Butt-joint aluminum-embedded crimping structure and method for overhead conductor seven-stranded steel wire

A technology for overhead conductors and steel strands, which is applied in the direction of connection, connection, line/collector components and other directions by deformation, and can solve problems such as overvoltage, unreasonable size of crimping die, and undervoltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

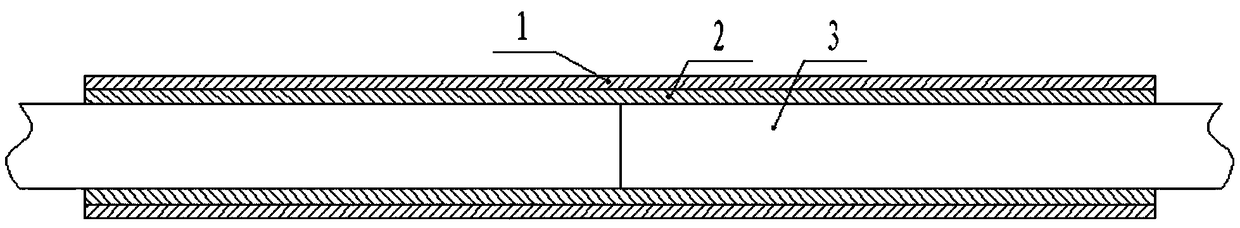

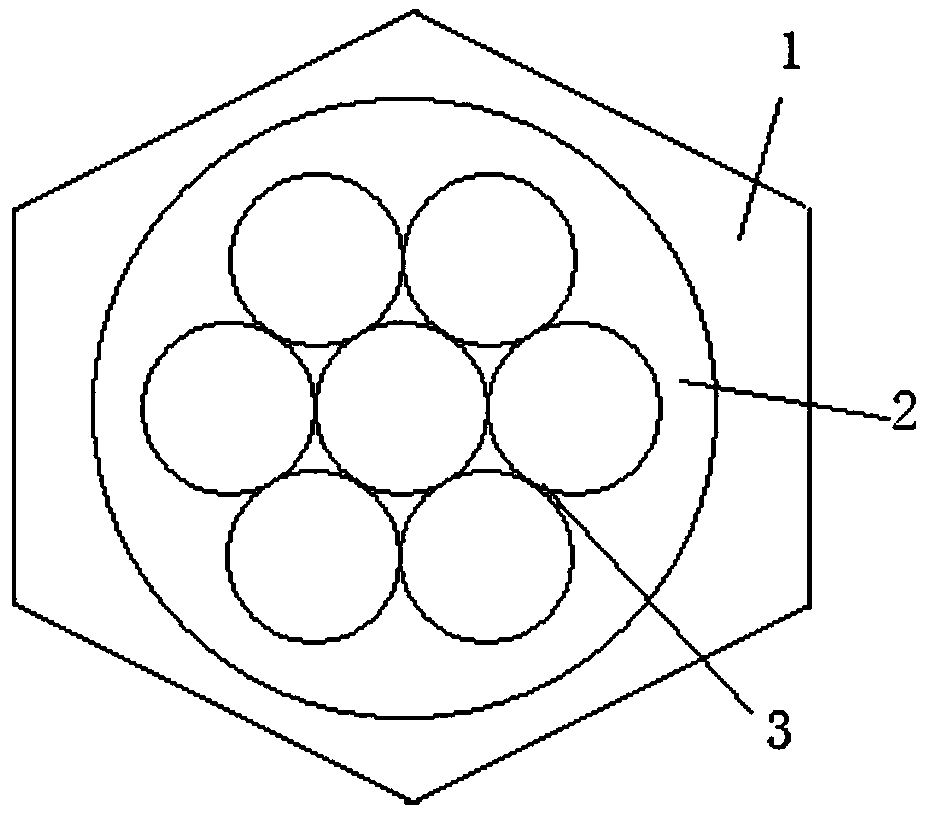

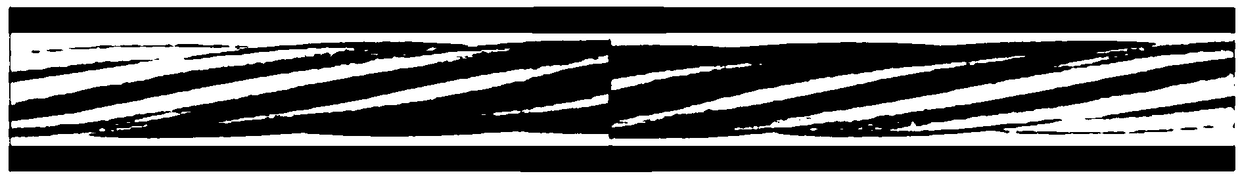

[0127] Embodiment 1: as Figure 1-Figure 5 As shown in the figure, an overhead conductor with 7 twisted steel strands butt joint aluminum embedded crimping structure, including steel pipe 1 and aluminum alloy pipe 2, the aluminum alloy pipe 2 is embedded in the steel pipe 1, and wraps two butt-connected round wire concentric stranded overhead conductors 7 twisted steel strands 3 are crimped to the steel pipe 1 so that the aluminum alloy tube 2 closely fits the round wire concentric strand overhead conductor and the 7 twisted steel strands 3 form a steel core connecting pipe.

[0128] The steel pipe 1 and the aluminum alloy pipe 2 have the same length, and both have a pitch of two steel core strands.

Embodiment 2

[0129] Embodiment 2: A crimping method for butt jointing of 7 stranded steel strands of overhead conductors to an aluminum-embedded crimping structure, the method comprising the following steps:

[0130] 1) Embedding the aluminum alloy tube into the steel tube;

[0131] 2) Insert the 7 stranded steel strands of the two butt-connected round wire concentric stranded overhead conductors from both ends of the aluminum alloy tube to ensure that the insertion depth of the 7 stranded steel strands of the two round concentric stranded overhead conductors is equal;

[0132] 3) The steel pipe is crimped with a crimping die, so that the aluminum alloy tube closely fits the surface of the 7 stranded steel strands of the round concentric stranded overhead conductor and fills the gap between the steel pipe and the 7 stranded steel strands of the round concentric stranded overhead conductor to form a steel Core connection tube.

[0133] A new type of round wire concentric stranded overhead ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com