Filter screen self-cleaning anti-blocking double-motor fresh air conveying equipment

A conveying equipment and self-cleaning technology, applied in mechanical equipment, lighting and heating equipment, ventilation systems, etc., can solve the problems of blockage of the filter surface of the filter, time-consuming, labor-intensive cost, and inability to meet the air supply needs of the building ventilation system, etc. Achieve the effect of avoiding blockage, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

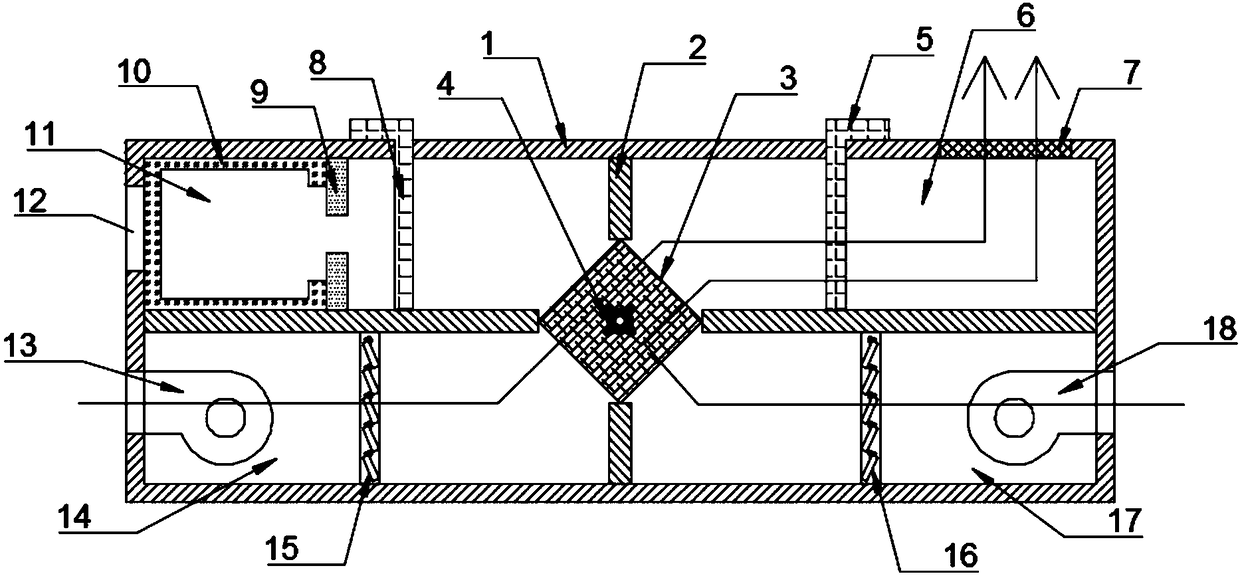

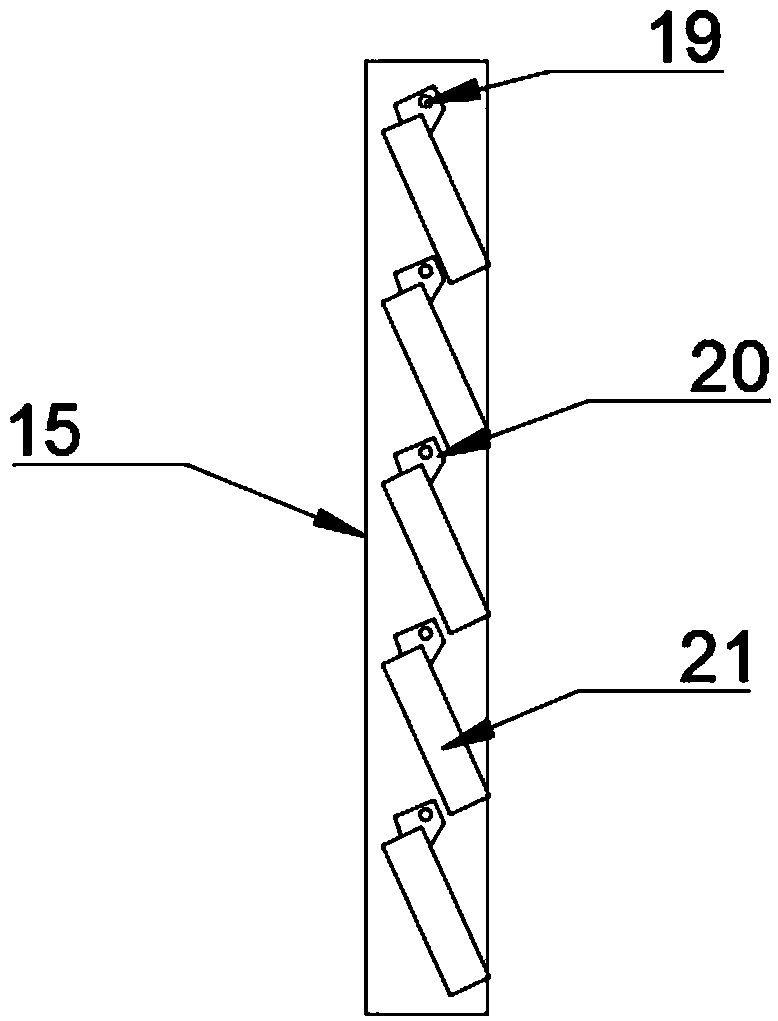

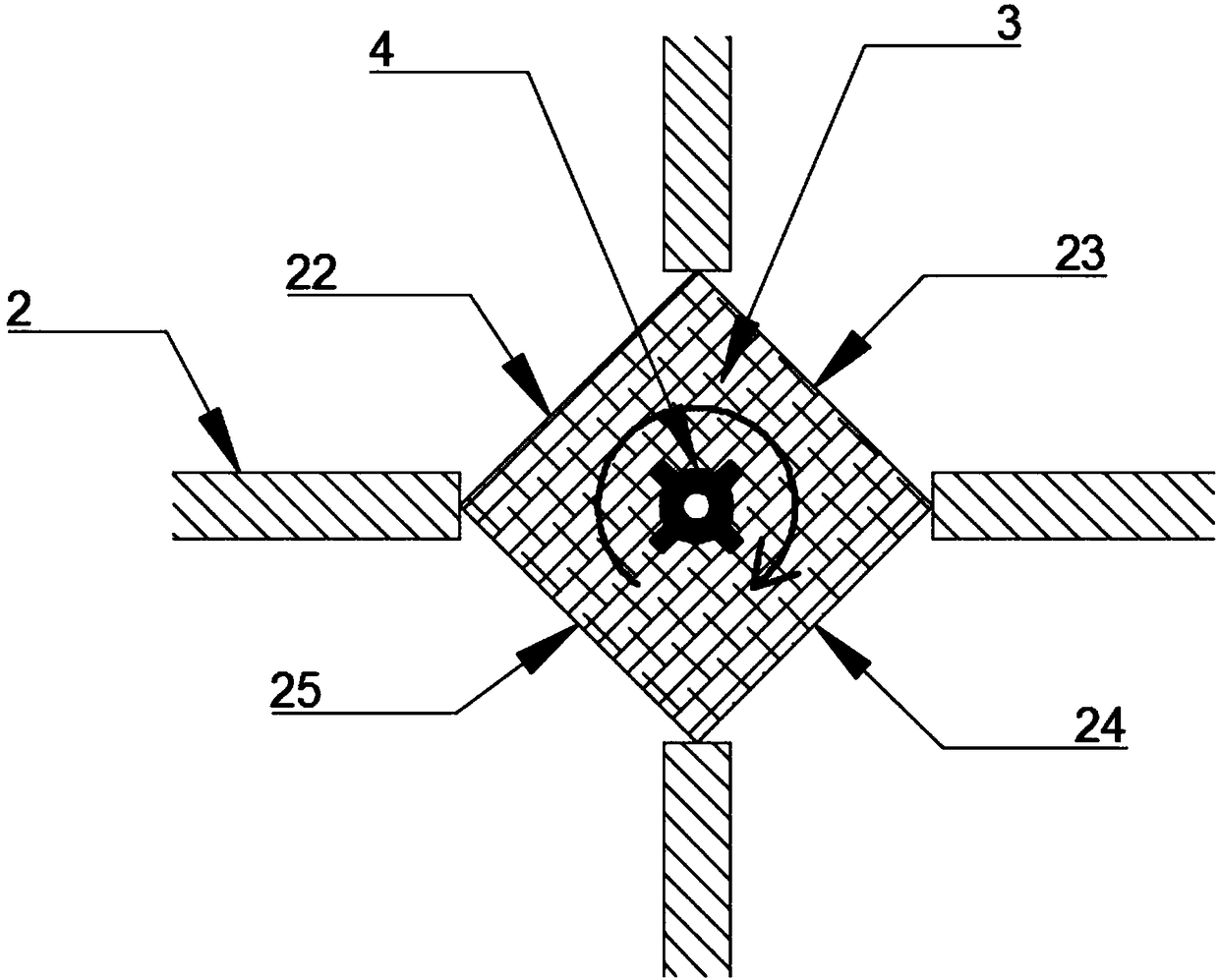

[0022] see Figures 1 to 3 , In the embodiment of the present invention, a dual-motor fresh air conveying equipment with self-cleaning and anti-clogging filter screen includes a fresh air fan casing 1, an inner partition 2, a filter 3, a rotating shaft 4, a fresh air valve 5, a dust removal valve 8, The dust filter bag 10, the first induced draft fan 13 and the second induced draft fan 18 are installed inside the fresh fan housing 1 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com