Optical module component coupling device

A technology of coupling device and optical module, which is applied in the coupling direction of optical waveguide, can solve the problems that affect the coupling accuracy of products, the height deviation of threaded holes, and the low coupling efficiency, so as to improve the adjustment accuracy and positioning speed, ensure the coaxiality, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the text of the description.

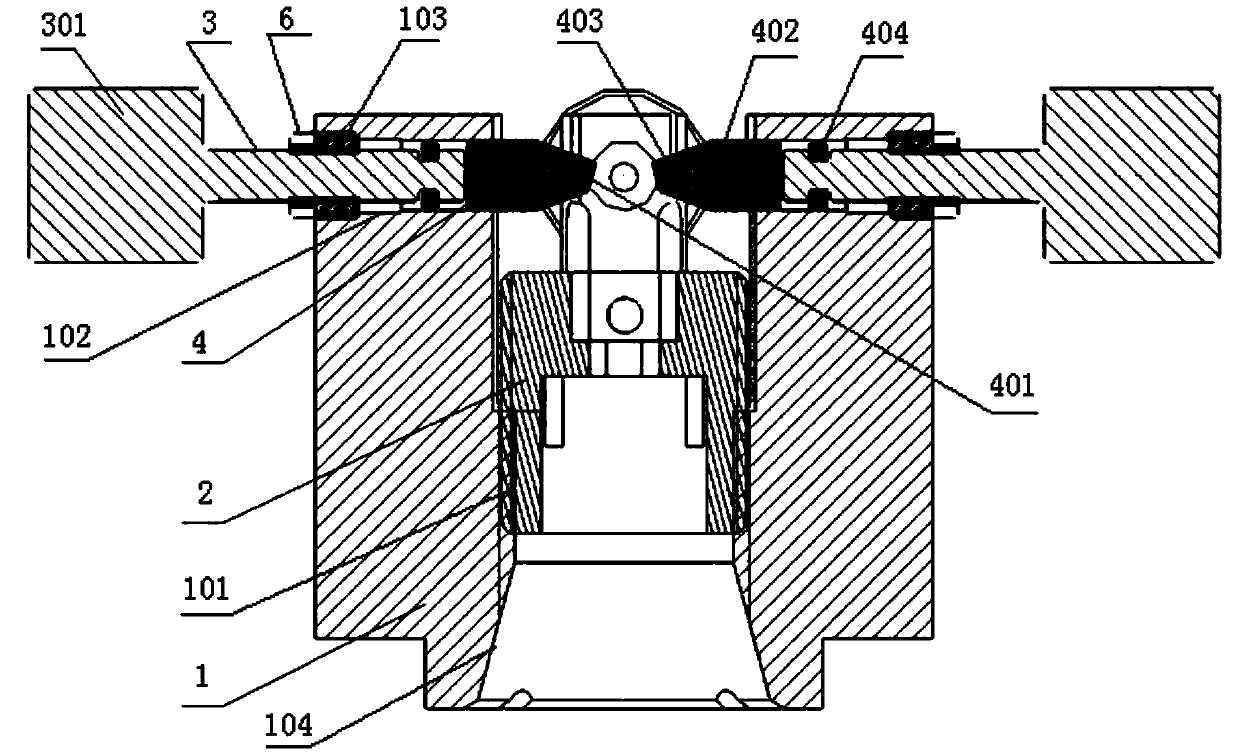

[0030] Such as Figure 1-2 As shown, the present invention provides an optical module assembly coupling device, which includes:

[0031] The upper base 1 for installing the light receiving device is hollow and the lower end is provided with an internal threaded hole 101; the lower base 2 for installing the light emitting device is provided with external threads on its outer circumference; wherein the lower base passes The external thread is connected to the internal threaded hole of the upper base, and the upper end of the upper base is provided with at least two horizontal through holes 102 extending radially along the upper base and penetrating the wall surface of the upper base. A lead screw 3 is threadedly connected; the lead screw has a guide pin 4 at one end close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com