Crimping pipe bending automatic controller

A technology of automatic controller and crimping tube, applied in the direction of connection, circuit/collector parts, electrical components, etc., to achieve the effect of improving crimping quality, improving crimping efficiency and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

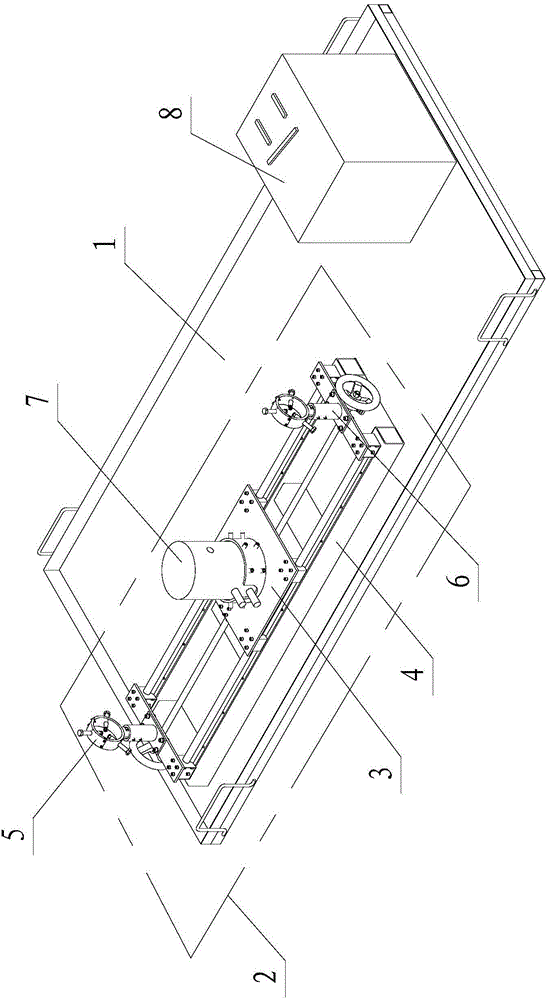

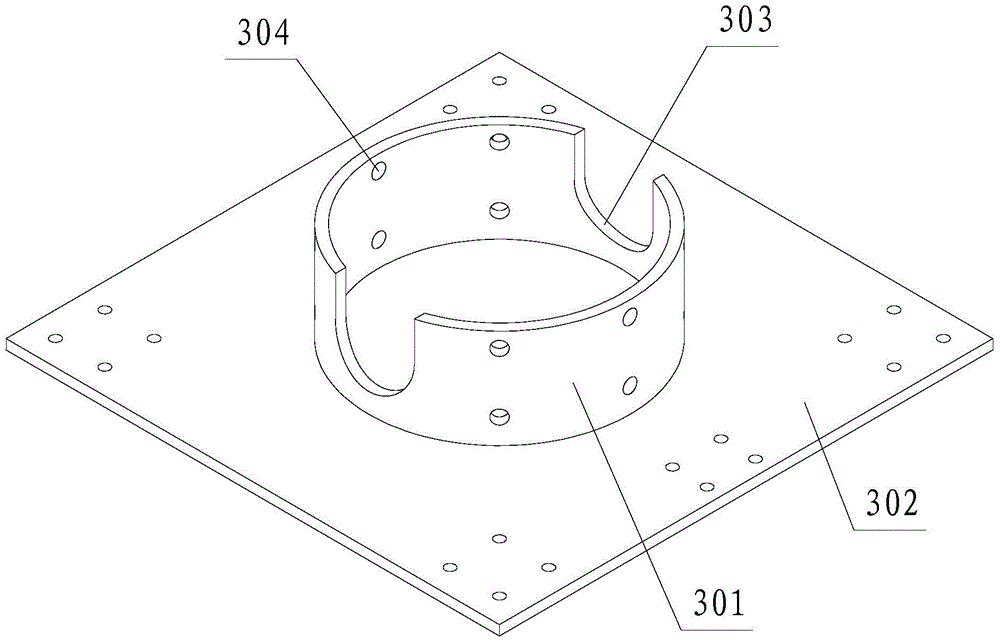

[0024] Such as figure 1 As shown, the present invention includes a base 1 and an anti-bending controller 2 installed on the base 1, wherein the anti-bending controller 2 includes a crimping machine bracket 3, a crimping machine moving platform 4, a wire fixing chuck 5 and a card head support6.

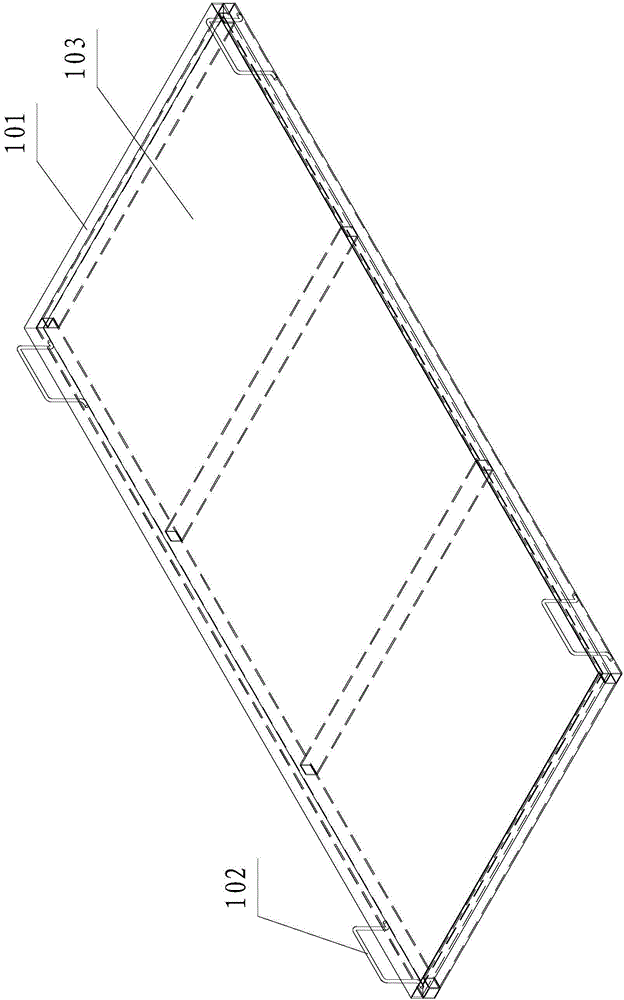

[0025] Such as figure 1 , figure 2 As shown, the base 1 of the present invention is rectangular and has a size of 1600 mm × 3300 mm. It is welded by a frame 101 with flanges, and a base plate 103 is laid in the center. Two handles 102 are respectively provided on both sides of the frame 101 in the length direction, which is convenient for manpower. Handling; the base 1 provides a stable and flat platform for wire crimping. Before crimping the wires, the power system 8 of the crimping machine and the anti-bending controller 2 should be reasonably arranged on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com