Wet blank transfer method and wet blank transfer device for plant fiber molding formation

A molding and plant fiber technology, applied in textiles and papermaking, etc., can solve problems affecting production, wear of piston seal rings, production troubles, etc., achieve the effects of improving production and quality, moving freely up and down, and solving hidden dangers of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

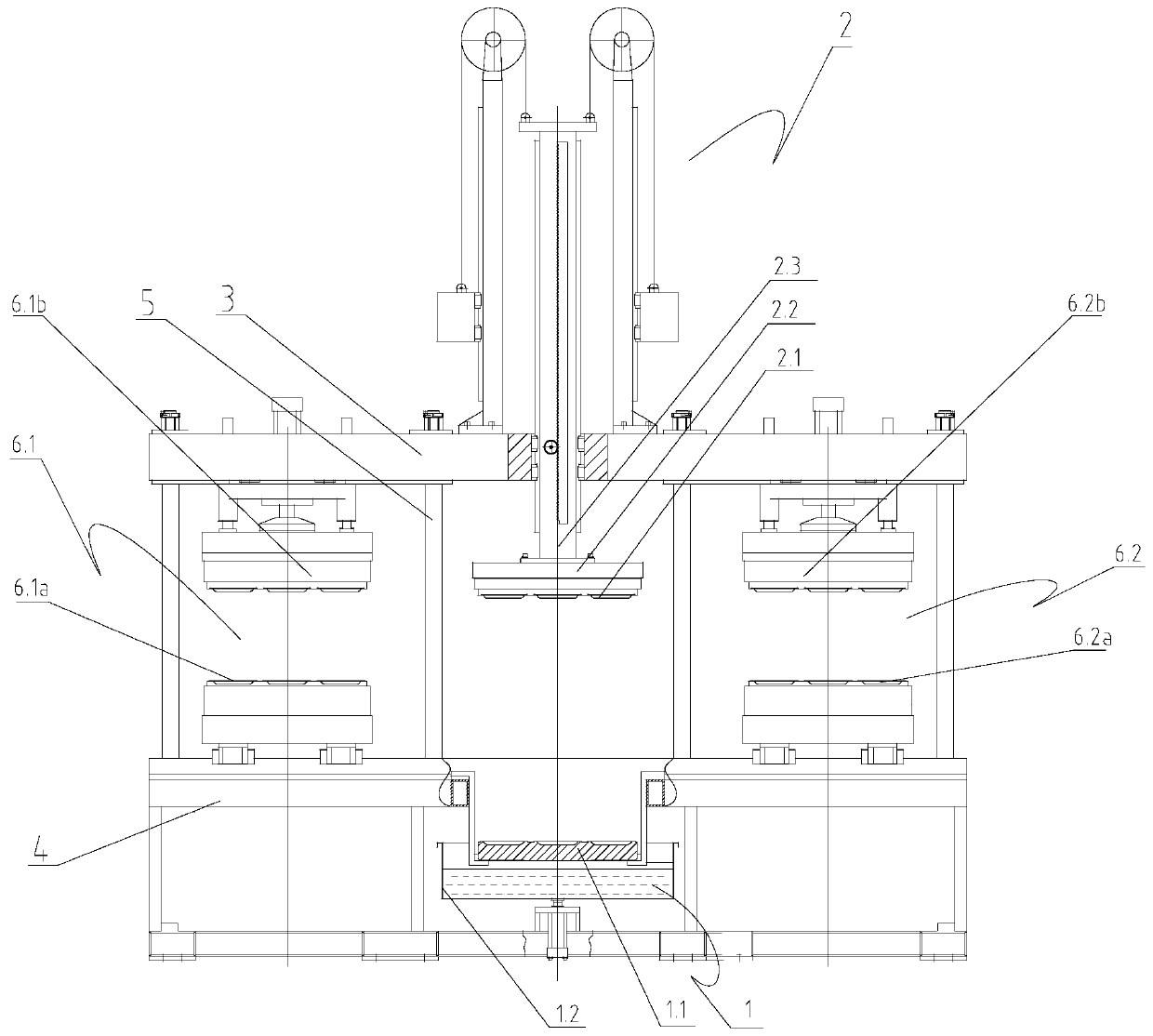

[0041] like figure 1 As shown, the plant fiber molding machine includes a suction filter forming device 1, a wet billet transfer device 2, and a frame (upper frame 3; lower frame 4; tie rod 5). The suction filter forming device 1 includes a suction filter forming mold 1.1 and a slurry tank 1.2, and the suction filter forming mold 1.1 vacuum-sucks the slurry in the slurry tank 1.2 to make the slurry into a wet billet; the frame consists of a pull rod 5, a lower frame 4 and an upper frame The frame 3 is composed of the upper frame 3 fixed on the lower frame 4 by the tie rod 5, so that the upper frame 3 and the lower frame 4 are kept at a certain distance; the suction filter forming device 1 is arranged in the lower frame 4, and the wet billet transfer device 2 is above the suction filter forming device 1, the wet base transfer mold 2.1 of the wet base transfer device 2 can move vertically up and down, so as to remove the wet base in the suction filter forming mold 1.1 from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com