A crimping method for butt jointing of 19 stranded steel strands with embedded aluminum in overhead conductors

A technology for overhead conductors and steel strands, which is used in conductive connections, connections, circuit/collector parts, etc., and can solve problems such as unreasonable crimping die size, insufficient crimping pressure, and bites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

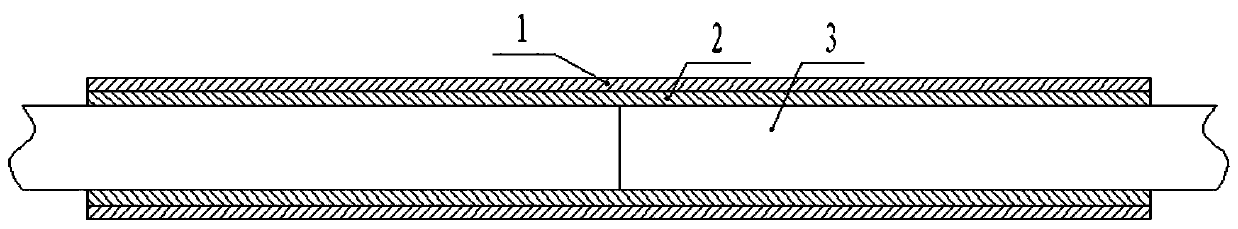

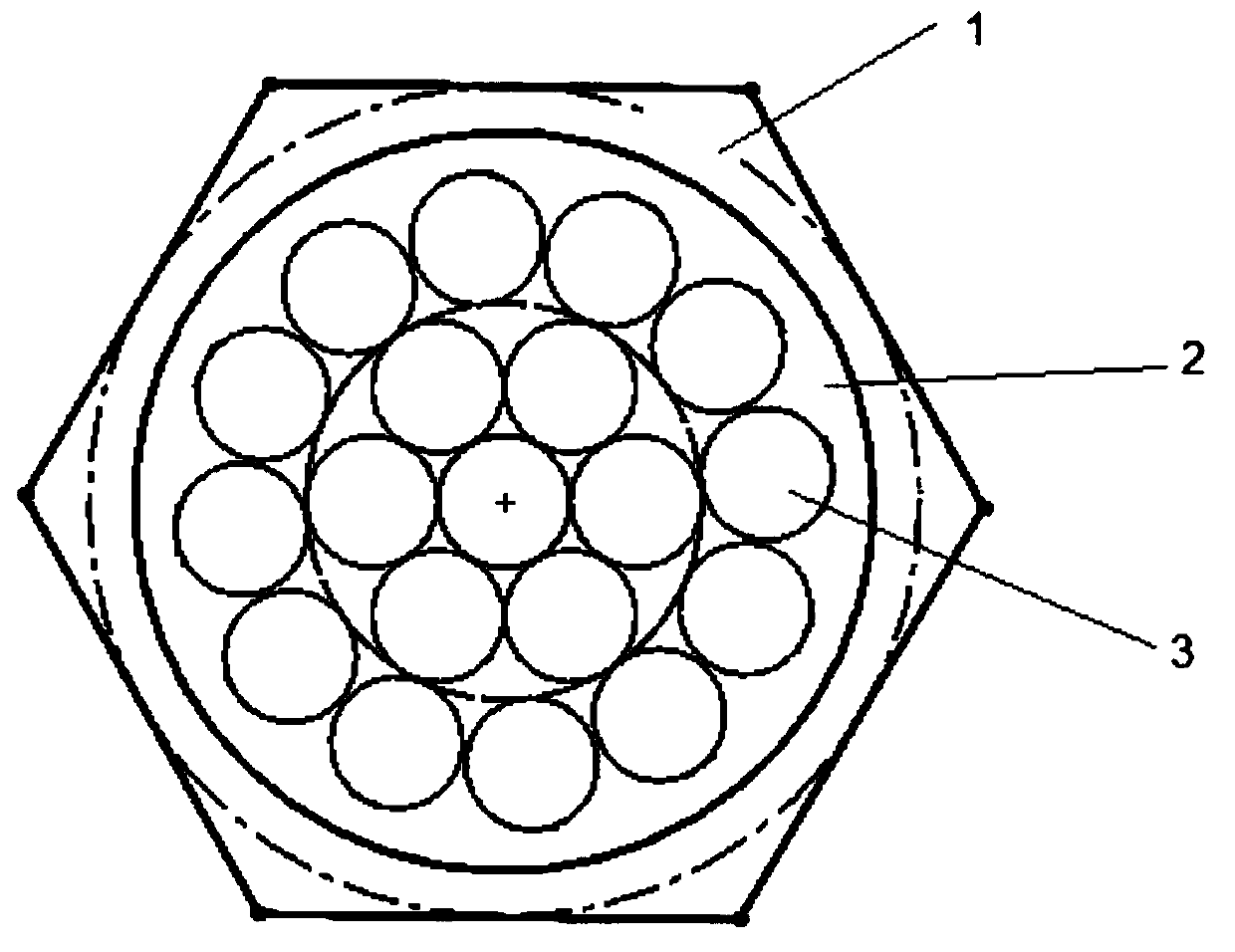

[0127] Embodiment 1: A method of butt jointing aluminum-embedded crimping of 19 stranded steel strands of overhead conductors, the method includes a butt-joint aluminum-embedded crimping structure, the structure includes a steel pipe 1 and an aluminum alloy pipe 2, and the aluminum alloy pipe 2 is embedded in the steel pipe 1 19 stranded steel strands 3 are wrapped in two butted round wire concentric stranded overhead conductors, and the steel pipe 1 is crimped so that the aluminum alloy tube 2 closely fits the round wire concentric stranded overhead conductors 19 stranded steel strands 3 to form a steel core connection Pipe, steel pipe 1 and aluminum alloy pipe 2 have the same length and are two pitches of steel core strands, the method includes the following steps:

[0128] 1) Embedding the aluminum alloy tube into the steel tube;

[0129] 2) Insert the 19 stranded steel strands of the two butt-connected round wire concentric stranded overhead conductors from both ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com