Pre-pressing and crimping machine

A crimping machine and pre-pressing technology, applied in the field of automation, can solve the problems of kneeling pins, defective products, and high precision requirements for connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

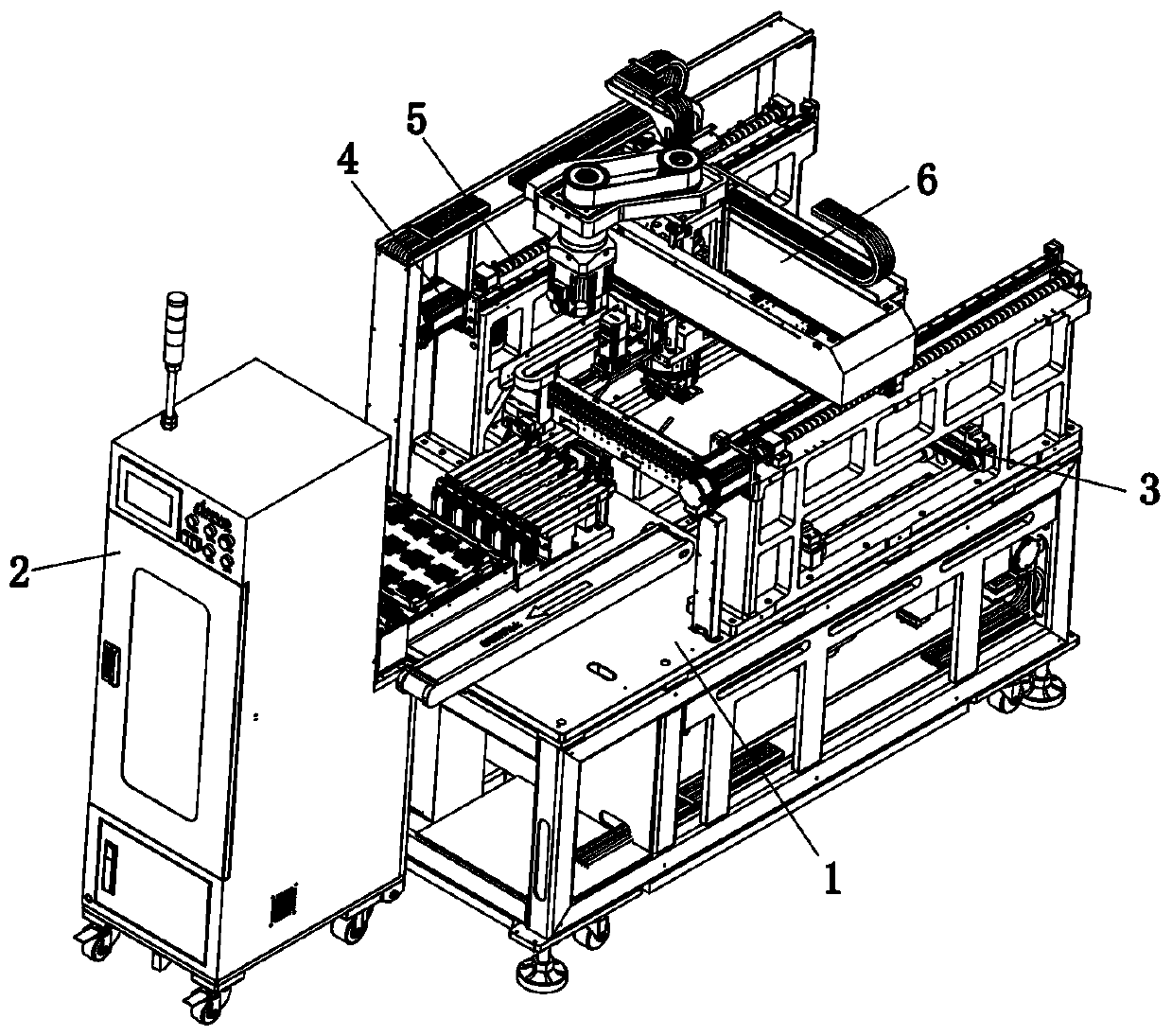

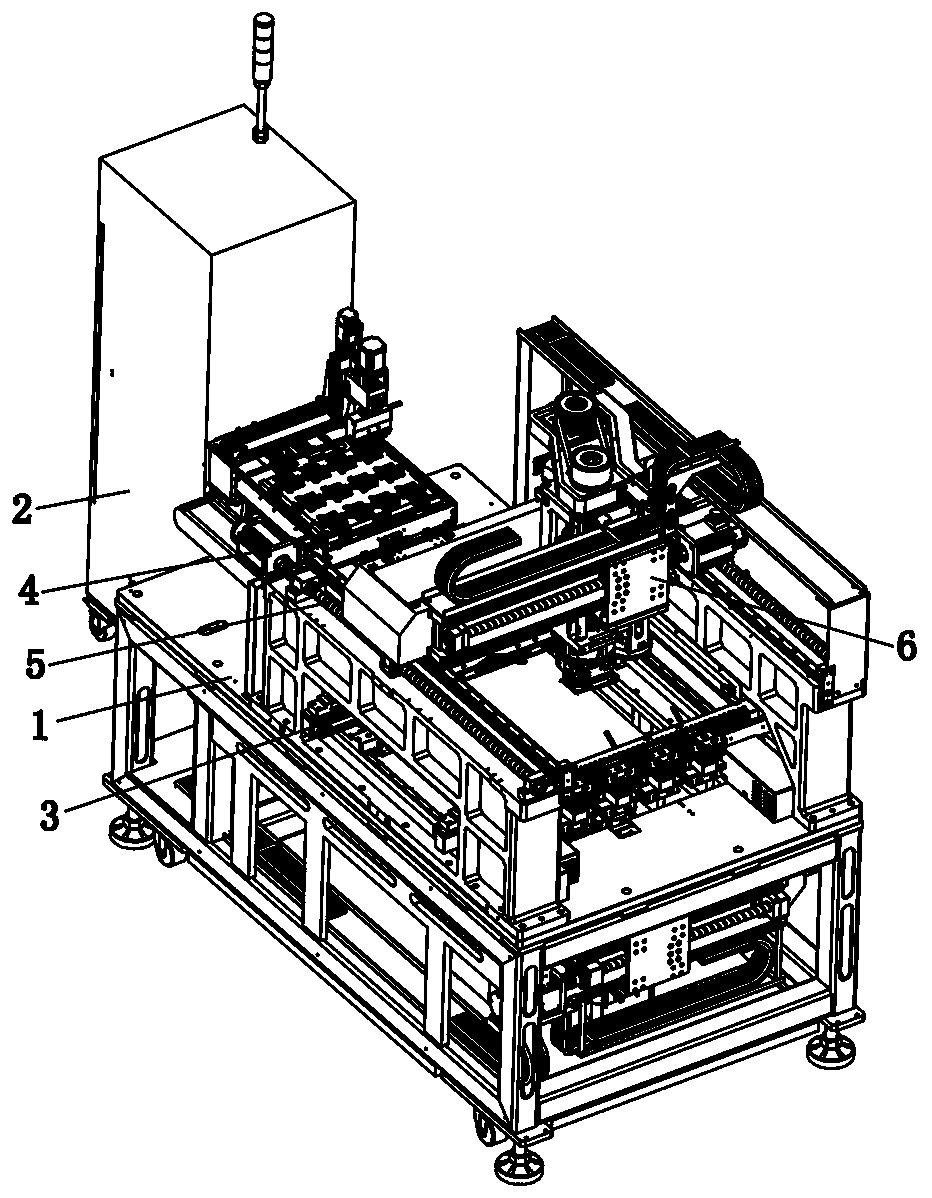

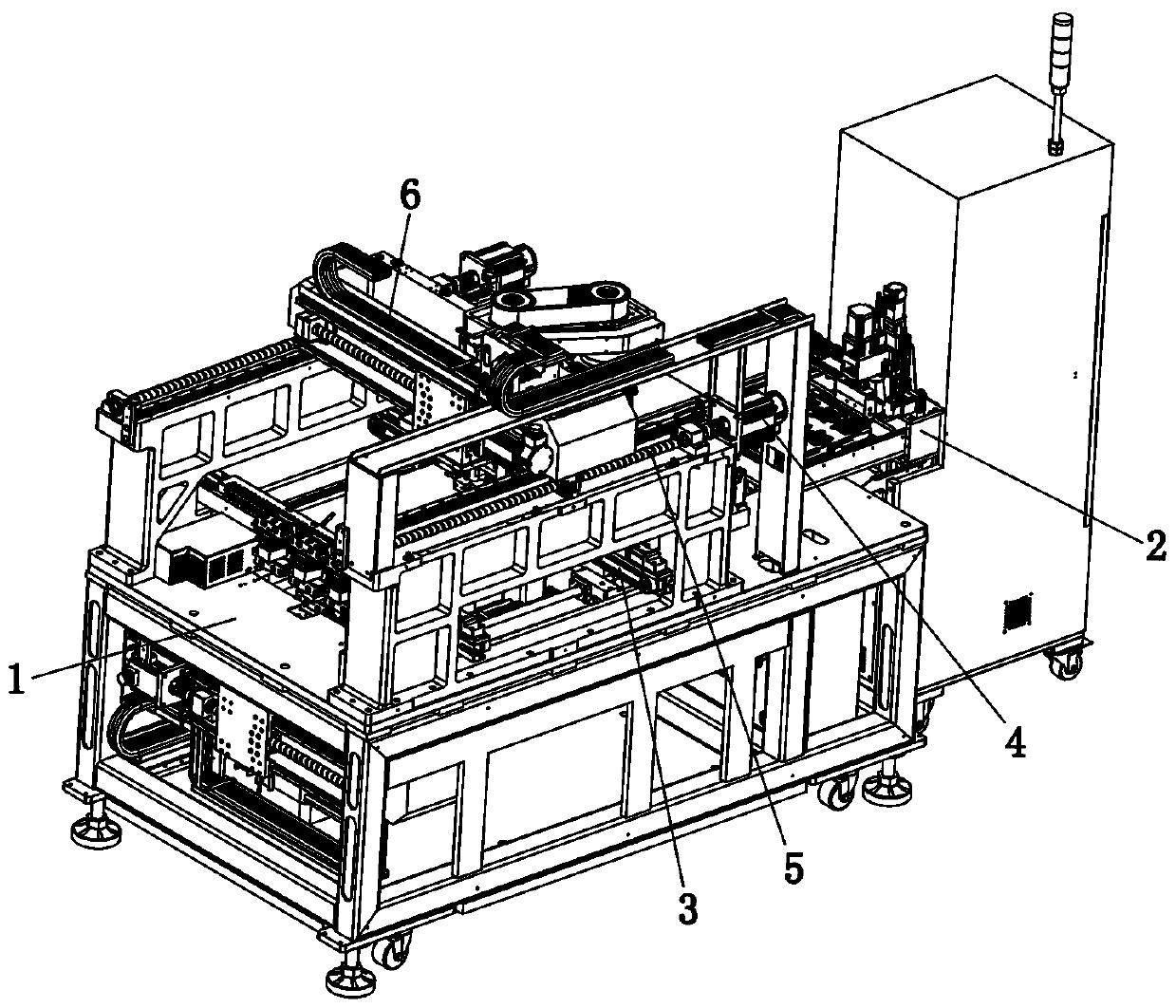

[0051] The present invention will be further described below in conjunction with accompanying drawing:

[0052] like Figure 1 to Figure 25 As shown, the technical scheme adopted by the present invention is as follows: a pre-pressing and crimping machine, including a frame 1 and a transmission mechanism 3 arranged on the frame 1, the two ends of the transmission mechanism 3 and the transmission of equipment located in the front and rear processes Mechanisms are connected, and a transmission space is formed between the transmission mechanisms. The PCB board to be processed is placed in the transmission space and transported straight forward, including the feeding mechanism 2, the upper pressing mechanism 6, the lower pressing mechanism 7 and the pressure head replacement seat 8 , wherein, the above-mentioned feeding mechanism 2 is arranged on one side of the frame 1, and the electronic components O to be assembled on the PCB board are stored in layers in the feeding mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com