304 stainless steel surface multielement coupling super-hydrophobic preparation method

A technology of 304 stainless steel and preparation process, which is applied in the field of multi-coupling super-hydrophobic preparation technology on the surface of 304 stainless steel, can solve the problems of poor hydrophobicity on the surface of 304 stainless steel, and achieve the effects of prolonging durability, high hardness and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

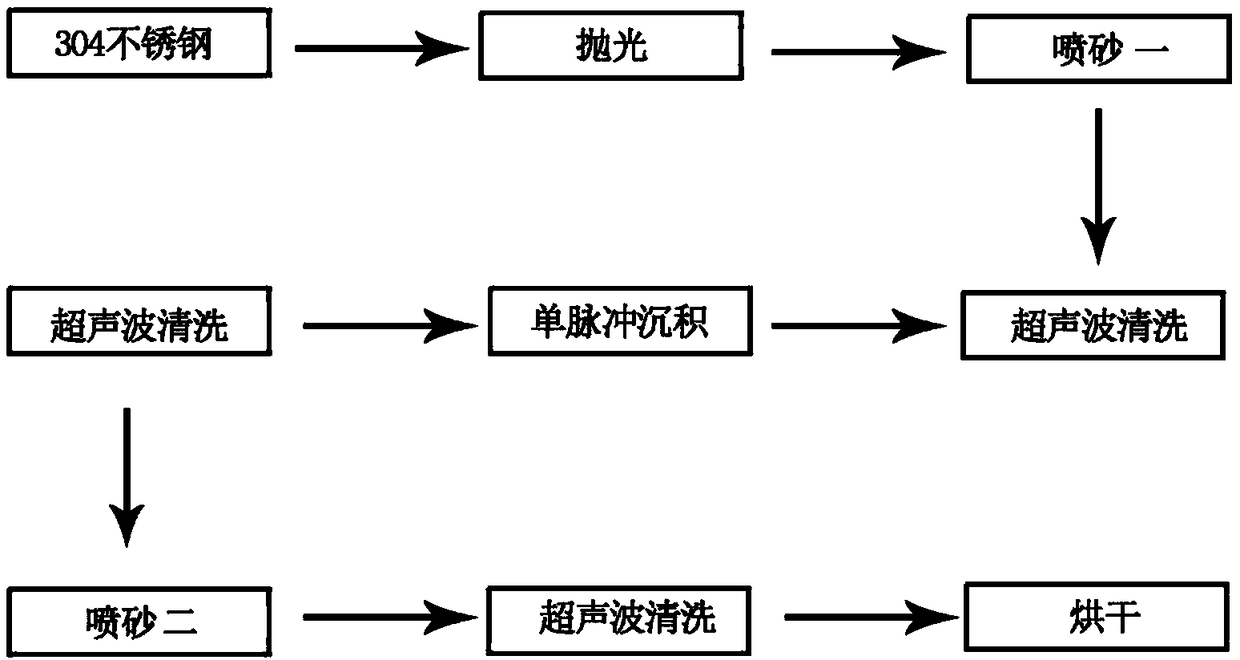

[0018] like figure 1 As shown, a 304 stainless steel surface multi-coupled super-hydrophobic preparation process, the preparation process includes the following steps:

[0019] Step 1: Initial grinding treatment: Grind the substrate on 600-mesh, 1000-mesh, 1500-mesh, 2000-mesh sandpaper in order to make the surface smooth;

[0020] Step 2: Polishing treatment: Polish the substrate that has been initially ground on a polishing machine to make the surface of the substrate smooth; then place the polished substrate in deionized water for ultrasonic cleaning for 4 minutes and then use deionized water Rinse for 30s;

[0021] Step 3: Sandblasting for the first time on the surface of the substrate: put the substrate in the spraying room for sandblasting process, the sandblasting parameters are: sandblasting pressure 0.55MP, sandblasting sand grains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com