Precise autoclaved aerated block guiding and transporting mechanism

A technology of handling mechanism and autoclaved gas filling, which is applied in the direction of mechanical equipment, linear motion bearings, bearings, etc., and can solve problems such as high failure rate and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

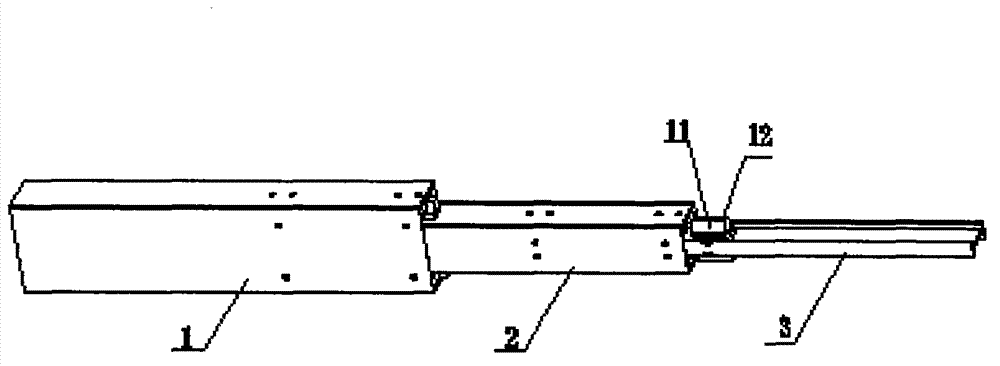

[0014] Such as figure 1 , 2 As shown, the precision guiding transport mechanism includes an outer section 1, a middle section 2 and an inner section 3, the outer section 1 and the middle section 2 are square cavities, the section of the inner section 3 is an "I" shaped support frame, and the middle section 2 can be placed outside The telescopic movement in the section 1, the inner section 3 can telescopically move in the middle section 2, the outer section 1 includes the outer section shell 4 and the outer section guide grooves 5 located on both sides of the outer section shell 4, the middle section 2 includes the middle section The casing 6 and the middle section guide grooves 7 located on both sides of the middle section casing 6, the two outer sides of the middle section casing 6 are respectively provided with two middle section wedges 8 and the middle section guide blocks 9, and the two sides of the inner section 3 Two inner segment wedges 10 and inner segment guide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com