Permanent magnet field electric spark ostiole compound processing method and device

A composite machining and EDM technology, which is applied in the field of permanent magnetic field EDM small hole composite machining and devices, can solve the problems of ensuring unfavorable guiding accuracy, reducing the rigidity of tool electrodes, reducing the shape and position accuracy of small holes, etc., and improving the processing speed , Reduced machining stability, and improved clearance chip removal conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

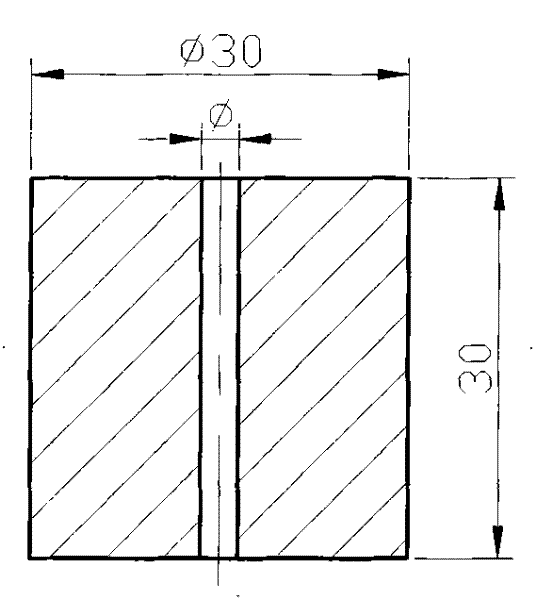

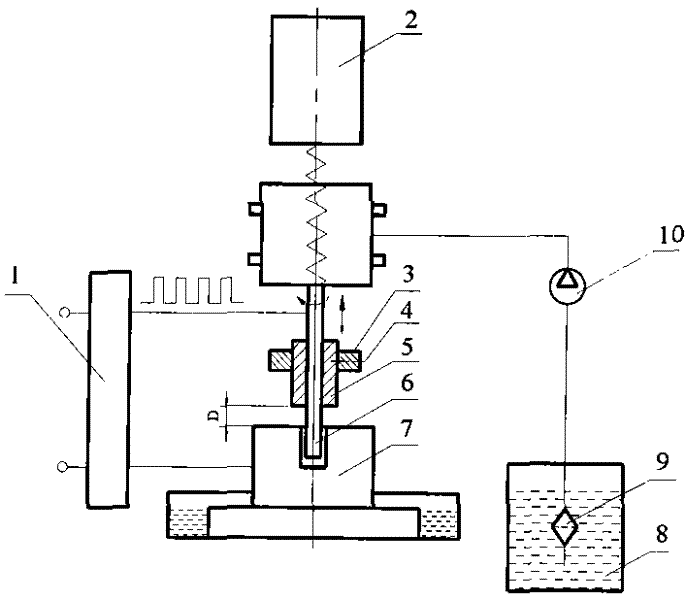

[0022] I. Select the prepared magnetic guide 5

[0023] The magnetic guide 5 used in the experiment is made of N35 NdFeB permanent magnet material, which is cylindrical and processed at the center of the magnetic guide 5 with a diameter of 1.5mm± 0 +0.05 The small hole is magnetized, and the direction of the magnetic field lines of the magnetic guide 5 is parallel to its axial direction;

[0024] II, the magnetic guide 5 prepared in the step I is fixed on the magnetic guide holder 3 with set screws 4;

[0025] III, fix the workpiece 7 on the machine tool table, adjust the relative position between the magnetic guide 5 and the workpiece 7, so that the magnetic guide 5 is located directly above the workpiece 7 and the vertical distance is 5mm, and the magnetic induction intensity at the upper surface of the workpiece 7 is now 190mT, the direction of the magnetic field line of the magnetic guide 5 is parallel to the axial direction of the small hole to be processed, and after t...

Embodiment approach 2

[0028] Embodiment 2: Change the vertical distance between the magnetic guide 5 and the workpiece to be 15mm. At this time, the magnetic induction intensity at the upper surface of the workpiece 7 is 70mT, and the others are the same as in Embodiment 1.

[0029] Implementation effect: the processing speed is 10mm / min before compound machining, and 12.33mm / min after permanent magnetic field EDM small hole compound machining, with a speed increase rate of 23.3%.

Embodiment approach 3

[0030] Embodiment 3: Change the vertical distance between the magnetic guide 5 and the workpiece to be 25mm. At this time, the magnetic induction intensity at the upper surface of the workpiece 7 is 40mT, and the others are the same as in Embodiment 1.

[0031] Implementation effect: the processing speed is 10mm / min before composite machining, and 10.30mm / min after permanent magnetic field EDM small hole composite machining, with a speed increase rate of 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com