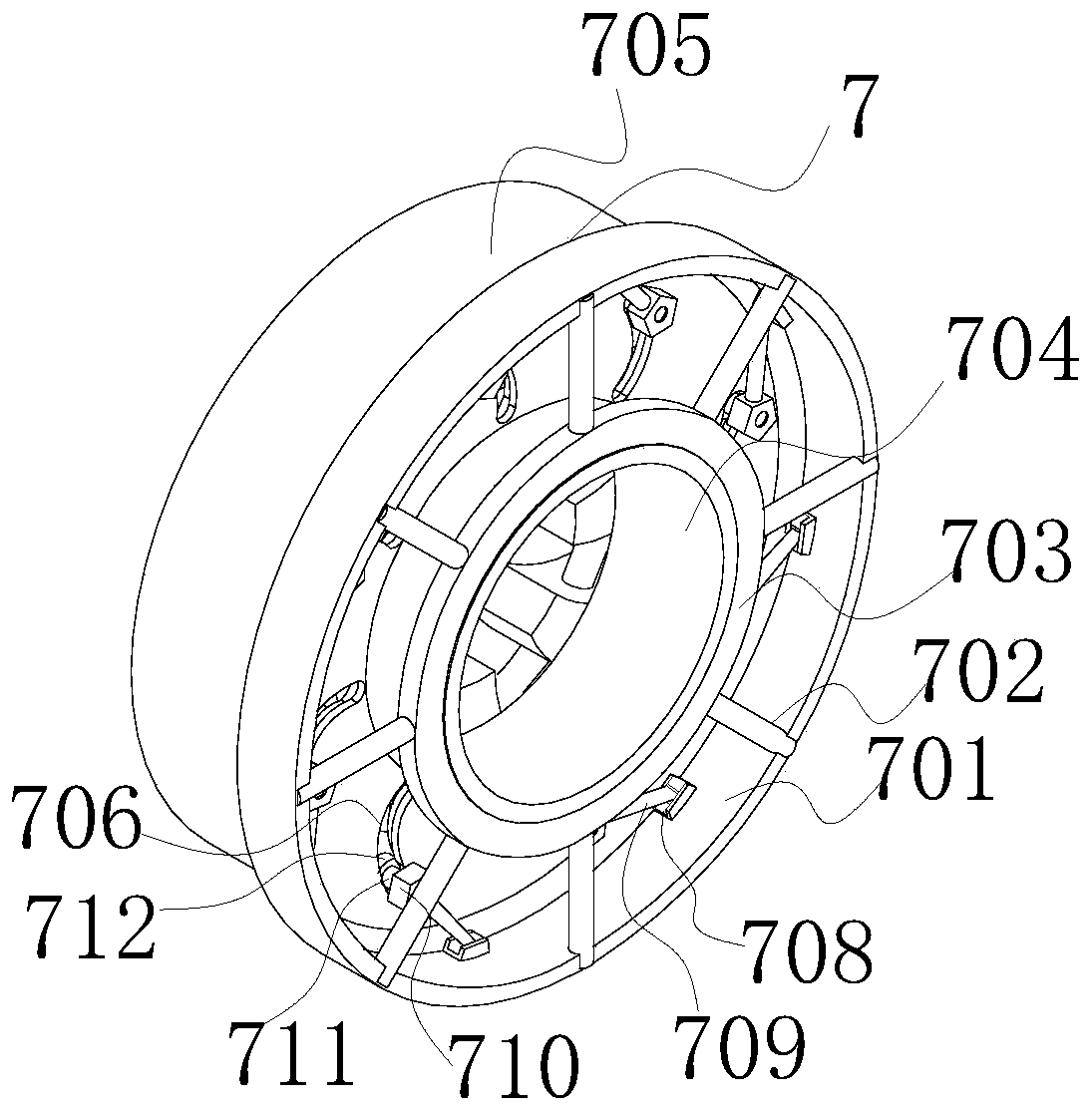

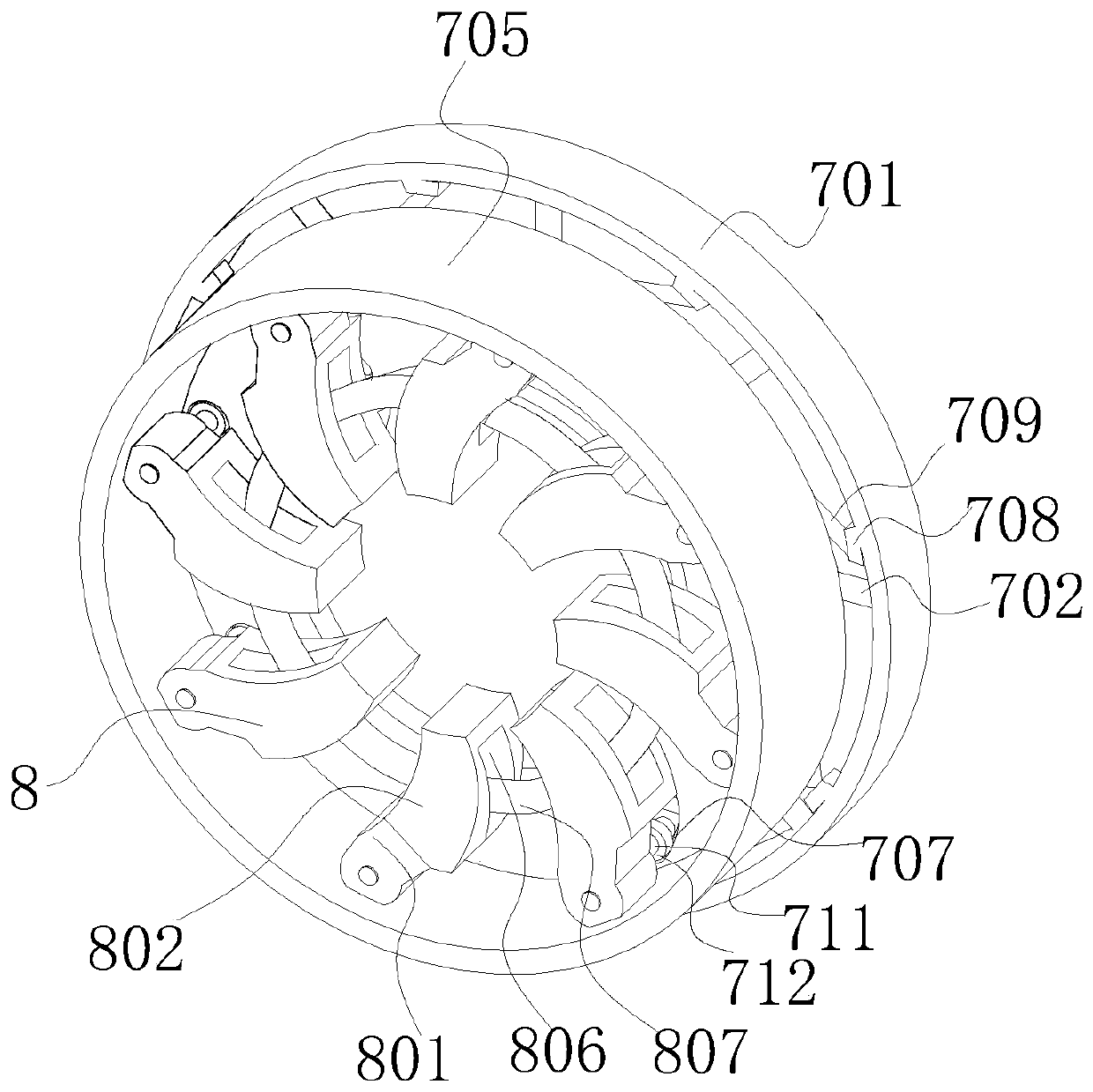

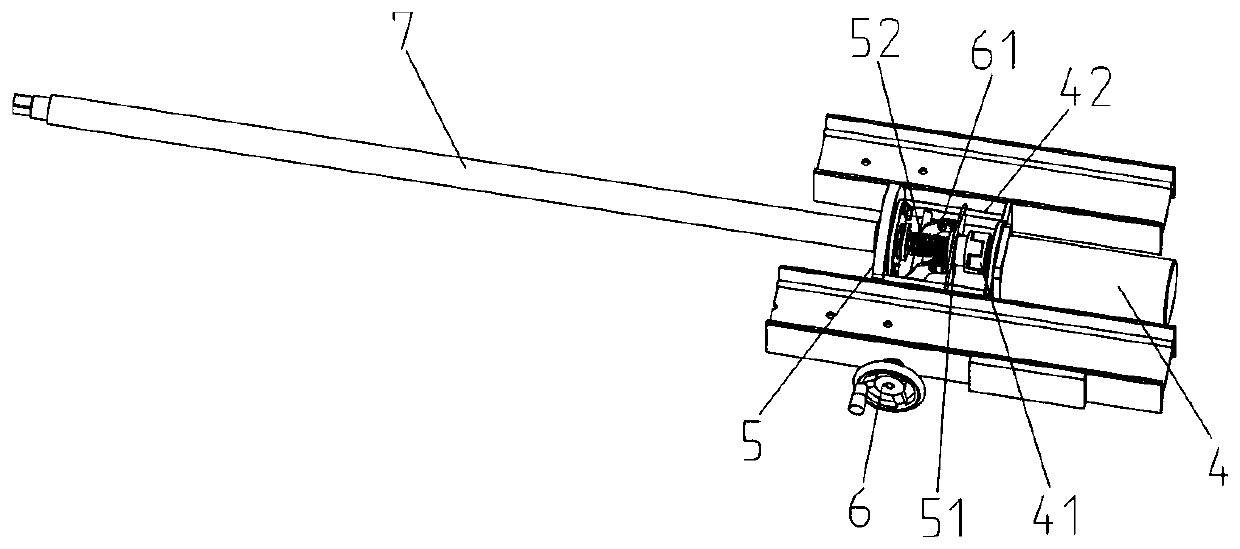

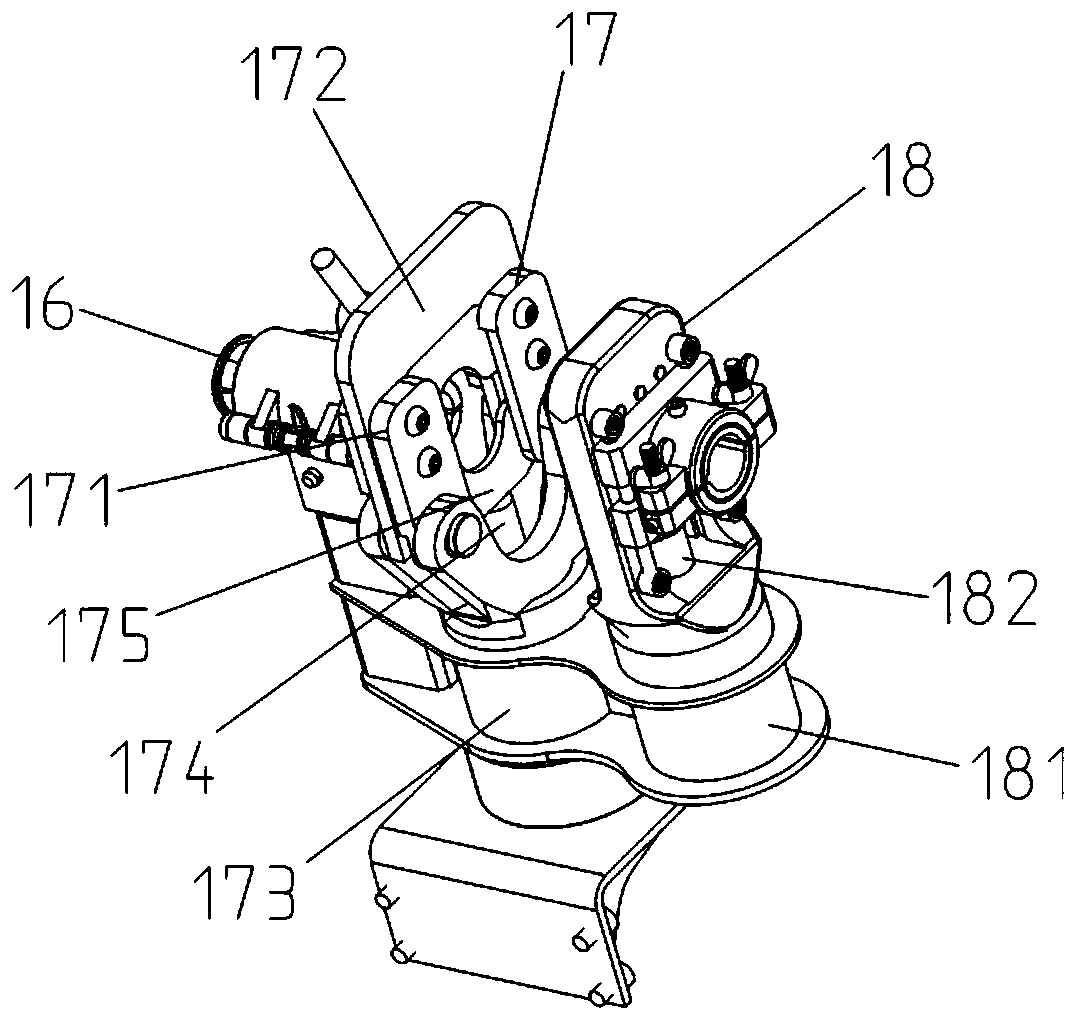

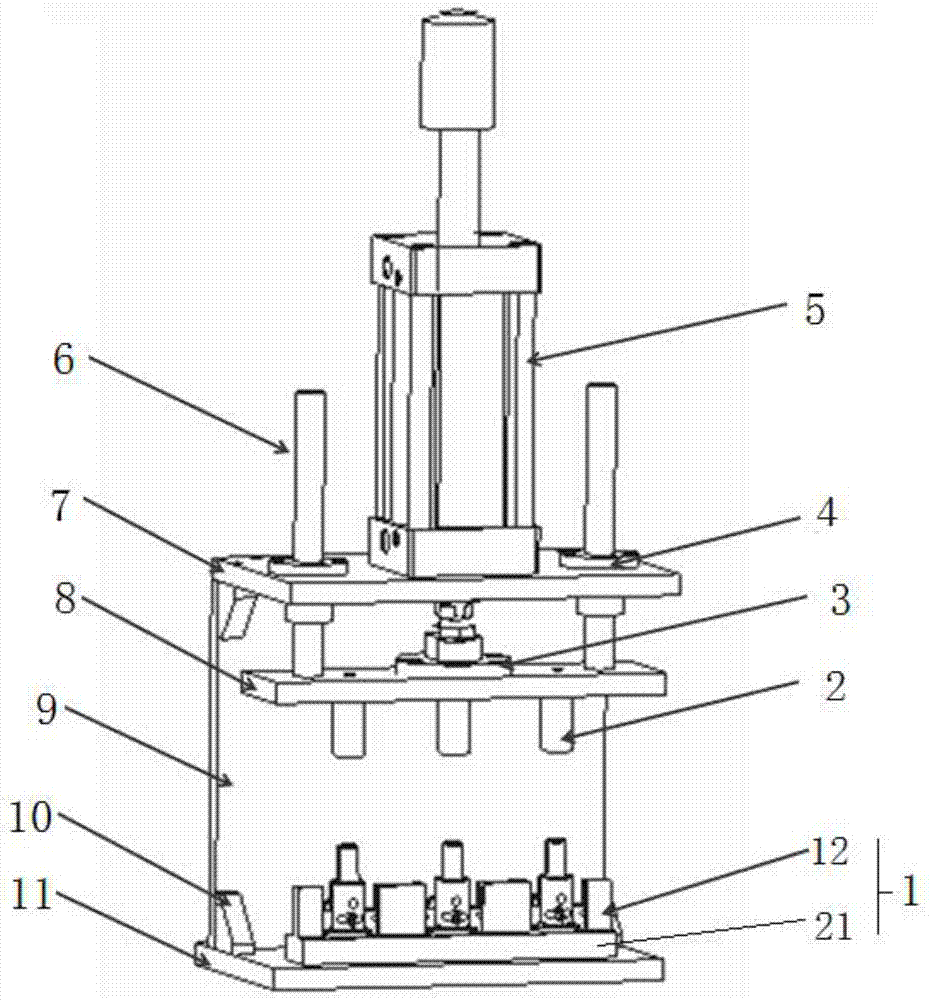

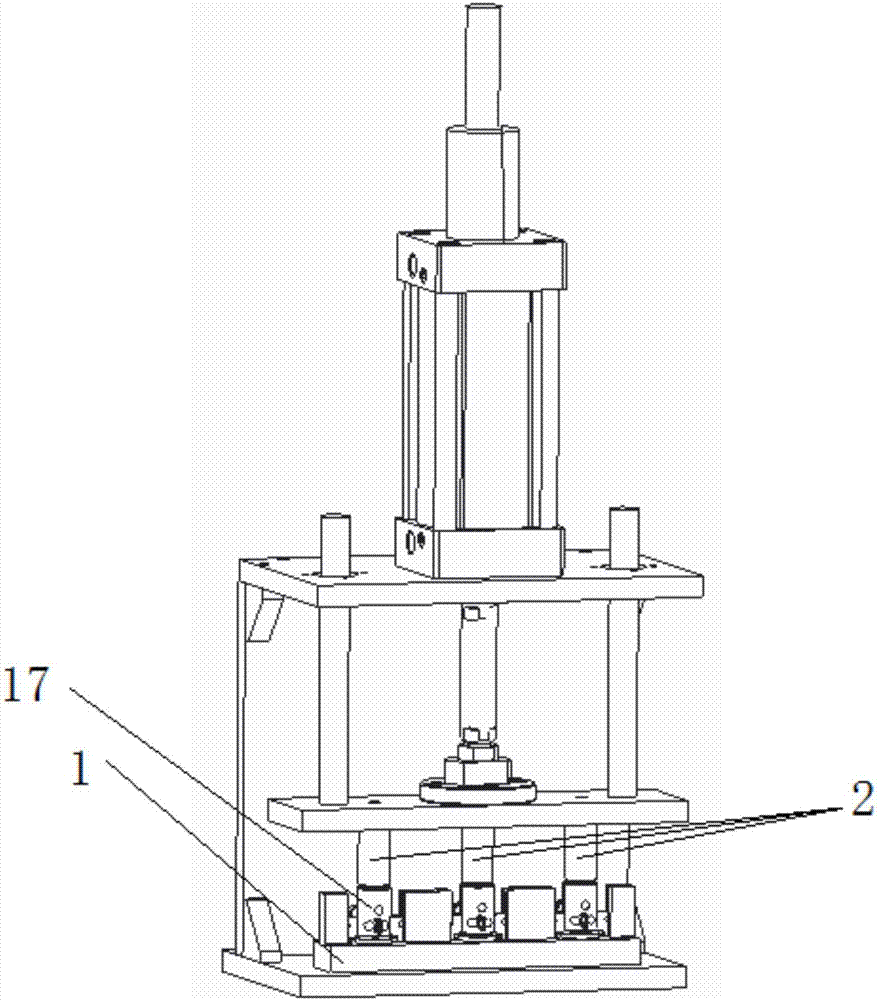

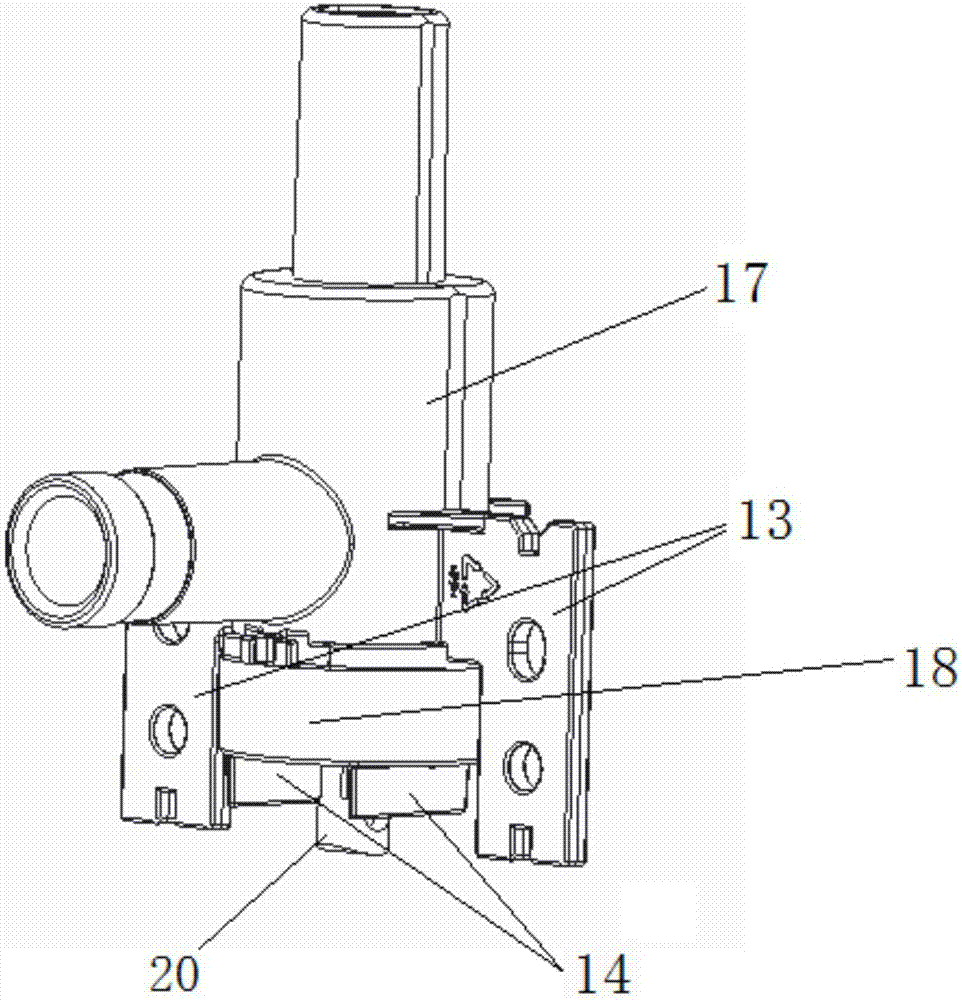

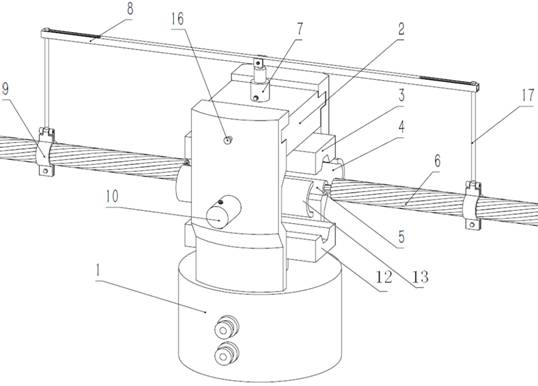

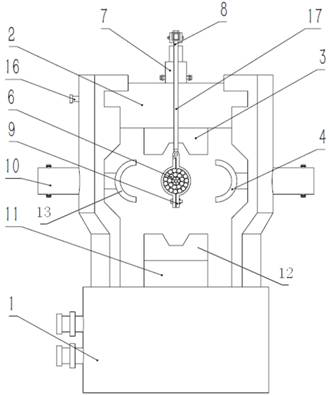

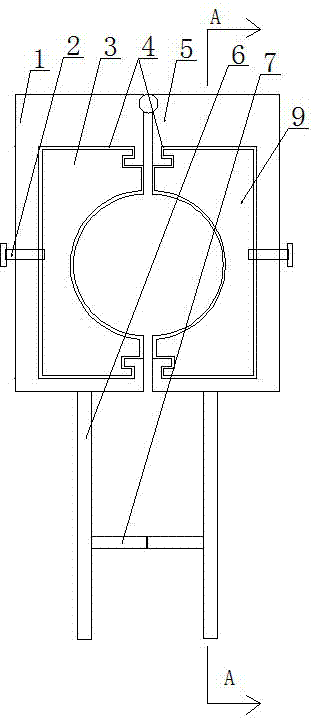

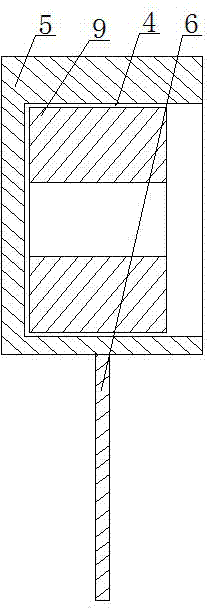

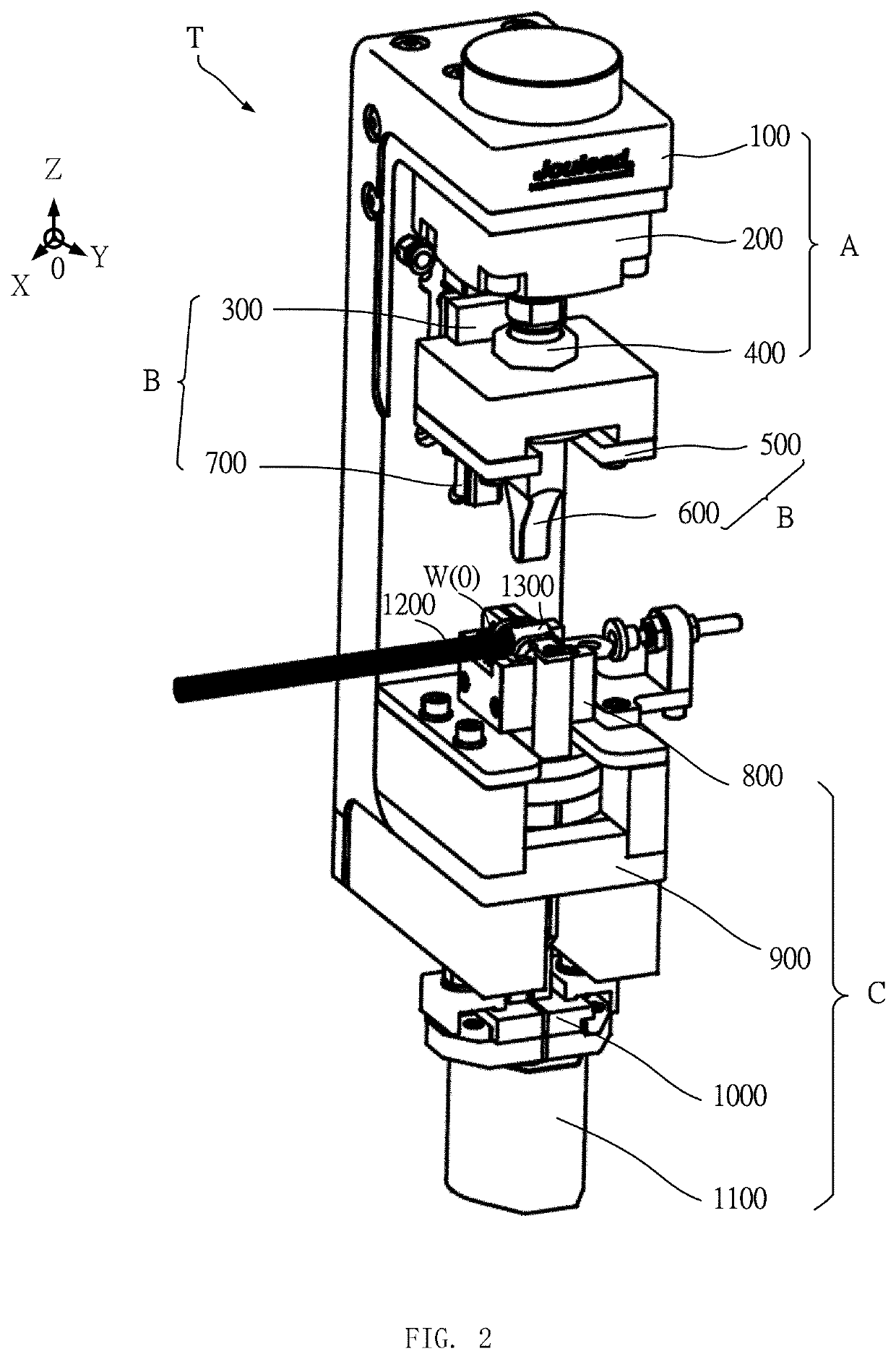

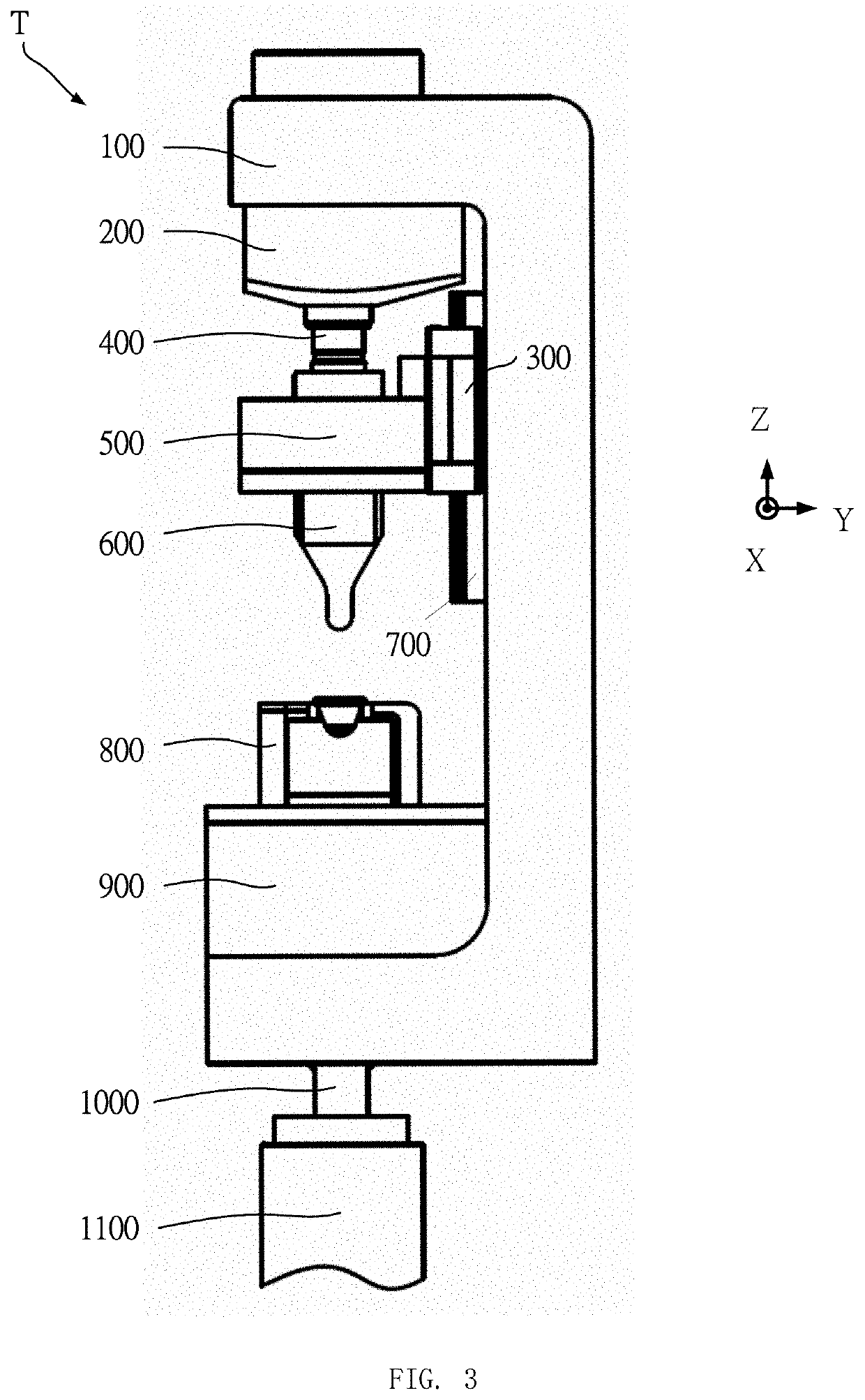

Full-automatic terminal crimping device convenient for cable positioning

ActiveCN110829138AImprove crimp qualityPrecise positioningLine/current collector detailsEngineeringStructural engineering

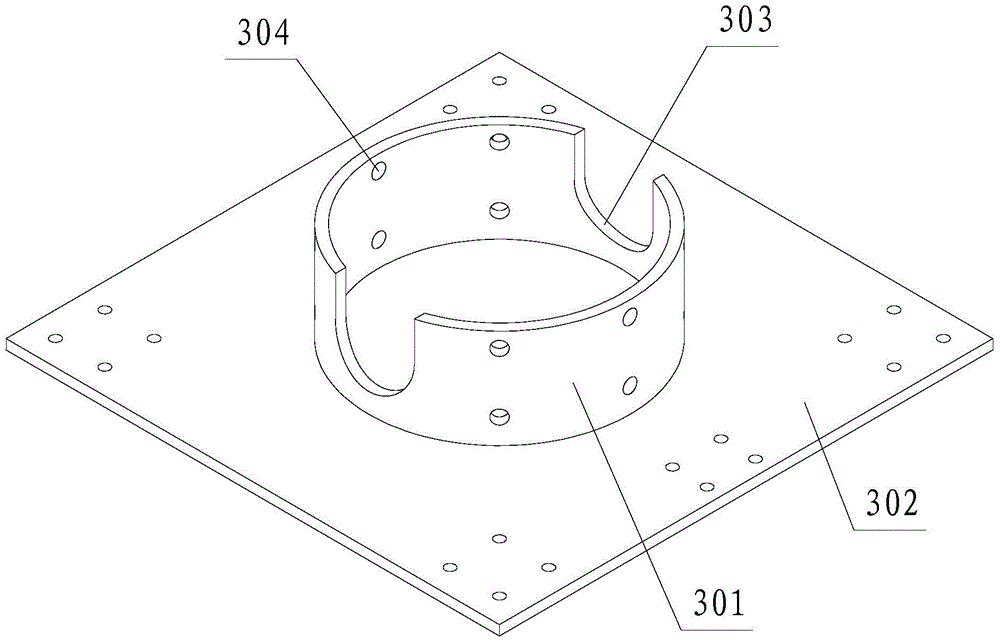

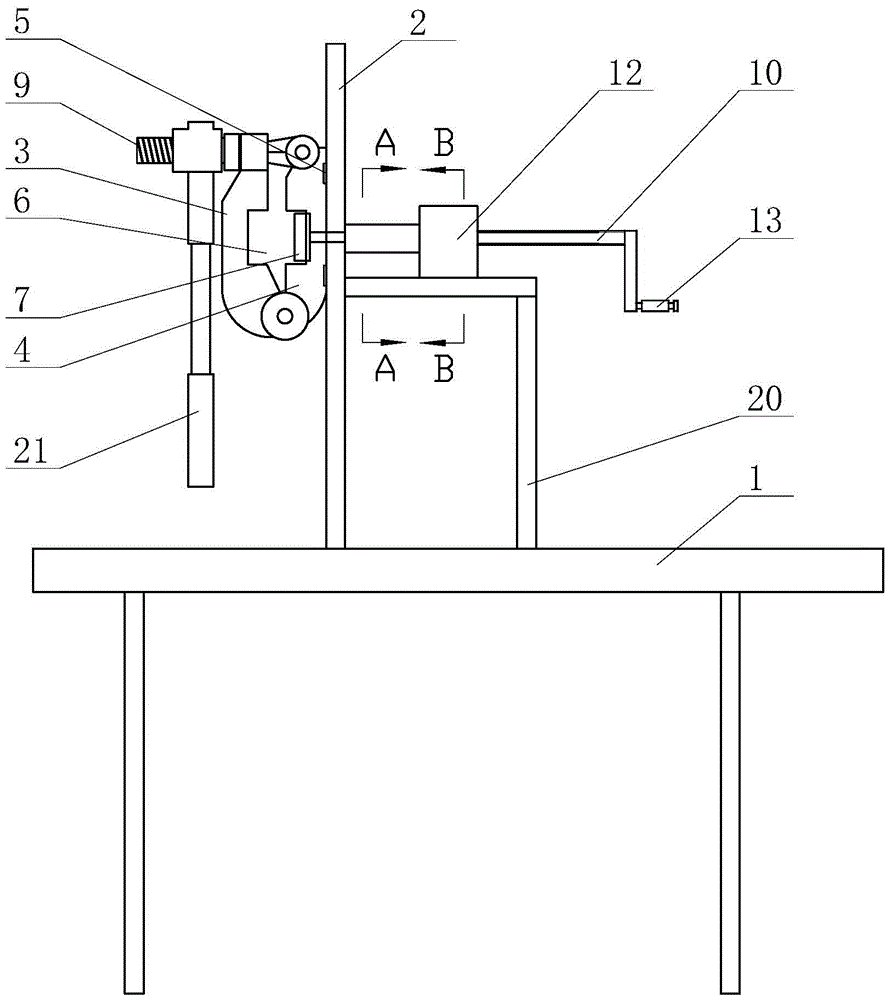

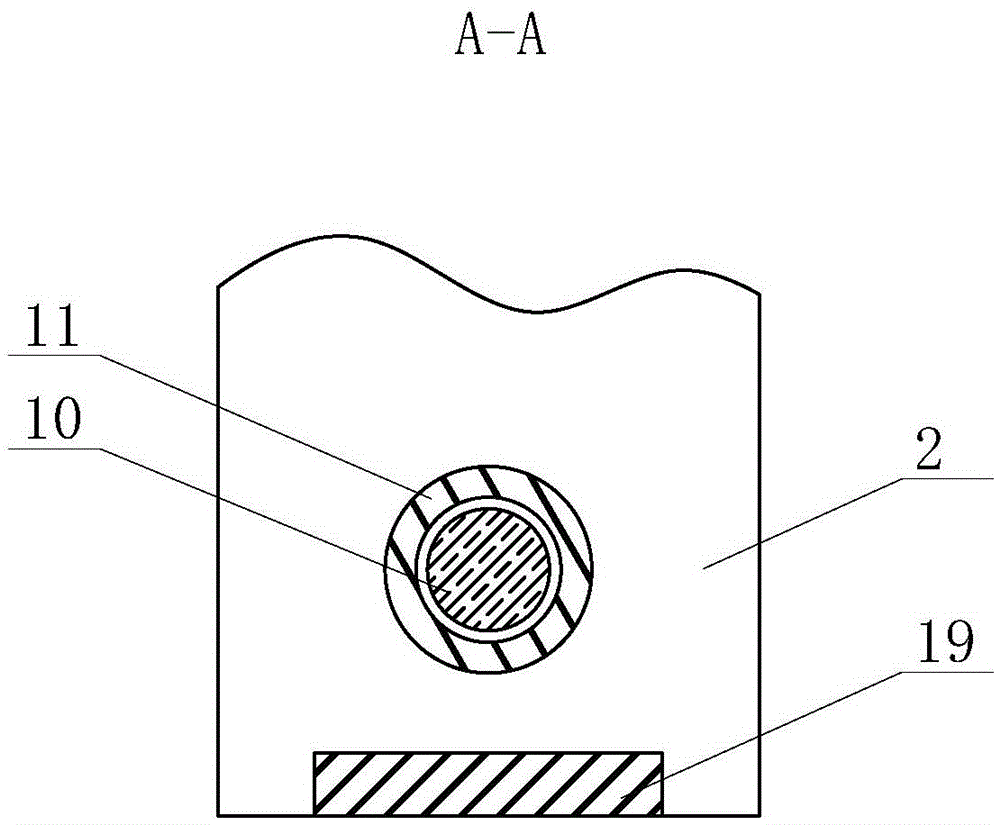

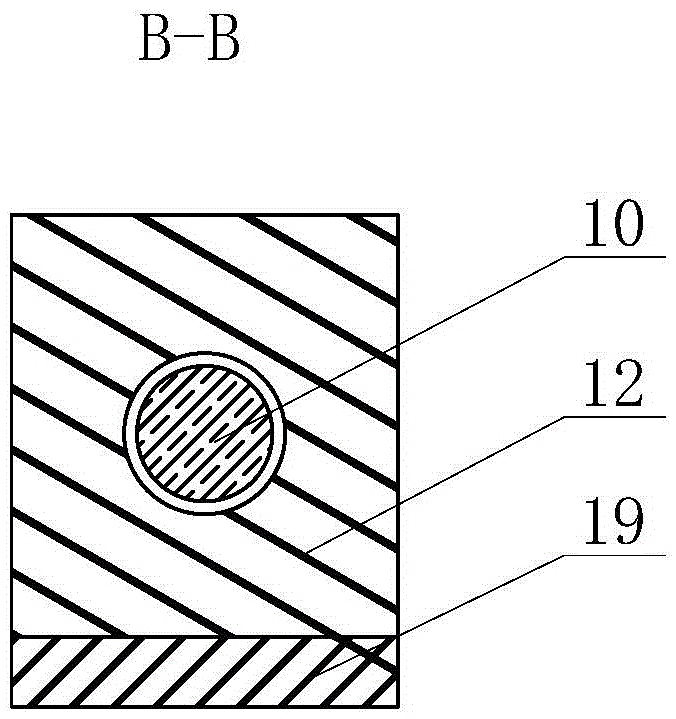

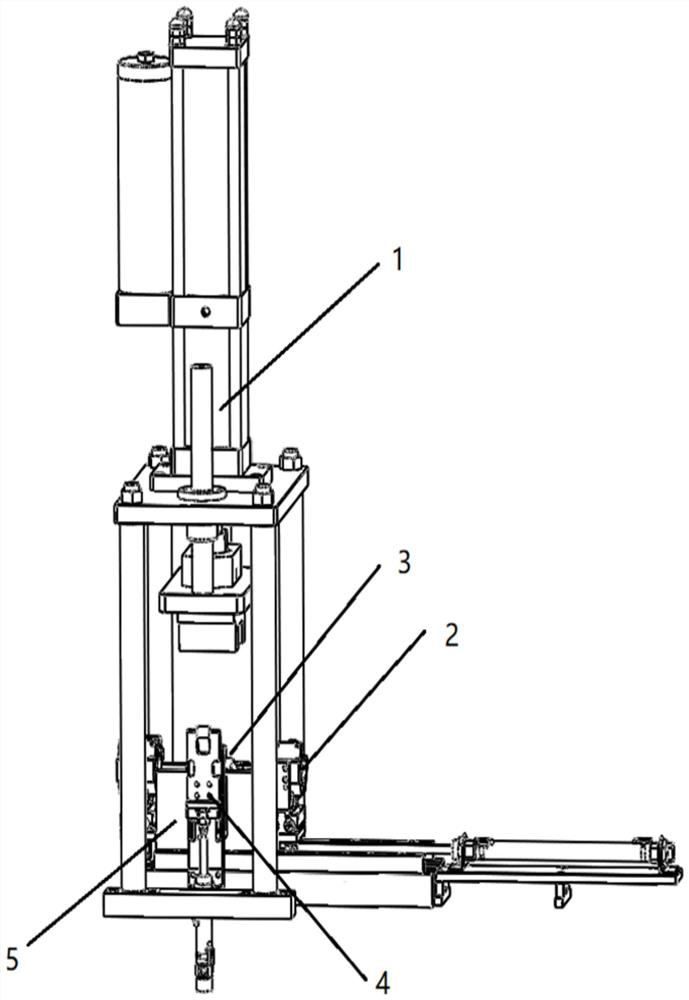

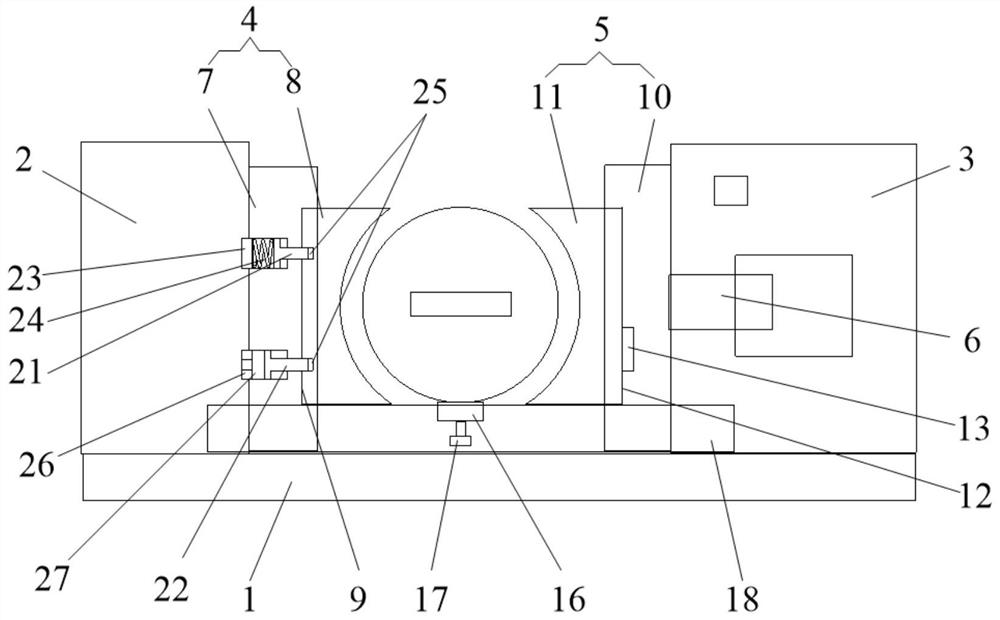

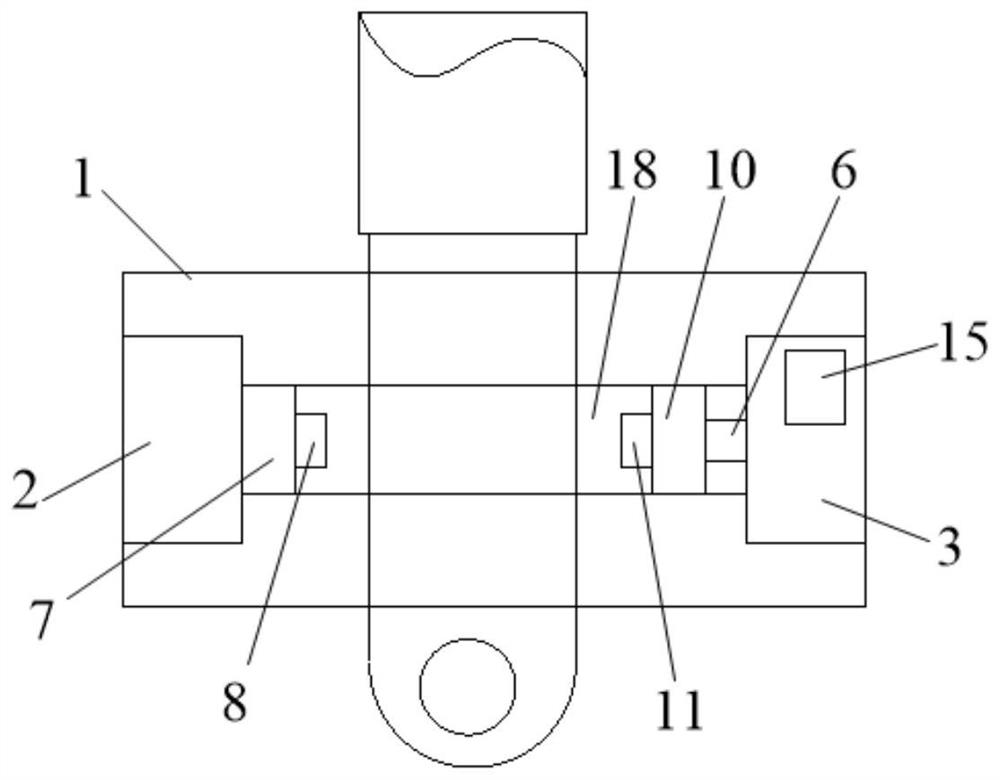

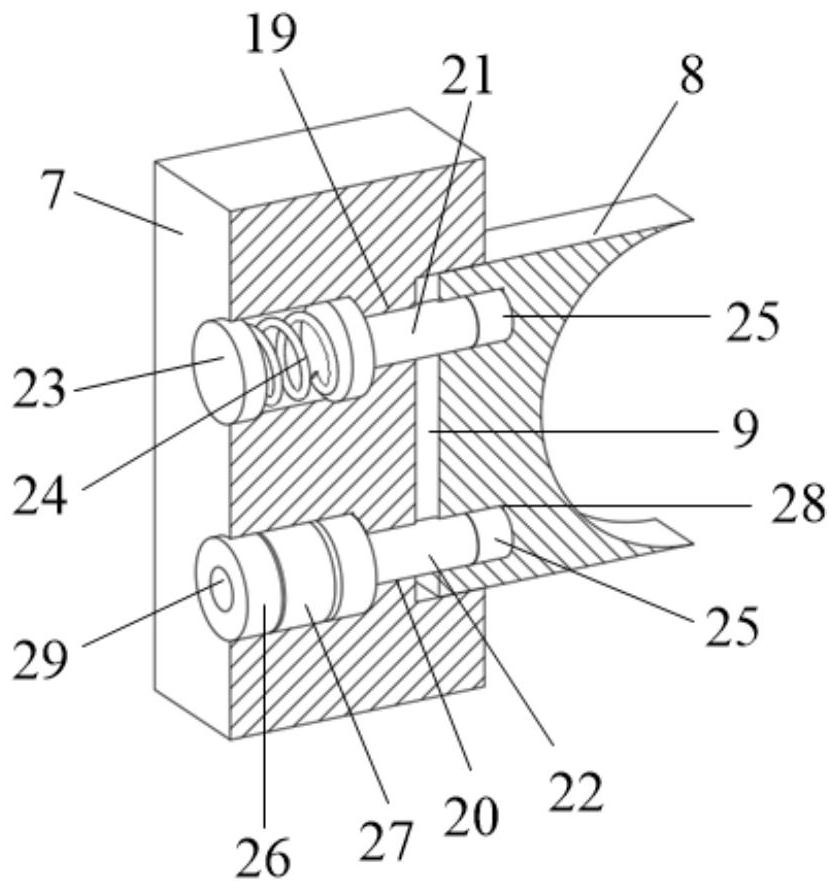

The invention discloses a full-automatic terminal crimping device convenient for cable positioning. The device comprises an upper pressing die crimping mechanism, a cable positioning mechanism, an ejection mechanism, a terminal pushing sliding block mechanism and a terminal clamping mechanism, wherein the terminal pushing sliding block mechanism is arranged under the upper pressing die pressing mechanism, a lower pressing die base is arranged on the terminal pushing sliding block mechanism, the terminal clamping mechanism and the ejection mechanism are arranged on a left side and a right sideof the lower pressing die base respectively, and a front end and a rear end of the lower pressing die base are respectively provided with a cable positioning mechanism. The device is advantaged in that multiple mechanisms cooperate with each other, coordinate and orderly complete a crimping function, crimping efficiency and the automation degree are improved, a clamping jaw assembly in the cable positioning mechanism is adopted to complete the effect of accurate cable positioning, the terminal clamping mechanism is adopted to improve the terminal crimping quality, the structure is simple, theuse is convenient, the service life is long, safety and reliability are high, and the crimping device is suitable for large, medium and small cable production enterprises and can be applied to crimping of various cable product terminals.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +1

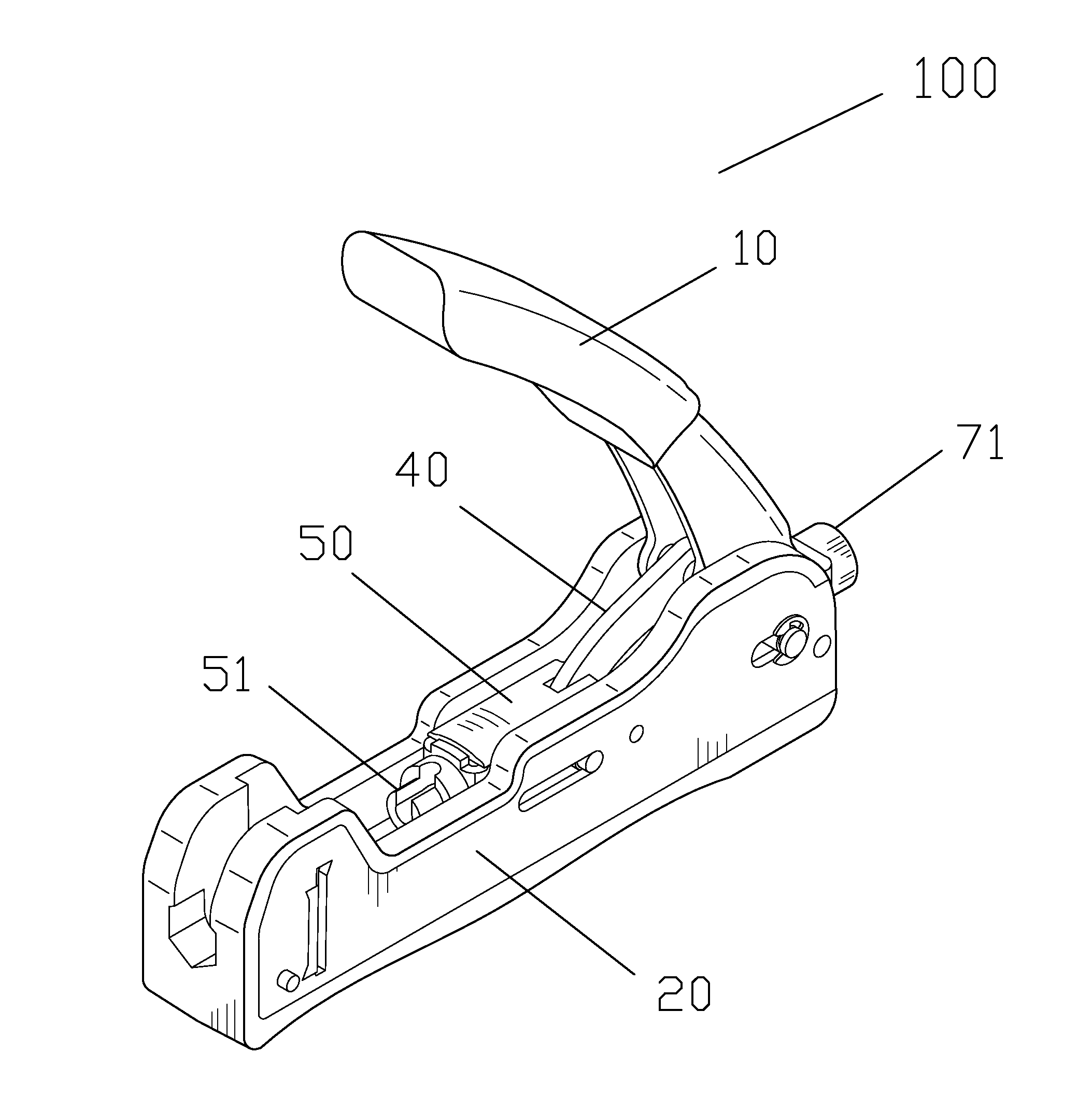

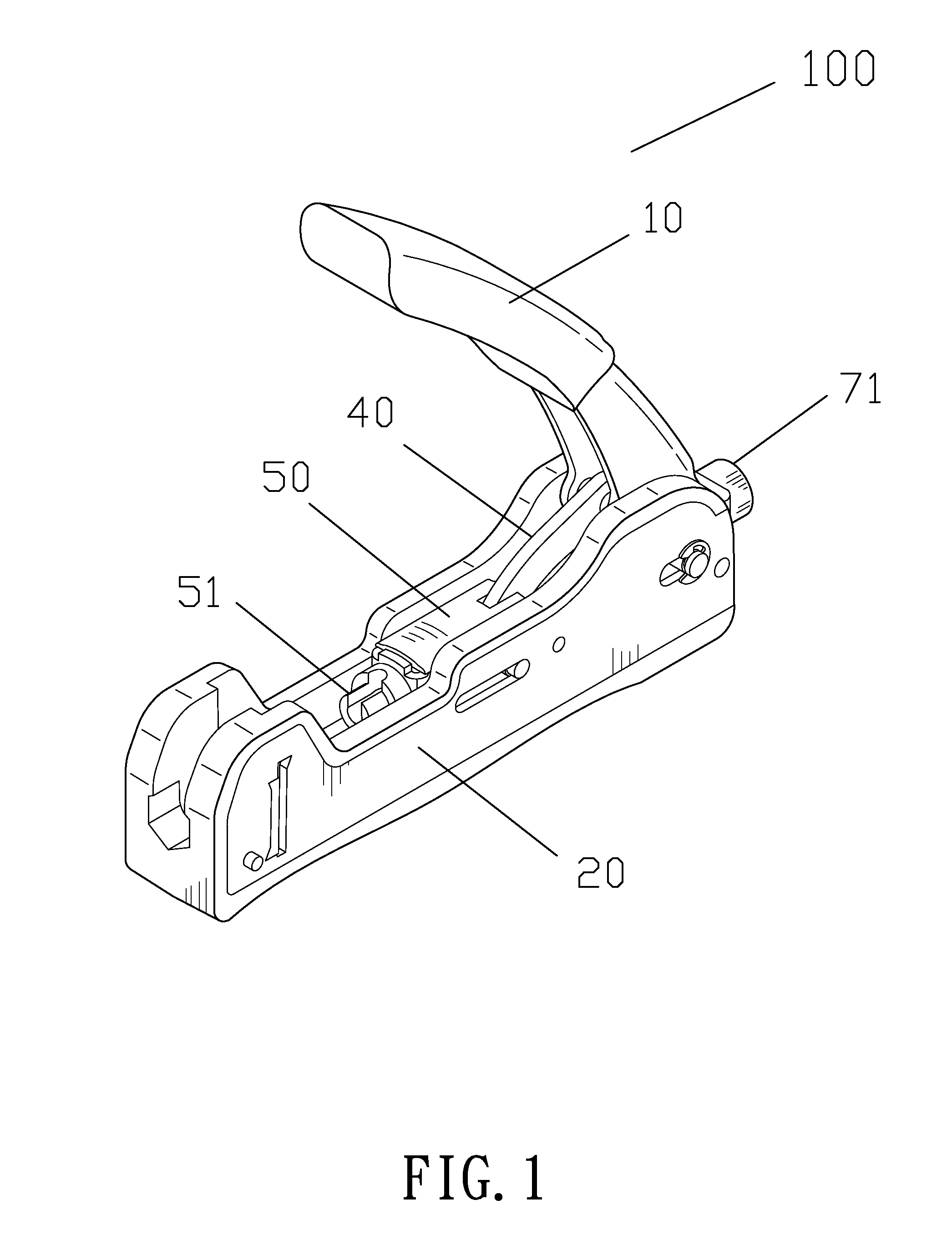

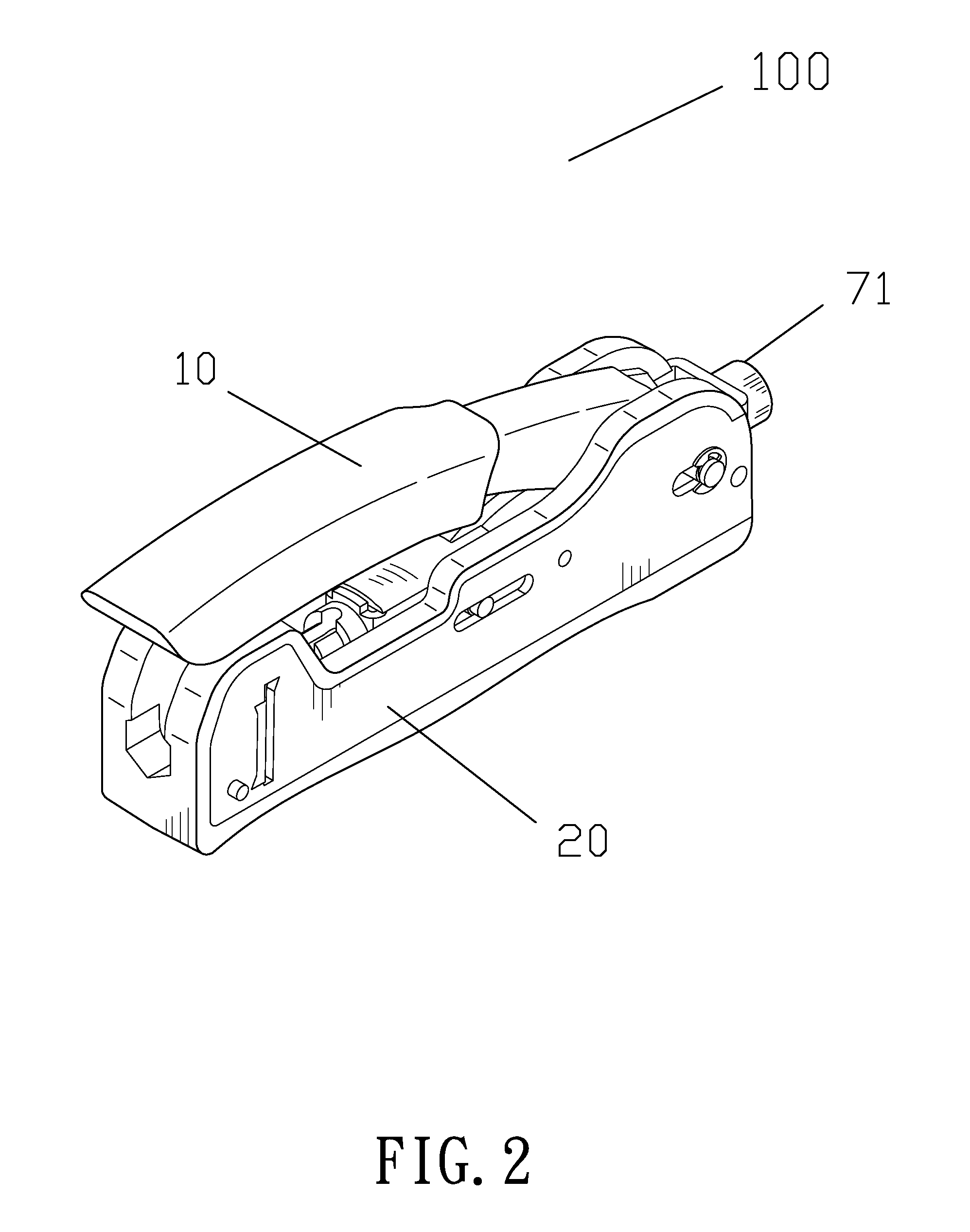

Crimping tool

ActiveUS20150372436A1Quality improvementImprove crimp qualityLine/current collector detailsElectrically conductive connectionsMechanical engineering

The invention is related to a crimping tool. The crimping tool includes a connection rod having one end pivotally connected to the first handle and the other end of the connection rod pivotally connected to a crimp section. A first screw rod is disposed at the second handle of the crimping tool. The first screw rod drives the connector which leads the first handle to displace. The movement of the first handle leads a connection rod to displace. As a result, the position of a crimp section on the first handle can be adjusted.

Owner:JETOOL

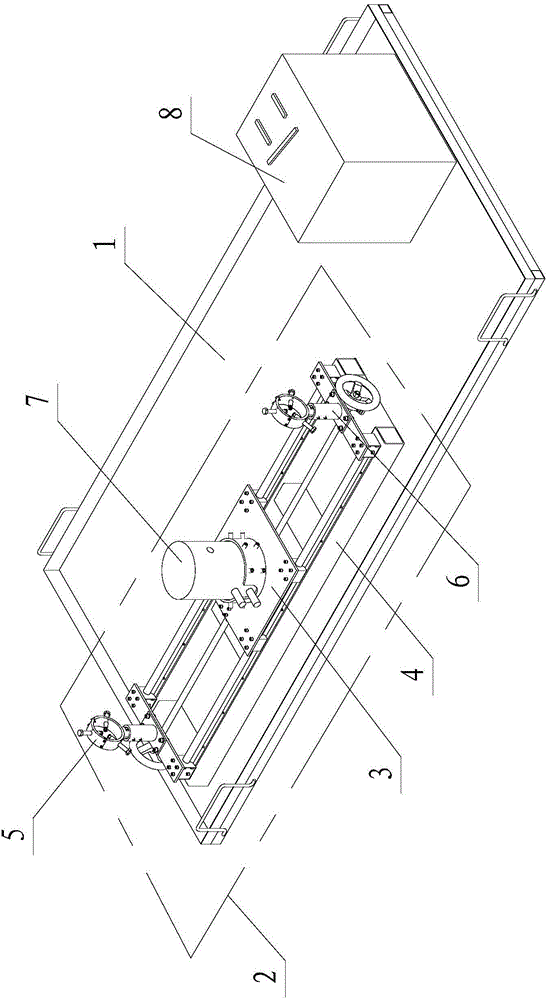

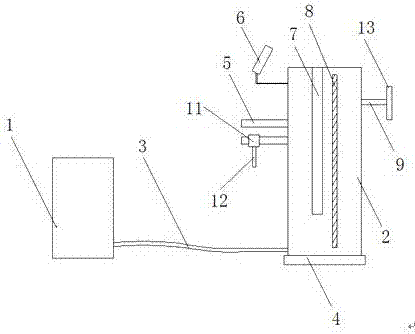

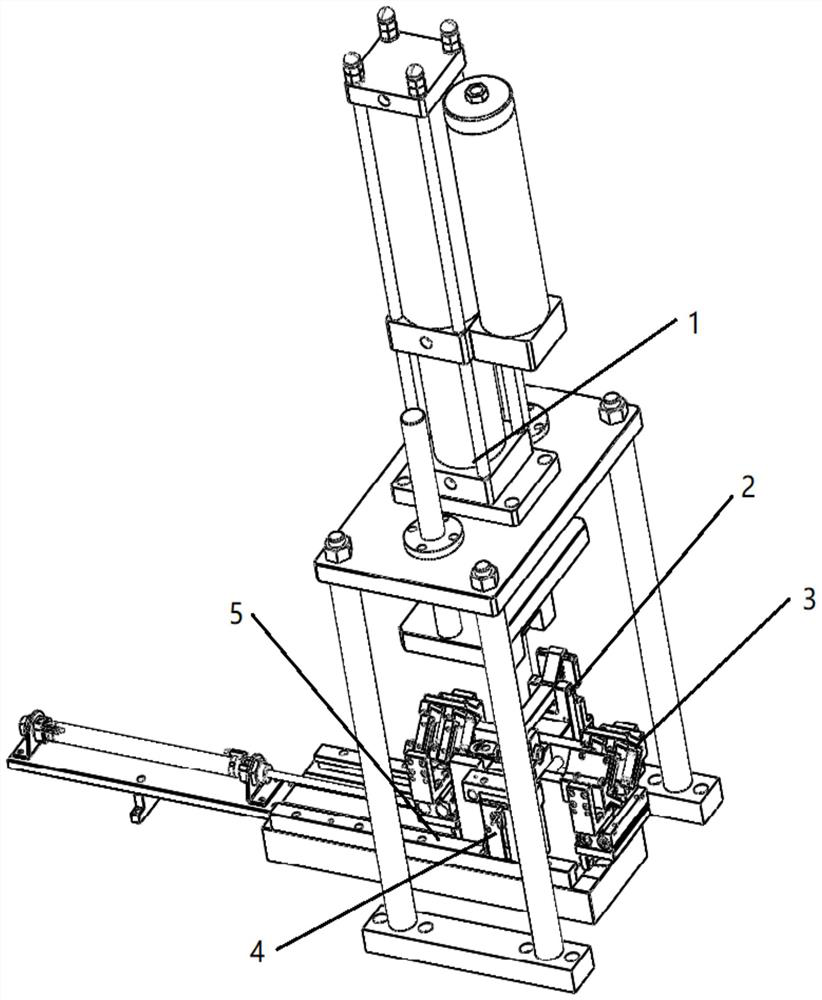

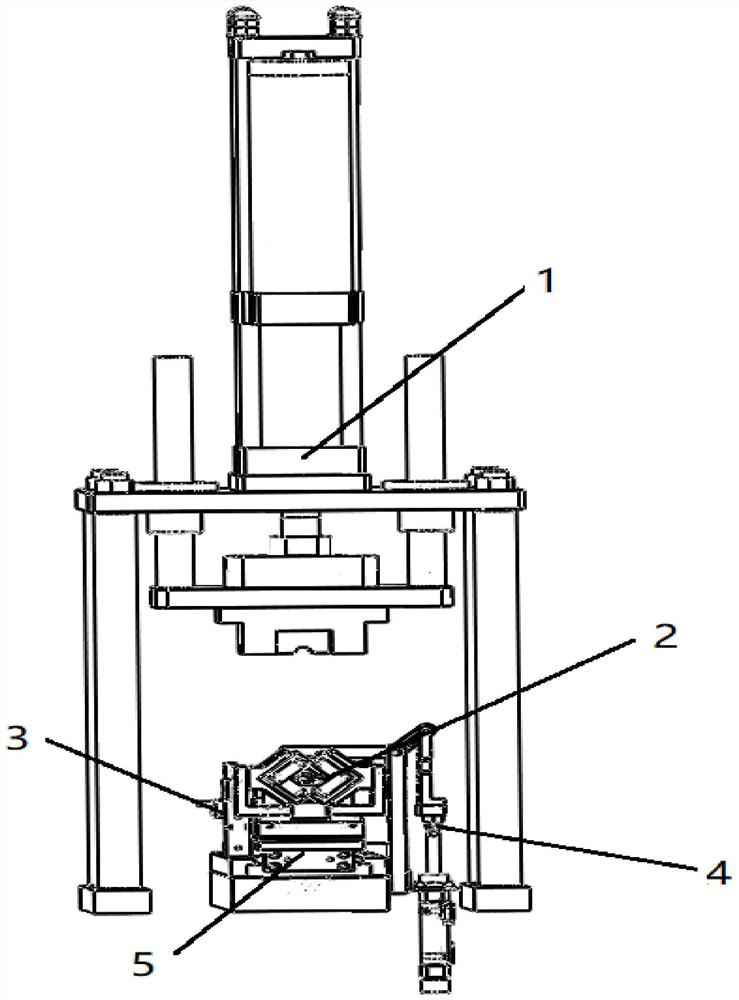

Crimping pipe bending automatic controller

InactiveCN106159628AImprove crimp qualityPrevent slidingLine/current collector detailsBall screwEngineering

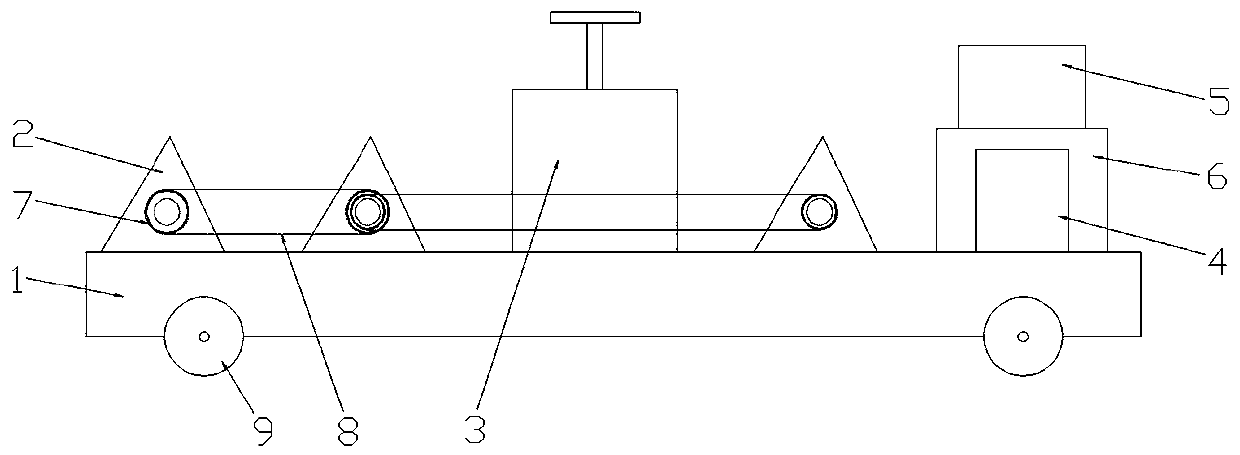

The invention relates to wire crimping equipment in the construction of power transmission and transformation lines, in particular to an automatic controller for crimping pipe bending, including a base and an anti-bending controller installed on the base, and the anti-bending controller includes a crimping machine support Frame, crimping machine mobile platform, wire fixed chuck and chuck support, crimping machine mobile platform is installed on the base, including frame body and ball screw pair, crimping machine bracket is connected with ball screw pair to realize pressing The reciprocating movement of the connecting machine; both ends of the frame body are equipped with wire fixing clips, and the wire fixing clips are respectively installed on the frame body through height-adjustable clip supports, and the wire fixing clips at both ends are maintained by the clip supports. The center is in line with the center of the mold on the crimping machine, and each wire fixing chuck clamps the wire to be crimped, and the crimping of the wire is realized by the reciprocating crimping machine. The crimping machine of the present invention can move back and forth, and the bending and twisting of the crimping tube will not occur when conducting wire crimping, which greatly improves the crimping quality.

Owner:LIAONING POWER TRANSMISSION & TRANSFORMATION PROJECT +4

Portable cable crimping platform

InactiveCN105490126AEasy to useEasy to carryLine/current collector detailsPiston cylinderEngineering

The invention provides a portable cable crimping platform. A vertical plate is mounted on a bracket; elephant-shaped press pliers and a power mechanism are mounted at two sides of the vertical plate; a press block is mounted in a groove formed in a second side plate in the elephant-shaped press pliers; the power mechanism comprises a screw rod and a piston cylinder; a piston rod is arranged at the right end of the piston cylinder; the piston cylinder and the piston rod are both ring-shaped; the middle part of the screw rod is connected with a fixed base through a threaded structure; the left end of the screw rod extends into the piston cylinder and the piston rod; the press block is of a two-layer structure comprising a first press block and a second press block; the first press block is provided with a through groove in which the second press block is arranged; a clamping structure is arranged between the through groove and the second press block; the right end of the second press block extends out of the first press block to get contact with the left end of the screw rod; the screw rod can drive the second press block to move horizontally alone; the right end of the first press block is in contact with the left end of the piston rod; the piston rod can drive the first press block and the second press block to move as a whole. The portable cable crimping platform is convenient to operate, is portable, is capable of cable crimping in many ways, and has relatively good crimping efficiency and crimping quality.

Owner:国网山东郓城县供电公司 +1

Flat cable crimping die

ActiveCN103354317AImprove crimp qualityReduce workloadLine/current collector detailsEngineeringElectrical and Electronics engineering

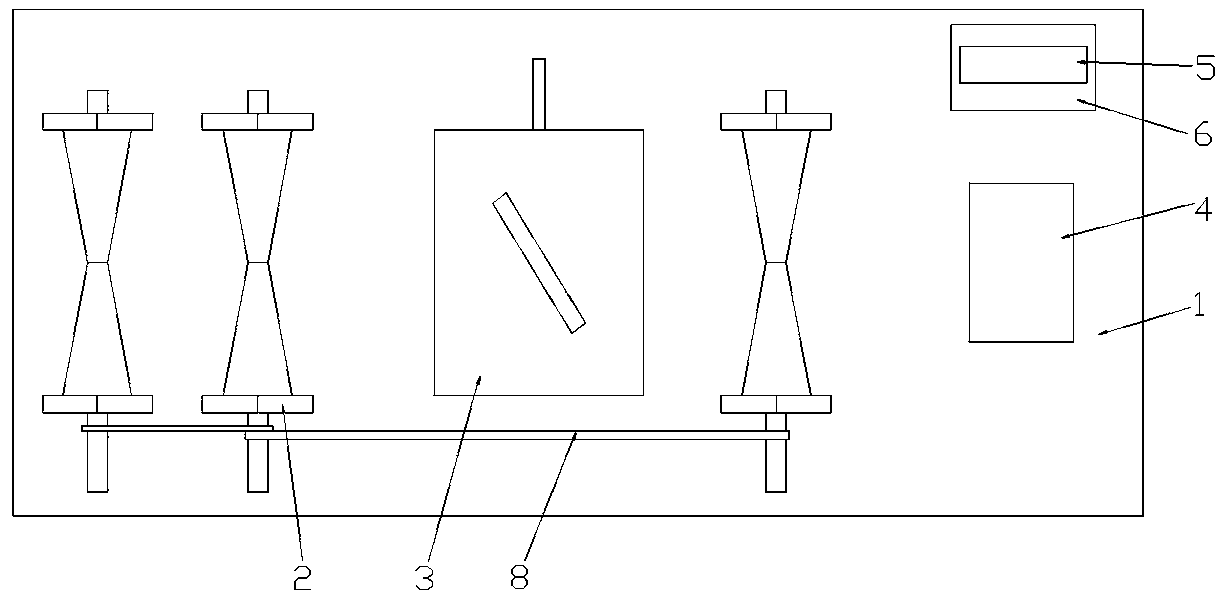

The invention discloses a flat cable crimping die, which comprises a cable feeding device and a crimping device, wherein the cable feeding device and the crimping device are arranged successively, the cable feeding device is used for feeding flat cables, and the crimping device is used for crimping the flat cables. The cable feeding device comprises a clamping mechanism for clamping the flat cables and a moving mechanism enabling horizontal movement of the clamping mechanism; and the crimping device comprises a slide-block pressing mechanism for pressing the flat cables, a first feeding mechanism for feeding the flat cables in the cable feeding device one by one, and a second feeding mechanism for pushing terminals one by one. According to the invention, the cable feeding device and the crimping device are arranged to automatically crimp the flat cables, thereby reducing workload, improving working efficiency, and greatly improving crimping quality of the flat cables.

Owner:XIAMEN HIPRECISE TECH CO LTD

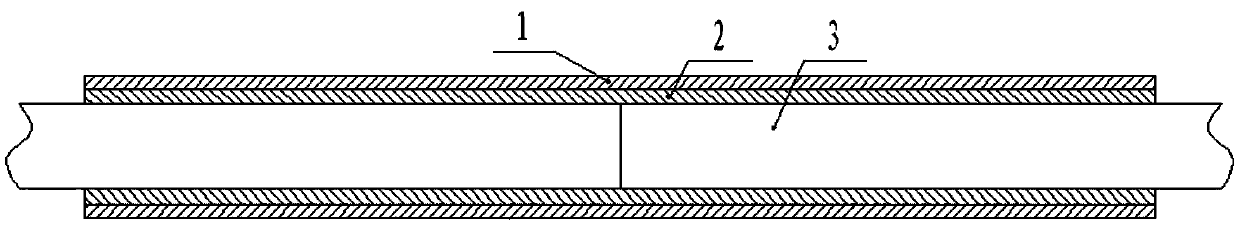

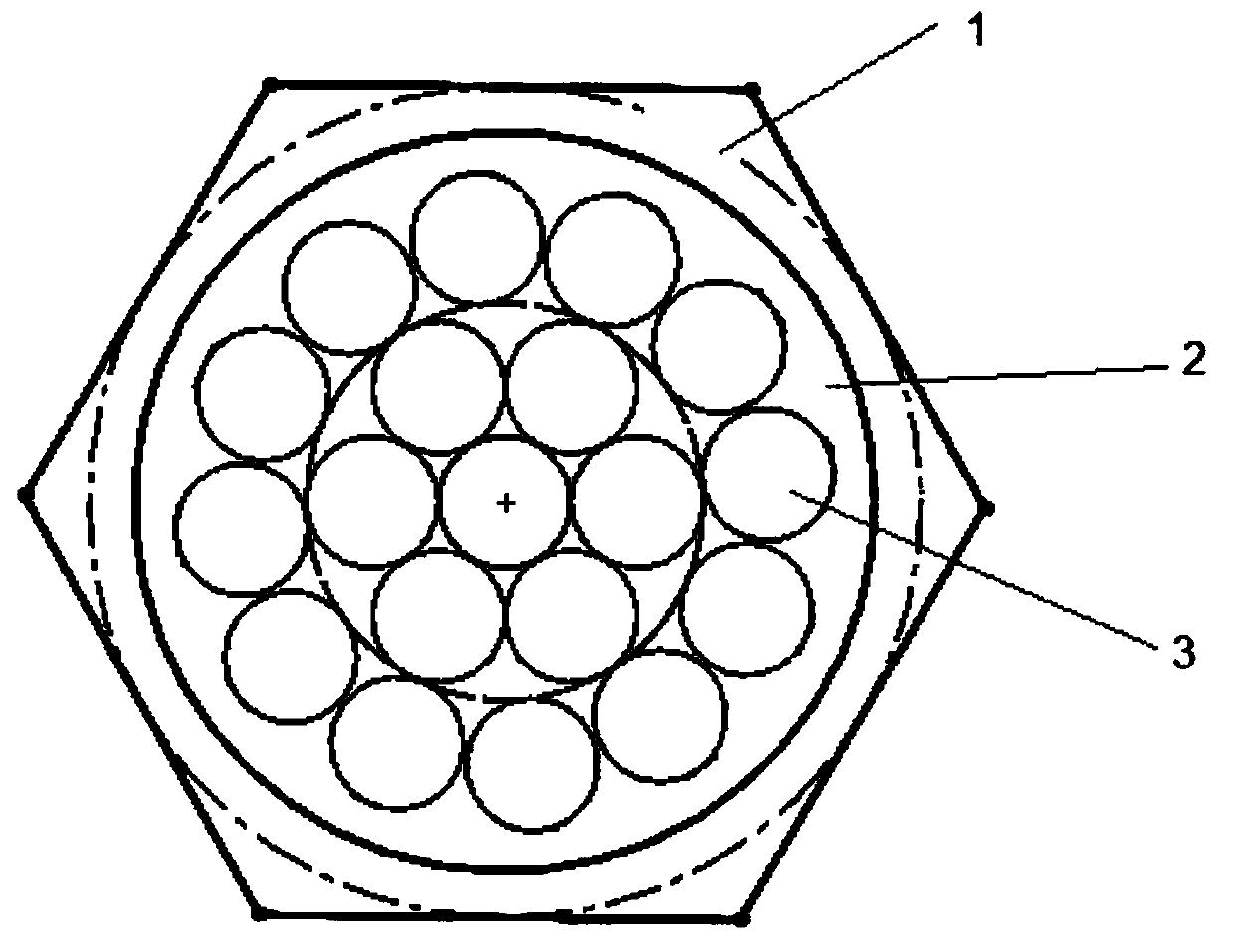

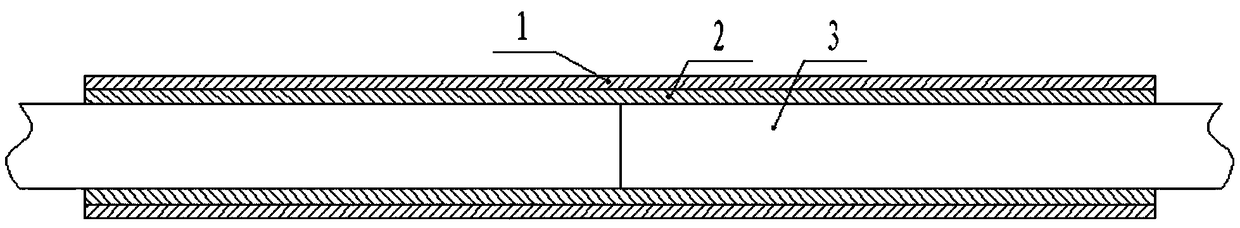

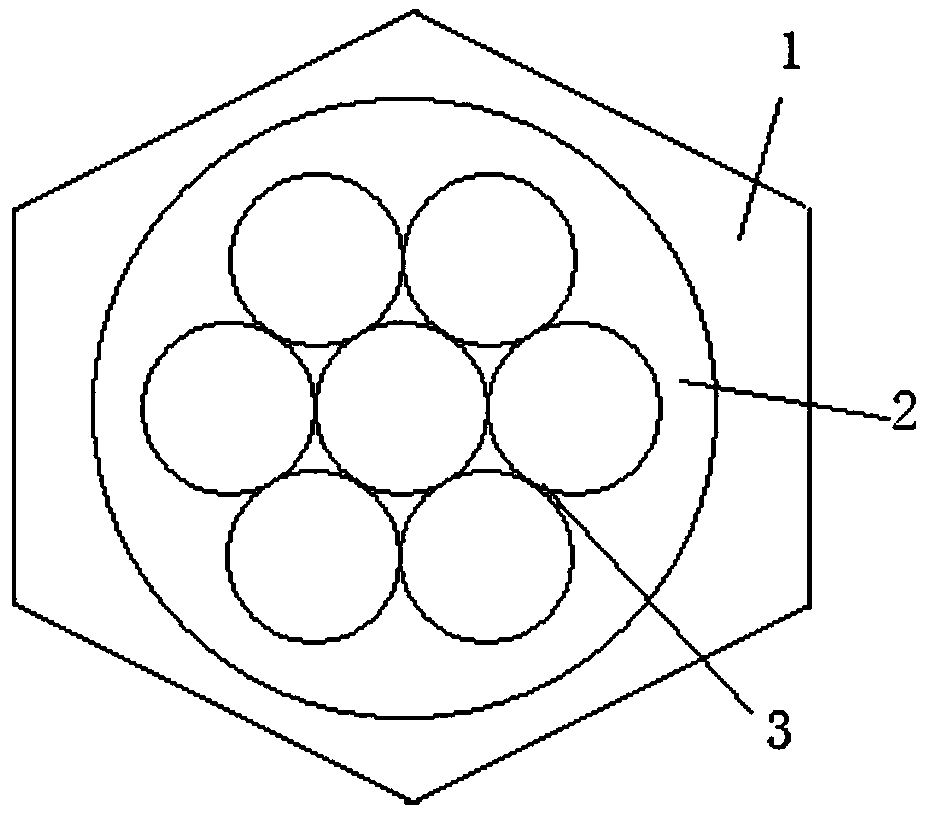

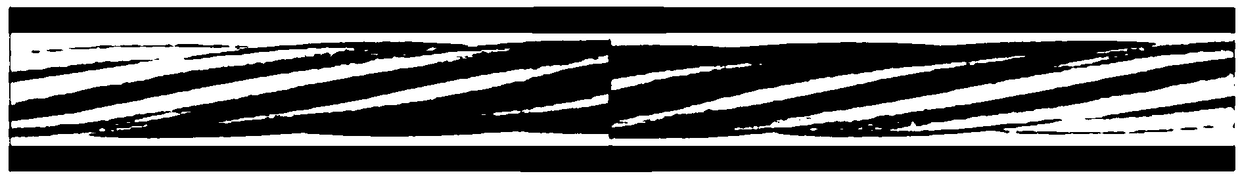

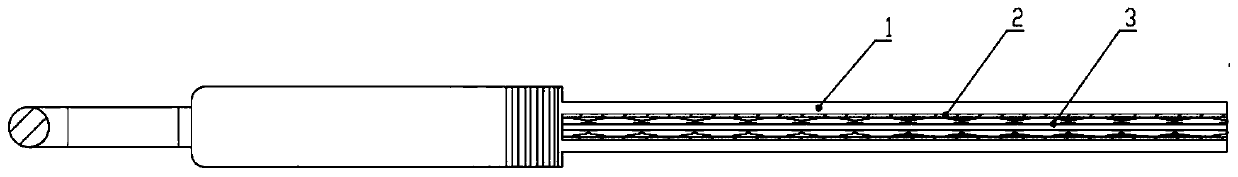

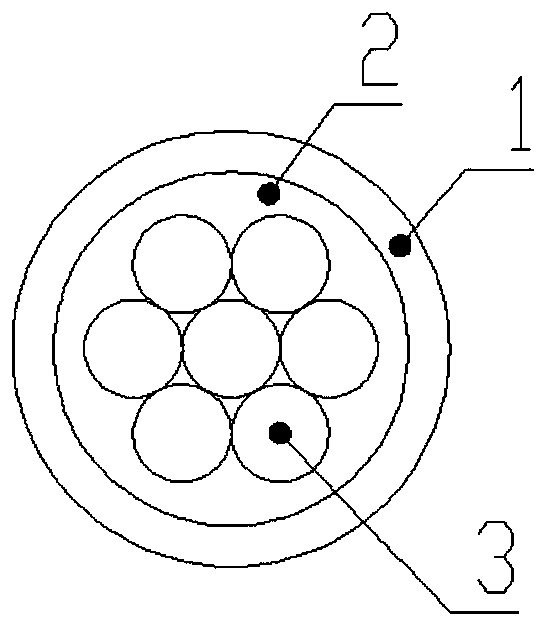

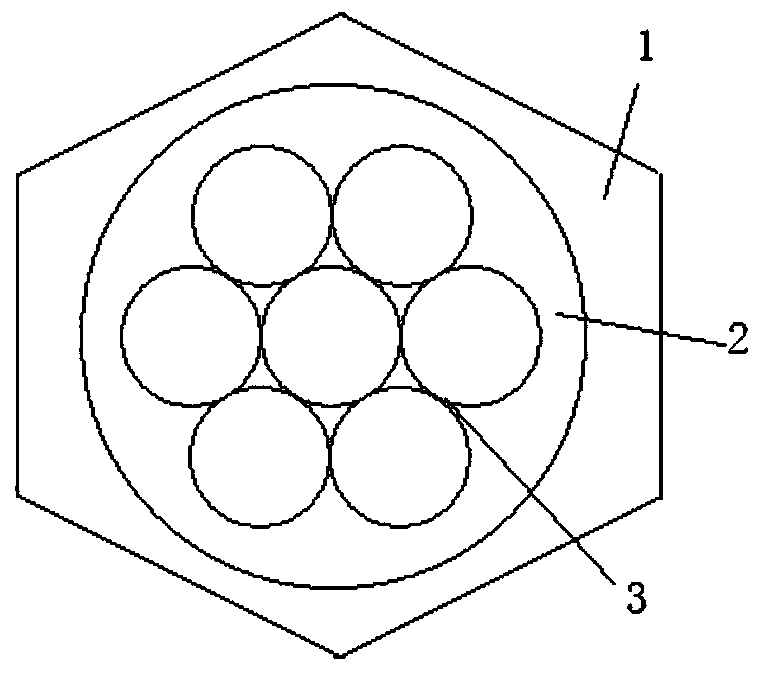

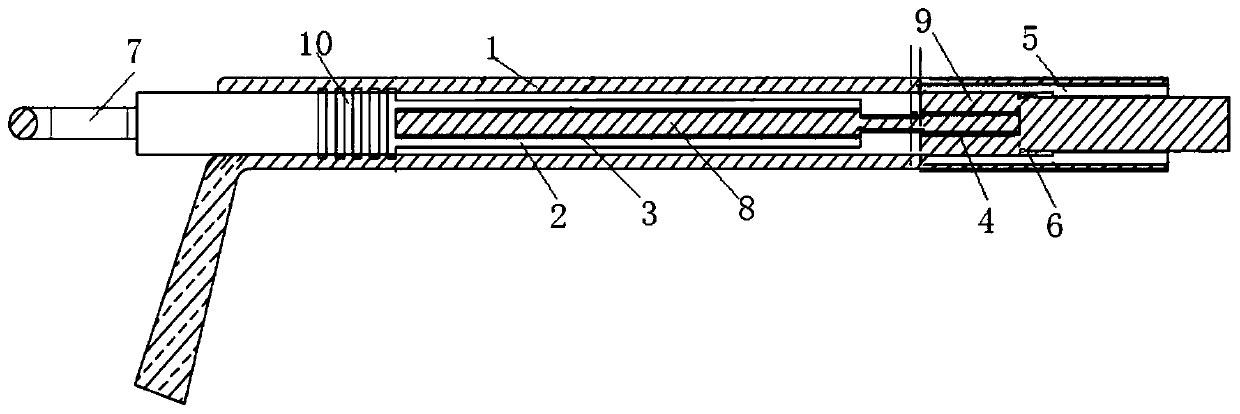

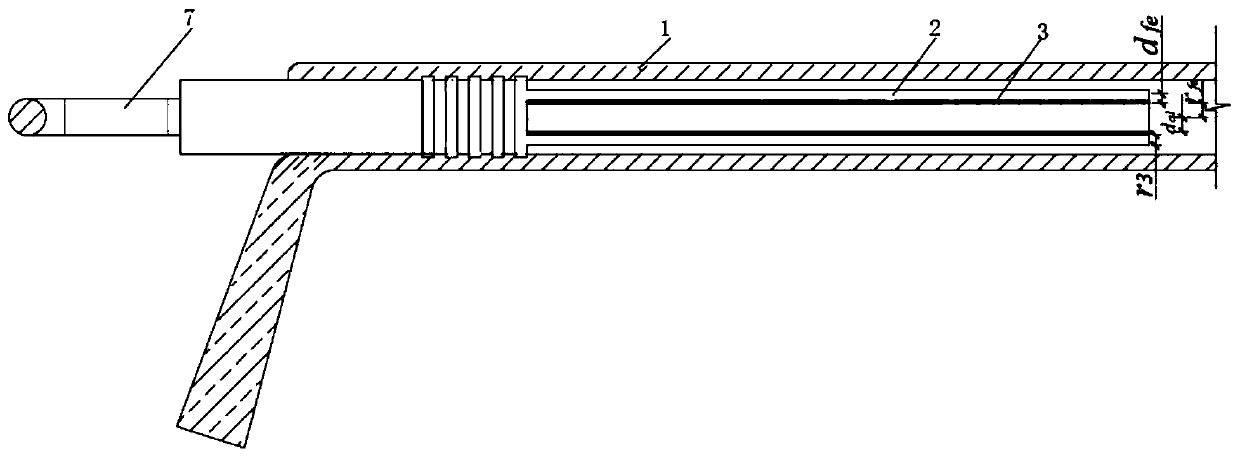

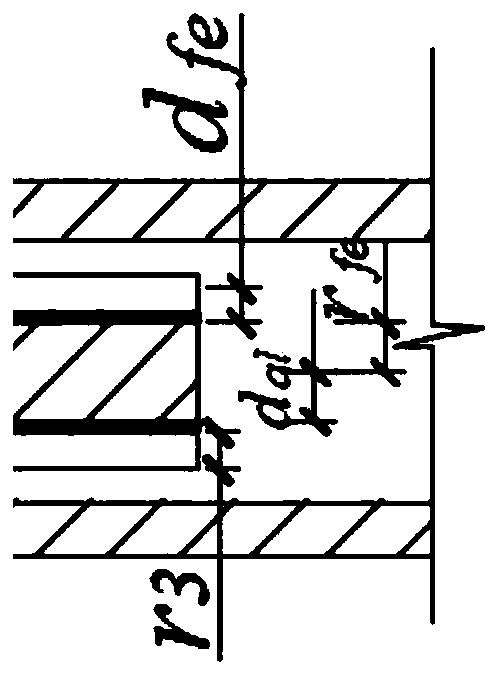

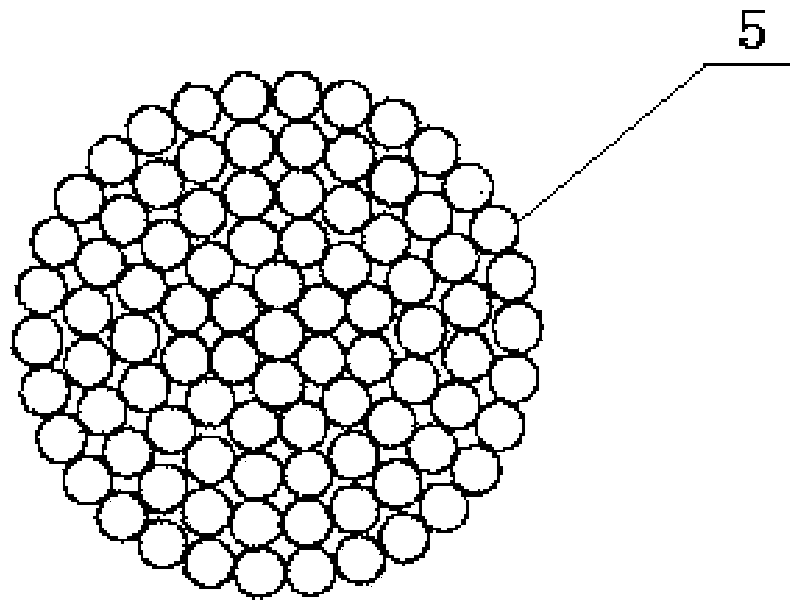

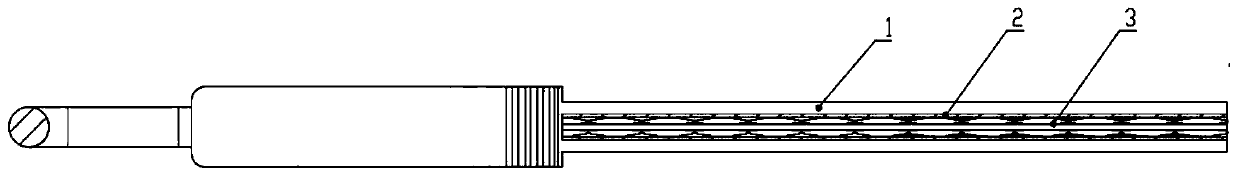

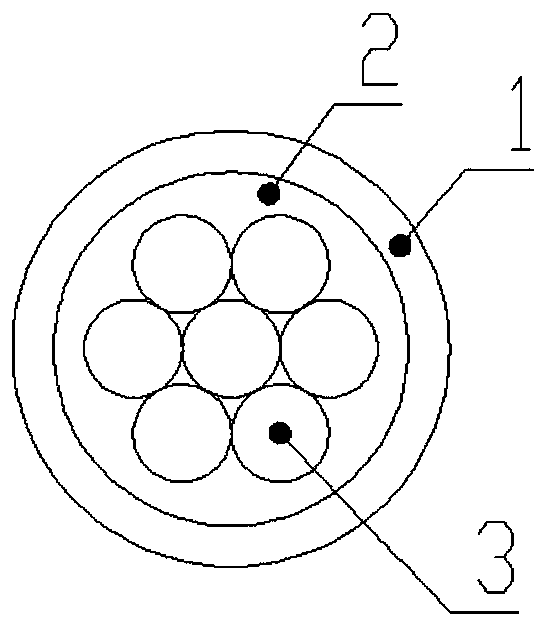

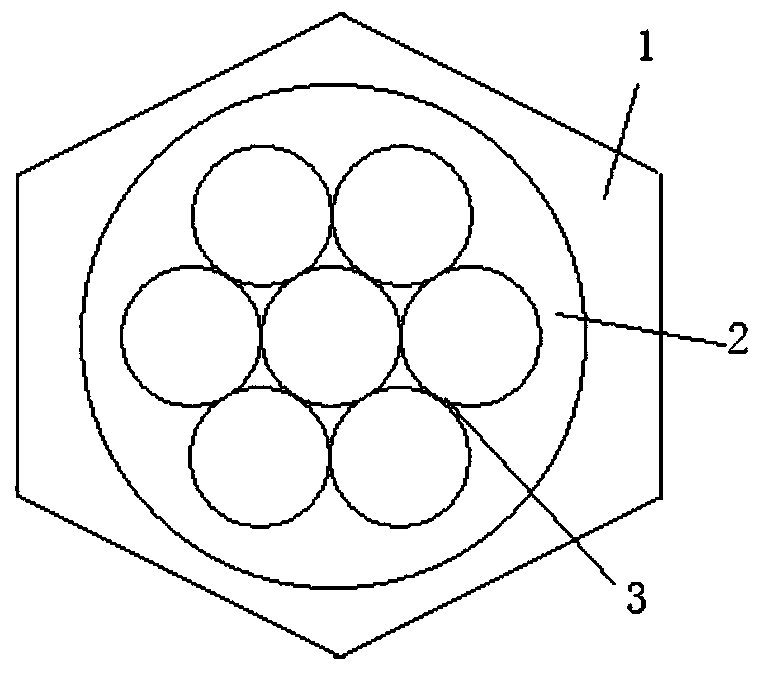

Method for embedded aluminum crimping of 19 steel strand wires of overhead conductor

ActiveCN109616849AMeet grip requirementsImprove crimp qualityLine/current collector detailsConnections effected by permanent deformationStatic friction coefficientNon destructive

The invention discloses a method for embedded aluminum crimping of 19 steel strand wires of an overhead conductor, the method comprises a steel pipe (1) and an aluminum alloy pipe (2), and the aluminum alloy pipe (2) is embedded in the steel pipe (1) and 19 stranded steel strand wires (3) of two butt-joined round wire concentric stranded overhead conductors are wrapped, and the steel pipe (1) is crimped to make the aluminum alloy pipe (2) closely fit the 19 stranded steel strand wires (3) of the round wire concentric stranded overhead conductors to form a steel core connecting pipe. A layer ofaluminum alloy pipe is added between the steel pipe and the 19 stranded steel strand wires of the round wire concentric stranded overhead conductors, based on the high plasticity and static frictioncoefficient of the aluminum alloy pipe, the 19 stranded steel strand wires of the round wire concentric stranded overhead conductors are prevented from being crushed, under-pressed, and loosened whenthe 19 stranded steel strand wires of the round wire concentric stranded overhead conductors and the steel pipe are crimped. The crimping of the 19 stranded steel strand wires of the round wire concentric stranded overhead conductors is easier to implement, and the crimping quality is higher. The crimping joints can avoid non-destructive testing and labor intensity and engineering cost are reduced.

Owner:GUIZHOU POWER GRID CO LTD

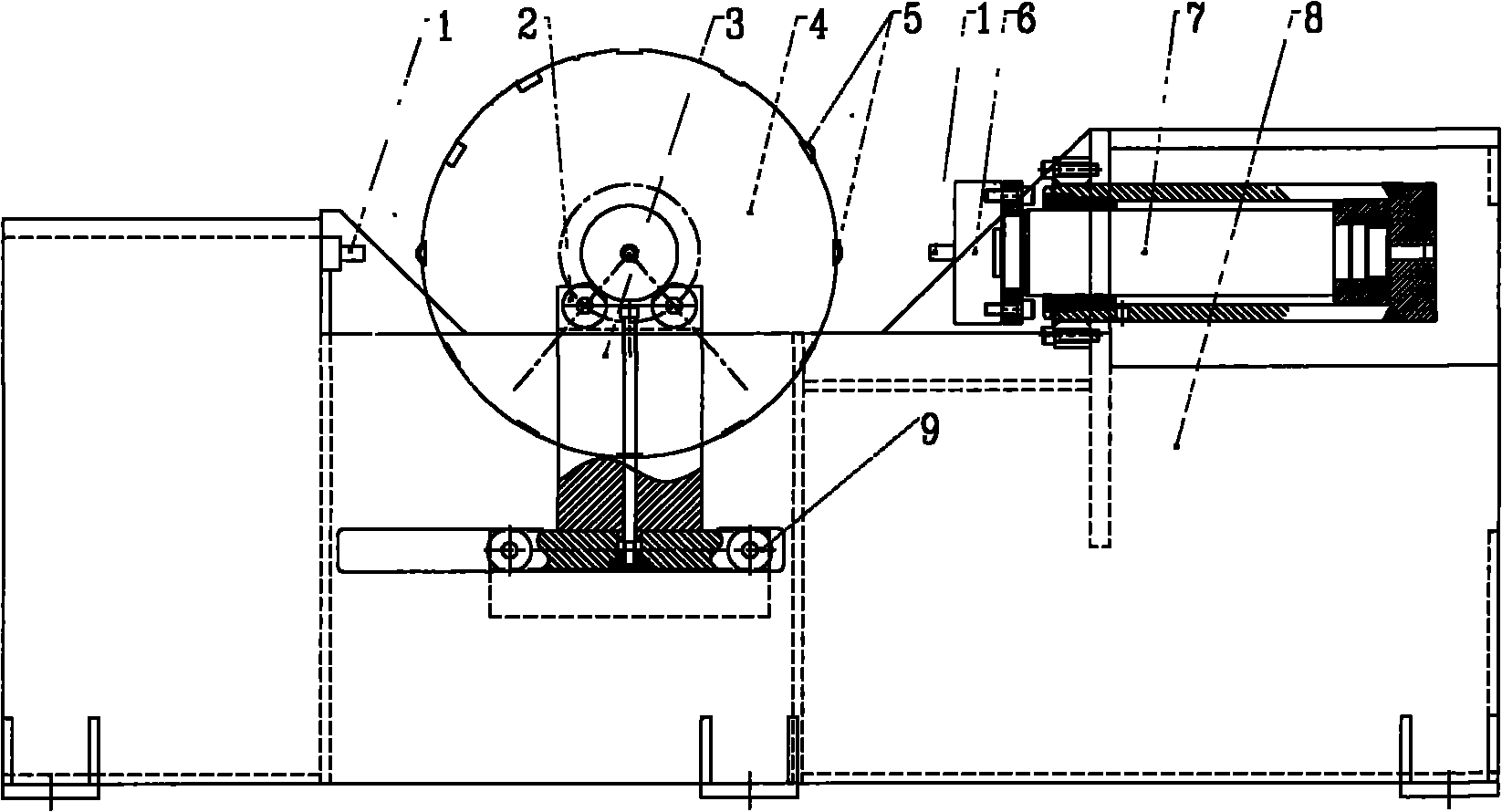

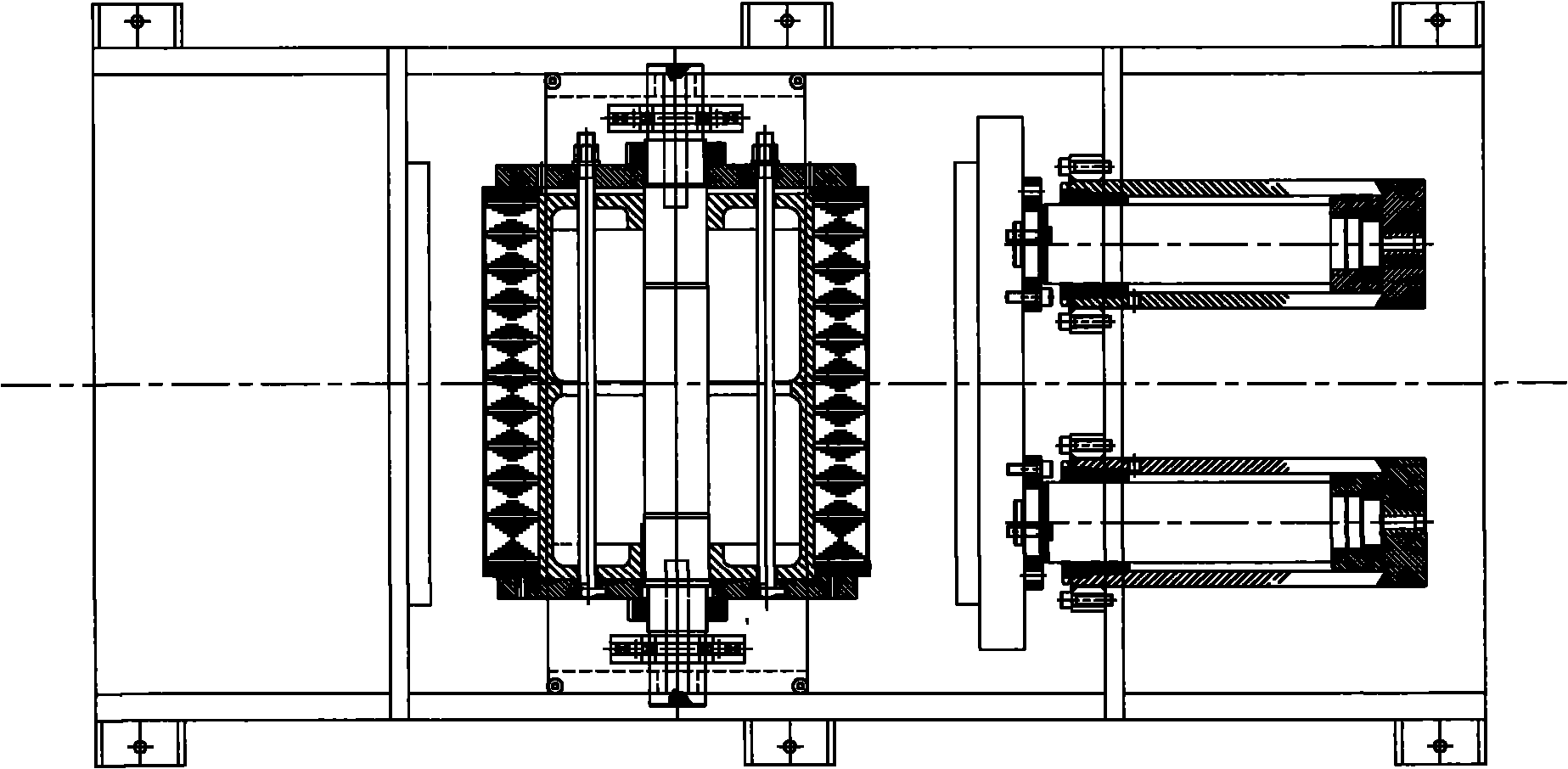

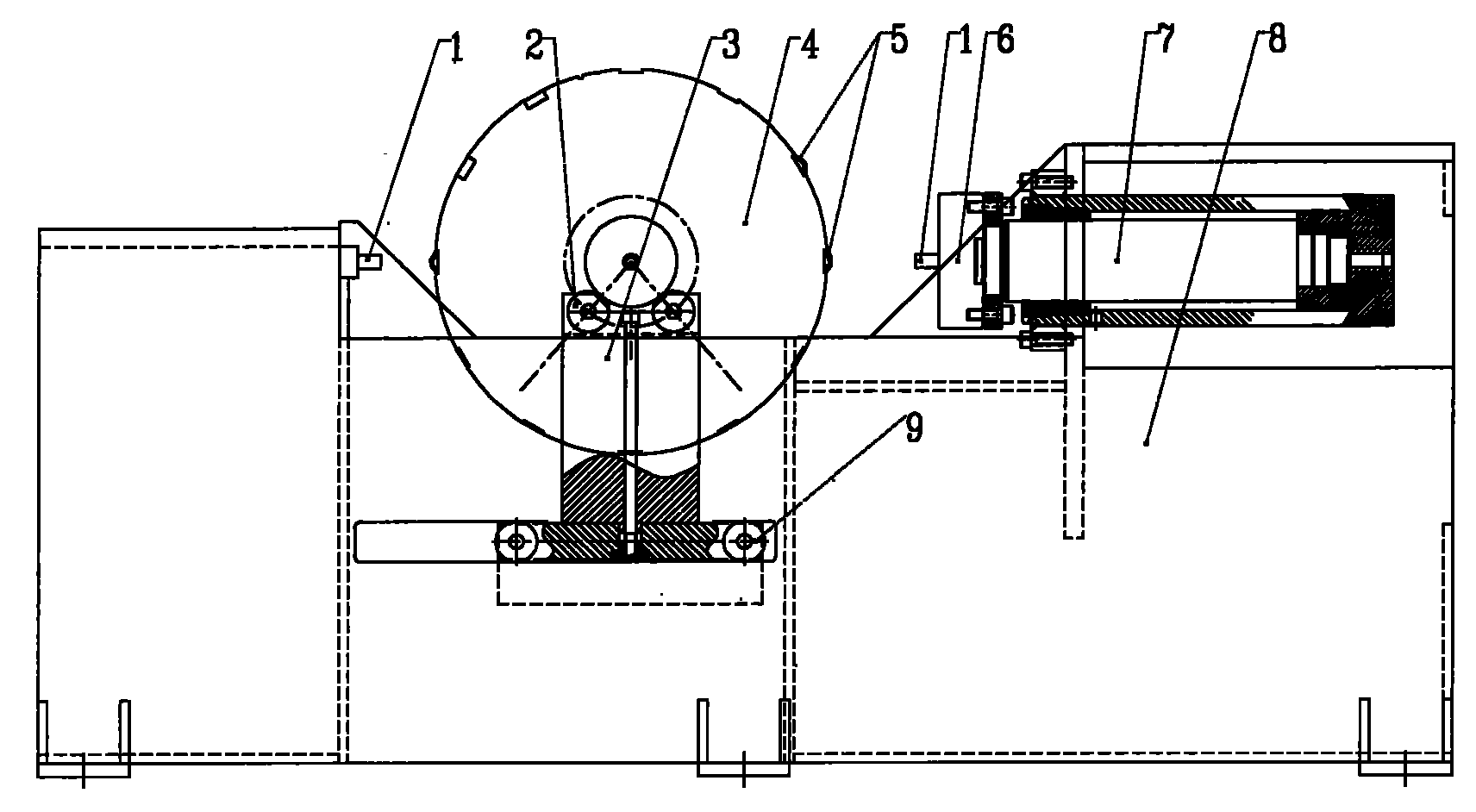

Horizontal stator buckle slab withholding equipment and method

ActiveCN101860131AImprove crimp qualitySimple processManufacturing stator/rotor bodiesPulp and paper industryFuselage

The invention discloses horizontal stator buckle slab withholding equipment and a horizontal stator buckle slab withholding method. The withholding equipment comprises a hydraulic machine body, and buckle slab pressing heads, a mobile bracket, an oil cylinder and a pressure head connecting plate arranged on the hydraulic machine body, wherein the pressure head connecting plate is arranged on the hydraulic head of the oil cylinder. The withholding equipment is characterized in that: the mobile bracket is arranged in the centre of the hydraulic machine body; the two buckle slab pressing heads are respectively arranged at the two ends of the hydraulic machine body, wherein one buckle slab pressing head is fixed on the pressure head connecting plate while the other buckle slab pressing head is fixed on the hydraulic machine body; and the lower end of the mobile bracket is provided with a bracket moving roller. Compared with the prior art, two buckle slab pressing heads are respectively arranged at the two ends of the mobile bracket of the hydraulic machine body in the withholding equipment, so that the two sides of a stator component on the mobile bracket are withheld at the same time. Therefore, buckle slab acting forces on the two symmetric sides are the same; the withholding quality of the buckle slab is good; a process is simple; and production efficiency is improved.

Owner:TIANJIN BINHAI TONGDA POWER TECH

Crimping machine

The invention provides a crimping machine, and relates to the field of hydraulic pipeline production equipment. The crimping machine comprises a crimping machine body, supporting legs are fixedly welded to the bottom of the crimping machine body, a driving hydraulic pump is fixedly connected to the top of the crimping machine body, the output end of the driving hydraulic pump is connected with a driving hydraulic cylinder, a transmission shaft is fixedly welded to a telescopic shaft of the driving hydraulic cylinder, the end, away from the driving hydraulic cylinder, of the transmission shaftis connected with a crimping transmission device through a hinge base, and a crimping extrusion device is arranged in the crimping transmission device. According to the crimping machine, when an extrusion moving rod moves to be close to a casing pipe along an arc channel, multiple wedge extrusion blocks can be driven to carry out closing extrusion operation, through the equivalent transmission force provided by the crimping transmission device, the stable radial extrusion force can be provided for the wedge extrusion block, seal buckled connection between a rubber pipe and an iron casing pipeis more tight, the defective percentage is reduced, and the crimping quality of the rubber pipe is improved.

Owner:临沂市天晟电器有限公司

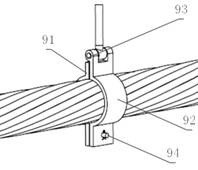

Butt-joint aluminum-embedded crimping structure and method for overhead conductor seven-stranded steel wire

PendingCN109494544AMeet grip requirementsImprove crimp qualityConnection formation by deformationStatic friction coefficientMetallurgy

The invention discloses a butt-joint aluminum-embedded crimping structure and method for an overhead conductor seven-stranded steel wire, and the structure comprises a steel pipe and an aluminum-alloypipe, wherein the aluminum-alloy pipe is embedded into the steel pipe, and wraps two round concentric overhead conductor seven-stranded steel wires in butt joint. The crimping of the steel pipe enables the aluminum-alloy pipe to be closely attached to the round concentric overhead conductor seven-stranded steel wires to form a steel core splicing sleeve. According to the invention, the aluminum-alloy pipe is added between the steel pipe and the round concentric overhead conductor seven-stranded steel wires, and the high plasticity and a large friction coefficient of the aluminum-alloy pipe are employed for avoiding the pressing damages, under-pressing and strand loosening of the round concentric overhead conductor seven-stranded steel wires during the crimping of the steel pipe and the round concentric overhead conductor seven-stranded steel wires. Meanwhile, the structure meets the requirements of a holding force of a connector, enables the butt joint crimping of the round concentricoverhead conductor seven-stranded steel wires to be easier, and is higher in crimping quality. A crimping head can be free of lossless detection, thereby reducing the labor intensity and the engineering cost.

Owner:GUIZHOU POWER GRID CO LTD

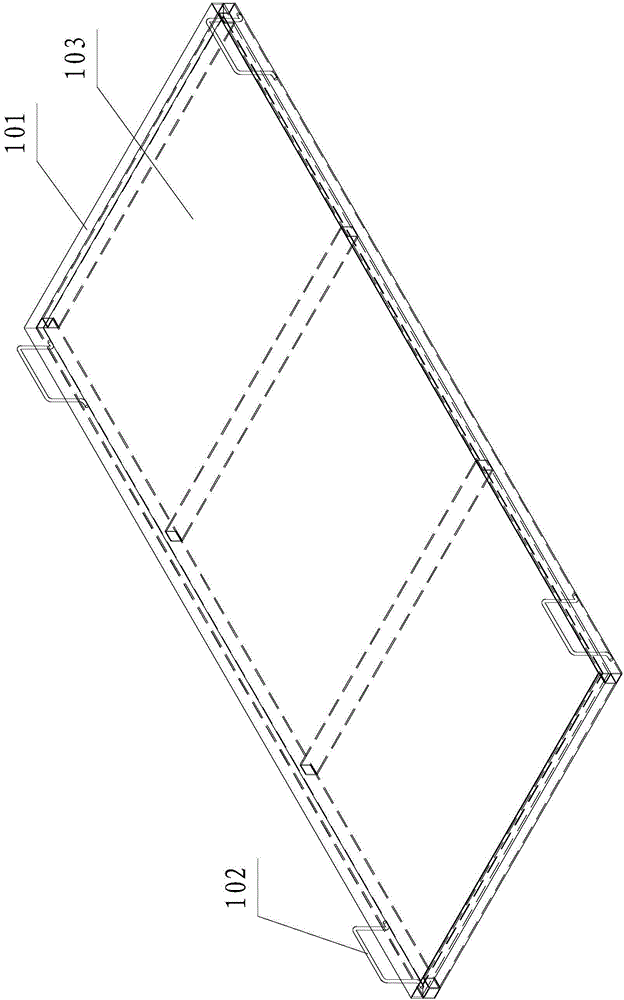

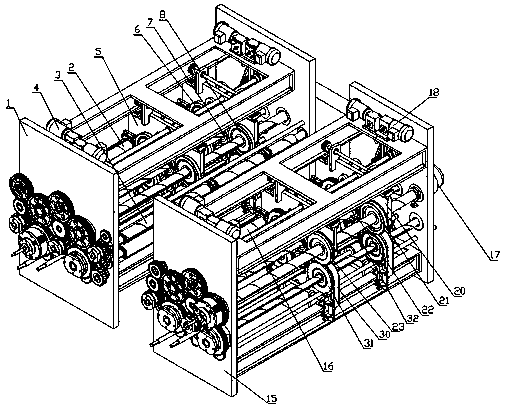

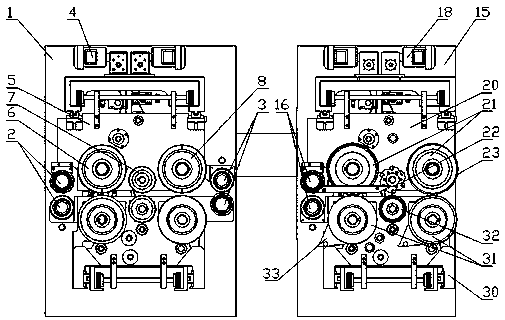

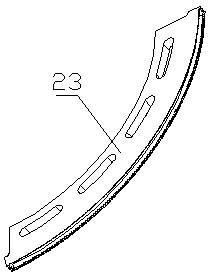

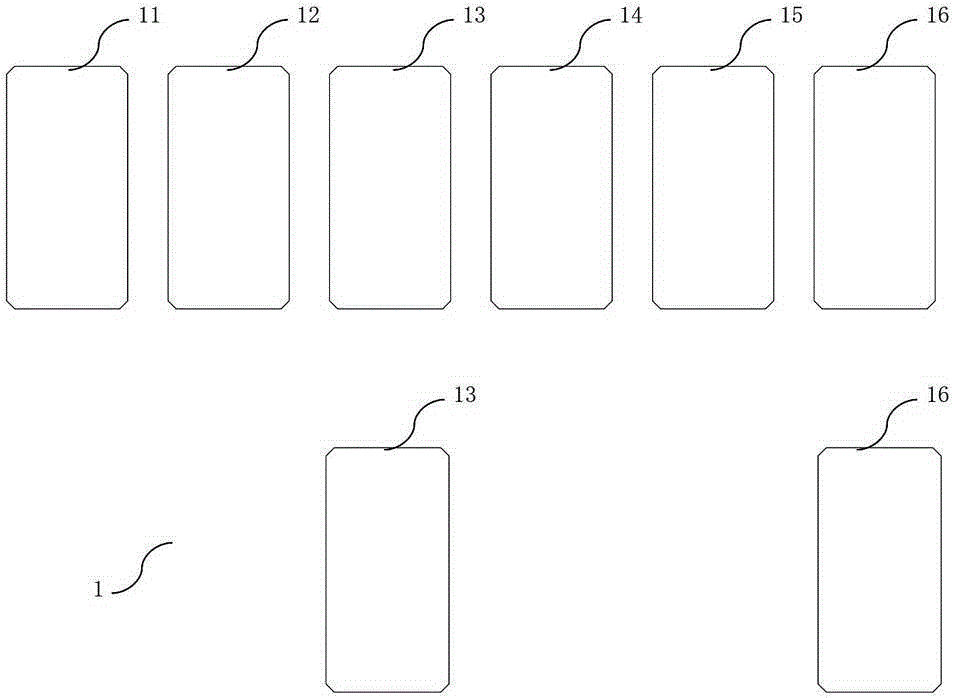

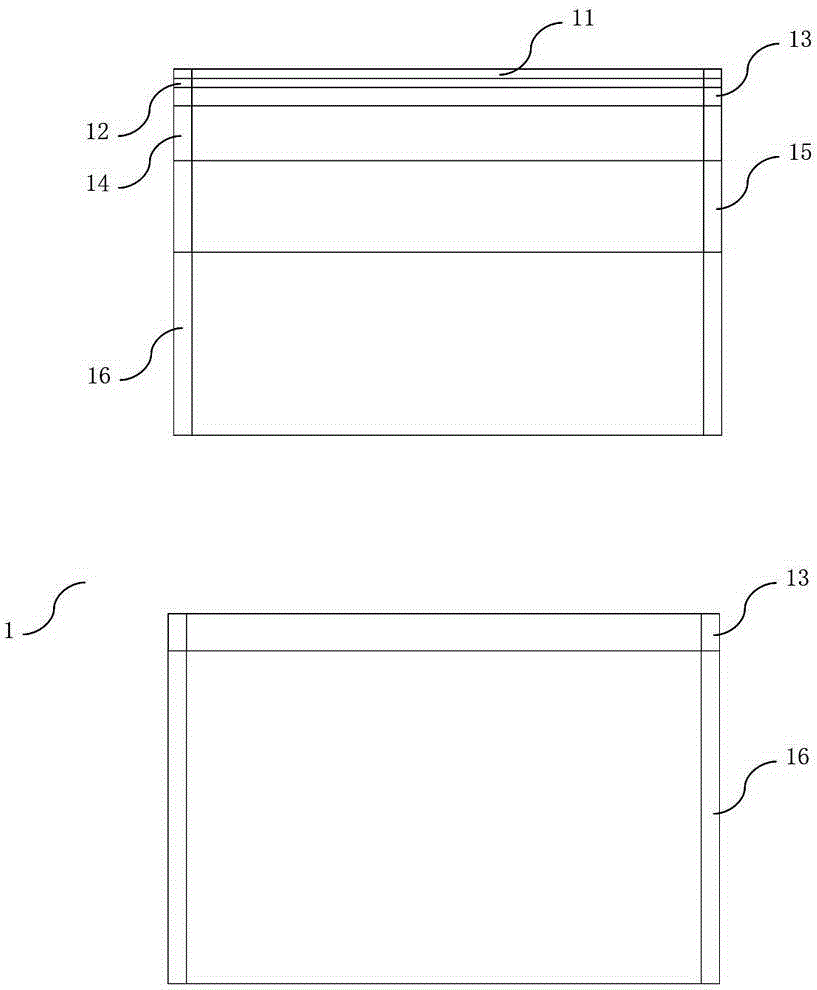

Line pressing and slotting system for corrugated board printing machine

PendingCN109551816AEasy to controlReduce high cost and low precisionPaper-makingBox making operationsSlot machinePaperboard

The invention relates to a line pressing and slotting system for a corrugated board printing machine. The line pressing and slotting system comprises a line pressing machine and a slotting machine, wherein the slotting machine is located on one side of the discharge end of the line pressing machine, the line pressing machine comprises a line pressing machine frame (1), a line pressing paperboard feeding pinch roller (2), a line pressing paperboard discharging pinch roller (3), a plurality of upper line pressing wheel sets, a plurality of lower line pressing wheel sets cooperating with the upper line pressing wheel sets for use, and a plurality of line pressing wheel set driving motors (4), the slotting machine comprises a slotting machine frame (15), a slotting paperboard feeding pinch roller (16), a plurality of slotting wheel sets, a plurality of paperboard supporting wheel sets cooperating with the slotting wheel sets for use, a slotting machine driving motor (17) and a plurality ofslotting wheel set driving motors (18). The line pressing and slotting system has the advantage that the line pressing part and the slotting part are independently adjusted and moved, and the distances between bases are adjusted separately by the corresponding screw rods, so that the precision of the line pressing and slotting positions is maintained, and the technical requirements of automatic packaging are met.

Owner:HUBEI JINGSHAN LIGHT INDAL MACHINERY

19 stranded steel core stranded aluminum conductor aluminum-embedded tensile wire clamp crimping method

ActiveCN110445061AMeet grip requirementsImprove crimp qualityLine/current collector detailsElectric connection structural associationsNon destructiveUltimate tensile strength

The invention discloses a 19 stranded steel core stranded aluminum conductor aluminum-embedded tensile wire clamp crimping method. The method comprises steps: the stranded aluminum conductor is stripped to expose the steel core; an aluminum sleeve clamp performs sleeving from the steel core stranded aluminum conductor end; the steel core stranded aluminum conductor passes through an outer-embeddedaluminum tube; a conductor shaping ring sleeves the steel core stranded aluminum conductor, and the conductor shaping ring is fixed on the stranded aluminum conductor layer of the steel core strandedaluminum conductor; the stranded aluminum conductor layer of the steel core stranded aluminum conductor is loosened, and an inner-embedded aluminum tube sleeves the steel core; a repaired stranded aluminum conductor is sleeved in the outer-embedded aluminum tube; a steel core aluminum-embedded tube is embedded in a steel anchor crimping tube; a steel core stranded steel conductor is inserted fromone end of the steel core aluminum-embedded tube; the steel anchor crimping tube is crimped; an aluminum sleeve clamp movably sleeves the steel core stranded aluminum conductor outer-embedded aluminum tube and the steel anchor crimping tube; and the aluminum sleeve clamp and the steel anchor crimping tube are crimped. Crushing, undercompaction and strand loosening of the 19 stranded steel core stranded aluminum conductor can be prevented, the connection reliability is good, making is easy, the crimping quality is higher, non-destructive testing is not needed, and the labor intensity and the engineering cost are reduced.

Owner:GUIZHOU POWER GRID CO LTD

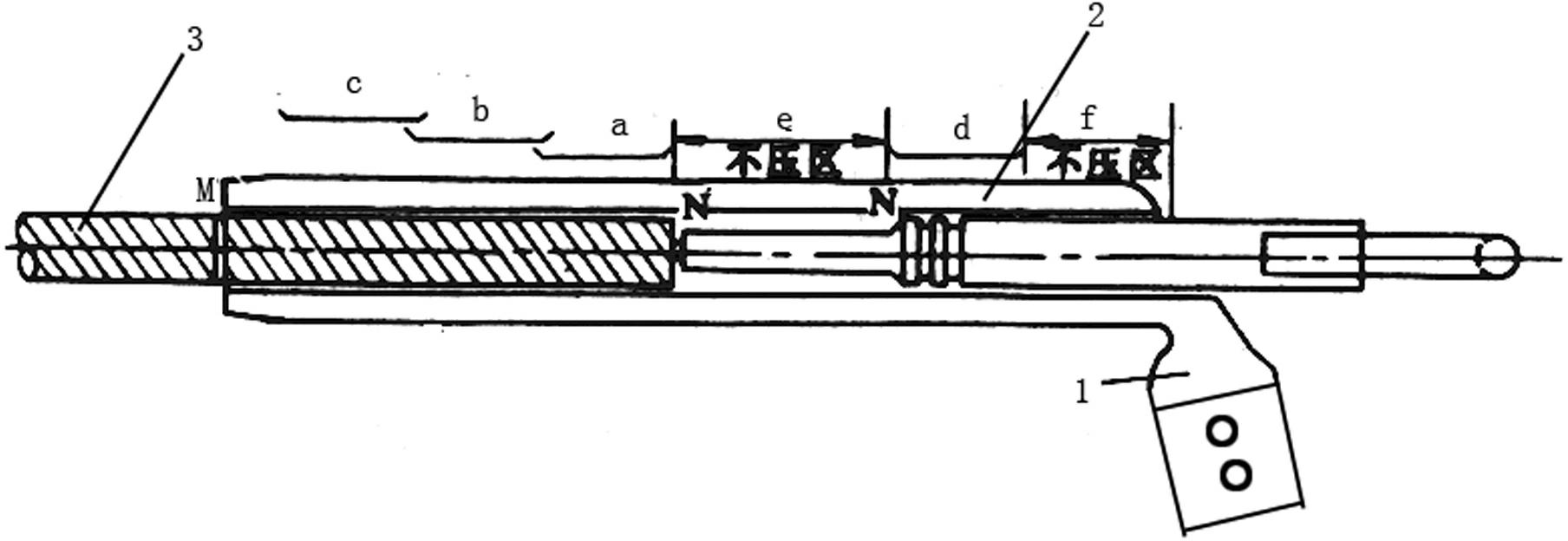

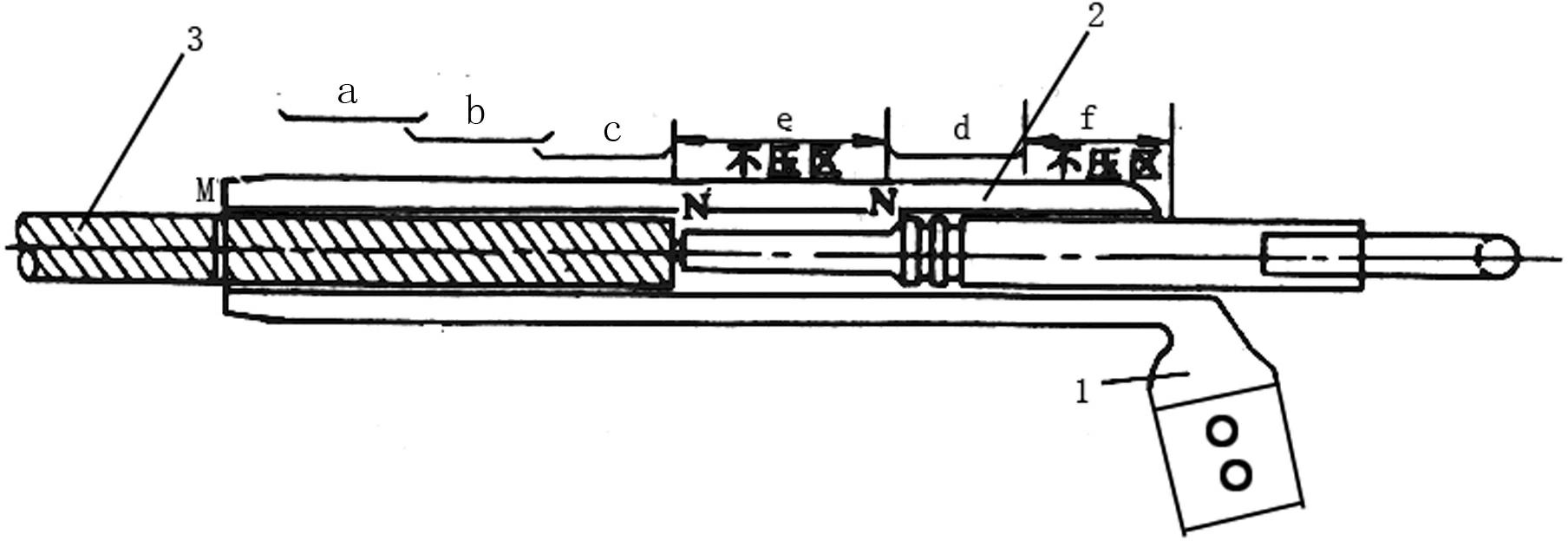

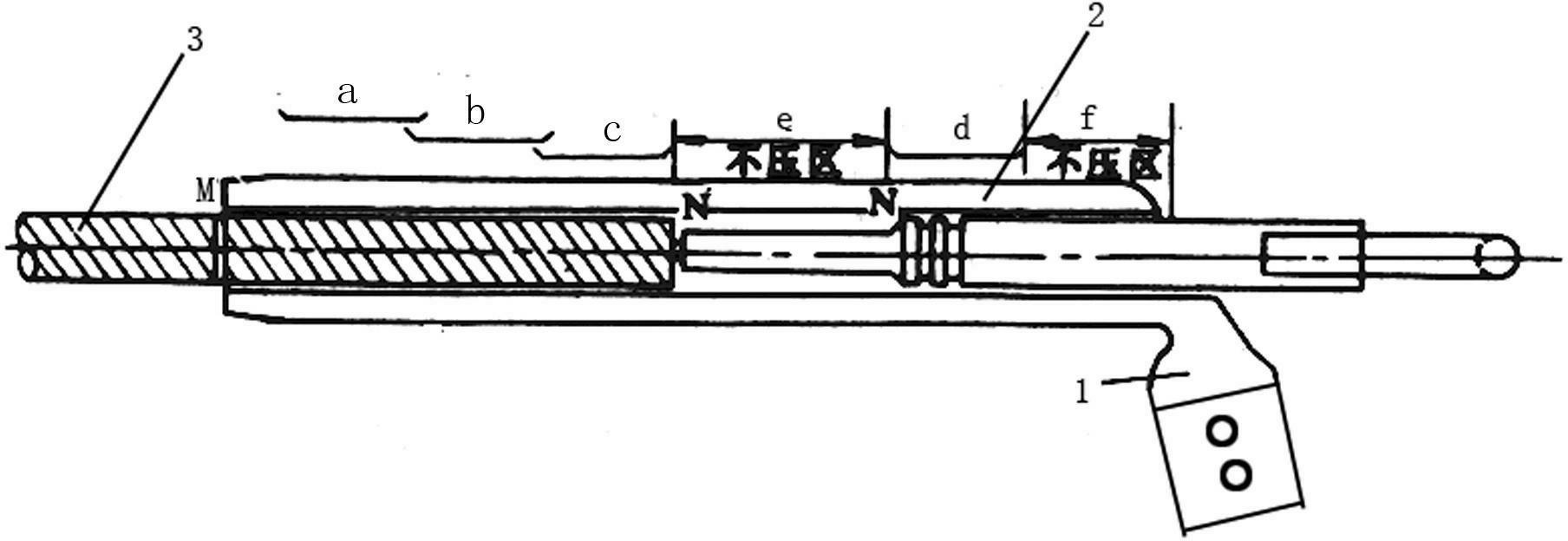

Hydraulic crimping method of strain clamp of bus in power substation

InactiveCN102545119AOvercoming the Phenomenon of "Lantern Flower"Improve crimp qualityBus-bar installationPower gridEngineering

The invention relates to a hydraulic crimping method of a strain clamp of a bus in a power substation, which comprises the following steps: (1) crimping a first mode a: outwards crimping the first mode a from an orifice end of a steel anchor in an aluminium wire steel anchor; (2) crimping a second mode b: on the basis of crimping the first mode, outwards crimping the second mode along the first mode; (3) crimping a third mode c: on the basis of crimping the second mode, outwards crimping the third mode along the second mode, and reserving a steel anchor part simultaneously; (4) crimping a fourth mode d: crimping the fourth mode d between the reserved steel anchor part and a lead plate; and (5) rubbing burrs down after crimping. The method is simple and easy to operate, the phenomenon of lantern flower after crimping wires is avoided, the quality and the efficiency for crimping the wires are improved, and the attractiveness, the electric conduction effect and the born tension of the wires are improved. Wastes of the wires and wire clamps caused by disqualified construction quality are saved, and the capacity of a power grid for resisting external force damage is enhanced.

Owner:LIAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Crimping surface adaptive crimping machine

PendingCN110676670ATroubleshoot disassemblySolve assembly problemsContact member assembly/disassemblyTransmission beltEngineering

The invention discloses a crimping surface adaptive crimping machine which comprises a first driving assembly, a crimping mechanism and a replacement mechanism. The first driving assembly spans abovea transmission belt along a direction perpendicular to the transmission belt. The crimping mechanism is connected on the first driving assembly. The crimping mechanism comprises a driving part, a connecting part and a crimping part. The driving part is connected on the output end of the first driving assembly. The connecting part is connected on the output end of the driving assembly. The crimpingpart is arranged below the connecting part and is arranged at intervals with the connecting part, and the lower part of the crimping part is detachably connected with a crimping joint. An adaptive sphere and a flexible connecting plate are arranged in a gap space between the crimping part and the connecting part, and the adaptive sphere is rotatably connected in the gap between the flexible connecting plate and the connecting part or the gap between the flexible connecting plate and the crimping part. The replacement mechanism is arranged at the side of the transmission belt. The adaptive parallel bonding of the crimping surface and the automatic disassembling and assembling of the crimping joint can be realized.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

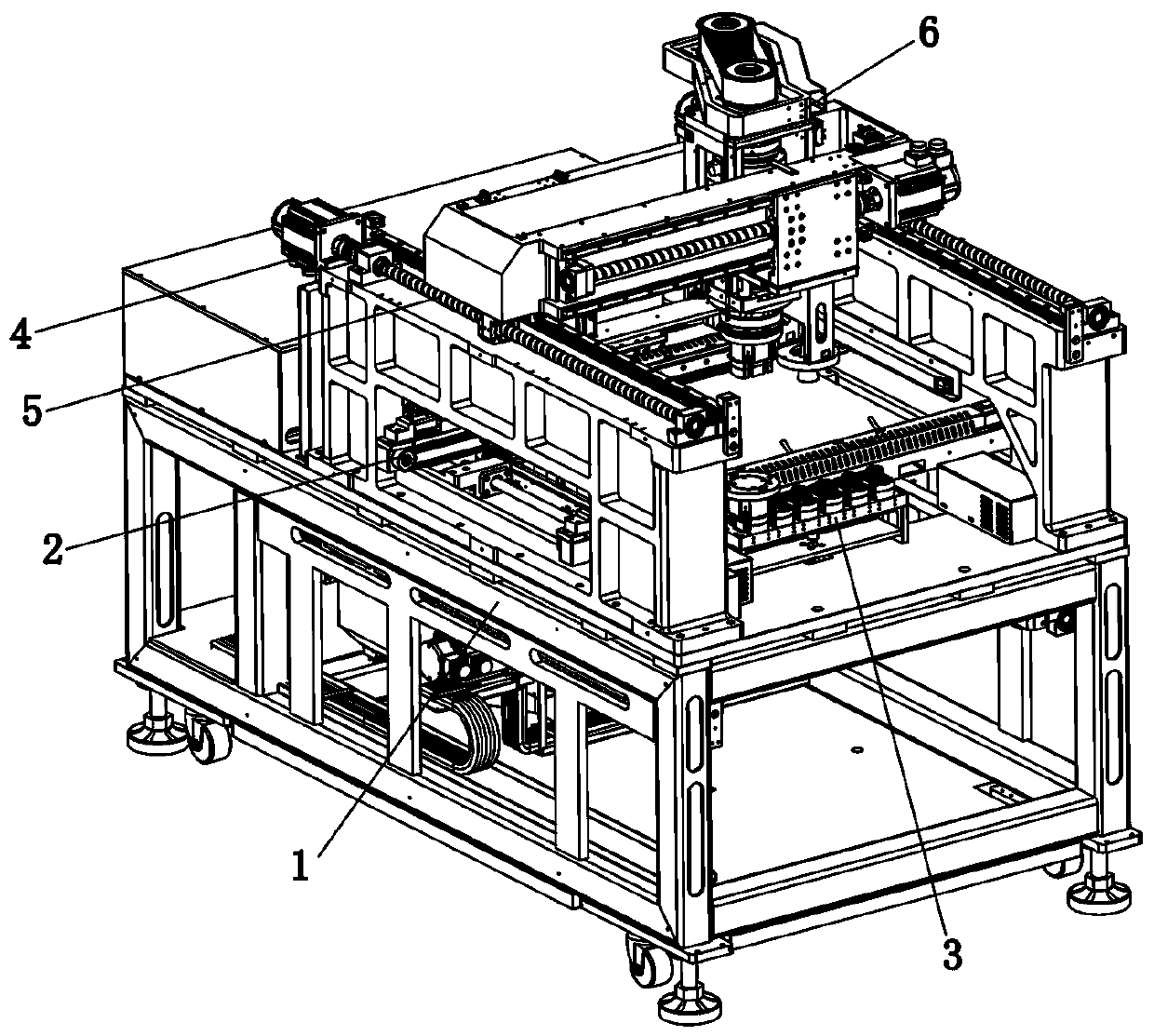

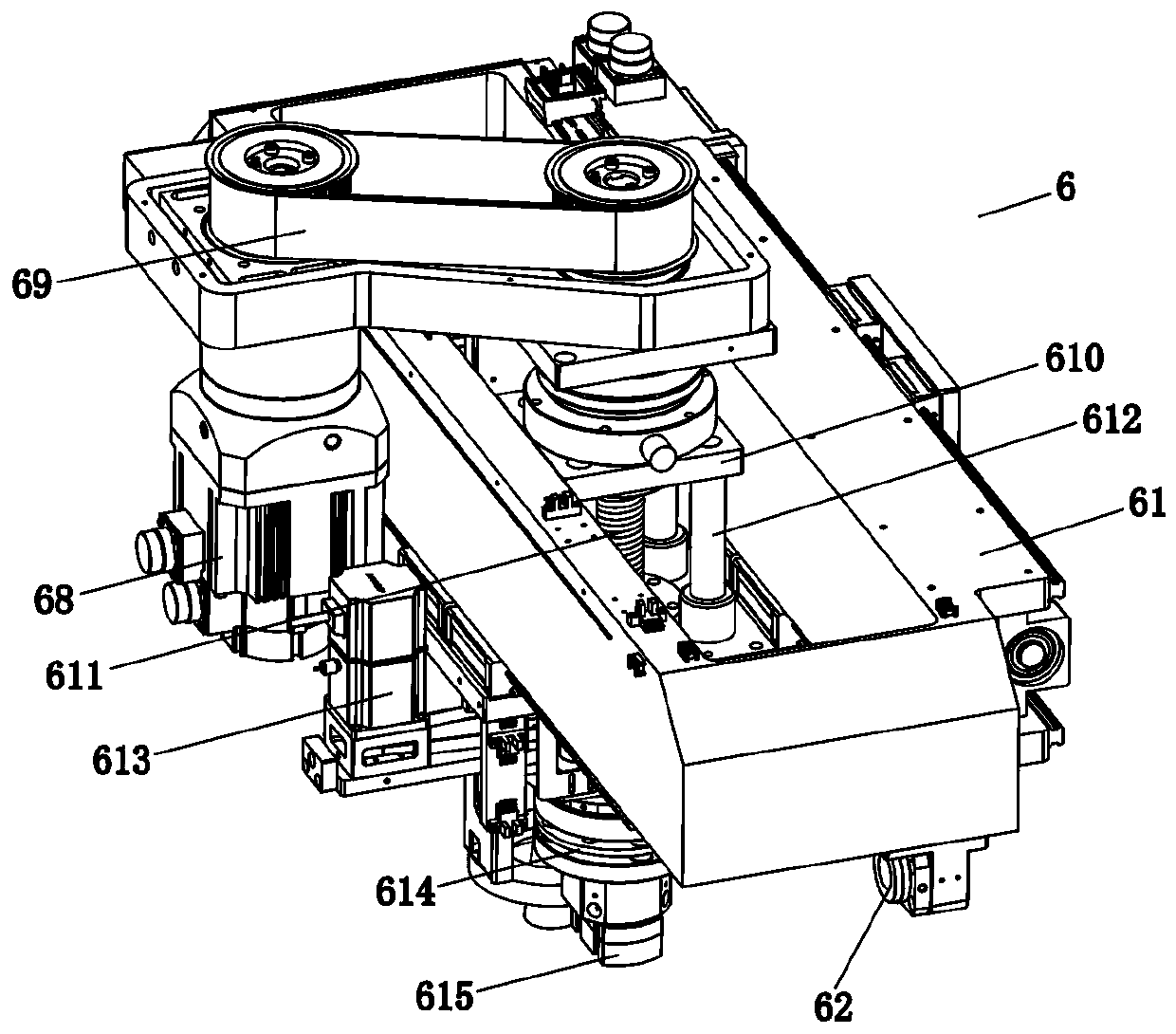

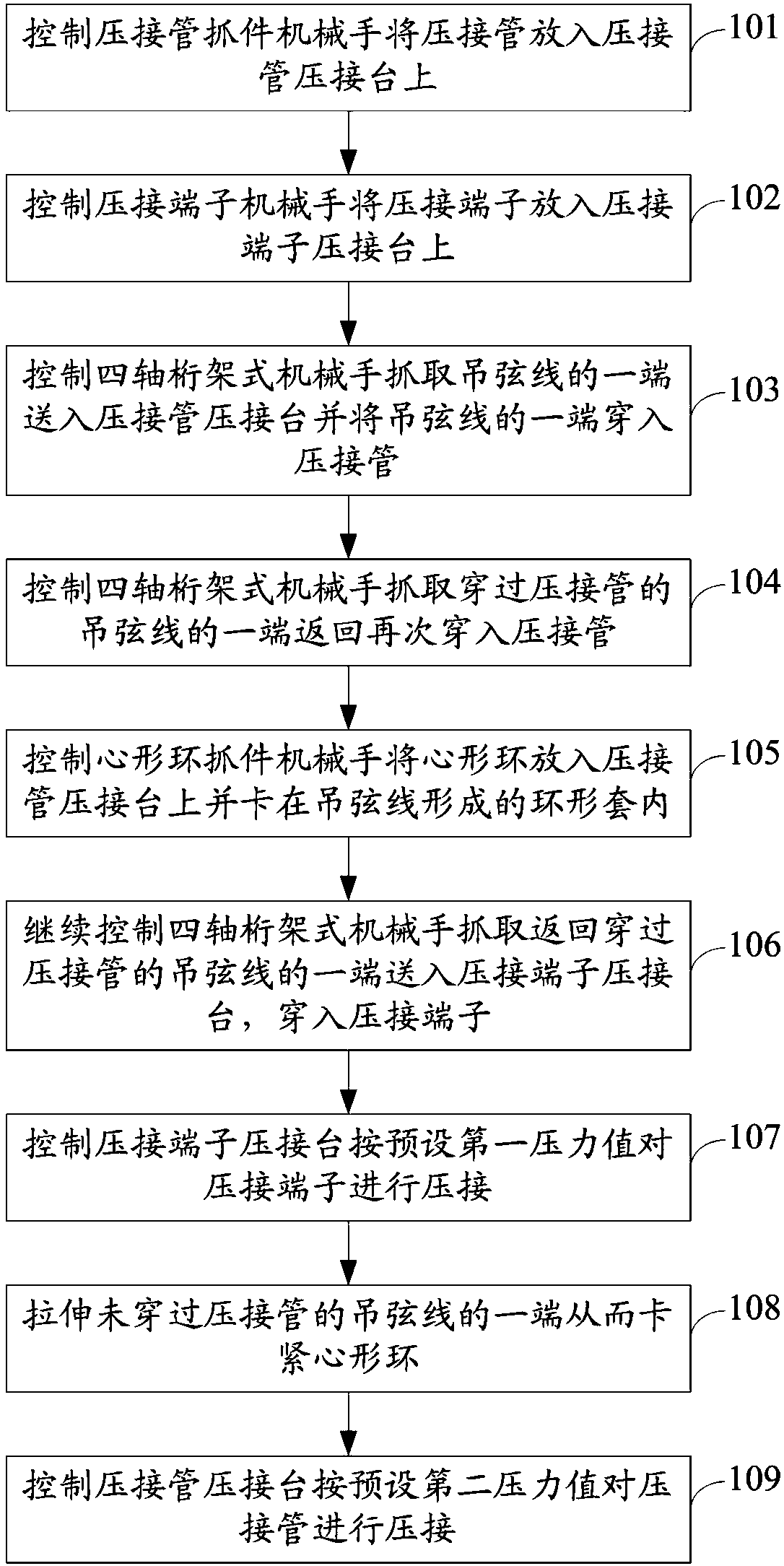

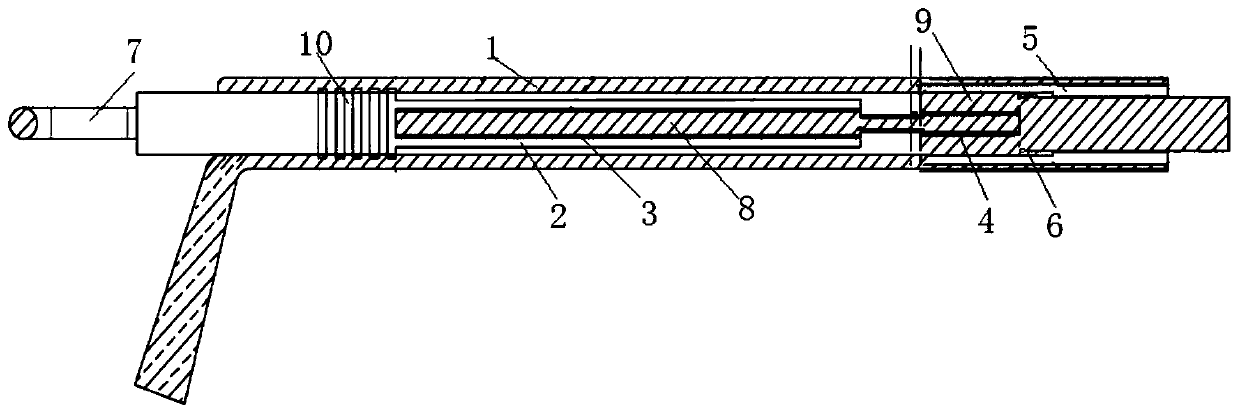

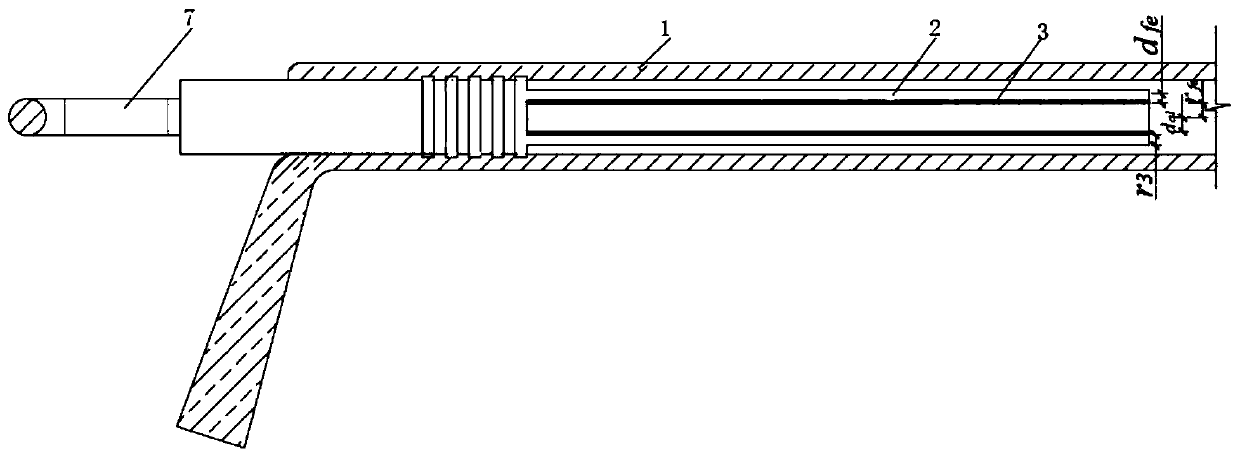

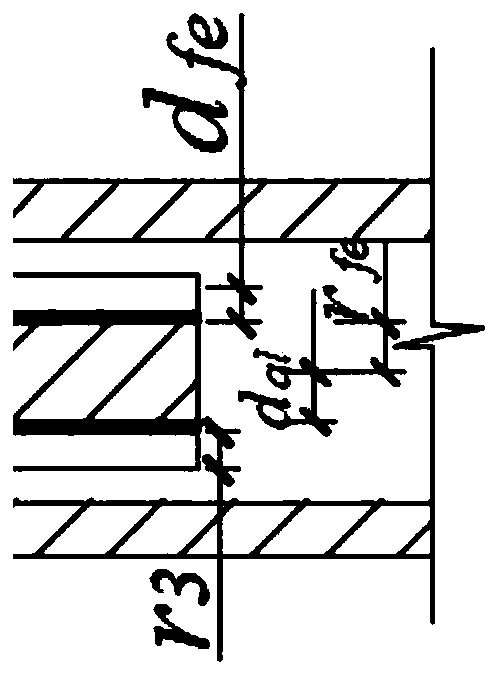

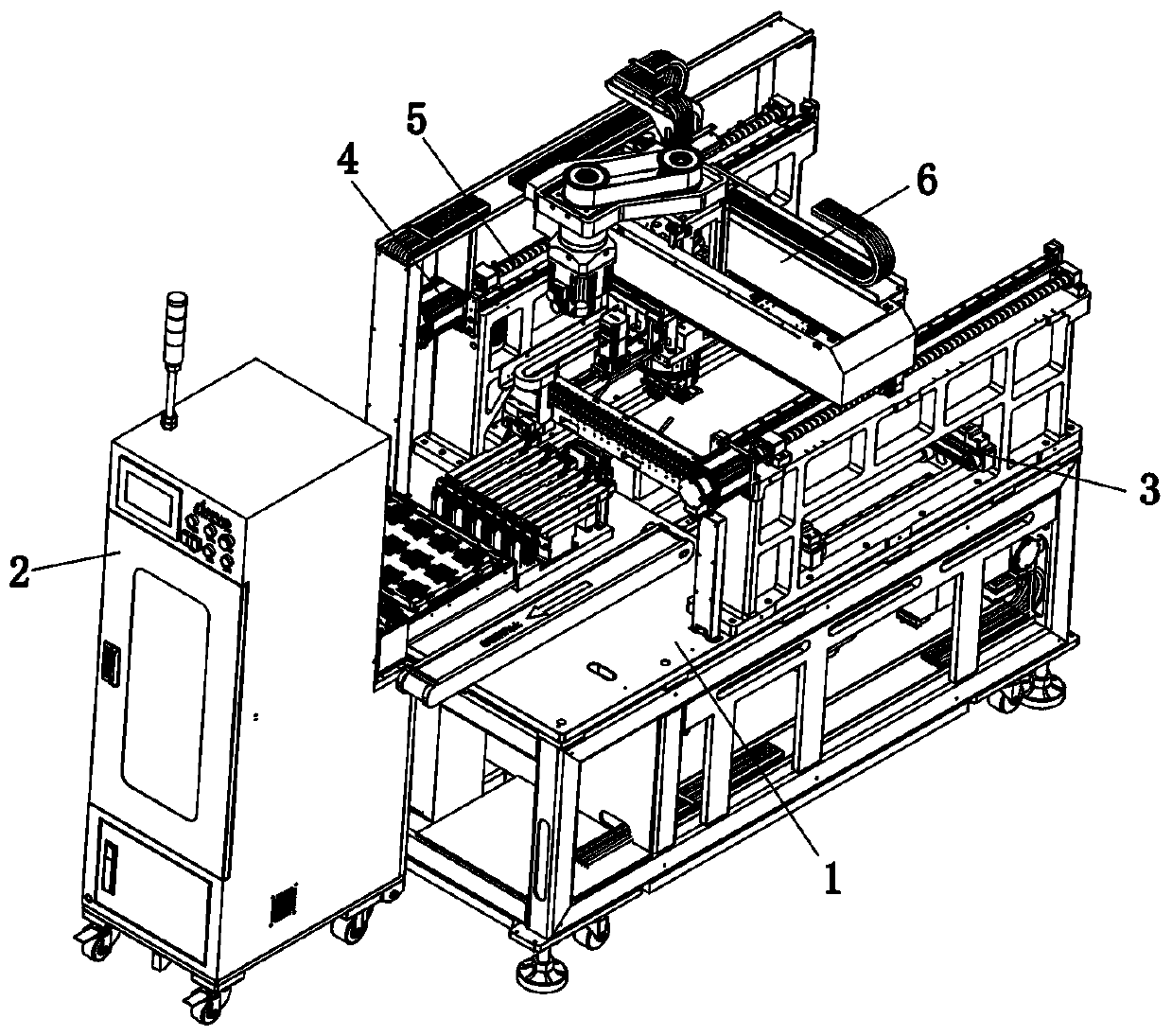

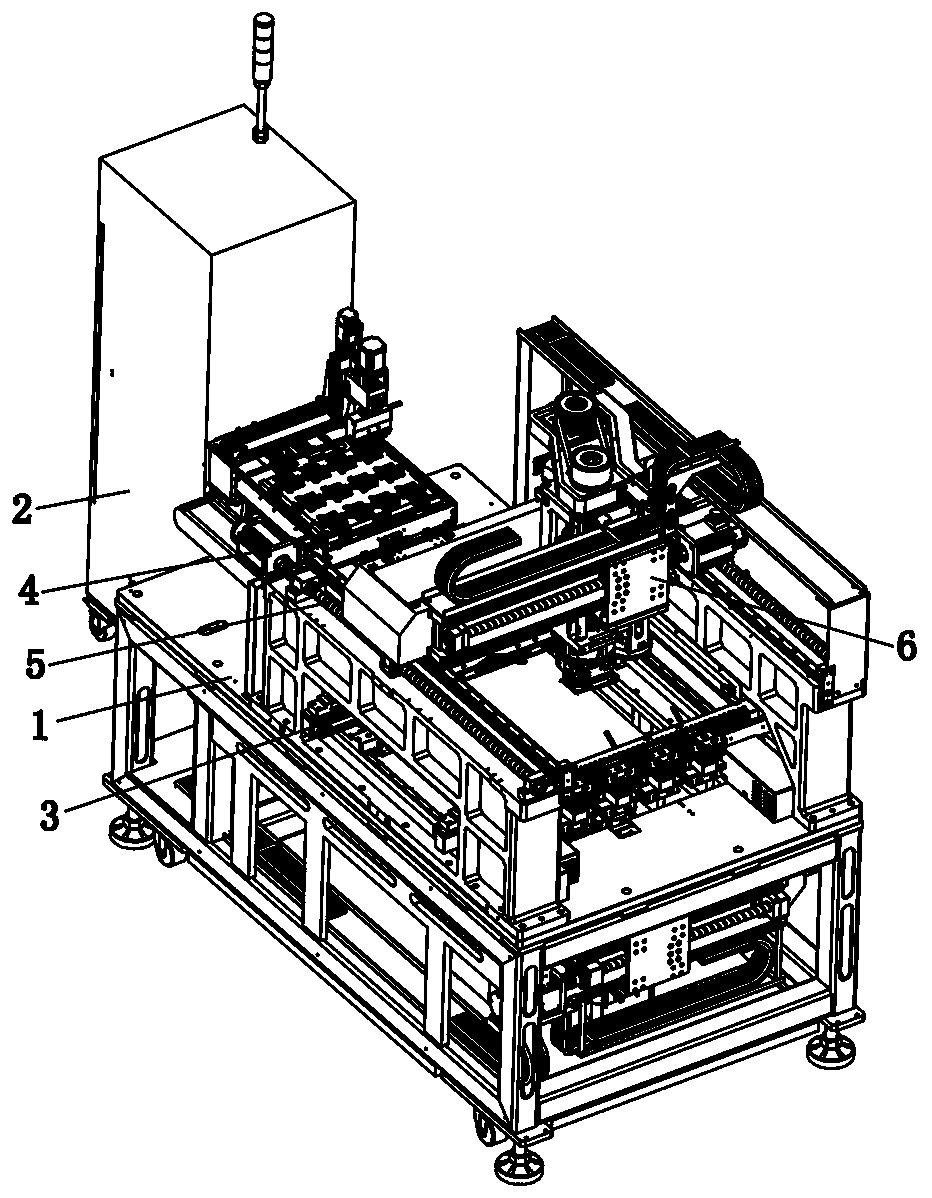

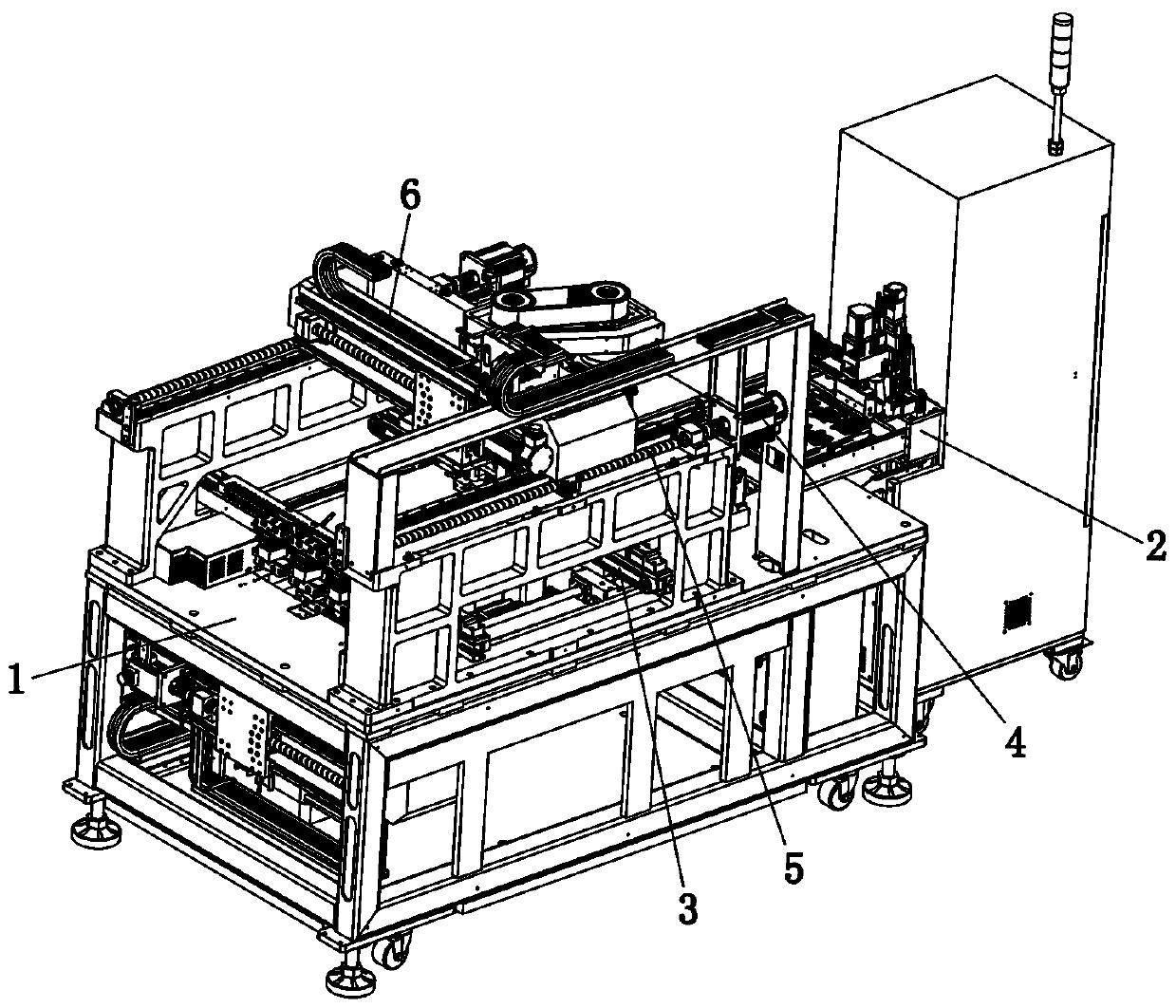

Method for crimping dropper crimp tube and dropper crimp terminal

The invention discloses a method for crimping a dropper crimp tube and a dropper crimp terminal, comprising: adding the crimp tube onto a crimp tube crimping table; adding the crimp terminal onto a crimp terminal crimping table; controlling a four-axis truss manipulator to grip one end of a dropper line and pass into the crimp tube; controlling the four-axis truss manipulator to grip one end, passed through the crimp tube, of the dropper line, and returning to pass again through the crimp tube; controlling a heart ring gripping manipulator to add a heart ring onto the crimp tube crimping table, and fastening the same in a circular sleeve formed by the dropper line; continuously controlling the four-axis truss manipulator to grip the end, returned to pass through the crimp tube, of the dropper line for passing the end through the crimp terminal; controlling the crimp terminal crimping tale to crimp the crimp terminal according to a preset first pressure value; drawing the end, not passed through the crimp tube, of the dropper line so as to fasten the heart ring; controlling the crimp tube crimping table to crimp the crimp tube according to a preset second pressure value. The methodcan provide improved crimping quality and improved crimping quality stability.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

Wire crimping machine

PendingCN111129905ALocate the crimping positionImprove crimp qualityConnection formation by deformationElectric machineBall screw

The invention discloses a wire crimping machine, and belongs to the technical field of power construction. The wire crimping machine comprises a bottom frame body and a linear guide rail module, a crimping module and a wire cutting and stripping module which are respectively arranged on the bottom frame body, wherein the linear guide rail module comprises a driving motor and a lead screw guide rail, and the output end of the driving motor is fixedly connected with the lead screw guide rail; the bottom end of the crimping module is screwed with the lead screw guide rail to form a ball screw structure; and the wire cutting and stripping module comprises a wire cutting module and a wire stripping module which are respectively and fixedly connected with the crimping module, and the wire cutting module and the wire stripping module are linearly and correspondingly arranged. According to the device, the crimping module can be effectively moved according to the linear guide rail module, the crimping position of the wire can be found accurately, automatic crimping can be realized, and the crimping quality and efficiency of the wire can be greatly improved.

Owner:北京争先甲电力科技开发有限公司 +1

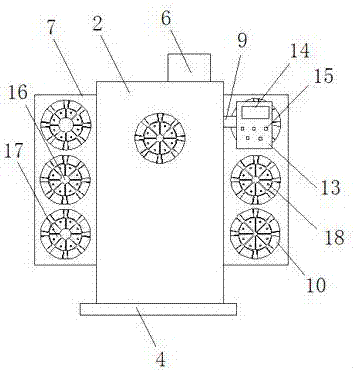

Hydraulic system hose crimping machine

InactiveCN107470883AImprove crimp qualityQuality improvementMetal working apparatusPulp and paper industryElectric wire

The invention is a hydraulic system pipe crimping machine, which includes a main machine and a crimping machine connected to the main machine through connecting wires, and is characterized in that: the crimping machine is arranged on a base, and a positioning rod and a reflector are arranged on the crimping machine , bearing block, dustproof layer, connecting rod, crimping ring mounting block, the positioning bar is provided with a positioning block, and a fixing rod is arranged on the positioning block, and the bearing block is symmetrically arranged on both sides of the crimping machine , the dust-proof layer is arranged symmetrically on both sides of the crimping machine. The present invention is provided with a plurality of crimping rings with different inner diameters on the crimping machine, which can satisfy different types of hydraulic system pipes, expands the scope of application of the crimping machine, and is provided with a reflector on the crimping machine to clearly see the It is convenient for the operator to work and improve work efficiency. The positioning rod is provided with a fixed rod, which can fix the hydraulic system tube when the hydraulic system tube is crimped, thereby improving the crimping quality of the hydraulic system tube.

Owner:乔斌

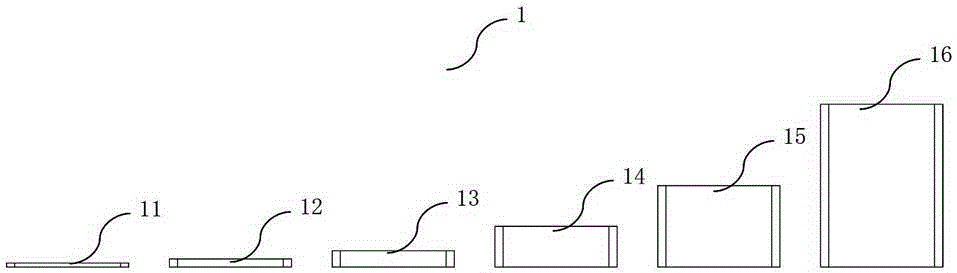

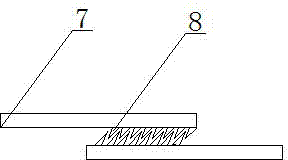

Crimping machine upper mold height adjustment device, system and method

ActiveCN105163572AReduce the number of rough adjustmentsImprove efficiencyElectrical componentsComputer engineering

The invention discloses a crimping machine upper mold height adjustment device, system and method. The device comprises at least one adjustment sheet group. The adjustment sheet group includes a plurality of adjustment sheets. Each adjustment sheet is a flat object or a block with certain thickness. The adjustment sheets are combined into different heights to assist in the adjustment of the upper mold height of a crimping machine, and the thinnest adjustment sheet is used for satisfying the requirement for adjustment precision. The thickest adjustment sheet in the adjustment sheet group can be selected according to the required maximum height, and the thinnest adjustment sheet in the adjustment sheet group can be selected according to the required precision. The invention can solve the technical problems that a conventional upper mold height adjustment method can only be used for rough adjustment of the upper mold height due to inaccurate height datum, the adjustment process is complex, the number of times of adjustment is too many, and the adjustment precision is too low.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Seven-stranded steel strand embedded aluminum strain clamp crimped structure and crimping method thereof

PendingCN110350327AMeet grip requirementsImprove crimp qualityLine/current collector detailsConnections effected by permanent deformationStatic friction coefficientButt joint

The invention discloses a seven-stranded steel strand embedded aluminum strain clamp crimped structure and a crimping method thereof. The seven-stranded steel strand embedded aluminum strain clamp crimped structure includes a steel anchor crimping pipe and an aluminum embedded pipe; the aluminum embedded pipe is embedded into the steel anchor crimping pipe and wraps and sleeves seven circular concentric stranded overhead conductor steel strands which connected with a strain clamp end; and the steel anchor crimping pipe enables the aluminum embedded pipe to be tightly attached to the seven circular concentric stranded overhead conductor steel strands, so that a steel strand strain joint is obtained. According to the seven-stranded steel strand embedded aluminum strain clamp crimped structure and the crimping method thereof of the invention, the aluminum embedded pipe layer is additionally arranged between the steel anchor crimping pipe and the seven circular concentric stranded overheadconductor steel strands. On the basis of the high plasticity and high static friction coefficient of the aluminum embedded pipe, damage to the seven steel strands due to the pressing of the strain clamp, insufficient pressing of the seven steel strands, and the looseness of the seven steel strands when the steel anchor crimping pipe and the seven steel strands are crimped can be avoided; requirements for the holding force of the joint are satisfied; the butt joint and crimping of the seven stranded steel strands are easier to implement; the crimping quality of the seven stranded steel strandsis higher; and nondestructive detection is not required to be performed on the crimped joint, and therefore, labor intensity and engineering cost are reduced.

Owner:GUIZHOU POWER GRID CO LTD

Equipment capable of automatically buckling tap of water dispenser and tap cover

ActiveCN107443046AAvoid buckle crushingImprove crimp qualityMetal working apparatusPunchingStructural engineering

The invention discloses equipment capable of automatically buckling a tap of a water dispenser and a tap cover. The equipment comprises a stand, a bottom mold, a punch and a punch driving device, wherein the bottom mold is mounted on the stand; the tap and the tap cover are oppositely mounted on the bottom mold in a punching direction; one of the tap and the tap cover is slidingly arranged in the punching direction; and the punch driving device drives one of the tap and the tap cover capable of sliding in the punching direction, and enables the one to buckle with the other one of the two. The equipment capable of automatically buckling the tap of the water dispenser and the tap cover not only can realize automatic buckling of a tap module to save the labor cost, but also can guarantee buckling in place of the tap module to solve the problem of water leakage of the tap module.

Owner:GREE ELECTRIC APPLIANCES INC

7 stranded steel core stranded aluminum conductor aluminum-embedded tensile wire clamp crimping method

ActiveCN110445062AEasy crimpingMeet grip requirementsLine/current collector detailsElectric connection structural associationsNon destructiveMetallurgy

The invention discloses a 7 stranded steel core stranded aluminum conductor aluminum-embedded tensile wire clamp crimping method. The method comprises steps: the stranded aluminum conductor is stripped to expose the steel core; an aluminum sleeve clamp performs sleeving from the steel core stranded aluminum conductor end; the steel core stranded aluminum conductor passes through an outer-embeddedaluminum tube; a conductor shaping ring sleeves the steel core stranded aluminum conductor, and the conductor shaping ring is fixed on the stranded aluminum conductor layer of the steel core strandedaluminum conductor; the stranded aluminum conductor layer of the steel core stranded aluminum conductor is loosened, and an inner-embedded aluminum tube sleeves the steel core; a repaired stranded aluminum conductor is sleeved in the outer-embedded aluminum tube; a steel core aluminum-embedded tube is embedded in a steel anchor crimping tube; a steel core stranded steel conductor is inserted fromone end of the steel core aluminum-embedded tube; the steel anchor crimping tube is crimped; an aluminum sleeve clamp movably sleeves the steel core stranded aluminum conductor outer-embedded aluminumtube and the steel anchor crimping tube; and the aluminum sleeve clamp and the steel anchor crimping tube are crimped. Crushing, undercompaction and strand loosening of the 7 stranded steel core stranded aluminum conductor can be prevented, the connection reliability is good, making is easy, the crimping quality is higher, non-destructive testing is not needed, and the labor intensity and the engineering cost are reduced.

Owner:GUIZHOU POWER GRID CO LTD

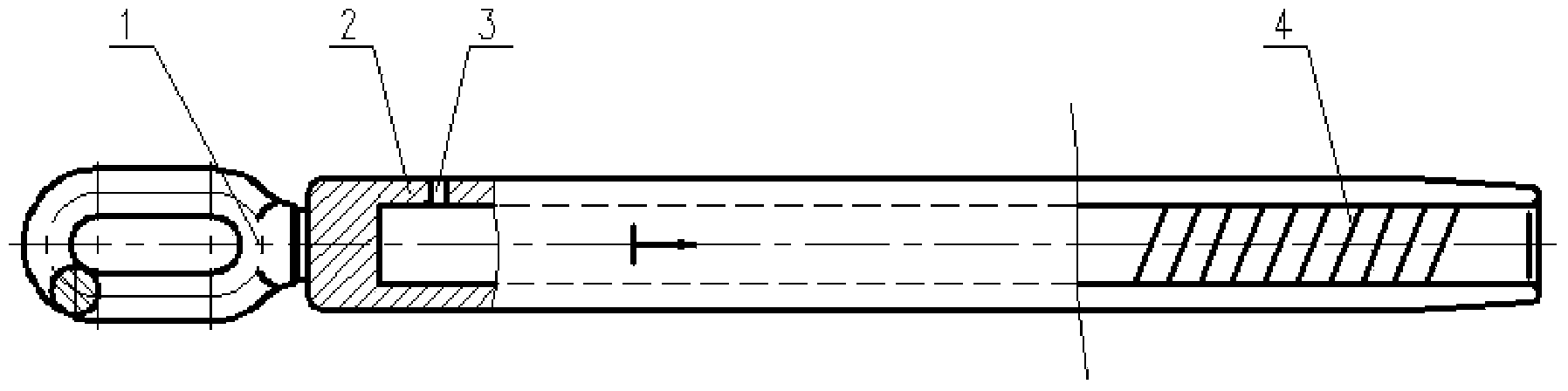

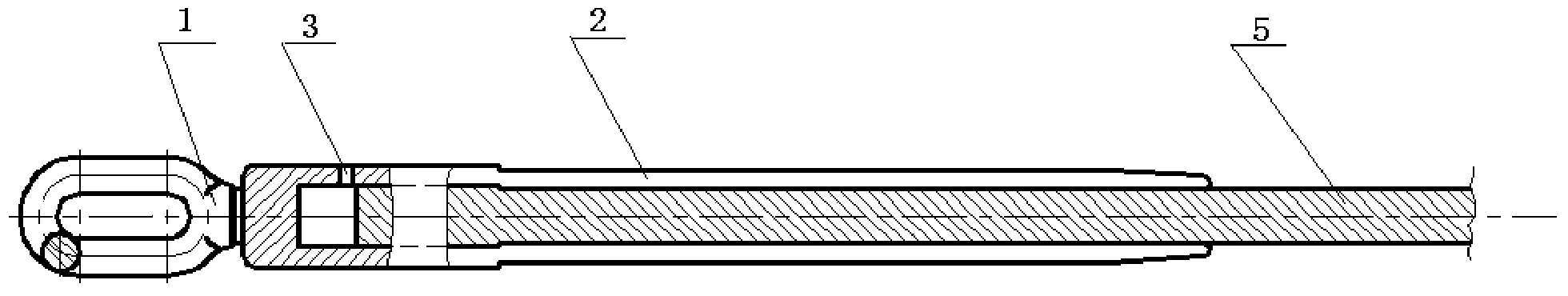

Forging integrated type oiling strain clamp for aluminum alloy stranded wire

InactiveCN104348123AAffect normal operationGuaranteed StrengthAdjusting/maintaining mechanical tensionEngineeringUltimate tensile strength

The invention provides a forging integrated type oiling strain clamp for an aluminum alloy stranded wire. A strain clamp is arranged on an overhead transmission line terminal and is used for anchoring a wire and keeping the electric and mechanical properties of the wire; the strain clamp is characterized in that the strain clamp comprises a pull ring, a connecting pipe and a drainage wire clamp; the connecting pipe and the pull ring are integrally formed along an axial direction; a fixing component and a pulling pin are respectively arranged on the inner wall and the outer wall at one end of the connecting pipe; an oiling hole is arranged in the side wall of the connecting pipe at a joint of the connecting pipe and the pull ring. Compared with the prior art, the forging integrated type oiling strain clamp for the aluminum alloy stranded wire provided by the invention has the advantages that the strain clamp is prevented from being damaged by inner frozen accumulated water, the strength of the strain clamp is increased, the holding capability of the strain clamp for the wire is increased, and a mature crimping technique is adopted so that the crimping quality is excellently ensured.

Owner:STATE GRID CORP OF CHINA +1

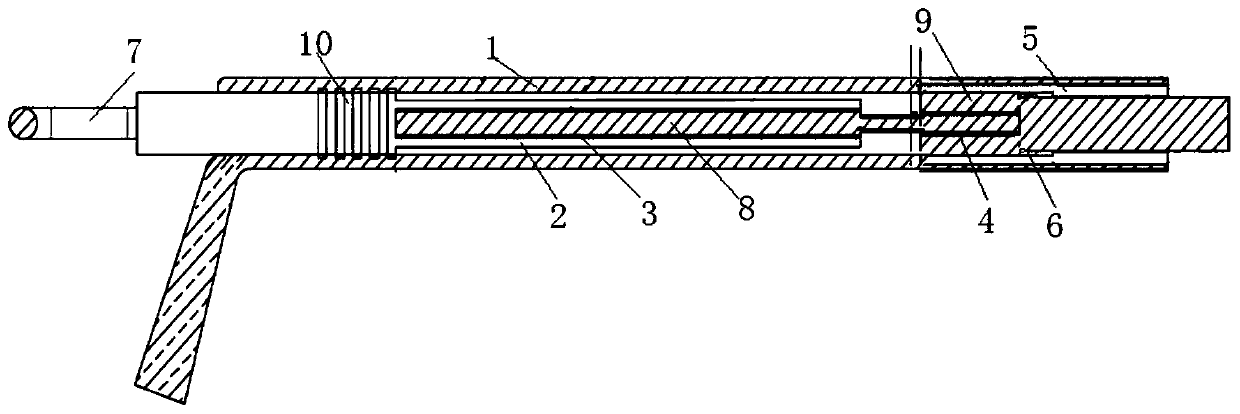

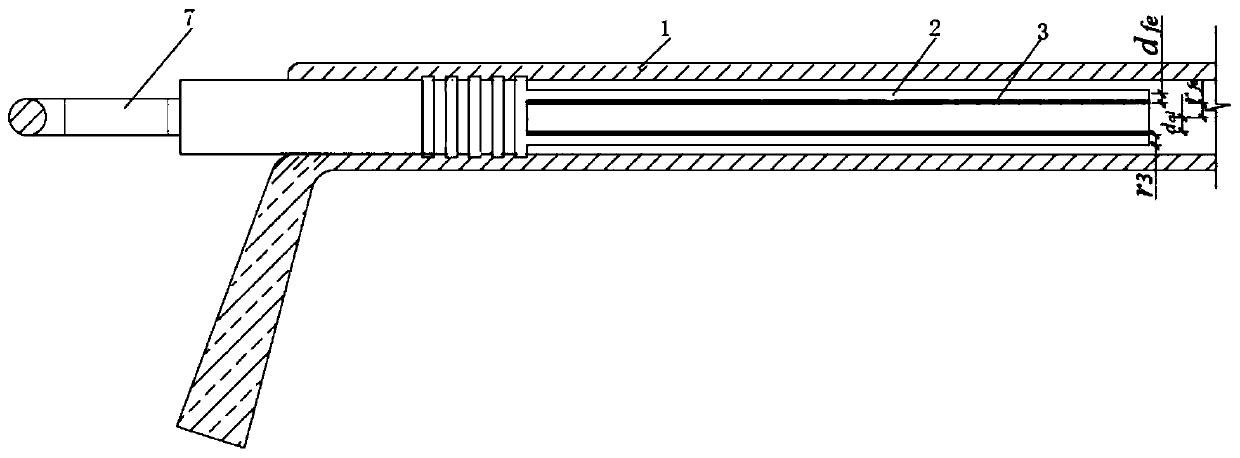

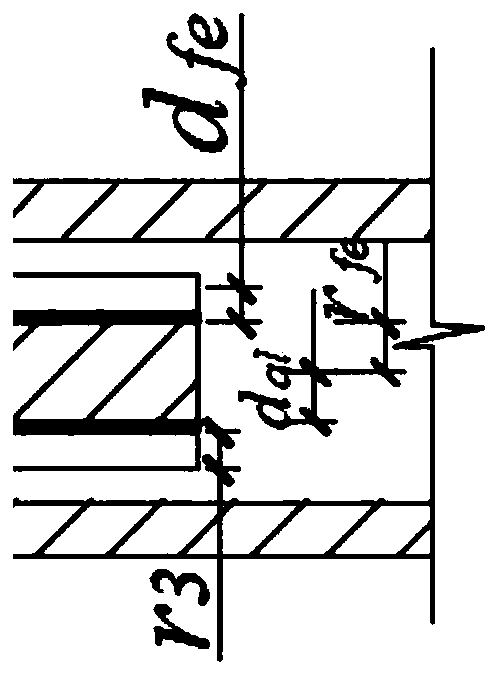

Wire crimping device and wire crimping method

ActiveCN113258399AEasy crimpingLower performance requirementsConnection formation by deformationHydraulic cylinderMachine

The invention provides a wire crimping device and a wire crimping method. The device comprises a supporting main body, a mold cover, a mold, an eddy current heating bent plate, a hydraulic cylinder and a hanging beam, the hydraulic cylinder on the supporting main body controls the mold to be closed and separated so as to realize crimping of a to-be-crimped wire, the eddy current heating bent plate heats the to-be-crimped wire, and the to-be-crimped wire is heated by the hanging beam so as to make the heated wire convenient to crimp, and the performance requirement of a hydraulic machine can be reduced; and the hydraulic mode is simple, the crimping quality is better, the to-be-crimped wire is fixed through the threaded connecting rod and the locking buckle which are connected through the hanging beam, the crimping error caused by position dislocation of the to-be-crimped wire and the mold is reduced, and the crimping quality is improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

19-twisted steel strand aluminum embedding strain clamp crimping method

InactiveCN110380308AMeet grip requirementsImprove crimp qualityLine/current collector detailsConnections effected by permanent deformationStatic friction coefficientNon destructive

The invention discloses a 19-twisted steel strand aluminum embedding strain clamp crimping method. The method comprises steps that 1), an aluminum embedding pipe is embedded into a steel anchor crimping pipe; 2), steel strands are inserted from one end of the aluminum embedding pipe, and steel strands are inserted into the bottom of a clamp anchor ring; 3), a crimping die is utilized to crimp thesteel anchor crimping pipe, the aluminum embedding pipe is tightly engaged with a surface of the steel strands, gaps between a steel anchor and the steel strands are further filled to form a steel strand strain joint. The method is advantaged in that the aluminum embedding pipe is added between the steel anchor crimping pipe and the circular concentric stranded overhead 19-stranded steel strands,high plasticity and a high static friction coefficient of the aluminum embedding pipe are utilized, the 19-stranded steel strands and the strain clamp are prevented from being crushed, under-pressuredand strand-loosen during crimping of the steel anchor crimping pipe and the 19-stranded steel strands, moreover, gripping requirements of the joint are further met, 19-stranded steel strand docking and crimping are easy to implement, the crimping quality is higher, the crimping joint can be free of non-destructive testing, and labor intensity and engineering cost are reduced.

Owner:GUIZHOU POWER GRID CO LTD

Steel core aluminum stranded wire aluminum embedded tensile wire clamp structure

PendingCN110416951ACrimping easyImprove crimp qualityAdjusting/maintaining mechanical tensionAluminiumNon destructive

The invention discloses a steel core aluminum stranded wire aluminum embedded tensile wire clamp structure which comprises a casing wire clamp, a steel anchor crimped pipe, a steel core aluminum embedded pipe, an internal embedded layer aluminum pipe, an external embedded layer aluminum pipe and a wire shaping ring. The steel core aluminum embedded pipe is placed between a steel stranded wire of asteel core aluminum stranded wire crimping end and the steel anchor crimping pipe. The internal embedded layer aluminum pipe is placed between a steel stranded wire of a crimping end steel core aluminum stranded wire and an internal aluminum stranded wire layer, the crimping end steel core aluminum stranded wire is sleeved in the external embedded layer aluminum pipe, and the a sleeve hole of thecasing wire clamp sleeves the external embedded layer aluminum pipe on the steel core aluminum stranded wire and the steel anchor crimped pipe. According to the invention, the crushing damage, underpressure and loose strand of the steel core aluminum stranded wire are avoided, the manufacture is easy, the crimping quality is high, the non-destructive detection is avoided, and the labor intensityand engineering cost are reduced.

Owner:GUIZHOU POWER GRID CO LTD

Aluminum cable steel reinforced press-connecting device for electric wire construction and using method thereof

ActiveCN103618191AHigh temperature resistance hasHigh temperature and corrosion resistance withLine/current collector detailsEngineeringElectric power

The invention discloses an aluminum cable steel reinforced press-connecting device for electric wire construction and a using method thereof. The aluminum cable steel reinforced press-connecting device comprises a cable core clamping block, a left clamping cover and a right clamping cover hinged to one end of the left clamping cover. The cable core clamping block comprises a left clamping block body and a right clamping block body. The left clamping block body and the right clamping block body are matched with clamping grooves formed in the left clamping cover and the right clamping cover respectively. Locking bolts are arranged in the clamping grooves, and the inner arc diameter after the left clamping block body and the right clamping block body are combined is matched with the specification of a cable core. The left clamping cover and the right clamping cover are respectively provided with an operation rod. The operation rods are connected through clamping tooth mechanisms arranged on the operation rods. The aluminum cable steel reinforced press-connecting device saves time and labor, when the aluminum cable steel reinforced press-connecting device is used for aluminum cable steel reinforced with the diameter more than 20mm, after wires are scattered, tension force is large, only the operation rods need to be pressed, the operation rods are locked in proper positions and move towards the scattered end, operation saves time and labor, is convenient and quick, and work efficiency is high.

Owner:STATE GRID CORP OF CHINA +1

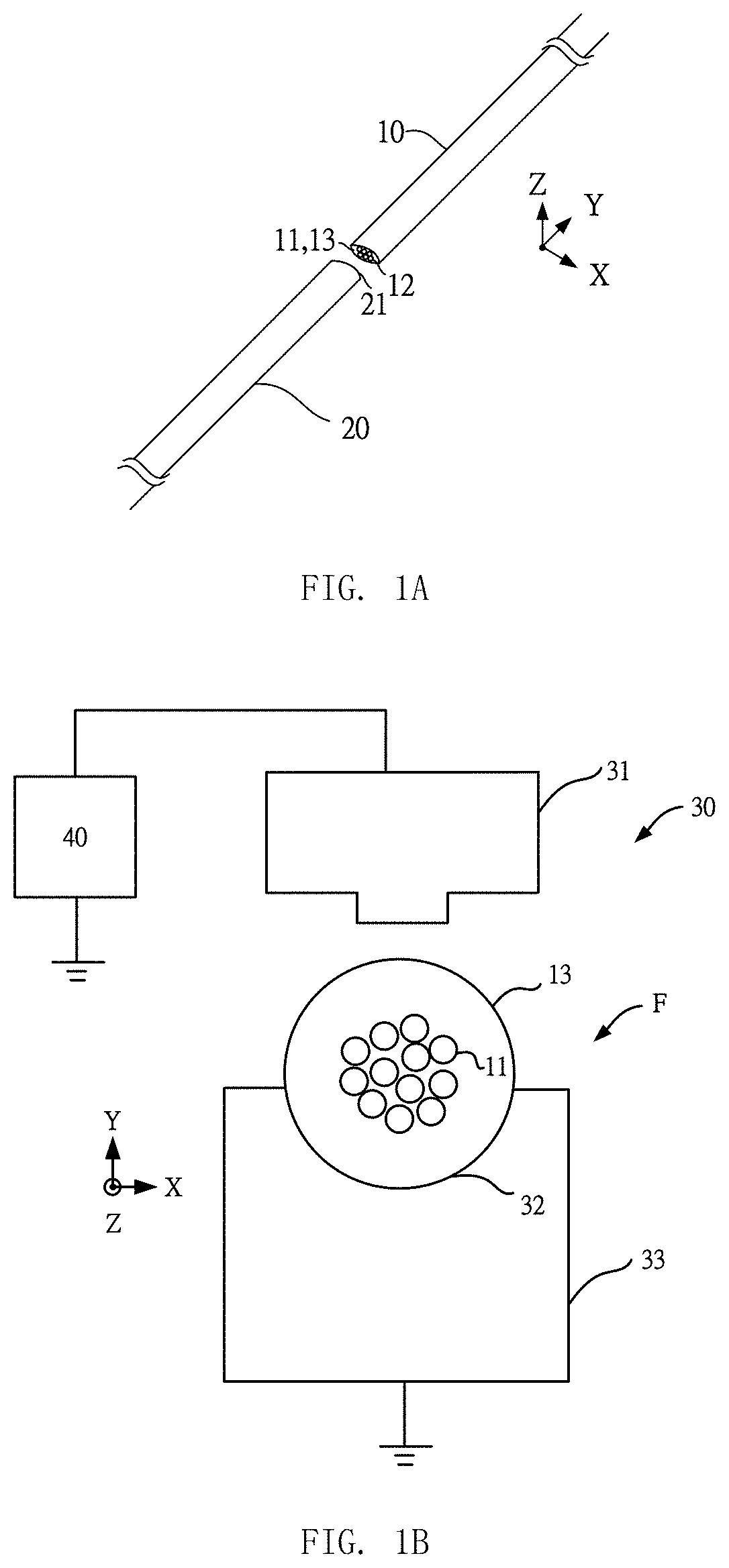

An inductive thermo-crimping apparatus

ActiveUS20200353693A1Increase capacityLow costLine/current collector detailsElectrically conductive connectionsEngineeringMechanical engineering

An inductive thermo-crimping apparatus is provided, which is provided for crimping a crimping body which is formed by the contact of the connecting body and the to-be-joined member. The inductive thermo-crimping apparatus includes a driving part, a stamper part, and a heating part, the driving part is connected to the stamper part, and the heating part is fixedly connected to the driving part. After the heating part is activated, the crimping body is disposed on the heating part. The heating part includes an inductive heating coil. The inductive heating coil surrounds in the heating part. The inductive heating coil is provided for heating the crimping body to soften the crimping body, in which the driving part is provided for driving the stamper part to press the soften crimping body, so that the connecting body and the to-be-joined member is crimped and to form a rigid crimping body after cooling. The present invention utilizes the coil with an alternative current to heat the crimping body by an electromagnetic induction, so that the process of the crimping technology is convenient and fast.

Owner:SHANGHAI JOULEAD ELECTRIC CO LTD

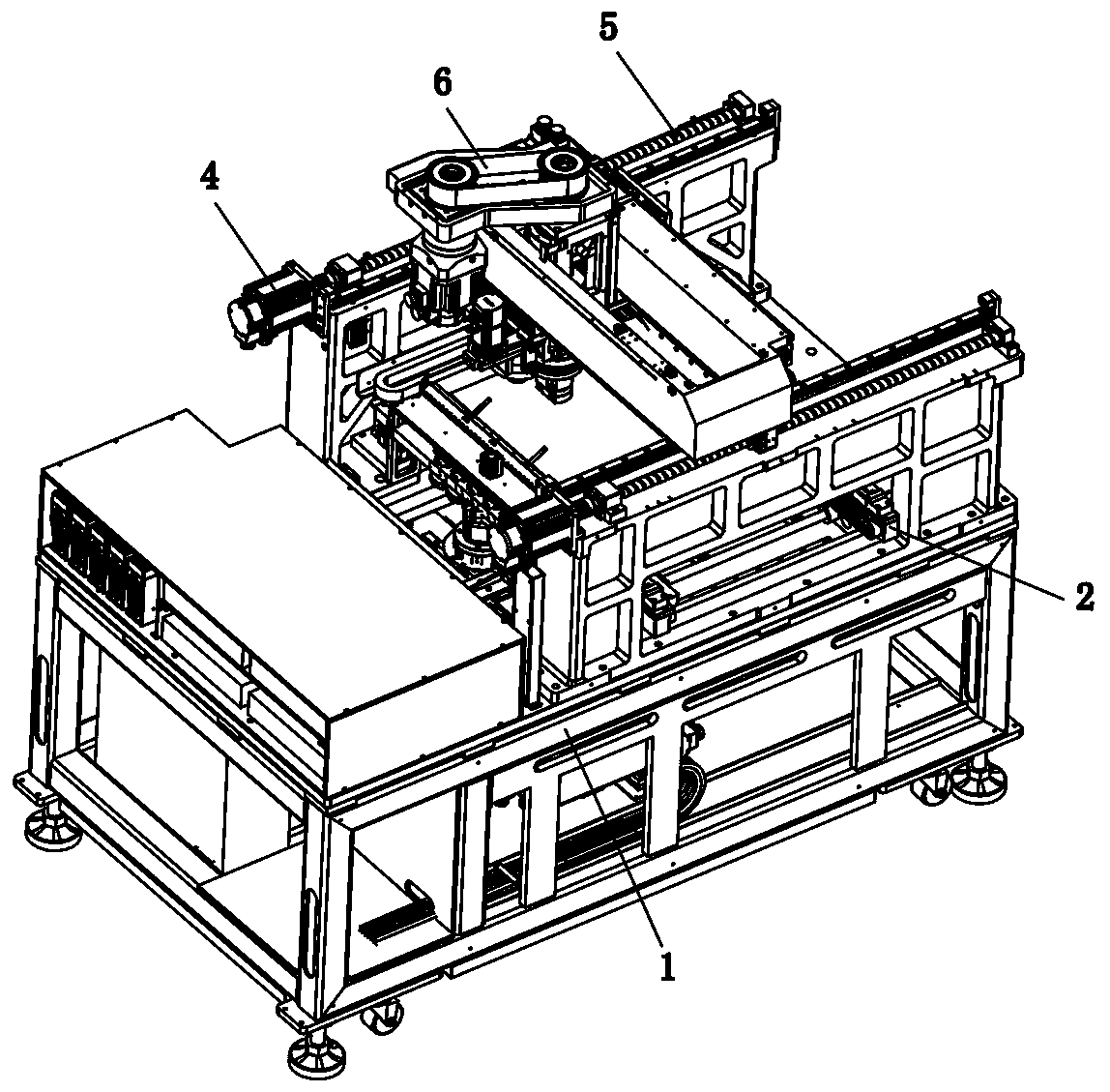

A fully automatic terminal crimping device for easy cable positioning

ActiveCN110829138BImprove crimp qualityPrecise positioningLine/current collector detailsEngineeringMechanical engineering

The invention discloses a fully automated terminal crimping device that facilitates cable positioning, including an upper die crimping mechanism, a cable positioning mechanism, an ejection mechanism, a terminal pushing slider mechanism and a terminal clamping mechanism. The terminal pushing slider mechanism It is arranged directly below the upper die crimping mechanism. The terminal pushing slider mechanism is provided with a lower die base. The terminal clamping mechanism and the ejection mechanism are respectively arranged on the left and right sides of the lower die base. The lower die base A cable positioning mechanism is provided at the front and rear ends respectively; the present invention uses multiple mechanisms to cooperate with each other in a coordinated and orderly manner to complete the crimping function, improve the crimping efficiency and automation level, and uses the clamping claw assembly in the cable positioning mechanism to complete the wire connection. The cable positioning is accurate, and the terminal clamping mechanism is used to improve the terminal crimping quality. It has a simple structure, is easy to use, has a long service life, is safe and reliable, and is suitable for large, medium and small cable production companies. It can also apply terminals for many types of cable products. Crimp.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +1

Pre-pressing and crimping machine

PendingCN110676671AImprove general performanceReduce kneelingContact member assembly/disassemblyStructural engineeringElectronic component

The invention discloses a pre-pressing and crimping machine which comprises a feeding mechanism, an upper pressing mechanism, a lower pressing mechanism and pressing head replacement bases. The feeding mechanism is arranged on one side of a frame. Electronic components to be assembled on a PCB are stored centrally in the feeding mechanism in a layered way. The upper pressing mechanism is arrangedacross the upper part of the transmission mechanism. The upper part and the lower part of the pressing base of the upper pressing mechanism are arranged at intervals and connected through a supportingsphere. The lower part of the pressing base is detachably connected with a first pressing head. The first press head is sucked upward by the pressing base and clamped and fixed from the two sides. The first pressing head pre-presses and / or crimps the electronic components inserted on the PCB from the upper part. The lower pressing mechanism is arranged below the transmission mechanism. There areat least two sets of pressing head replacement bases are arranged at the side part of the transmission mechanism. A large amount of automatic storage and automatic feeding of connectors can be realized, and the planes are automatically adapted and mutually bonded in parallel during crimping so that the condition of kneeling pins can be effectively reduced, the crimping quality can be improved, and the machine has the pressing head replacement function and high universality.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Automatic cable crimping device

PendingCN111711045ARealize crimpingImprove crimping efficiencyLine/current collector detailsEngineeringElectric cables

Owner:CHINA TOBACCO HENAN IND

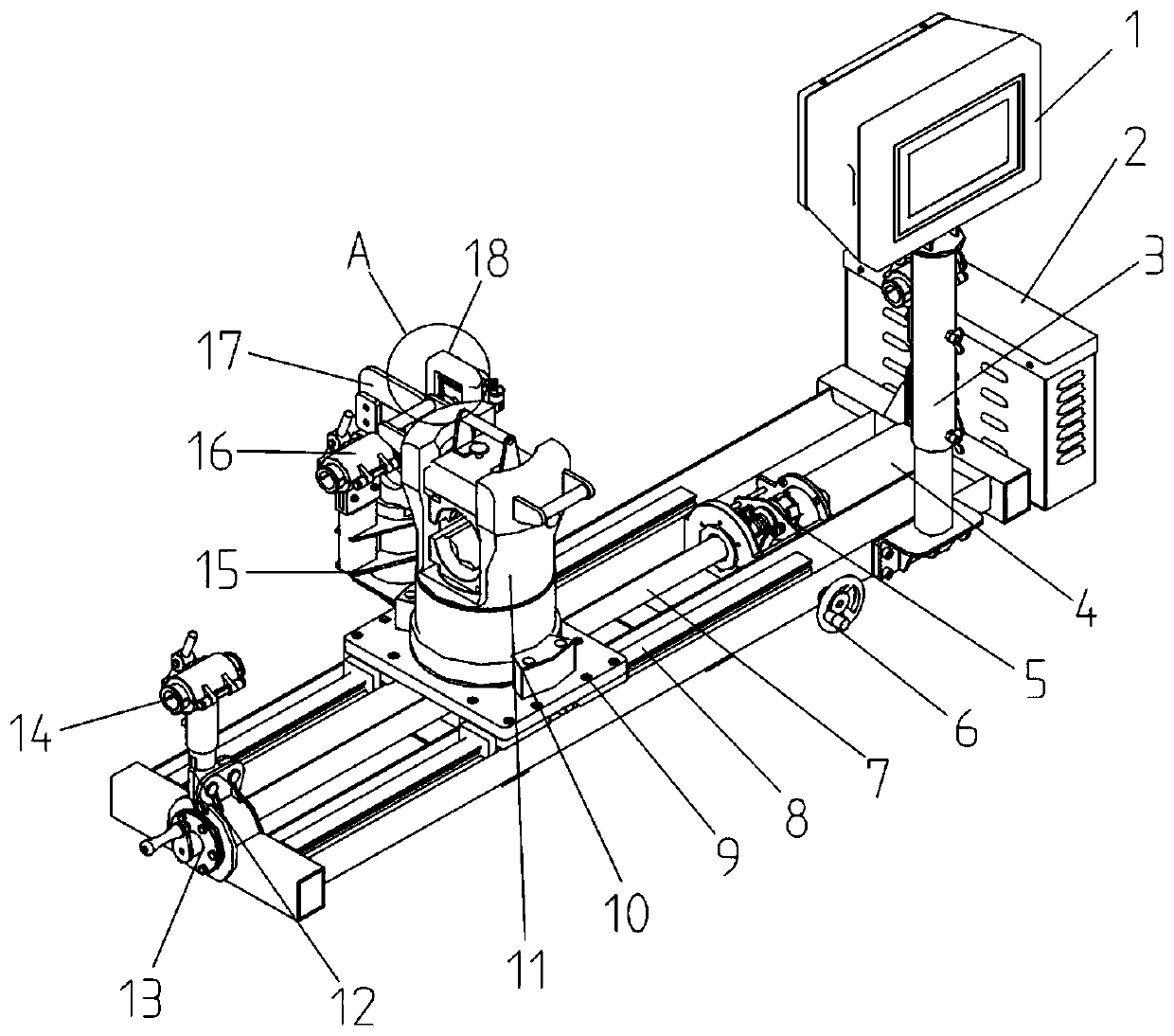

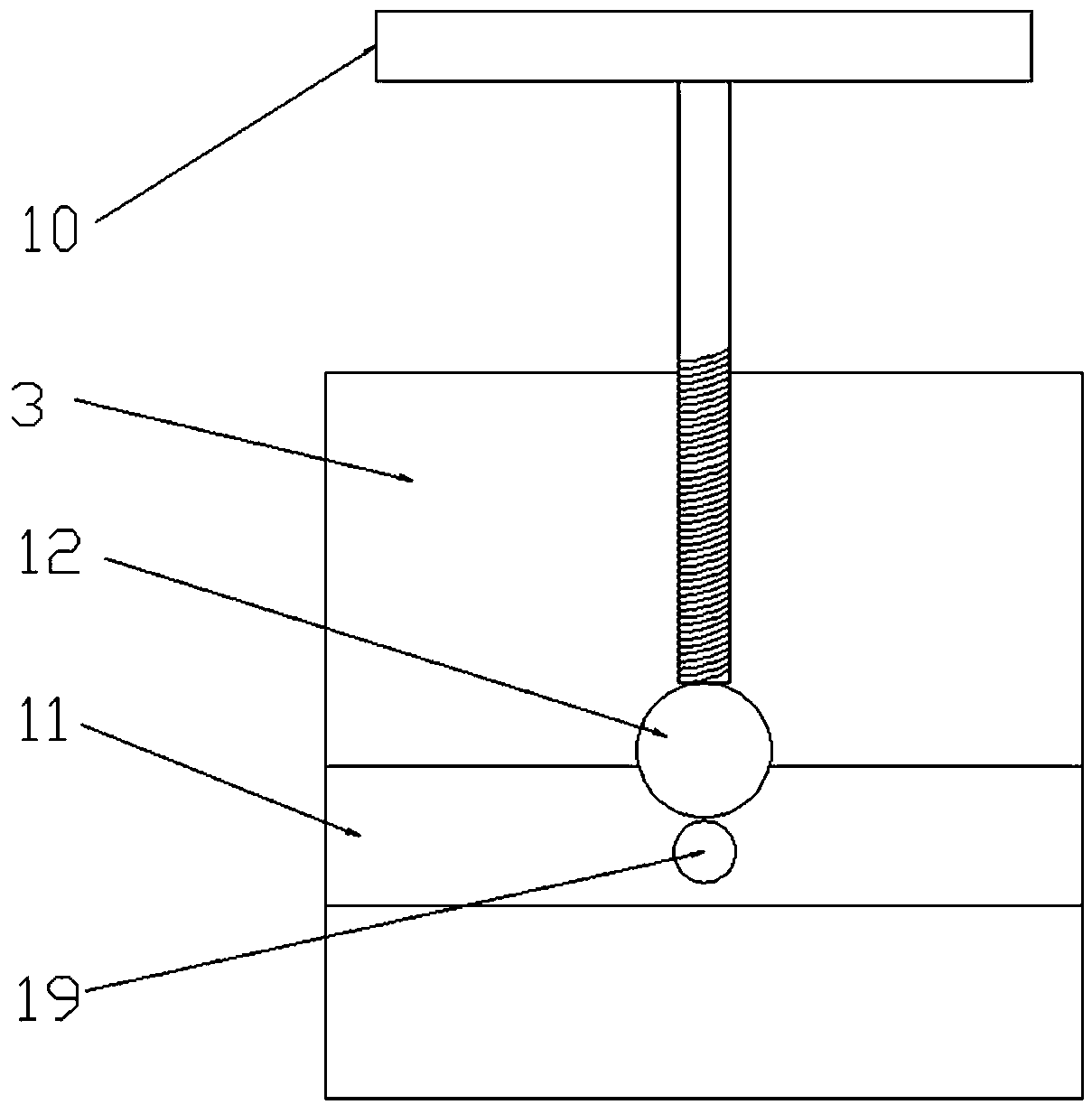

Ground wire crimping correction and pressure detection control device

ActiveCN111262111AImprove securityReal-time monitoring of crimp strengthLine/current collector detailsEngineeringMechanical engineering

The invention discloses a ground wire crimping correction and pressure detection control device. The device comprises a crimping platform (1); a transmission wheel (2), a positioning device (3), a crimping device (4) and a pressure monitoring and alarming device are fixedly arranged on the crimping platform (1); the transmission wheel (2), the positioning device (3) and the crimping device (4) arehorizontally arranged in sequence; the pressure monitoring and alarming device comprises a pressure sensor, a control device, a display screen (5) and an alarming device (6); the crimping device (4)is connected with the pressure sensor; the pressure sensor is connected with the control device; and the control device is respectively connected with the display screen (5) and the alarming device (6). The problems that the construction time is long, and repeated crimping correction is needed are solved, the crimping process of the ground wire is standardized through the crimping integrated device, and the crimping quality is ensured.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com