Quick positioning device for shape measuring instrument

A positioning device and measuring instrument technology, applied to measuring devices, instruments, etc., can solve problems such as low efficiency and limited clamping range, and achieve the effects of simplifying the operation process, improving work efficiency, and shortening the auxiliary operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

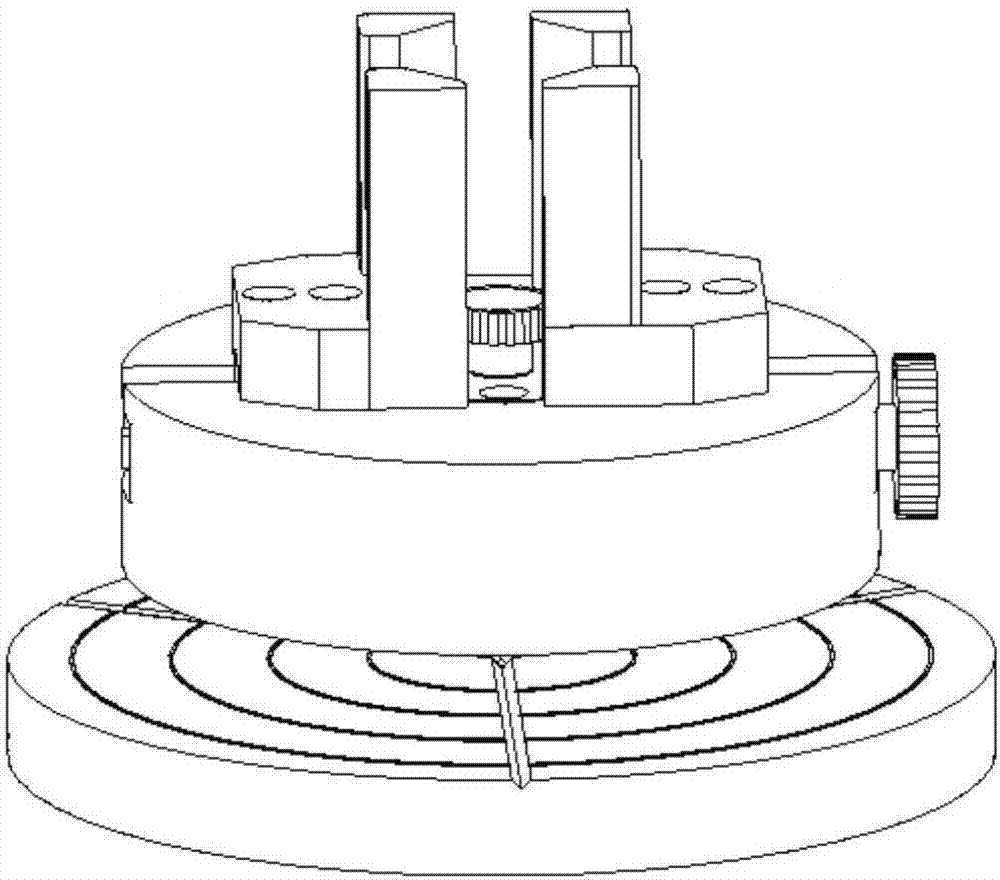

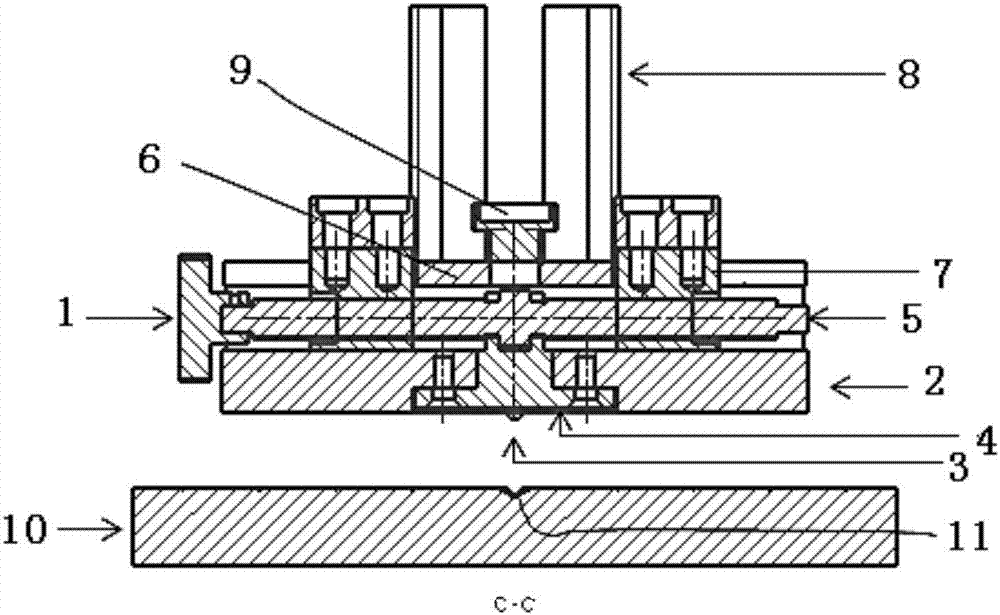

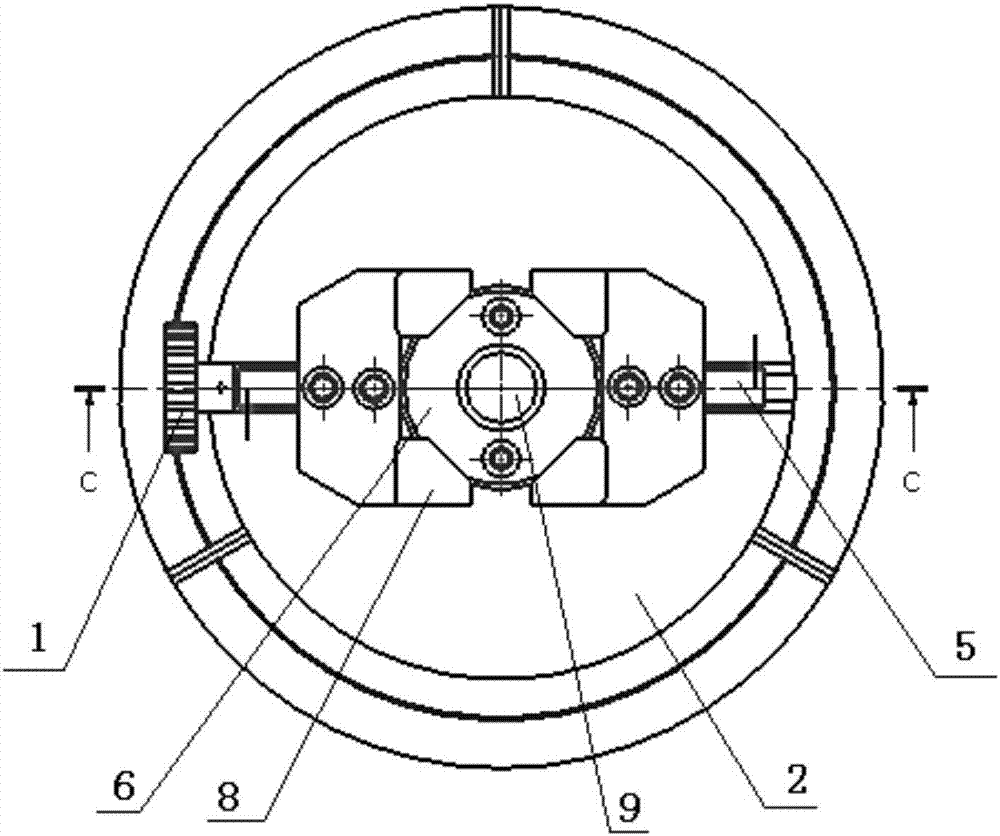

[0016] The rapid positioning device of the shape measuring instrument of the present invention is composed of a clamping mechanism, a self-centering mechanism and an auxiliary mechanism

[0017] (1) The auxiliary mechanism consists of an outer support 2, an inner support 4, a support block 6 and a steel ball 3. The outer support 2 is the carrier for other parts to be installed. There is a support installation hole in the center of the bottom surface of the outer support 2. The outer support There are four threaded holes at the bottom of the mounting hole of the seat 2, and there are 6 mounting holes at the center of the upper surface of the outer support 2, and there are two threaded holes at the bottom of the mounting hole of the support block 6, and the inner support 4. The mounting hole and the supporting block 6 are penetrated through a smaller circular hole. There are blind holes distributed evenly around the circumferential direction on the lower surface of the outer supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com