Transportation vehicle capable of automatically loading building steel structures

A technology for handling vehicles and steel structures, which is applied to motor vehicles, goods transport vehicles, and vehicles for freight transportation, etc., can solve the problems of inappropriate steel structure transfer transportation or replacement of workshops, long transportation distances, and high use costs. The effect of a large power and transfer speed range, low manufacturing costs and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

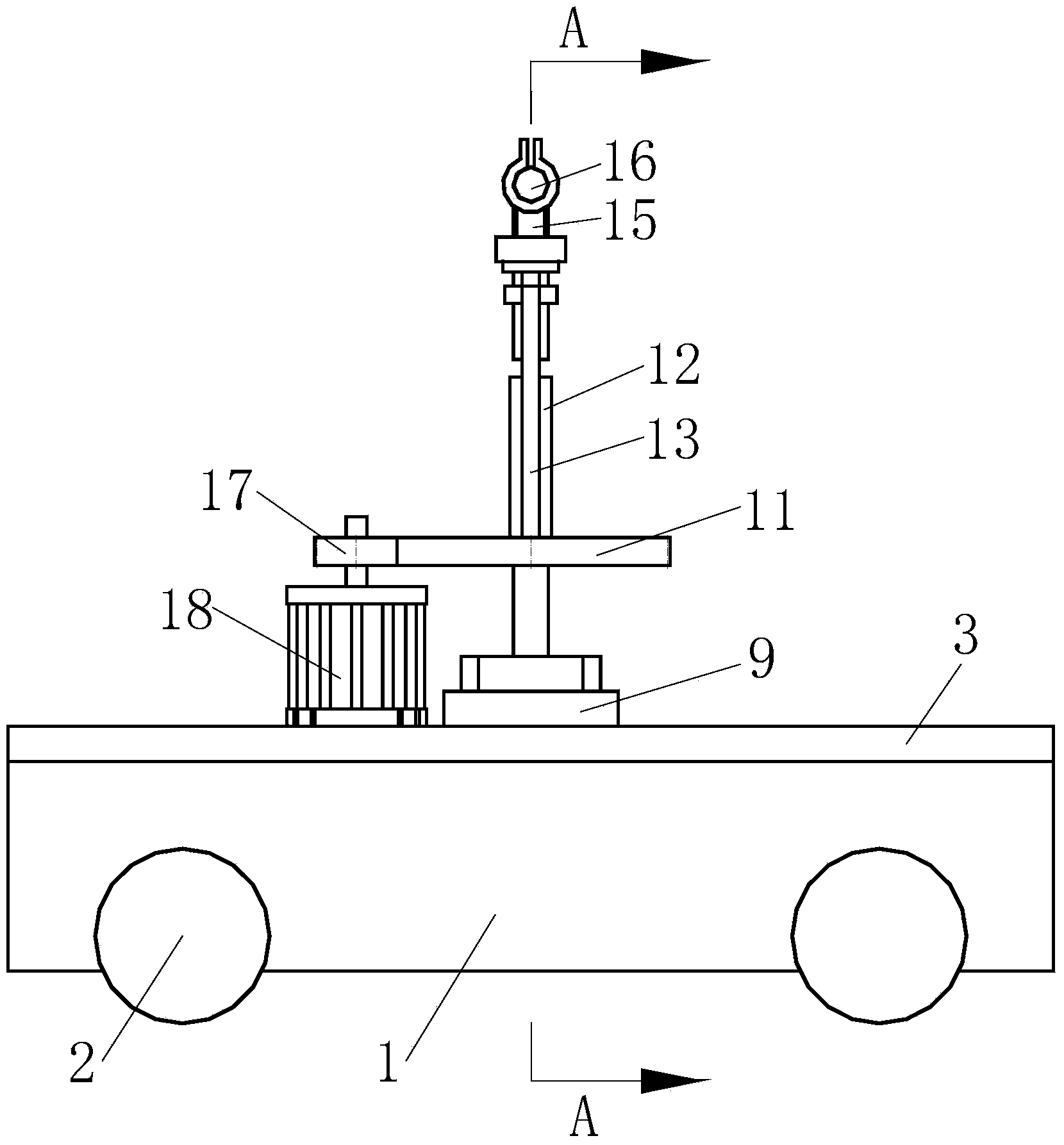

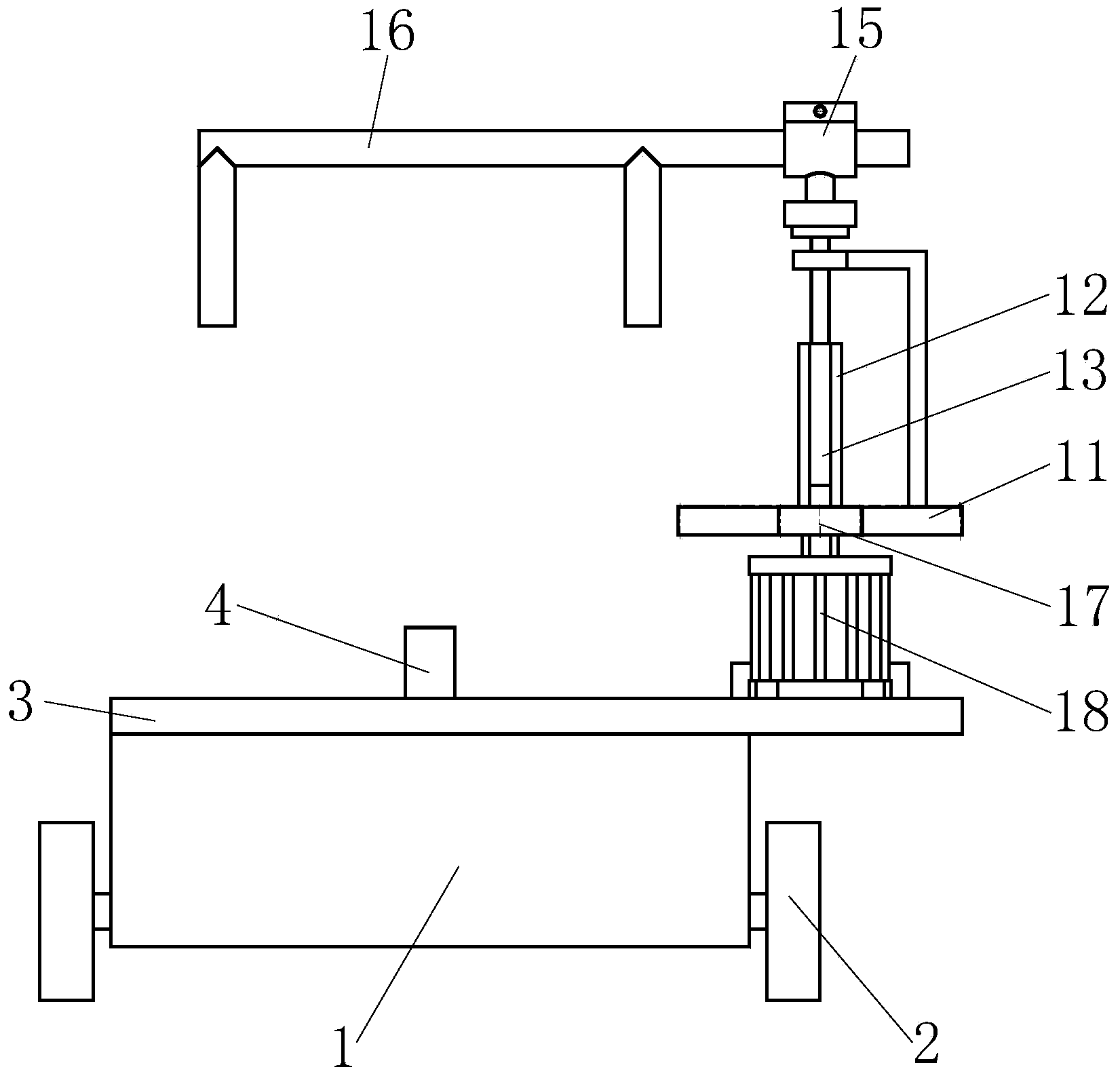

[0034] Such as Figure 1 to Figure 10 As shown, a construction steel structure automatic loading truck includes a vehicle body 1, road wheels 2 are installed on both sides of the vehicle body 1, a bearing plate 3 is installed on the upper end of the vehicle body 1, and the middle of the bearing plate 3 The lower part is equipped with a lower compression clamping device, and the right side of the bearing plate 3 is equipped with an upper indexing clamping device. When the middle part of the steel structure is placed sideways on the bearing plate 3 by driving, the lower compression clamping device will be driven to work, so as to limit the two sides of the lower part of the steel structure. After that, the upper indexing clamping device will start to work , when it rotates to the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com