Welding device for electric tool part machining

A technology for electric tools and welding devices, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of local overheating during welding time, reduce people's cleaning efficiency, and not meet the needs of use, so as to achieve smooth welding work and solve clamping problems. Difficulty, the effect that meets the needs of modern use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

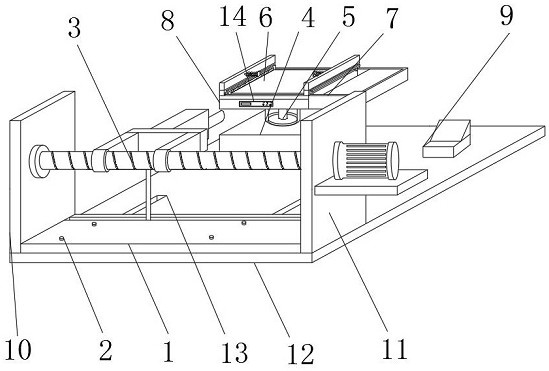

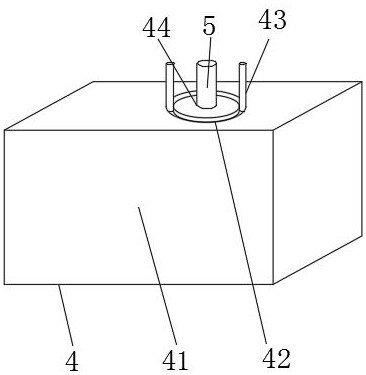

[0032] A welding device for processing electric tool parts, such as figure 1As shown, including the bottom plate 12, two No. 1 chutes 13 are opened on the front part of the upper end of the bottom plate 12, and the inside of the two No. 1 chute 13 is jointly slidably connected with the slide plate 1, and the left part of the slide plate 1 and the right part of the slide plate 1 are screwed. Fasten the knob 2, and the lower end of the fastening knob 2 is internally threaded with the two No. 1 chute 13. The left end of the skateboard 1 and the right end of the skateboard 1 are respectively fixedly connected to the No. 1 side plate 10 and the No. 2 side plate 11, and the No. 2 side plate 11 The upper part is penetrated with a welding mechanism 3, the left end of the welding mechanism 3 is fixedly connected with the right end of the No. Behind the mechanism 3 and to the left of the numerical control table 9, a driving device 5 is fixedly installed inside the cabinet 4, and the upp...

Embodiment 2

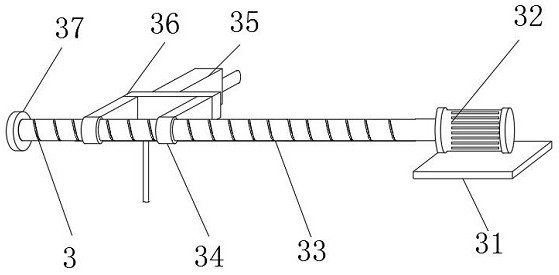

[0035] On the basis of Example 1, as Figure 2-4 As shown, a welding device for processing electric tool parts includes a base plate 12, two No. The left part and the right part of the skateboard 1 are threadedly connected with a fastening knob 2, and the lower end of the fastening knob 2 is internally threaded with two No. No. 2 side plate 11, welding mechanism 3 runs through the upper part of No. 2 side plate 11, the left end of welding mechanism 3 is fixedly connected with the right end of No. 1 side plate 10, and the upper right part of the bottom plate 12 is fixedly equipped with a numerical control table 9, and the left part of the upper end of the bottom plate 12 is fixed. A chassis 4 is installed, and the chassis 4 is located behind the welding mechanism 3 and on the left of the numerical control table 9. The drive device 5 is fixedly installed inside the chassis 4, and the upper end of the drive device 5 and the upper end of the chassis 4 are fixedly connected with a ...

Embodiment 3

[0038] On the basis of Example 1, as Figure 5-7 As shown, a welding device for processing electric tool parts includes a base plate 12, two No. The left part and the right part of the skateboard 1 are threadedly connected with a fastening knob 2, and the lower end of the fastening knob 2 is internally threaded with two No. No. 2 side plate 11, welding mechanism 3 runs through the upper part of No. 2 side plate 11, the left end of welding mechanism 3 is fixedly connected with the right end of No. 1 side plate 10, and the upper right part of the bottom plate 12 is fixedly equipped with a numerical control table 9, and the left part of the upper end of the bottom plate 12 is fixed. A chassis 4 is installed, and the chassis 4 is located behind the welding mechanism 3 and on the left of the numerical control table 9. The drive device 5 is fixedly installed inside the chassis 4, and the upper end of the drive device 5 and the upper end of the chassis 4 are fixedly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com