Injection mold of staggered spiral line type hollow propelling pipe

A technology of injection molds and propulsion tubes, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of complex structure and cumbersome demoulding process, and achieve the effect of uniform product quality, stable performance, and rapid injection molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

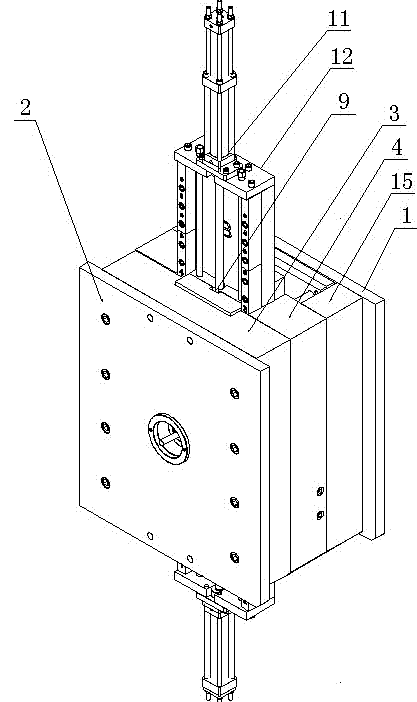

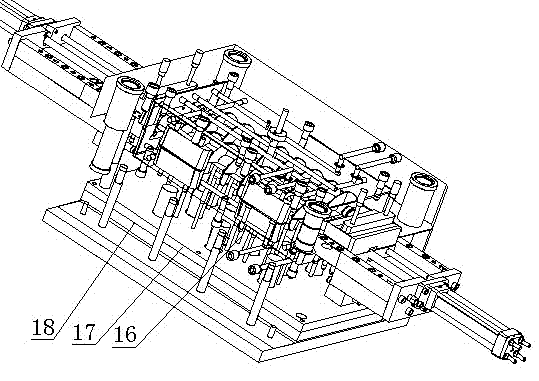

[0042] like figure 1 , figure 2 and image 3 As shown, an injection mold for a dislocated helical hollow propulsion tube includes a mold bottom plate 1, a pressure plate 2, a moving template 3 with two halves combined, a fixed template 4, a pouring system 5, a cooling system 6 and a core-pulling mechanism 9, The movable template 3 and the fixed template 4 are respectively provided with insert components 7, and the cavity surface formed by the insert components 7 is processed with a half-helix structure 8, and the two half-helix structures 8 are staggered and combined, so that A core 10 with a circular section is inserted in the middle of the cavity surface, an axial groove is arranged on one side of the core 10, the core pulling mechanism 9 is connected to a hydraulic cylinder 11, and slider structures 12 are fixed on both sides of the mold. The hydraulic cylinder 11 is arranged on the slider structure 12 through the cylinder fixing block.

[0043] The slider structure 12 ...

specific Embodiment 2

[0053] The difference from Embodiment 1 is that: the cooling water channels include two groups uniformly distributed outside the cavity.

specific Embodiment 3

[0054] The difference from the first embodiment is that the number of gates is four evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com