Clamping mechanism for centrifugal microfluidics CD chip

A clamping mechanism and microfluidic technology, used in laboratory containers, laboratory utensils, supporting utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention is further described in detail below in conjunction with the embodiment shown in the accompanying drawings:

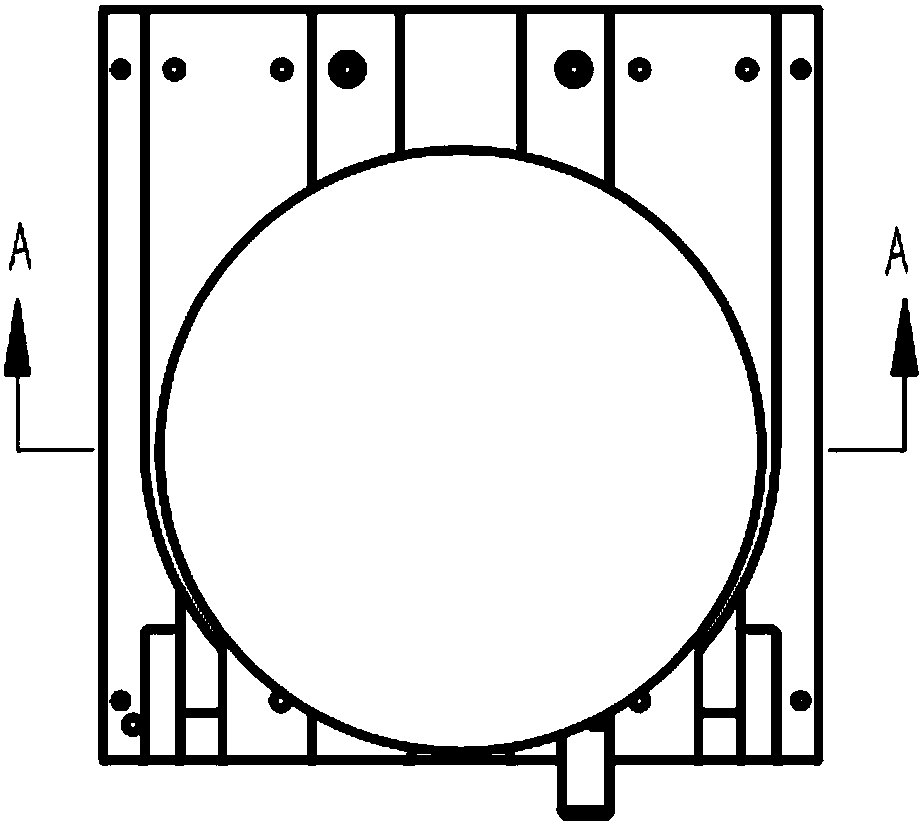

[0015] refer to figure 1 , The present invention includes: a chip bracket 1, a guide groove 7, a guide block 6, a lever 2, a push rod 3, a positioning marble 4, and a motor shaft slot 5.

[0016] Chip radius r=30mm, thickness d=5mm, PC material, processed by Jingdiao machine tool. The radius of the chip positioning block and the motor card slot is 10mm, the chip positioning block and the chip are bonded together by shadowless glue, and the motor card slot and the motor shaft are fixed by screws. Position the marbles with a radius of 2mm and polish them. The chip bracket is made of plexiglass material, and the chip bracket is selected according to the size of the chip to leave a 10mm gap on both sides to prevent the chip from colliding with the bracket.

[0017] When using, firstly connect the motor card slot and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com