Horizontal stator buckle slab withholding equipment and method

A horizontal stator and buckle technology, which is used in the manufacture of stator/rotor bodies, etc., can solve the problems of complex procedures, low production efficiency, and high difficulty, and achieve the effects of simple procedures, improved production efficiency, and good crimping quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

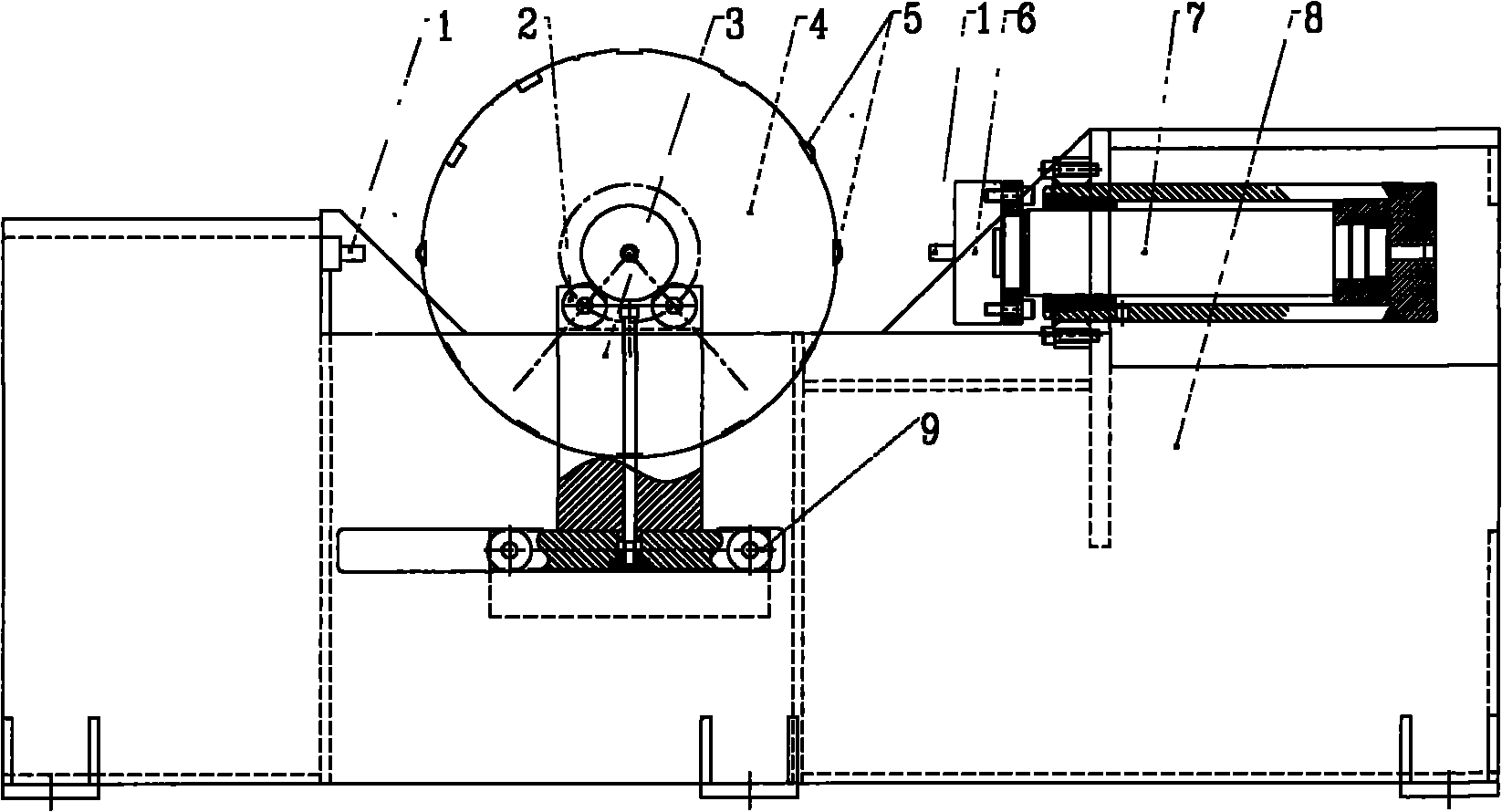

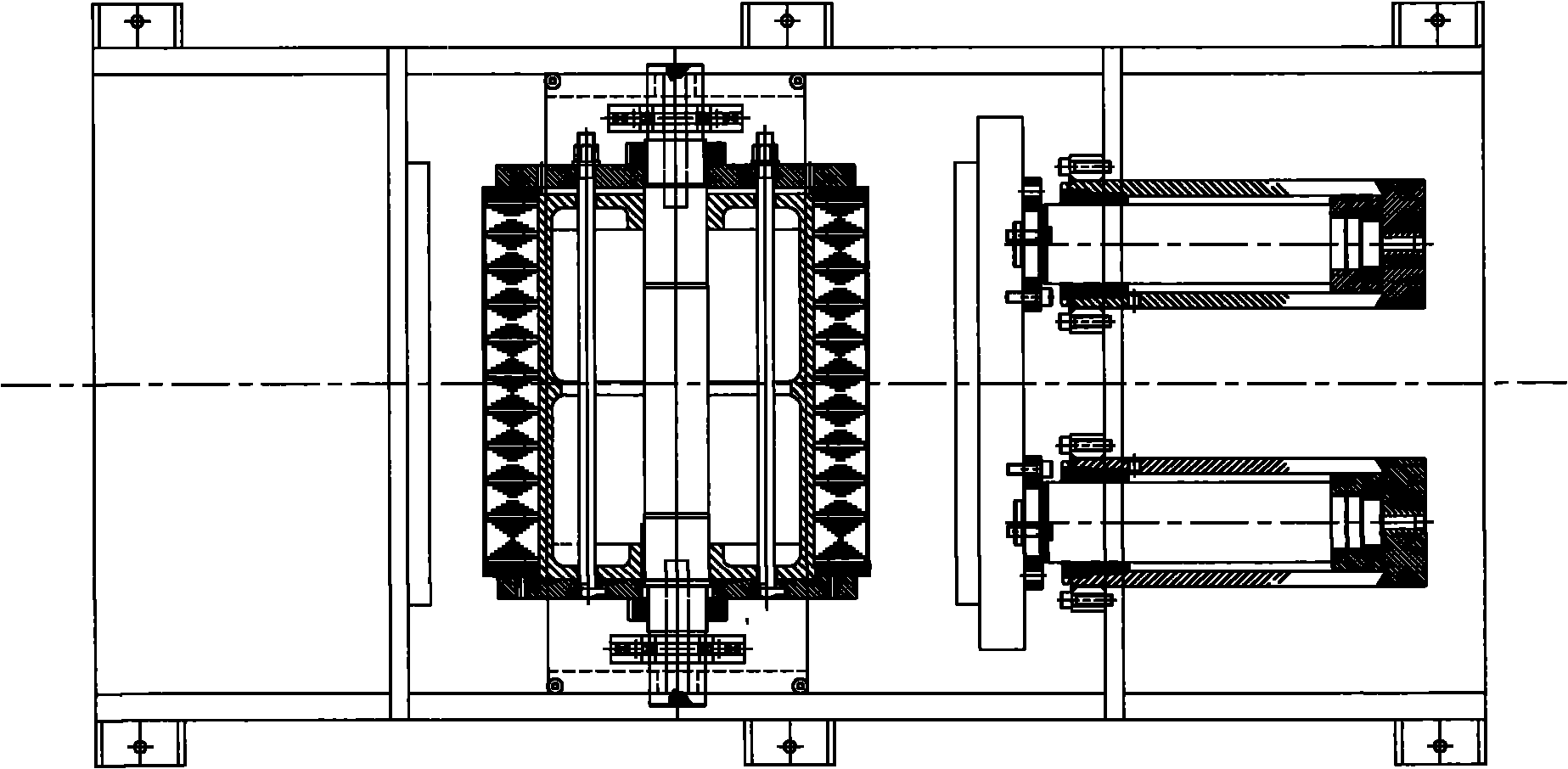

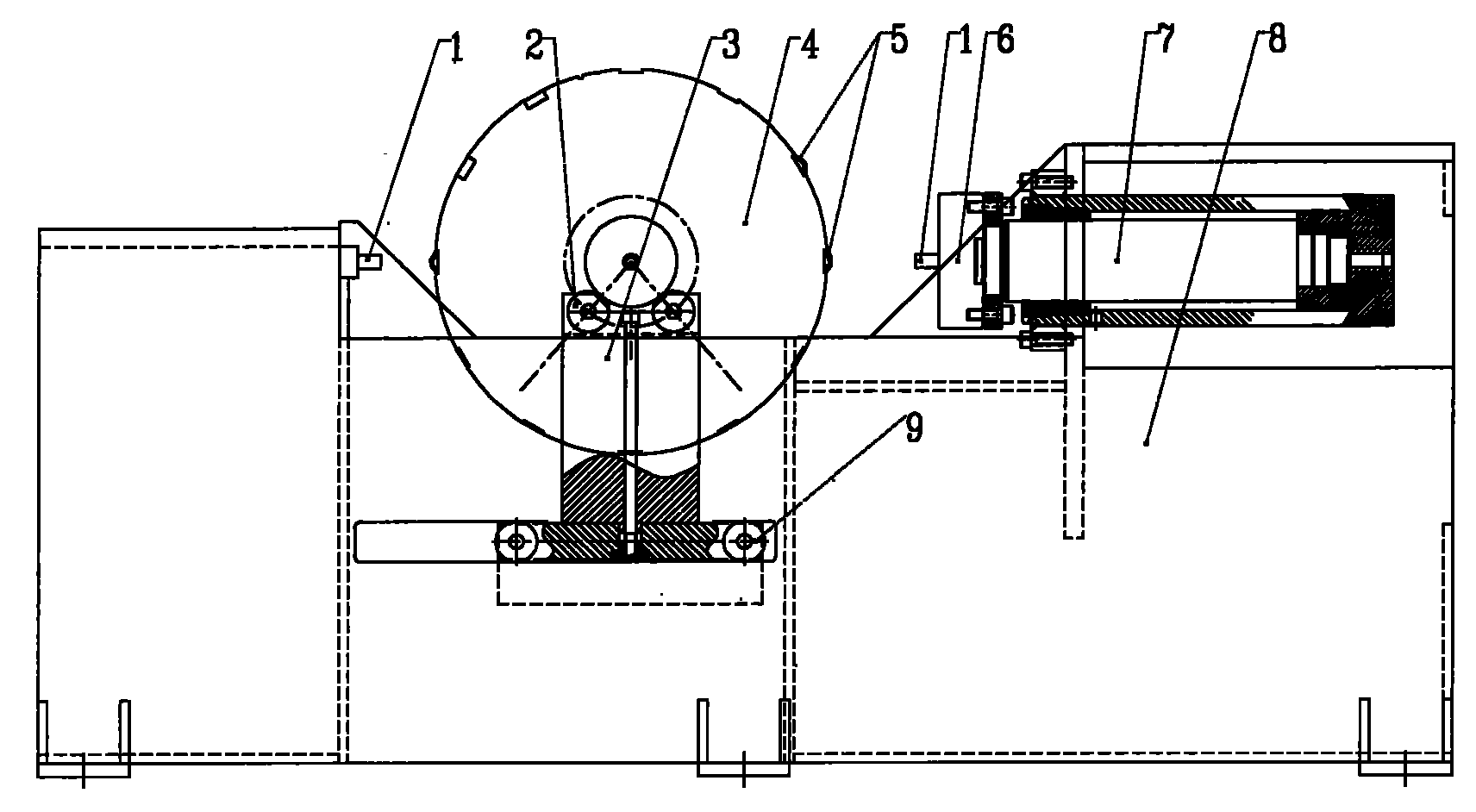

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. The special stator buckle pressing hydraulic machine of the present invention adopts two groups of horizontally placed 100-ton hydraulic cylinders, the hydraulic head is rigidly connected by a 120mm thick pressure head connecting plate 6, and the equipment is equipped with two groups of roller moving brackets 3, and the pre-installed stator assembly 4 Hang it on the rollers 2 of the two sets of mobile brackets, then place the two buckles 5 in two symmetrical grooves in the horizontal direction, and start the hydraulic press to press the buckle and the adjustable pressure head 1 against each other. The entire stator assembly 4 and the moving bracket 3 move to the left through the bracket moving roller 9, adjust the buckles on both sides of the stator to be at the same height, then start the hydraulic press to flatten the buckles, release the hydraulic press to return the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com