Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Guaranteed guide accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

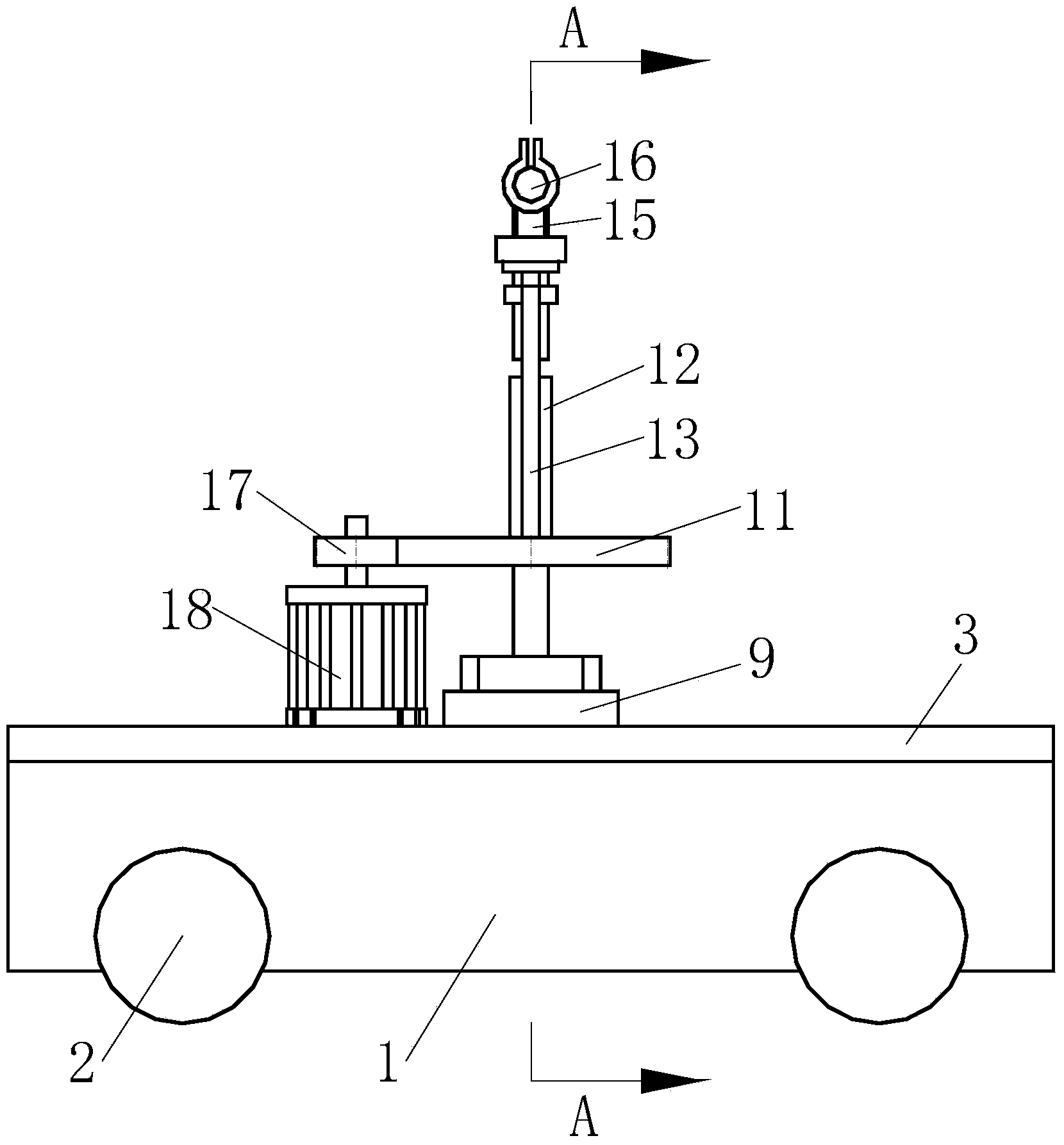

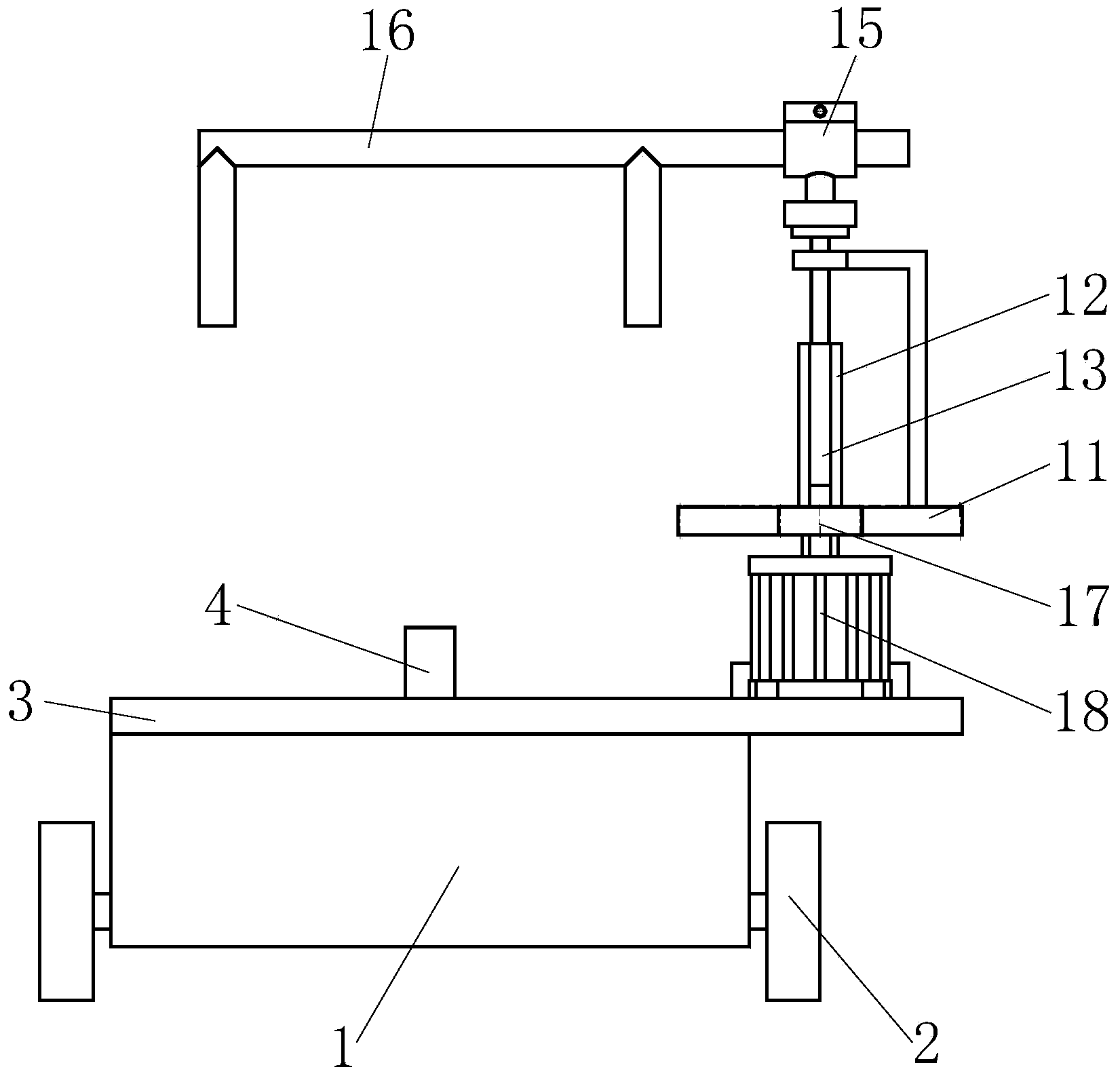

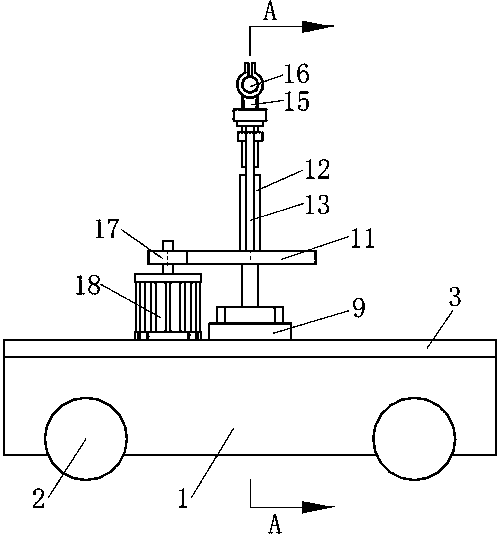

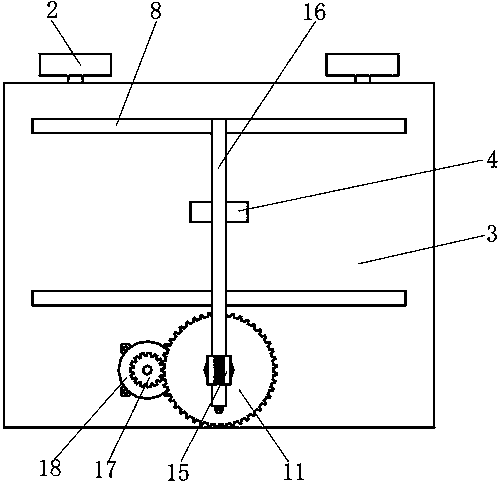

Transportation vehicle capable of automatically loading building steel structures

InactiveCN104015647AGuaranteed stabilityAvoid misalignmentLoad securingItem transportation vehiclesEngineeringLower upper

The invention relates to a transportation vehicle capable of automatically loading building steel structures. The transportation vehicle comprises a vehicle body, the two sides of the vehicle body are provided with walking wheels, the upper end of the vehicle body is provided with a bearing plate, the lower upper portion of the bearing plate is provided with a lower compression and clamping device, and the right of the bearing plate is provided with an upper transposition clamping device. The transportation vehicle has the advantages of being high in automation degree, reasonable in structural design, low in manufacturing cost and the like, replaces a traditional mode that the steel structures are hung and conveyed through a crane, manufacturing cost is reduced, the defect that the application range of a traditional crane conveying mode is small is overcome, the steel structures can be quickly transferred and conveyed or can be placed in another workshop, convenience is brought to production, machining and transportation of the steel structures, and the transportation vehicle is easy to control and high in stability and safety.

Owner:ANHUI XINRONG STEEL STRUCTURE

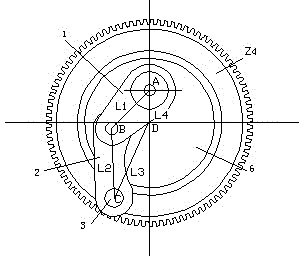

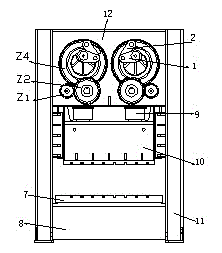

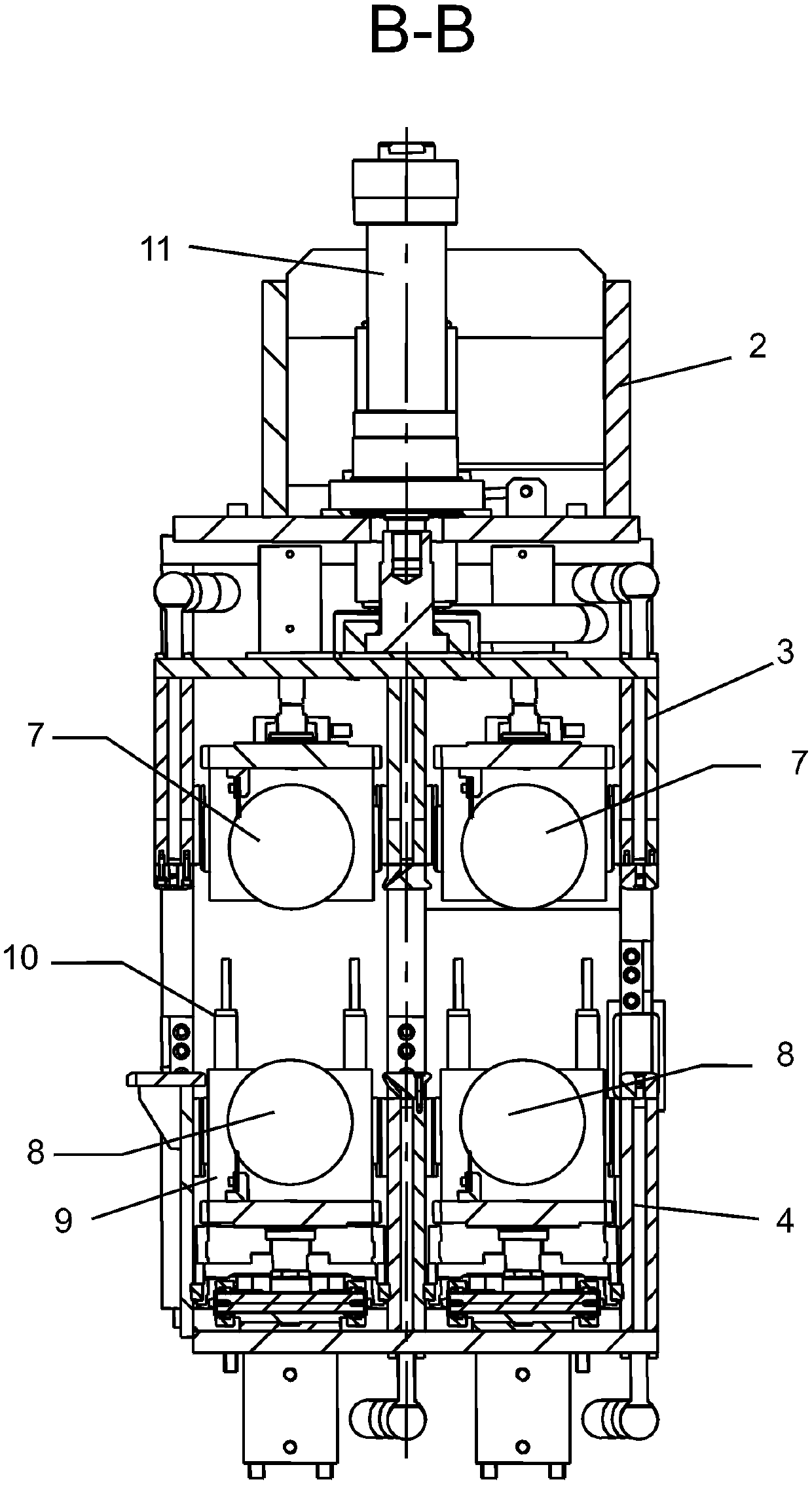

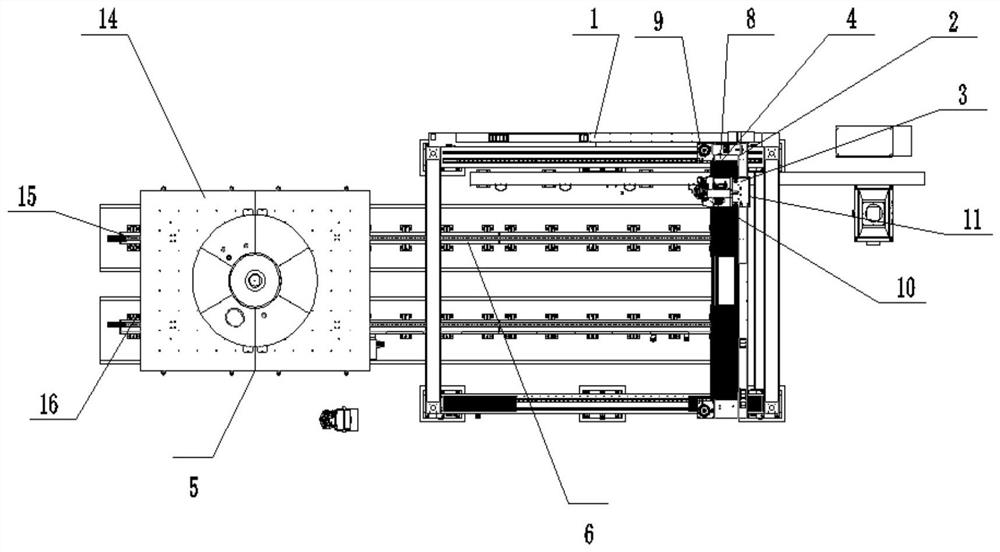

Double-crank driving double-point servo press

The invention relates to a double-crank driving double-point servo press which comprises a machine body, a sliding block and two sets of independent driving systems formed by a double-crank mechanism. The two sets of double-crank driving systems are arranged in a beam on the machine body symmetrically, and an output connecting rod of the driving system is hinged to a guiding column on the sliding block. The double-crank mechanism comprises a big gear wheel, a pin shaft, a small connecting rod, an output rod and an eccentric base. The pin shaft is fixedly arranged on an edge of the big gear wheel, one end of the small connecting rod is hinged to the pin shaft, the other end of the small connecting rod is hinged to the output rod, one end of the output rod is hinged to the small connecting rod, the other end of the output rod is fixedly connected with crank shaft supported on the eccentric base movably, and a four bar mechanism is formed by arm length between a pin shaft center and a rotation center of the big gear wheel, the small connecting rod, the output rod and an eccentric distance between the rotation center of the output rod and the rotation center of the big gear wheel. By means of the double-crank driving double-point servo press, the sliding block of the press can obtain the characteristics of large down stroke corners and small back tracking corners, and good forming curves and a remarkable reinforcement effect near a bottom dead center of the sliding block are obtained.

Owner:江苏省(扬州)数控机床研究院 +1

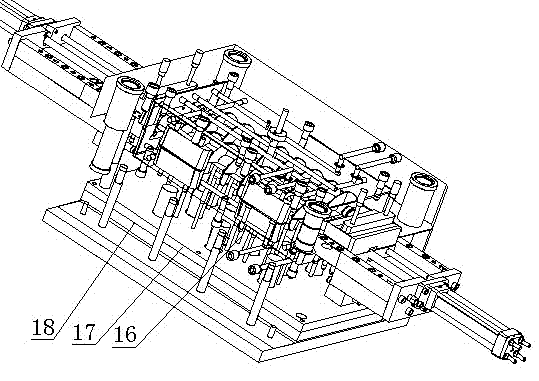

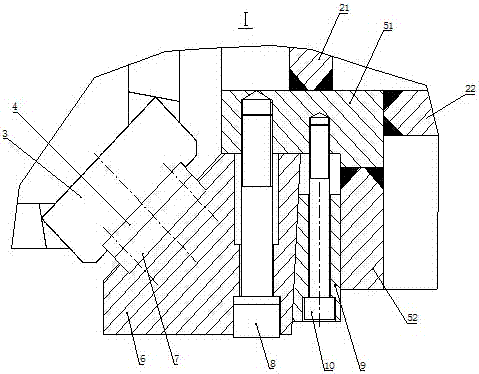

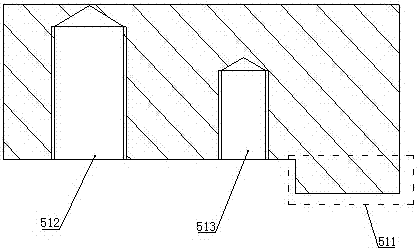

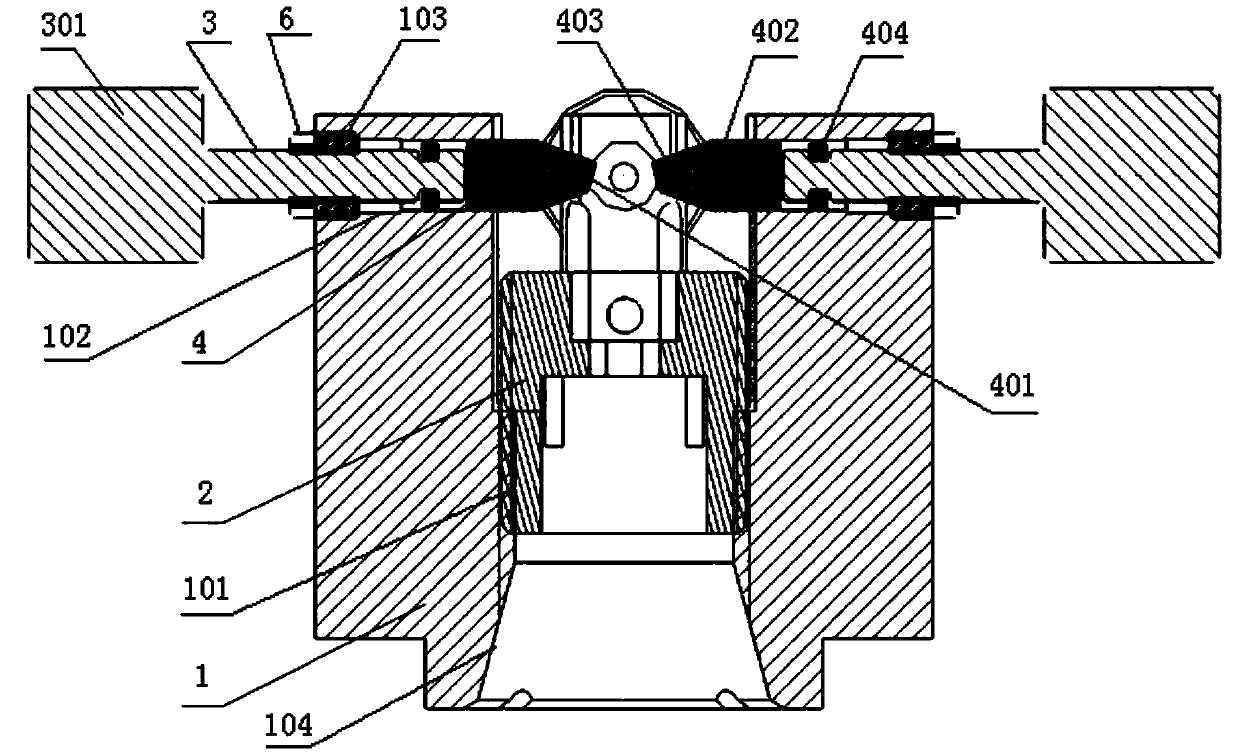

Injection mold of staggered spiral line type hollow propelling pipe

The invention discloses an injection mold of a staggered spiral line type hollow propelling pipe. The injection mold comprises a mold bottom plate, a pressing plate, a half movable template, a half fixed template, a pouring system, a cooling system and a core pulling structure, wherein the half movable template and the half fixed template are put together, the inside of the movable template and the inside of the fixed template are respectively provided with an insert component, a semi-spiral structure is machined on a mold cavity face formed by each insert component, the two semi-spiral structures are staggered and put together oppositely, a cylindrical mold core with one axial groove in one side is inserted into the middles of the mold cavity faces, the core pulling structure is connected with a hydraulic cylinder, the two sides of the mold are respectively and fixedly provided with a sliding block structure, and oil cylinder fixing blocks used for the hydraulic cylinder are arranged on the sliding block structures. According to the injection mold, the mold cavities can be in two halves and are put together oppositely, the semi-spiral structures are staggered and put together oppositely, a transition plane is formed at the joint portion of the spiral faces, the mold finished product rate is substantially improved, product performance is excellent, the long cylindrical mold core can provide power through the core pulling structure connected with the hydraulic cylinder, the hydraulic cylinder slides in a limited mode, the guide accuracy is high, the injection mold is of a structure with two cavities, and the production rate is high.

Owner:HENAN POLYTECHNIC INST

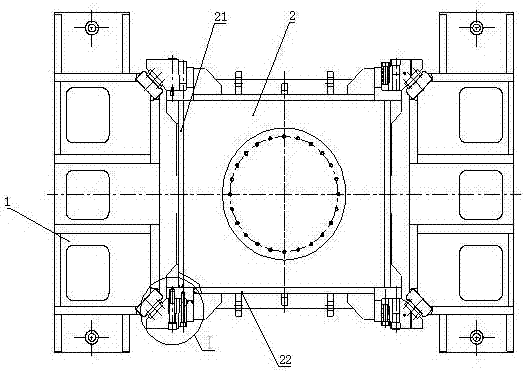

Frame type hydraulic machine guiding structure special for hot press forging of high-speed rail part

InactiveCN105344913AMeet working conditionsReduce in quantityForging/hammering/pressing machinesWear resistanceWedge shape

The invention relates to a frame type hydraulic machine guiding structure special for hot press forging of a high-speed rail part. The frame type hydraulic machine guiding structure comprises a pair of frame type stand columns and a sliding block arranged between the pair of frame type stand columns. The frame type hydraulic machine guiding structure is characterized in that wedge type guide rail assemblies are arranged between the four corners of the sliding blocks and the stand columns on the two sides; and the wedge type guide rail assemblies comprise guide rails, guide rail side wear resistance pieces, adjusting seats, adjusting blocks, sliding block side wear resistance pieces, adjusting block locking screws, wedge-shaped blocks and wedge-shaped block locking screws. The frame type hydraulic machine guiding structure special for hot press forging of the high-speed rail part has the beneficial effects that the included angles of 45 degrees are formed between the guide rails and a longitudinal panel and a transverse panel of the sliding block so that the sliding block can bear longitudinal lateral force and transverse lateral force at the same time in the moving process, the requirement for working conditions of the sliding block is met, and the number of the guide rails and the number of wear resistance blocks can be reduced.

Owner:NANTONG GAOYE HEAVY IND CO LTD

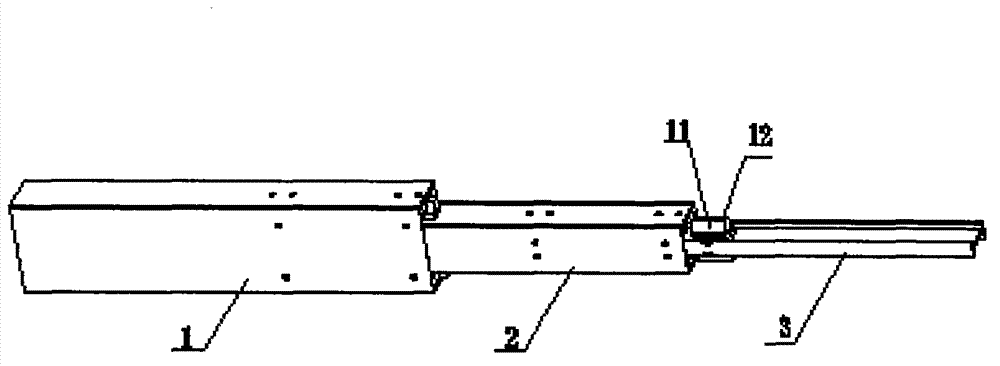

Precise autoclaved aerated block guiding and transporting mechanism

The invention discloses a precise autoclaved aerated block guiding and transporting mechanism. The precise autoclaved aerated block guiding and transporting mechanism comprises an outer segment, a middle segment and an inner segment, wherein the outer segment and the middle segment are square cavities; the section of the inner segment is an I-shaped supporting frame; the middle segment can do telescopic movement inside the outer segment; the inner segment can do telescopic movement inside the middle segment; the outer segment comprises an outer segment shell and outer segment guiding slots on the two inner sides of the outer segment shell; the middle segment comprises a middle segment shell and middle segment guiding slots on the two inner sides of the middle segment shell; a middle segment wedge and a middle segment guiding block are arranged on the two outer sides of the middle segment shell respectively; an inner segment wedge and an inner segment guiding block are arranged on the two sides of the inner segment respectively; and guiding block regulating bolts are arranged on the middle segment guiding block and the inner segment guiding block respectively. The precise autoclaved aerated block guiding and transporting mechanism has the advantages of simple structure, precise guiding and strong wear resistance.

Owner:DONGYUE MACHINERY GRP

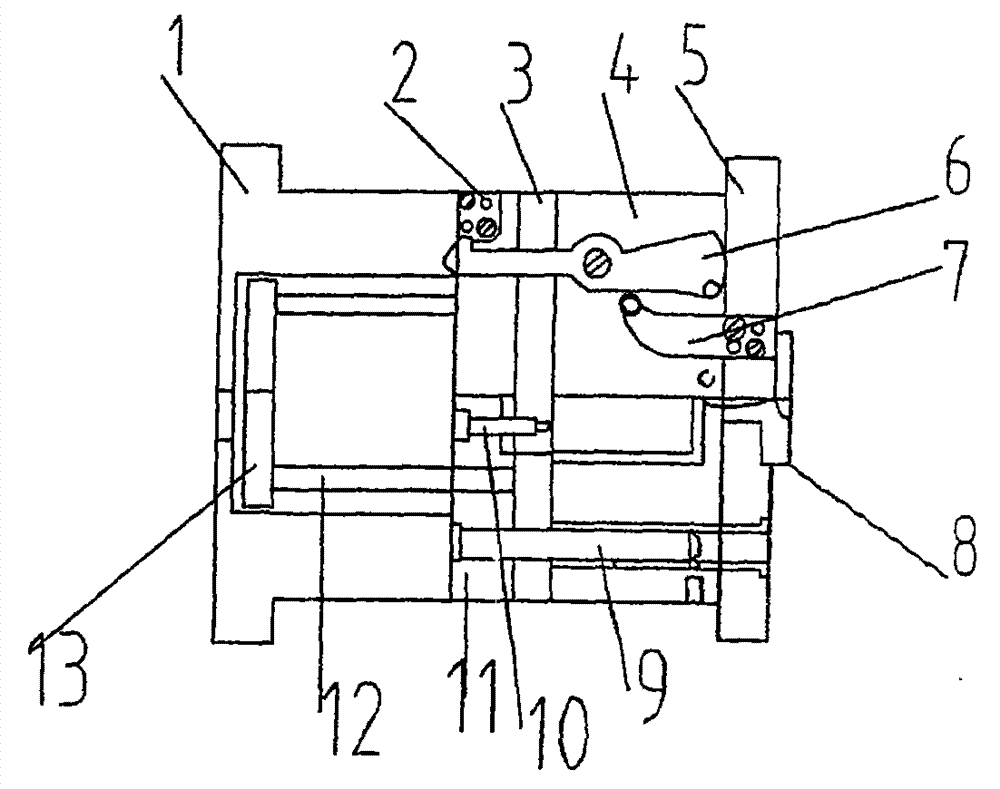

Metal pressure casting die swing hook dual-division swage die mechanism

A metal pressure casting die swing hook dual-division swage die mechanism comprises a die fixed clamping plate, a fixed die plate, a moving die plate, a moving die base plate, a moving clamping plate, a push plate arranged inside the die and a venting pin, a swing hook (6) is movably connected onto the outer side face of the fixed die plate(4) through screws, a pulling hook (7) is fastened onto the outer side face of the fixed clamping plate (5), a limited block (2) is fastened onto the outer side face of the moving die plate (11), the swing hook (6) and the limited block (2) are in buckled fitting, and a roller on the swing hook (6) and a roller on the pulling hook (7) are in sliding fitting. The action of the swing hook and the action of the pulling hook are adopted in the die, so that when the die is opened, a sprue of a gating system is automatically cut off, the problem that a sprue cannot be cut off automatically in a metal pressure casting die is solved, meanwhile, the design is optimized, it is achieved that the structure is simple, the sprue is cut off by utilizing the time of die opening, clotted materials fall out of the die as a result of the self weight, the motion is firm and reliable, and the demoulding is conducted smoothly.

Owner:牟维军

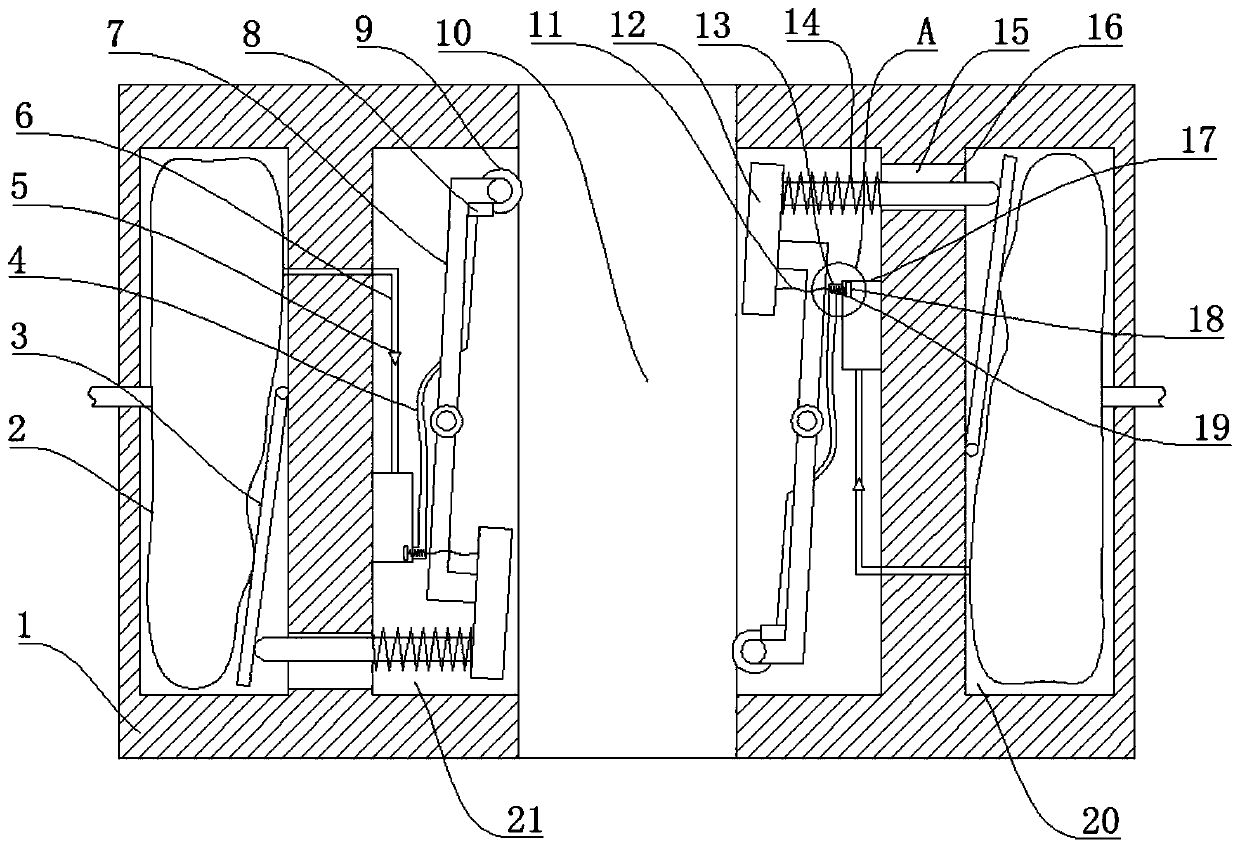

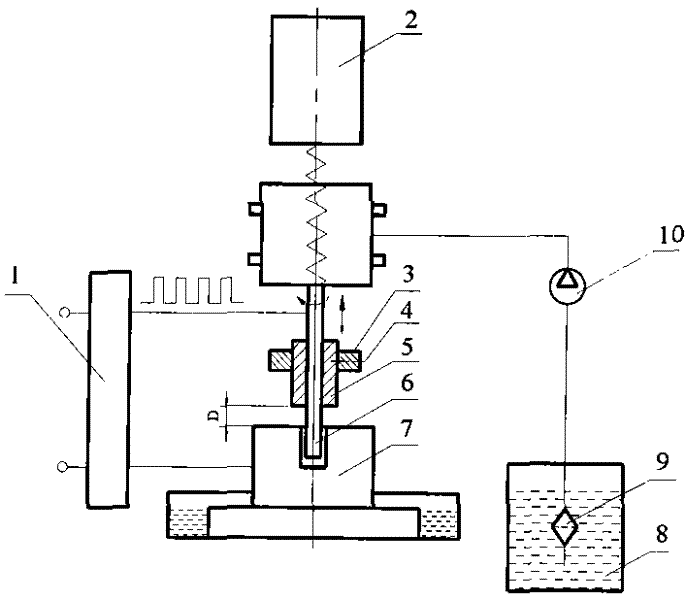

Ultrahigh-strength strip steel surface cleaning device

ActiveCN110052502AReduce sizeShorten the lengthWork cleaning devicesMetal rolling arrangementsHydraulic cylinderSurface cleaning

The invention discloses an ultrahigh-strength strip steel surface cleaning device. The ultrahigh-strength strip steel surface cleaning device mainly comprises a machine body, a squeezing and drying roller assembly, an upper inverted E-shaped frame driving mechanism, an upper squeezing and drying roller box driving mechanism and an air sweeping mechanism. According to the device, frame lifting andpressure adjustment of an squeezing and drying roller are controlled separately, the number of large hydraulic cylinders is reduced from four to two, the hydraulic cylinder used for adjusting the pressure of the squeezing and drying roller can be a small hydraulic cylinder, and follow-up automatic roller changing is possible; and the squeezing-dry pressure adjusting range is widened by adopting the small hydraulic cylinder. The overall device is high in structural rigidity and is suitable for production of high-strength steel. The structure is compact, and the two devices for purging and squeezing are combined into one, so that the requirement for the distance between a roller and a reeling machine is shortened as much as possible by a single-machine reversible rolling mill, and the yieldis improved.

Owner:BAOSHAN IRON & STEEL CO LTD

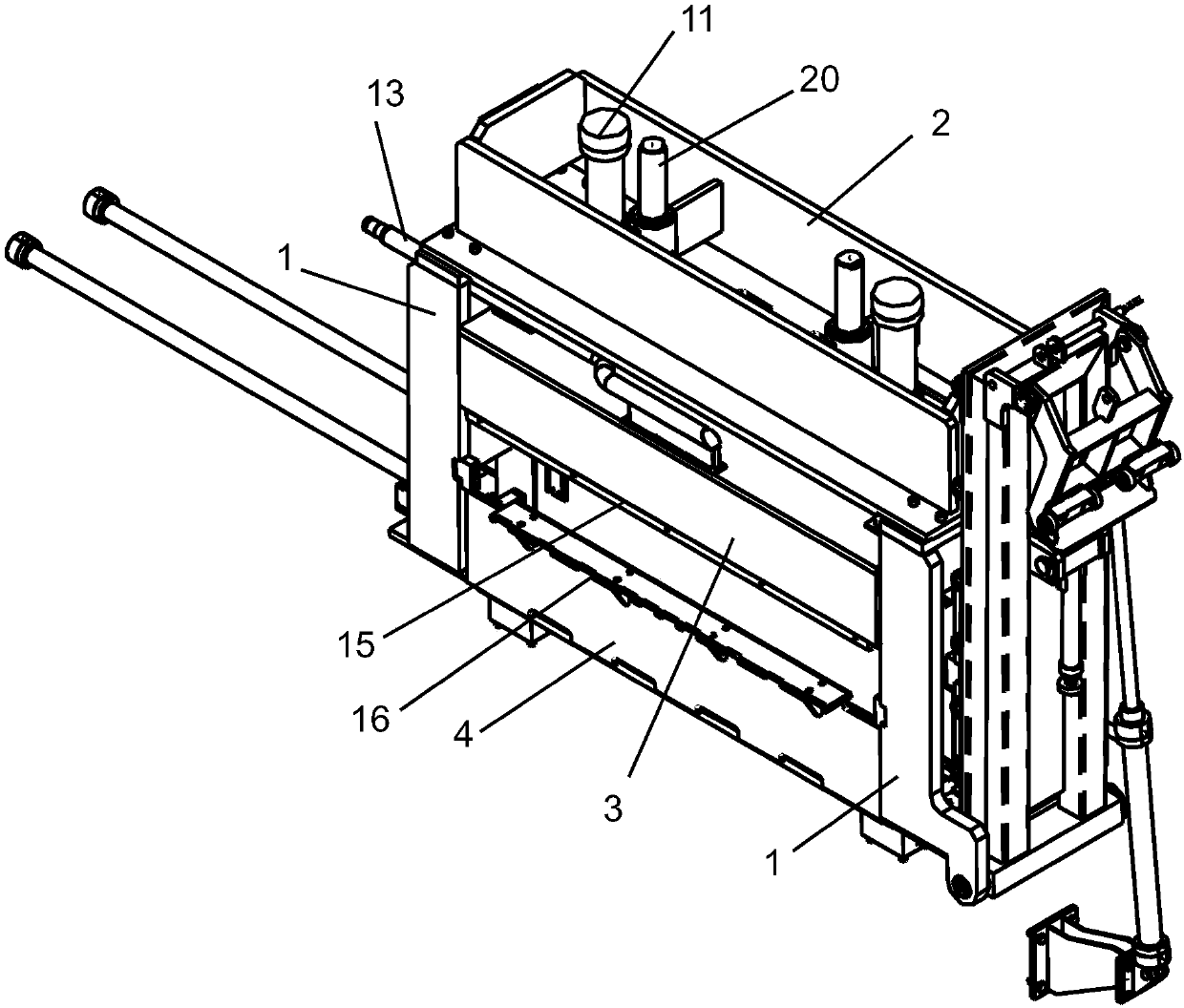

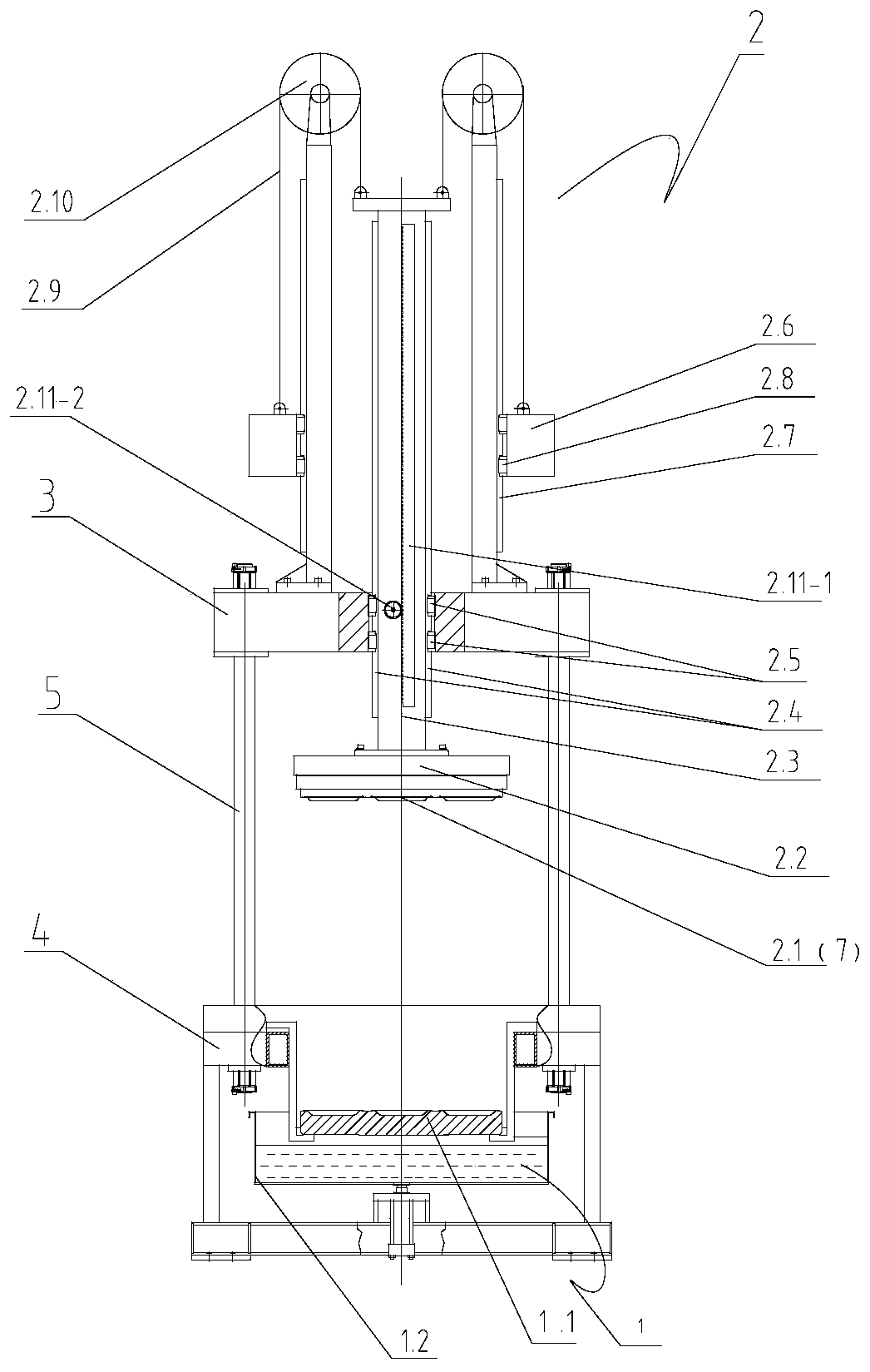

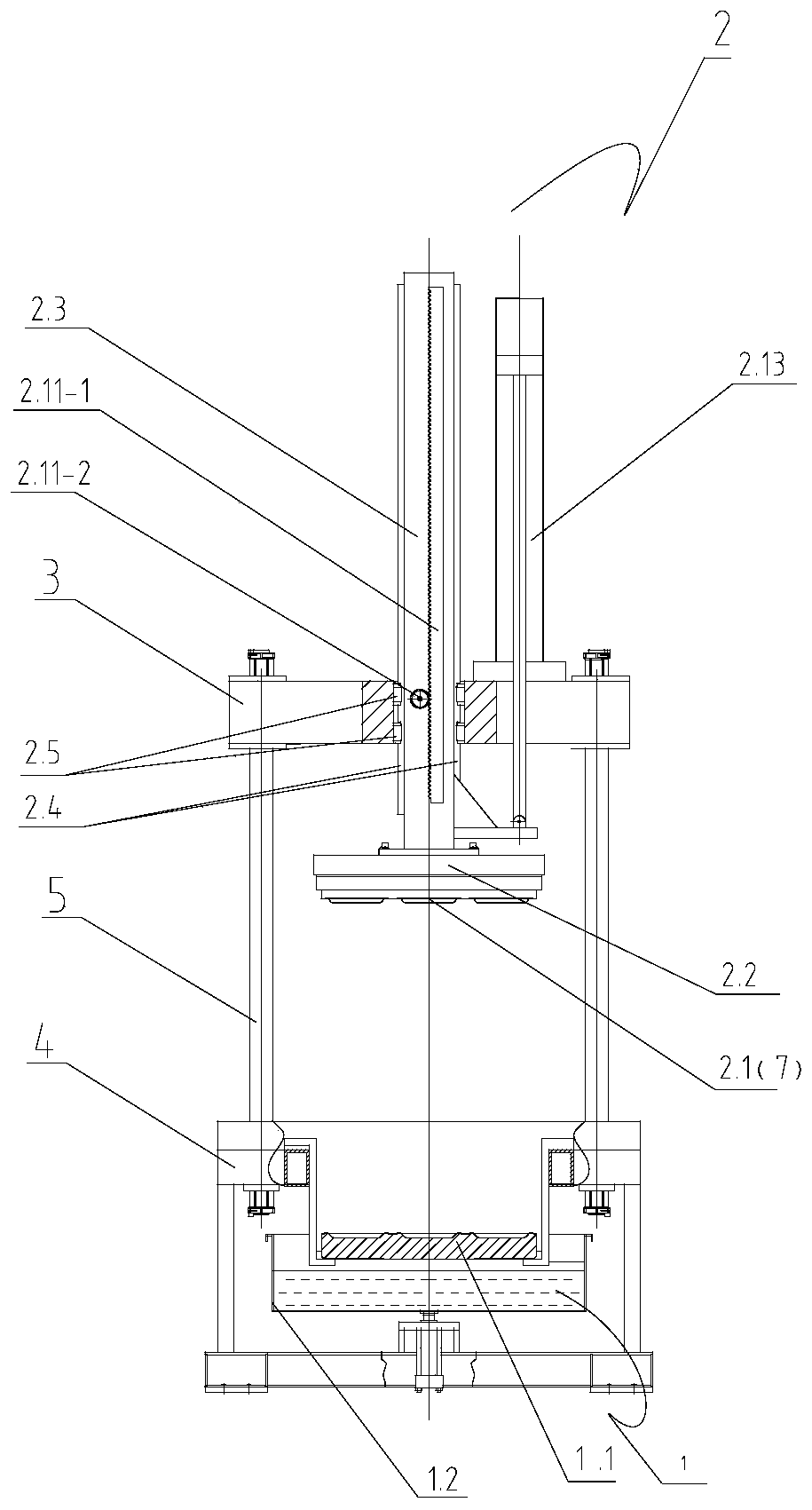

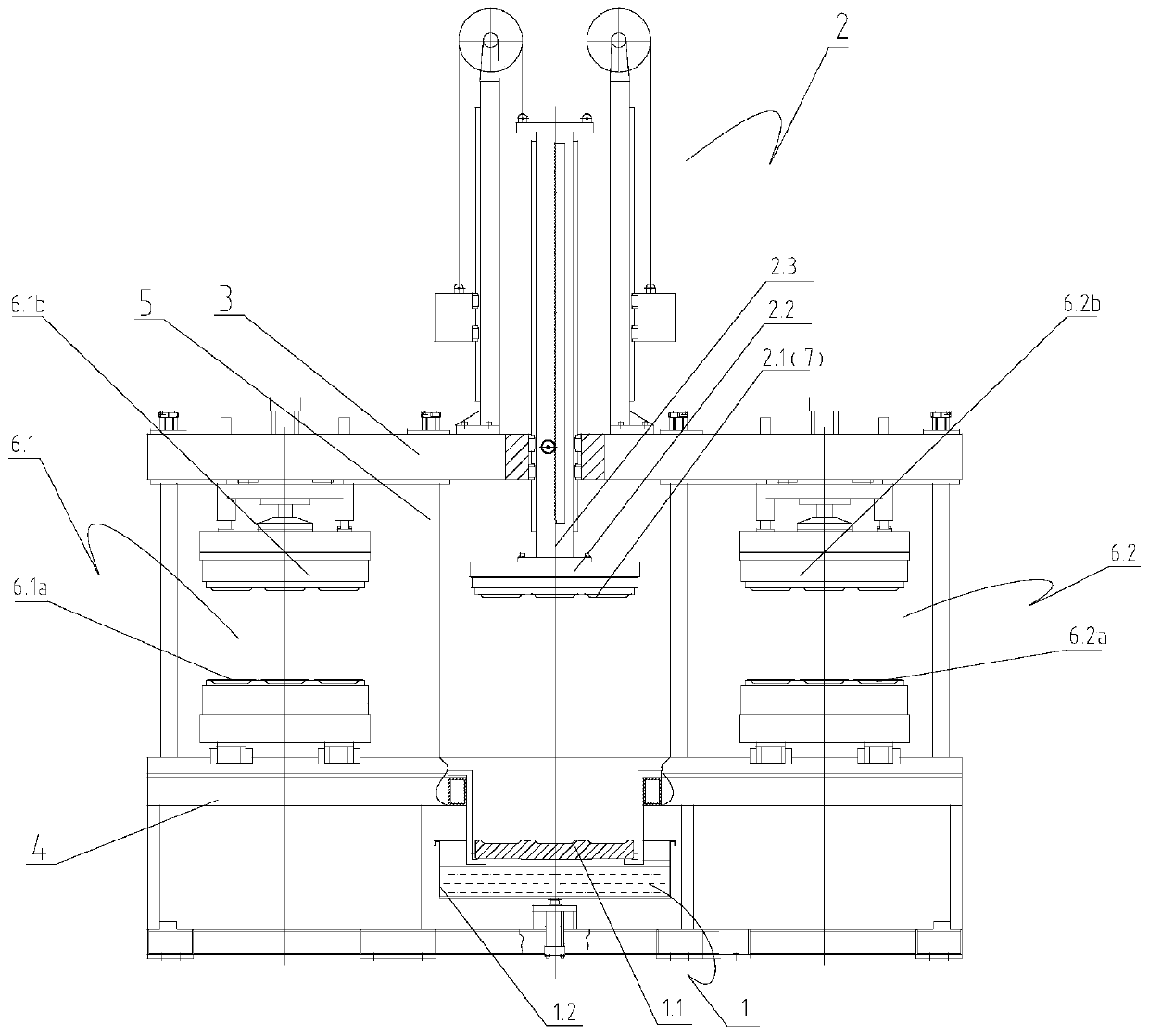

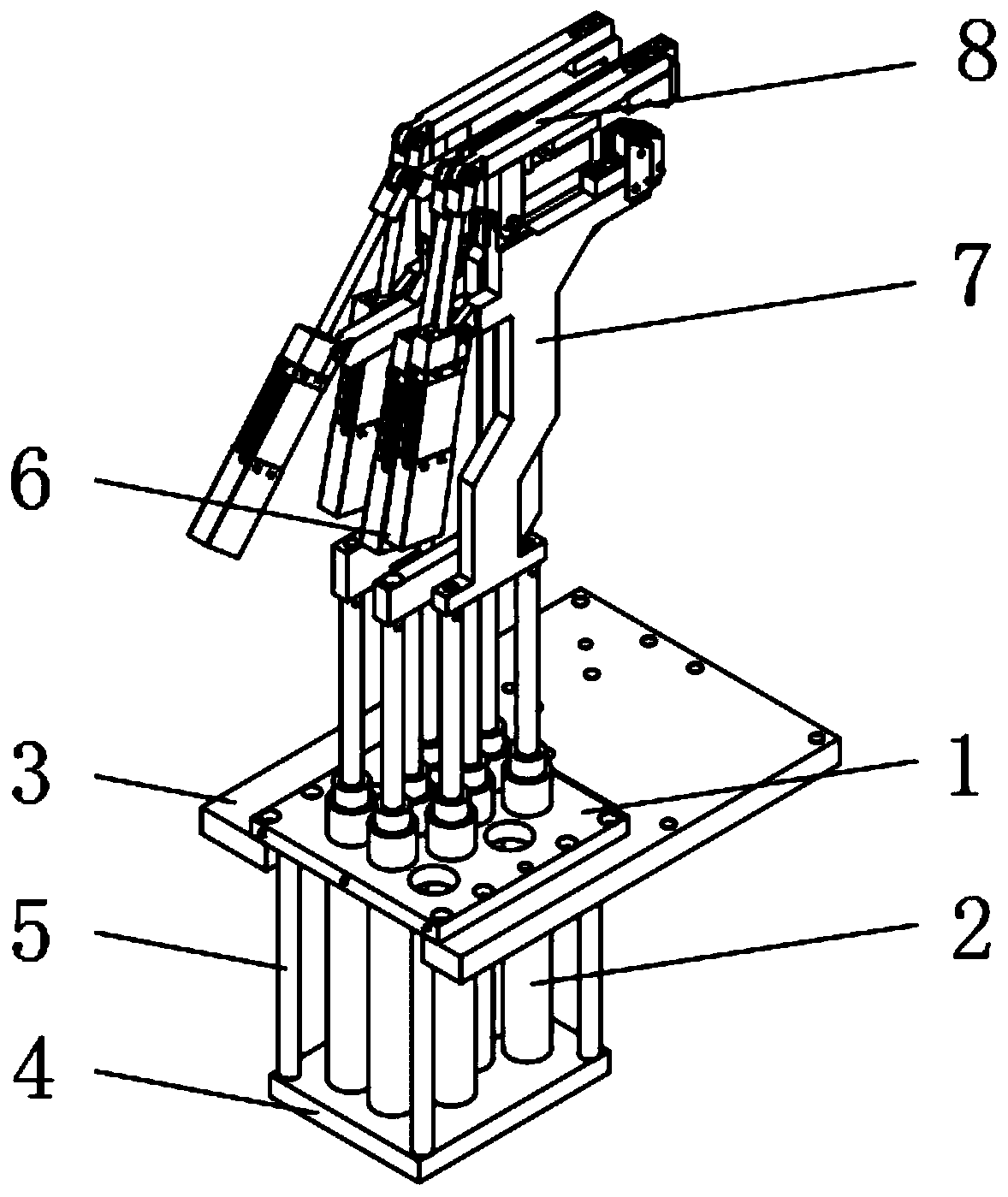

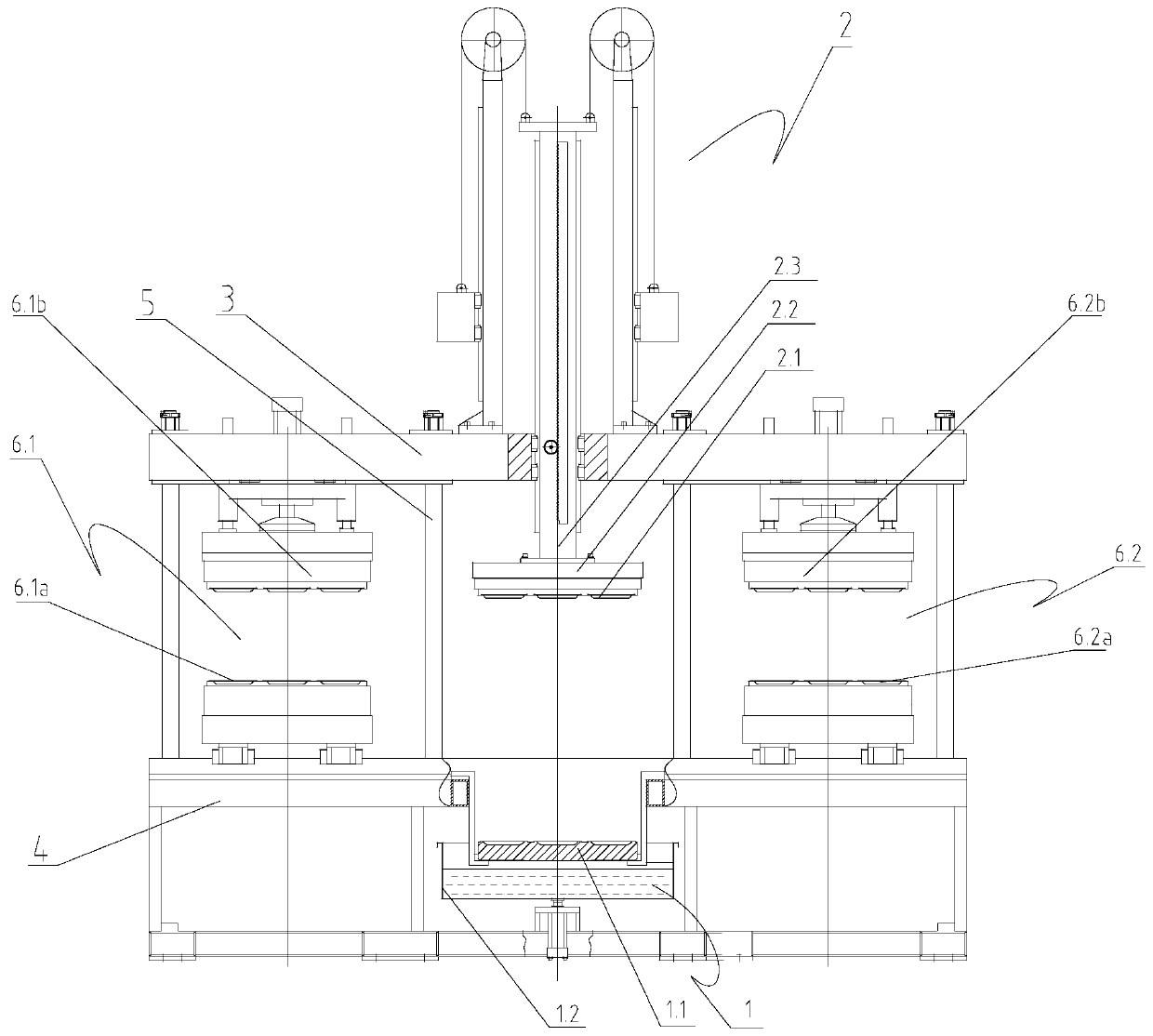

Method for moving mold of plant fiber molding machine up and down and line rail type up and down mold moving device

PendingCN110725158AReduce or eliminate gravity loadsEliminates gravity loadsTextiles and paperPlant fibreMolding machine

The invention relates to a method and a device for making a plant fiber product with paper pulp by means of molding. According to the technical scheme, a method for moving a mold of a plant fiber molding machine up and down comprises the following steps: 1) while a plant fiber molding product is manufactured, fixing a vertical moving mold which can make up and down straight line movement at one end of a sliding column, or fixing the vertical moving mold at one end of the sliding column through a mold mounting plate, and driving the vertical moving mold to make up and down straight line movement through the sliding column which is positioned on an upper rack and is capable of sliding vertically up and down relative to the upper rack; and 2) connecting the sliding column with a weight balance block through a weight balance connecting line or a chain mounted on a fixed pulley in a span manner, rotationally positioning the fixed pulley or a sprocket on the upper rack, and tracking the weight balance block of the sliding column through the weight balance connecting line or the chain. The method and the device are high in guiding precision, short in forming cycle, stable in operation, high in output, and capable of eliminating hydraulic oil pollution of wet blanks.

Owner:EURASIA LIGHT IND EQUIP MFR +1

Cut-off device of metal sheet cut-off machine

The invention discloses a cut-off device of a metal sheet cut-off machine. The cut-off device of the metal sheet cut-off machine comprises a cut-off power driving assembly, a cut-off guiding part and a cut-off execution assembly; a motor provides power for the cut-off device integrally; an eccentric wheel on a driving shaft is driven to rotate through driving of synchronous wheels and a synchronous belt; eccentric movement acts on a framework through bearing driving; meanwhile, under the guiding action of the guiding part, a cutter is finally driven to perform vertical linear cut-off movement. By means of the cut-off device of the metal sheet cut-off machine, multiple metal sheets can be cut off at the same time; the cutter is convenient to mount; the work efficiency and cut-off size accuracy are high; cut notches are neat; manual assistance is not needed during cut-off action; control is simple; the cost is low.

Owner:NANJING INST OF TECH

Back focus adjusting mechanism and a gun type camera applying the same

PendingCN109803083AOrientation structure is simpleMeet the precision requirementsTelevision system detailsColor television detailsGear wheelElectric machinery

The invention provides a back focus adjusting mechanism and a gun type camera applying the same. The back focus adjusting mechanism comprises a driving motor, a reduction gear set and a positioning guide assembly. The positioning guide assembly comprises a mounting plate, a fixing plate and a guide assembly, the guide assembly is mounted on the mounting plate, and the mounting plate is connected with the fixing plate; The guide assembly comprises a guide rod, a transmission screw rod and a guide seat fixedly connected with the mounting plate; a central hole for inserting the guide rod is formed in the guide seat; A threaded hole for inserting one end of the transmission screw is formed in the guide rod, the other end of the transmission screw is connected with an output gear of the reduction gear set, and the output gear of the reduction gear set drives the transmission screw to rotate coaxially; The driving motor is connected with the reduction gear set, the reduction gear set drivesthe transmission screw to rotate to drive the guide rod to move, and the guide rod penetrates through the fixing plate to push the mounting plate. The back focus adjusting mechanism provided by the invention has a simpler guide structure under the condition of meeting the requirement of pushing the fixing plate.

Owner:重庆紫光华山智安科技有限公司

Construction steel structure carrying vehicle

InactiveCN110386397AAvoid misalignmentGuaranteed stabilityManual conveyance devicesEngineeringMachining

The invention relates to a construction steel structure carrying vehicle. The vehicle comprises a vehicle body, wherein walking wheels are installed on two sides of the vehicle body, a bearing plate is installed at the upper end of the vehicle body, a lower compression clamping device is installed at the lower middle part of the bearing plate, and an upper transposition clamping device is installed on the right side of the bearing plate. The vehicle has the advantages of being high in automation degree, reasonable in structural design, low in manufacturing cost and the like, a traditional modeof lifting and conveying steel structure through a crane is replaced, so that the production and manufacturing cost is reduced, the defect that the traditional crane conveying mode is narrow in application range is overcome, the rapid transfer conveying or the workshop replacing of the steel structure is achieved, convenience is brought to the production, machining and transportation of the steelstructure, the operation and control are simple, and the stability performance and the safety performance are high.

Owner:SUIZHOU ZHUFENG STEEL STRUCTURE ENG

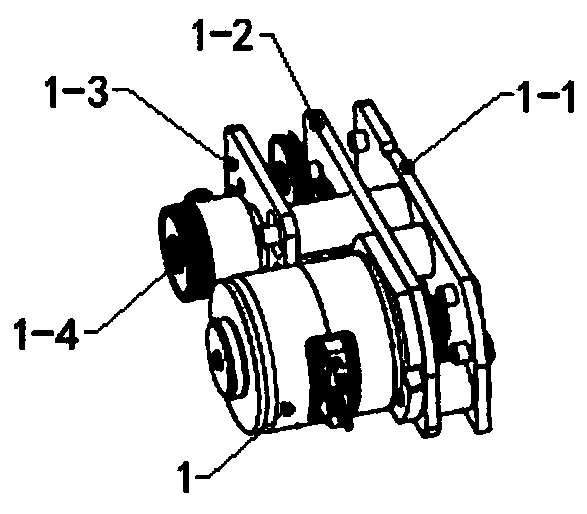

Clamping mechanism for centrifugal microfluidics CD chip

ActiveCN107552119AEasy to insertGuaranteed horizontal positioningLaboratory glasswaresSupporting apparatusEngineeringMotor shaft

The invention belongs to the microfluidics field and discloses a clamping mechanism for a centrifugal microfluidics CD chip. The mechanism comprises chip support racks 1, a lever 2, a push rod 3, a positioning marble 4, a motor shaft clamping groove 5, a guide block 6 and a guide slot 7. The chip is inserted to the bottom along the guide slot 7 and can reach the accurate position by means of the horizontal positioning function of the guide block 6 and cooperation with the motor shaft clamping groove 5, and the chip is completely positioned when the positioning marble 4 in the motor shaft clamping groove 5 bounces; when the chip is required to be taken out, all that is required is to push the push rod 3 and the chip can automatically bounce under the action of the lever 2. The distance between the chip support racks 1 can be conveniently adjusted and thus the mechanism can adapt to chips with different sizes. The clamping mechanism for the centrifugal microfluidics CD chip is designed in the CD driver principle, can conveniently clamp and position the chip and has the advantages of being simple in structure, convenient to operate, reliable and high in adaptability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

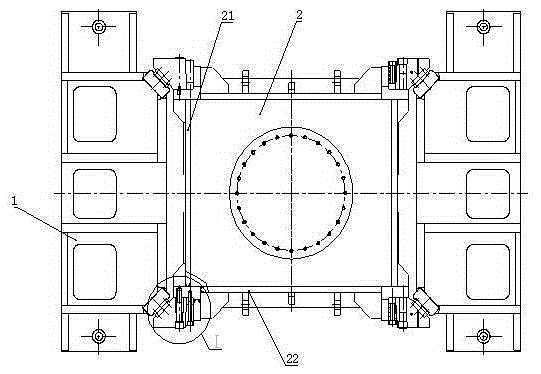

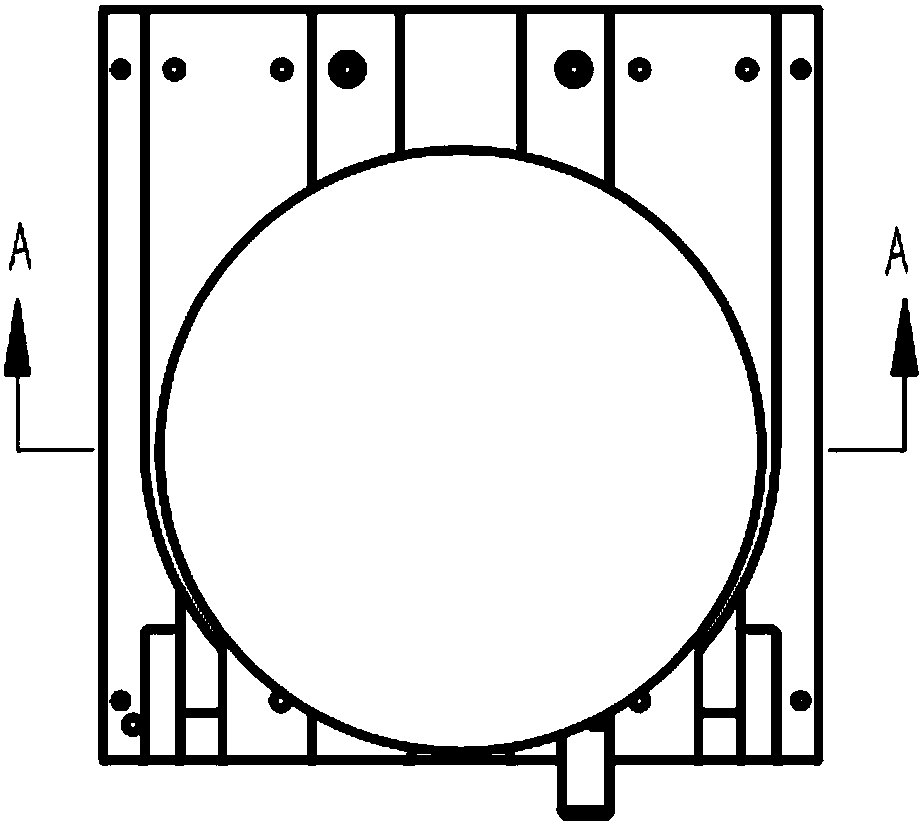

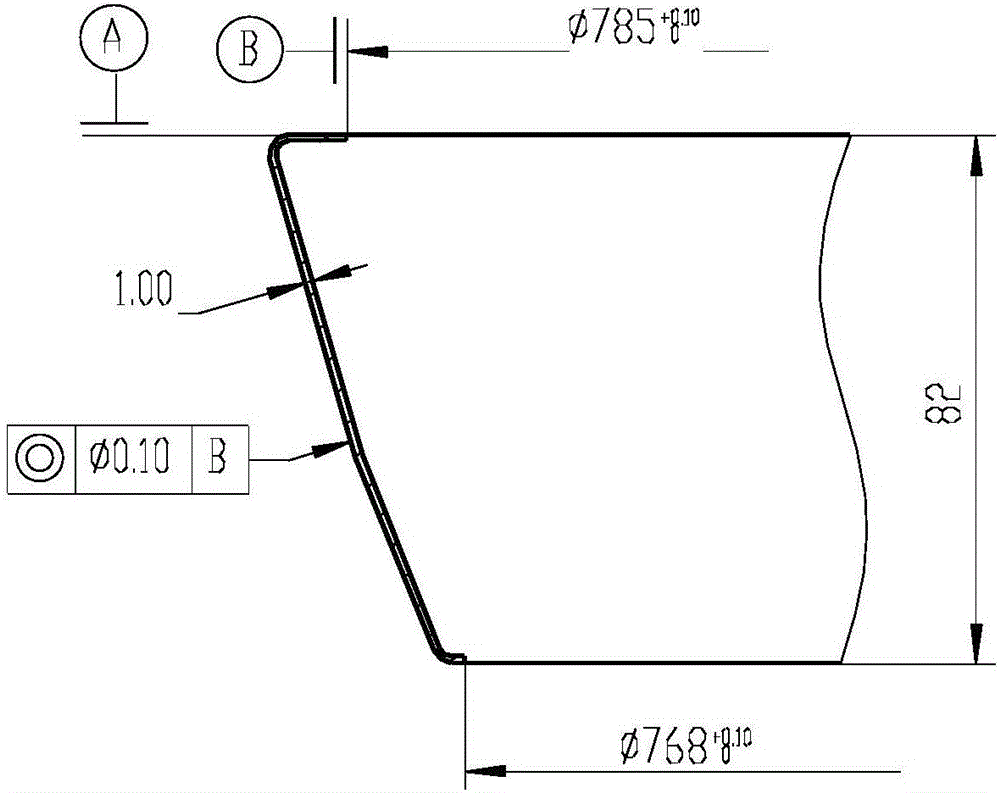

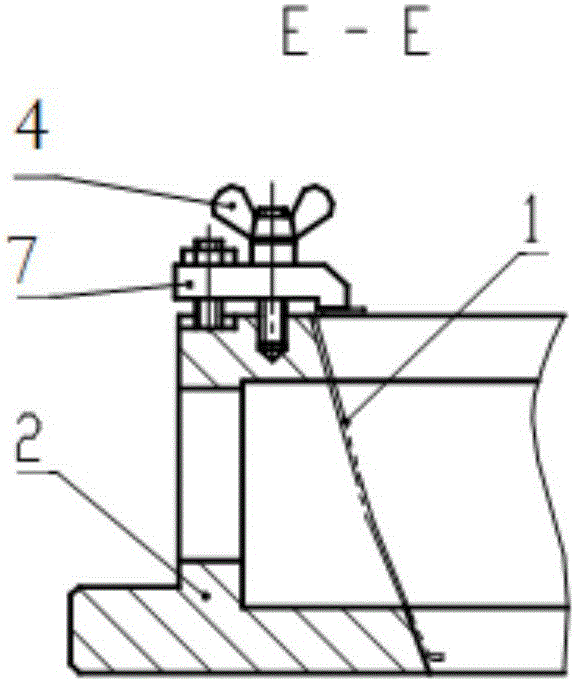

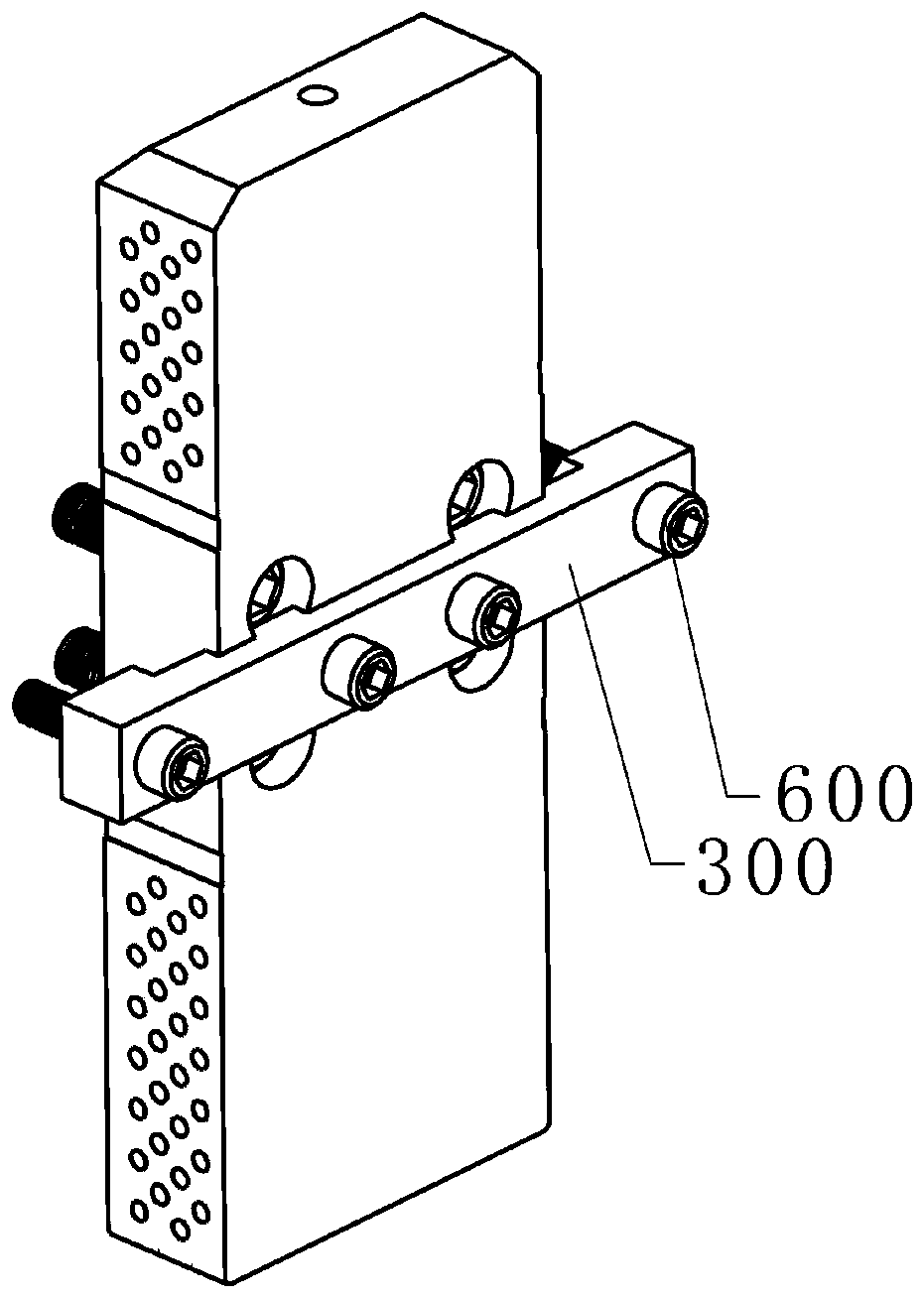

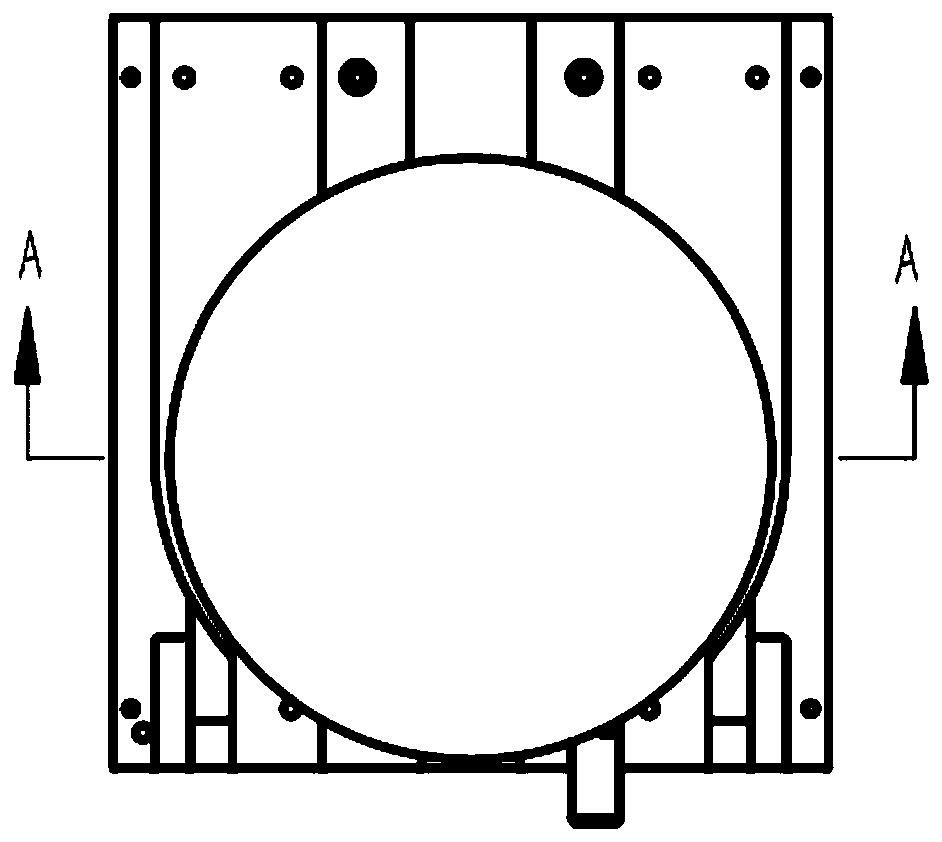

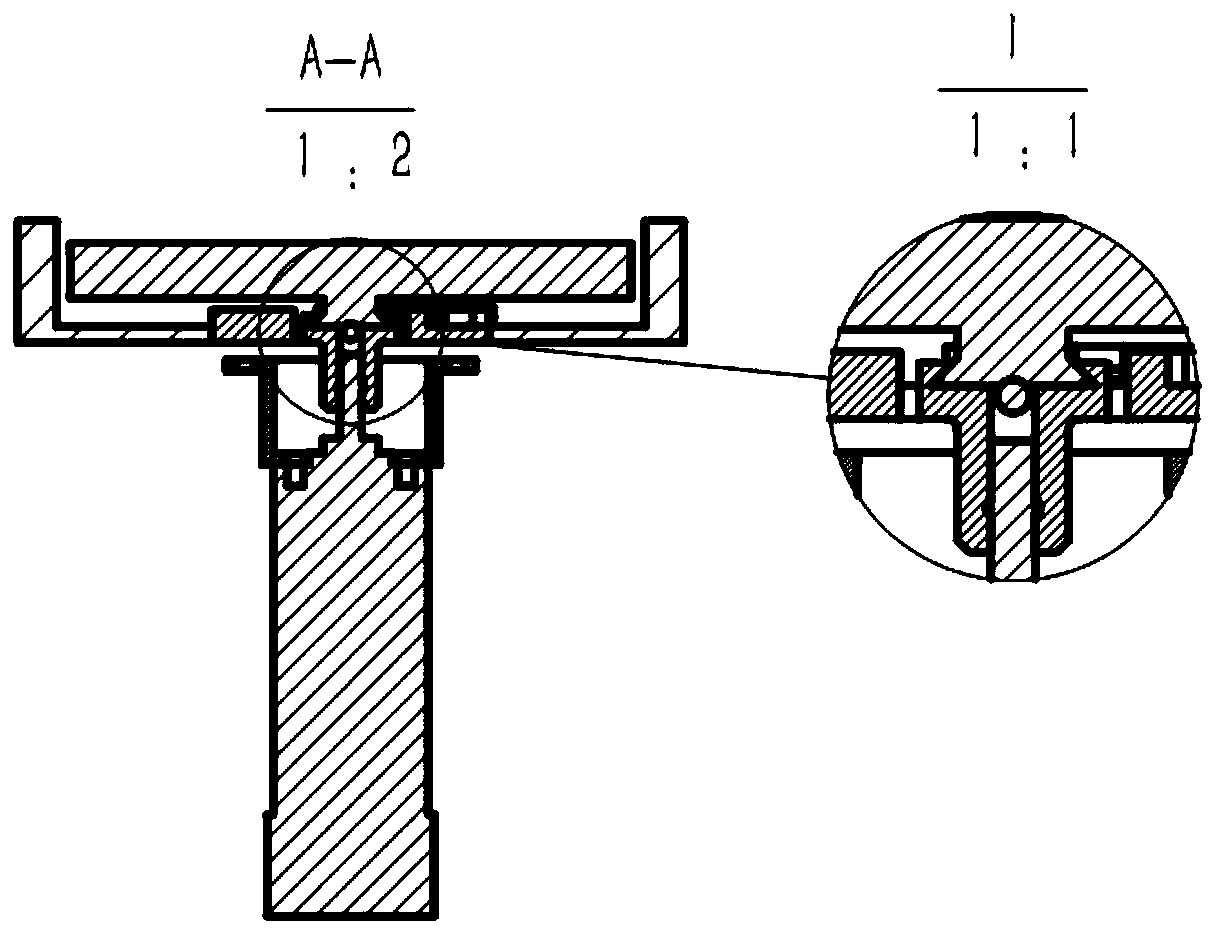

Positioning and clamping tool and method for inner hole laser cutting of thin-walled annular sheet metal part

ActiveCN106238931AReduce forceSmall clamping deformationLaser beam welding apparatusGas compressorLaser cutting

The invention discloses a positioning and clamping tool and method for inner hole laser cutting of a thin-walled annular sheet metal part, belongs to the technical field of metal plate forming and provides a positioning and clamping scheme using the outer profile of a part as standard. The part is clamped by adopting a cross-shaped horizontal retainer to improve the positioning precision. The problem that a thin-walled annular sheet metal part deforms during clamping and is low in machining precision can be solved, and the higher concentricity requirement is ensured. The method can be applied to manufacture of stator inner rings of an aero-engine gas compressor, can be popularized and applied to the manufacturing field of thin-walled annular parts with similar structures. The clamping tool is simple in structure and convenient to operate, rapid and accurate positioning is achieved, and the machining precision and production efficiency are improved.

Owner:AECC AVIATION POWER CO LTD

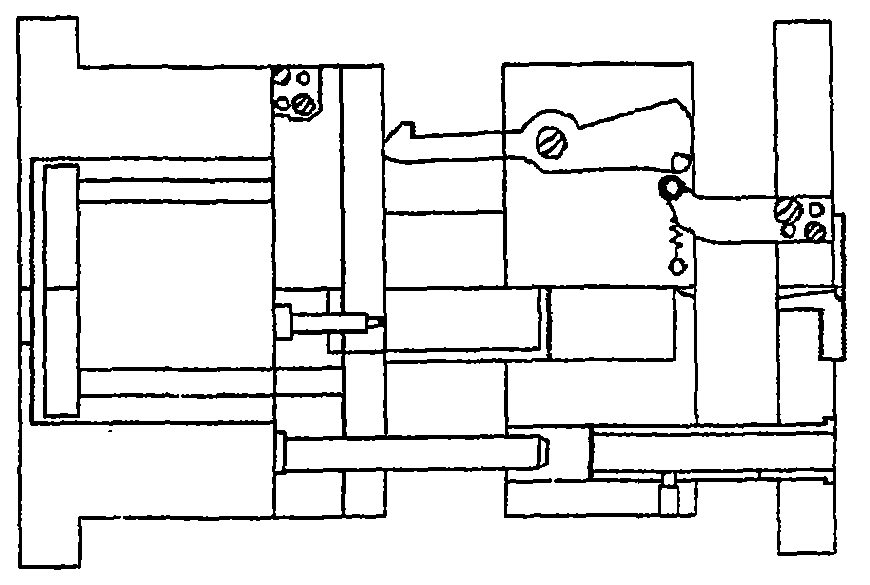

Rolling and sliding compound guide track and manufacturing method thereof

InactiveCN102528467BGuaranteed guide accuracyHigh movement sensitivityLarge fixed membersProcess efficiencyEngineering

The invention discloses a rolling and sliding compound guide track and a manufacturing method thereof. The rolling and sliding compound guide track comprises a rolling and sliding positioning compound guide track and a rolling guide track, wherein the rolling and sliding positioning compound guide track comprises a first positioning block, a second positioning block, a first rolling body and a first positioning baffle plate, the first rolling body is sequentially fixedly connected with the second positioning block and the first positioning block, and the outward surface of the first positioning block is of a circular arc surface; and the rolling guide track comprises a third positioning block, an adjusting wedge block, a second rolling body and a second positioning baffle plate, wherein the second rolling body is sequentially fixedly connected with the adjusting wedge block and the third positioning block, and the outward surface of the third positioning block is of the circular arc surface. The rolling and sliding compound guide track provided by the invention can ensure the guide precision of motion of a ram and the bearing capacity of the guide track, simultaneously reduce the friction force between the ram and a transmission mechanism, and upgrade the sensitivity, the rigidity and the vibration resistance of the motion of the ram by combining the advantages of a rolling guide track and a sliding guide track; and furthermore, not only geometric tolerance requirement of a guide track mounting groove is ensured, but also processing efficiency can be greatly improved.

Owner:SANY GRP

Multiple-unit-form positioning mechanism

PendingCN111390479AStrong applicabilityGood fixed effectWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses a multiple-unit-form positioning mechanism. The multiple-unit-form positioning mechanism comprises a multiple-unit mechanism connecting plate and a mounting frame; a pluralityof sets of unit clamping mechanisms are arranged in the mounting frame and each comprise two sets of unit air cylinders and a clamping mechanism, wherein the telescopic ends of the two sets of unit air cylinders are arranged on the positions, close to the two sides, of the outer surface of the lower end of the clamping mechanism correspondingly; and the unit air cylinders on the multiple sets of unit clamping mechanisms are mounted on the mounting frame in a staggered mode. According to the multiple-unit-form positioning mechanism, the unit clamping mechanisms are mounted on the mounting framein a staggered mode, thus the limited space is utilized, the number of the unit clamping mechanisms can be increased, thus different vehicle models can be fixed, quickly flexible switching of the positioning mechanism on the same station and among the different vehicle models can be achieved, the problem that switching cannot be conducted due to limitation of the narrow space is solved, the manufacturing cost of enterprises is effectively lowered, the occupied area of the enterprises is effectively saved, and thus better use prospects are brought.

Owner:广州富士汽车整线集成有限公司

High-rigidity lifting device for ultra-precision machining

ActiveCN112453926AEasy to adjustIncrease stiffnessLarge fixed membersHigh stiffnessMachining process

The invention relates to a high-rigidity lifting device for ultra-precision machining. The lifting device is provided with a base and a lifting panel, a lower wedge-shaped block with an upward inclined plane is arranged on the base, an upper wedge-shaped block with an inclined plane oppositely matched with the lower wedge-shaped block is fixed to the bottom surface of the lifting panel, and a first friction guide rail is fixed to the inclined plane of the upper wedge-shaped block; the inclined plane of the lower wedge-shaped block is in sliding fit with the first friction guide rail, a secondfriction guide rail is fixed to the base, the bottom face of the lower wedge-shaped block is in sliding fit with the second friction guide rail, a trapezoidal lead screw is rotationally arranged in the lower wedge-shaped block, and a trapezoidal nut rotationally matched with the trapezoidal lead screw is fixedly connected to the lower wedge-shaped block; and the height of the device is adjusted through the lifting effect under the wedge-shaped motion effect of the translation of the lower wedge-shaped block on the upper wedge-shaped block, and sliding friction is adopted to replace rolling friction motion used by a traditional lifting device, so that the overall rigidity and precision of the device are improved, and the guiding precision in the lifting process and the anti-vibration effectin the machining process are guaranteed.

Owner:姜堰经济开发区科创中心

A method for installing guide components of a frame-type hydraulic press dedicated to hot-press forging of high-speed rail components

The invention relates to an installation method for a frame type hydraulic machine guide assembly special for high-iron part hot press forging. The installation method is characterized in that guide rail abrasion resistant pieces and abrasion resistant pieces of sliding blocks of the frame type hydraulic machine guide assembly are arranged at 45-degree angle, and an adjusting base used for adjusting the gap between the abrasion resistant pieces is composed of a strip-type connecting block A and a strip-type connecting block B, and installed and manufactured through a sectioning method to ensure the installation precision. The installation method has the advantages that guide rails form 45-degree included angles with both longitudinal and transverse face plates of the sliding blocks, and the sliding blocks can bear yawing force in the longitudinal and transverse directions in the moving process, so that the number of the guide rails and the abrasion resistant pieces thereof is reduced while the working condition requirement for the sliding blocks is met. Meanwhile, the adjusting base is manufactured through the sectioning method, the large-size material consumption of the L-shaped adjusting base made through integral cutting can be reduced at first, and the welding deformation of the L-shaped adjusting base during integral welding is avoided, and the phenomenon that the L-shaped adjusting base cannot be corrected after the integral welding is avoided, so that the guide precision is ensured.

Owner:NANTONG GAOYE HEAVY IND CO LTD

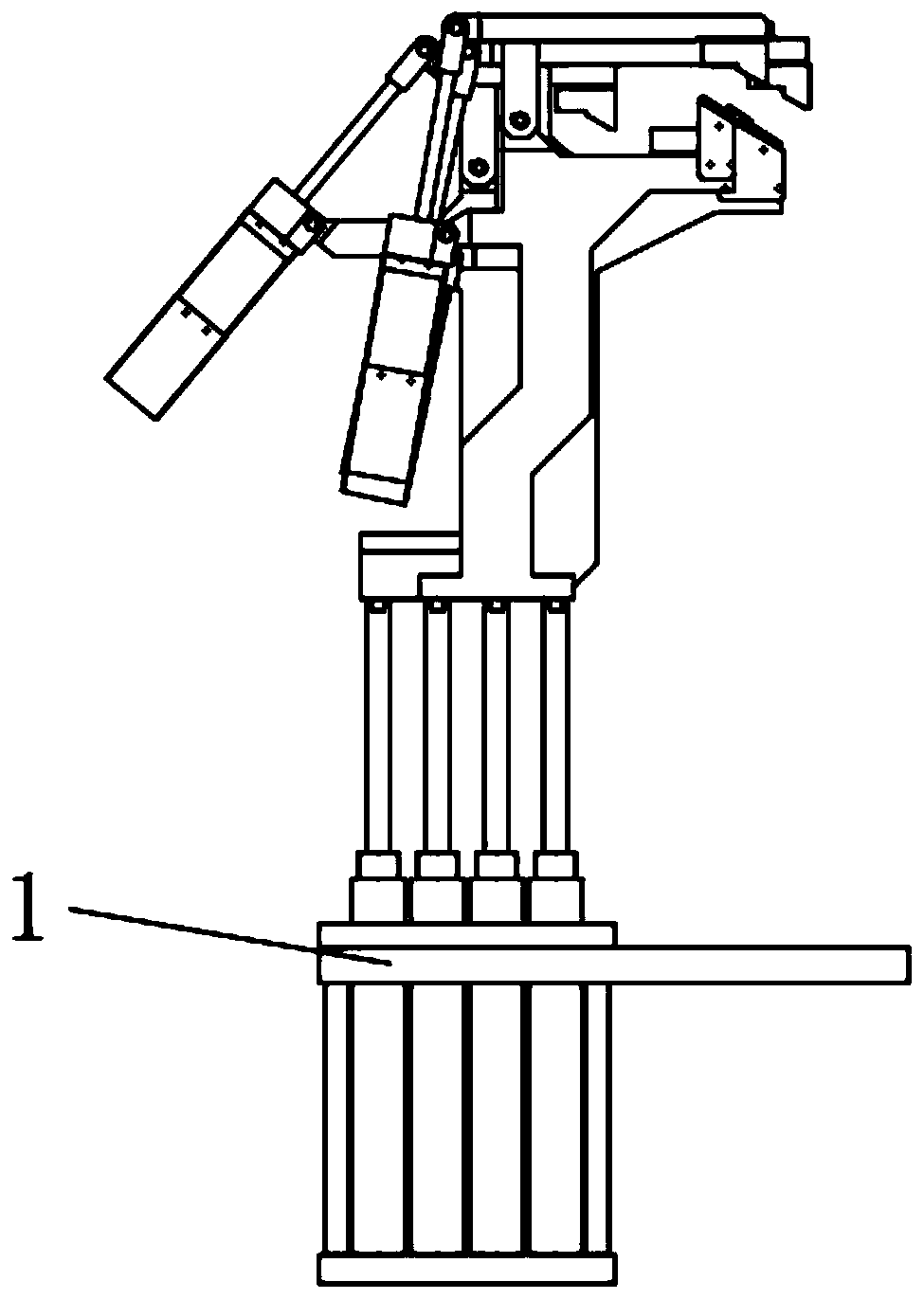

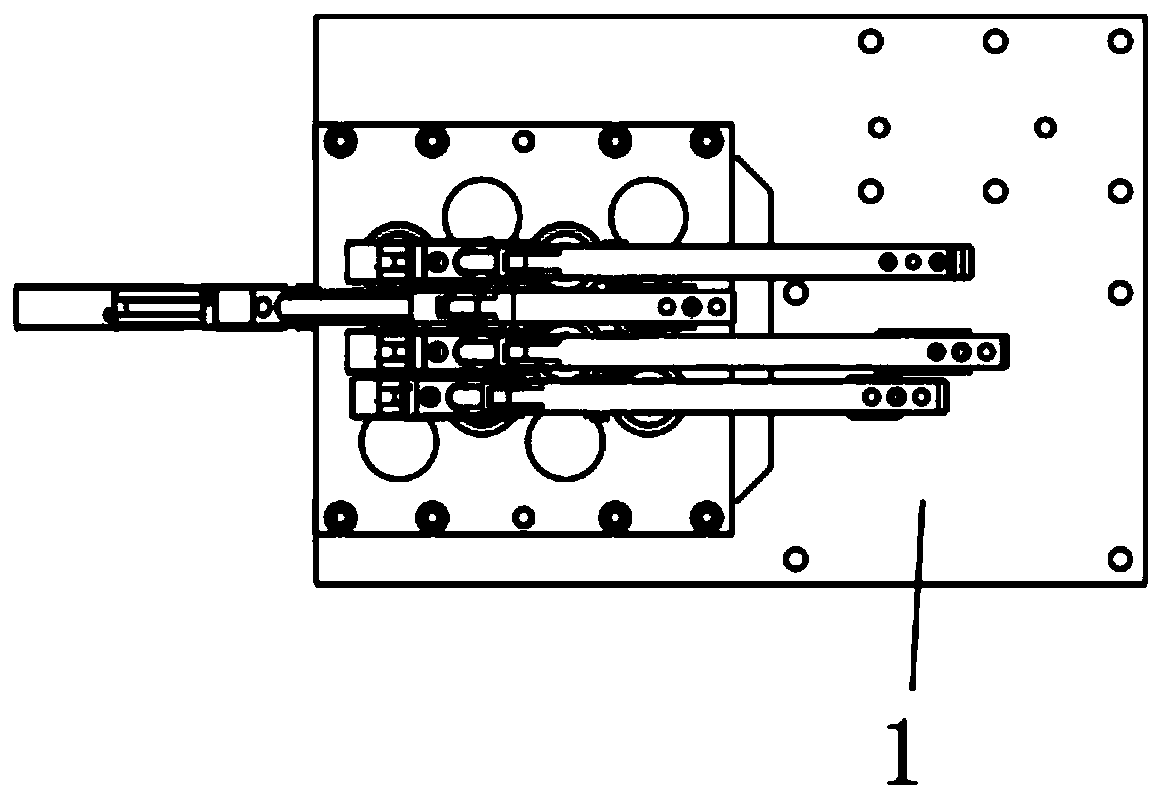

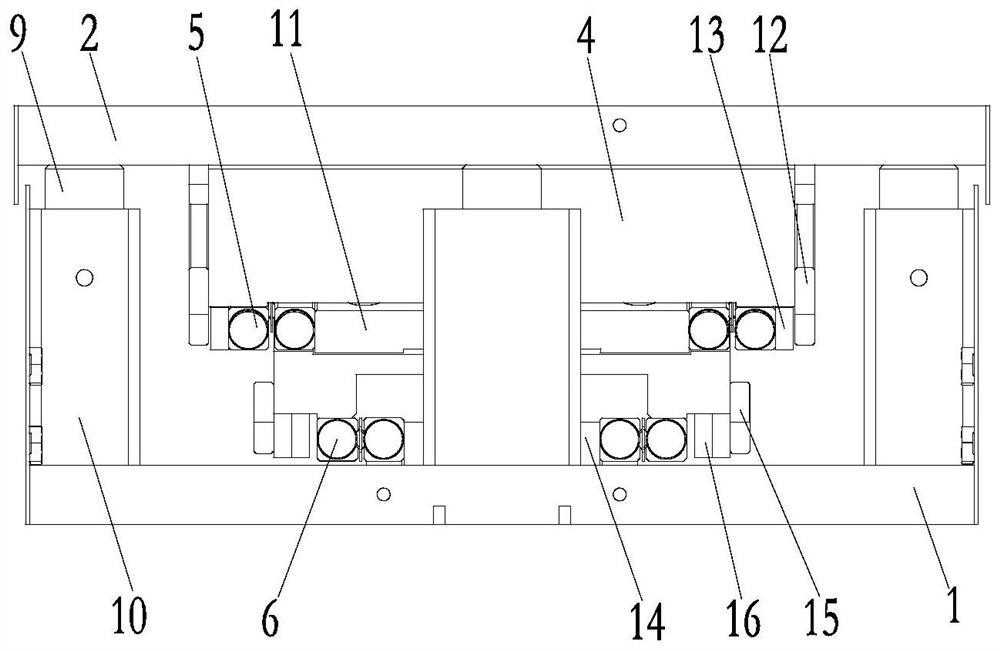

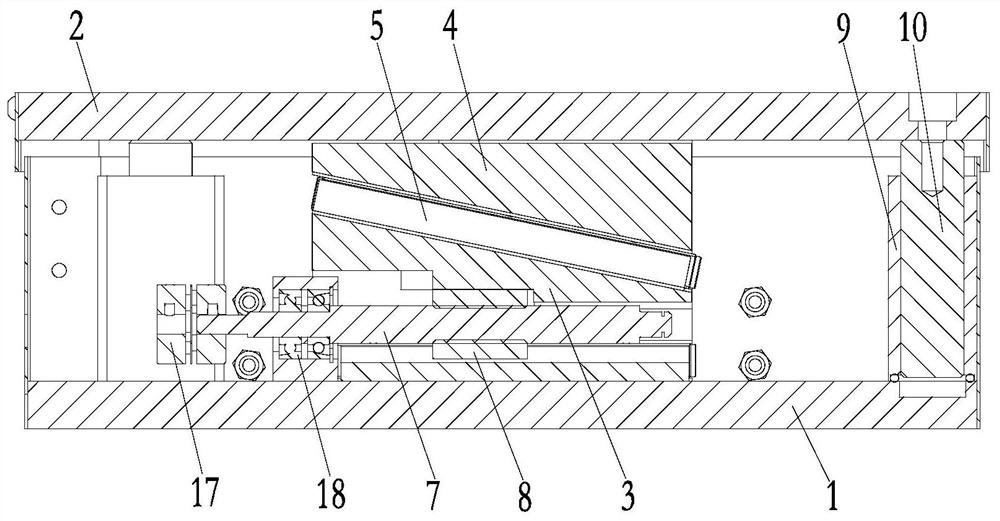

Gripper with guided cleaning function

ActiveCN110181310AStable movement without shakingReduce wastePositioning apparatusMaintainance and safety accessoriesNumerical controlMachine tool

The invention discloses a gripper with a guided cleaning function and belongs to the field of machine tool grippers. The gripper comprises a substrate. An open slot is formed in the substrate in a penetrating manner, clamping cavities are formed in the positions, on two sides of the open slot, of the substrate, the clamping cavities are formed toward the opening of one side of the open slot, a lever is arranged in each clamping cavity, one end of each lever is connected to a clamping block while the other end of each lever is connected to a guide wheel, a tension spring is connected between each clamping block and the wall of the corresponding clamping cavity, a driving cavity is formed in the substrate of one side, deviated from the open lot, of each clamping cavity, a hydraulic driving mechanism is arranged in each driving cavity, and the output end of each hydraulic driving mechanism is rigidly connected to the corresponding clamping block. The gripper can effectively solve the problem that the processing quality of a workpiece is affected as a result of severe wear of a clamping structure of a clamping block of an existing numerically controlled machine tool for a long time.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

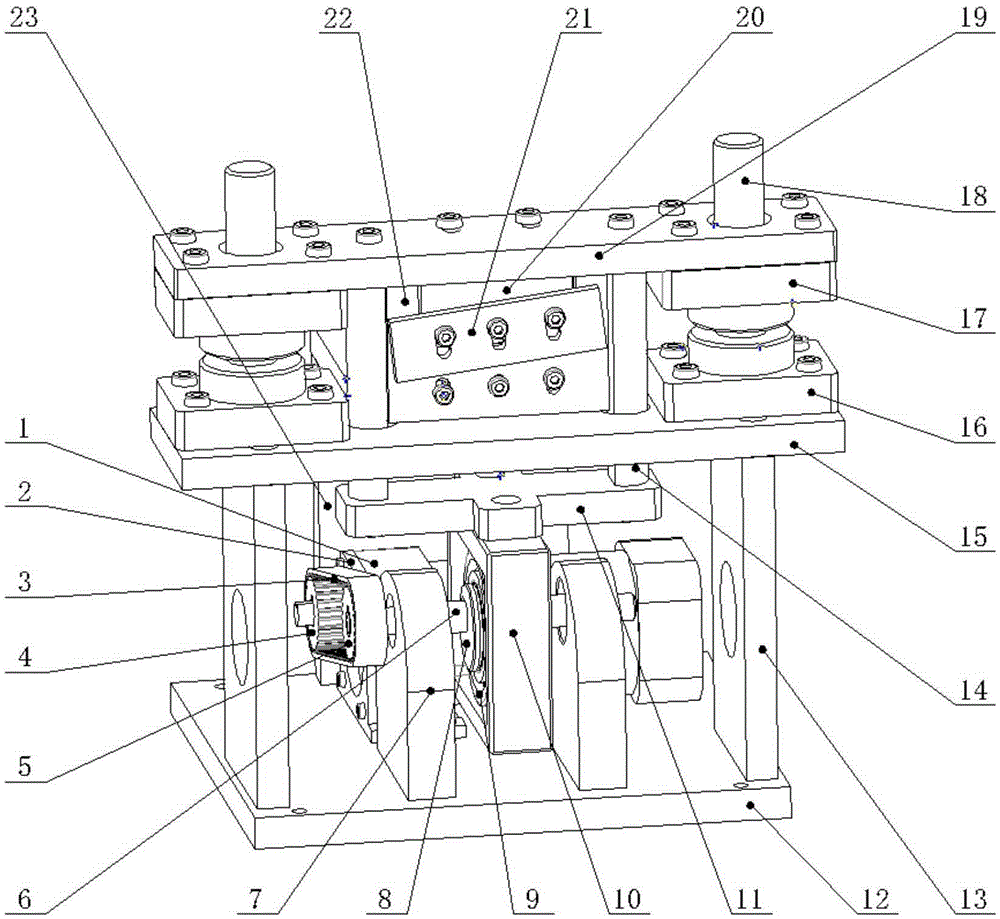

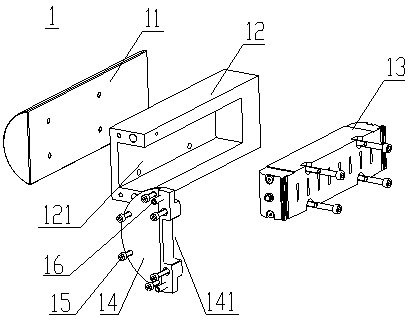

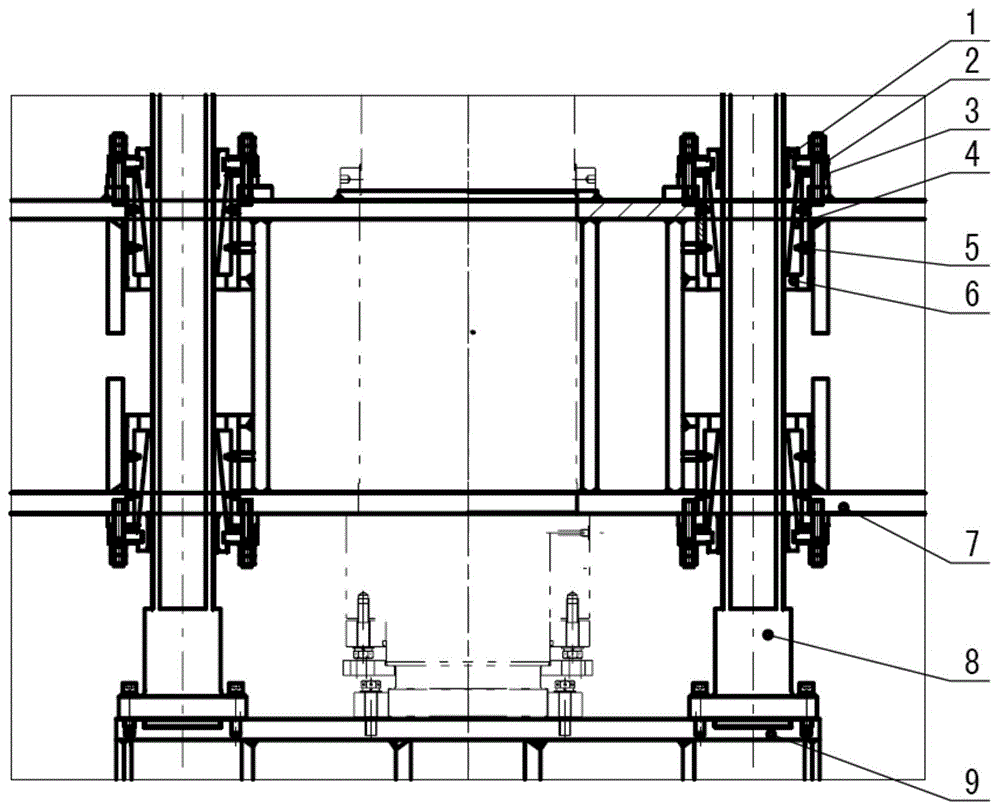

Wet blank transfer method and wet blank transfer device for plant fiber molding formation

PendingCN110578274AGuaranteed guide accuracyFreedom of movement up and downTextiles and paperFiberFiltration

The invention relates to a method and a device for manufacturing a plant fiber product comprising paper pulp in a molding formation mode. The wet blank transfer method for plant fiber molding formation comprises the following steps: (1) a slurry is processed by a suction filtration forming mold to form a wet blank for the product, and the wet blank transfer mold sucks up the wet blank from the suction filtration forming mold and upwards moves the wet blank out of the suction filtration forming mold; (2) a sliding column is arranged above the suction filtration forming mold, the wet blank transfer mold is fixed at one end of the sliding column, or the wet blank transfer mold is fixed at one end of the sliding column through a wet blank transfer mold mounting plate, and the sliding column drives the wet blank transfer mold to linearly move up and down; and (3) two or more transfer mold linear guide rails are fixed on the sliding column, the transfer sliding block is fixed on an upper rack, and the sliding column can vertically slide up and down on the transfer sliding block through the transfer die linear guide rails. The method and the device can ensure the high moving precision when the wet blank transfer mold moves up and down for a long distance, and make the wet blank transfer mold accurately positioned in the height direction.

Owner:EURASIA LIGHT IND EQUIP MFR +1

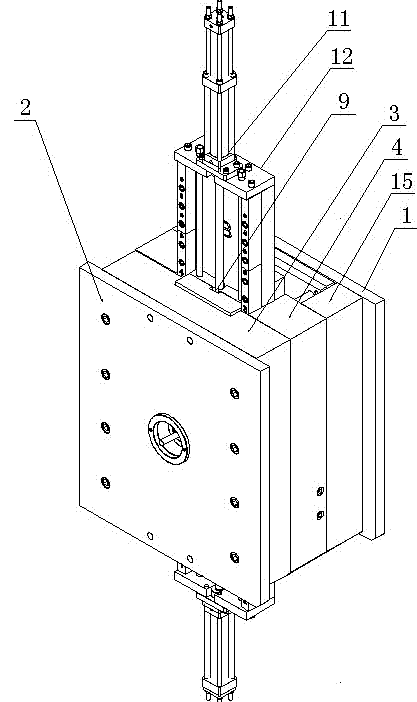

Pneumatic lifting device of shooting barrel of core shooting machine

The invention discloses a pneumatic lifting device of a shooting barrel of a core shooting machine. The pneumatic lifting device comprises a shooting barrel connection plate, wherein a plurality of first through holes are formed in the middle of the shooting barrel connection plate; the first through holes are internally fixedly connected with guide columns. The pneumatic lifting device further comprises an air cylinder, wherein the air cylinder comprises an air cylinder body and an air cylinder connector; the air cylinder connector is connected with the shooting barrel connection plate through a locking nut; the air cylinder body is connected with a T-shaped shooting barrel connection frame; a plurality of vertical guide holes, which are in slide match with the guide columns, are formed in one side, close to the shooting barrel connection plate, of the T-shaped shooting barrel connection frame; and the T-shaped shooting barrel connection frame is internally provided with the shooting barrel. Compared with the prior art, the air cylinder moves up and down so that the ascending and descending process of the shooting barrel is stable; and a stress working condition of the shooting barrel connection frame is improved and the service life of the equipment is prolonged.

Owner:CHONGQING HONGQI CYLINDER HEAD MFG

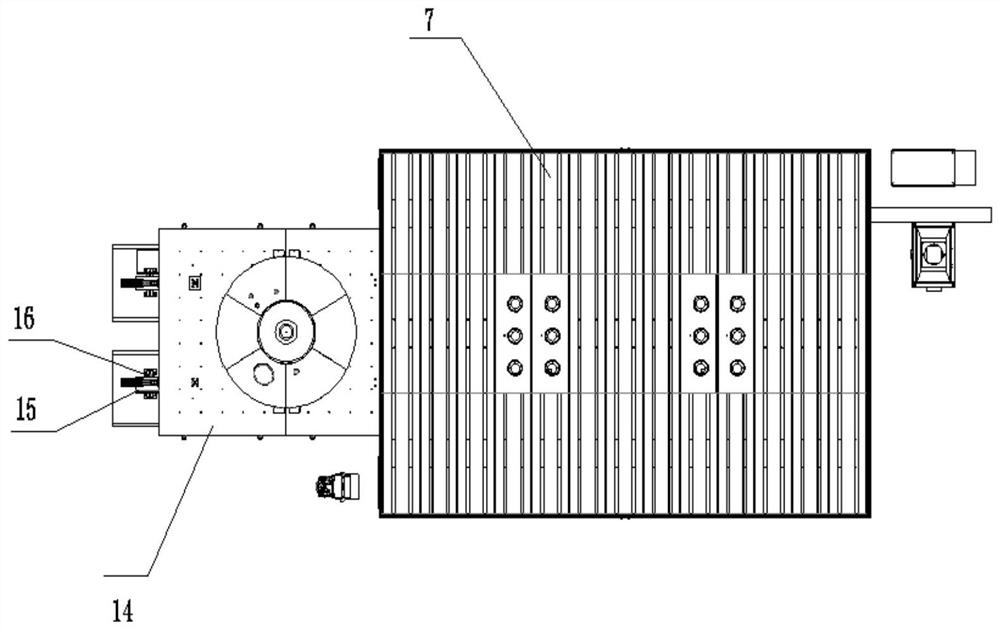

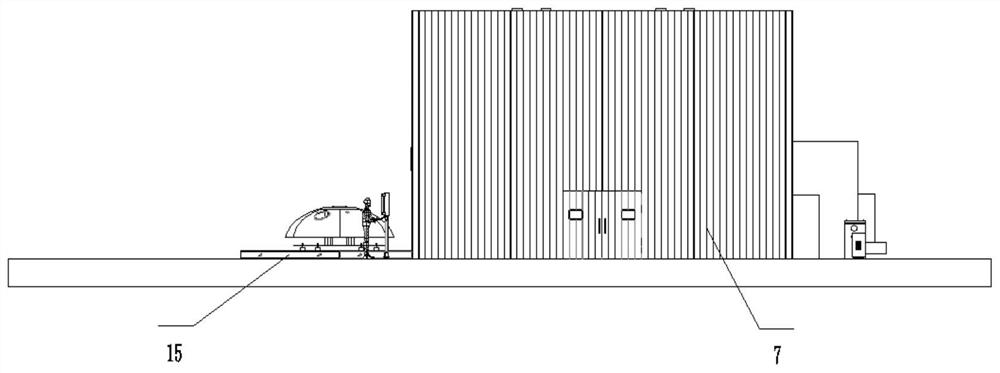

Large-breadth gantry type three-dimensional five-axis laser cutting machine

PendingCN111872578AEasy to transportEnsure personal safetyLaser beam welding apparatusElectric machineStructural engineering

The invention relates to a large-breadth gantry type three-dimensional five-axis laser cutting machine. An X-axis assembly is connected to the upper end of a lathe bed rack, an X-axis driving assemblyis tightly connected to the upper end of the lathe bed rack in a tiled mode, a movable cross beam is connected to the upper end of the X-axis driving assembly, and the exterior of the upper end of the movable cross beam is wrapped with a Y-axis assembly; and a Z-axis assembly is installed on the left side of the Y-axis assembly, a three-dimensional laser cutting head is perpendicularly installedat the lower end of the Z-axis assembly in a connected manner, workbench assemblies are installed in the lathe bed rack and on the left side of the lathe bed rack, and the exterior of the lathe bed rack is wrapped with a laser protection room. According to the large-breadth gantry type three-dimensional five-axis laser cutting machine, the movable cross beam is connected with the X-axis driving assembly through a sliding block, and the movable cross beam is made to slide left and right at the upper end of the lathe bed rack through the X-axis driving assembly in a bilateral gear and rack synchronous driving manner by means of a high-speed rotating motor.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

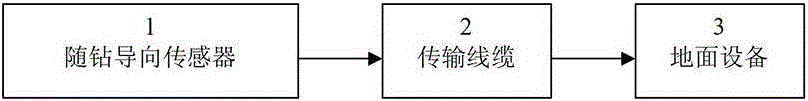

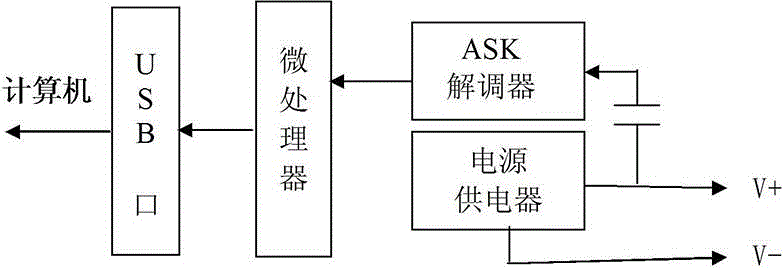

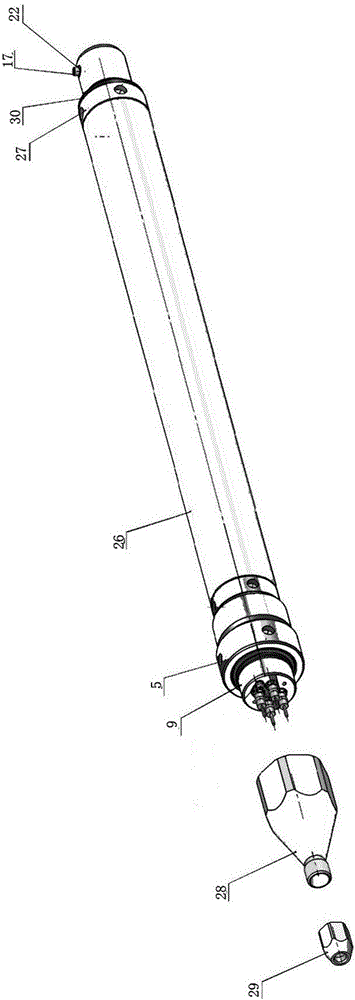

Wired geomagnetic guide while drilling and its measurement method

ActiveCN104060983BMeet construction requirementsHigh measurement accuracyConstructionsAccuracy and precisionPetroleum engineering

The invention provides a wired geomagnetic guide while drilling and a measurement method, which uses the earth's gravitational field and geomagnetic field as reference points to establish a three-dimensional reference coordinate system, and uses inertial devices such as quartz flexible gravity accelerometers and fluxgate magnetometers as reference points. The measurement-while-drilling sensor calculates the drilling azimuth, pitch angle and drill face angle according to the measurement data of the measurement-while-drilling sensor. The special software package for the wired geomagnetic guidance instrument is used for engineering design before drilling. trajectory, and calculate and process the steering data, guide the drilling trajectory to track the design trajectory, record and print the drilling trajectory data table. The invention adopts ground power supply, the measurement data of the guiding sensor is transmitted by the cable, the measurement accuracy is high, the guiding is accurate, and the depth and distance of directional crossing are not limited, and it can meet the construction requirements of long-distance and large-depth guiding drilling.

Owner:HENAN HUABEI ENG TECH CO LTD

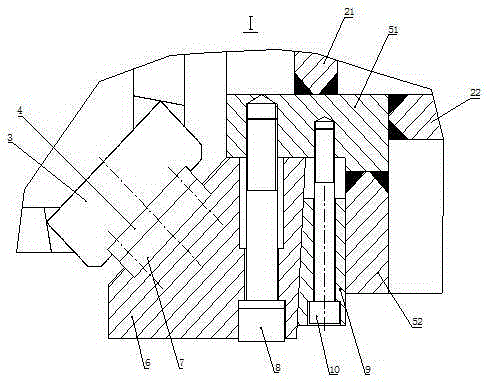

Optical module component coupling device

ActiveCN104199155AGuaranteed guide accuracyGuaranteed coaxialityCoupling light guidesOptical ModuleCoupling

The invention discloses an optical module component coupling device which comprises an upper base and a lower base. The upper base is used for mounting an optical receiver, the inside of the upper base is hollow, an internal threaded hole is formed in the lower end of the upper base, the lower base is used for mounting an optical transmitter, an external thread is arranged on the periphery of the lower base, the lower base is connected into the internal threaded hole of the upper base through the external thread, at least two horizontal through holes are formed in the upper end of the upper base, radially extend along the upper base and penetrate the wall of the upper base, each horizontal through hole is connected with a guide screw rod in a threaded manner, a guide pin is coupled at one end of each guide screw rod close to the middle of the upper base and provided with an inclined end face and a lateral plane, and the lateral plane of each guide pin is abutted by a first screw fixed onto the upper base, so that the corresponding inclined end face constantly faces the optical transmitter positioned on the lower base. A traditional coupling device is numerously improved, so that the coupling precision of the optical module component coupling device is improved, and production efficiency is ensured.

Owner:四川华拓光通信股份有限公司 +1

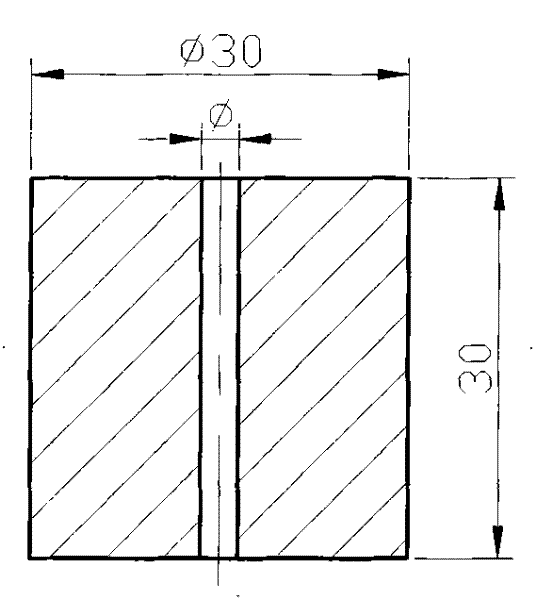

Permanent magnet field electric spark ostiole compound processing method and device

InactiveCN101288917BFast processingGuaranteed electrode guidance accuracyHigh concentrationMagnetization

The invention provides a method of permanent magnetic field electric spark small hole compound processing and a device thereof, pertaining to the field of special processing, in particular to a technical proposal of a method of permanent magnetic field electric spark small hole compound processing and a device thereof, which is mainly used for the processing of high-speed electric spark small hole of magnetic conductive material. The device of the invention consists of a magnetic guider, a magnetic guider fixed base (non-magnetic conductive material) and a fastening screw (non-magnetic conductive material). The magnetic guider which is arranged above a workpiece has magnetization on corrosion removed metal particles and after the particles are magnetized, the discharging interval speed isincreased under the effect of magnetization, thus preventing the non-magnetic guider from blocking the circumfluence to the hole and further avoiding the second discharge of the hole. The invention has the advantages of improving the interval discharging conditions, avoiding the accumulation of corrosion removed product in the processing area and the arcing and short circuit caused by over-high concentration of the corrosion removed product, ensuring the stable process, increasing the processing speed and integrating the electrode guider and the discharging condition improver. Furthermore, the invention also has the advantages that the lathe structure is compact, the installation and replacement are convenient, the cost is low and the promotion is easy.

Owner:TAIYUAN UNIV OF TECH

Automatic clutch gear shifting arm assembly, engine and motorcycle

The invention discloses an automatic clutch gear shifting arm assembly, an engine and a motorcycle. The automatic clutch gear shifting arm assembly comprises a gear shifting shaft, a limiting plate, a moving plate, a clutch operating arm and a return torsional spring used for enabling the gear shifting shaft to return, and further comprises a guide part rotatably sleeving the gear shifting shaft, wherein the moving plate movably sleeves the gear shifting shaft and axially presses the limiting plate fixed to the gear shifting shaft under the action of elastic force; the clutch operating arm is fixedly arranged on the gear shifting shaft in the circumferential direction; the gear shifting shaft drives the moving plate to achieve gear shifting through rotational hysteresis with the clutch operating arm; and the guide part performs sliding guiding on the moving plate in the axial direction. According to the automatic clutch gear shifting arm assembly, a gear shifting moving block stably slides in a reciprocating manner in the axial direction through the guide part, reliability of motion of the moving block is improved, automatic clutch gear shifting is smooth, and the structure is simple and compact.

Owner:CHONGQING LONCIN ENGINE +1

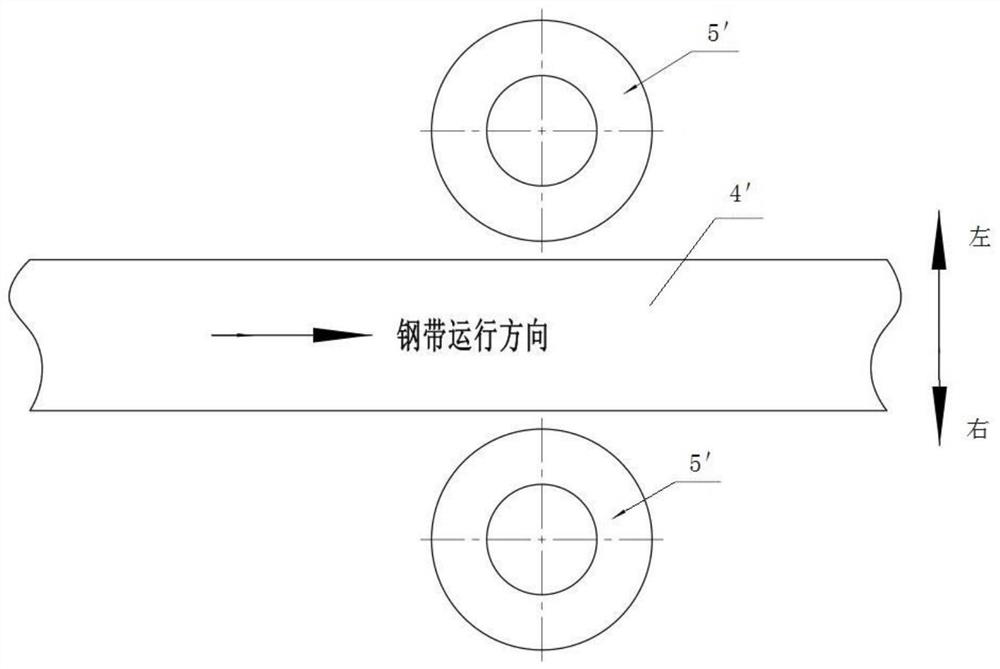

Guide roller, steel belt guide mechanism and material receiving system

ActiveCN112551240AReceiving levelNarrow band receiving is safe and reliableWebs handlingScrew threadSteel belt

The invention provides a guide roller, a steel belt guide mechanism and a material receiving system. The guide roller comprises a screw, an adjustable sleeve and a positioning sleeve, wherein a firstbearing support and a second bearing support are arranged at two ends of the screw respectively, an external thread section is arranged on the screw and is close to the first bearing support, the adjustable sleeve is in threaded connection with the external thread section, one end of the positioning sleeve is installed on the screw through a third bearing, and the other end of the positioning sleeve is connected with the corresponding end of the adjustable sleeve in a sleeved mode; a guide cavity is formed between the positioning sleeve and the adjustable sleeve; and a first check ring is arranged on the vertical side wall, forming the guide cavity, of the adjustable sleeve, and a second check ring is arranged on the vertical side wall, forming the guide cavity, of the positioning sleeve.Compared with the prior art, the guide roller solves the problem that edge cutting and material receiving are not orderly, guarantees that material receiving is smooth, guarantees that narrow-belt material receiving is safe and reliable, avoids the phenomenon of material collapse, and meanwhile greatly prolongs the service life of the guide mechanism.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

Locking structure with bidirectional insertion type guide plates

PendingCN110814178ALow costAvoid the tendency to flare outShaping toolsSoftware engineeringLocked plate

The invention discloses a locking structure with bidirectional insertion type guide plates. The locking structure comprises an assembly basic body, the bidirectional insertion type guide plates and alocking plate. The two bidirectional insertion type guide plates are arranged and located on the two sides of the assembly basic body correspondingly. A guide plate locating key is arranged between the bidirectional insertion type guide plates and the assembly basic body, and the bidirectional insertion type guide plates and the assembly basic body are located by the guide plate locating key in the mold working process. The bidirectional insertion type guide plates and the assembly basic body are further fixed through multiple first bolts. The locking plate is arranged on the outer sides of the assembly basic body and the bidirectional insertion type guide plates and connected with the assembly basic body and the bidirectional insertion type guide plates through multiple second bolts. By the adoption of the locking structure with the bidirectional insertion type guide plates, the service life of each bidirectional guide plate can be prolonged, the guide accuracy can be guaranteed, thereliability of screws at the fixing end is improved, and the expense generated by the later-period repair and debugging of a mold is reduced.

Owner:XIAMEN GOLDEN DRAGON AUTO BODY

CD-type chip clamping mechanism for centrifugal microfluidics

ActiveCN107552119BEasy to insertGuaranteed horizontal positioningLaboratory glasswaresSupporting apparatusEngineeringMotor shaft

The invention belongs to the microfluidics field and discloses a clamping mechanism for a centrifugal microfluidics CD chip. The mechanism comprises chip support racks 1, a lever 2, a push rod 3, a positioning marble 4, a motor shaft clamping groove 5, a guide block 6 and a guide slot 7. The chip is inserted to the bottom along the guide slot 7 and can reach the accurate position by means of the horizontal positioning function of the guide block 6 and cooperation with the motor shaft clamping groove 5, and the chip is completely positioned when the positioning marble 4 in the motor shaft clamping groove 5 bounces; when the chip is required to be taken out, all that is required is to push the push rod 3 and the chip can automatically bounce under the action of the lever 2. The distance between the chip support racks 1 can be conveniently adjusted and thus the mechanism can adapt to chips with different sizes. The clamping mechanism for the centrifugal microfluidics CD chip is designed in the CD driver principle, can conveniently clamp and position the chip and has the advantages of being simple in structure, convenient to operate, reliable and high in adaptability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

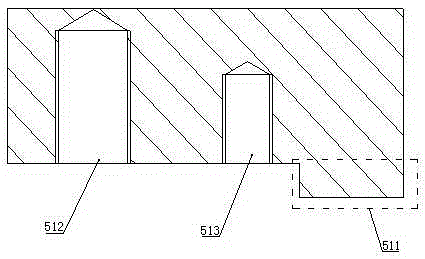

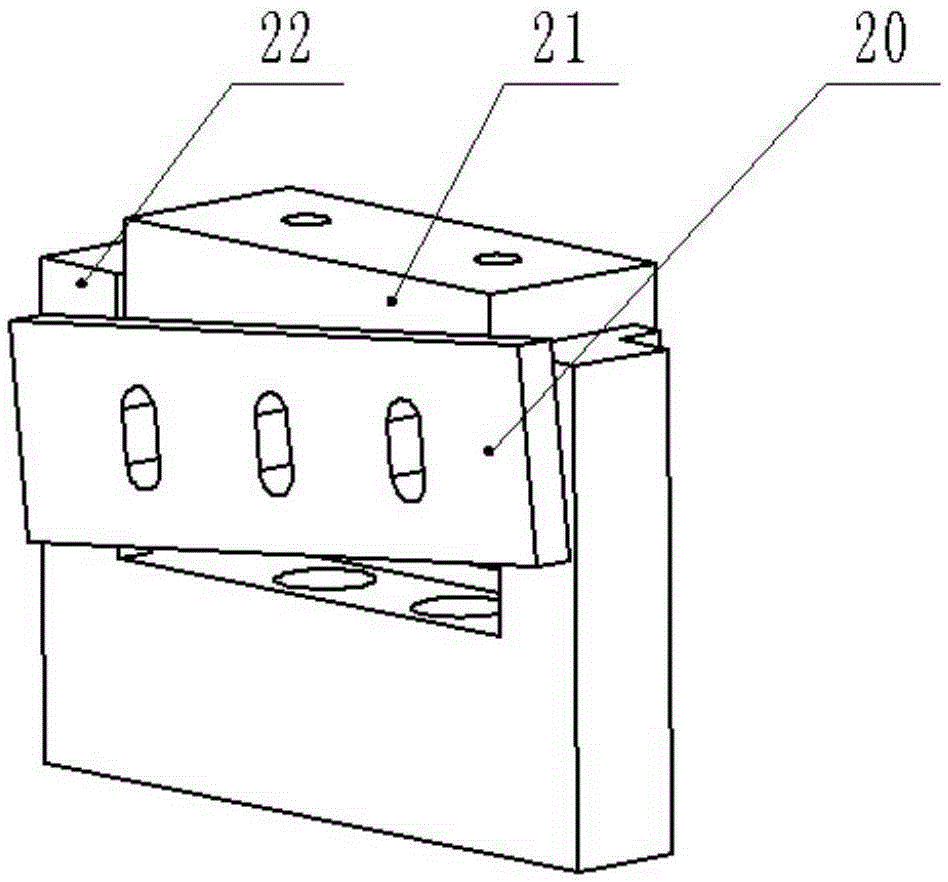

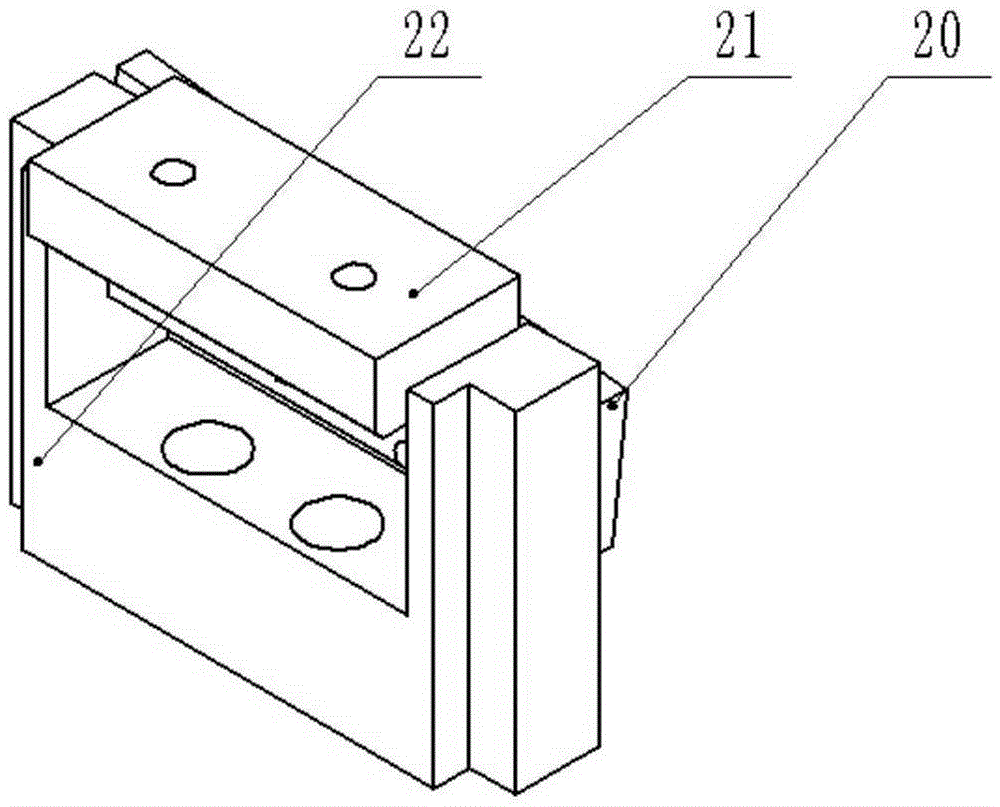

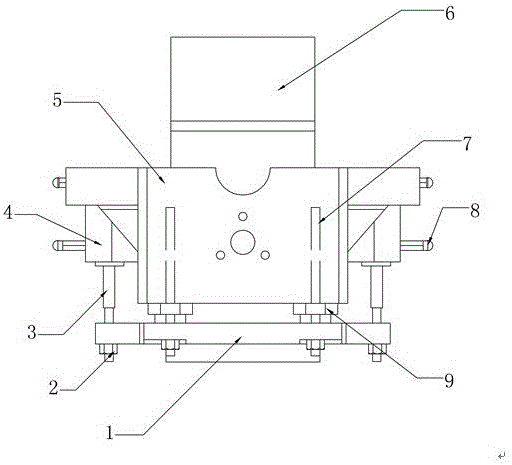

Accuracy adjusting device for isothermal thermal forming hydraulic machine

InactiveCN105436386AAffect guide accuracyGuaranteed guide accuracyForging/hammering/pressing machinesEngineeringMechanical engineering

The invention discloses an accuracy adjusting device for an isothermal thermal forming hydraulic machine. The isothermal thermal forming hydraulic machine comprises four guide columns fixed to a sliding block, and is characterized in that the cross section of each guide column is square; upper transverse beams are disposed on the guide columns; positioning sleeves are disposed between the upper transverse beams and the corresponding guide columns; each positioning sleeve is of a Z-shaped structure with the 90-degree corners; one end of each positioning sleeve is transversely arranged on the corresponding upper transverse beam; adjusting pads are put on the transversely arranged surfaces of the positioning sleeves; the end faces of the other ends of the positioning sleeves make contact with the guide columns; sliding wedges and fixed wedges which are equal in slant angle are disposed in gaps between the positioning sleeves and the guide columns; the slopes of the sliding wedges and the slopes of the fixed wedges are in close contact; the fixed wedges are fixedly connected with the positioning sleeves; a board is connected to the tail of each sliding wedge; the adjusting pads are located between the boards and the transversely arranged surfaces of the positioning sleeves; the boards, the adjusting pads and the positioning sleeves are connected through double-threaded screws.

Owner:TIANJIN TIANDUAN PRESS CO LTD

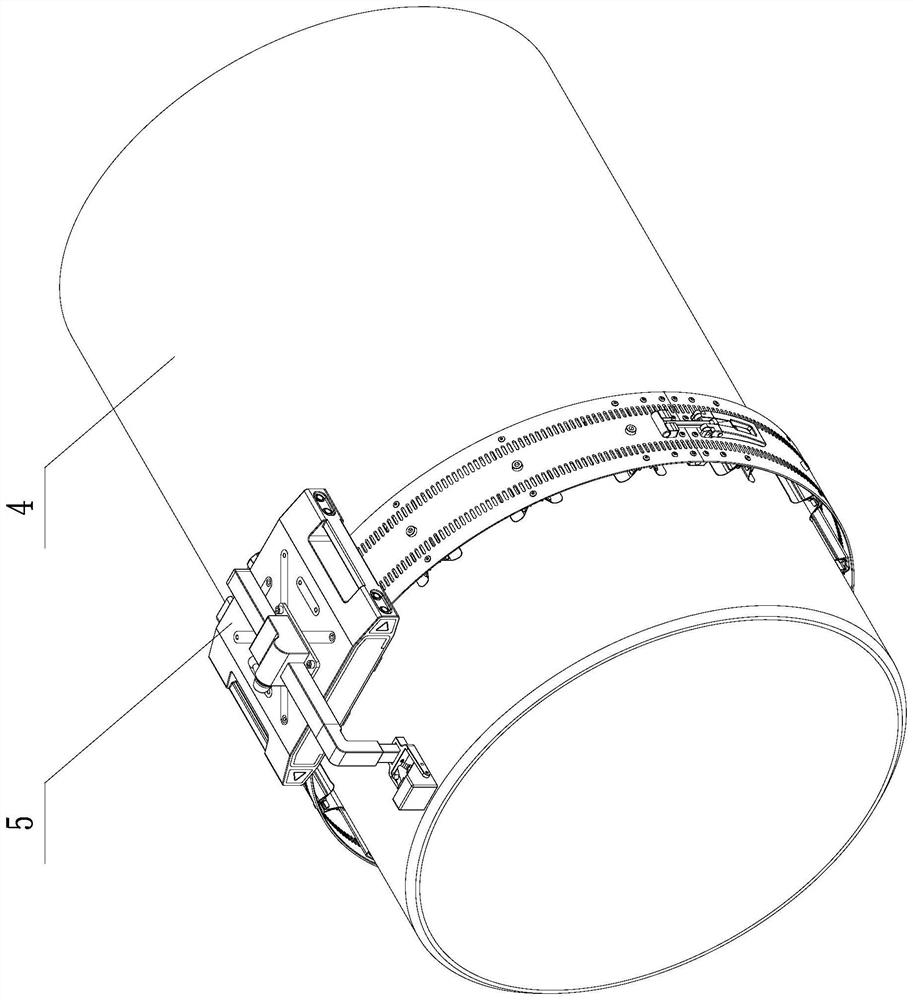

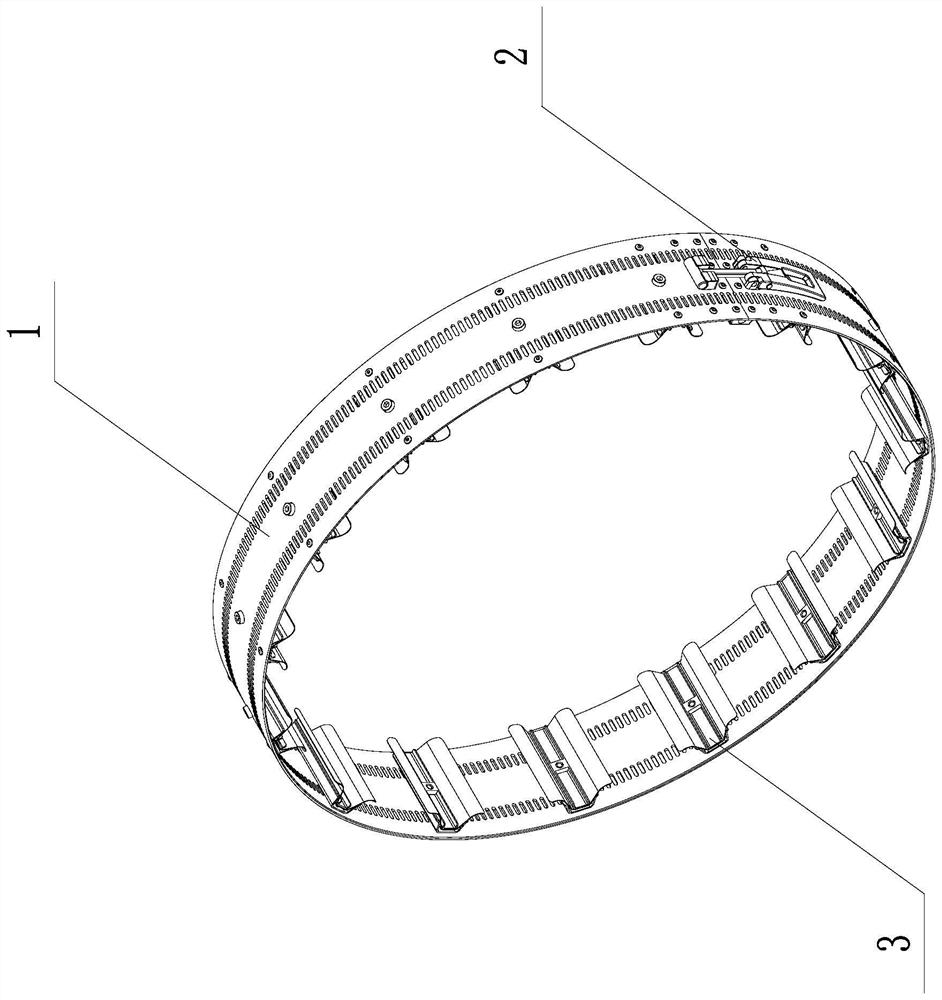

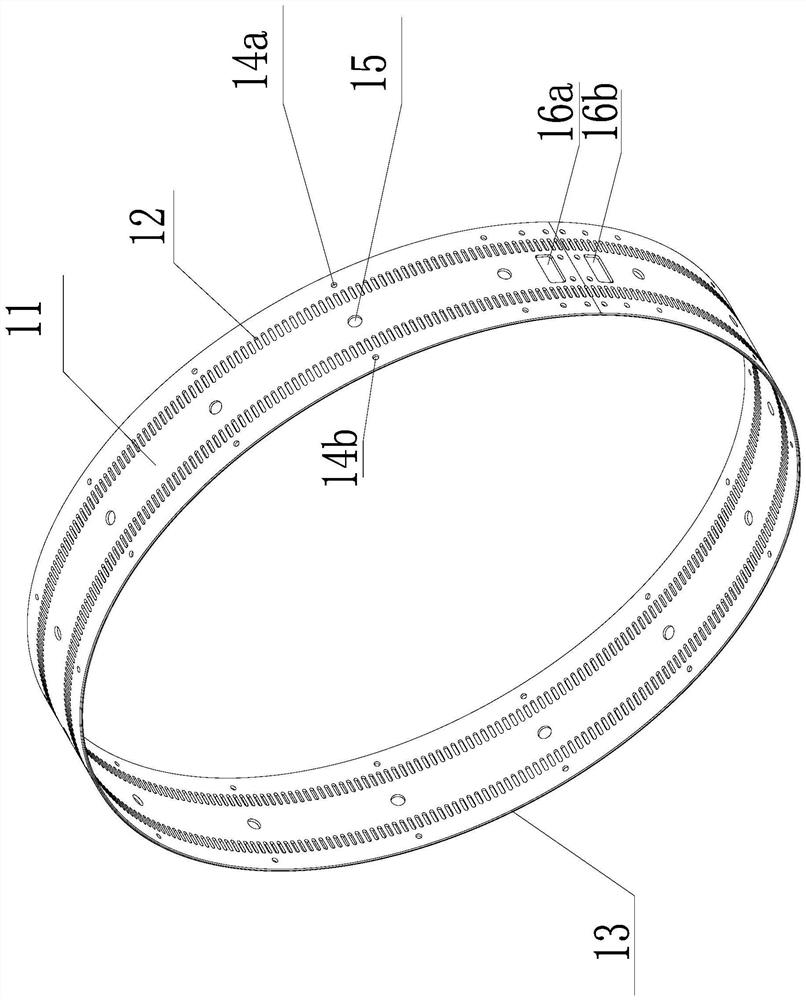

Adjustable flexible track device for pipeline

PendingCN114211088AEasy to assemble and disassembleReduce the number of operatorsMetal working apparatusTubular articlesTrackwayStructural engineering

The invention discloses an adjustable flexible track device for a pipeline, which is characterized by comprising a flexible track, a hasp component and a plurality of double-folded combined springs, two free ends of the flexible track are butted through the hasp component, the plurality of double-folded combined springs are mounted on an inner ring of the flexible track, and the double-folded combined springs are adjustably clamped on the pipeline. The device can automatically adapt to the deformation of the pipeline and a small amount of size errors, operators do not need to guess a covering belt on site to consider that the tightness degree is appropriate, the number of needed operators is small, the number of operation actions is small, and the device is more user-friendly. Due to the fact that the pull rod with the fixed length and the hasp assembly with the two-way positioning function are adopted, accurate closing of the track is guaranteed, and operators can conveniently assemble and disassemble the track on site.

Owner:DOFSIM TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com