Building construction concrete spraying unit with protection mechanism

A technology of concrete injection unit and building construction, which is applied in the direction of construction, building structure, and construction material processing, etc., and can solve the problems of unfavorable operation efficiency, poor use effect of concrete injection unit, easy blockage of pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

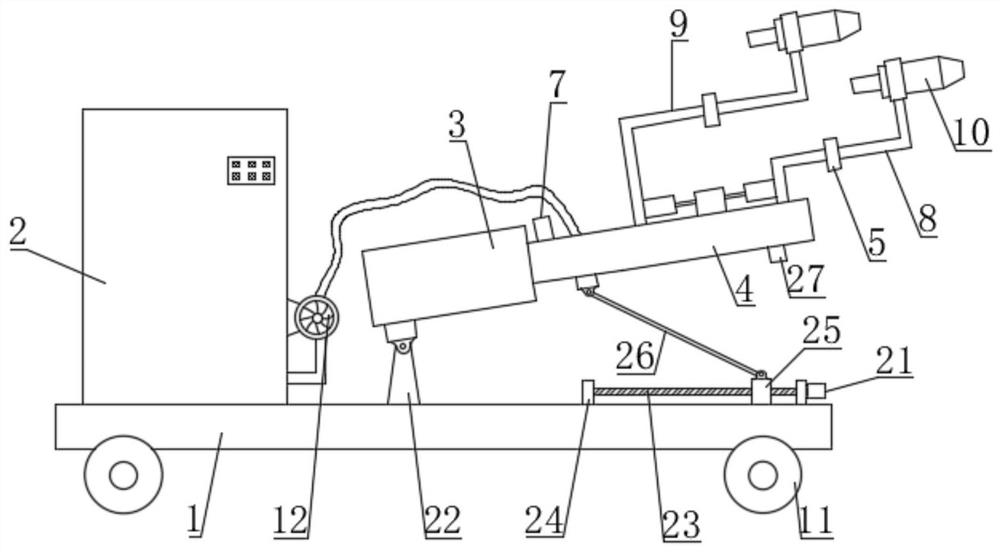

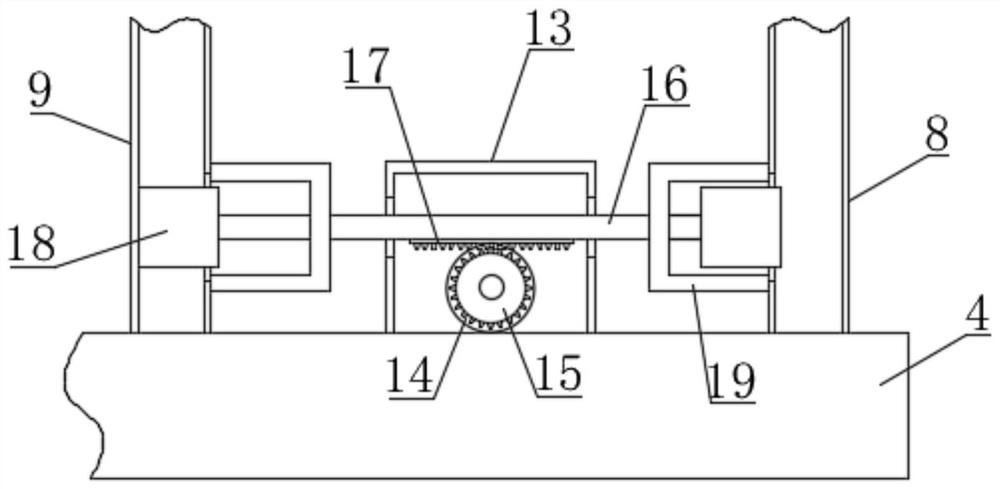

[0041] Such as Figure 1-8 As shown, a concrete injection unit for building construction with a protective mechanism proposed by the present invention includes a base plate 1, a material storage box 2, a delivery pipe 4, a roller 11 and a feed pump 12, and the bottom of the base plate 1 is installed with multiple sets of The roller 11 and the material storage box 2 are fixedly installed on the top of the bottom plate 1 by bolts, and the material storage box 2 is equipped with a material delivery pump 12, which transports the concrete in the material storage box 2 to the delivery pipe 4, and the material storage An air pump or an air compressor is also installed on the box 2, and the delivery pipe 4 is located above the bottom plate 1 and connected to the fixed box 3. An anti-blocking component 6 for cleaning the inside of the delivery pipe 4 is installed in the fixed box 3. On the delivery pipe 4, The first spray pipe 8 and the second spray pipe 9 are installed, the end of the...

Embodiment 2

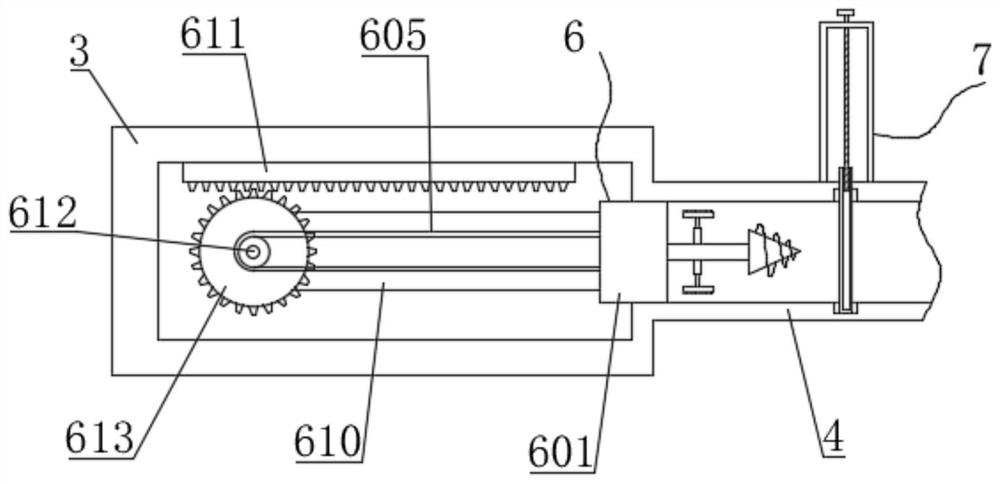

[0047] Such as image 3 and Figure 9As shown, the difference between this embodiment and Embodiment 1 is that a sealing assembly 7 is installed on the delivery pipe 4, the sealing assembly 7 and the anti-blocking assembly 6 are located on the same side, and the sealing assembly 7 includes a hollow plate 701, a screw 702, a knob 703, Sealing plate 704, thread groove 705 and draw-in groove 706, hollow plate 701 is vertically arranged on the top of delivery pipe 4, screw rod 702 is installed in hollow plate 701 by bearing rotation, knob 703 is arranged on the top of screw rod 702 and is positioned at hollow plate 701 Turn the knob 703 to make the screw 702 rotate, the sealing plate 704 is vertically provided with an upward threaded groove 705, the screw 702 is threadedly connected with the sealing plate 704, and the inner wall of the bottom of the delivery pipe 4 is provided with a card with an upward opening. slot 706, and the sealing plate 704 is inserted downwards into the c...

Embodiment 3

[0049] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the material storage box 2 includes a box body 201, a first motor 202, a rotating shaft 203, a stirring rod 204, a sealing box 205 and a spiral stirring shaft 206, and the box The body 201 is fixedly installed on the top of the base plate 1 by bolts, the first motor 202 is fixedly installed on the top of the box body 201 through the motor base, the output end of the first motor 202 is connected with the rotating shaft 203, and the first motor 202 is used to drive the rotating shaft 203, a plurality of groups of stirring rods 204 are arranged horizontally and are connected with the rotating shaft 203. When the rotating shaft 203 rotates, each group of stirring rods 204 rotates in a horizontal direction to stir the concrete in the box body 201 to prevent The inner concrete is solidified; the inner wall of the bottom of the box body 201 is fixedly equipped with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com