Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Implement cleanup operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

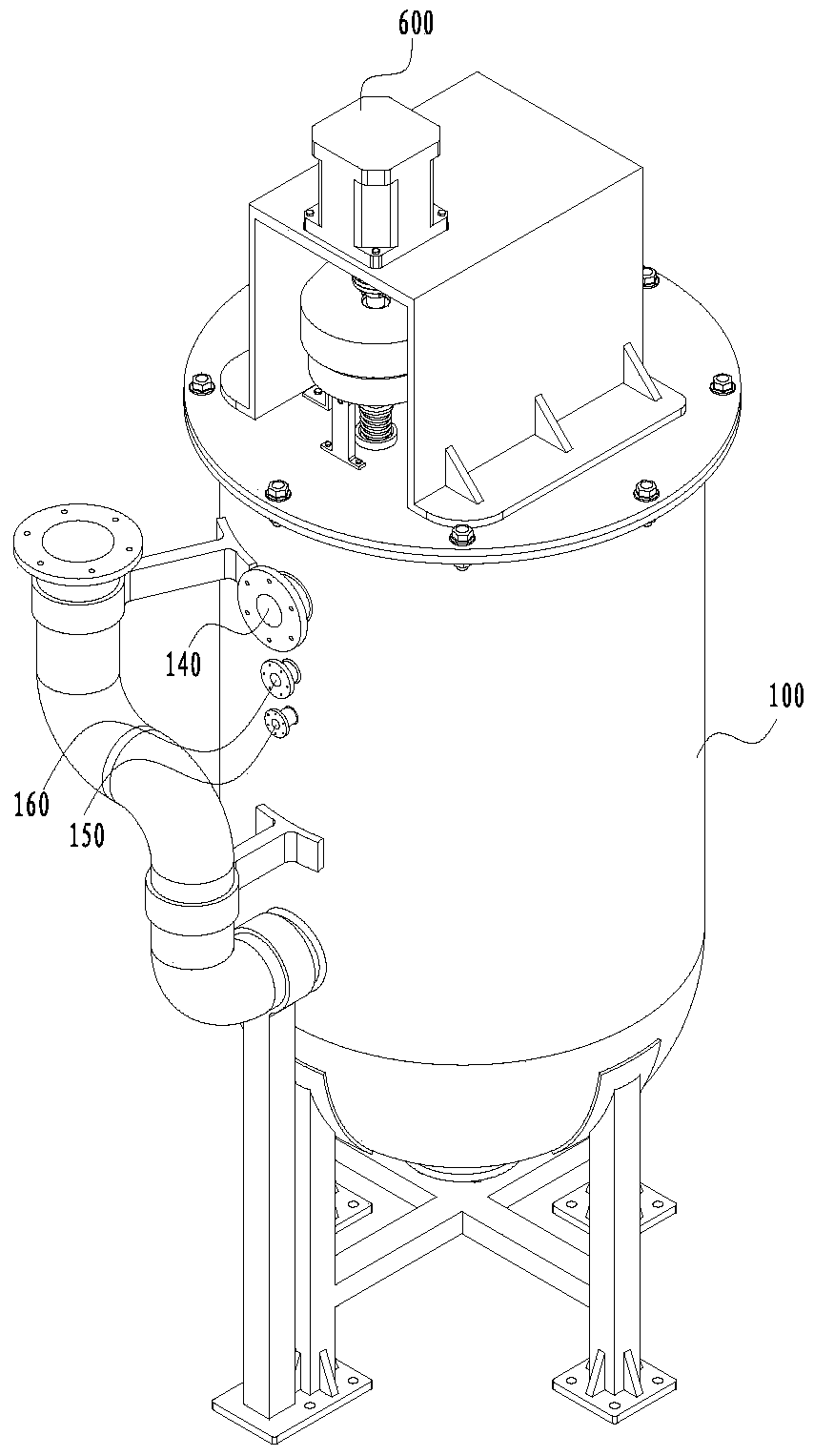

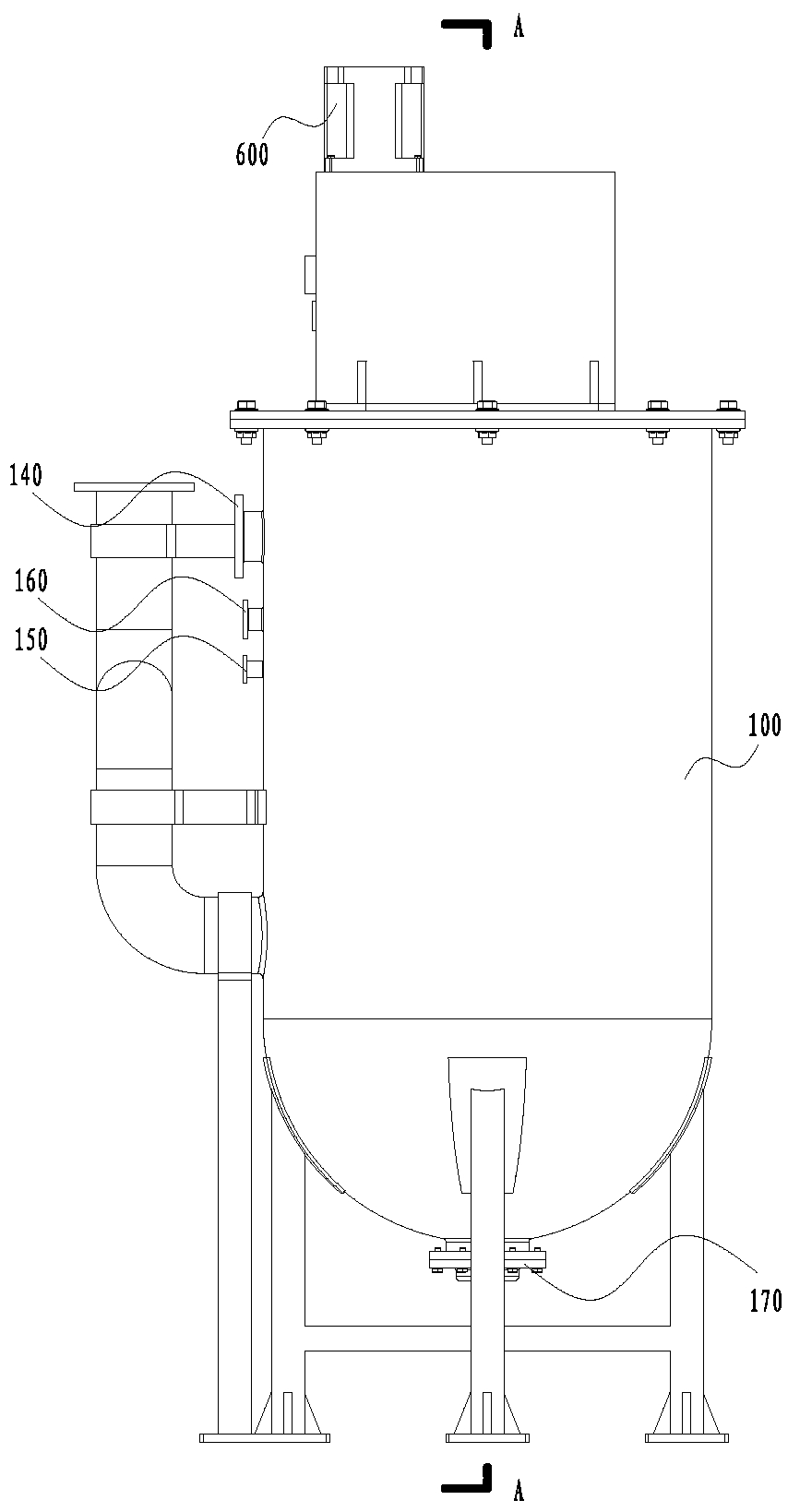

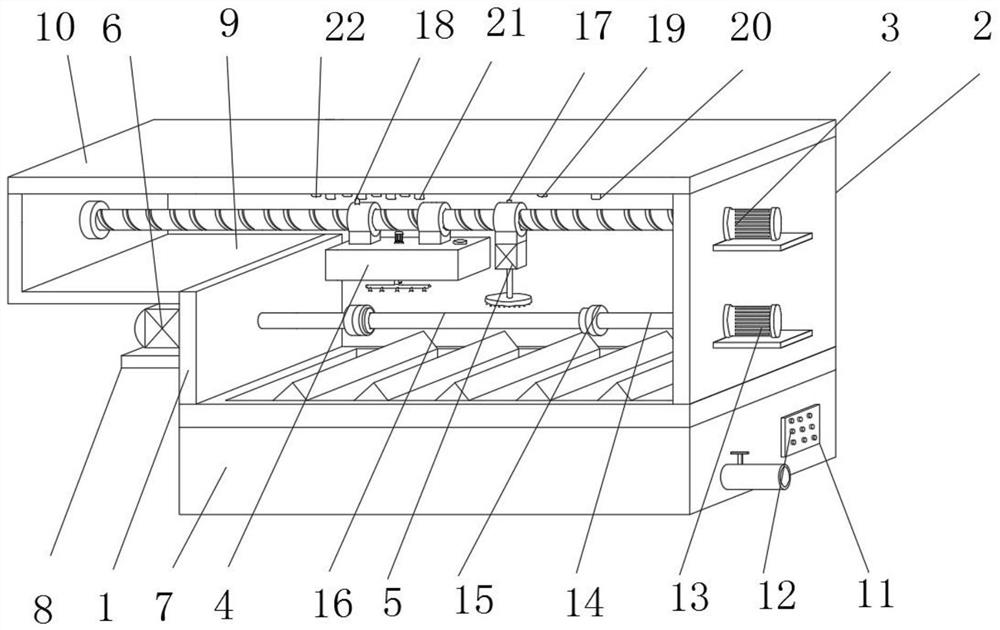

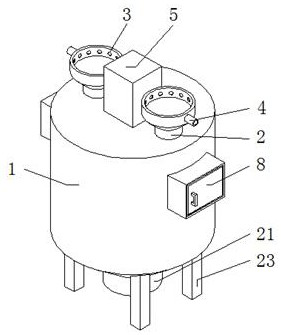

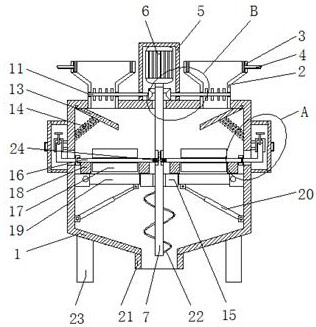

Circulating filtration system for water pollution prevention and control, and using method of circulating filtration system

ActiveCN113087175AImprove stabilityFacilitates centralized collection operationsFatty/oily/floating substances removal devicesSpecific water treatment objectivesElectric machineryWater reservoir

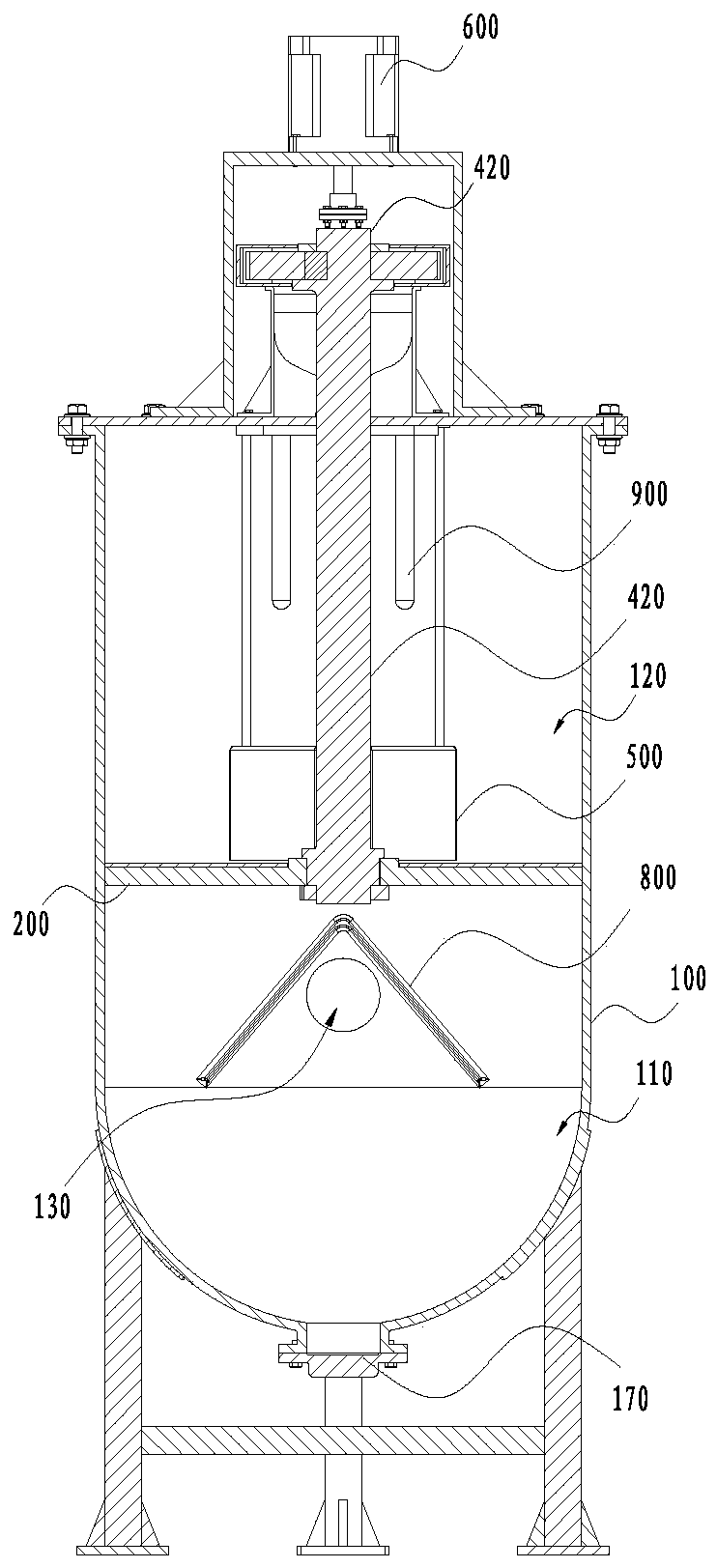

The invention discloses a circulating filtration system for water pollution prevention and control, and a using method of the circulating filtration system, belonging to the technical field of circulating filtration. The circulating filtration system for water pollution prevention and control comprises a reservoir, wherein the outer wall of the reservoir is fixedly connected with a fishing motor, and the output end of the fishing motor is provided with a threaded rod that is rotationally connected with the outer wall of the reservoir. According to the circulating filtration system for water pollution prevention and control and the using method of the circulating filtration system, a rotating plate is arranged, and the rotating plate rotates to drive a first adjusting pore plate and a second adjusting pore plate to rotate at the same time; since the initial position of a first guide column on the first adjusting pore plate is different from the initial position of a second guide column on the second adjusting pore plate, the rotating plate rotates to drive a first moving pore plate to move, so a gate moves firstly to seal the bottom of a settling tank; and then a second moving pore plate moves to drive the settling tank to slide along the inner wall of a working frame, and the settling tank is transferred to the outside of the working frame, so sewage is thoroughly filtered.

Owner:SUSHENG TECH WUXI

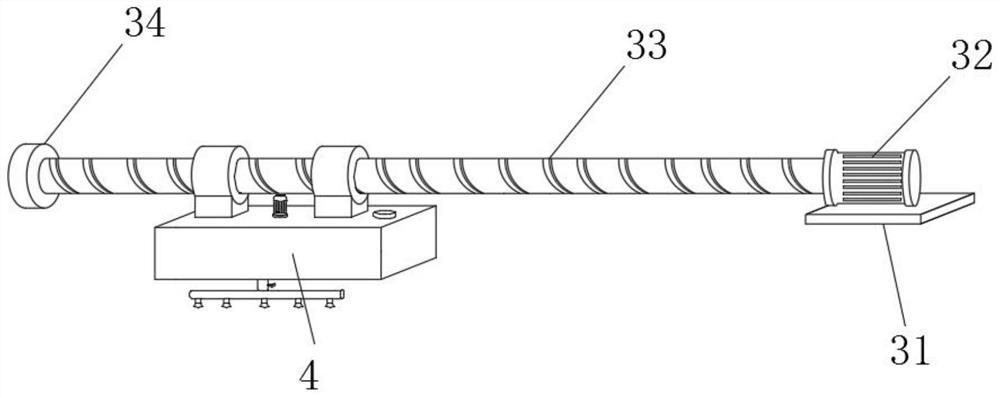

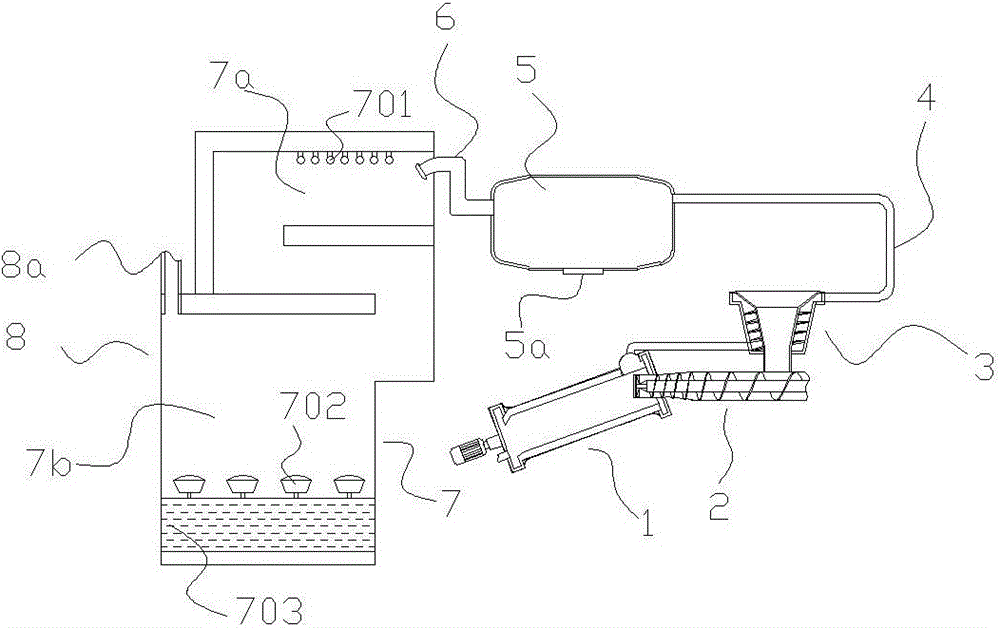

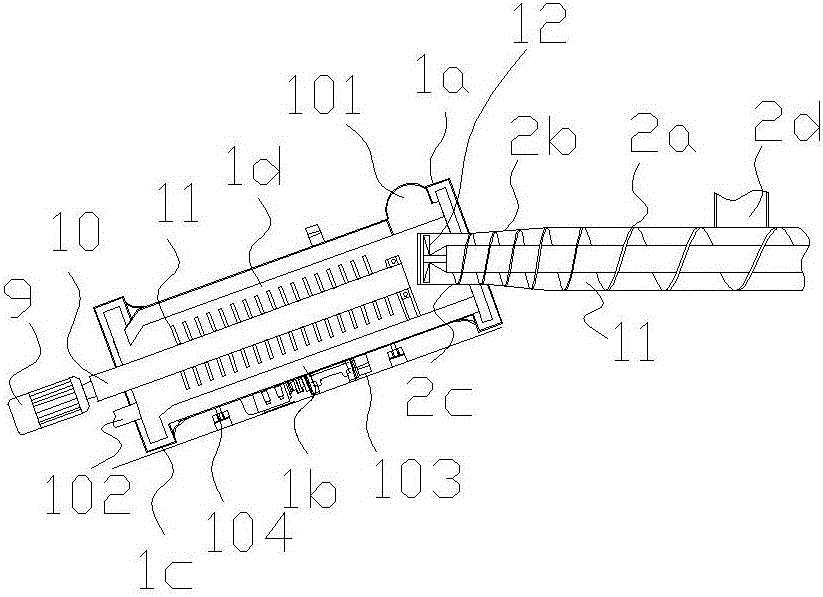

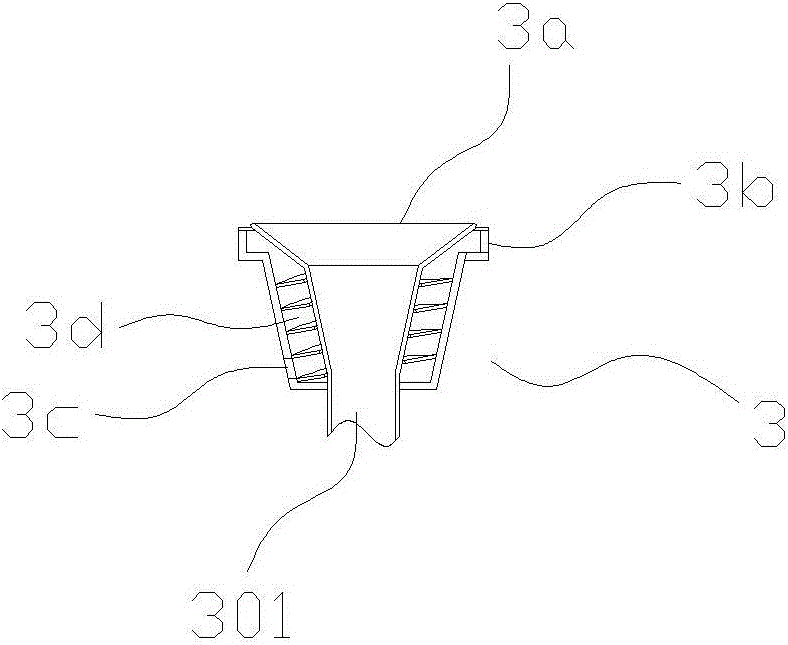

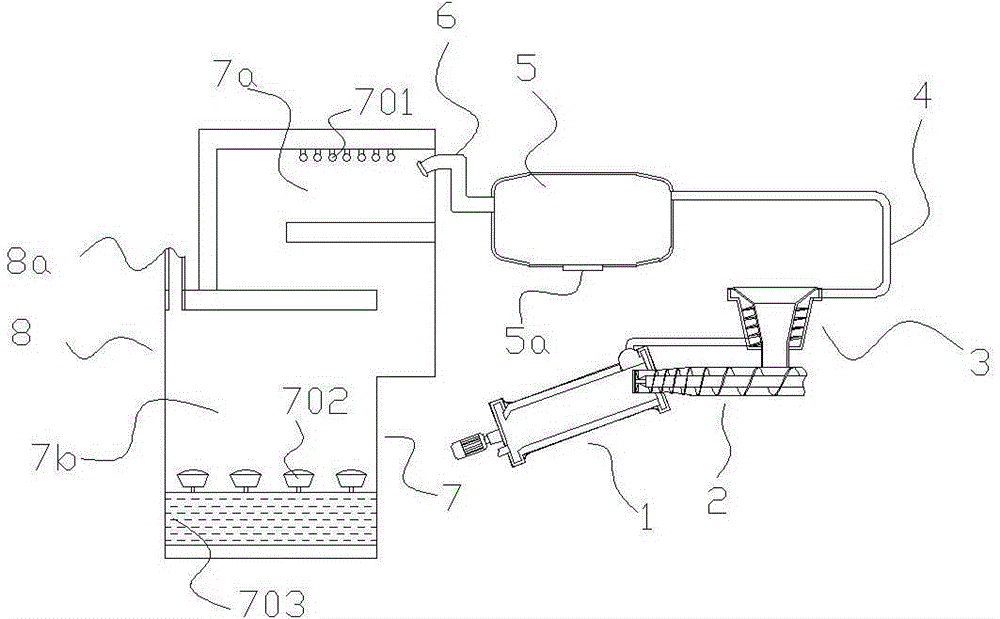

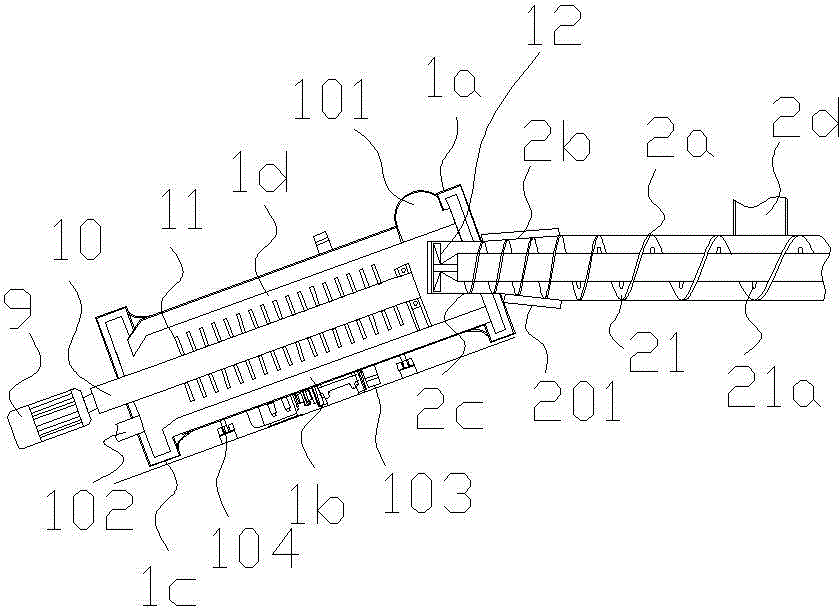

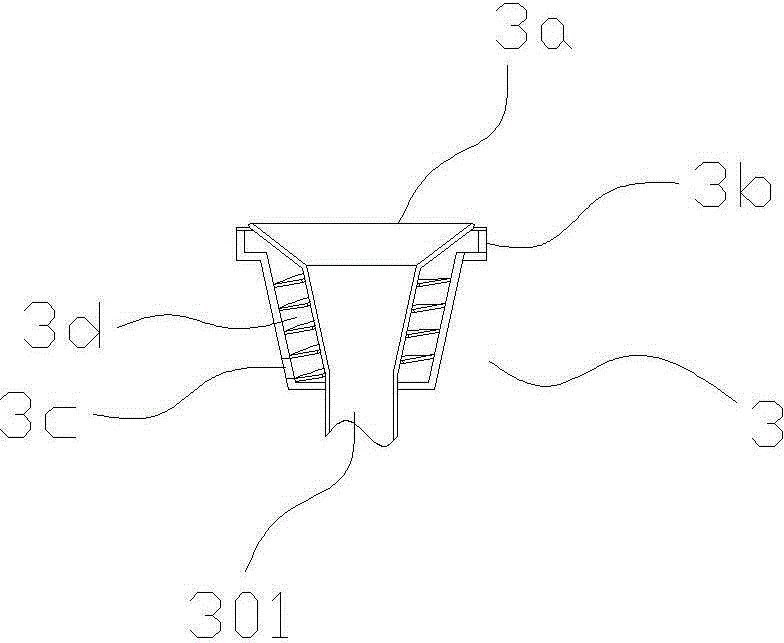

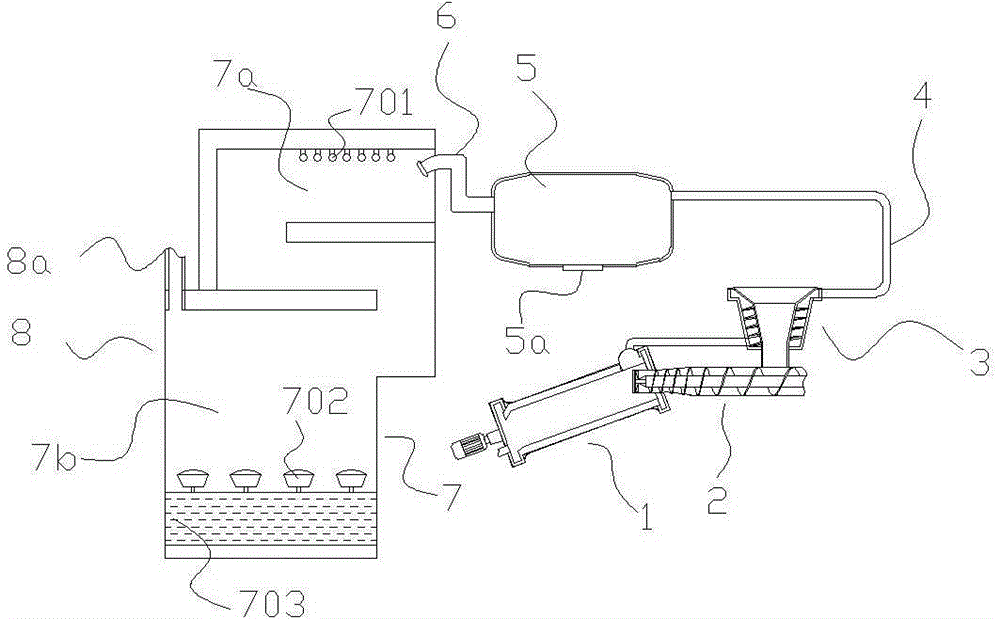

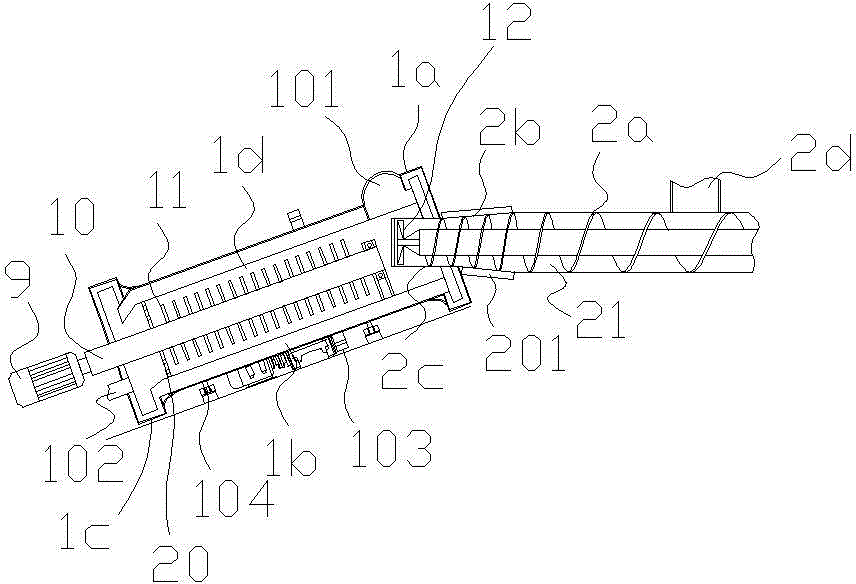

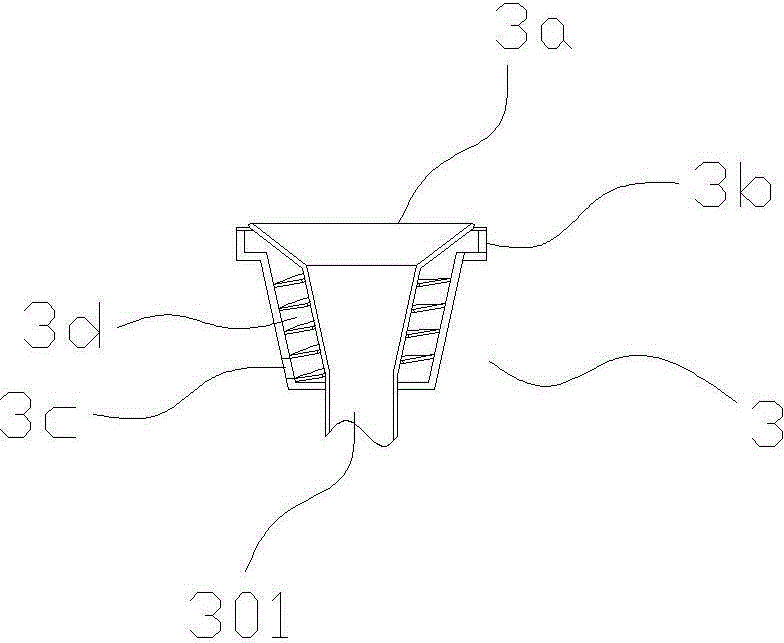

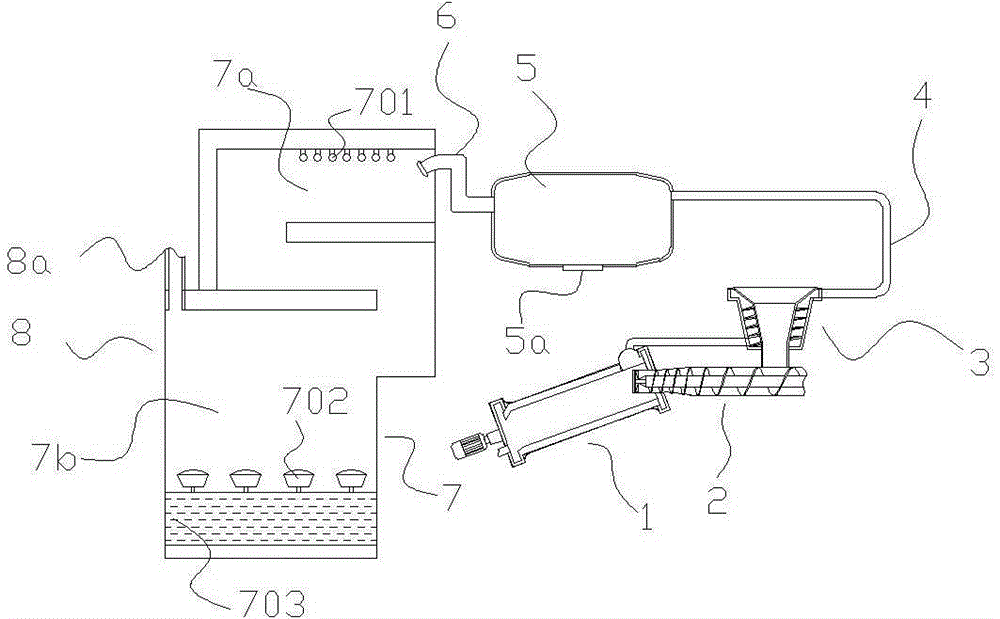

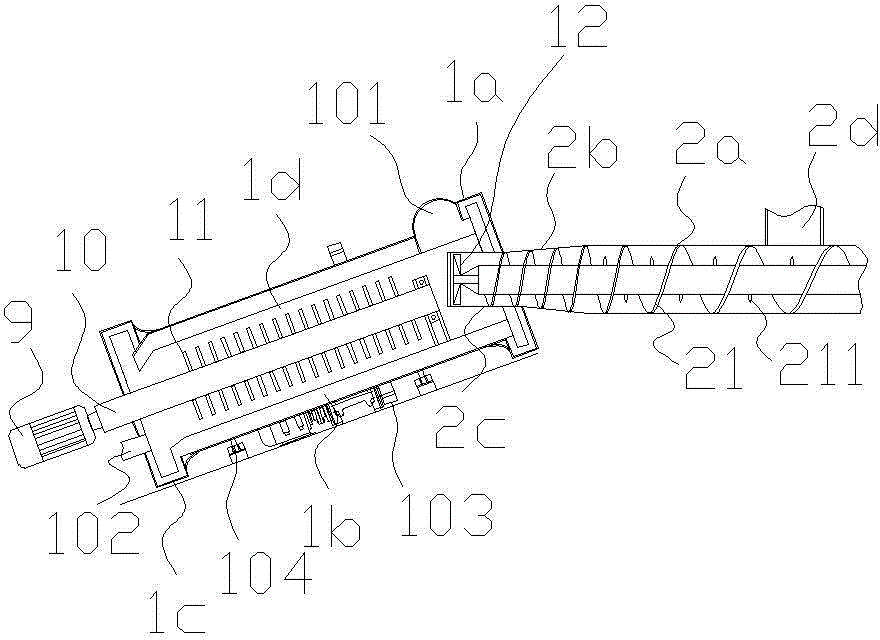

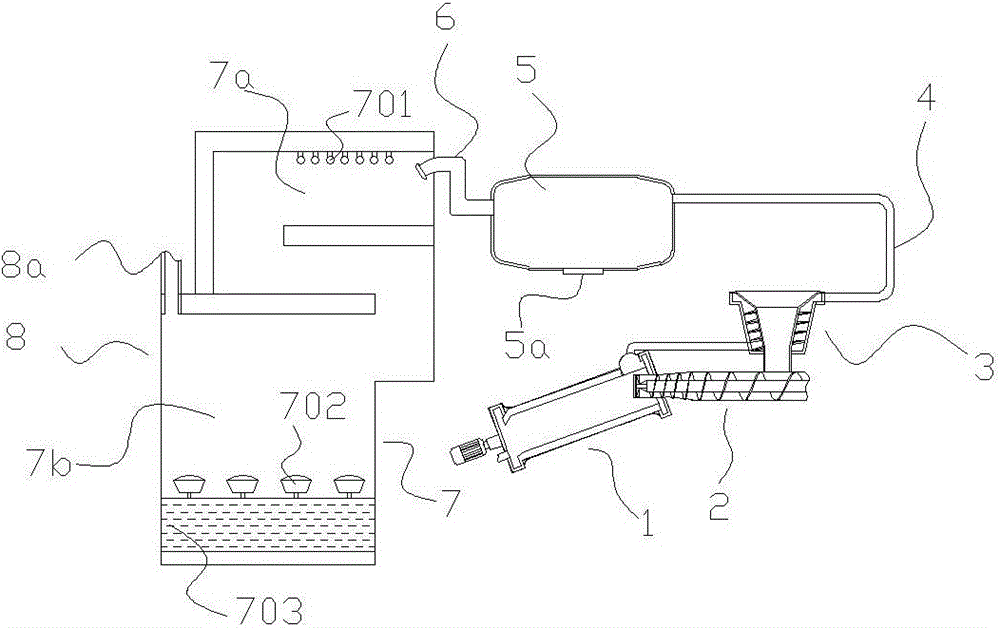

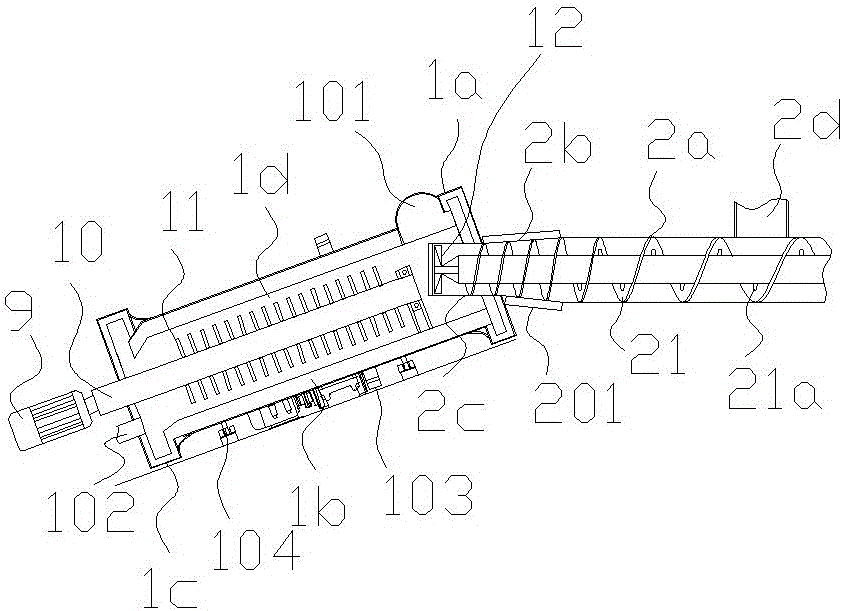

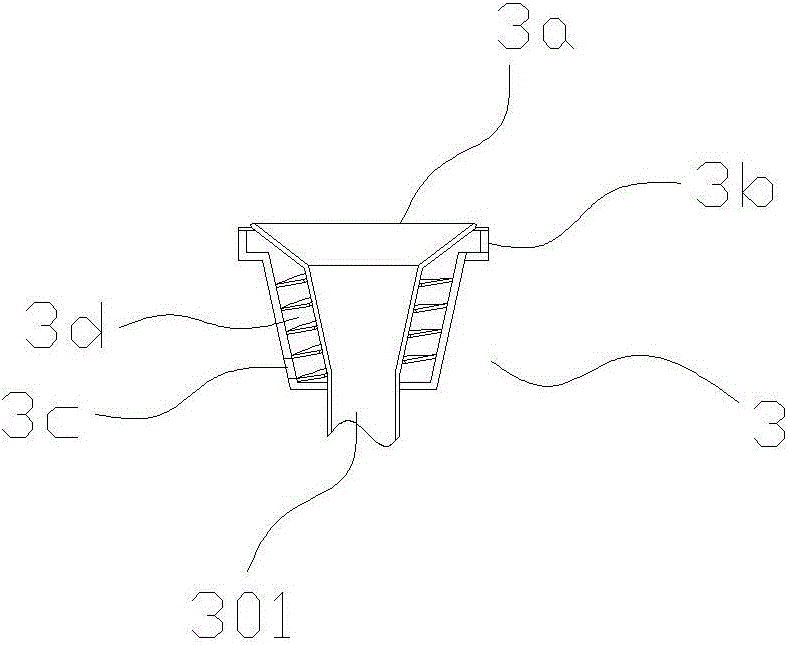

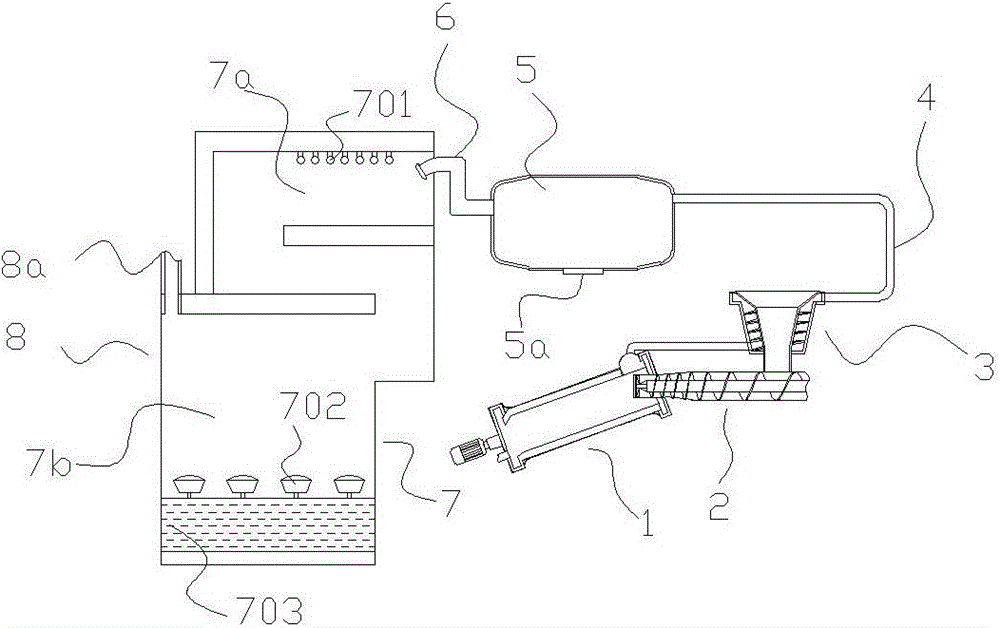

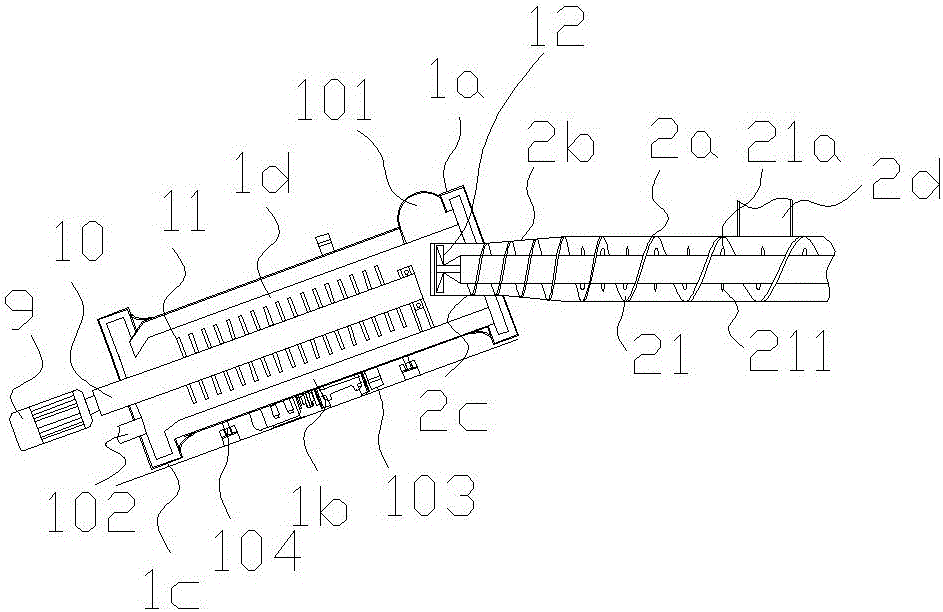

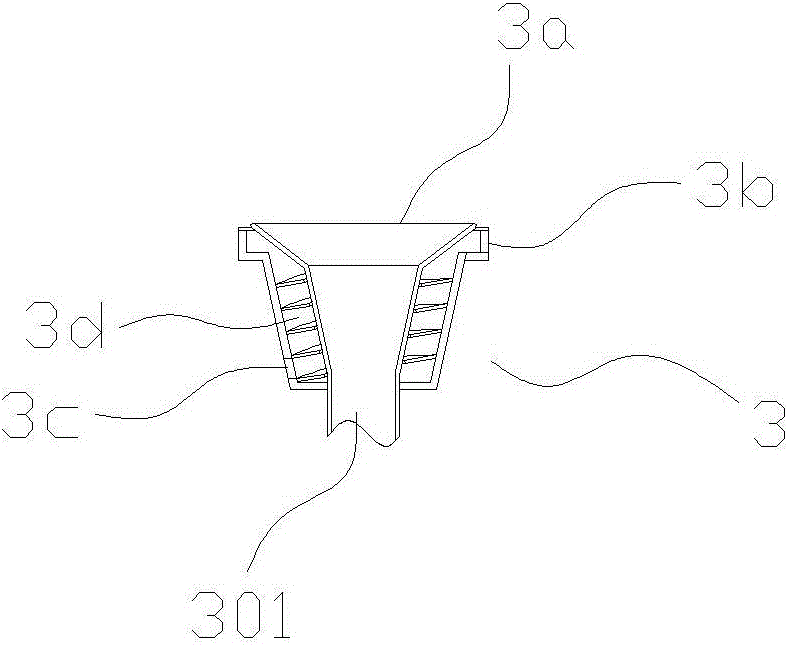

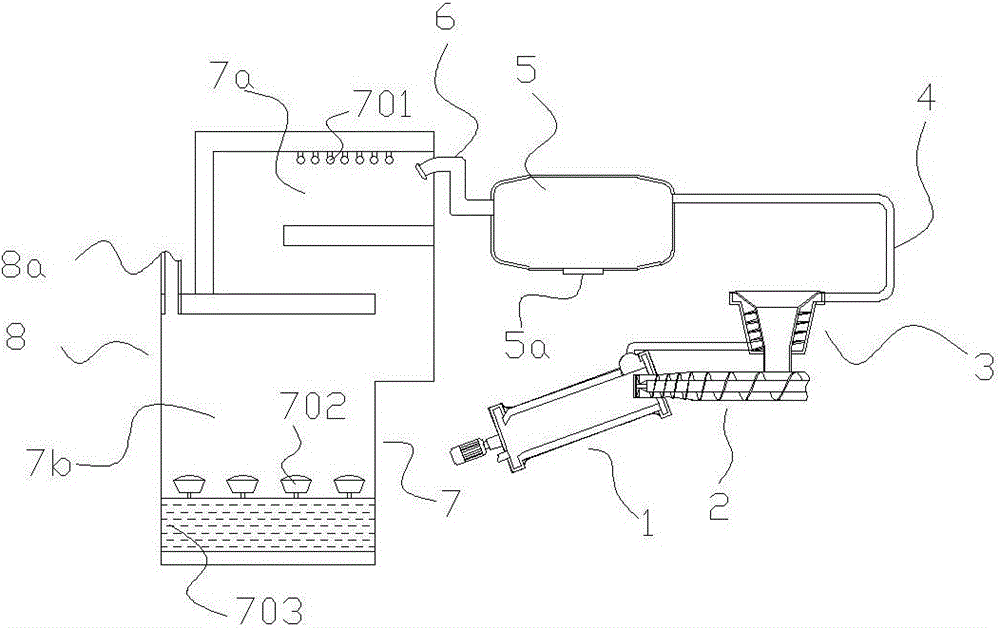

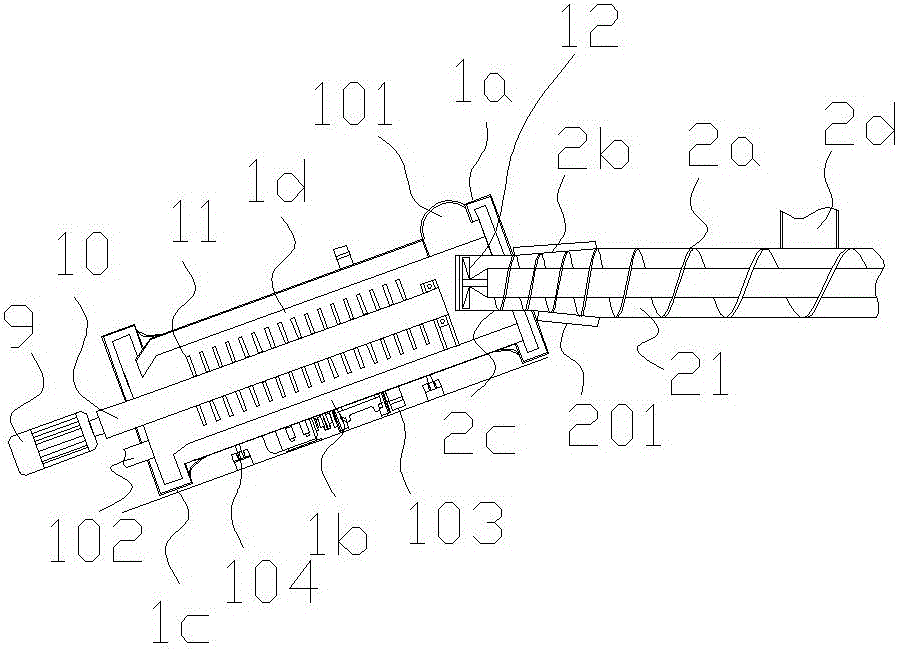

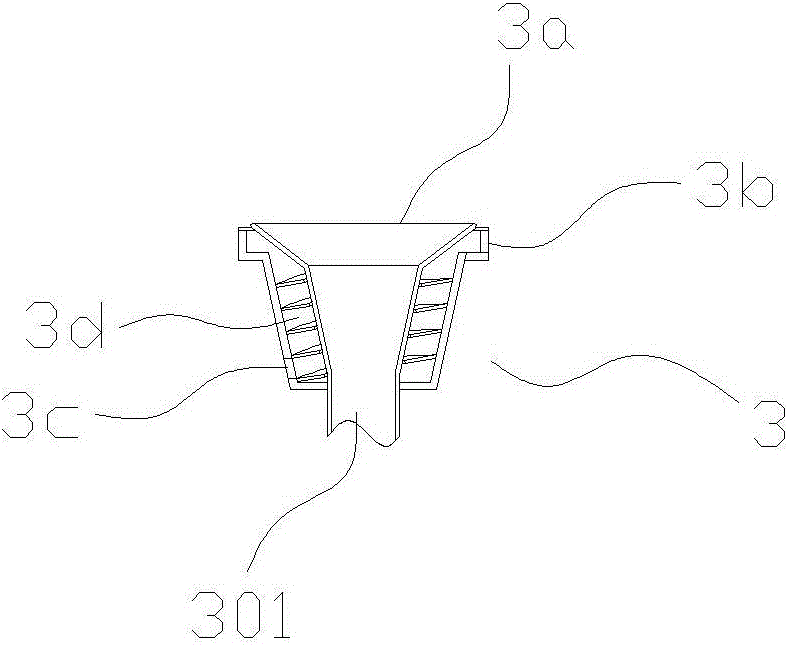

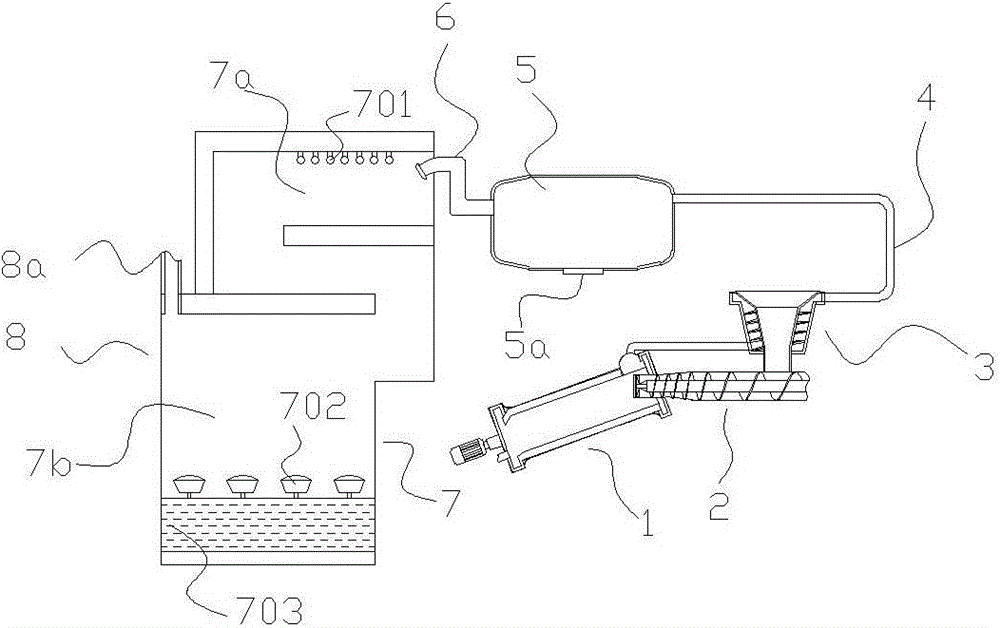

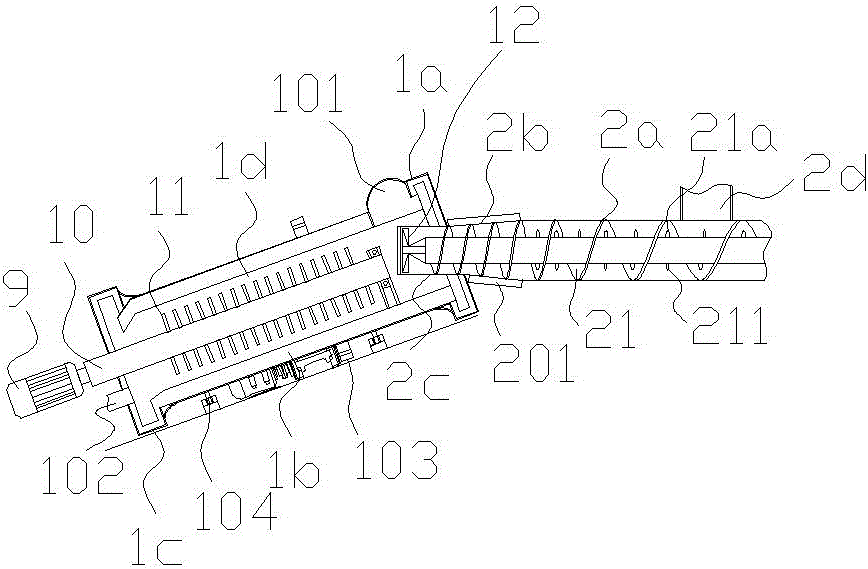

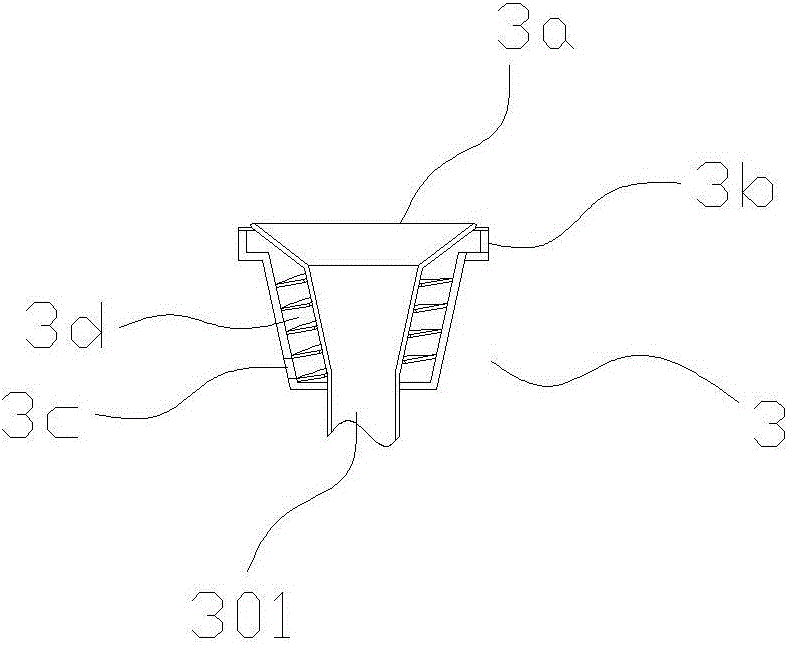

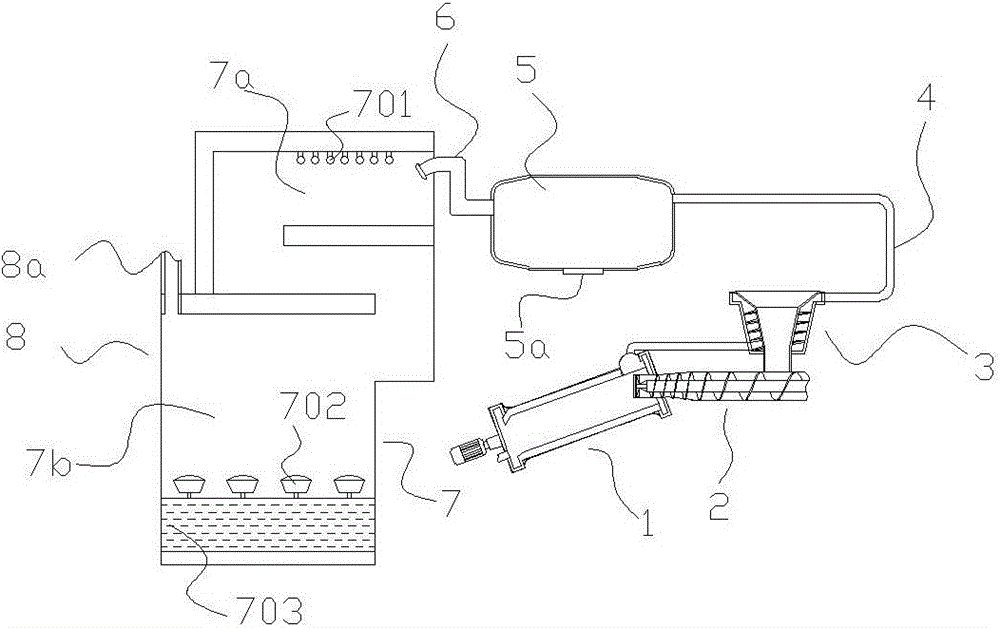

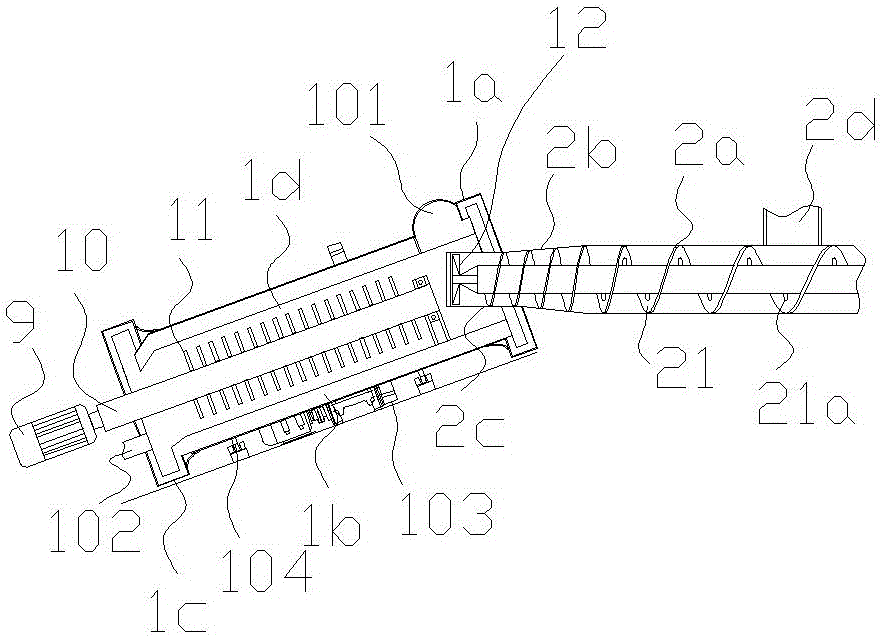

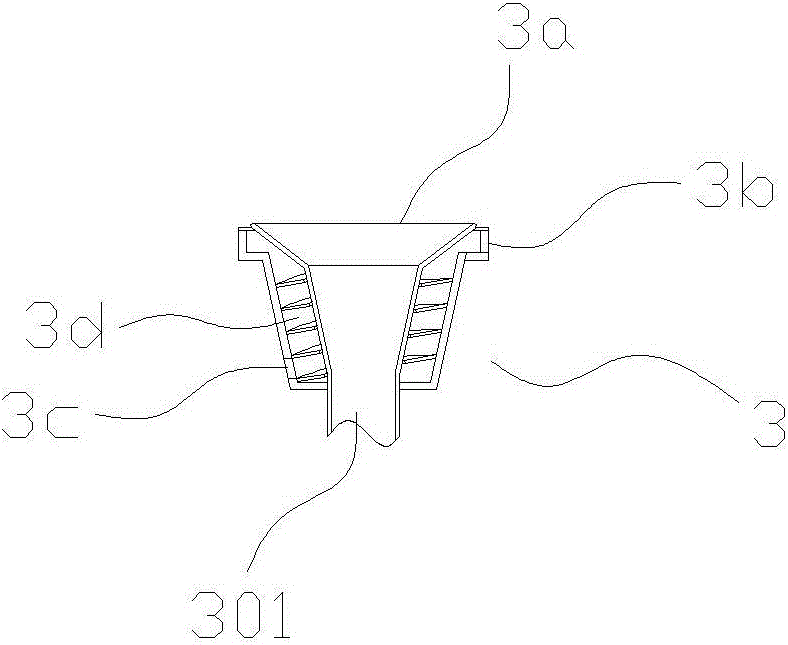

Fallen leaf incineration system

InactiveCN104654319AImprove firing effectReduce material sizeIncinerator apparatusFlueProcess engineering

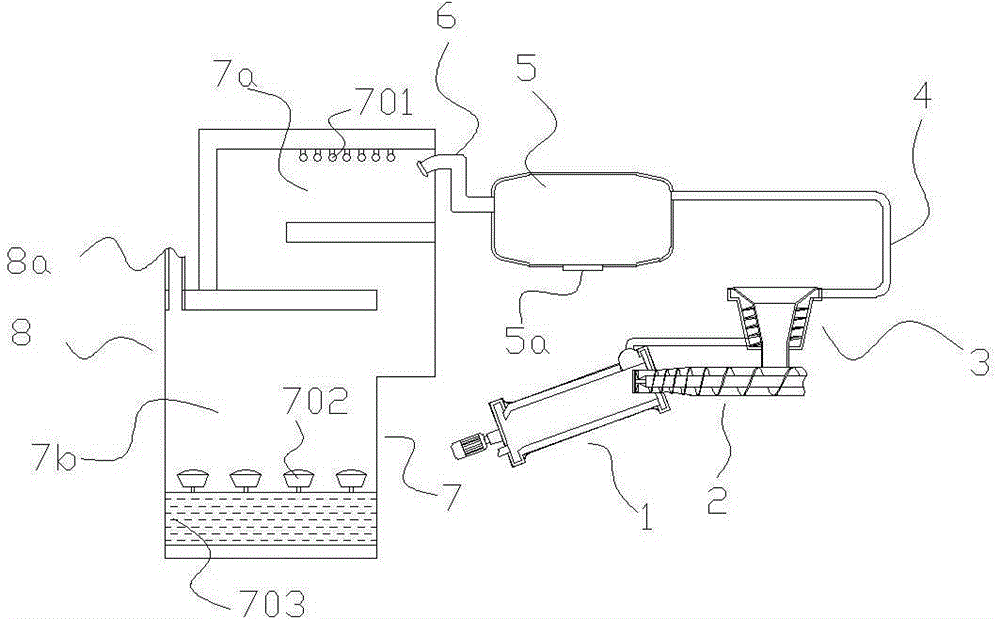

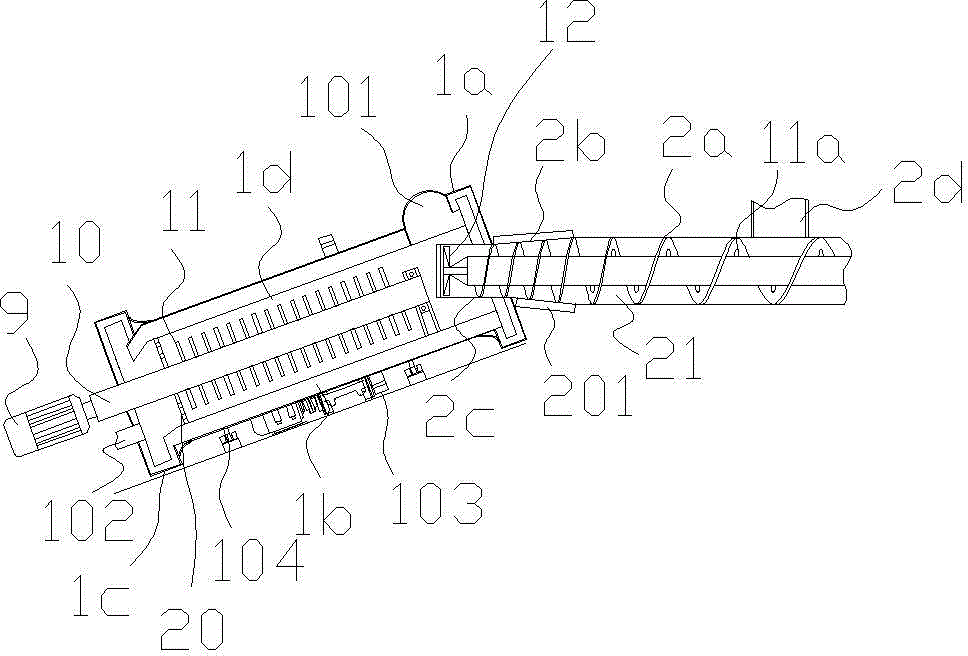

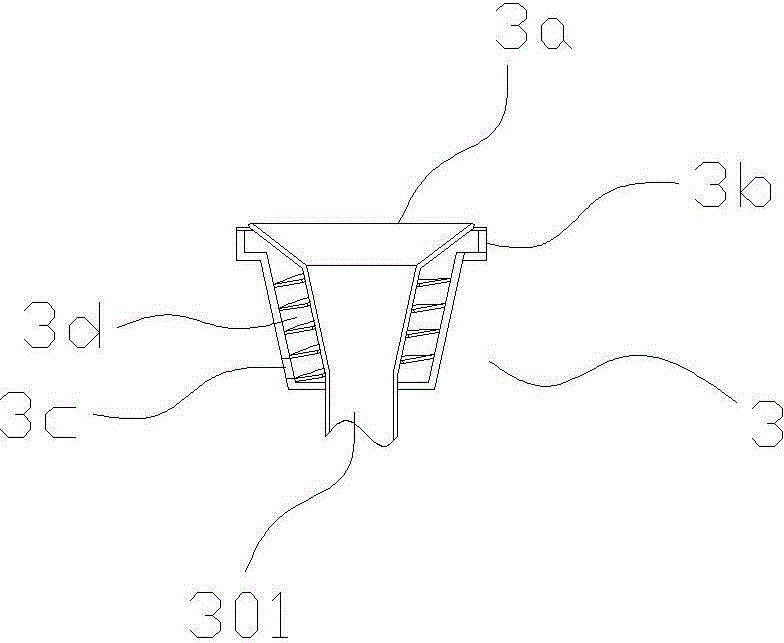

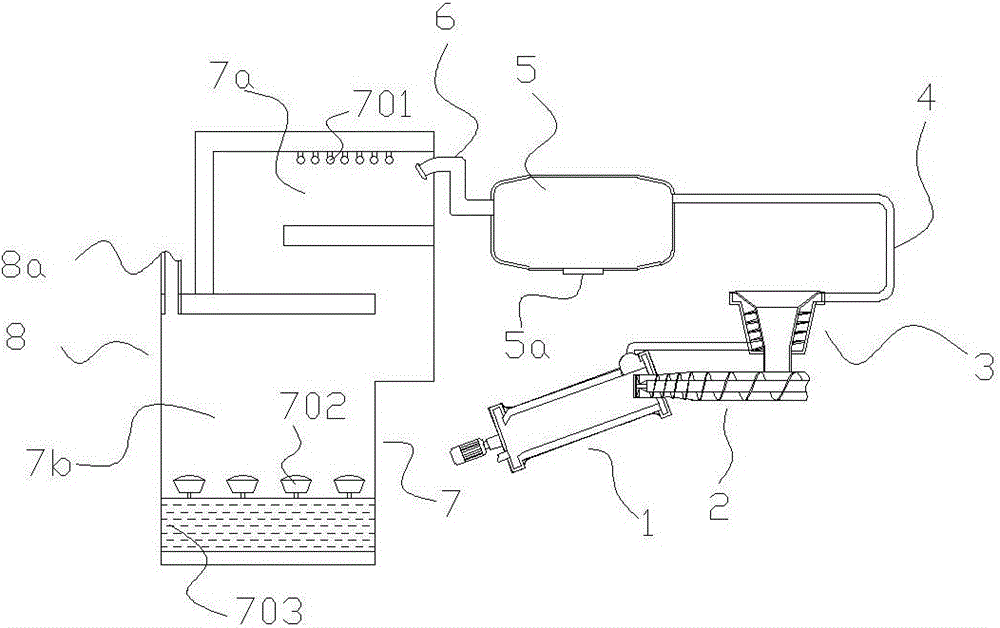

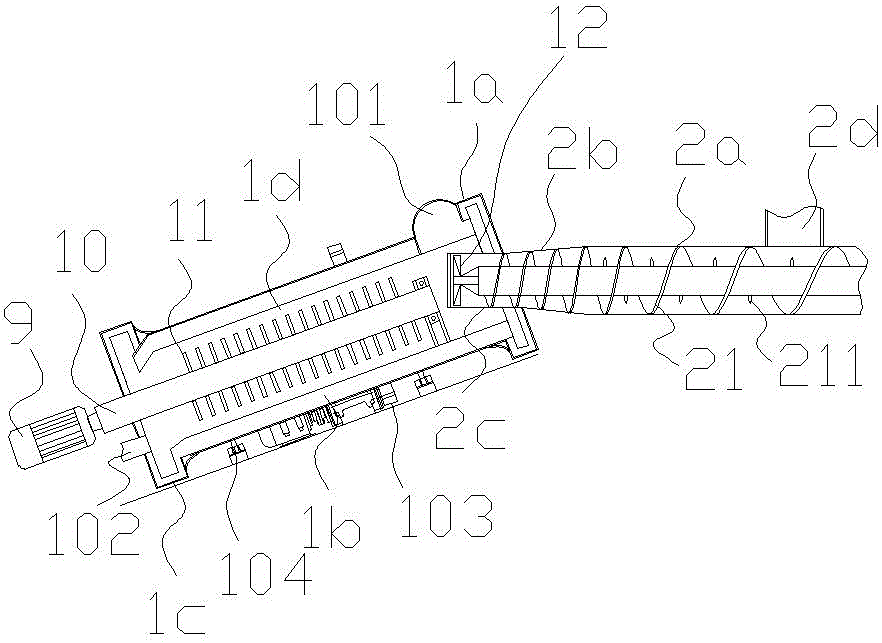

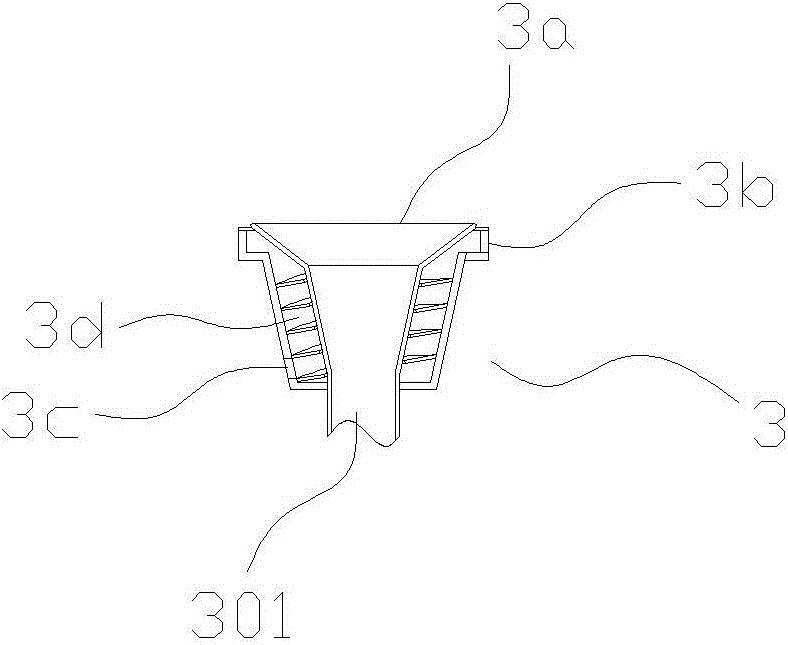

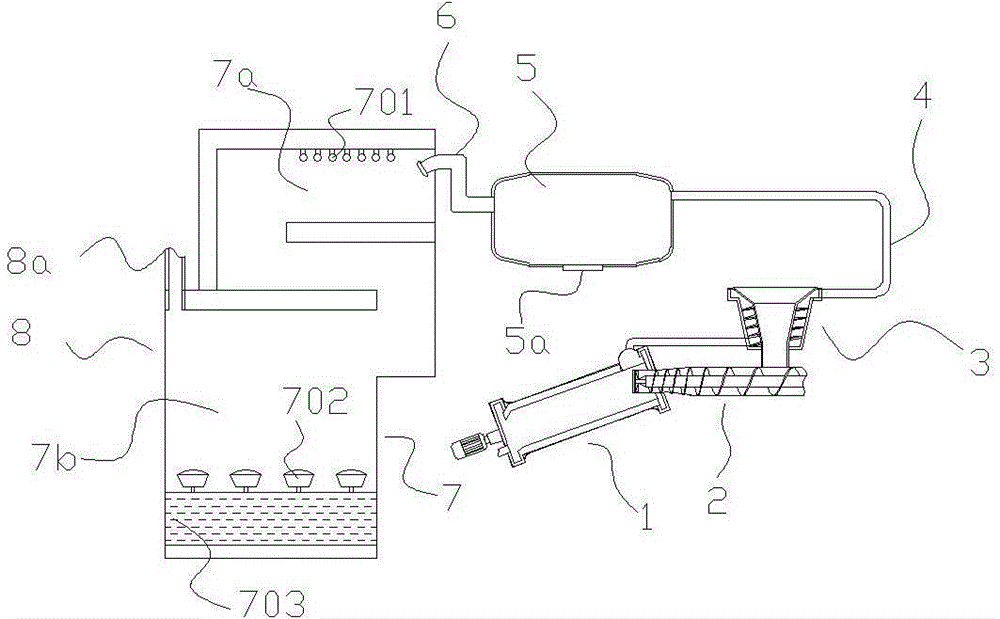

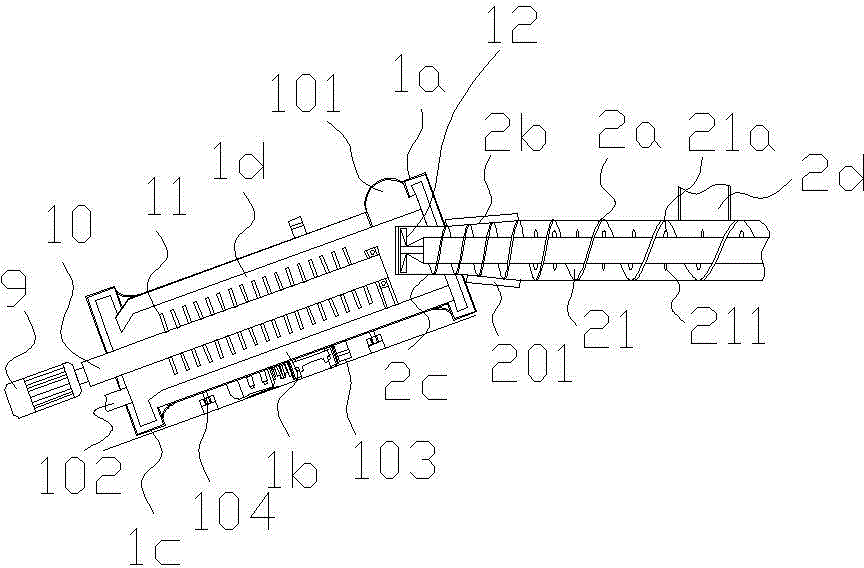

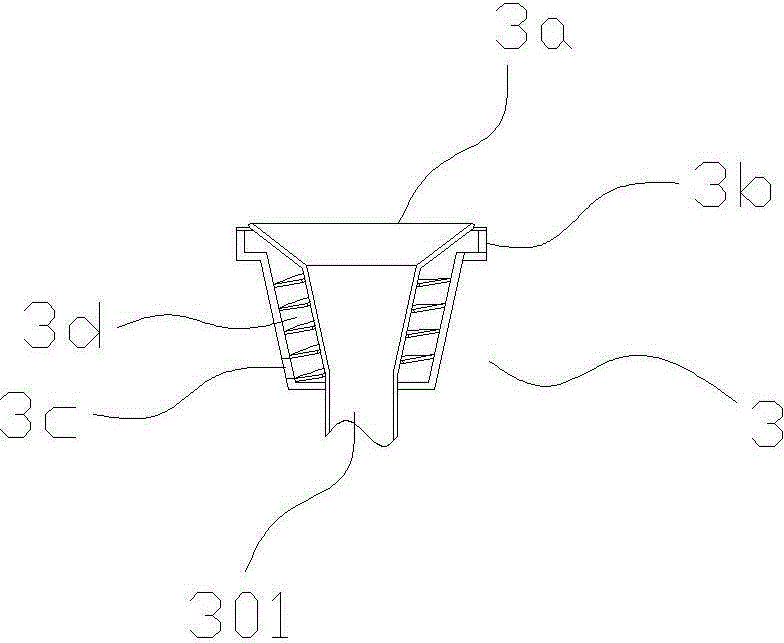

The invention discloses a fallen leaf incineration system. The fallen leaf incineration system comprises an incinerator, a feeding device used for feeding materials into the incinerator, a smoke purifying device used for purifying flue gas exhausted from the incinerator, and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail; a driving main shaft driven by a main motor is arranged in an incineration cavity of the incinerator; a plurality of material dispersing bodies used for shifting the materials are arranged on the driving main shaft; the feeding device comprises a feeding cylinder stretching into the incineration cavity from a feeding inlet; a feeding auger is arranged in the feeding cylinder; the preheating device comprises a preheating hopper and a spiral flue which winds around the preheating hopper; the smoke purifying device comprises a smoke exhausting outer passage and a water falling pond; a plurality of water spraying heads are arranged above the interior of the smoke exhausting outer passage. The invention aims to provide the fallen leaf incineration system, which can effectively incinerate animal carcasses in a concentrating way, is stable and effective in an incineration process, can guarantee full incineration, can effectively treat generated flue gas and can prevent flue dust pollution.

Owner:ZHEJIANG SCI-TECH UNIV

Sewage filtration equipment

ActiveCN110270160AImplement cleanup operationsEasy to cleanSpecific water treatment objectivesTreatment involving filtrationFiltrationSewage

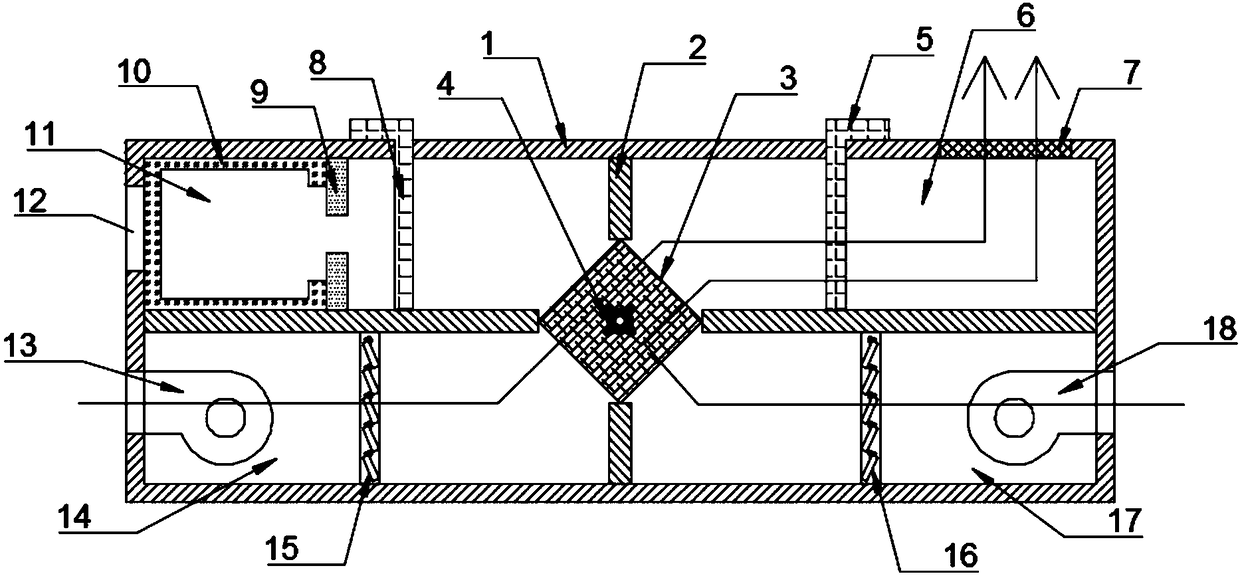

The invention relates to sewage filtration equipment. The sewage filtration equipment comprises a casing, a filtering assembly, a flushing assembly and an adjusting mechanism. The filtering assembly divides an inner chamber of the casing into a sewage chamber and a clean water chamber, is used for intercepting impurities in sewage flowing from the sewage chamber to the clean water chamber and composed of m A areas, wherein m is a positive integer and is greater than or equal to 2; the flushing assembly is used for cleaning away deposited substances on the A areas, and the cleaning range of the flushing assembly is greater than or equal to each A area every time; the adjusting mechanism is used for adjusting the flushing assembly to clean the A areas on the filtering assembly separately. According to the sewage filtration equipment, the flushing assembly is adjusted to clean the A areas on the filtering assembly separately through the adjusting mechanism, so that when the flushing assembly cleans one of the A areas, sewage in the other A areas can also be filtered, and therefore the cleaning operation of the filtering assembly is facilitated without shutting down the equipment; since the cleaning range of the flushing assembly is greater than or equal to each A area every time, thorough cleaning of all the A areas is facilitated.

Owner:安徽清蓝环保工程有限公司

Filter screen self-cleaning anti-blocking double-motor fresh air conveying equipment

ActiveCN108469093AEasy inputAdjust the size of fresh air deliveryMechanical apparatusLighting and heating apparatusWaste managementSelf cleaning

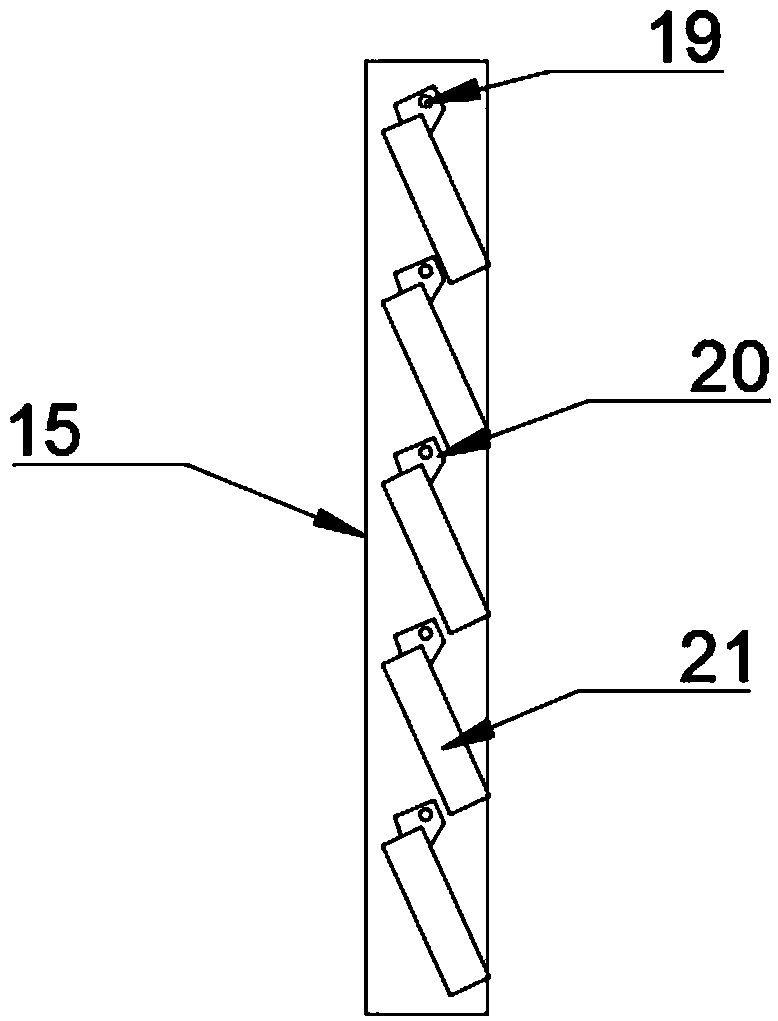

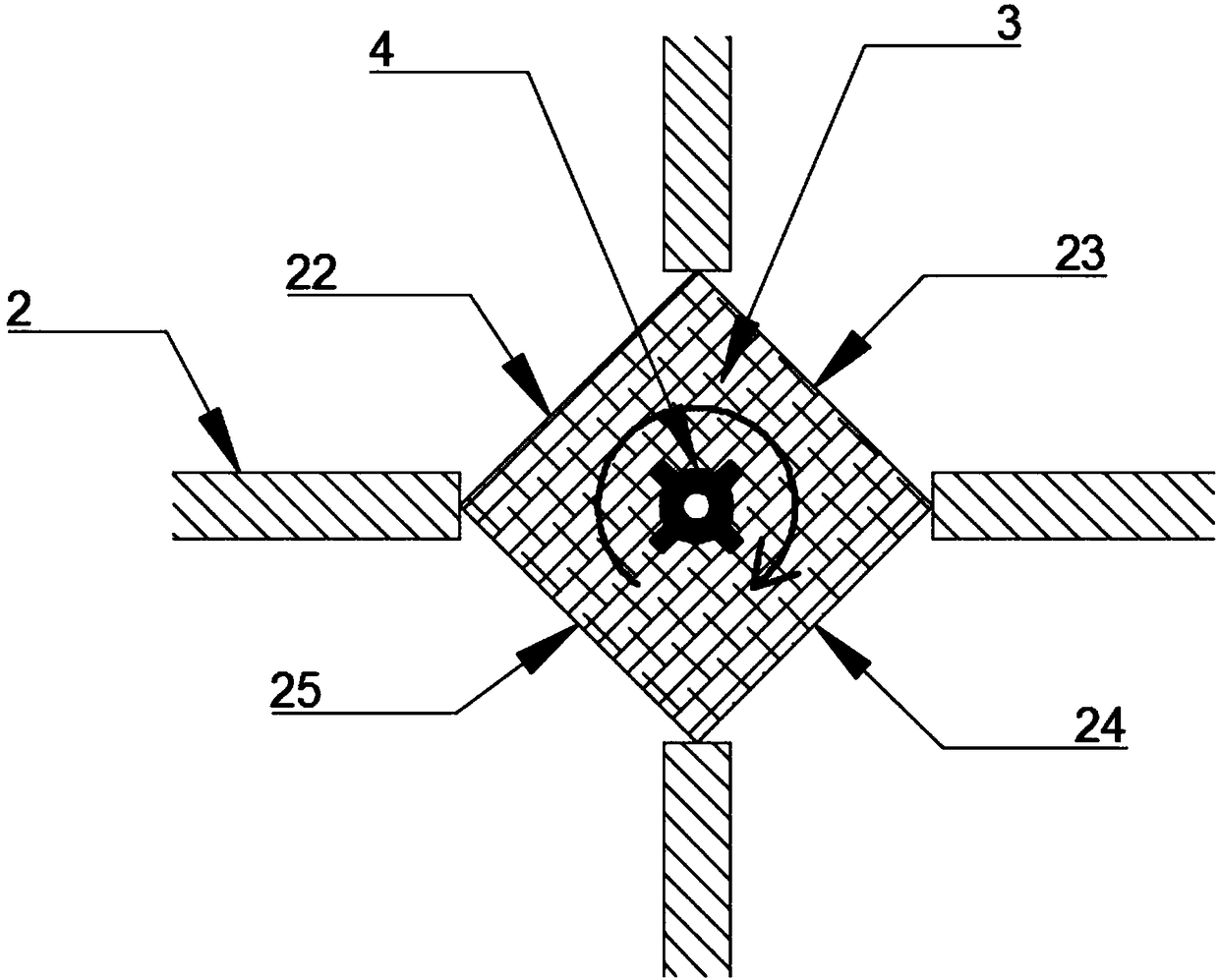

The invention discloses filter screen self-cleaning anti-blocking double-motor fresh air conveying equipment. The equipment comprises a fresh air machine shell body, inner partition plates, a filter,a rotating shaft, a dust removal filter bag, an induced draft fan I and an induced draft fan II, wherein the inner partition plates which are arranged in a cross-shaped mode are installed inside the fresh air machine shell body, the filter is installed among the inner partition plates, the cross section of the filter is of a rectangular structure, and the filter is fixedly installed on the rotating shaft; and the inner partition plates and the filter separate the interior of the fresh air machine shell body into a fresh air input channel I, a fresh air conveying channel II, a dust collecting cavity and a fresh air output channel, wherein the induced draft fan I is installed in the fresh air input channel I, and the induced draught fan II is installed in the fresh air conveying channel II.According to the filter screen self-cleaning anti-blocking double-motor fresh air conveying equipment, conveying of fresh air is achieved; the automatic blowing and cleaning operation on a first filter screen surface of the filter is realized, so that the blockage of the filter is avoided; and according to the use condition of the filter, the filter is sequentially rotated clockwise by 90 degreesso that blowing and cleaning can be carried out on the side faces one by one, so that the conveying efficiency and quality are improved, and the situation that the filter is blocked is avoided.

Owner:深圳市美佳空调有限公司

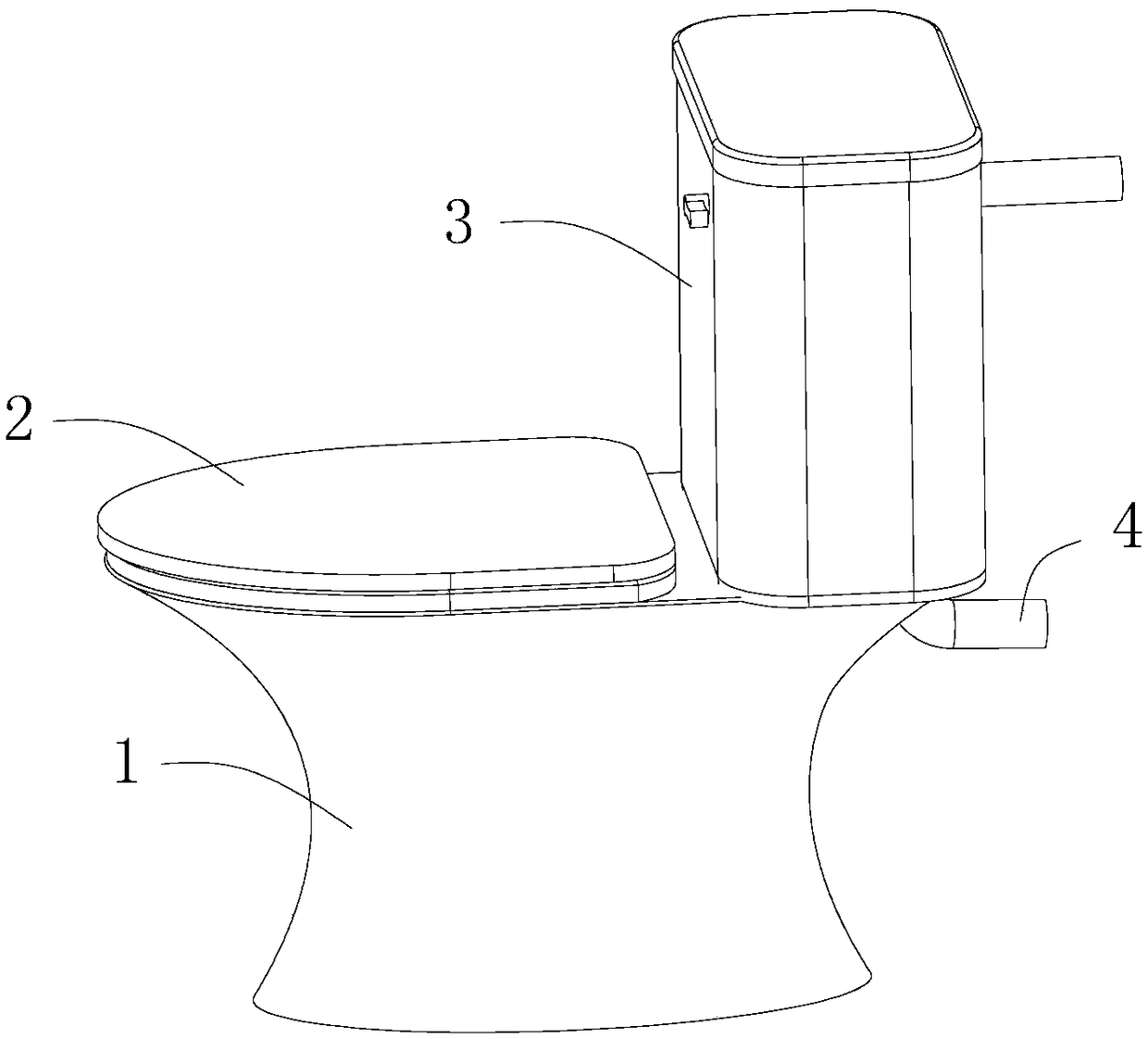

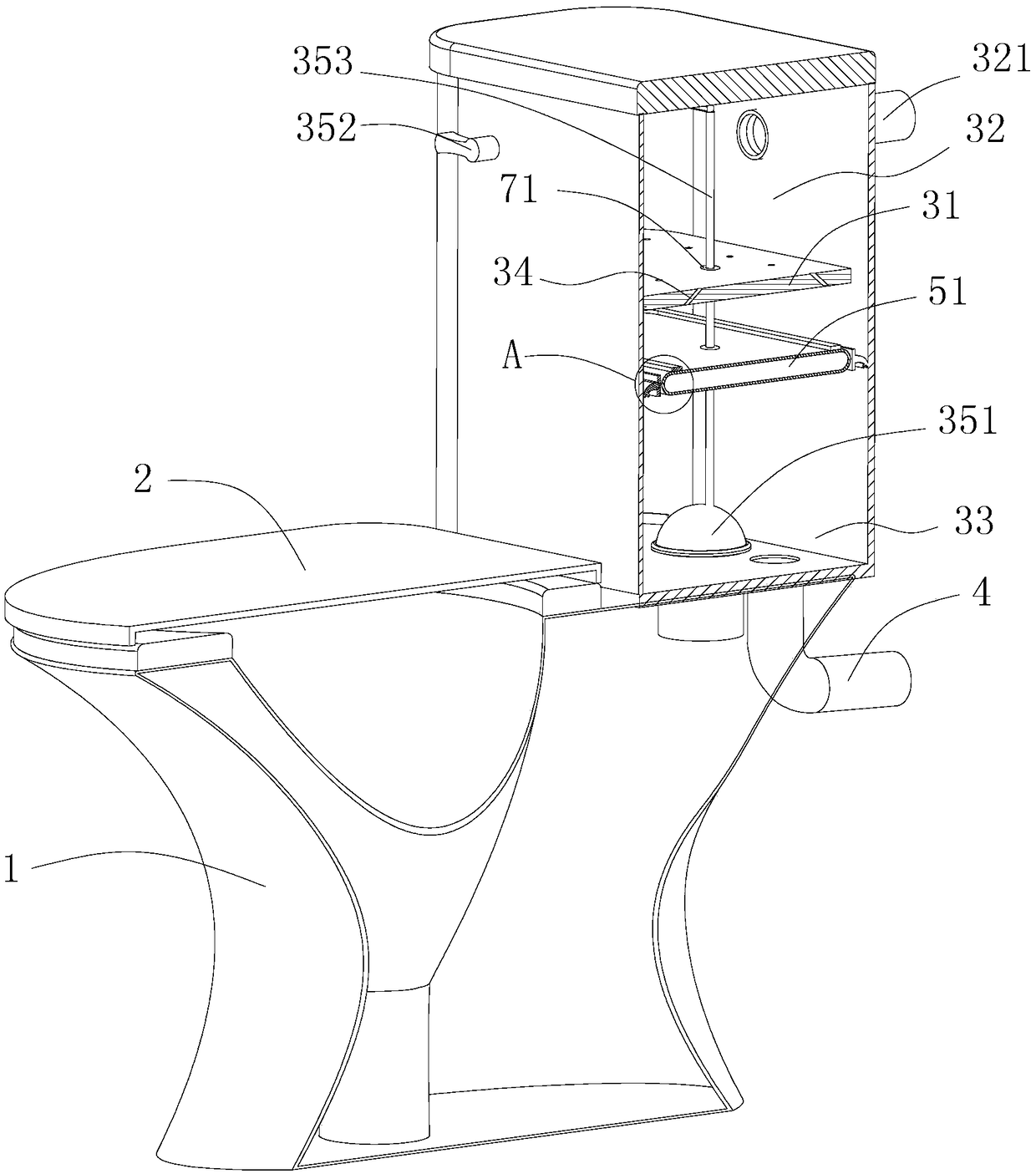

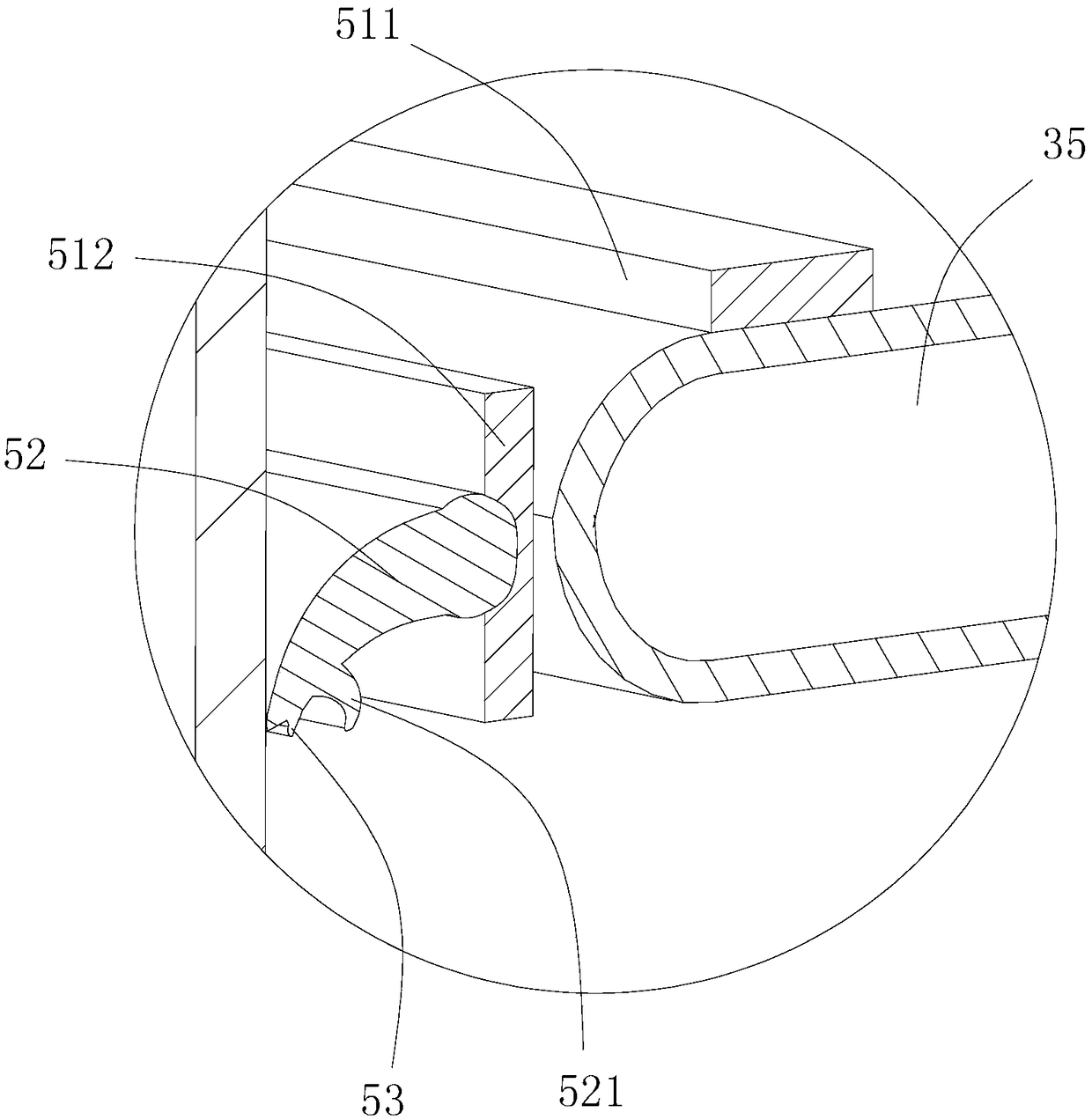

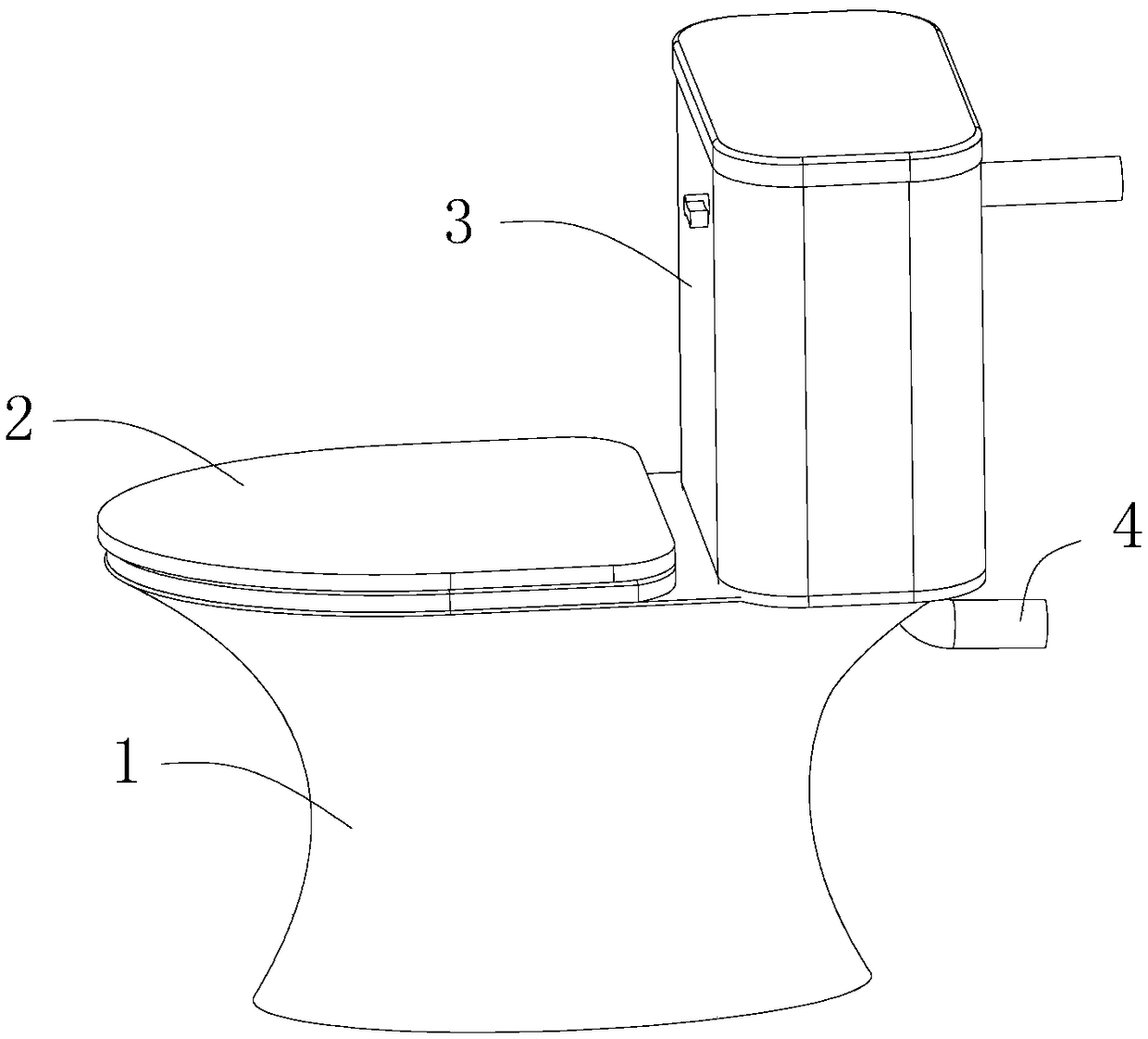

Water closet capable of achieving recycling of domestic sewage

InactiveCN108978829ATake advantage ofAchieve reuseWater closetsDomestic plumbingWater resourcesSewage

The invention discloses a water closet capable of achieving recycling of domestic sewage. The water closet comprises a water closet body, a toilet lid, a water tank, a flushing device, a domestic sewage conveying pipe and a water tank cleaning device, wherein the toilet lid is connected to the water closet body in a mode of turning up and down; a water outlet is formed in the bottom of the water tank, and a sealing piece is arranged on the water outlet; the flushing device is used for conducting a flushing operation on the water closet body by water in the water tank; the domestic sewage conveying pipe is connected to the water tank and is used for supplying processed domestic sewage into the water tank; and the water tank cleaning device is used for automatically cleaning the inner wall of the water tank in a process of flushing the water closet body by virtue of the flushing device. The water closet provided by the invention achieves full use of water resource, realizes recycling ofthe water resource and reduces waste of the water resource; in addition, by arranging the water tank cleaning device, an operation of cleaning the interior of the water tank can be directly implemented in a water tank flushing process, so that manual cleaning of the water tank at regular period can be avoided; and the water closet is high in practical performance and capable of effectively reducing workload of users.

Owner:羊双燕

Uniformly-spraying paint spraying device for hardware machining

InactiveCN112295822ASpray evenlyPrevent leakageCleaning using toolsSpray boothsElectric machineryStructural engineering

The invention discloses a uniformly-spraying paint spraying device for hardware machining. The paint spraying device comprises a recycling piece, a first vertical plate and a second vertical plate arefixedly installed on the left side and the right side of the upper end of the recycling piece correspondingly, and a third vertical plate is fixedly installed on the upper side of the left end of thefirst vertical plate. A top plate is fixedly installed at the upper end of the third vertical plate and the upper end of the second vertical plate jointly, a clamping piece penetrates through the middle of the first vertical plate, a driving device is fixedly installed on the upper portion of the right end of the second vertical plate, and the outer surface of the driving device is sleeved with aspraying piece and a cleaning device in a threaded mode. According to the uniformly-spraying paint spraying device for hardware machining, a driving motor and the driving device drive hardware to rotate and drive the spraying piece to move left and right correspondingly, so that the surface of the hardware can be sprayed more uniformly, waste liquid can be recycled by the recycling piece, and waste of spraying materials is avoided. In addition, the clamping piece can be suitable for clamping operation of hardware of different lengths, and the application range of the paint spraying equipmentis widened.

Owner:李禹

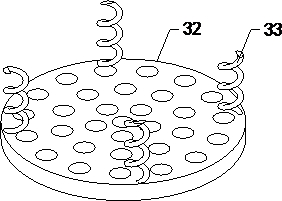

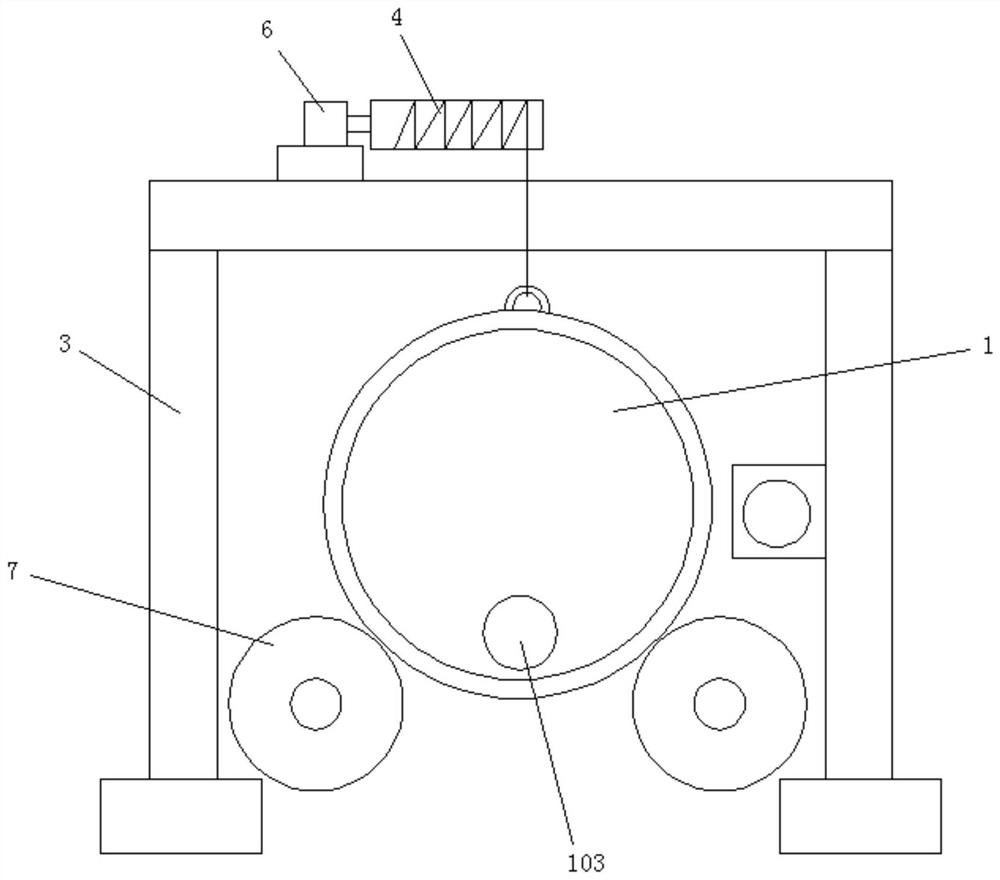

Grinding device with cleaning mechanism for brown fused alumina abrasive material machining and grinding method

InactiveCN112264153AImplement cleanup operationsRealize the grinding operationDirt cleaningGrain treatmentsElectric machineryEngineering

The invention discloses a grinding device with a cleaning mechanism for brown fused alumina abrasive material machining and a grinding method. The grinding device comprises a round shell, two feedingpipes are fixedly connected to the top face of the round shell in a left-right symmetry mode, the feeding pipes penetrate through the round shell and communicate with the interior of the round shell,and the feeding pipes are arranged in a funnel shape. Dust collectors are fixedly connected to the top faces of the feeding pipes, a plurality of dust collection openings are formed in the inner wallsof the dust collectors, dust collection pipes are fixedly connected to the side walls of the sides, away from the center of the round shell, of the dust collectors, penetrate through the dust collectors and communicate with the dust collection openings, and a protection box is fixedly connected to the center of the top face of the round shell. A motor is installed in the protection box, a rotating shaft is fixedly connected to an output shaft of the motor, a first bevel gear is fixedly connected to the side wall of the rotating shaft, and the first bevel gear is located on the outer side of the round shell. Through a series of structures, the device has the characteristics of being high in grinding efficiency, high in use efficiency and the like.

Owner:HUZHOU HUA TONG GRINDER MFG CO LTD

An animal carcass treatment device

The invention discloses a disposal device for animal carcasses. The disposal device comprises an incinerator, a feeding device for feeding to the incinerator, a smoke purifying device for purifying heat smoke exhausted from the incinerator as well as a preheating device, wherein the incinerator comprises an incinerator body, an incinerator head and an incinerator tail; a driving main shaft driven by a main motor is arranged in an incinerator cavity in the incinerator; a plurality of bulk material bodies for stirring materials are arranged on the driving main shaft; the feeding device comprises a feeding cylinder extending into the incineration cavity from a feed opening; a feeding auger is arranged in the feeding cylinder; the preheating device comprises a preheating hopper and a spiral flue around the preheating hopper; the smoke purifying device comprises a smoke exhausting outer channel and a water falling pool; a plurality of sprinkling heads are arranged at the upper part in the smoke exhausting outer channel. The invention aims at providing the disposal device for the animal carcass; according to the disposal device, the animal carcasses can be effectively and centrally fired; the firing process is stable and efficient; the sufficient incineration can be guaranteed; the smoke gas generated by incineration can be effectively disposed; smoke contamination can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

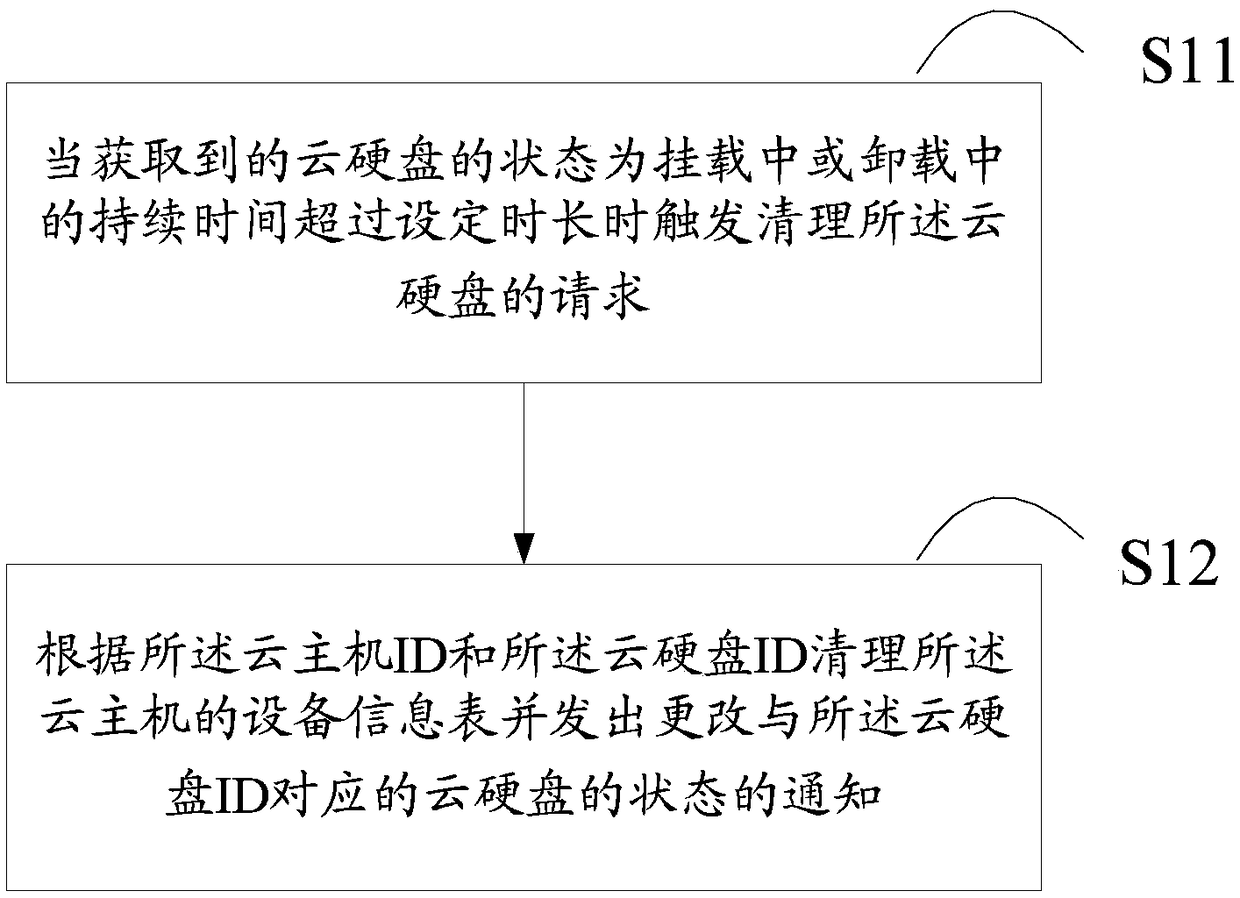

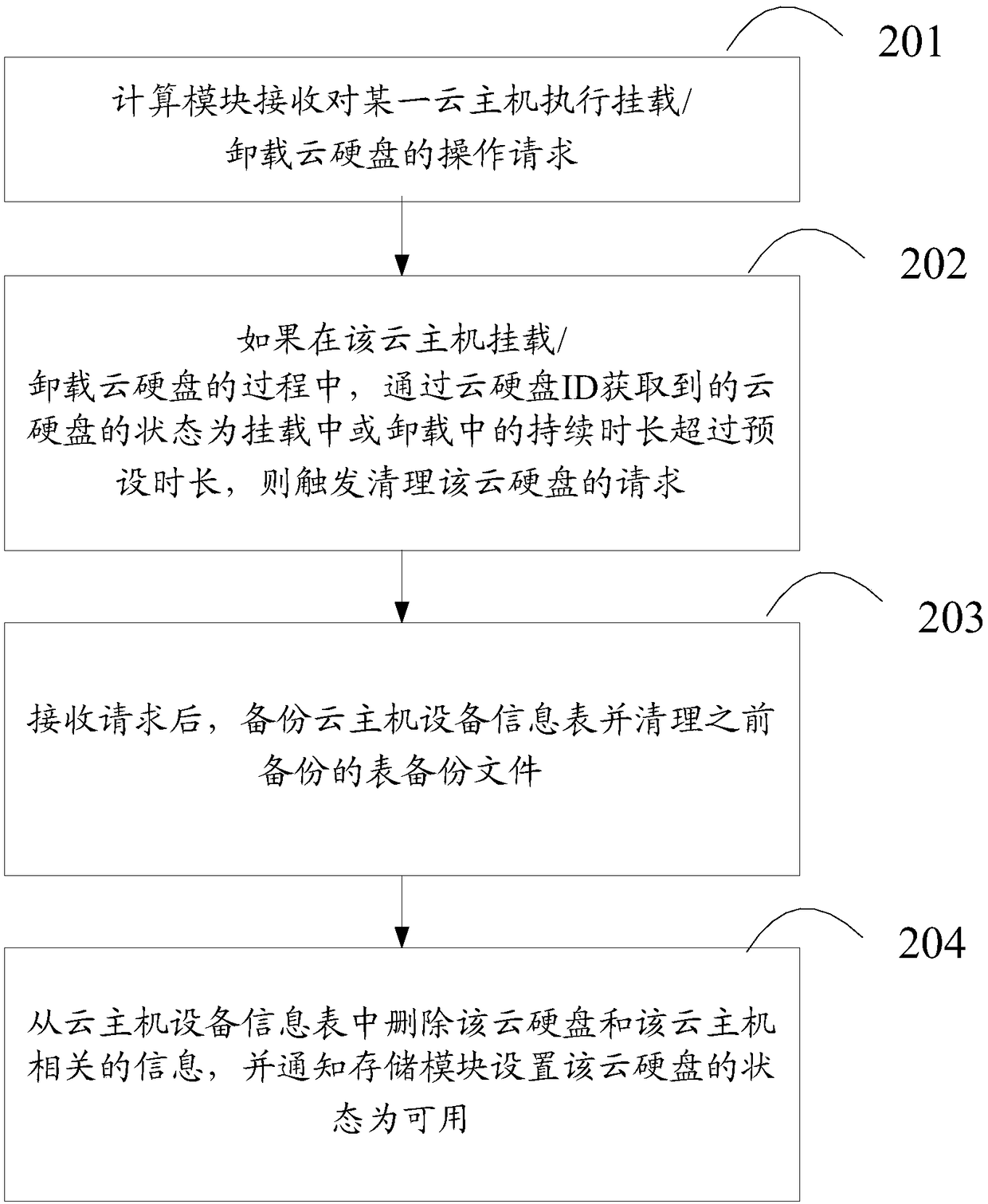

A cloud hard disk cleaning method and apparatus based on a cloud platform

InactiveCN109388350AImplement cleanup operationsImprove usabilityInput/output to record carriersOperating systemDuration time

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

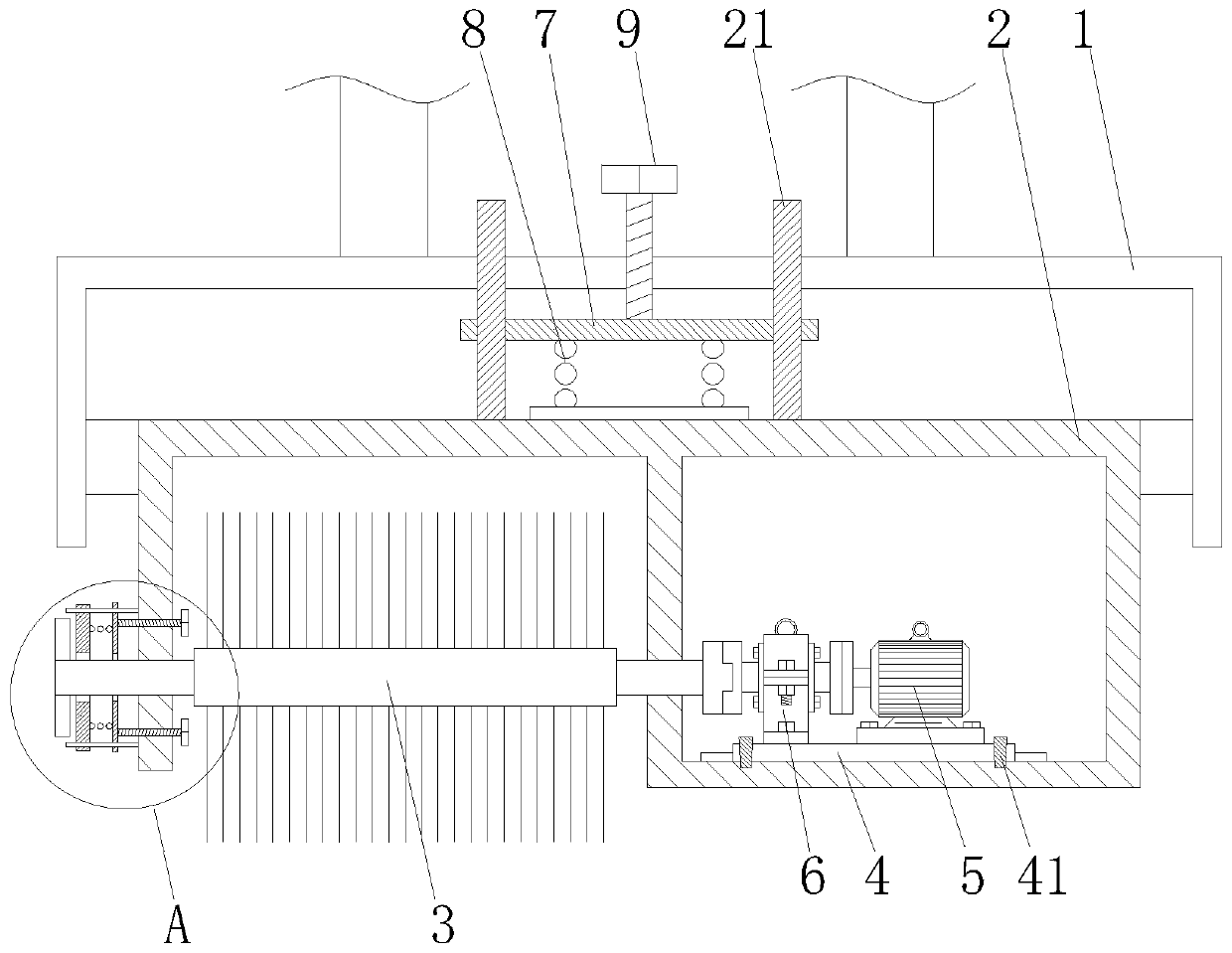

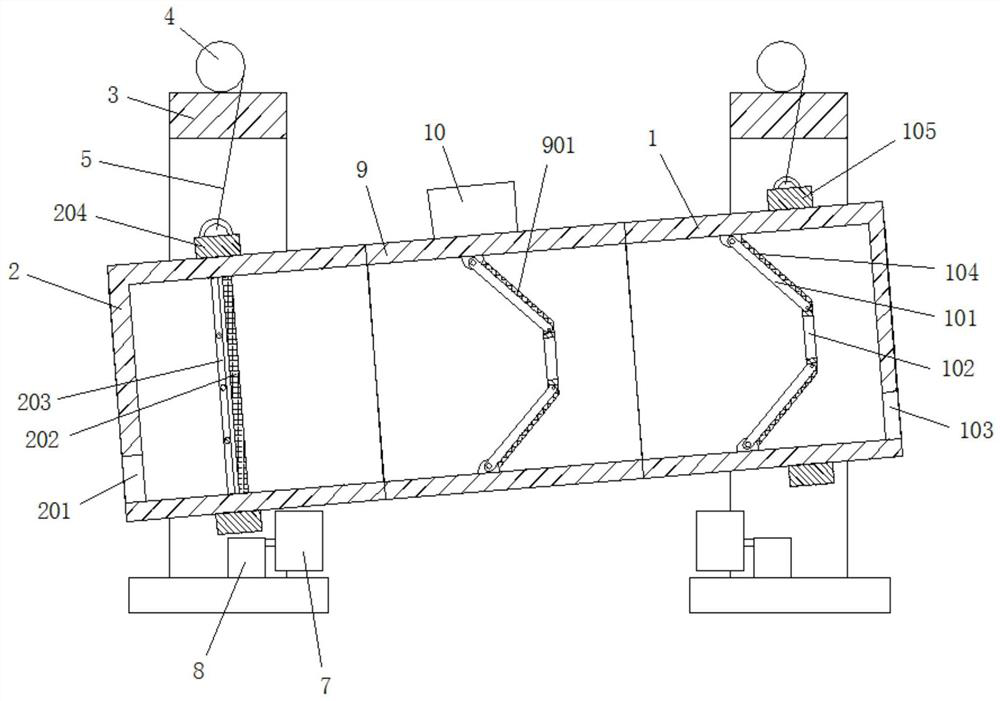

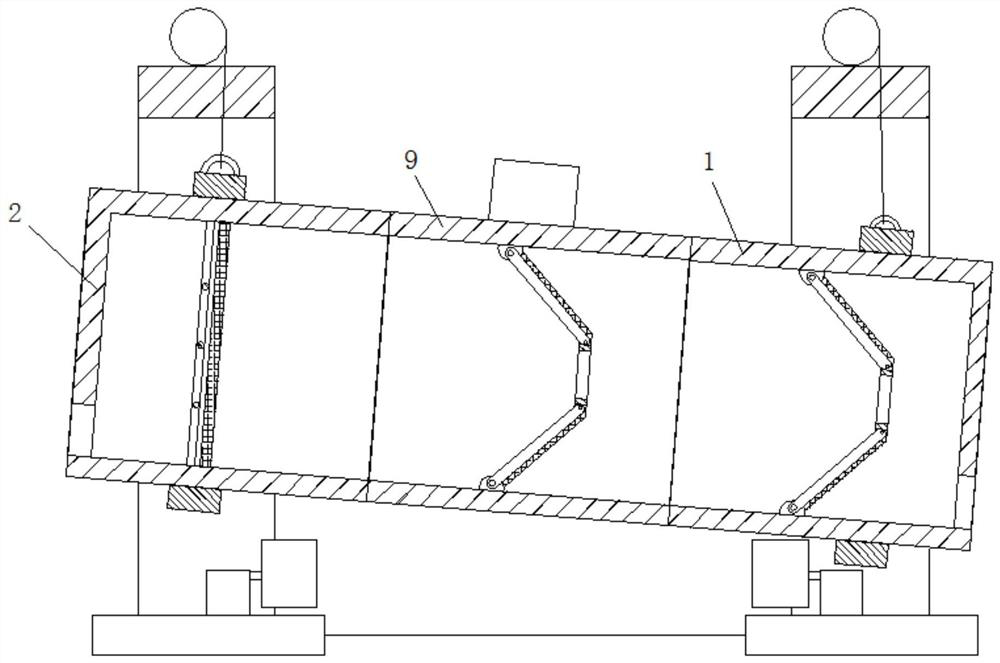

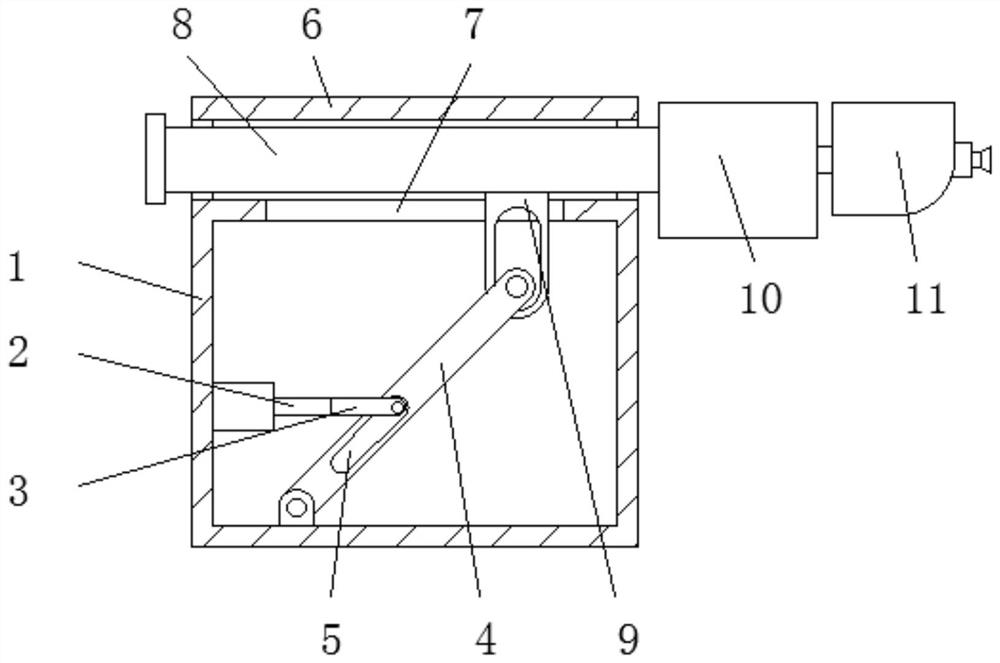

Screen cleaning brush

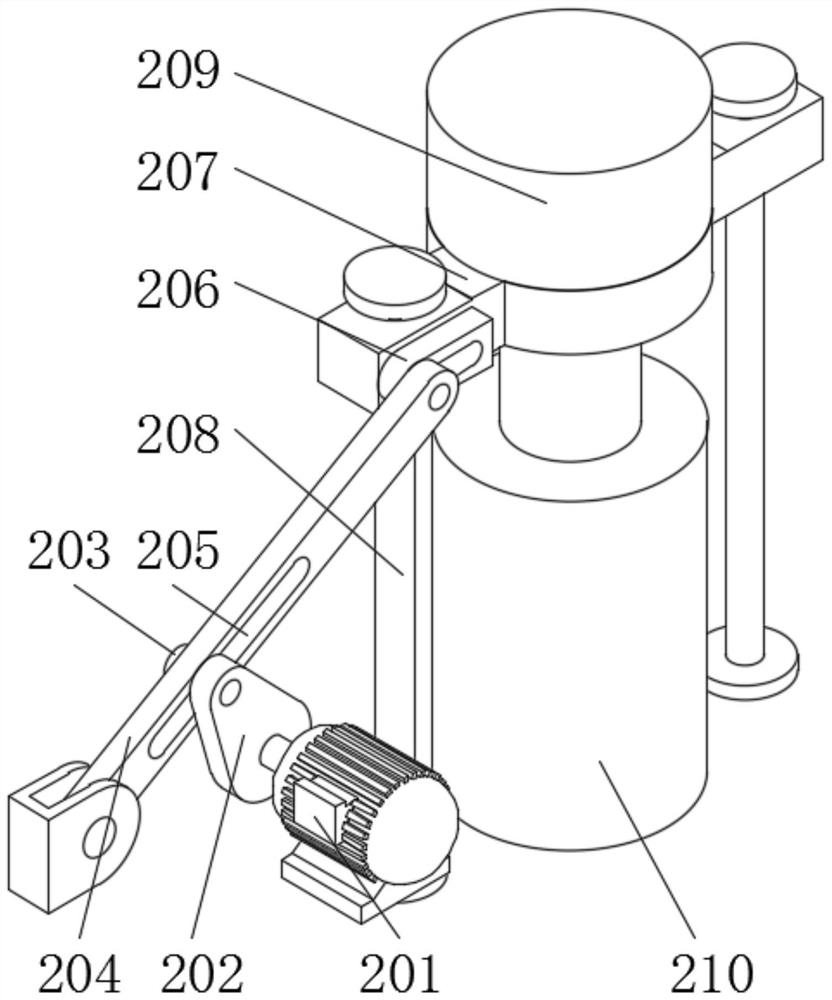

InactiveCN111451121APressure adjustable and controllableImplement cleanup operationsSievingScreeningReduction driveElectric machinery

The invention discloses a screen cleaning brush, and belongs to the field of screening equipment. The screen cleaning brush comprises a rack, a sliding frame is slidably connected with the rack, a roller shaft is rotatably connected with the sliding frame, and flexible brush wires are arranged on the roller shaft; a power device is fixedly installed on the sliding frame and comprises a base, a motor and a speed reducer, the motor and the speed reducer are installed on the base, the base is connected with the sliding frame in a sliding mode and fixed through a locking mechanism, the motor is mechanically connected with the input end of the speed reducer, and the output end of the speed reducer is connected with the roller shaft through a cross-shaped sliding block coupler; and a push plateis further connected with the rack in a sliding mode, the sliding direction of the push plate is parallel to the sliding direction of the sliding frame, a compression spring is connected between the push plate and the sliding frame, an adjusting screw rod is connected with the rack in a threaded mode, and the adjusting screw rod abuts against the push plate. The screen cleaning brush is simple instructure and reasonable in design, the cleaning effect on the screen can be effectively improved, and damage to equipment is reduced.

Owner:安徽省潜山县志发机电配件有限公司

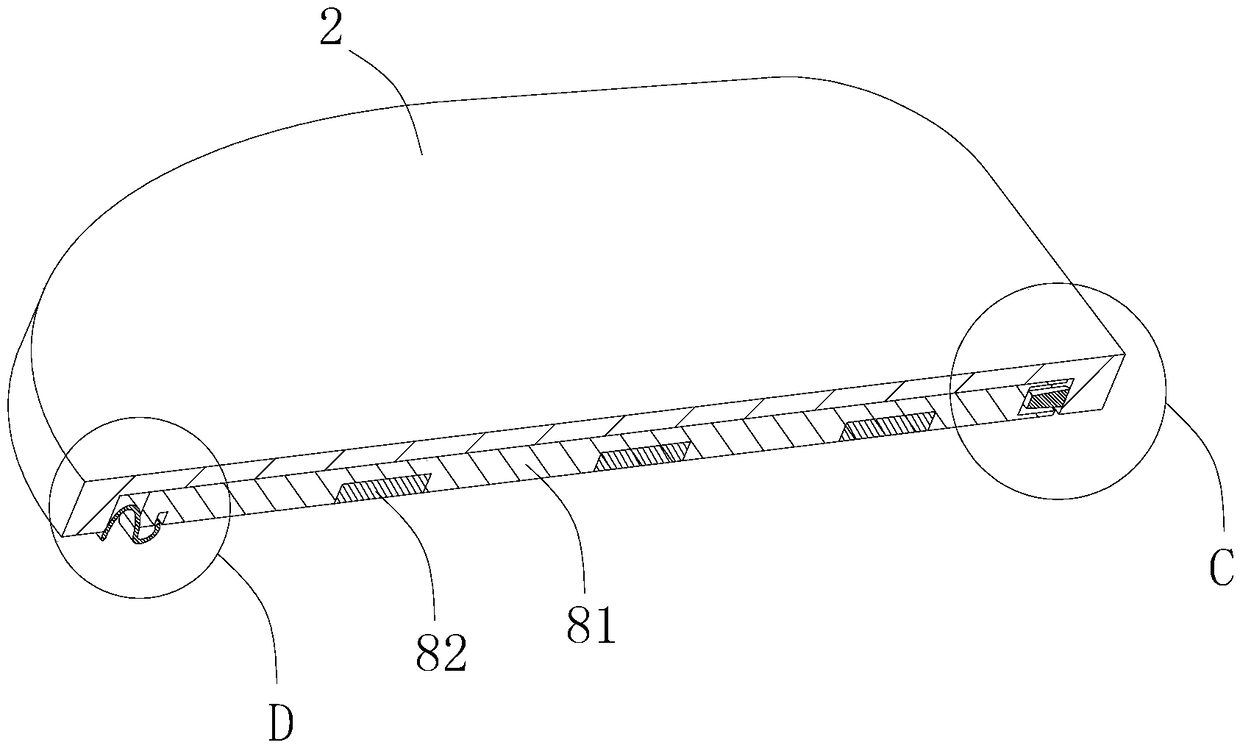

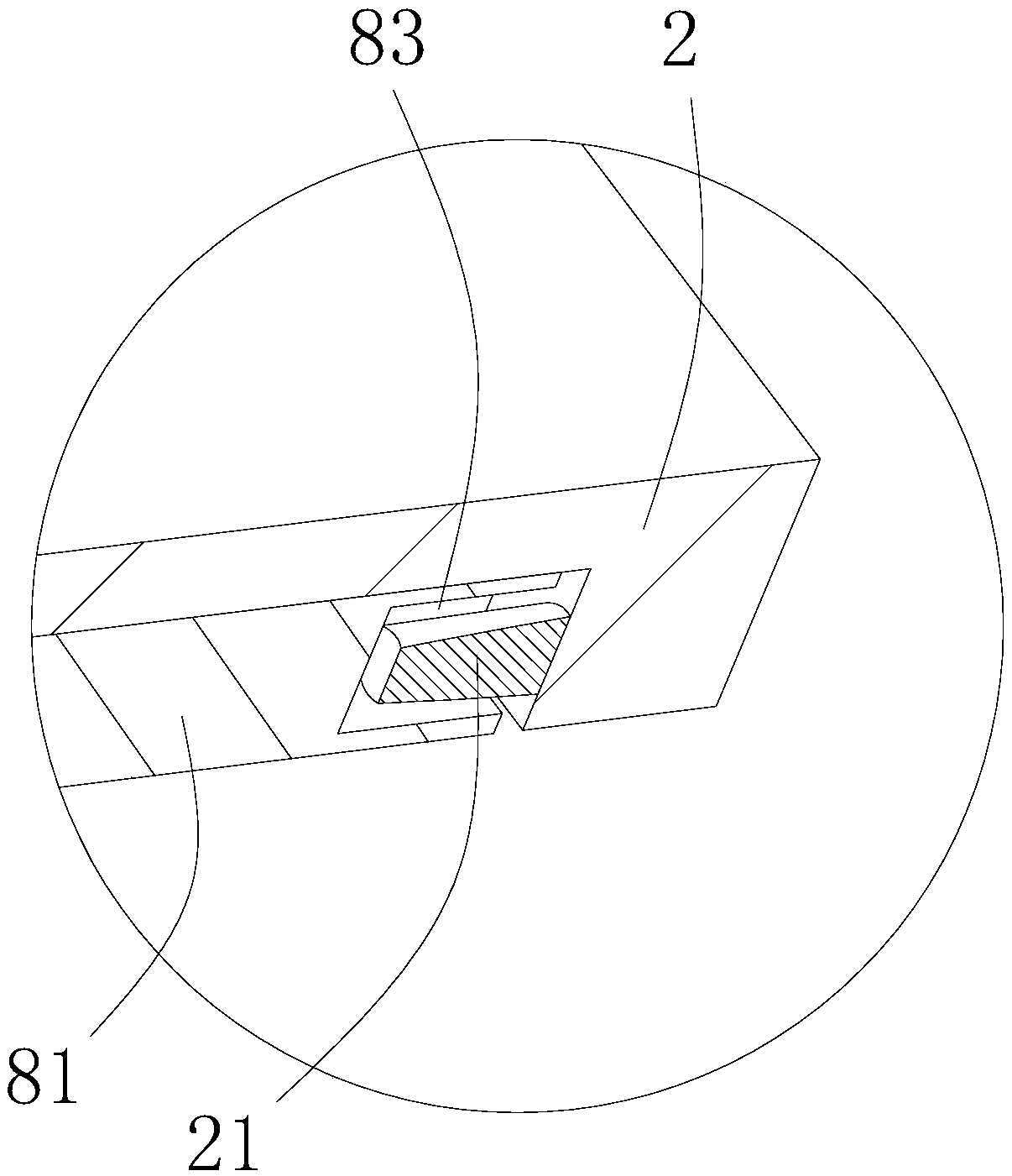

Ultraviolet disinfecting toilet bowl utilizing domestic wastewater

ActiveCN109056932ATake advantage ofAchieve reuseFlushing devicesLavatory sanitoryUv disinfectionWater resources

The invention discloses an ultraviolet disinfecting toilet bowl utilizing domestic wastewater. The toilet bowl comprises a toilet lid, a water tank, a flushing device, a domestic wastewater supply pipe, a water tank cleaning device and an ultraviolet disinfecting device. The toilet lid is connected to the toilet bowl body in a vertical turnover mode, the flushing device is used for flushing the toilet bowl body by means of water inside the water tank, the domestic wastewater is connected with the water tank and used for supplying processed domestic sewage into the water tank, the water tank cleaning device is detachably arranged on the toilet lid through an assembling and disassembling structure and used for disinfecting the toilet bowl body and a toilet seat. Water resources are sufficiently utilized, water resources are recycled, and waste of the water resources is lowered; the ultraviolet disinfecting device is directly detachably arranged on the toilet lid through the dissembling and assembling structure, the whole ultraviolet disinfecting device can be directly disassembled from the toilet lid, and maintenance is convenient.

Owner:河南洛多卫浴有限公司

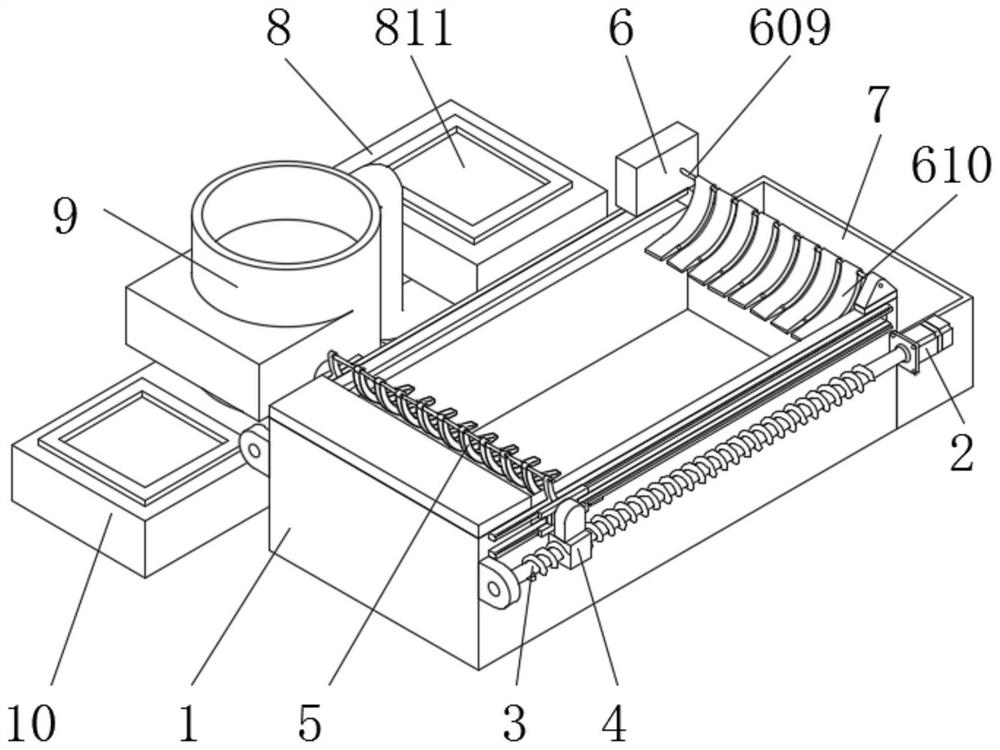

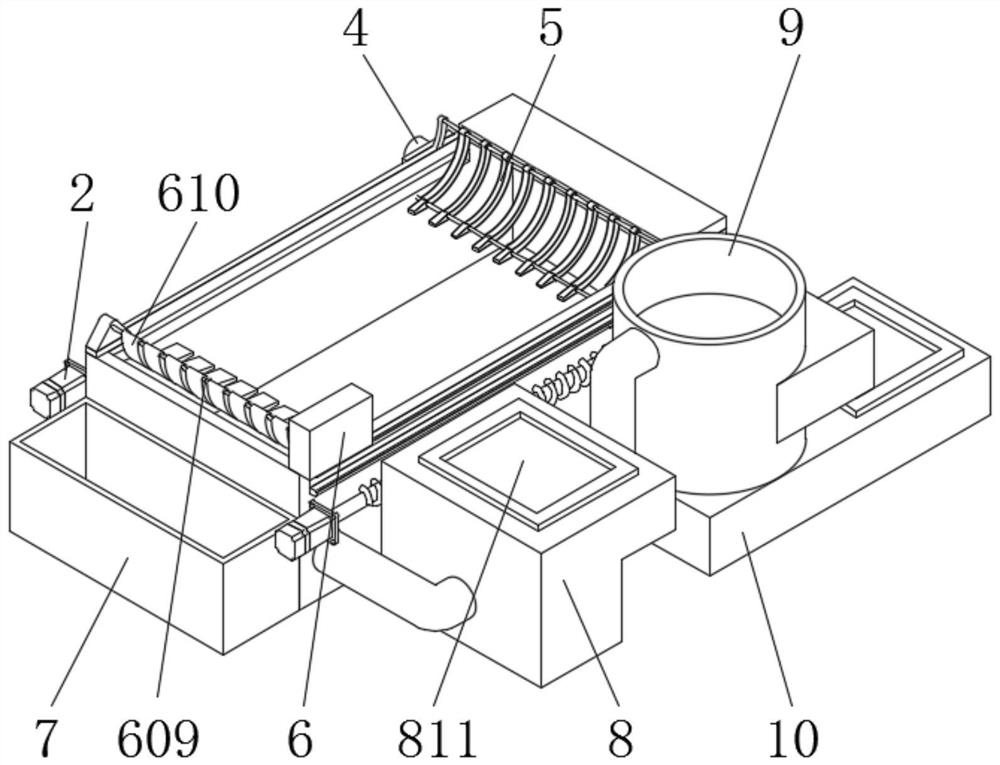

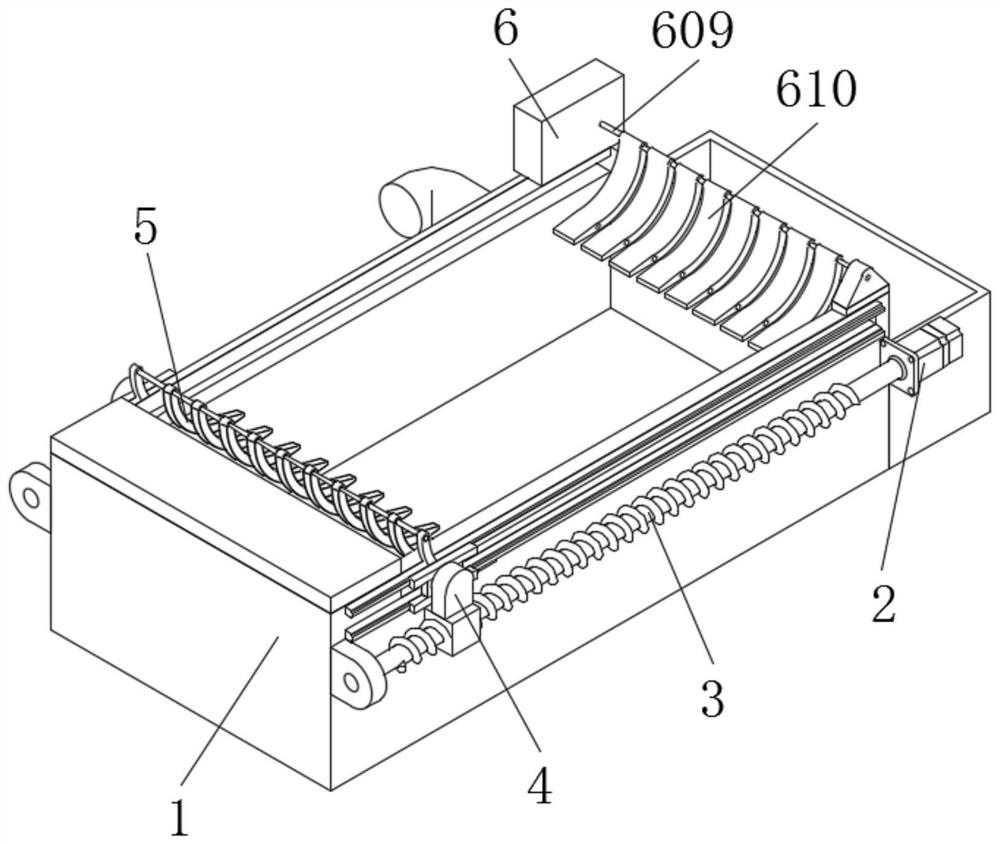

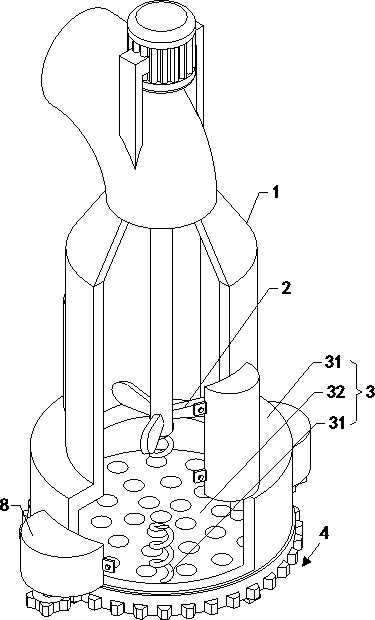

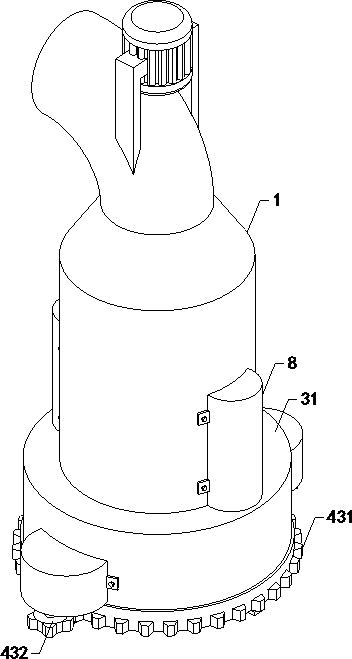

Livestock and poultry disease carcass process equipment

InactiveCN104654307APerfect removalAchieve clearingCremation furnacesIncinerator apparatusPoultry diseaseProcess equipment

The invention discloses a piece of livestock and poultry disease carcass process equipment. The livestock and poultry disease carcass process equipment comprises an incinerator, a feeding device for feeding materials to the incinerator, a smoke purifying device for purifying hot smoke discharged by the incinerator and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail; a transmission main shaft driven by a main motor is arranged in an incineration chamber in the incinerator; a plurality of material scattering bodies for stirring materials are arranged on the transmission main shaft; the feeding device comprises a feeding tube which extends into the incineration chamber from a feeding hole; a feeding packing auger is arranged in the feeding tube; the preheating device comprises a preheating hopper and a spiral flue around the preheating hopper; the smoke purifying device comprises a smoke discharging outer channel and a fall pool; a plurality of shower heads are arranged in the upper side of the smoke discharging outer channel. The invention aims to provide the livestock and poultry disease carcass process equipment which can burn and process animal carcasses in a concentrated manner, is high and efficient in burning process and full in incineration, can effectively process the generated smoke, and can avoid smoke pollution.

Owner:ZHEJIANG SCI-TECH UNIV

Building construction concrete spraying unit with protection mechanism

InactiveCN113389384APrevent solidificationEasy to sprayHollow article cleaningBuilding material handlingArchitectural engineeringBuilding construction

The invention belongs to the technical field of building construction equipment, and particularly relates to a building construction concrete spraying unit with a protection mechanism. The building construction concrete spraying unit with a protection mechanism aims at solving the problems that a pipeline of an existing concrete spraying unit is prone to blockage, the protection effect is poor, the use effect of the concrete spraying unit is poor, and when a spraying pipe is blocked, the concrete spraying unit needs to be shut down and unblocked, and use is not facilitated. The building construction concrete spraying unit with the protection mechanism comprises a bottom plate; a conveying pipe is located above the bottom plate and is connected with a fixed box; an anti-blocking assembly is installed in the fixed box; a first spraying pipe and a second spraying pipe are installed on the conveying pipe; spraying heads are installed at the tail ends of the first spraying pipe and the second spraying pipe; and a cleaning assembly is mounted on each spraying head. According to the concrete spraying unit, the interior of the conveying pipe is cleaned through the anti-blocking assembly, blockages blocked in the spraying pipes are loosened through a vibration assembly, materials in the spraying heads are removed through the cleaning assemblies, the first spraying pipe and the second spraying pipe are standby for each other, and the protection effect and the use effect of the concrete spraying unit are improved.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

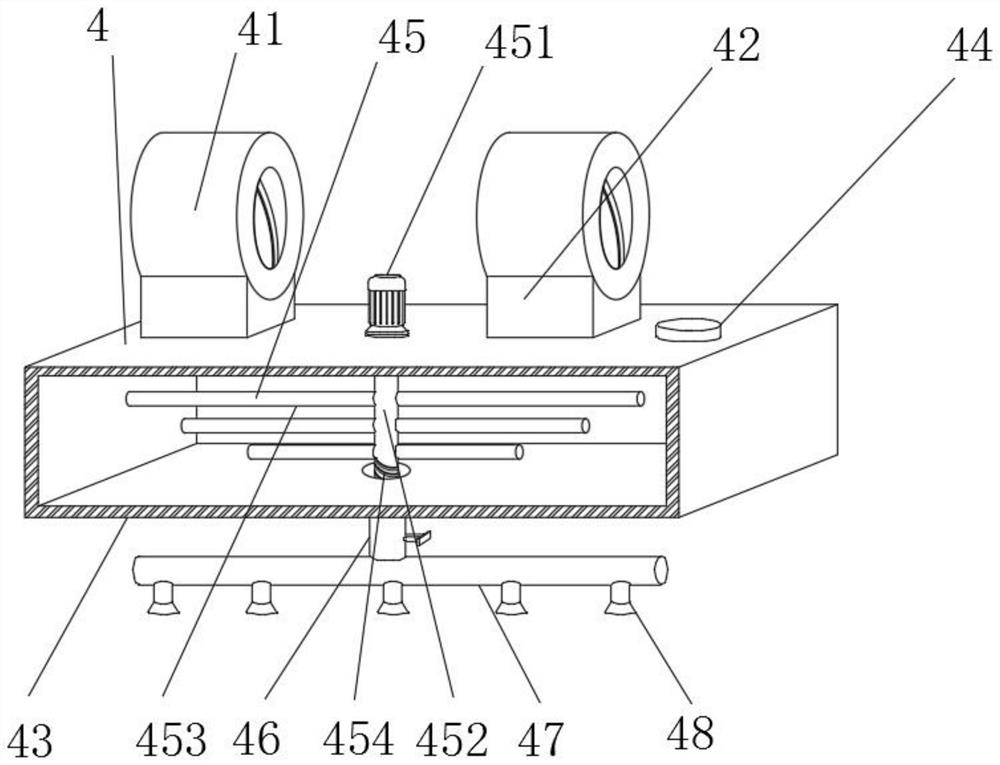

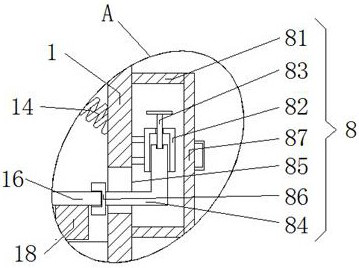

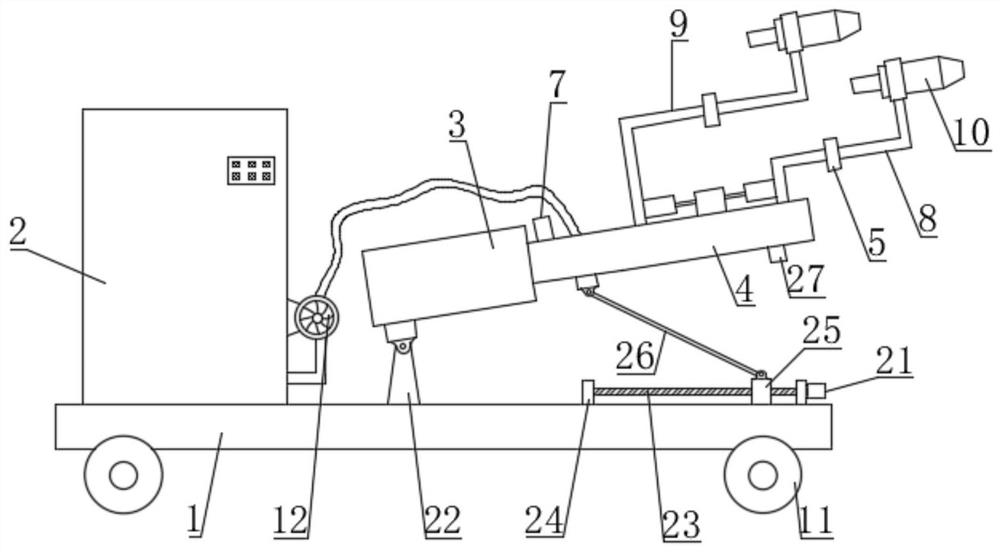

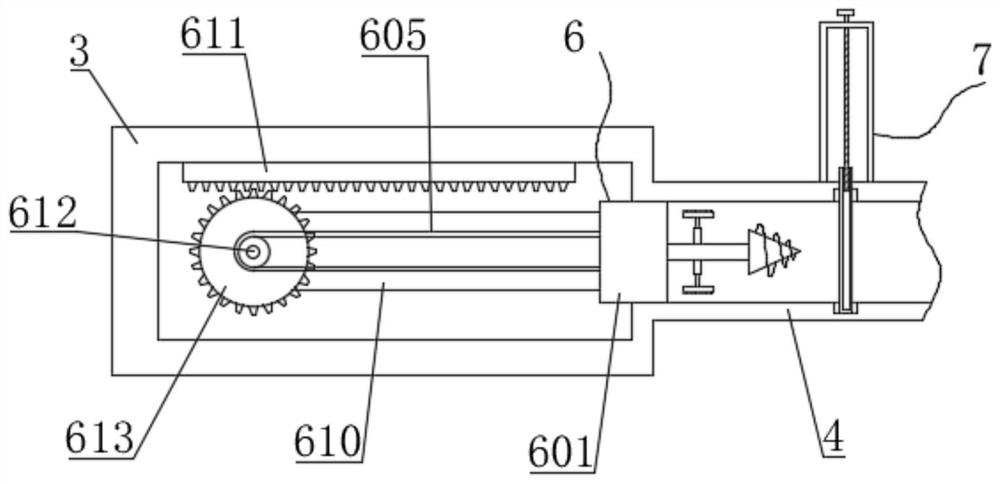

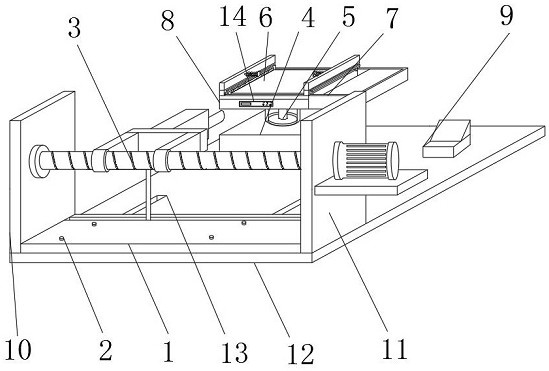

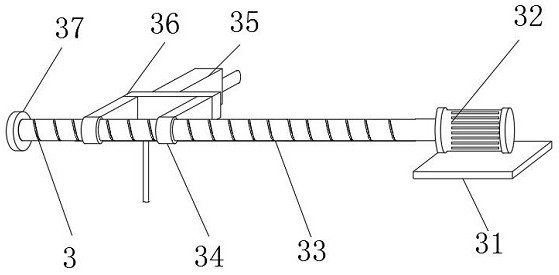

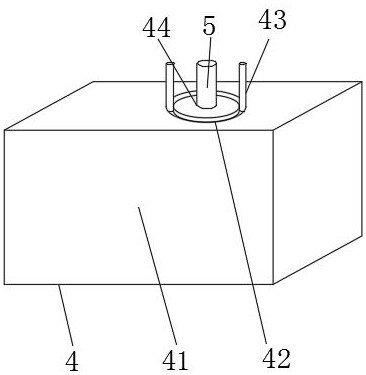

Engineering geological exploration system

PendingCN113153158AImplement cleanup operationsRealize adjustment operationDrill bitsDrilling rodsElectric machineryDrill hole

The invention discloses an engineering geological exploration system. The engineering geological exploration system comprises a hole diameter adjusting mechanism and is characterized in that an adjusting motor is fixedly connected to the inner wall of the hole diameter adjusting mechanism, a threaded rod is installed at the output end of the adjusting motor, a threaded sliding block is in threaded connection to the outer wall of the threaded rod, supporting rods are rotationally connected to the outer wall of the threaded sliding block, and the end, away from the threaded sliding block, of the supporting rods is rotationally connected with a connecting plate. According to the engineering geological exploration system, through the arrangement of the connecting plate, in the hole diameter adjusting mechanism, the adjusting motor works to drive the threaded rod to rotate, the threaded rod rotates to drive the threaded sliding block to move, the threaded sliding block drives the connecting plate to rotate through the supporting rods, the number of the supporting rods is three, the connecting plate moves to drive an energy absorption spring to move, force borne by a rotating blade is transferred through the energy absorption spring, the service life of the rotating blade is prolonged, the connecting plate rotates to drive the rotating blade to adjust the angle, the rotating angle of the connecting plate is 30 degrees, and the hole diameter of a drilled hole is adjusted.

Owner:范静

Inorganic Phosphate Fertilizer Manufacturing Equipment

InactiveCN104654309BPerfect removalAchieve clearingCremation furnacesIncinerator apparatusInorganic phosphateBurn treatment

The invention discloses an inorganic phosphate fertilizer manufacturing device. The inorganic phosphate fertilizer manufacturing device comprises an incinerator, a feeding device for feeding materials to the incinerator, a smoke purification device for purifying hot smoke exhausted by the incinerator and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail, a transmission main shaft driven by a main motor is arranged in an incineration cavity in the incinerator, and the transmission main shaft is provided with multiple bulk cargo bodies which are used for stirring the materials; the feeding device comprises a feeding tube stretching from a feed inlet into the incineration cavity, and a feeding auger is arranged in the feeding tube; the preheating device comprises a preheating hopper and a spiral flue surrounding the preheating hopper; the smoke purification device comprises an outer smoke discharging channel and a water falling pool, and multiple sprinkler heads are arranged on the upper side in the outer smoke discharging channel. According to the inorganic phosphate fertilizer manufacturing device provided by the invention, burning treatment can be effectively carried out on animal carcasses, the burning process is stable and efficient, full incineration is ensured, the generated smoke can be effectively treated, and smoke dust pollution can be prevented.

Owner:ZHEJIANG SCI-TECH UNIV

Kitchen garbage disposal system

The invention discloses a kitchen garbage disposal system. The kitchen garbage disposal system comprises an incinerator, a feeding device, a smoke purifying device and a preheating device, wherein the feeding device feeds materials to the incinerator; the smoke purifying device is used for purifying hot smoke discharged from the incinerator; the incinerator comprises an incinerator body, an incinerator head and an incinerator tail; a transmission spindle which is driven by a main motor is arranged in an incineration cavity in the incinerator; a plurality of material scattering bodies which are used for shifting the materials are arranged on the transmission spindle; the feeding device comprises a feeding barrel which extends into the incineration cavity from a feeding opening; a feeding auger is arranged in the feeding barrel; the preheating device comprises a preheating hopper and a spiral flue surrounding the preheating hopper; the smoke purifying device comprises a smoke discharging outer channel and a pond; and a plurality of shower heads are arranged on the upper portion of the inside of the smoke discharging outer channel. By the kitchen garbage disposal system, dead animals can be incinerated effectively in a centralized manner, an incinerating process is stable and efficient, sufficient incineration can be guaranteed, generated smoke can be treated effectively, and smoke pollution can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

Inorganic phosphate fertilizer manufacturing device

InactiveCN104654309AImprove firing effectReduce material sizeCremation furnacesIncinerator apparatusGastric tube feedingFlue

The invention discloses an inorganic phosphate fertilizer manufacturing device. The inorganic phosphate fertilizer manufacturing device comprises an incinerator, a feeding device for feeding materials to the incinerator, a smoke purification device for purifying hot smoke exhausted by the incinerator and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail, a transmission main shaft driven by a main motor is arranged in an incineration cavity in the incinerator, and the transmission main shaft is provided with multiple bulk cargo bodies which are used for stirring the materials; the feeding device comprises a feeding tube stretching from a feed inlet into the incineration cavity, and a feeding auger is arranged in the feeding tube; the preheating device comprises a preheating hopper and a spiral flue surrounding the preheating hopper; the smoke purification device comprises an outer smoke discharging channel and a water falling pool, and multiple sprinkler heads are arranged on the upper side in the outer smoke discharging channel. According to the inorganic phosphate fertilizer manufacturing device provided by the invention, burning treatment can be effectively carried out on animal carcasses, the burning process is stable and efficient, full incineration is ensured, the generated smoke can be effectively treated, and smoke dust pollution can be prevented.

Owner:ZHEJIANG SCI-TECH UNIV

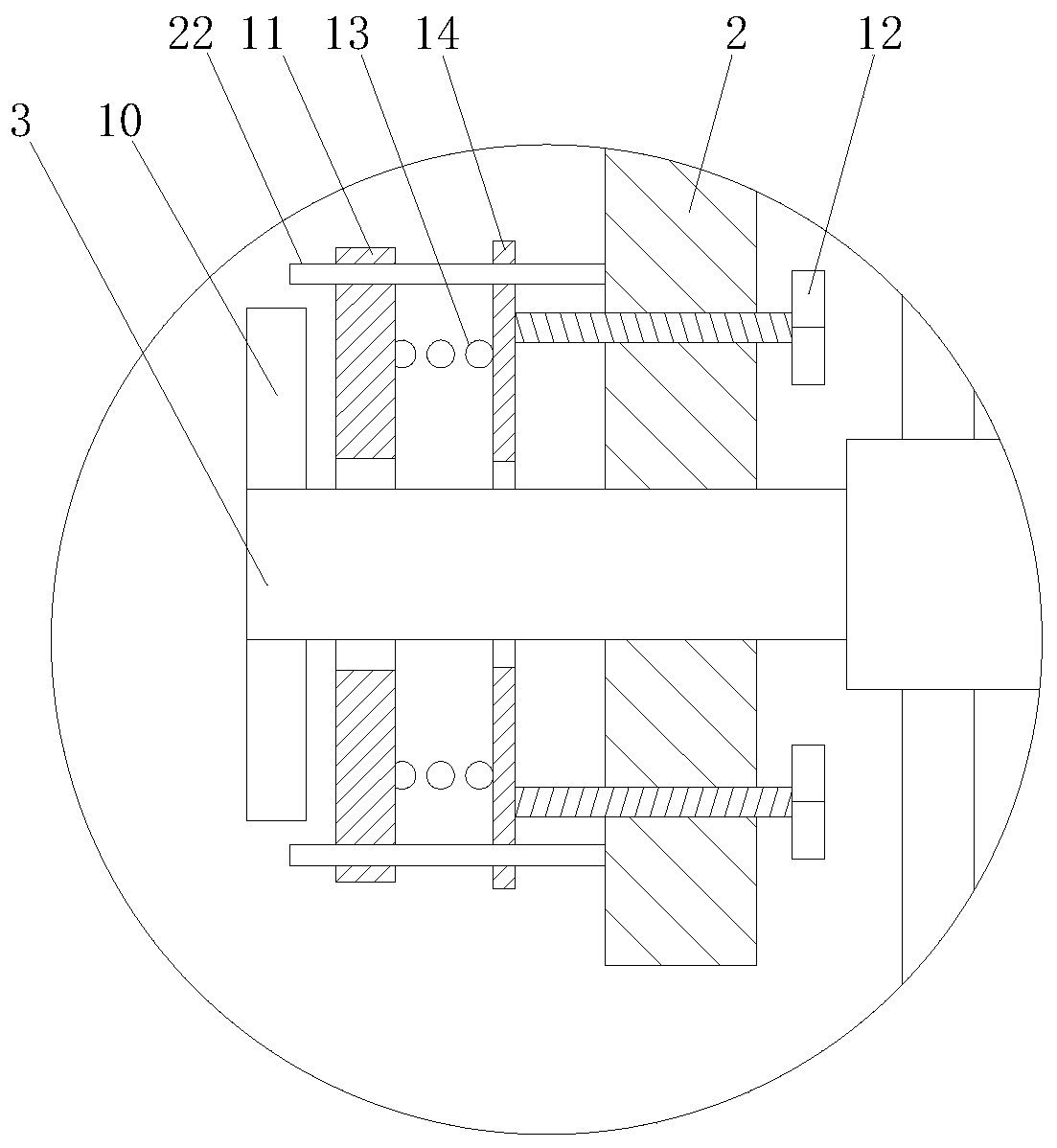

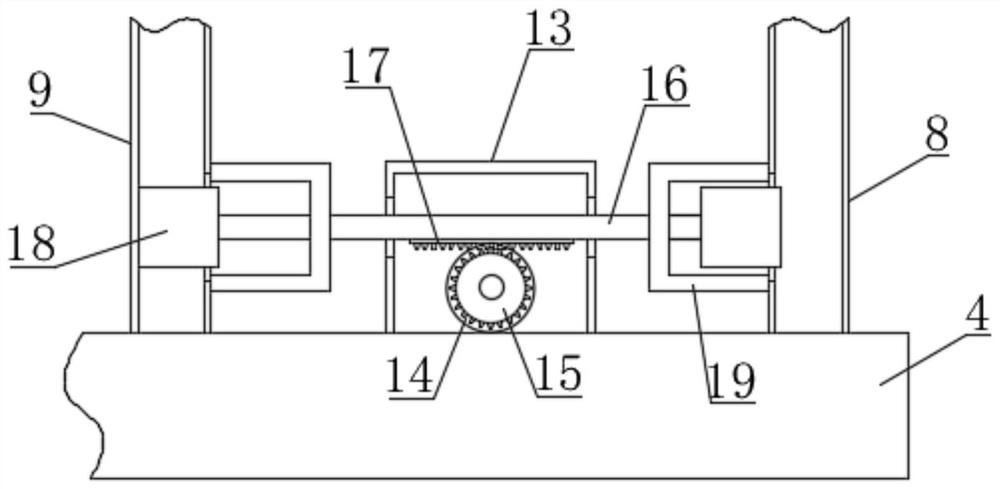

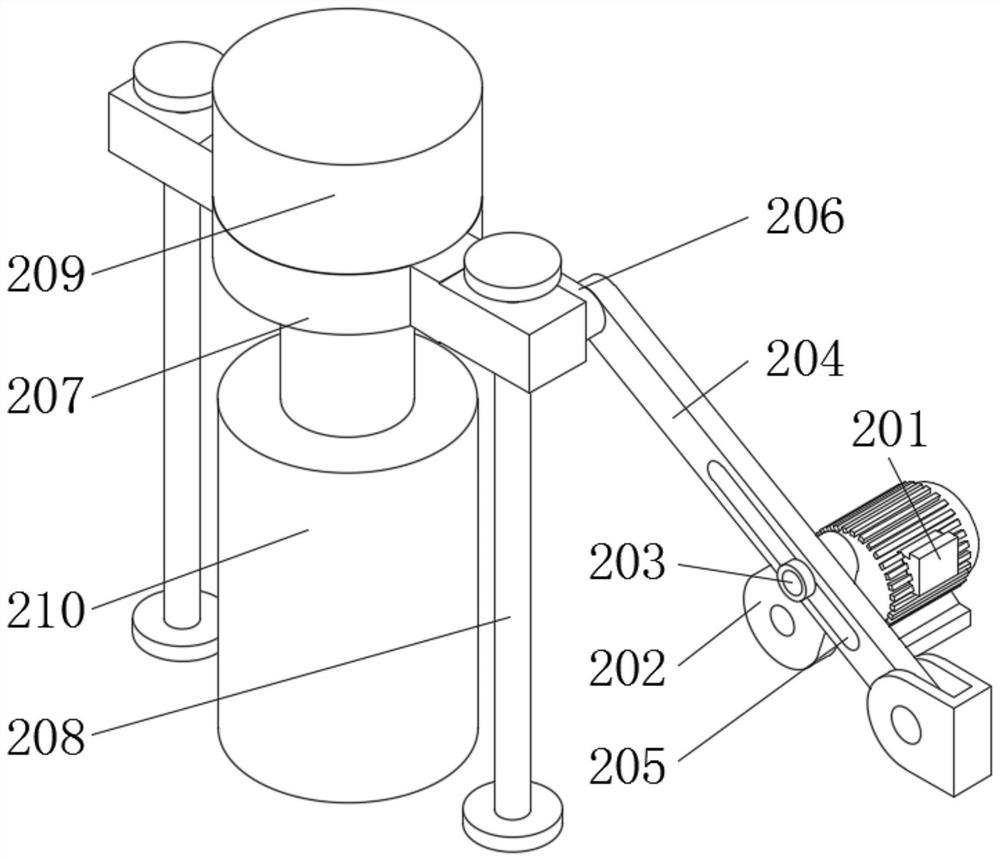

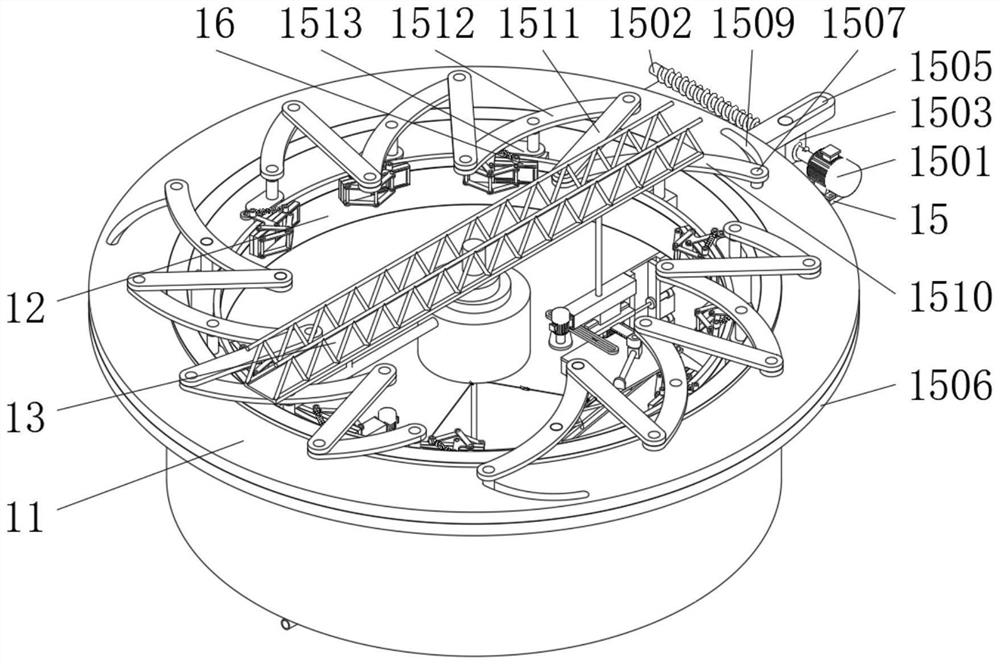

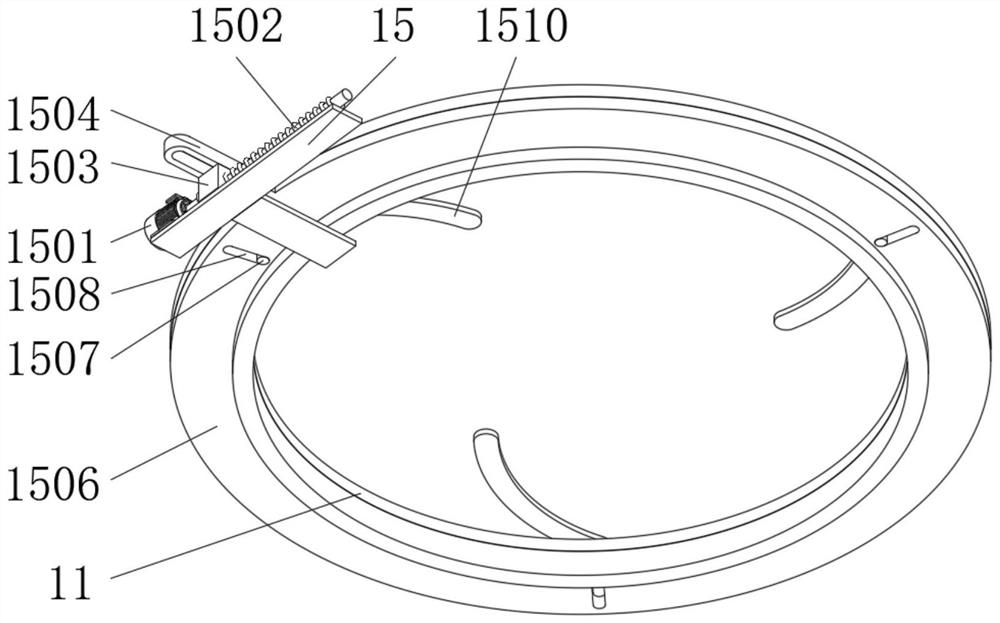

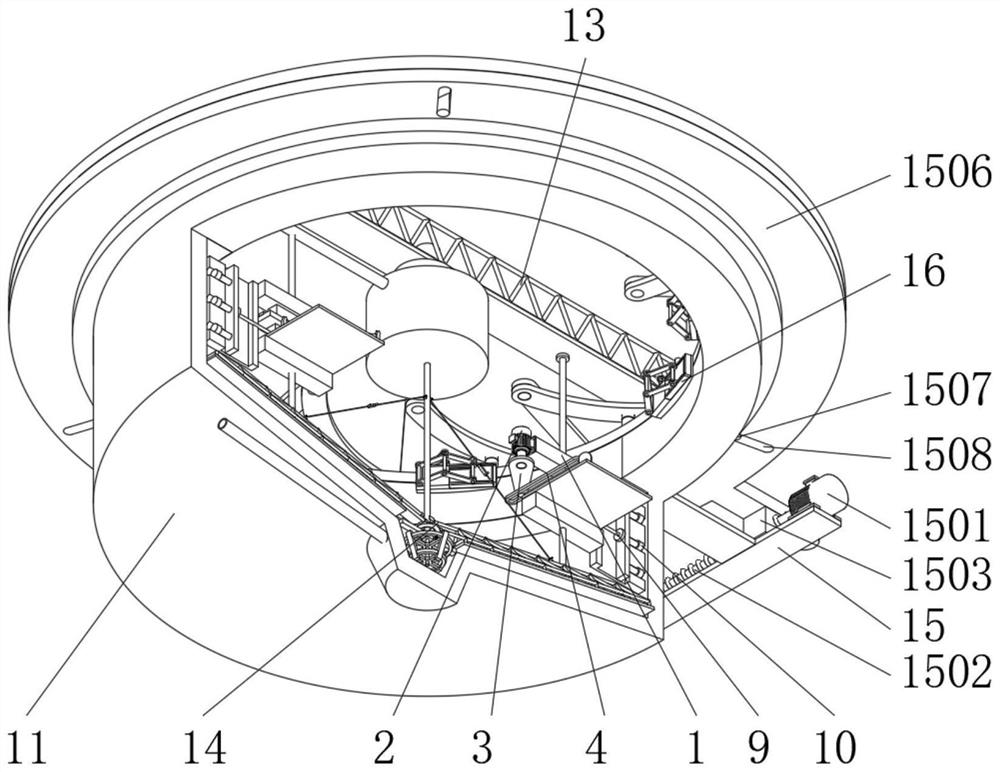

Central transmission mud scraper and use method thereof

InactiveCN113797609AImplement cleanupImplement cleanup operationsSedimentation settling tanksElectric machineryStructural engineering

The invention discloses a center transmission mud scraper and a using method thereof, and belongs to the technical field of mud scrapers, the center transmission mud scraper comprises a cleaning mechanism, a rotating plate, a telescopic hole plate, a sliding block, a limiting rod, a rotating shaft and a cleaning brush, the outer wall of the cleaning mechanism is fixedly connected with a cleaning motor, the cleaning motor rotates to drive a telescopic hole plate to horizontally slide along the outer wall of the cleaning mechanism through the rotating plate, and the side wall of the telescopic hole plate is slidably connected with a toothed plate, so that the telescopic hole plate moves to drive a sliding block to horizontally slide along a limiting rod through the toothed plate, According to the invention, by arranging the telescopic pore plate, in the cleaning mechanism, the rotating plate rotates to drive the telescopic pore plate to horizontally slide along the outer wall of the cleaning mechanism, so that the telescopic pore plate moves to drive a cleaning brush to be close to the inner wall of a working pool through the rotating shaft, and the work of cleaning waste attached to the outer wall of the working pool at different heights is achieved.

Owner:JIANGSU YIHUAN GROUP

Bone incinerating equipment

InactiveCN104676594APerfect removalAchieve clearingCremation furnacesIncinerator apparatusDead bodyEngineering

The invention discloses bone incinerating equipment comprising an incinerator, a feeder, a smoke purifier and a preheater. The feeder is used for feeding materials into the incinerator. The smoke purifier is used for purifying hot smoke discharged by the incinerator. The incinerator comprises a body, a head and a tail; an incinerating chamber in the body is provided with a transmission spindle driven by a main motor; the transmission spindle is provided with a plurality of scattering members used for stirring the materials. The feeder comprises a feed cylinder extending into the incinerating chamber from a feed opening. A feed screw is disposed within the feed cylinder. The preheater comprises a preheating hopper and a spiral flue surrounding the preheating hopper. The smoke purifier comprises a discharge outer duct and a water receiver; a plurality of sprinklers are arranged in the upper portion of the inside of the discharge outer duct. The bone incinerating equipment has the advantages that animal corpses can be effectively centrally incinerated, the incinerating process is stable and efficient, sufficient incineration is guaranteed, produced smoke can be effectively treated, and smoke pollution can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

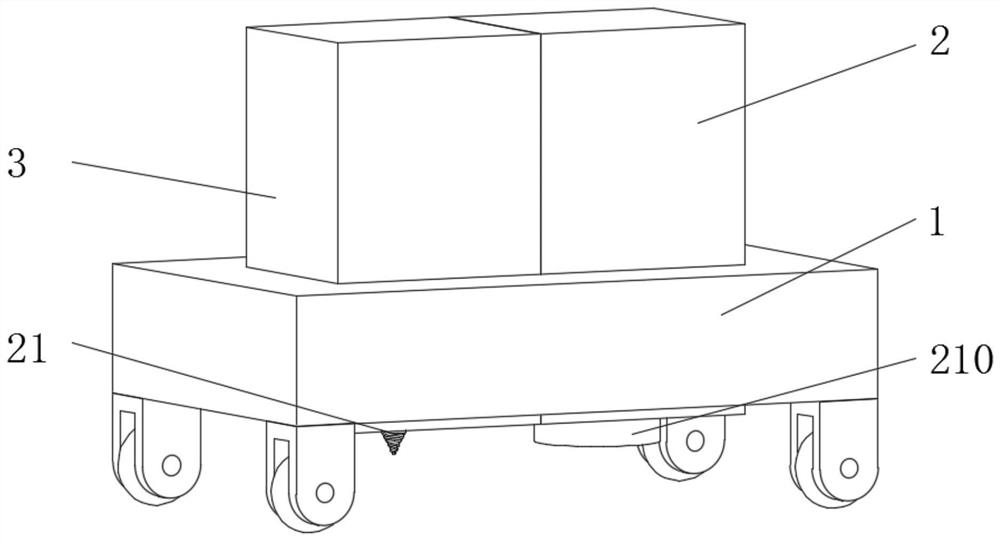

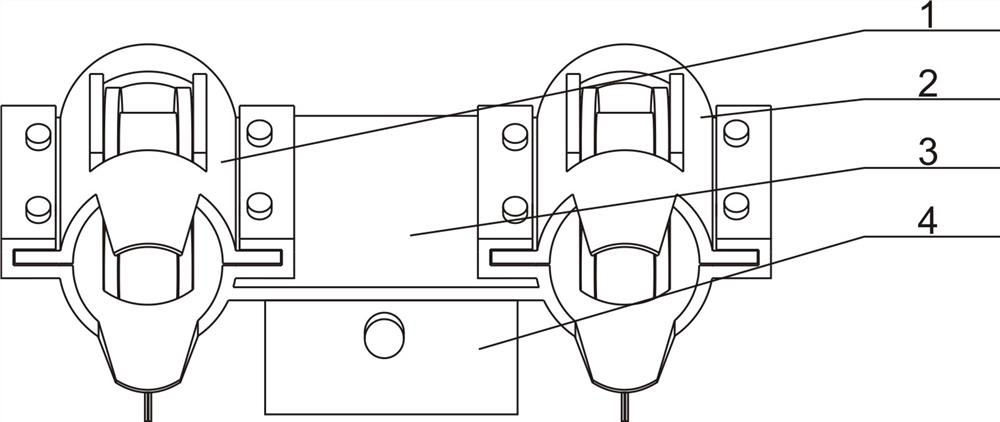

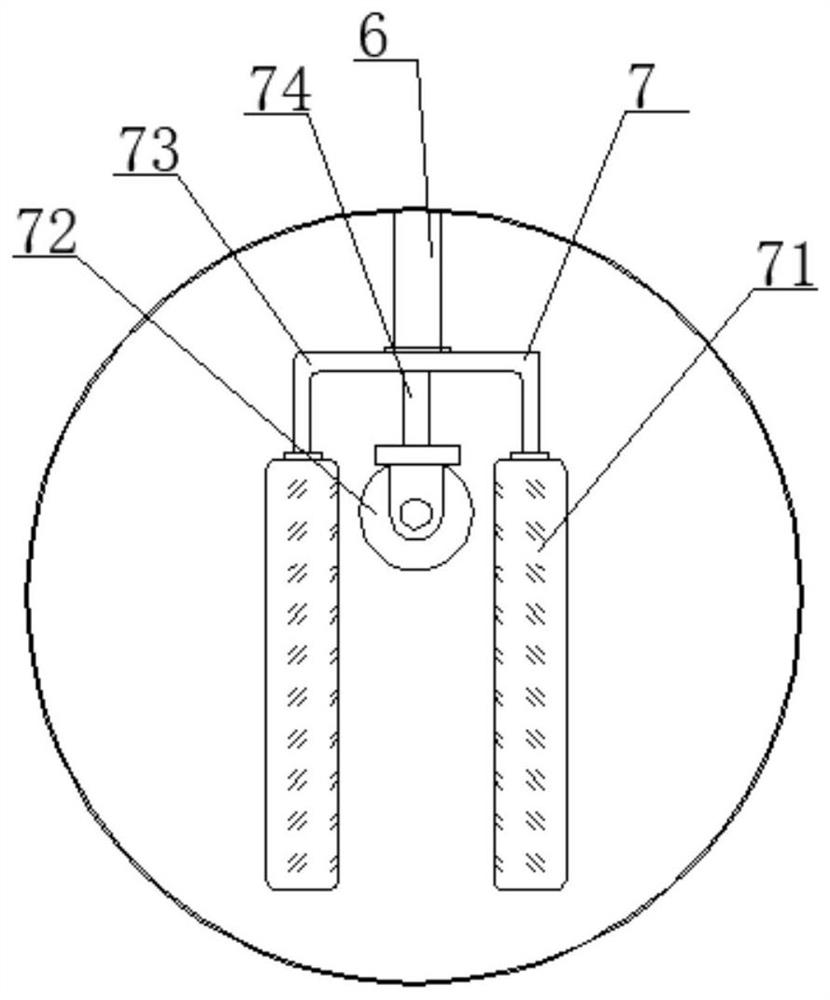

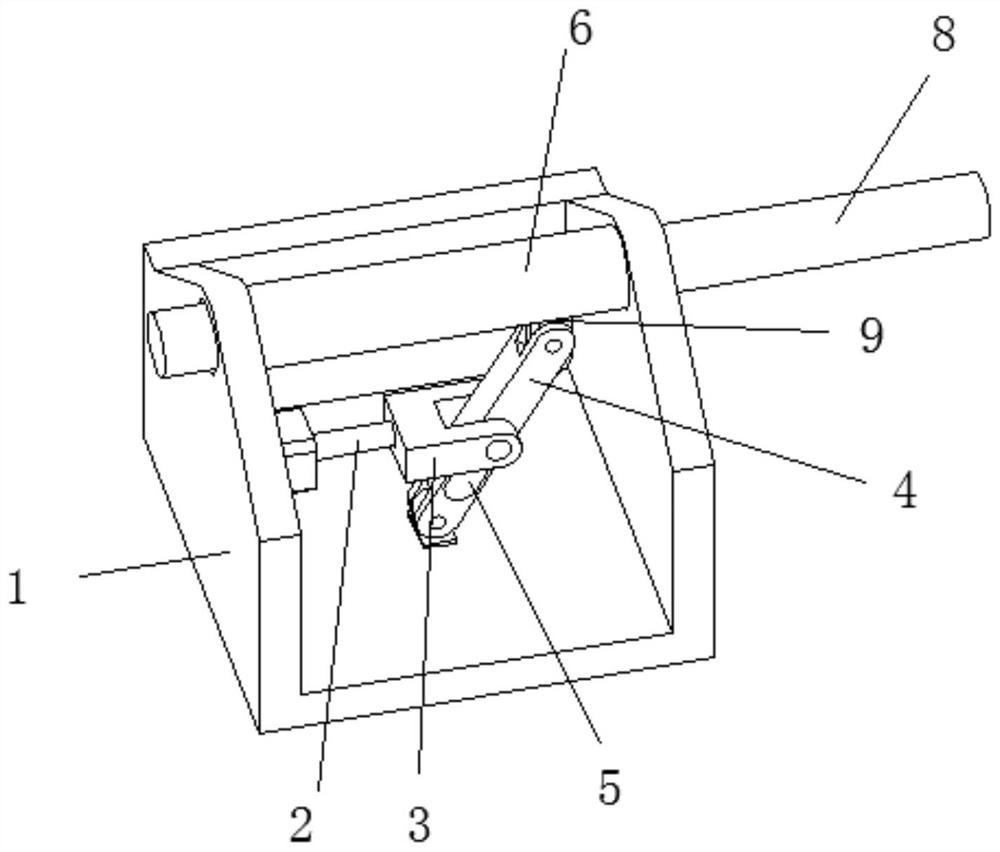

Power transmission line foreign matter cleaning device

ActiveCN113809685AGuaranteed stabilityImprove cleaning efficiencyApparatus for overhead lines/cablesForeign matterPower transmission

The invention discloses a power transmission line foreign matter cleaning device which comprises a walking mechanism A and a walking mechanism B. The walking mechanism A and the walking mechanism B are installed on two adjacent power transmission lines respectively and synchronously driven to walk along the power transmission lines, and each of the walking mechanism A and the walking mechanism B comprises a semi-ring pipe A and a semi-ring pipe B which are matched with each other. The openings of the semi-ring pipes A and the semi-ring pipes B are opposite and are buckled and fixed on the power transmission lines, and cutting mechanisms for cutting foreign matters on the power transmission lines are arranged at the front ends of the semi-ring pipes B. The walking mechanisms for cutting foreign matters are mounted on the adjacent power transmission lines, so that the foreign matters on the multiple power transmission lines can be synchronously cut and cleaned, and the cleaning efficiency is greatly improved. Through the multiple walking mechanisms fixed side by side, the stability of the walking mechanisms is effectively guaranteed, the walking mechanisms can stably and effectively walk along the power transmission lines, and powerful support is provided for cutting and cleaning of foreign matters by the cutting mechanisms.

Owner:STATE GRID CORP OF CHINA +1

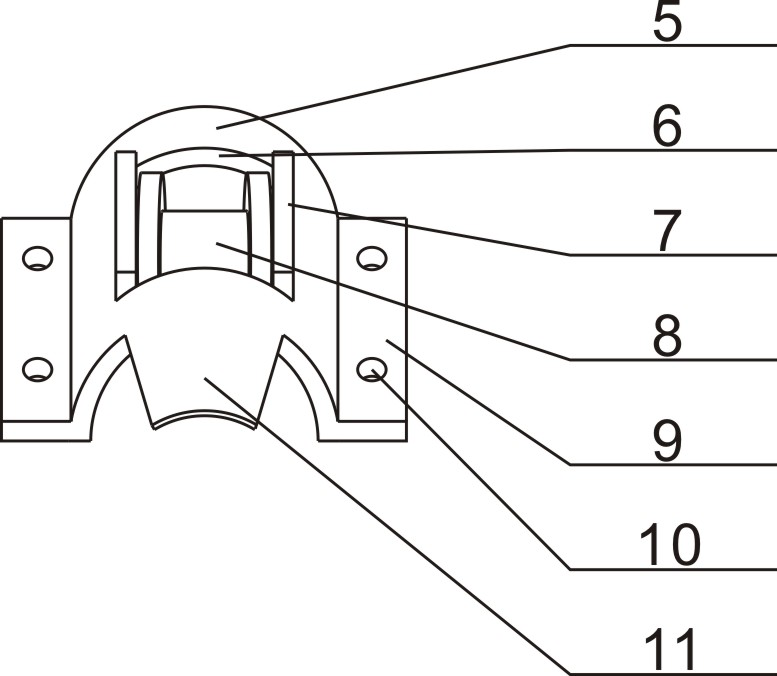

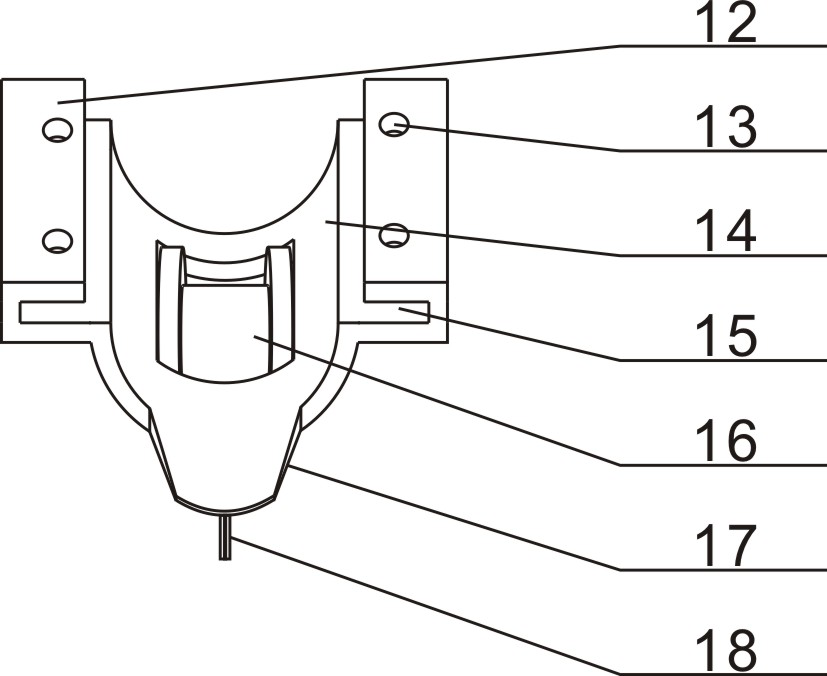

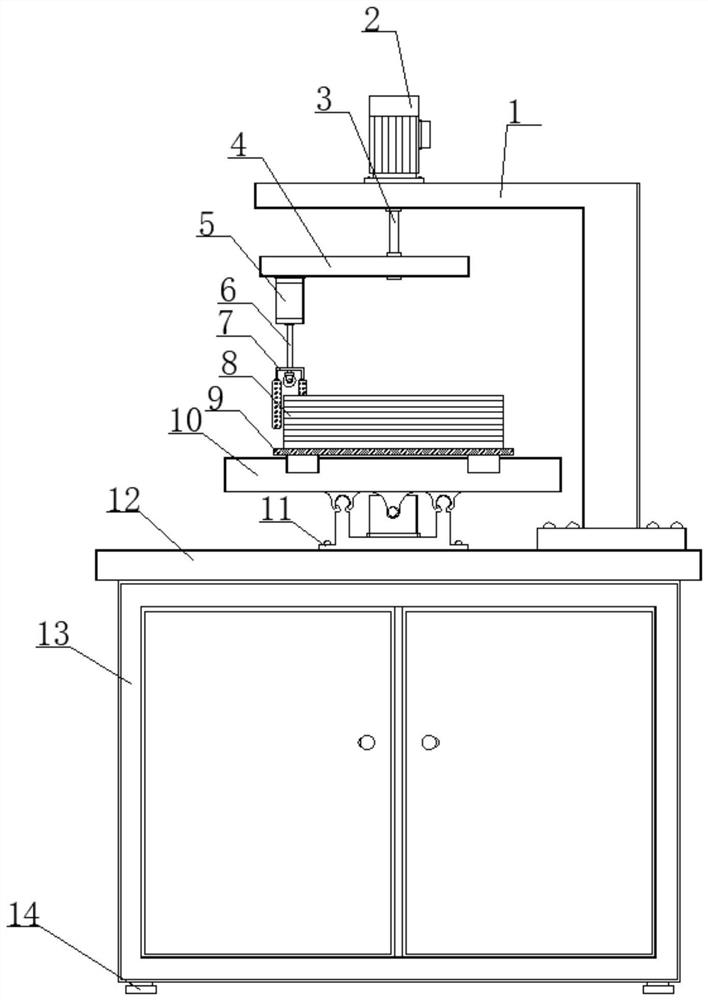

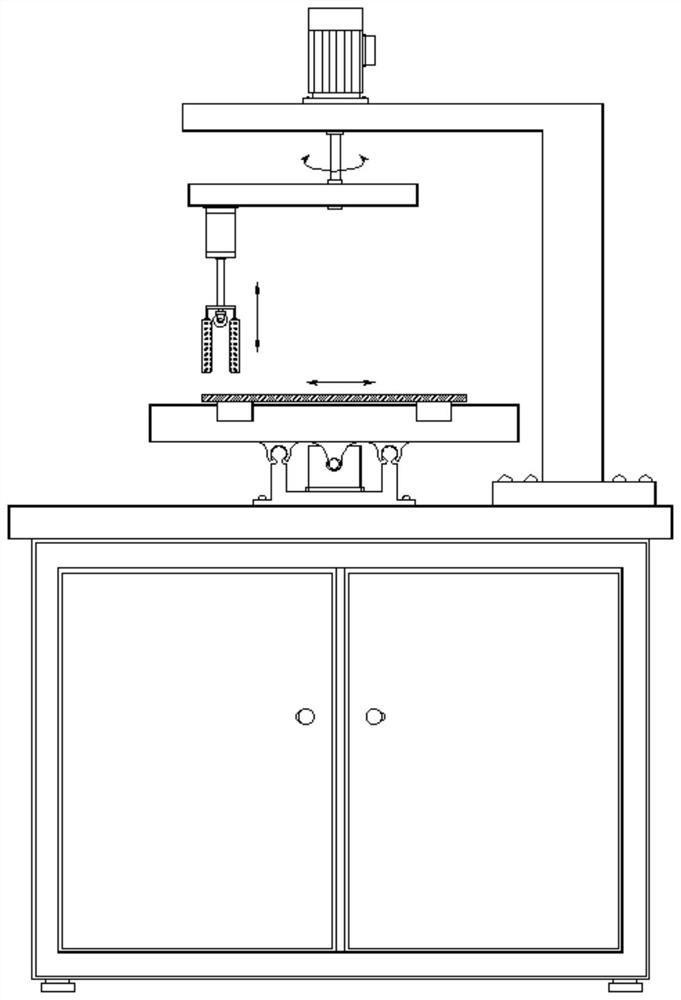

A glass fiber board deburring cleaning machine

ActiveCN112025468BImplement cleanup operationsHigh speedEdge grinding machinesGrinding carriagesGlass fiberStructural engineering

Owner:苏州赫伯特电子科技有限公司

Welding device for electric tool part machining

InactiveCN113084401ARealize multi-directional welding operationSolve clamping difficultiesWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlSlide plate

The invention discloses a welding device for electric tool part machining. The welding device for electric tool part machining comprises a bottom plate, two first sliding grooves are formed in the front portion of the upper end of the bottom plate, the interiors of the two first sliding grooves are jointly and slidably connected with a sliding plate, and the left portion and the right portion of the sliding plate are both in threaded connection with fastening rotary knobs; and the lower ends of the fastening rotary knobs are in threaded connection with the inner parts of the two first sliding grooves, a first side plate and a second side plate are fixedly connected to the left end and the right end of the sliding plate correspondingly, a welding mechanism penetrates through the upper portion of the second side plate, the left end of the welding mechanism is fixedly connected with the right end of the first side plate, and a numerical control table is fixedly installed on the right portion of the upper end of the bottom plate. According to the welding device for electric tool part machining, multidirectional welding operation can be achieved, the problem that heated parts are difficult to clamp is solved, local overheating of the parts caused by too long welding time in the subsequent machining process can be avoided, and the welding quality is guaranteed; and in addition, cleaning efficiency can be improved, and modern use requirements are met.

Owner:东莞市浩恒工业设计有限公司

Livestock and poultry disease meat carcasses processing equipment

InactiveCN104654307BPerfect removalAchieve clearingCremation furnacesIncinerator apparatusIncineration

The invention discloses a piece of livestock and poultry disease carcass process equipment. The livestock and poultry disease carcass process equipment comprises an incinerator, a feeding device for feeding materials to the incinerator, a smoke purifying device for purifying hot smoke discharged by the incinerator and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail; a transmission main shaft driven by a main motor is arranged in an incineration chamber in the incinerator; a plurality of material scattering bodies for stirring materials are arranged on the transmission main shaft; the feeding device comprises a feeding tube which extends into the incineration chamber from a feeding hole; a feeding packing auger is arranged in the feeding tube; the preheating device comprises a preheating hopper and a spiral flue around the preheating hopper; the smoke purifying device comprises a smoke discharging outer channel and a fall pool; a plurality of shower heads are arranged in the upper side of the smoke discharging outer channel. The invention aims to provide the livestock and poultry disease carcass process equipment which can burn and process animal carcasses in a concentrated manner, is high and efficient in burning process and full in incineration, can effectively process the generated smoke, and can avoid smoke pollution.

Owner:ZHEJIANG SCI-TECH UNIV

A kind of bone china raw material preparation device

InactiveCN104676593BPerfect removalAchieve clearingCremation furnacesIncinerator apparatusPollutionBone china

The invention discloses production equipment of bone china materials. The production equipment comprises an incinerator, a feeder, a smoke purifier and a preheater; the feeder is used for feeding materials into the incinerator, and the smoke purifier is used for purifying hot smoke discharged by the incinerator; the incinerator comprises a body, a head and a tail, and an incinerating chamber in the body is provided with a transmission spindle driven by a main motor; the transmission spindle is provided with scattering members used for stirring materials; the feeder comprises a feed cylinder extending into the incinerating chamber from a feed opening; a feed screw is disposed within the feed cylinder; the preheater comprises a preheating hopper and a spiral flue surrounding the preheating hopper; the smoke purifier comprises a discharge outer duct and a water receiver; a plurality of sprinklers are arranged in the upper portion of the inside of the discharge outer duct. The production equipment has the advantages that animal corpses can be effectively centrally incinerated, the incinerating process is stable and efficient, sufficient incineration is guaranteed, the produced smoke can be effectively treated, and smoke pollution can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

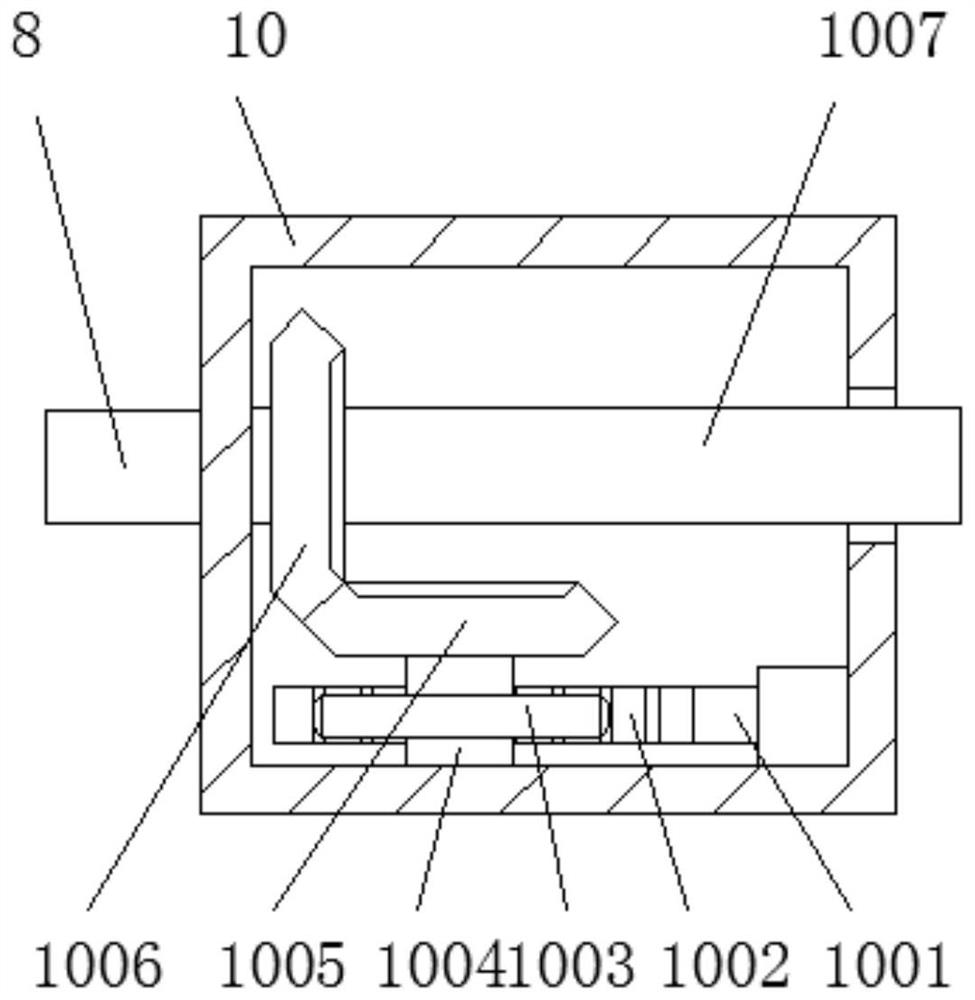

Energy-saving axial flow pump

PendingCN114593068AImplement cleanup operationsReduce cloggingPump componentsAxial flow pumpsAxial-flow pumpWater filter

The invention relates to the technical field of liquid conveying equipment, in particular to an energy-saving axial flow pump which is additionally provided with a water filtering assembly, so that the phenomenon of water blockage is reduced, and the influence on water conveying is reduced. Comprising a pump body and further comprises a filtering device, the filtering device is arranged at the bottom end of the pump body and comprises a filtering cylinder fixedly arranged at the bottom end of the pump body, a filtering groove is formed in the bottom end of the filtering cylinder, a through hole is formed in the top end of the filtering cylinder, the output end of the through hole communicates with the bottom end of a cavity, a filtering plate is arranged in the filtering groove, and a buffering assembly is arranged at the top end of the filtering plate; the cleaning device is arranged at the bottom end of the filter cylinder, and the cleaning device comprises an X-shaped plate arranged on the lower side of the cleaning cylinder, a brush group fixedly arranged at the top end of the X-shaped plate and a driving assembly connected with the X-shaped plate.

Owner:YANGZHOU HONGYUE MECHANICAL CO LTD

An organic waste incinerator

Owner:ZHEJIANG SCI-TECH UNIV

Ash burning equipment

InactiveCN104676594BPerfect removalAchieve clearingCremation furnacesIncinerator apparatusDead bodyEngineering

Owner:ZHEJIANG SCI-TECH UNIV

A leaf treatment device

The invention discloses a tree leaf treatment device. The tree leaf treatment device comprises an incinerator, a feeding device, a flue gas purifying device and a preheating device, wherein the feeding device is used for feeding materials to the incinerator; the flue gas purifying device is used for purifying hot flue gas discharged from the incinerator; the incinerator comprises an incinerator body, an incinerator head and an incinerator tail; a transmission spindle which is driven by a main motor is arranged in an incineration cavity in the incinerator; a plurality of material scattering bodies which are used for shifting materials are arranged on the transmission spindle; the feeding device comprises a feeding barrel which extends into the incineration cavity from a feeding opening; a feeding auger is arranged in the feeding barrel; the preheating device comprises a preheating hopper and a spiral flue which surrounds the preheating hopper; the flue gas purifying device comprises a flue gas discharging external channel and a pond; and a plurality of shower heads are arranged on the upper portion of the inside of the flue gas discharging external channel. By the tree leaf treatment device, dead animals can be effectively incinerated in a centralized manner, an incineration process is stable and efficient, sufficient incineration can be guaranteed, generated flue gas can be treated effectively, and smoke pollution can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

A sewage treatment device for water resource reuse

ActiveCN112138458BExtended service lifeImprove filtration efficiencyMoving filtering element filtersWater resourcesSewage treatment

The invention discloses a sewage treatment device for reuse of water resources, which includes a filter, the filter includes a water inlet assembly and a water outlet assembly, and the water inlet assembly and the water outlet assembly are detachably connected; the water inlet assembly includes a water inlet shell body, the water inlet shell is in the shape of a round tube with one end sealed, and a first support mechanism is arranged in the water inlet shell; the sealing end of the water inlet shell is provided with a water inlet, and the side of the first support mechanism close to the water inlet is fixedly connected There is a primary filter, the primary filter is in the shape of a ring, the outer edge of the primary filter is in sealing connection with the inner wall of the water inlet housing, the inner edge of the primary filter is in sealing connection with the outer wall of the first fixing ring; the first support mechanism is in contact with the primary filter A funnel structure with a smaller opening facing the water inlet is formed, and the end of the water inlet housing away from the water inlet is detachably connected to the water outlet assembly.

Owner:石超杰

Ultrasonic transduction equipment capable of performing internal cleaning

InactiveCN112452922AImplement cleanup operationsRealize control operationCleaning using liquidsEngineeringPhysics

The invention discloses ultrasonic transduction equipment capable of performing internal cleaning. The ultrasonic transduction equipment comprises a main body frame, a first pneumatic push rod is fixedly connected to the inner wall of the main body frame, a push rod is welded to the output end of the first pneumatic push rod, a rotating rod is connected to the end, away from the first pneumatic push rod, of the push rod in a rotating mode and is located on the inner wall of the main body frame, in addition, a first groove is arranged at the connection portion between the rotating rod and the push rod, a telescopic cylinder barrel is welded to the top end of the main body frame, and a motion groove is formed in the connecting portion between the telescopic cylinder barrel and the main bodyframe. According to the ultrasonic transduction equipment capable of performing internal cleaning, the rotating rod is arranged, the first pneumatic push rod works to drive the push rod to move, the push rod drives the rotating rod to move through the first groove, the rotating angle of the rotating rod is 60 degrees, the rotating rod drives the telescopic rod to move along the telescopic cylinderbarrel through a second groove, and cleaning operation of workpieces at different depths is realized.

Owner:嘉兴赛秦医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com