Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "High performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for effectively improving high-seeping and high-water-content oil deposit polymer flooding effect

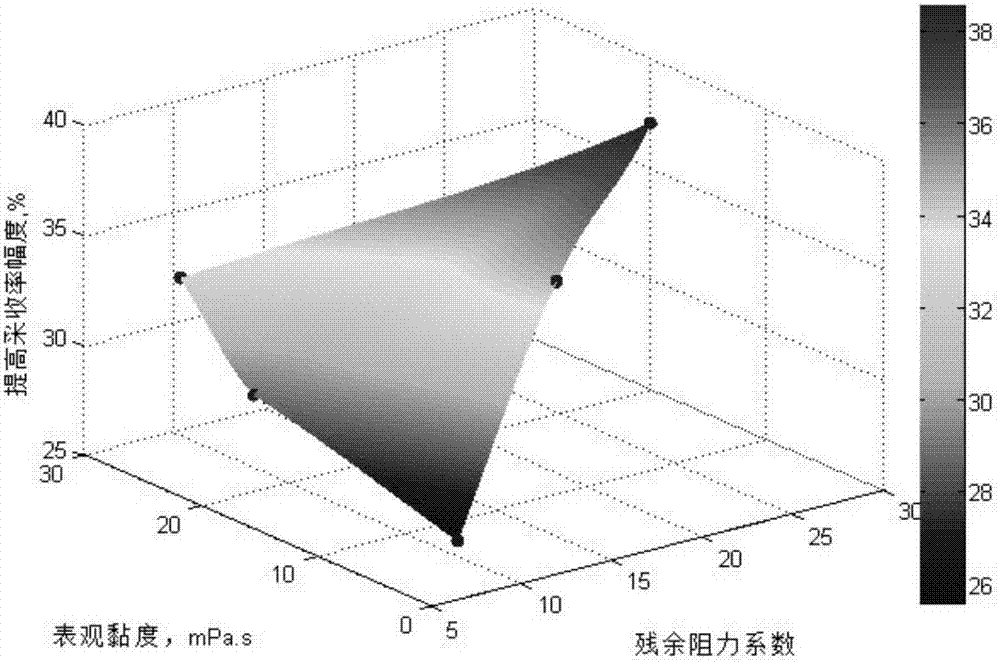

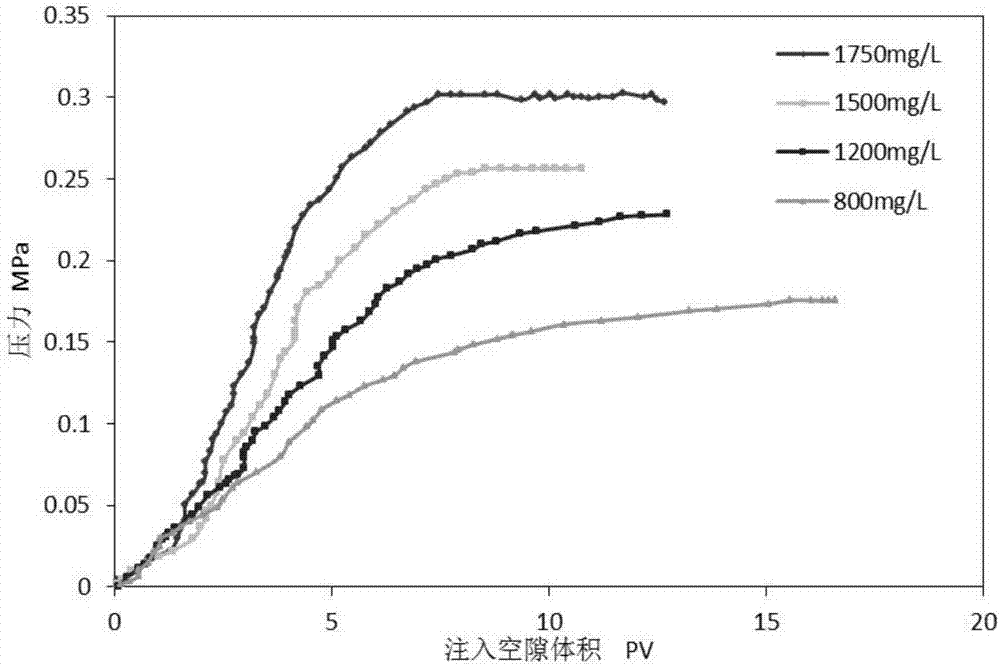

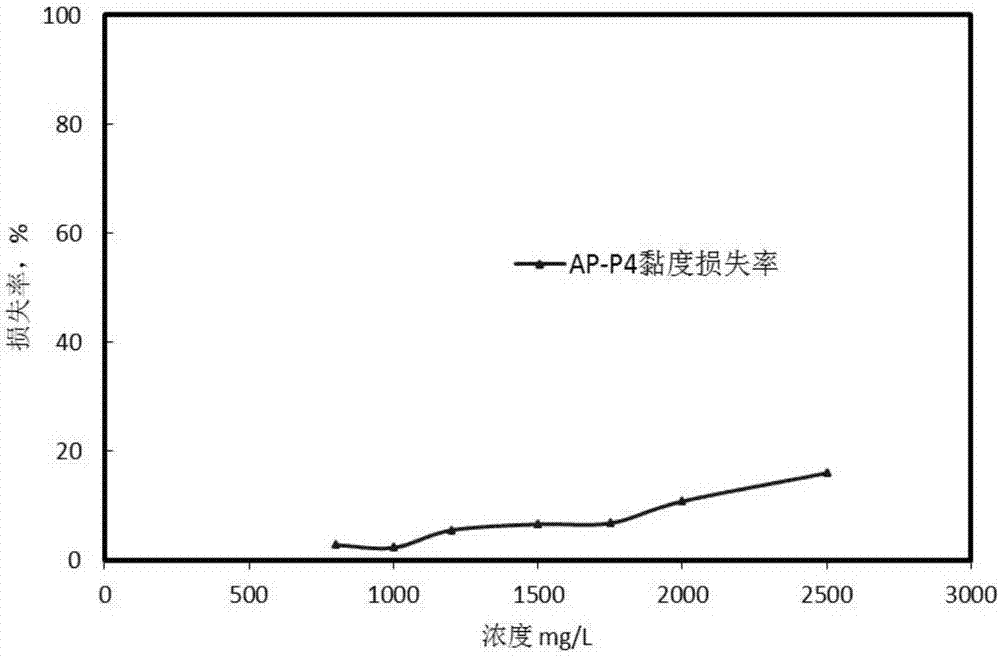

ActiveCN107503721ADetermine performance requirementsEnhanced overall recoverySurveyFluid removalApparent viscosityPorous medium

The invention discloses a method for effectively improving the high-seeping and high-water-content oil deposit polymer flooding effect. The method comprises the following steps of determining an oil deposit condition; building a corresponding core model according to the oil deposit condition, and building an experimental platform for simulating oil deposit flooding oil production; measuring the apparent viscosity of a polymer; conducting a percolation characteristic experiment to analyze the resistance coefficient and the residual resistance coefficient of the polymer in a porous medium; calculating the recovery efficiency improvement amplitude of a polymer solution; building a correlation graph of the solution viscosity, the residual resistance coefficient and the recovery efficiency improvement amplitude; analyzing the relation of the influence of the apparent viscosity and the residual resistance coefficient on the recovery efficiency improvement amplitude; judging the amplitude of the influence of the apparent viscosity and the residual resistance coefficient on the recovery efficiency improvement amplitude to thus determine the performance requirement for a polymer system under an oil deposit condition. The method for effectively improving the high-seeping and high-water-content oil deposit polymer flooding effect improves the adaptability of the polymer solution in the oil deposit.

Owner:SOUTHWEST PETROLEUM UNIV

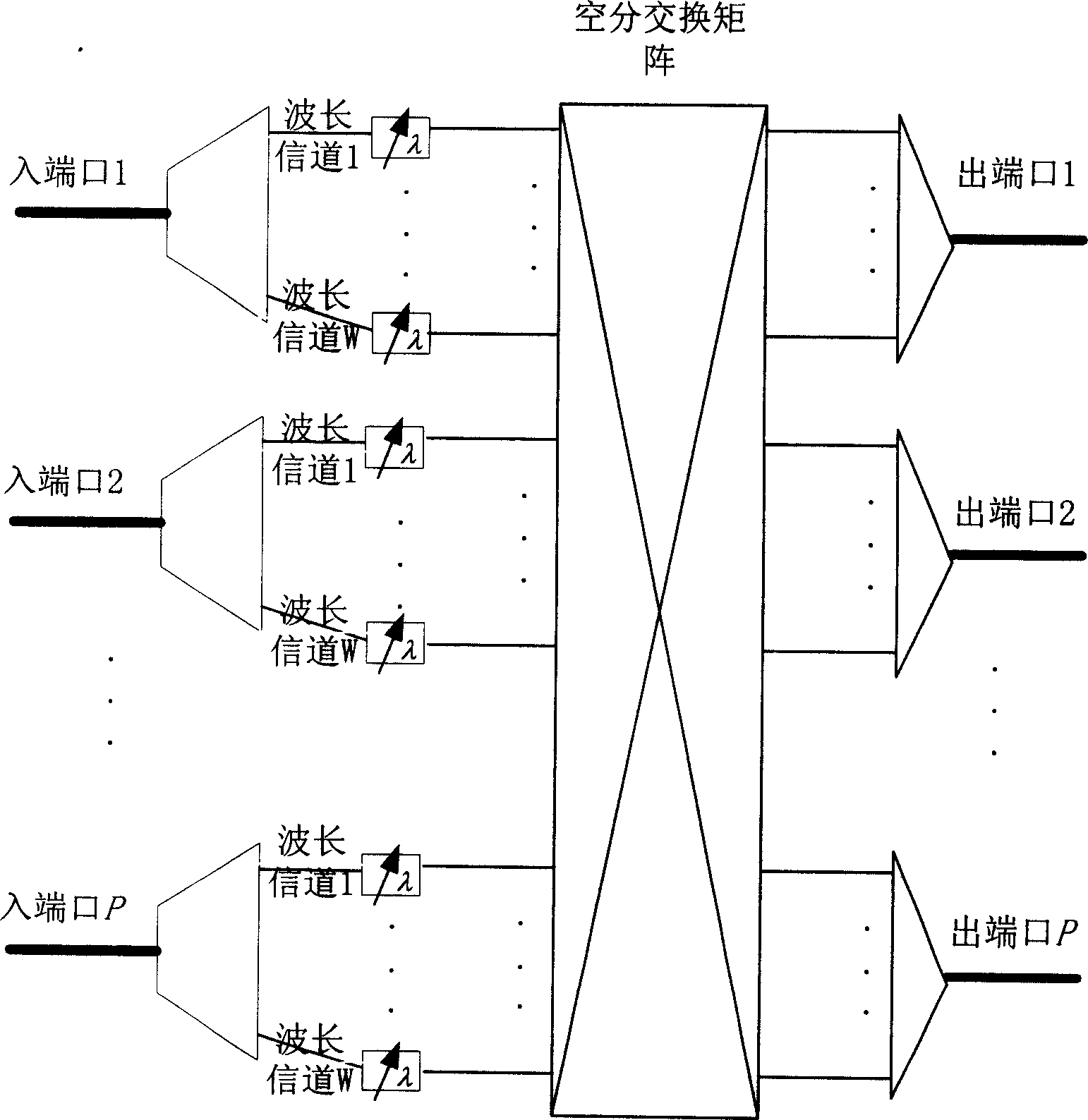

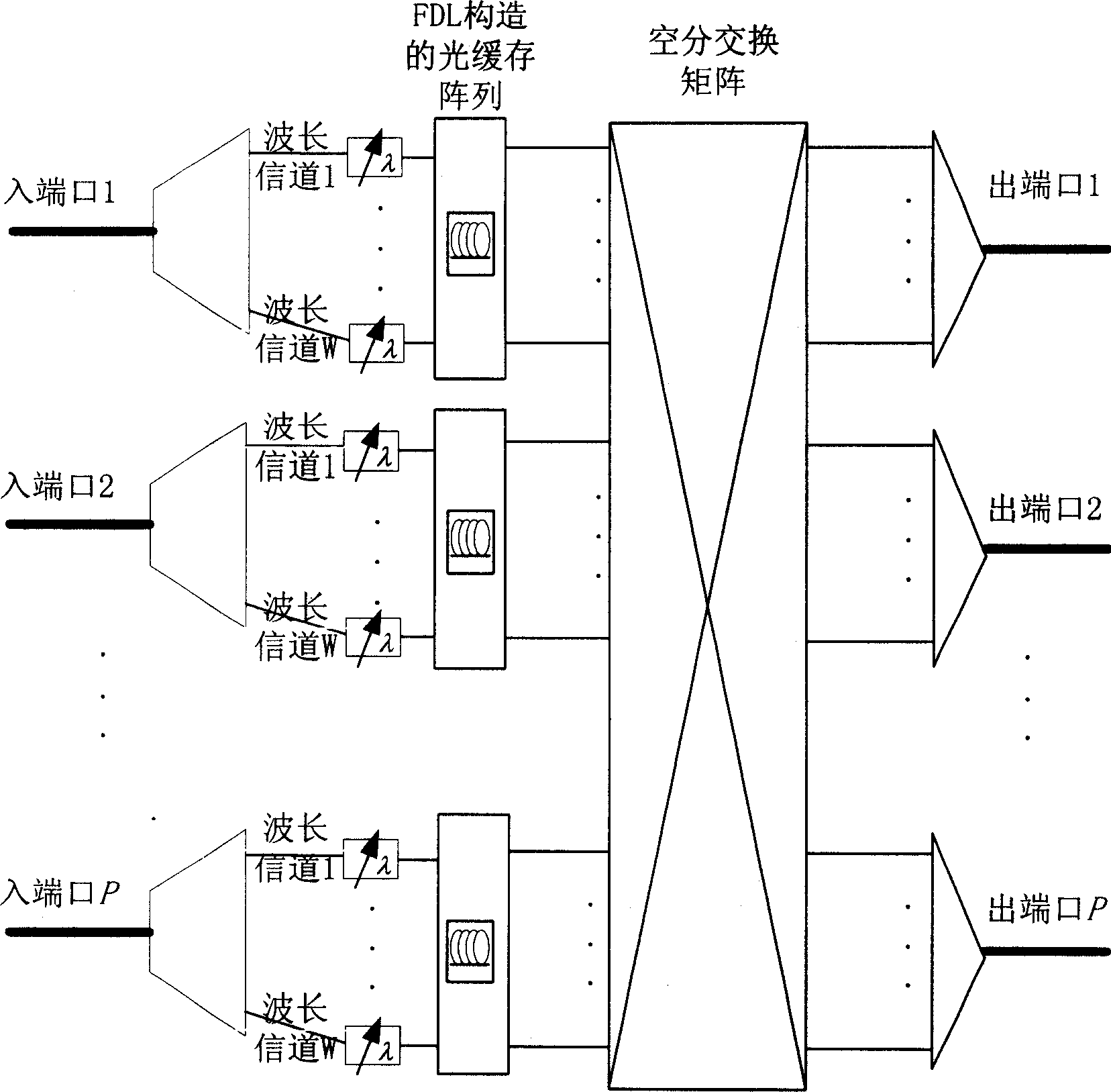

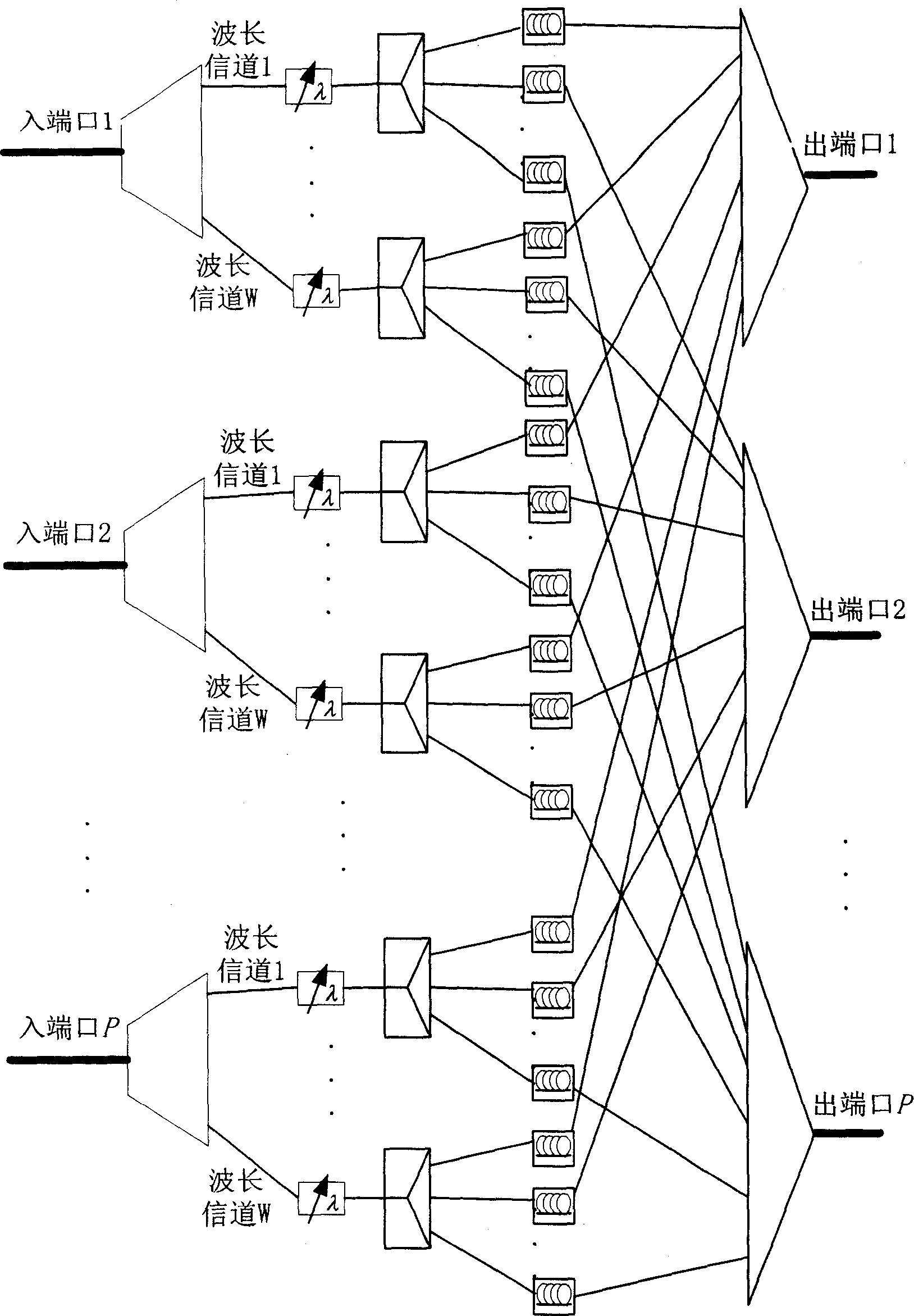

Light burst/grouping switching structure without team head block

InactiveCN1716903ASolve the blockageClear Loss RateWavelength-division multiplex systemsData switching networksTime delaysLength wave

This invention provides an optical burst / packet exchange structure without head block, which separates burst data of different wavelengths at the entry port with a WDM then to transform it to any wavelengths according to the dispatch with a wavelength converter to be selected on any FDL in P group by 1xp optical switch, finally to be sent to a related exit port from the selected FDL to reach the aim of switching the burst data of any wavelength of any entry port to any wavelength of any exit port via a controlled time delay.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

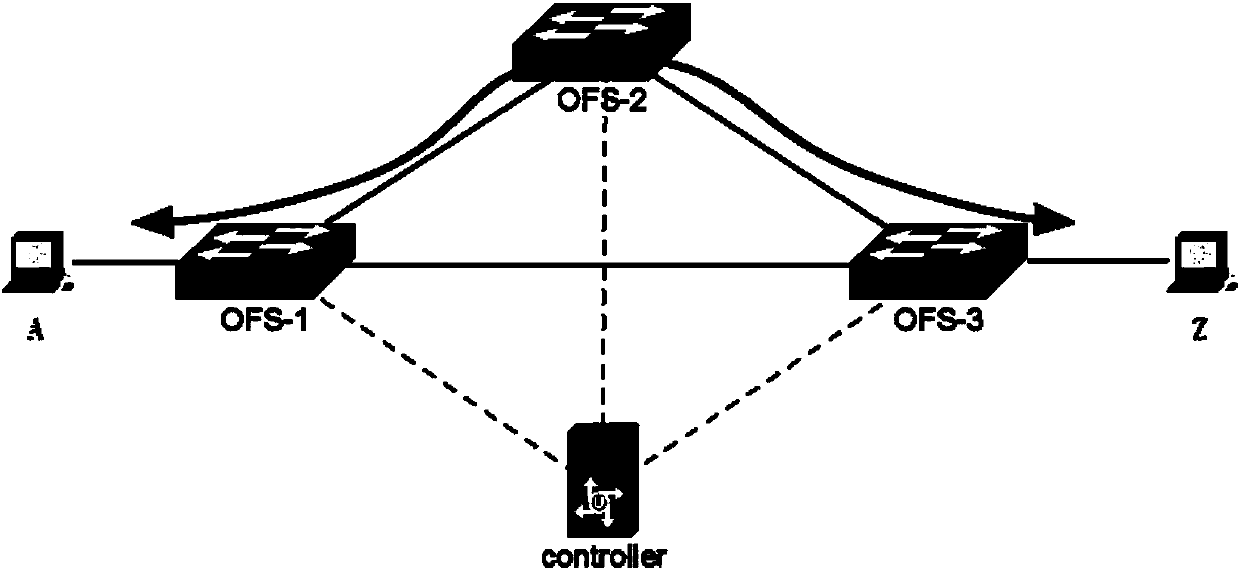

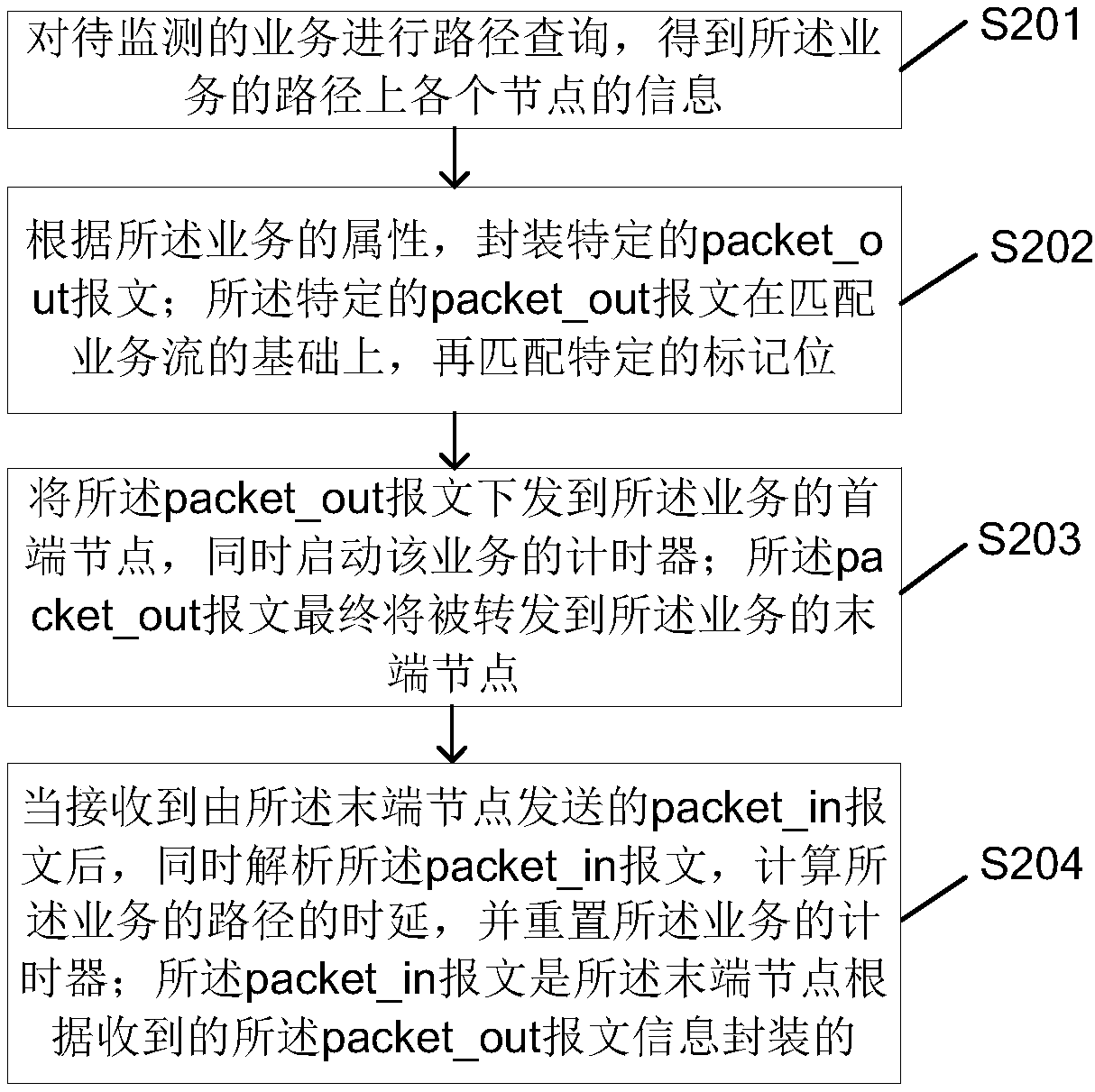

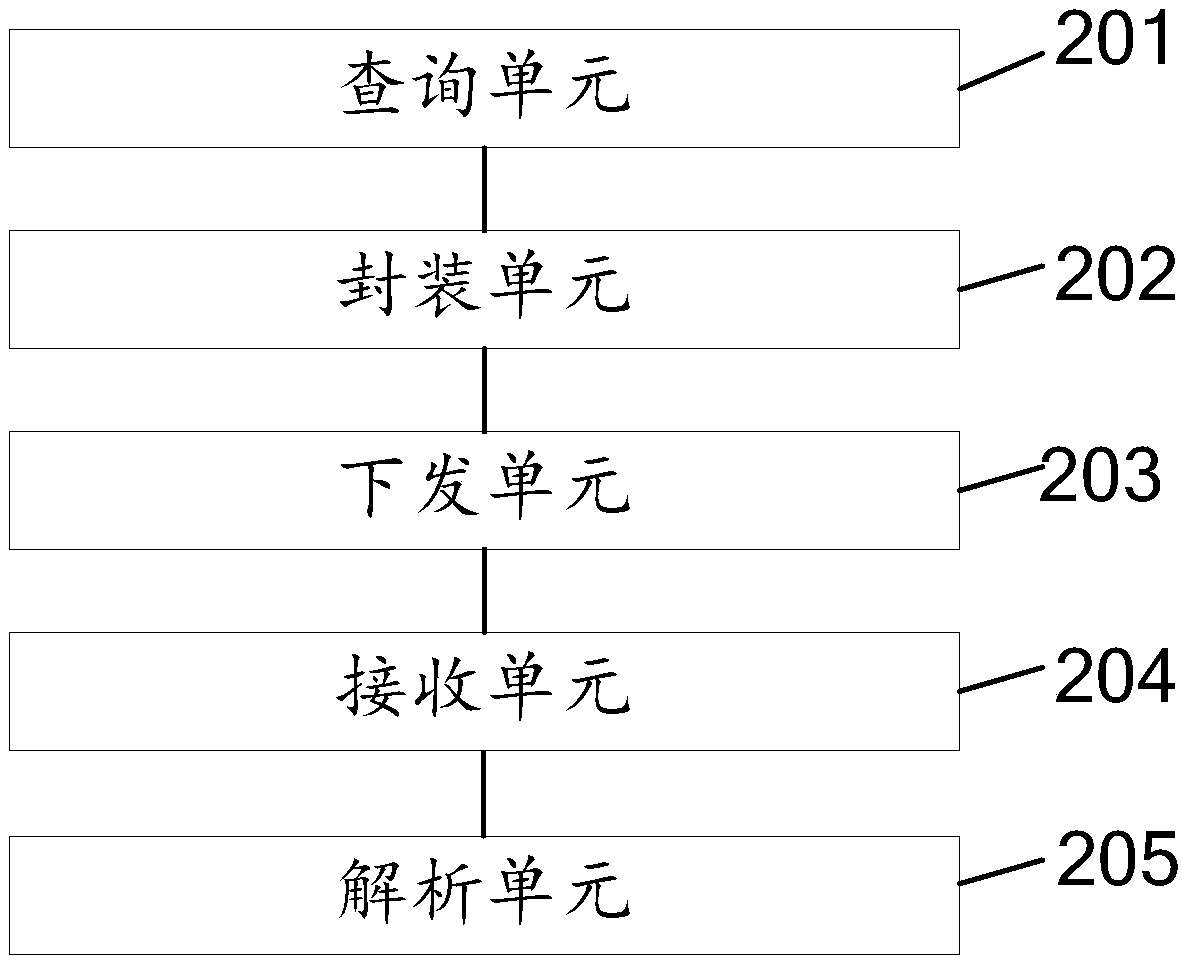

End-to-end service monitoring method and apparatus based on SDN

ActiveCN109660414ADoes not affect normal forwardingHigh performance requirementsData switching networksTraffic volumeTraffic capacity

The invention discloses an end-to-end service monitoring method based on an SDN. The method comprises the following steps: performing path query on a service to be monitored to obtain the informationof each node on a path of the service; packaging a specific packet_out message according to the attributes of the service; on the basis of matching the specific packet_out message with a service stream, matching a specific flag bit; issuing the packet_out message to a head end node of the service, and meanwhile starting a timer of the service; finally forwarding the packet_out message to a tail end node of the service; and after a packet_in message sent by the tail end node is received, parsing the packet_in message at the same time, calculating the delay of the path of the service, and resetting the timer of the service, wherein the packet_in message is packaged by the tail end node according to the received packet_out message information. By adoption of the end-to-end service monitoringmethod disclosed by the invention, the end-to-end monitoring of the service is achieved, the normal forwarding of the data traffic of the service is not affected, the performance requirements of a controller are not increased, and the end-to-end service monitoring method can be applied to a large SDN.

Owner:臻乐尔科技服务(上海)有限公司

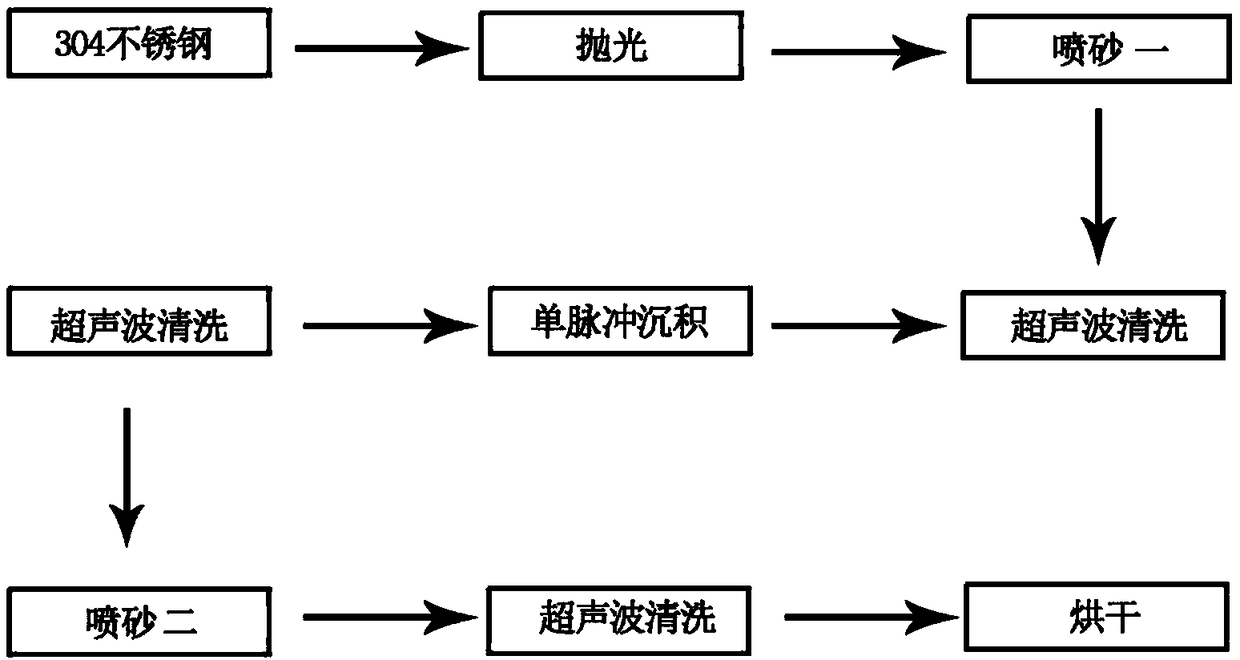

304 stainless steel surface multielement coupling super-hydrophobic preparation method

The invention discloses a 304 stainless steel surface multielement coupling super-hydrophobic preparation method, and belongs to the field of metal part and material surface super hydrophobicity. The304 stainless steel surface multielement coupling super-hydrophobic preparation method is capable of solving the adverse hydrophobic problem of the surface of prepared 304 stainless steel. The 304 stainless steel surface multielement coupling super-hydrophobic preparation method comprises following steps: polishing, a first time of sandblasting, monopulse deposition, a second time of sandblasting,and drying. The 304 stainless steel surface multielement coupling super-hydrophobic preparation method is capable of obtaining grading scale structures (submillimeter grade, and micrometer-nanometergrade) of the 304 stainless steel hydrophobic surface, wherein the scale of a cauliflower-like protruding main structure formed through monopulse deposition on a matrix is micrometer-nanometer grade,the scale of second time sandblasting formed surface destroyed cauliflower-like protrudings and protruding gaps is submillimeter grade; a rough structure formed through the first time of sandblastingis capable of increasing the bonding force of the coating layer with the matrix, a rough structure formed through the second time of sandblasting is capable of forming a multi-scale multi-stage microstructure on coating surfaces, and surface hydrophobicity is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Anti-wearing extreme-pressure-resistant lubricating oil

InactiveCN106467838AHigh performance requirementsImprove the performance requirements and improve the oxidation resistance of lubricating oil in an all-round wayAdditivesDispersityRhenium

The invention discloses anti-wearing extreme-pressure-resistant lubricating oil which consists of base oil, an antioxidant, a detergent, a dispersing agent, an extreme-pressure anti-wearing agent, a viscosity index improver, a nano-grade rhenium-molybdenum alloy powder material, polyacrylate, a thyoxyl phenol, benzotriazole and vulcanized dipolybutylene, wherein the antioxidant is shielding bisphenol; the detergent calcium-based phenolate; the dispersing agent is sodium polyacrylate; the extreme-pressure anti-wearing agent is chlorinated paraffin; the viscosity index improver is a styrene diene copolymer. The anti-wearing extreme-pressure-resistant lubricating oil has the advantages of being scientific in preparation scheme and simple in preparation method, the price of a prepared product is lower than that of a similar product, various property requirements of the anti-wearing extreme-pressure-resistant lubricating oil can be effectively and comprehensively improved, the oxidation resistance, the corrosion resistance, the detergence and dispersity, the anti-rusting property, the bubble resistance and the greasy sludge prevention property of the anti-wearing extreme-pressure-resistant lubricating oil can be comprehensively improved, the effects of wearing resistance and extreme pressure resistance can be improved to the maximum extent, meanwhile a very good remediation function on a wearing surface of an engine can be achieved, the lubricating oil change period can be prolonged, the noise can be reduced, and the exhaust gas emission can be reduced.

Owner:华信凯伟科技(天津)有限公司

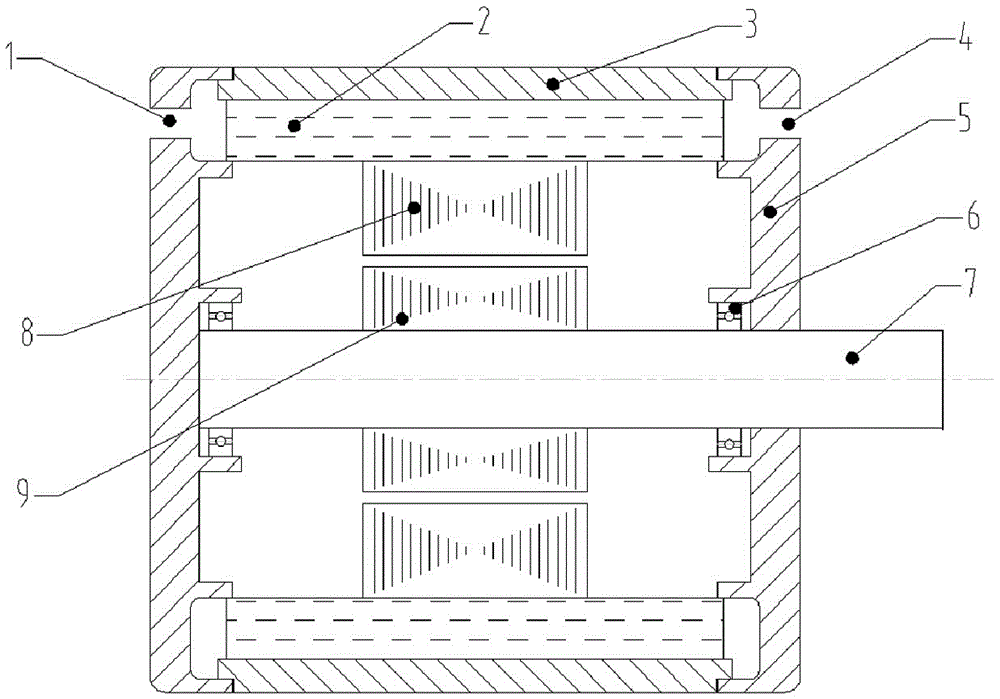

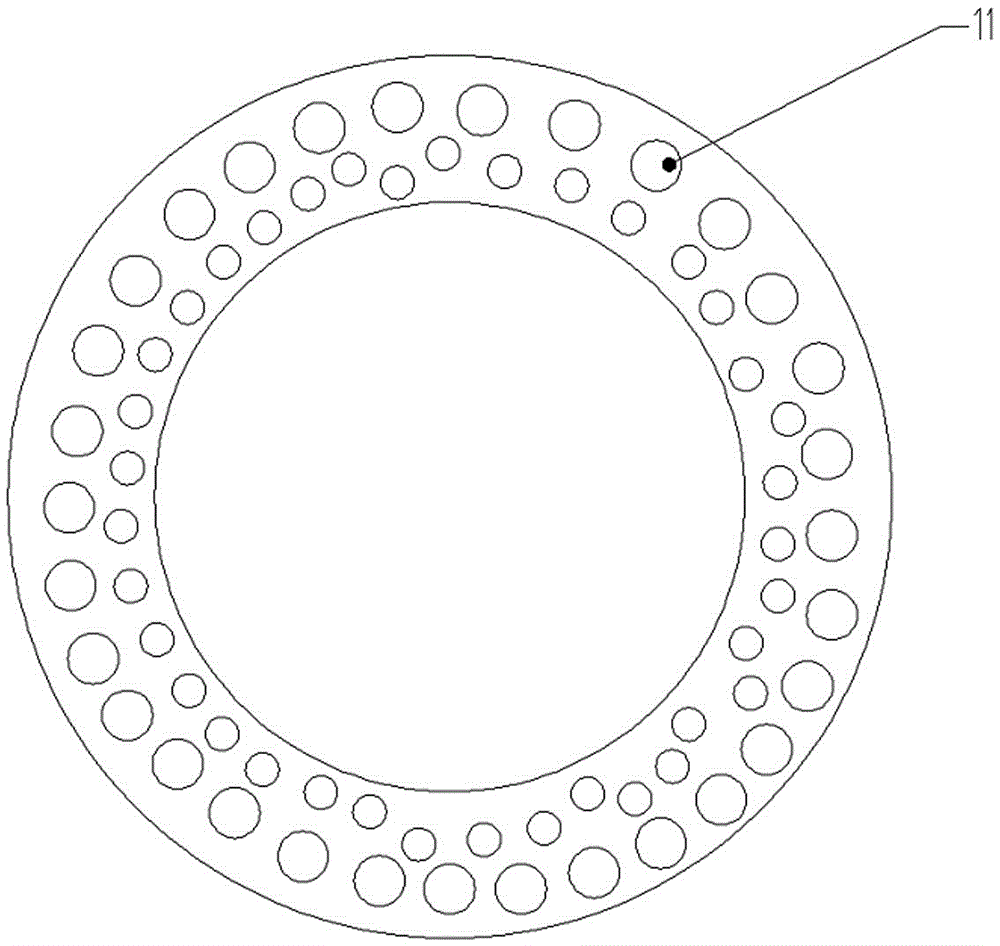

Large-aperture Gasar porous metal material low vibration noise water-cooled motor

InactiveCN106230159AGood shock absorption and sound absorption characteristicsGood thermal conductivityCooling/ventillation arrangementSupports/enclosures/casingsThermal conductionStator

The invention provides a large-aperture Gasar porous metal material low vibration noise water-cooled motor, which comprises an end cover and a stator, wherein a water cooling channel made of a Gasar porous metal material is formed between the end cover and the stator and surrounds the outside of the stator. Improvement is carried out on the structure of an existing water-cooled motor; and an existing spiral water cooling channel is replaced with a large-aperture Gasar porous metal material, and the porous metal material has good shock absorption and sound absorption characteristics and has a good thermal conduction characteristic, so that the processing problem of a traditional fluid hole is better solved. Therefore, the annular water cooling channel manufactured by the large-aperture porous metal material greatly absorbs vibration and noise generated by electromagnetic excitation force, the heat dissipation effect is strengthened and the application of the water-cooled motor is further improved.

Owner:SHENYANG POLYTECHNIC UNIV

Composite additive for turbine oil

InactiveCN103773562AHigh performance requirementsImprove extreme pressure performanceAdditivesSludgeAlkylphenol

The invention discloses a composite additive for turbine oil. The composite additive comprises base oil, an anti-oxidant, a rusting inhibitor, a foam inhibitor, a metal deactivator, an extreme pressure additive, a demulsification agent, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of diarylamine and alkylphenol. The rusting inhibitor is an alkylsuccinic acid derivative. The foam inhibitor is polydimethylsiloxane. The metal deactivator is triazole. The extreme pressure additive comprises alkyl phosphate ester and salt. The demulsification agent is polyalkoxypolyamine. The composite additive comprises, by weight, 12-14% of the anti-oxidant, 9-11% of the rusting inhibitor, 7-9% of the foam inhibitor, 10-12% of the metal deactivator, 6-8% of the extreme pressure additive, 11-13% of the demulsification agent, 1-2% of the copper oxide powder, 1-2% of the magnesium metal powder and the balance the base oil. The composite additive is prepared by the simple processes, has a price lower than those of the same types of other products, has high quality, effectively and comprehensively improves performances of the turbine oil, prolongs a use period of the turbine oil, improves turbine oil extreme pressure resistance, comprehensively improves oxidation resistance, corrosion resistance, foam resistance and oily sludge resistance of the turbine oil, is biodegradable and completely exceeds environmental requirements on the same type of products.

Owner:TIANJIN ZEYA TECH

Fully effective lubricating oil used for engine

InactiveCN105602663AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumMechanical equipment

The invention relates to fully effective lubricating oil used for engine. The fully effective lubricating oil is composed of base oil, base liquid, lecithin, a tungsten-rhenium alloy, an anti-oxidant, clearing agent, a dispersant, a corrosion inhibitor, an anti-foaming agent, a metal passivator, a demulsifying agent, an anti-wear agent, an extreme pressure additive, and a viscosity index improver. A production scheme of the lubricating oil is simple, the price of the lubricating oil is lower than that of the other same kind products, and the lubricating oil has high quality and can effectively and comprehensively enhance the performance requirements of the lubricating oil. Anti-oxidation, corrosion resistance, detergency and dispersibility, foaming resistance, rust prevention, and oil sludge generation resistance of the lubricating oil can be comprehensively increased, and anti-wear and anti-extreme pressure performances can be increased at maximum limit. The lubricating oil can prolong the usage period, reduces noise of mechanical equipment, reduces energy consumption, and reduces tail gas discharge. The lubricating oil completely exceeds the environmental protection requirement of the current same kind products.

Owner:TIANJIN ZECHANG TECH

Composite additive for turbine oil

InactiveCN103773563AHigh performance requirementsImprove extreme pressure performanceAdditivesOxidation resistantMagnesium

The invention discloses a composite additive for turbine oil. The composite additive comprises base oil, an anti-oxidant, a rusting inhibitor, a foam inhibitor, a metal deactivator, an extreme pressure additive, a demulsification agent, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of diarylamine and alkylphosphite. The rusting inhibitor is ethoxyphenol. The foam inhibitor is polydimethylsiloxane. The metal deactivator is toluyltriazole derivative. The extreme pressure additive comprises alkyl phosphate ester and salt. The demulsification agent is polyalkoxypolyol. The composite additive comprises, by weight, 12-14% of the anti-oxidant, 9-11% of the rusting inhibitor, 7-9% of the foam inhibitor, 10-12% of the metal deactivator, 6-8% of the extreme pressure additive, 11-13% of the demulsification agent, 1-2% of the copper oxide powder, 1-2% of the magnesium metal powder and the balance the base oil. The composite additive is prepared by the simple processes, has a price lower than those of the same types of other products, has high quality, effectively and comprehensively improves performances of the turbine oil, prolongs a use period of the turbine oil, improves turbine oil extreme pressure resistance, comprehensively improves oxidation resistance, corrosion resistance, foam resistance and oily sludge resistance of the turbine oil, is biodegradable and completely exceeds environmental requirements on the same type of the existing products.

Owner:TIANJIN ZEYA TECH

Full-function lubricating oil applied to engine

InactiveCN105886037AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumAntioxidant

The invention relates to full-function lubricating oil applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Full-function lubricating oil capable of being applied to engine

InactiveCN105886062AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumAntioxidant

The invention relates to full-function lubricating oil capable of being applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Lubricating oil used in engine

InactiveCN106467833AHigh performance requirementsImprove the performance requirements and improve the oxidation resistance of lubricating oil in an all-round wayLubricant compositionRheniumDispersity

The invention discloses lubricating oil used in an engine. The lubricating oil consists of base oil, an antioxidant, a detergent, a dispersing agent, an extreme-pressure anti-wearing agent, a viscosity index improver, a nano-grade rhenium-molybdenum alloy powder material, polyacrylate, an ethyoxyl phenol, benzotriazole and vulcanized dipolybutylene, wherein the antioxidant is sterically hindered phenol; the detergent is barium hydroxide; the dispersing agent is succinate; the extreme-pressure anti-wearing agent is an alkyl phosphorus-containing acid ester and salt; the viscosity index improver is poly(alkyl methacrylate). The lubricating oil has the advantages of being scientific in preparation scheme and simple in preparation method, the price of a prepared product is lower than that of a similar product, various property requirements of the lubricating oil can be effectively and comprehensively improved, the oxidation resistance, the corrosion resistance, the detergence and dispersity, the anti-rusting property, the bubble resistance and the greasy sludge prevention property of the lubricating oil can be comprehensively improved, the effects of wearing resistance and extreme pressure resistance can be improved to the maximum extent, meanwhile a very good remediation function on a wearing surface of the engine can be achieved, the lubricating oil change period can be prolonged, the noise can be reduced, and the exhaust gas emission can be reduced.

Owner:华信凯伟科技(天津)有限公司

Nano-metal composite additive applied to turbine oil

InactiveCN104178259AHigh performance requirementsImprove oxidation resistanceAdditivesRheniumAntioxidant

The invention discloses a nano-metal composite additive applied to turbine oil. The nano-metal composite additive is characterized by consisting of base oil, an antioxidant, a rusting inhibitor, a dispersant, a metal deactivator, an extreme pressure additive, a demulsification agent, metal molybdenum powder, metal rhenium powder and vitamin (E). The antioxidant is a mixture of diarylamine and tributyl phosphite; the rusting inhibitor is ethoxy phenol; the dispersant is polyisobutene maleimide; the metal deactivator is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate ester; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, and the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

Fully effective lubricating oil containing rhenium tungsten alloy

InactiveCN105087109AHigh performance requirementsImprove antioxidant capacityLubricant compositionExhaust gasViscosity index

A fully effective lubricating oil containing rhenium tungsten alloy is characterized by consisting of a base oil, a base liquid, a liquid vitamin E, a rhenium tungsten alloy, an anti-oxidant, a detersive, a dispersant, a corrosion inhibitor, an anti-foaming agent, a metal passivator, a demulsifying agent, an antiwear agent, an anti-extreme pressure agent, and a viscosity index improver. The fully effective lubricating oil containing rhenium tungsten alloy is easy to manufacture, is lower in price than other congeneric product and high in quality, and can fully improve performances of the lubricating oil effectively. The fully effective lubricating oil containing rhenium tungsten alloy can fully improve the performances of the lubricating oil such as inoxidizability, corrosion resistance, lustration decentralization, anti-foamable property, antirust property, and anti greasy filth generation, and maximize the anti-wear and extreme pressure performance. Moreover, the fully effective lubricating oil containing rhenium tungsten alloy can lengthen the lifecycle of lubricating oil, reduce the noise of the equipment, reduce the tail gas discharge, and can surpass present congeneric products in environmental protection.

Owner:DONGGUAN HAINA LUBRICATING OIL CO LTD

Nano-metal composite additive applied to turbine oil

InactiveCN104178316AHigh performance requirementsImprove oxidation resistanceLubricant compositionRheniumAntioxidant

The invention discloses a nano-metal composite additive applied to turbine oil. The nano-metal composite additive consists of base oil, an antioxidant, a rusting inhibitor, a dispersant, a metal deactivator, an extreme pressure additive, a demulsification agent, metal molybdenum powder, metal rhenium powder and vitamin (E). The antioxidant is a mixture of diarylamine and tributyl phosphite; the rusting inhibitor is ethoxy phenol; the dispersant is a Mannich base ashless dispersant; the metal deactivator is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate ester; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, and the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

Anti-wear lubricating oil for engine

InactiveCN106467834AHigh performance requirementsImprove the performance requirements and improve the oxidation resistance of lubricating oil in an all-round wayLubricant compositionRheniumPhosphate

The invention provides an anti-wear lubricating oil for an engine. The anti-wear lubricating oil is composed of base oil, an anti-oxidant, a detergent additive, a dispersing agent, an anti-wear reagent at extreme pressure, a viscosity index improver, nanometer rhenium-molybdenum alloy powder, polyacrylate, ethoxyphenol, benzotriazole and sulfurized dipolybutene, wherein the anti-oxidant is aryl phosphite; the detergent additive is sulfite; the dispersing agent is succimide; the anti-wear reagent at extreme pressure is molybdenum phosphate; and the viscosity index improver is a styrene-diene copolymer. The anti-wear lubricating oil provided by the invention has the advantages that a preparation scheme for the lubricating oil is scientific; a manufacturing method for the lubricating oil is simple; the prepared lubricating oil is lower in price compared with products of a same kind; each performance of the lubricating oil is comprehensively improved; the anti-wear and anti-extreme pressure performance of the lubricating oil are maximally enhanced while corrosion resistance, cleaning performance, dispersing performance, rust resistance, foaming resistance and resistance to generation of greasy filth are improved; and the lubricating oil exerts strong repair effect on the magic surface of the engine, prolongs an oil change period, reduces noise and decreases discharge of tail gas.

Owner:华信凯伟科技(天津)有限公司

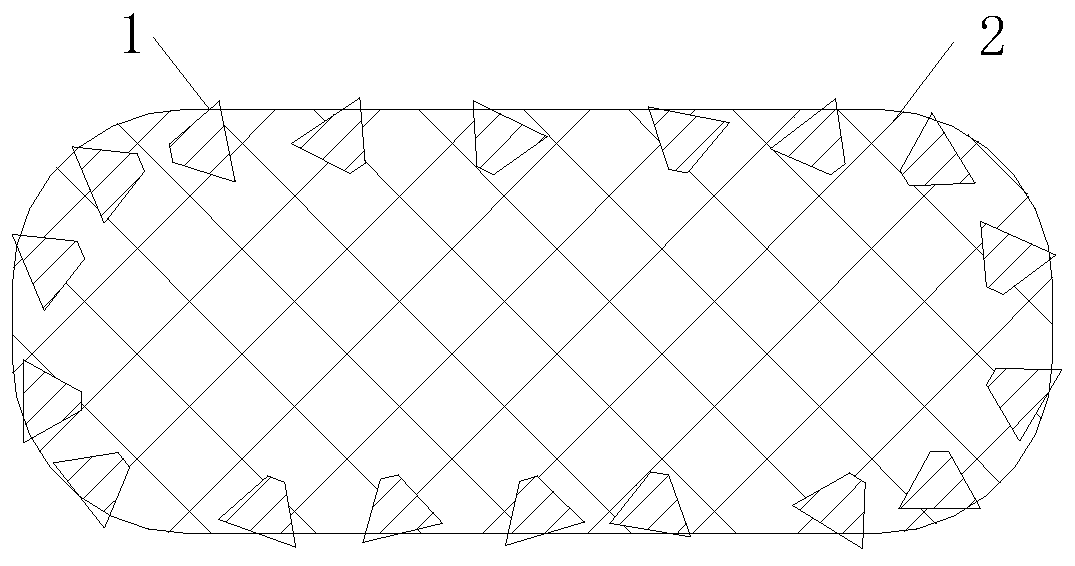

Method for producing small-specification C72DA rubber tube steel wire at high speed based on double modules

InactiveCN109988966AHigh performance requirementsStable performanceCarbon dioxideDimensional precision

The invention belongs to the technical field of steel wire production, and relates to a method for producing a small-specification C72DA rubber tube steel wire at a high speed based on double modules.The small-specification C72DA rubber tube steel wire is prepared from the components in percentage by weight: 0.70%-0.74% of C, 0.15%-0.25% of Si, 0.50%-0.60% of Mn, less than or equal to 0.018% of P, less than or equal to 0.010% of S, less than or equal to 0.05% of Cr, less than or equal to 0.05% of Ni, less than or equal to 0.05% of Cu, less than or equal to 0.05% of Al, less than or equal to 0.03% of As, and the balance of Fe and inevitable impurities. According to the method, demands of high performance requirements, stable properties, small dimensional deviation and good product drawingproperty can be met; and the technological process adopts double module rolling, the requirement for improving the product dimensional precision and the surface quality is met, the production speed isgreatly increased, the production cost is lowered, energy is saved, emission of carbon dioxide is reduced, and the method belongs to low-cost manufacturing.

Owner:RIZHAO STEEL HLDG GROUP

Full-function lubricating oil capable of being applied in engine

InactiveCN105886053AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumMechanical equipment

The invention provides full-function lubricating oil capable of being applied in an engine. The lubricating oil is characterized by being composed of base oil, base fluid, liquid vitamin E, a rhenium-tungsten alloy, an anti-oxidant, a detergent, a dispersant, a rusting inhibitor, an anti-foaming agent, a metal deactivator, a demulsifying agent, an antiwear agent, an extreme pressure resisting agent and a viscosity index improver. The lubricating oil provided by the invention has the following advantages: a manufacturing scheme of the invention is simple; the prepared lubricating oil has a price lower than the price of products of a same kind, has high quality, and can effectively and comprehensively improve the requirements for performances of the lubricating oil; oxidation resistance, corrosion resistance, detergency, dispersibility, foaming resistance, rusting resistance and oil sludge generation resistance of the lubricating oil are comprehensively improved; meanwhile, the functions of wear resistance and extreme pressure resistance of the lubricating oil are maximumly improved; the life cycle of the lubricating oil is prolonged; the noise of mechanical equipment is reduced; energy consumption is lowered; exhaust emission is decreased; and the requirement for environmental protection of the lubricating oil is completely beyond the requirement for environmental protection of products of a same kind.

Owner:TIANJIN ZECHANG TECH

Nano-metal composite additive applied to turbine oil

InactiveCN104178274AHigh performance requirementsImprove oxidation resistanceAdditivesRheniumAntioxidant

The invention discloses a nano-metal composite additive applied to turbine oil. The nano-metal composite additive consists of base oil, an antioxidant, a rusting inhibitor, a dispersant, a metal deactivator, an extreme pressure additive, a demulsification agent, metal molybdenum powder, and metal rhenium powder. The antioxidant is a mixture of diarylamine and tributyl phosphite; the rusting inhibitor is ethoxy phenol; the dispersant is succinic ester; the metal deactivator is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate ester; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, and the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

Full-efficient lubricating oil applied to engines

InactiveCN105602669AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumMechanical equipment

The invention provides full-efficient lubricating oil applied to engines. The lubricating oil is characterized in that the lubricating oil comprises the following components: base oil, base liquid, liquid vitamin E, rhenium-tungsten alloy, an anti-oxidant, a cleaning agent, a dispersant, a corrosion inhibitor, an anti-forming agent, a metal passivator, a demulsifying agent, an antiwear agent, an anti-extreme pressure agent, and a viscosity index improver. The lubricating oil has a simple manufacture scheme, the price of the prepared product is lower than prices of other products of the same kind, the lubricating oil has high quality, and each performance of the lubricating oil is comprehensively and effectively improved. The full-efficient lubricating oil has the advantages of antioxidation, corrosion resistance, detergency and dispersibility, foaming resistance, rust protection, greasy generation resistance, and improvements of antiwear efficacy and antiwear efficacy at extreme pressure to the largest extent. The lubricating oil has the advantages of prolonged service cycle, reduced noise of mechanical equipment, reduced energy consumption, and reduced tail gas discharge. The lubricating oil completely exceeds environmental protection requirements of products of the same kind.

Owner:TIANJIN ZECHANG TECH

Full-function lubricating oil capable of being applied to engine

InactiveCN105886060AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumAntioxidant

The invention relates to full-function lubricating oil capable of being applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Fully effective lubricating oil used for engine

InactiveCN105602665AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumOil sludge

The invention relates to fully effective lubricating oil used for engine. The fully effective lubricating oil is composed of base oil, base liquid, liquid vitamin E, a tungsten-rhenium alloy, an anti-oxidant, a clearing agent, a dispersant, a corrosion inhibitor, an anti-foaming agent, a metal passivator, a demulsifying agent, an anti-wear agent, an extreme pressure additive, and a viscosity index improver. A production scheme of the lubricating oil is simple, the price of the lubricating oil is lower than that of the other same kind products, and the lubricating oil has high quality and can effectively and comprehensively enhance the performance requirements of the lubricating oil. Anti-oxidation, corrosion resistance, detergency and dispersibility, foaming resistance, rust prevention, and oil sludge generation resistance of the lubricating oil can be comprehensively increased, and anti-wear and anti-extreme pressure performances can be increased at maximum limit. The lubricating oil can prolong the usage period, reduces noise of mechanical equipment, reduces energy consumption, and reduces tail gas discharge. The lubricating oil completely exceeds the environmental protection requirement of the current same kind products.

Owner:TIANJIN ZECHANG TECH

Engine oil nano metal complexing agent

InactiveCN104178326AHigh performance requirementsImprove oxidation resistanceLubricant compositionOxidation resistantBenzotriazole

An engine oil nano metal complexing agent consists of base oil, an antioxidant, a corrosion inhibitor, a dispersant, a metal passivator, an extreme pressure additive, a detergent, a viscosity index improver, a metal molybdenum powder, a metal rhenium powder and vitamin (E). The antioxidant is a mixture of hindered phenol and aromatic amine; the corrosion inhibitor is ethoxy phenol; the dispersant is succimide; the metal passivator is benzotriazole; the extreme pressure additive is molybdenum salt of phosphate; the detergent is polyisobutene; and the viscosity index improver is a styrene-diene copolymer. The manufacturing method is simple, the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil, prolong usage period of the lubricant, improve anti extreme pressure efficacy of the lubricating oil, and comprehensively enhance the oxidation resistance, corrosion resistance, foaming resistance, oxidation resistance and sludge resistance of lubricating oil, so as to improve the comprehensive efficacy.

Owner:TIANJIN ZECHANG TECH

Nano-metal composite agent applied to turbine oil

InactiveCN104178276AHigh performance requirementsImprove oxidation resistanceAdditivesRheniumPhosphate

The invention discloses a nano-metal composite agent applied to turbine oil. The nano-metal composite agent consists of base oil, an antioxidant, a rusting inhibitor, a dispersant, a metal deactivator, an extreme pressure additive, a demulsification agent, metal molybdenum powder, metal rhenium powder and vitamin (E). The antioxidant is a mixture of diarylamine and tributyl phosphite; the rusting inhibitor is ethoxy phenol; the dispersant is ash-free phosphate ester; the metal deactivator is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate ester; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, and the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

Turbine oil nano-metal composite additive

InactiveCN104178319AHigh performance requirementsImprove oxidation resistanceLubricant compositionRheniumAntioxidant

The invention relates to a turbine oil nano-metal composite additive, which is characterized by comprising: base oil; an antioxidant; a rusting inhibitor; a dispersant; a metal deactivator; an extreme pressure additive; a demulsification agent; metal molybdenum powder; metal rhenium powder; and vitamin (E). The antioxidant is a mixture of diarylamine and tributyl phosphite; the rusting inhibitor is ethoxy phenol; the dispersant is succinate; the metal deactivator is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate ester; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, and the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

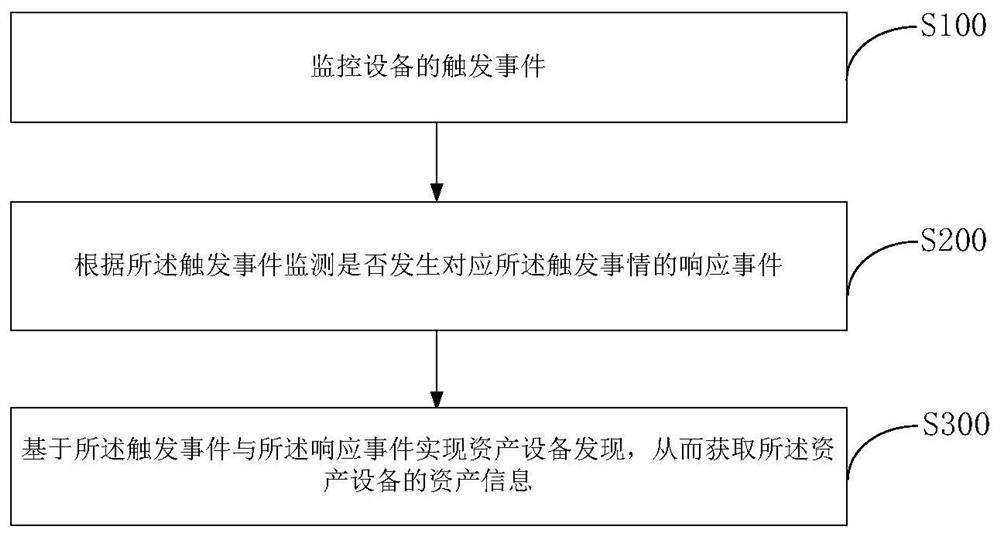

Asset management method and system based on event triggering and computer readable medium

PendingCN113411378AHigh performance requirementsRealize managementTransmissionData trafficSystems engineering

The invention discloses an asset management method and system based on event triggering and a computer readable medium. The method comprises the following steps of: monitoring a trigger event of equipment; monitoring whether a response event corresponding to the trigger event occurs or not according to the trigger event; and based on the trigger event and the response event, realizing asset equipment discovery, thereby acquiring asset information of the asset equipment. According to the asset management method and system, the trigger event and the response event are collected, and the association information between the trigger event and the response event is analyzed to obtain the newly accessed asset information, thereby achieving the purpose of asset discovery; the detection frequency does not need to be set or asset equipment does not need to be managed through network data flow, the influence of a firewall is small, and the performance requirement for discovery equipment is high; and asset equipment management can be realized by using the operation data of the equipment.

Owner:深圳万物安全科技有限公司

Complexing agent used in turbine oil

InactiveCN103773558AHigh performance requirementsImprove extreme pressure performanceAdditivesSludgeAlkylphenol

The invention discloses a complexing agent used in turbine oil. The complexing agent comprises base oil, an anti-oxidant, a rusting inhibitor, a foam inhibitor, a metal deactivator, an extreme pressure additive, a demulsification agent, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of sterically hindered phenol and alkylphenol. The rusting inhibitor is substituted imidazoline. The foam inhibitor is polyacrylate. The metal deactivator is triazole. The extreme pressure additive is antimony dialkyldithiocarbamate. The demulsification agent is polyalkoxypolyol. The complexing agent is prepared by simple processes, has high quality, effectively and comprehensively improves performances of the turbine oil, prolongs a use period of the turbine oil, improves turbine oil extreme pressure resistance, comprehensively improves oxidation resistance, corrosion resistance, foam resistance and oily sludge resistance of the turbine oil, completely improves the comprehensive performances, is biodegradable and completely exceeds environmental requirements on the same type of the existing products.

Owner:TIANJIN ZEYA TECH

Extinction master batch for plastics and preparation method thereof

InactiveCN111483072AHigh performance requirementsIncrease shear rateCoatingsPolyesterMechanical engineering

The invention relates to the technical field of plastic machining, in particular to an extinction master batch for plastics and a preparation method thereof. The extinction master batch for the plastics comprises a main body and a carrier; the main body comprises titanium dioxide and silicon dioxide materials; the main body forms a powdery cone through a crushing tank; the carrier is a polyester material; and the carrier and the main body are melted into a mixture and then the mixture is granulated into the extinction master batch. Since different shearing effects on the particles of titaniumdioxide and silicon dioxide exist in the shearing process, the overall quality of the extinction master batch formed by subsequent preparation is reduced, and the extinction effect on the plastics isreduced. Therefore, the cut main body of the extinction master batch is controlled within the required size range through the combined screening action of a coarse screen and a fine screen which are arranged, the cut unqualified part of the main body of the extinction master batch is screened out, the overall performance requirements of the prepared extinction master batch is further improved, andthe use effect of the extinction master batch for the plastics is stabilized accordingly.

Owner:唐杰

Nano-metal composite agent added in turbine oil

InactiveCN104178275AHigh performance requirementsImprove oxidation resistanceAdditivesOxidation resistantTributyl phosphite

The invention relates to a nano-metal composite agent added in turbine oil. The nano-metal composite agent is composed of base oil, an antioxidant, a rusting inhibitor, a dispersant, a metal deactivating agent, an extreme pressure additive, a demulsification agent, metal molybdenum powder, metal rhenium powder, and vitamin (E). The antioxidant is a mixture of diarylamine and tributyl phosphate. The rusting inhibitor is ethoxy phenol; the dispersant is polyacrylic ester; the metal deactivating agent is benzotriazole; the extreme pressure additive is a molybdenum salt of phosphate; and the demulsification agent is polyalkoxy polyol. The making method is simple, and the prepared product can effectively and comprehensively enhance various performance requirements of turbine lubricating oil. The service cycle of lubricating oil is extended, the anti-extreme pressure efficacy of lubricating oil is improved, the oxidation tolerance, corrosion resistance, blistering resistance, oxidation resistance, oil sludge generation resistance and other efficacy of lubricating oil are comprehensively enhanced. And the comprehensive efficacy can be comprehensively improved.

Owner:TIANJIN ZECHANG TECH

Fully effective lubricating oil used for engine

InactiveCN105623807AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumAlloy

The invention relates to fully effective lubricating oil used for an engine. The fully effective lubricating oil is characterized by comprising base oil, base liquid, liquid vitamin E, a tungsten-rhenium alloy, an anti-oxidant, a dispersant, a corrosion inhibitor, an anti-foaming agent, a metal passivator, a demulsifying agent, an anti-wear agent, an anti-extreme pressure agent, and a viscosity index improver. A preparation scheme is simple, the price of the prepared product is lower than that of the same kind products, quality is high, and each performance requirement of the lubricating oil is effectively and comprehensively increased. The performances such as antioxidation, corrosion resistance, cleaning and dispersion performances, foaming resistance, rust resistance, and greasy filth generation resistance are comprehensively increased, and antiwear and anti-extreme pressure efficacy can be enhanced at maximum degree. The usage period of the lubricating oil is prolonged, equipment noise of a machine is reduced, energy consumption is reduced, and tail gas discharge is reduced. Environmental protection requirement of the same kind products can be completely exceeded.

Owner:TIANJIN ZECHANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com