Pneumatic lifting device of shooting barrel of core shooting machine

A technology of pneumatic lifting and core shooting machine, applied in the field of foundry sand core modeling, can solve the problems of guide post damage, equipment damage, guide post fracture, etc., and achieve the effect of avoiding movement deviation and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

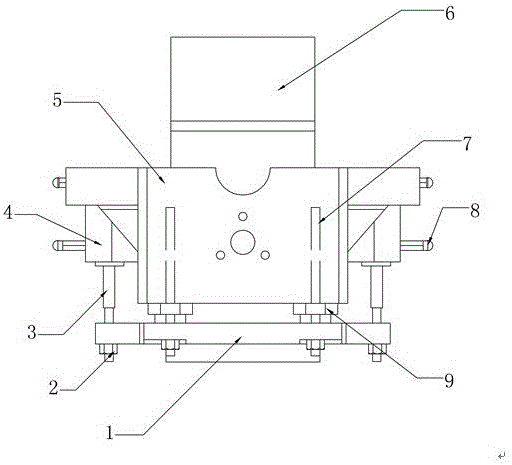

[0015] The reference signs in the accompanying drawings of the specification include: barrel connecting plate 1, lock nut 2, cylinder connecting head 3, lifting cylinder 4, T-shaped barrel connecting frame 5, barrel 6, guide post 7, magnetic induction switch 8, Guide post cover 9.

[0016] The embodiment is basically as attached figure 1 Shown:

[0017] The cylinder pneumatic lifting device of the core shooter in this solution includes a cylinder connection plate 1, and four first through holes are opened in the middle of the cylinder connection plate 1, and the first through holes are arranged in a rectangular array on the cylinder connection plate 1 Arranged, each first through hole is interference-fit connected with a guide post 7; a T-shaped connecting plate is arranged above the barrel connecting plate 1, and the T-shaped connecting plate includes a transverse part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com