Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Guaranteed fit clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

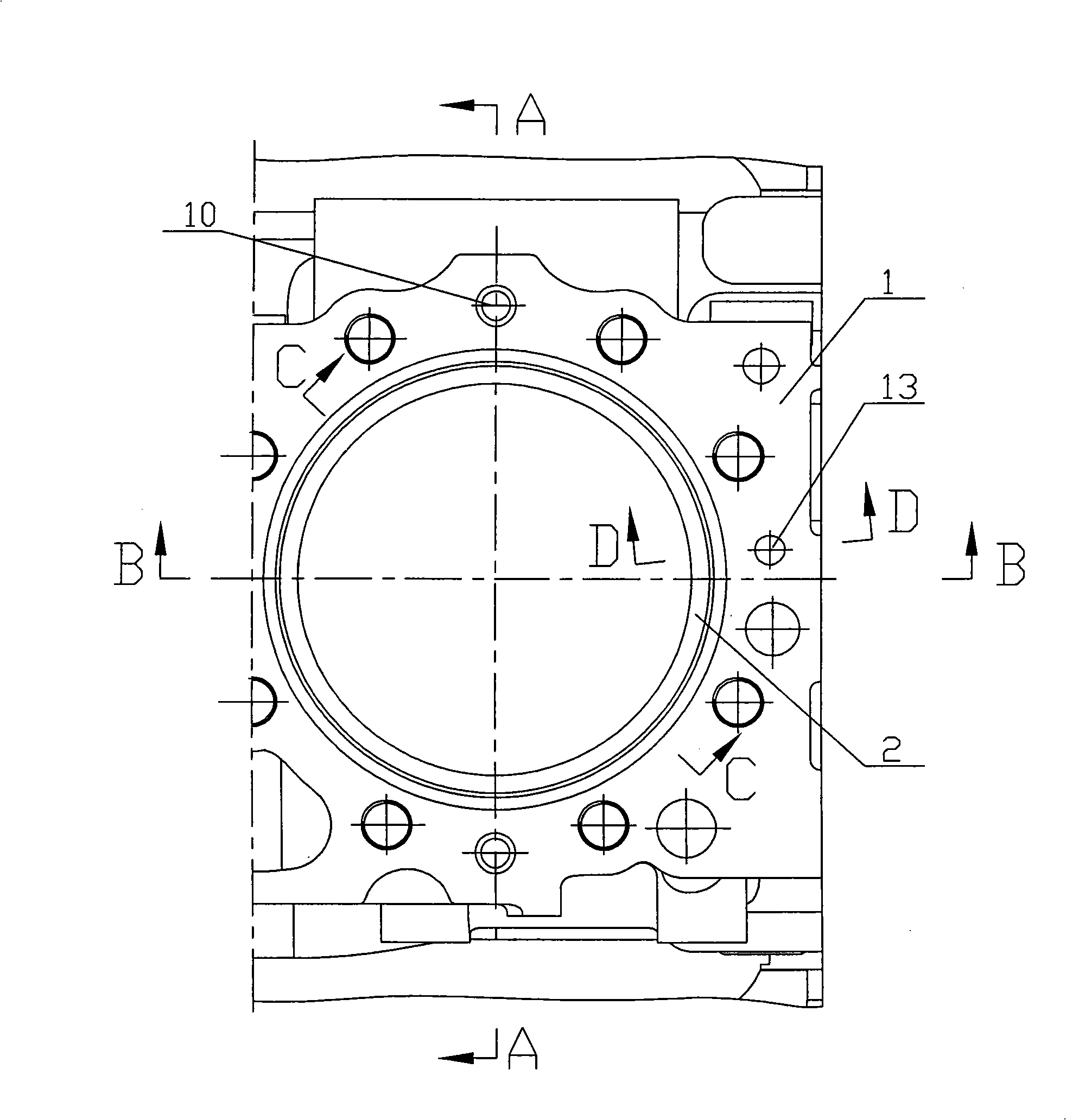

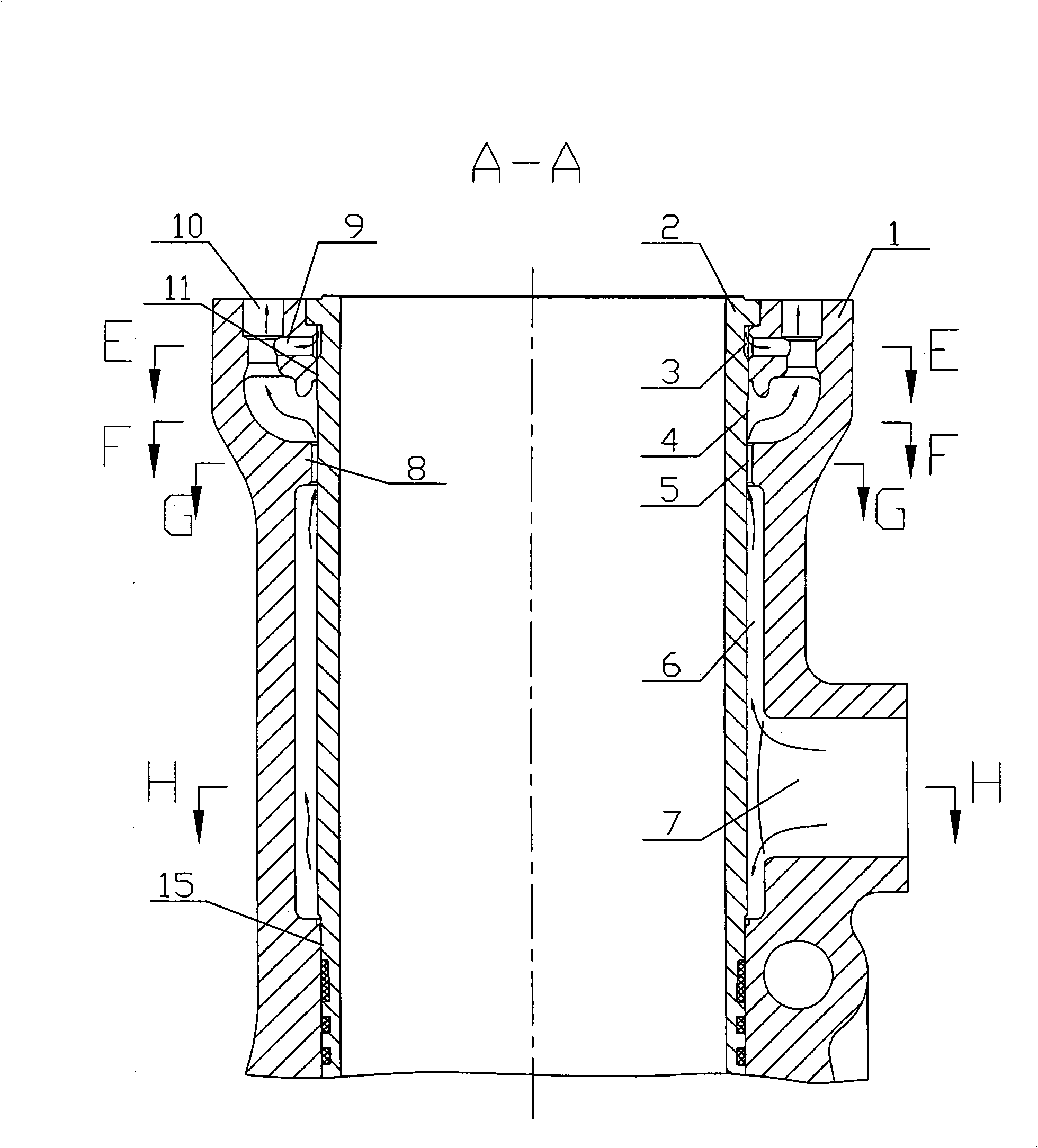

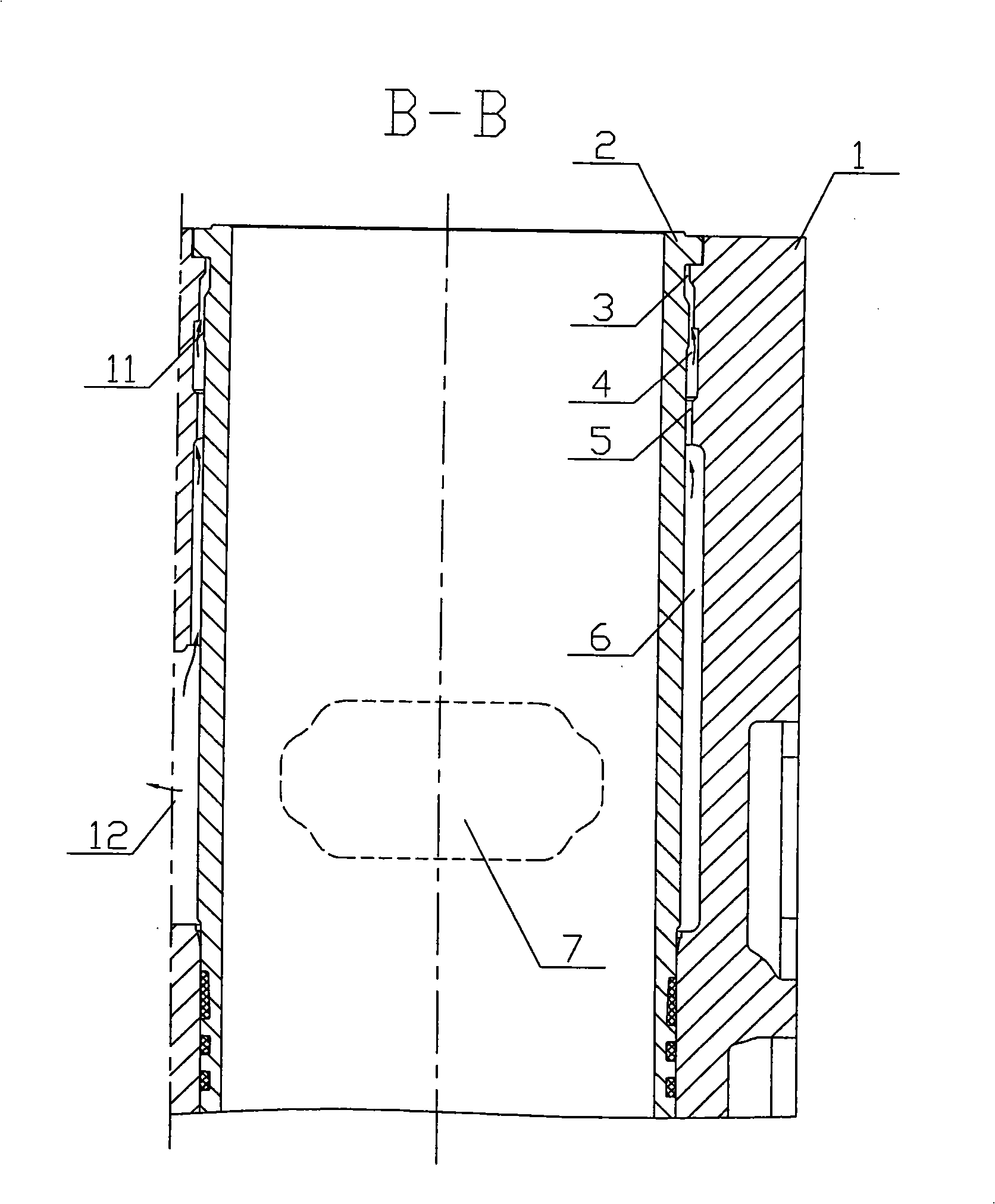

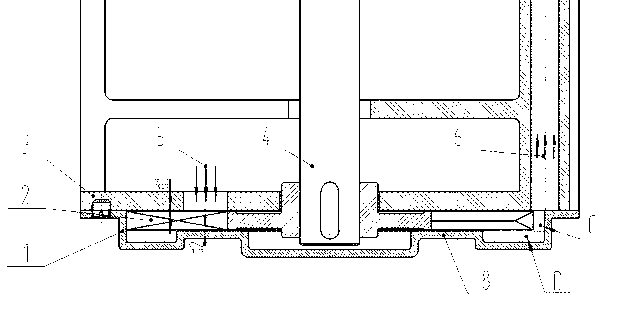

Water-cooled engine body

InactiveCN101349213AIncrease flow rateHigh trafficLiquid coolingCylinder headsCooling chamberEngineering

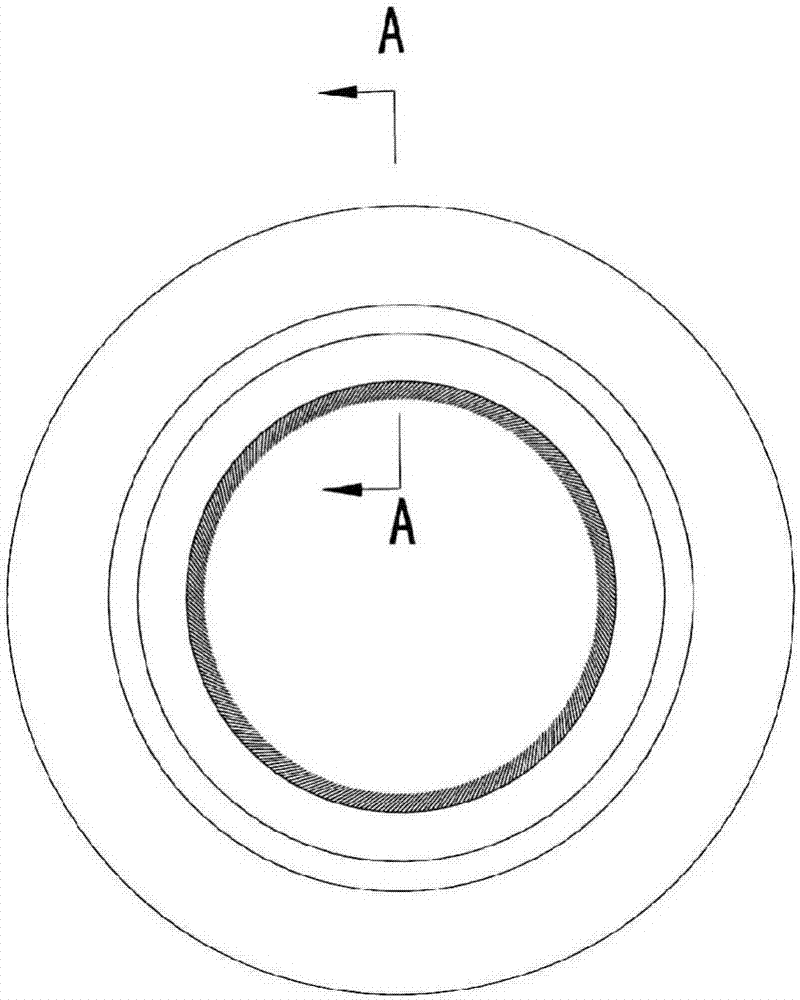

The invention relates to a water-cooled engine body, in particular to an air cylinder body of a wet-type cylinder liner engine. The air cylinder body comprises a cylinder body and a cylinder liner, and is characterized in that an upper positioning belt and a lower positioning belt are arranged on the cylinder liner; the inner surface of the cylinder body is provided with a convex ring; a cooling water channel formed between the lower positioning belt and the convex ring is used as a first cooling chamber; the cooling water channel formed between the convex ring and the upper positioning belt is used as a second cooling chamber; the cooling water channel formed over the upper positioning belt is used as a third cooling chamber; the cross-sectional area of the second cooling chamber is less than that of the first cooling chamber; and the cross-sectional area of the third cooling chamber is less than that of the second cooling chamber. The invention has the advantages that the air cylinder body can raise the flow velocity of cooling liquid, increase the flow rate of the cooling liquid, raise the heat dissipation rate of a high-temperature area, ensure that the whole cylinder liner is uniform in temperature, guarantee normal fit clearances among parts of the cylinder body and guarantee the normal work of the engine.

Owner:WUXI KIPOR POWER CO LTD

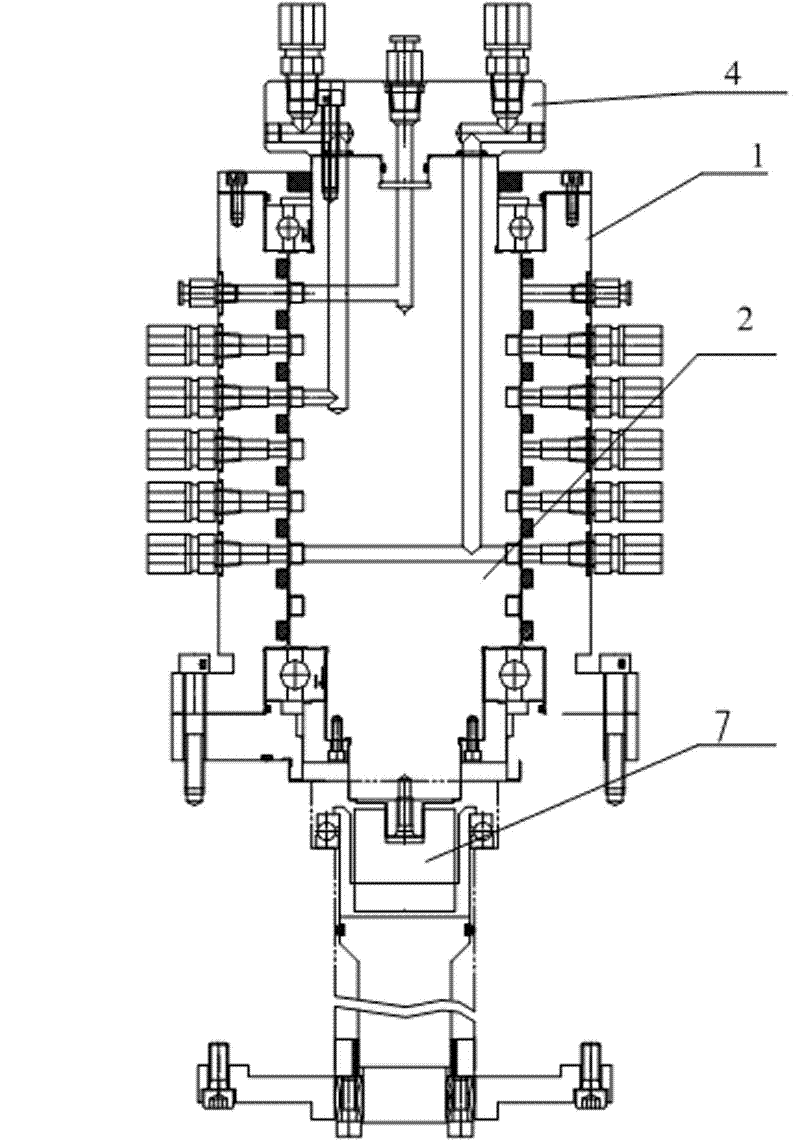

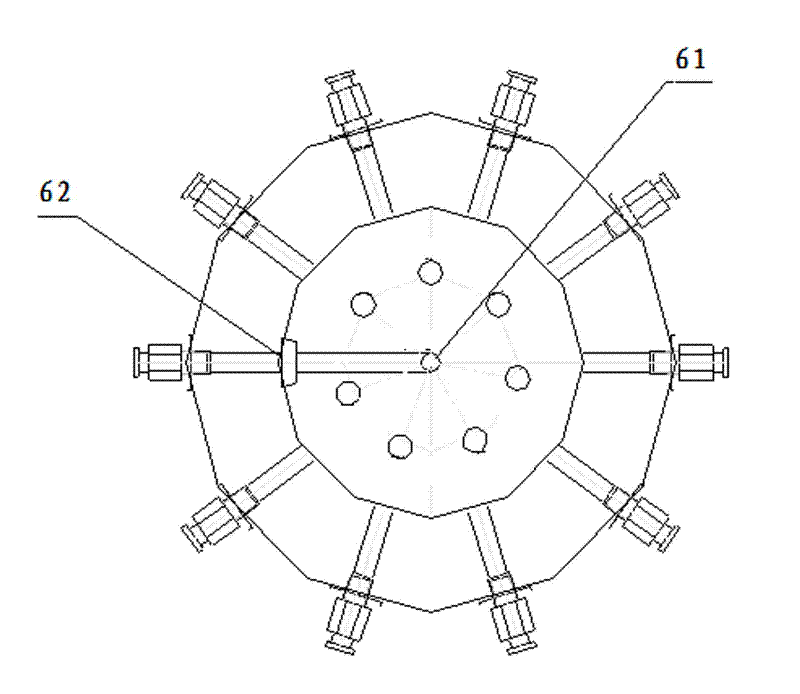

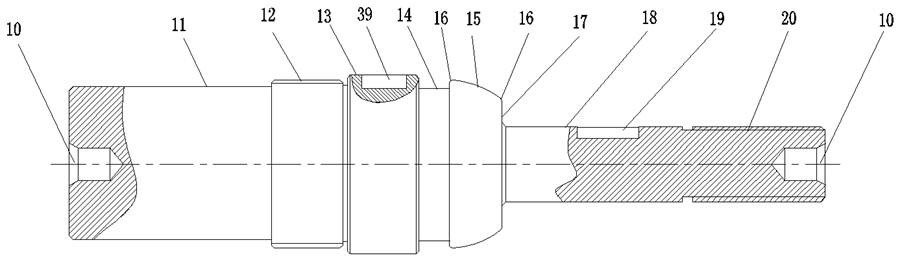

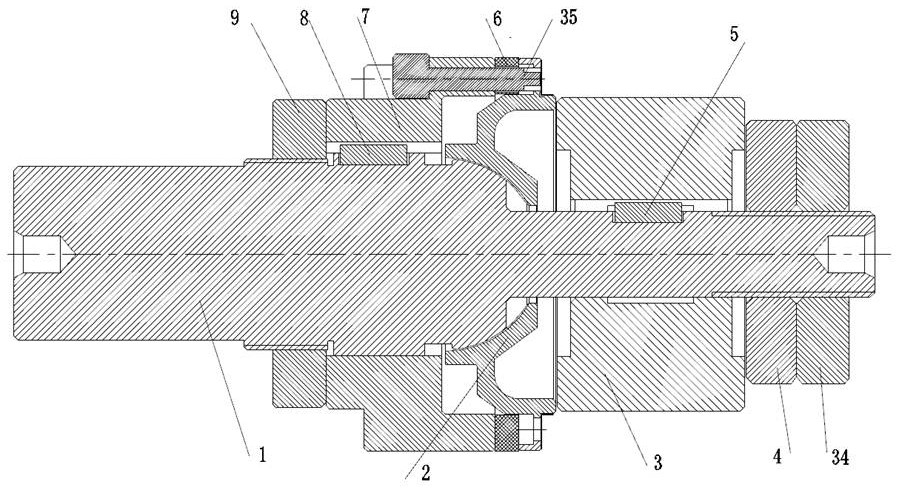

Central oil distributor for rotary machine tool

InactiveCN102229055AEasy to processHigh precisionPositioning apparatusMetal-working holdersLocking mechanismDistributor

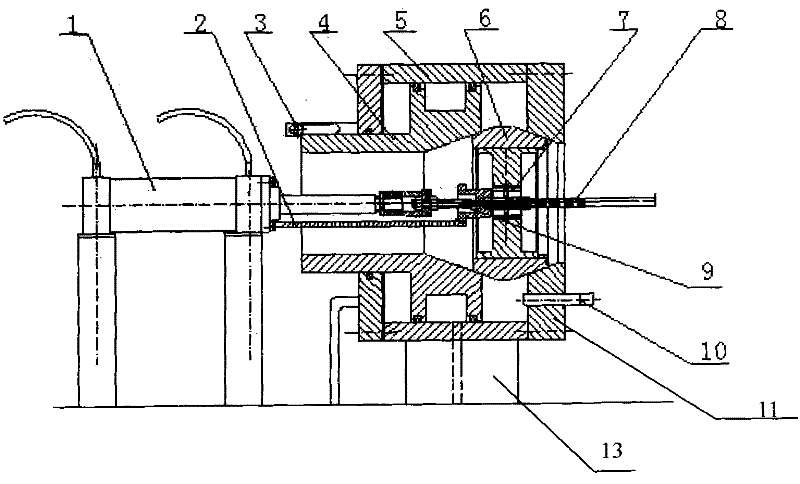

The invention relates to a central oil distributor for a rotary machine tool, comprising an oil distributor casing and a mandrel arranged in the oil distributor casing, wherein a blowing and cleaning mechanism, an oil cylinder clamping mechanism, an oil cylinder loosening mechanism, an auxiliary support mechanism, a tapered pin locking mechanism and a tapered pin loosening mechanism are arranged on the mandrel from top to bottom. The central oil distributor disclosed by the invention has the beneficial effects of realizing various functional requirements of the machine tool, reducing the costas much as possible, improving the machining manufacturability of parts, improving the precision of the parts and being convenient for operation and maintenance.

Owner:北京北方红旗精密机械制造有限公司

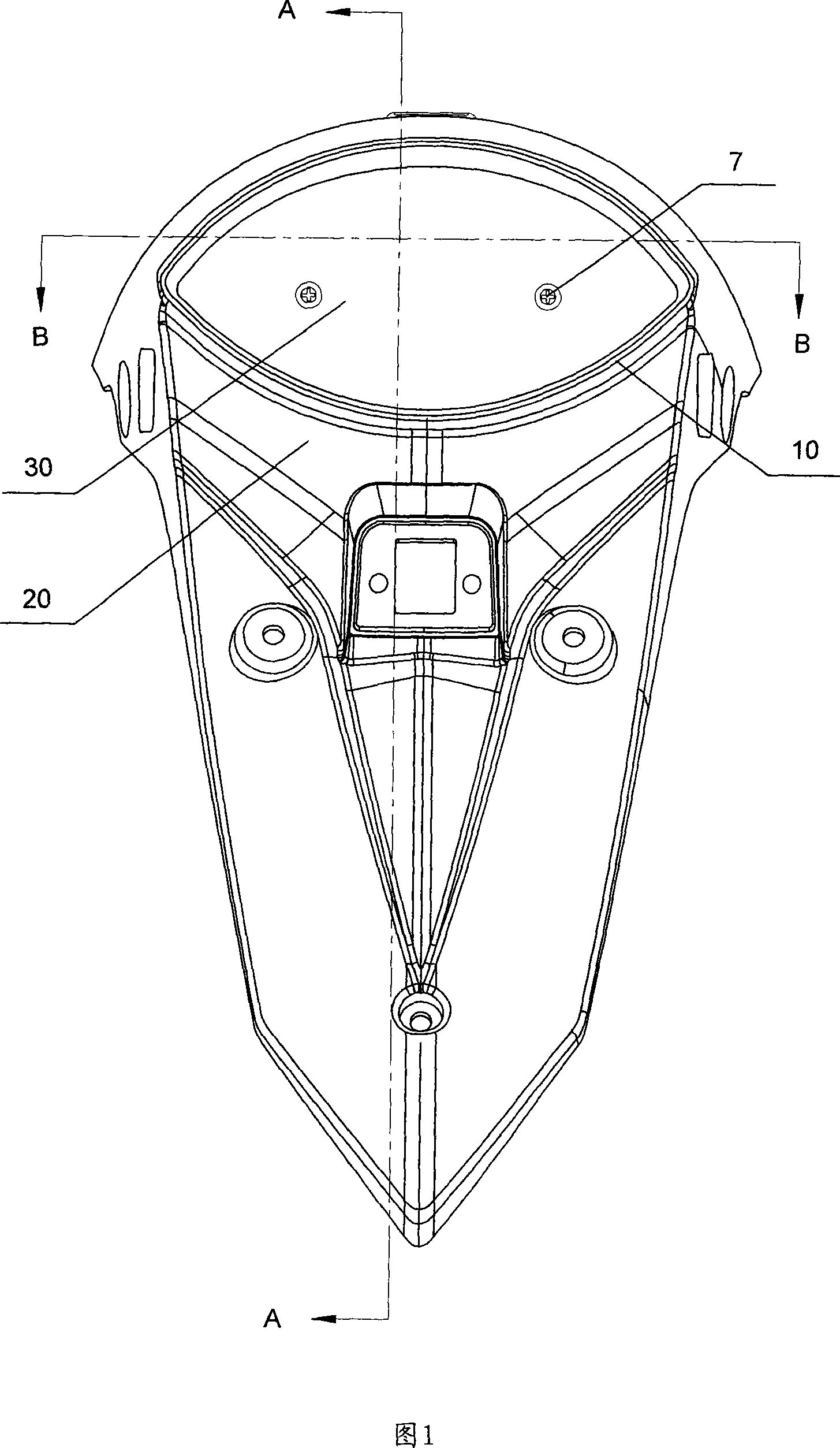

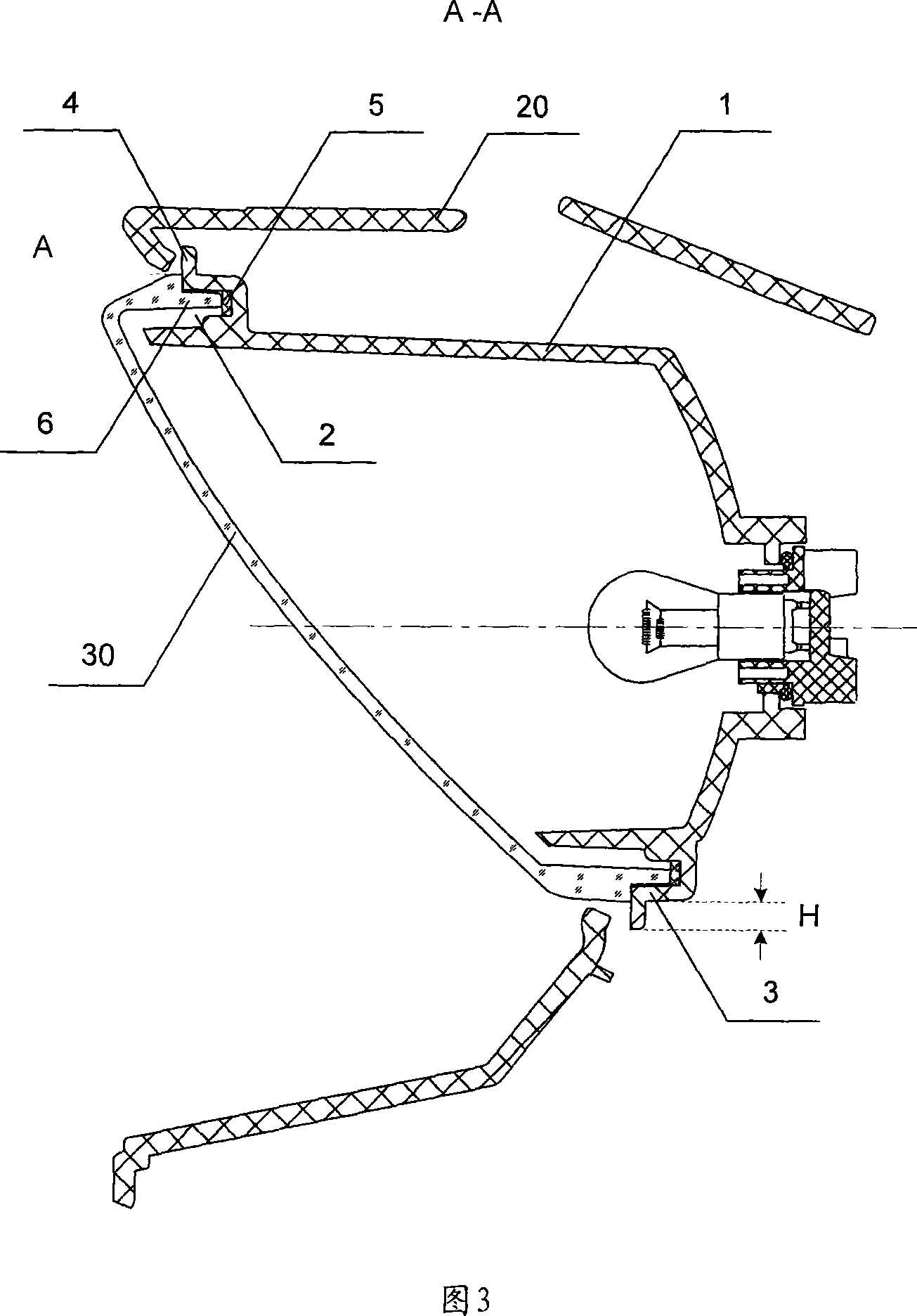

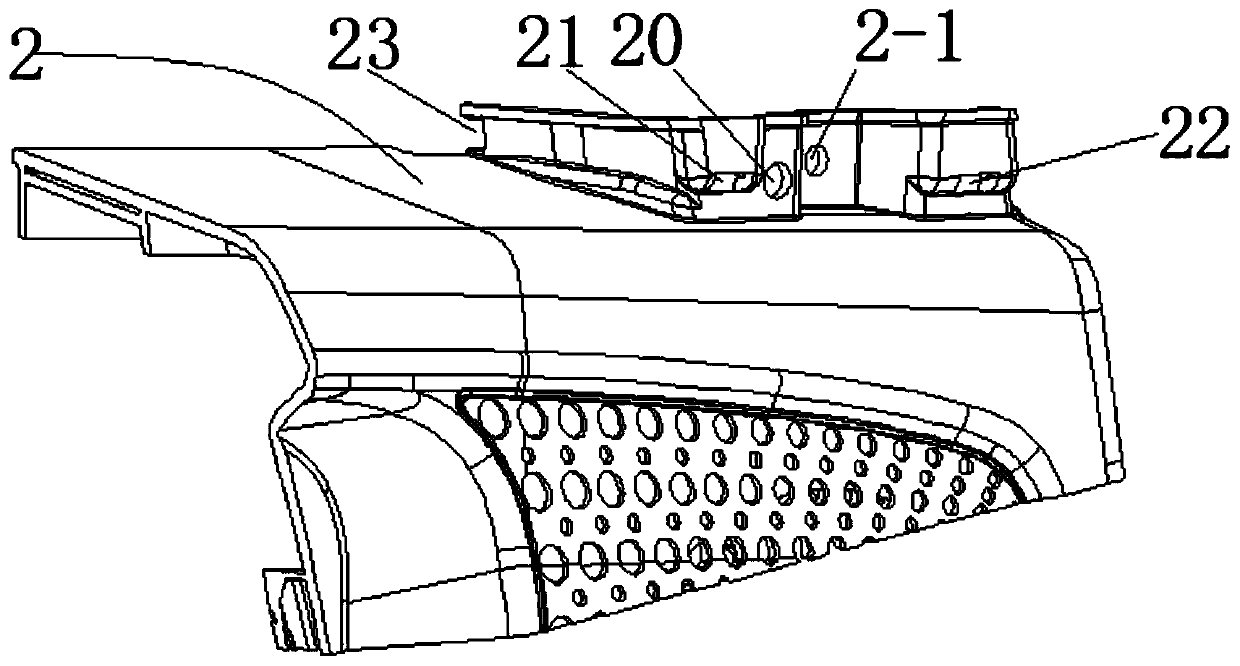

Motorcycle taillight base

InactiveCN101042216AImprove structural rigidityImprove appearance qualityRoad vehiclesLight fasteningsEngineeringImpurity

The motorcycle tail lamp base comprises the base body with sealed slot outside the base with protruding light block rib. It can be installed from inside the covering piece to outside, through setting a ring of extending light block rib to avoid the impurities inside the vehicle to effectively solve the issue of light leakage to ensure the convenience for light bulb change.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

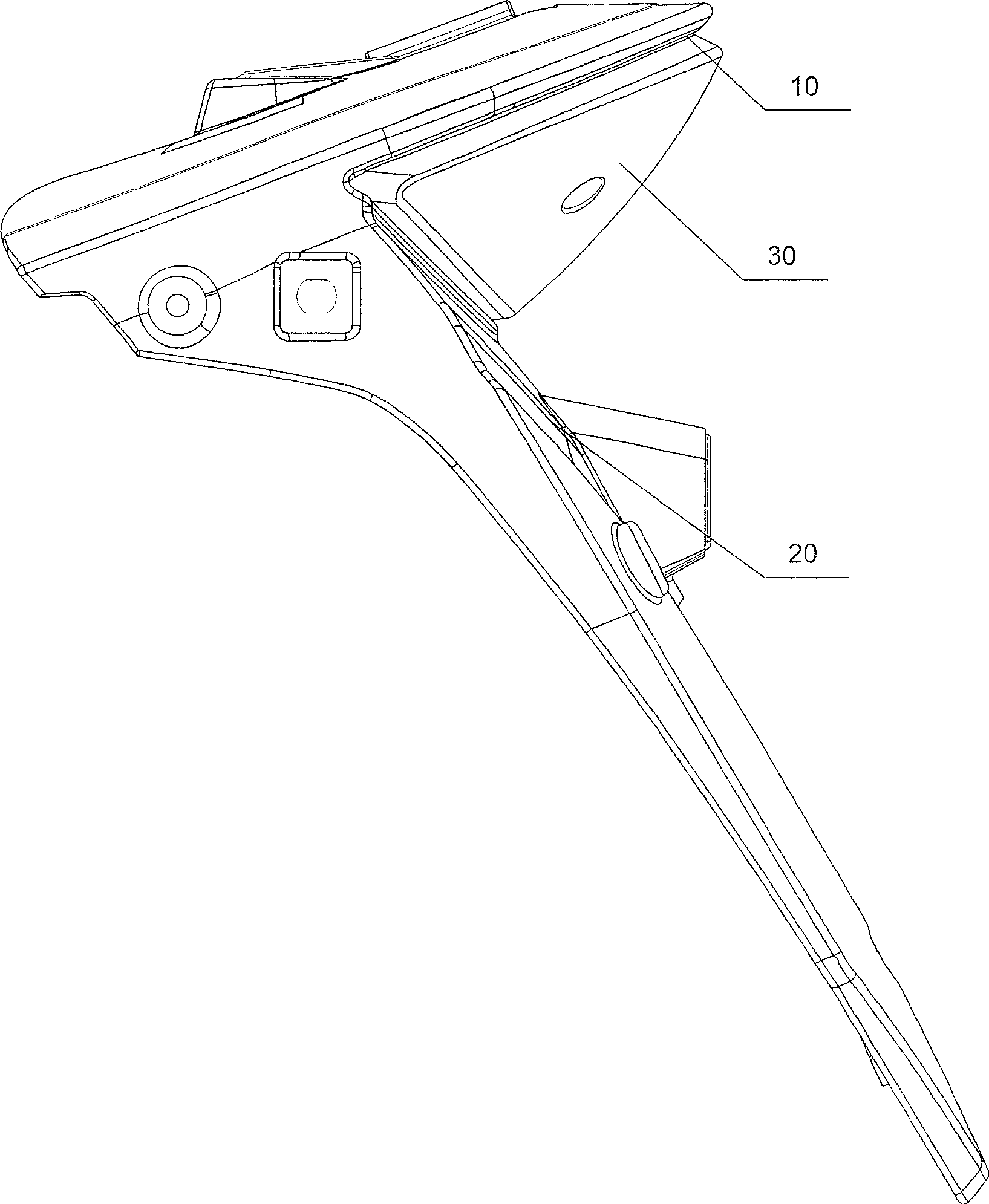

A ground wire assembly

ActiveCN105703097AGuaranteed path of movementAvoid offsetElectric connection structural associationsSwitchgearEngineeringMechanical engineering

The invention discloses a ground wire assembly comprising a main rod body and an auxiliary rod body which are arranged in parallel. The top end of the main rod body is provided with a fixing head restraint matched with a wiring terminal. The top end of the auxiliary rod body is provided with a movable head restraint clamped and matched with the fixing head restraint. A guiding aperture is arranged in the fixing head restraint along an axial direction of the main rod body. The tail end of the movable head restraint is movably inserted in the guiding aperture and is in hinged connection with the auxiliary rod body. The middle portion of the main rod body is provided with an adjusting gear in a rotatable mode. The axis of the adjusting gear is perpendicular to the axis of the main rod body. A matched surface between the tail end of the auxiliary rod body and the main rod body is provided with a tooth bar engaged with the adjusting gear in a matched mode. The connection structure of the ground wire assembly is safe and reliable, and the operation process is simple to perform.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +2

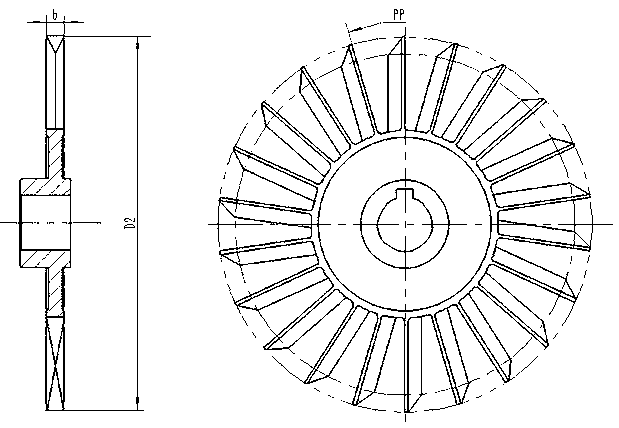

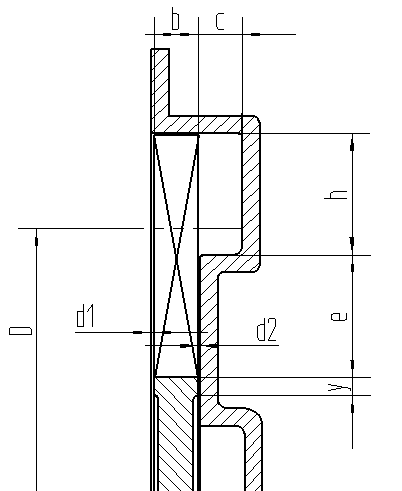

Cooling pump of machine tool

InactiveCN103256256AGuaranteed delivery requirementsLow powerPump componentsPumpsImpellerEngineering

The invention discloses a cooling pump of a machine tool. An impeller is in a full-open vortex long-blade structure; the blade length is 1 / 6-1 / 4 of the outer diameter D2 of the impeller; an axial clearance d1 between the impeller and a pump body is 0.1-0.3mm; annular bulges are arranged on a pump cover and used for adjusting an axial clearance d2 between the pump cover and the impeller to be 0.1-0.3mm; a water inlet is formed in the pump body, and takes a cut-water position A as a starting point circumferentially; and a radial position of the water inlet corresponds to a blade area of the impeller. According to the cooling pump of the machine tool, the novel vortex impeller is strictly matched with the pump cover and the end face of the pump body, and the matched clearances between the impeller and the pump cover and between the impeller and the pump cover are ensured, so that a small-flow and high-lift cooling liquid conveying requirement is met; the efficiency is improved; a distance from the water inlet to the bottom of a cooling liquid box can be shortened with the increasing of a lift; a use ratio of cooling liquid is increased; the characteristic requirements on the efficiency, small flow and high lift are met; and the cooling pump can be widely applied to cooling of the machine tool.

Owner:JIANGSU UNIV

Laser repair method for hub tenon tooth of heavy-duty gas turbine

ActiveCN106757005ALittle impact on working statusGuaranteed fit clearanceContinuous combustion chamberMetallic material coating processesPre treatmentWear resistant

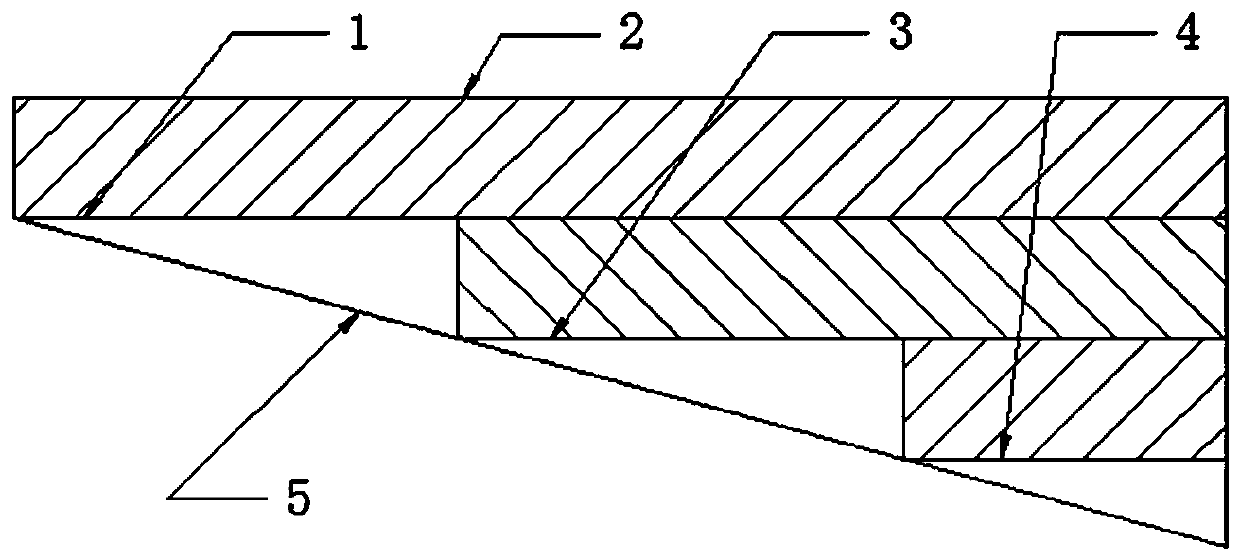

The invention discloses a laser repair method for a hub tenon tooth of a heavy-duty gas turbine. The laser repair method comprises the following steps: 1, detecting damage situations; 2, determining maintenance contents; 3, formulating a process scheme; 4, pre-treating a damaged part, detecting a tongue-and-groove damage surface, and determining the maintenance process sequence; 5, protecting a non-laser cladding surface; 6, performing laser cladding processing; and 7, performing examination after repair. The process parameters of laser cladding and the ratio of all element ingredients in a powder material are optimally designed to clad crack-free and impurity-free compactly-textured wear-resistant alloy powder in the hub tenon tooth tongue-and-groove of the heavy-duty gas turbine, so that the service life of the heavy-duty gas turbine is prolonged.

Owner:沈阳大陆激光工程技术有限公司

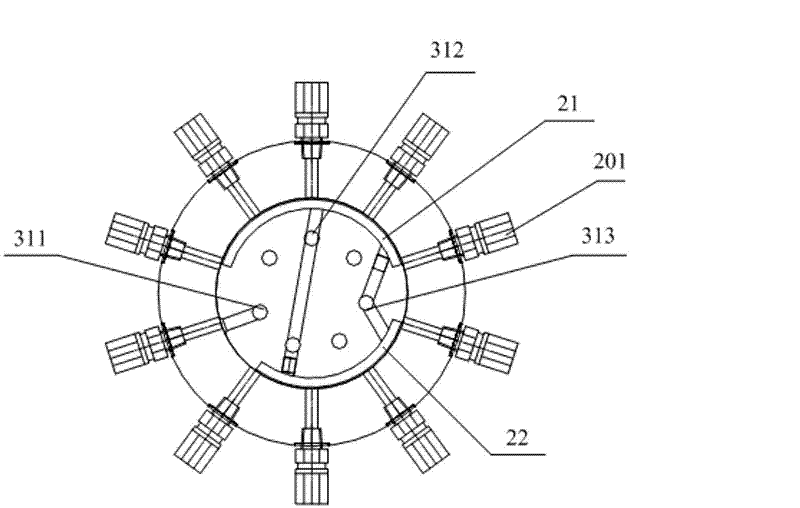

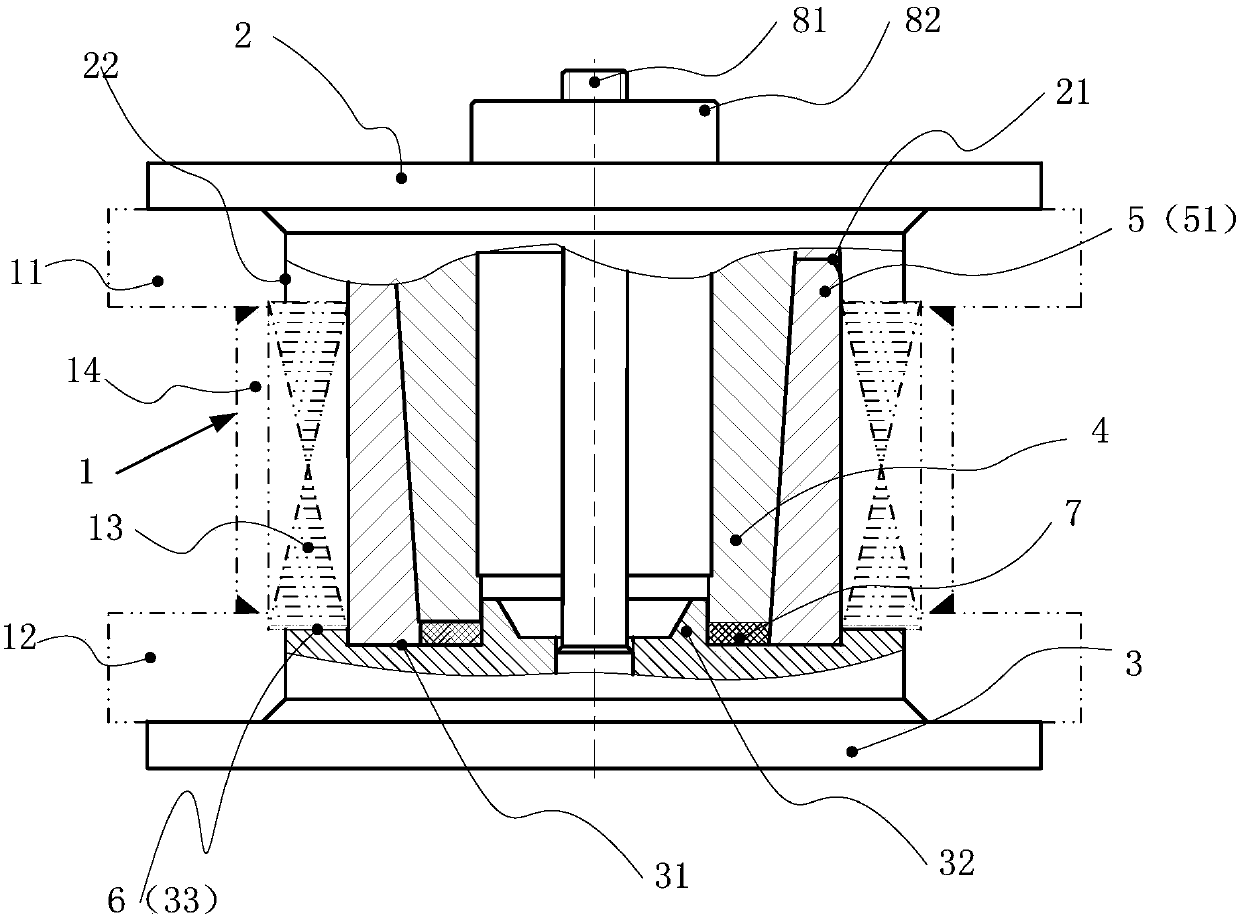

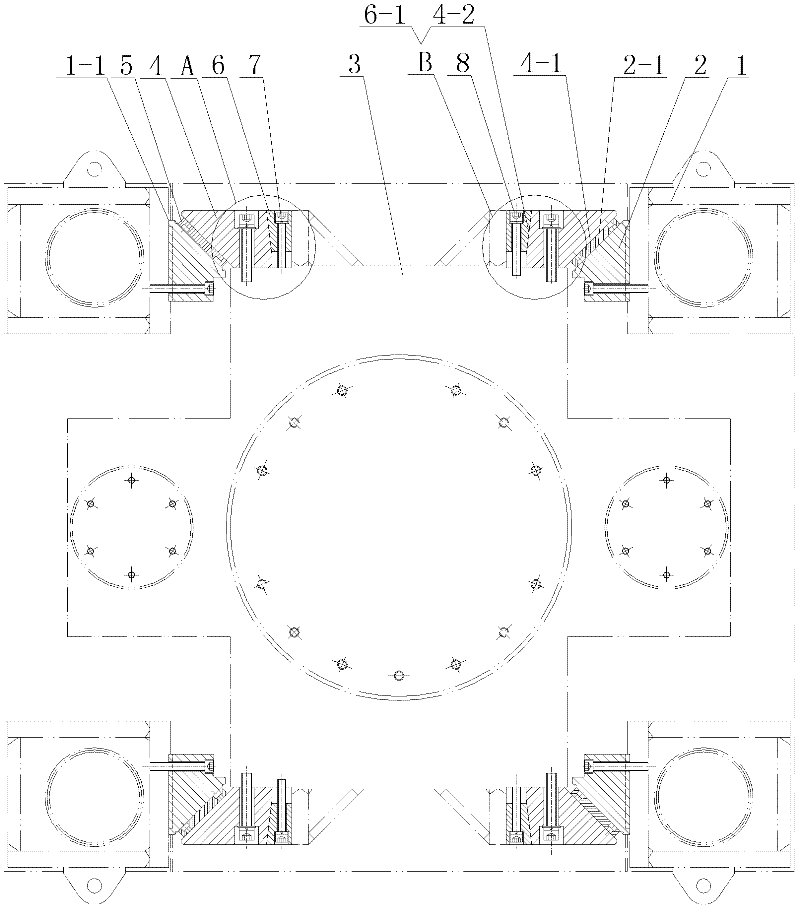

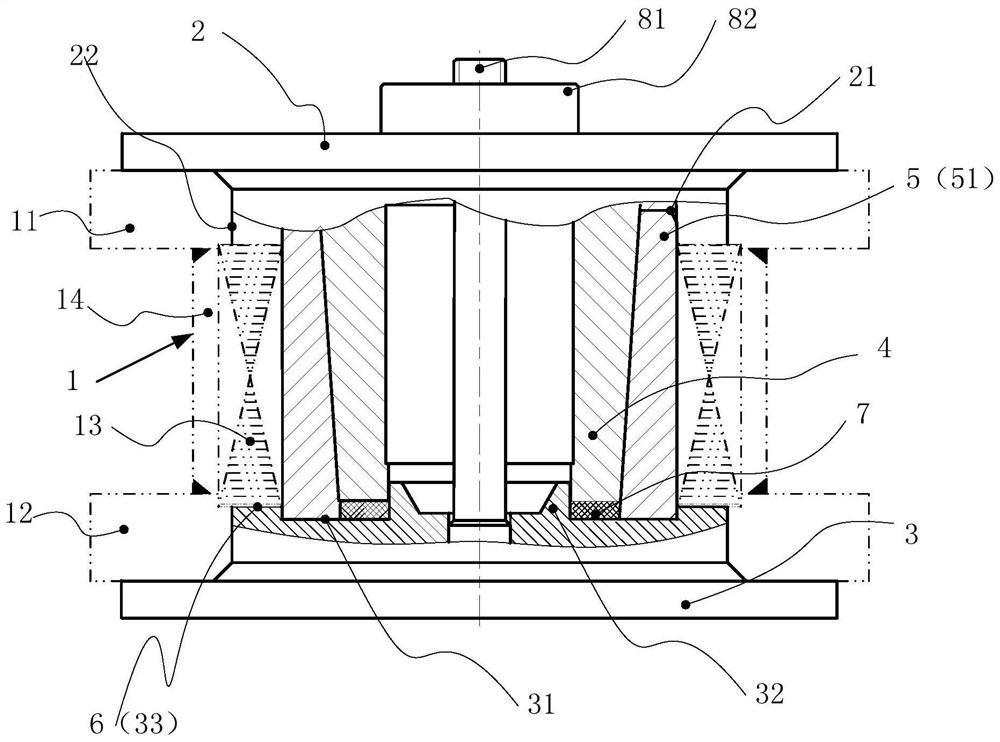

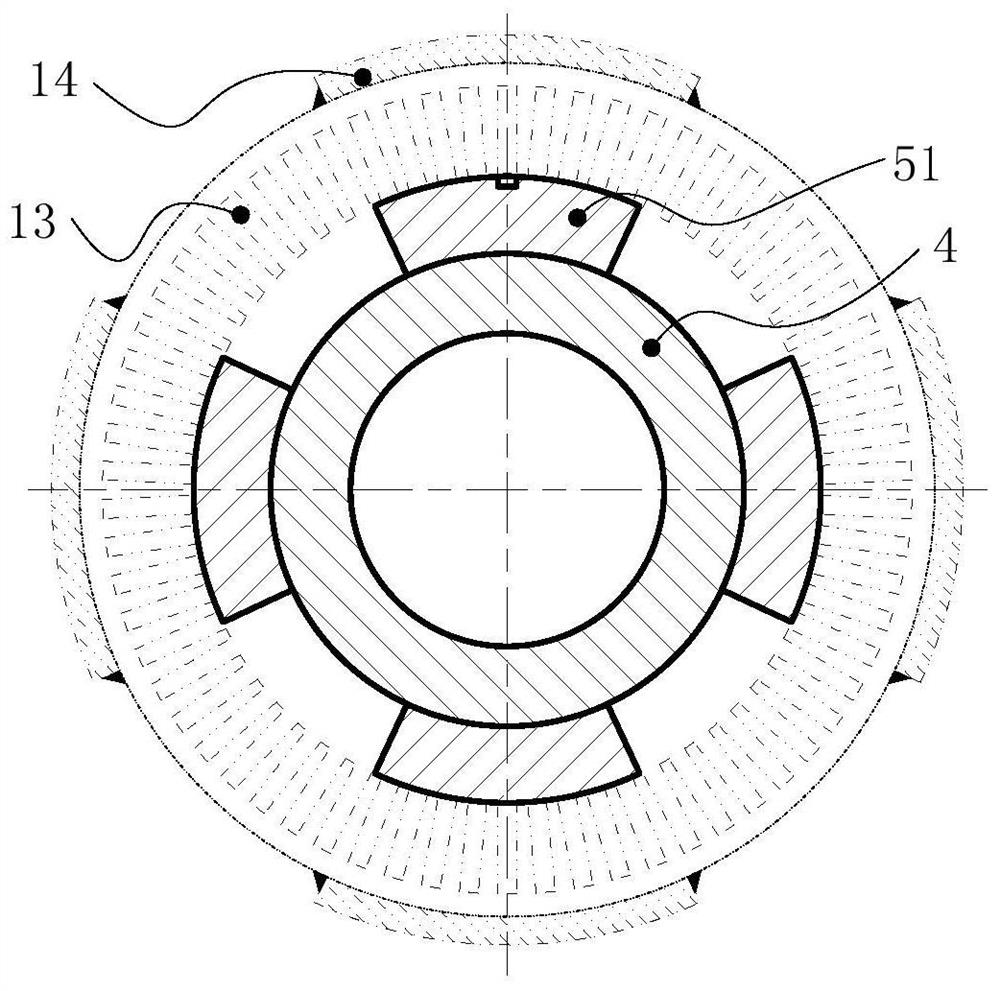

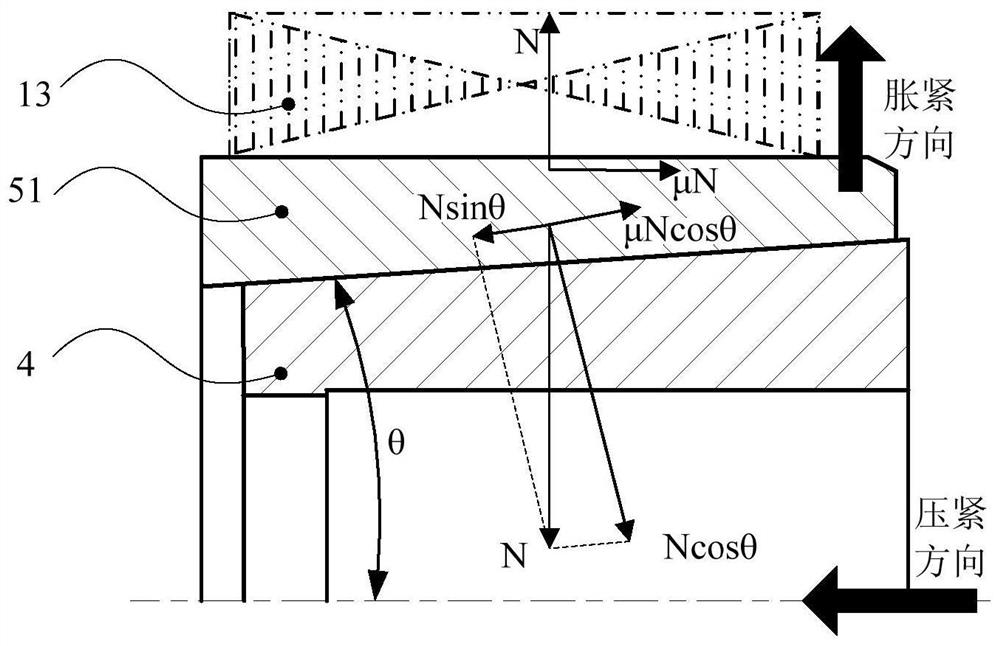

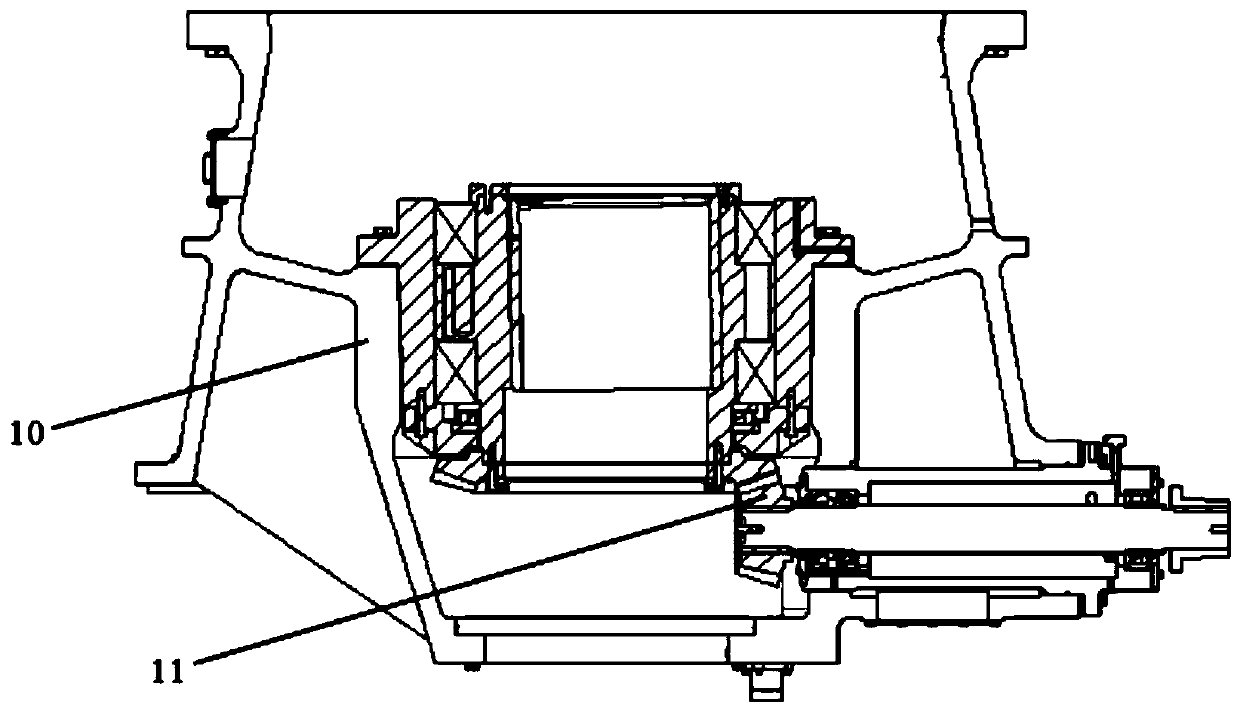

Stator iron core overlaying welding mold

ActiveCN109702403AGuaranteed roundnessWon't strainWelding/cutting auxillary devicesAuxillary welding devicesPunchingWelding deformation

The invention discloses a stator iron core overlaying welding mold. A stator iron core comprises a stator upper pull ring, a stator lower pull ring, a stator punching piece and multiple stator pull plates; the stator punching piece is arranged between the stator upper pull ring and the stator lower pull ring; the multiple stator pull plates are uniformly distributed at the outer periphery of the stator punching piece; the welding mold comprises an upper pressing plate, a lower pressing plate, an inner mold and an outer mold; the inner mold and the outer mold are arranged between the upper pressing plate and the lower pressing plate; the outer mold comprises multiple fan-shaped blocks; the fan-shaped blocks are as many as the stator pull plates; the inner surfaces and the outer surfaces ofthe fan-shaped blocks are arcs; the multiple fan-shaped blocks are uniformly arranged at the outer periphery of the inner mold; limiting pieces are arranged at the outer peripheries of the multiple fan-shaped blocks; the outer surface of the inner mold is an inner mold conical surface; the inner surfaces of the fan-shaped blocks are outer mold conical surfaces matched with the inner mold conical surface; and the outer surfaces of the fan-shaped blocks are matched with the inner surface of the stator punching piece. The reversible deformation is only applied to welding deformation positions ofthe stator pull plates, so that the welding deformation is effectively counteracted, and the inner circle roundness of the stator iron core can be guaranteed.

Owner:湖南中车商用车动力科技有限公司

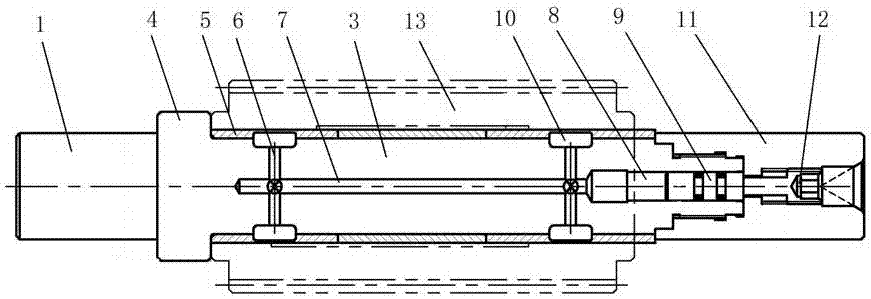

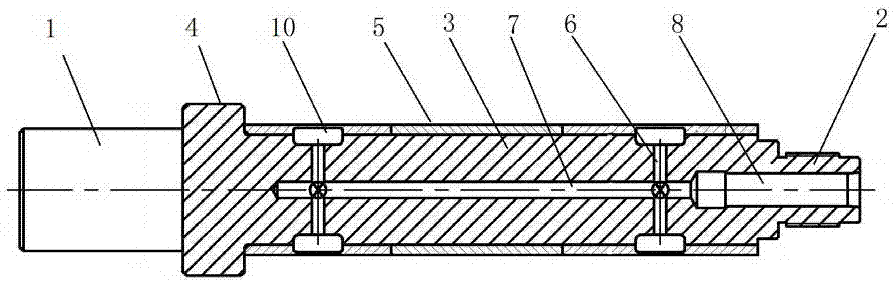

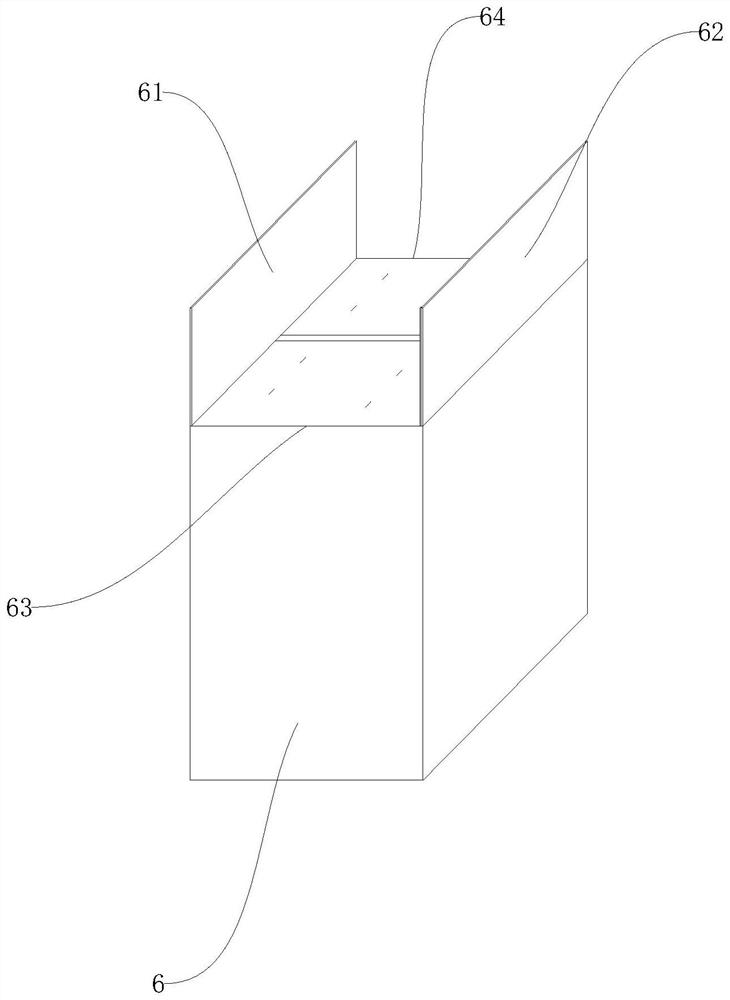

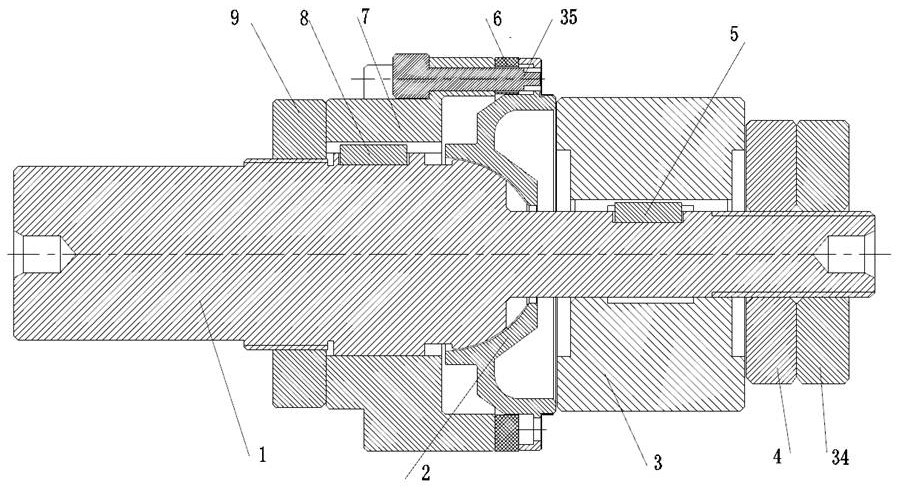

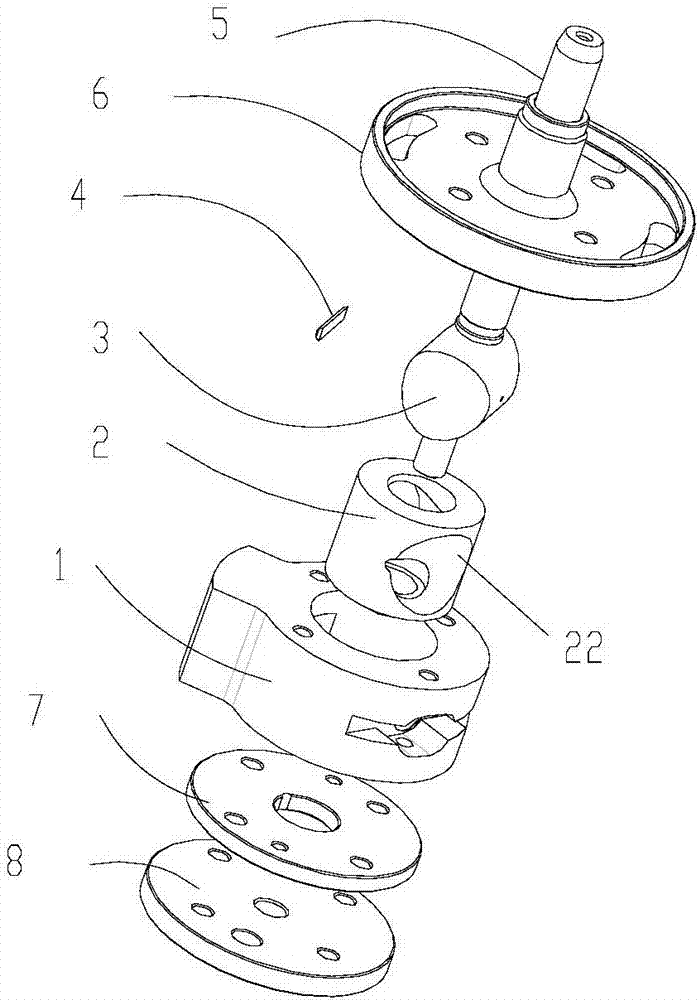

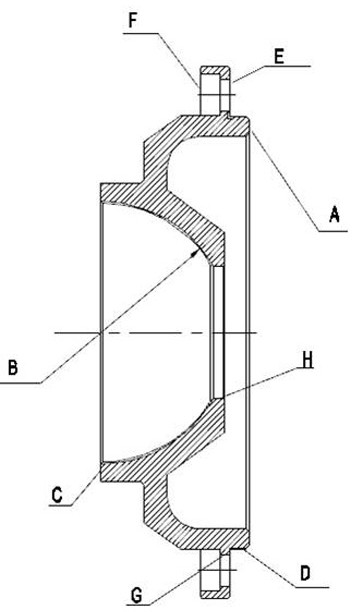

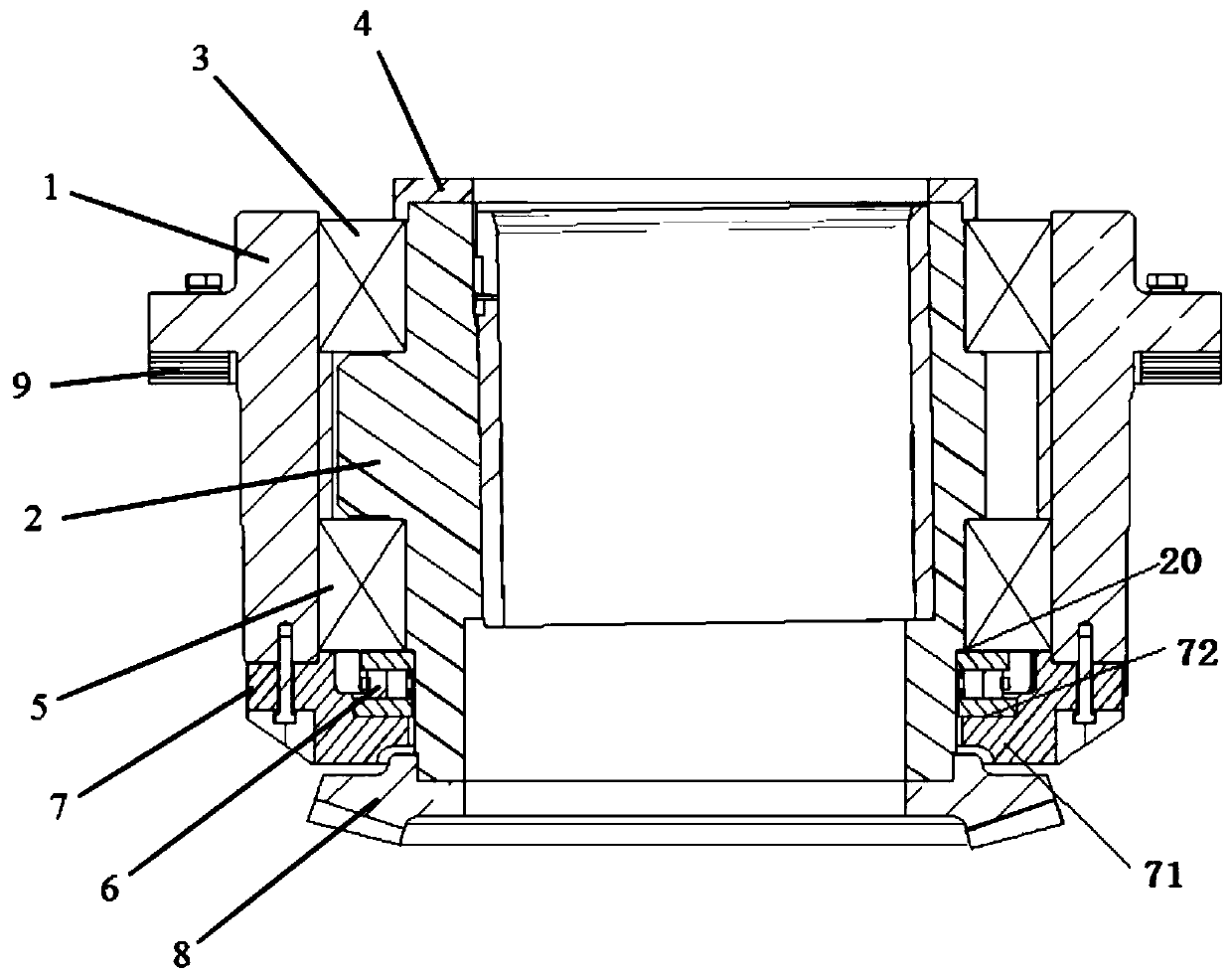

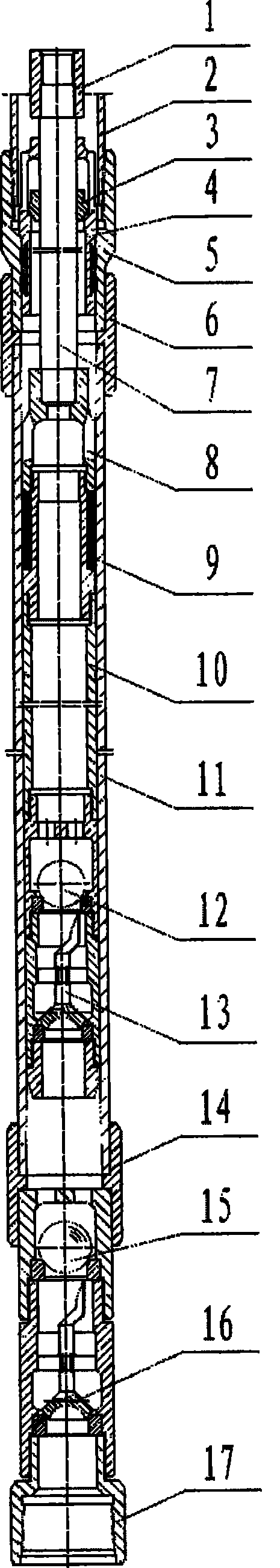

Liquid expansion mandrel

InactiveCN107414115AQuick clampingGuaranteed fit clearanceExpansion mandrelsEngineeringMechanical engineering

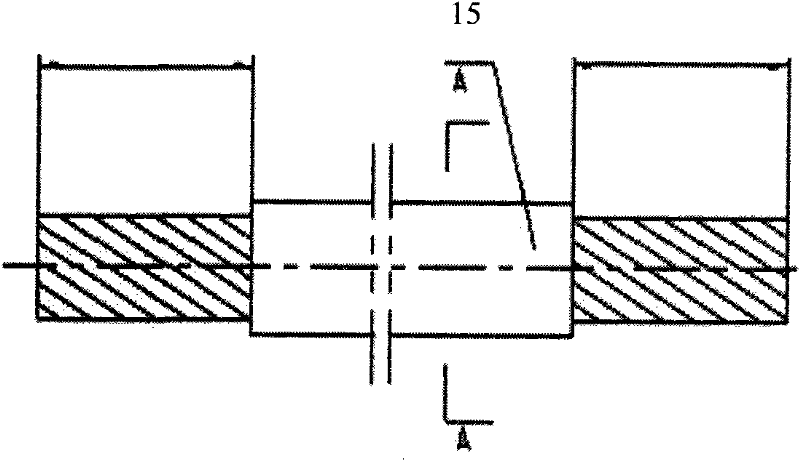

The invention discloses a liquid expansion mandrel, which comprises a mandrel. The mandrel includes a mounting section and a liquid expansion control section respectively located at two ends, and a workpiece clamping section is arranged between the installation section and the liquid expansion control section. A collar for limiting the workpiece is provided between the workpiece clamping section and the installation section; a liquid expansion center hole is provided in the mandrel, and a liquid expansion thin film is set on the workpiece clamping section. A wall sleeve, a liquid expansion communication hole is provided between the liquid expansion center hole and the liquid expansion thin-walled sleeve; the entrance of the liquid expansion center hole is located on the end surface of the liquid expansion control section, and the liquid expansion center The hole includes a small diameter section corresponding to the workpiece clamping section and a large diameter section corresponding to the liquid expansion control section, the liquid expansion communication hole communicates with the small diameter section, and the large diameter section is provided with There is a piston for controlling the hydraulic expansion pressure. The liquid-expanding mandrel of the invention can not only ensure the matching clearance between the workpiece and the mandrel, but also fix the position of the workpiece on the mandrel.

Owner:重庆工具厂有限责任公司

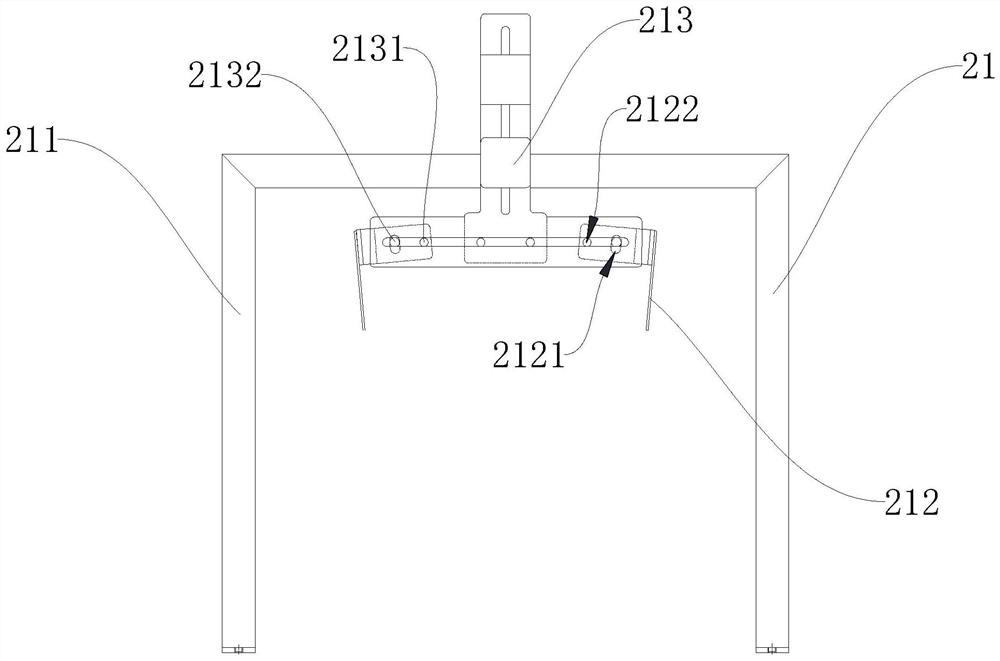

Full-automatic cover folding and carton sealing machine

PendingCN114590450AIncrease coarse positioningGuaranteed fit clearanceWrapper twisting/gatheringCartonStructural engineering

The invention discloses a full-automatic cover folding and carton sealing machine which comprises a rack assembly, a cover folding assembly and a carton sealing assembly. The folding assembly is installed on the front portion of the rack assembly and comprises a paging part, a front-back folding part and two-side folding parts, the paging part is installed on the front portion of the folding assembly, paging plates are arranged on the left side and the right side of the paging part, and the paging plates are suitable for limiting the angle between the carton left side wing and the carton right side wing; the front-back folding part is installed in the middle of the folding assembly and suitable for folding the front side wing and the rear side wing of the carton. The two-side folding part is installed on the rear portion of the folding assembly, two-side folding mechanisms are rotatably arranged on the left side and the right side of the two-side folding part, and the two-side folding mechanisms are suitable for turning over a carton left side wing and a carton right side wing; and the gluing assembly is mounted between the front and rear folding parts and the two side folding parts, and the gluing assembly is suitable for spraying hot melt glue on the front side wing and the rear side wing of the carton. The full-automatic cover folding and carton sealing machine is efficient and stable.

Owner:宁波嘉德轻工机械有限公司

Positioning clamp and machining method for rotor cover of dynamic pressure air bearing of gyro motor

ActiveCN114589520APrecise positioningRestricted freedom of movementWork clamping meansPositioning apparatusAir bearingGyroscope

The invention relates to a thin-wall part precision turning machining method and a positioning clamp, in particular to a positioning clamp and a machining method of a gyroscope motor dynamic pressure air bearing rotor cover. The positioning clamp comprises a spherical surface positioning mandrel, a positioning lantern ring, an anti-vibration pad and a back supporting seat. The spherical positioning mandrel is a step shaft with center holes formed in the two end faces, and comprises a clamping section, a large thread section, a second guide cylindrical section, a spherical positioning section, a spherical table end face, a first guide cylindrical section and a small thread section from left to right in sequence. The machining method comprises the steps of first-step machining of the rotor cover, machining of a series of spherical positioning mandrels, machining of a positioning lantern ring and a back supporting seat, selection of a proper spherical positioning mandrel, turning of the rotor cover and the like. The problems that an existing machining method is poor in positioning precision and low in machining efficiency, and the concave spherical surface is crushed are solved, damage to the concave spherical surface is avoided by limiting six degrees of freedom, and the machining precision of the rotor cover is guaranteed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

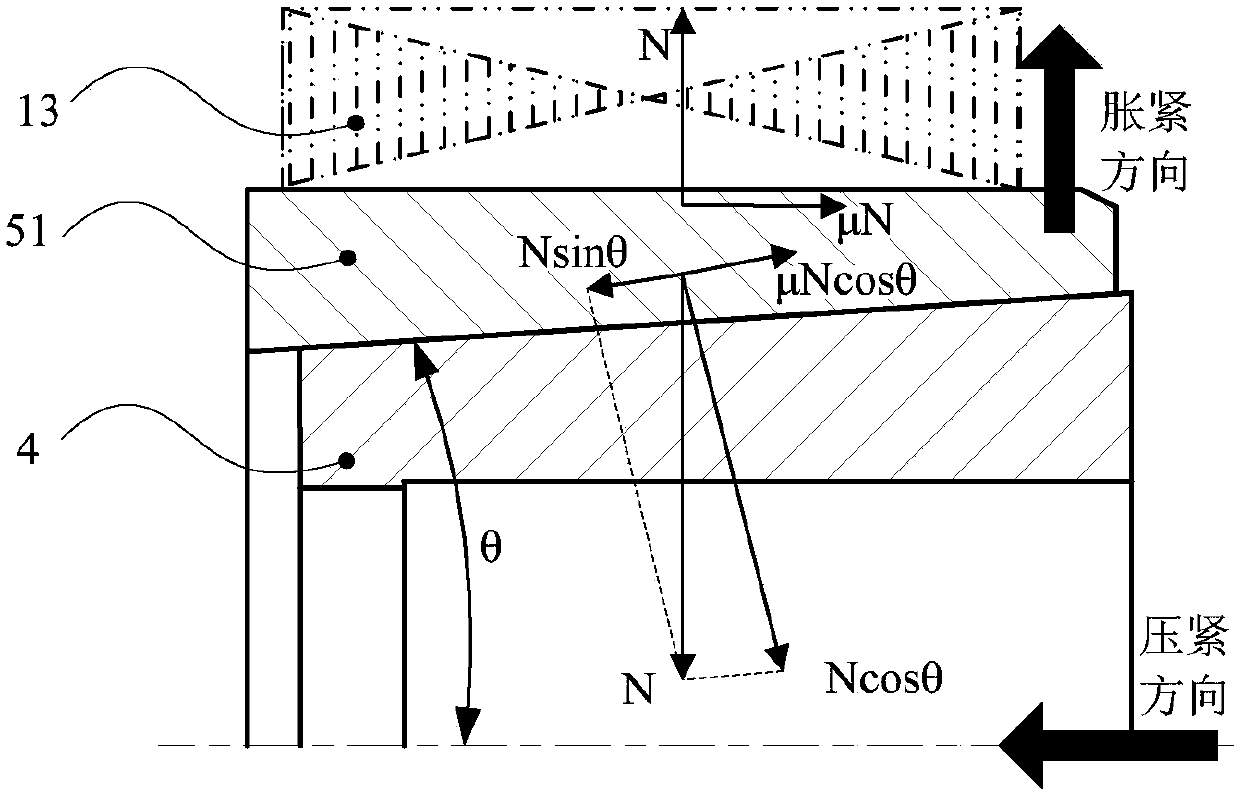

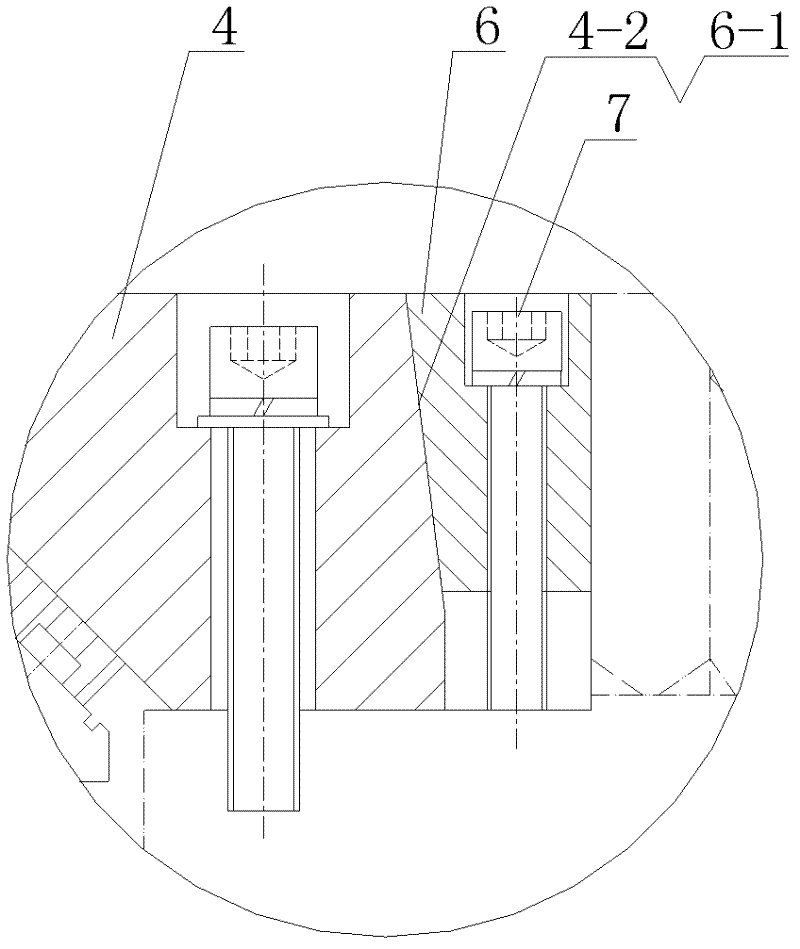

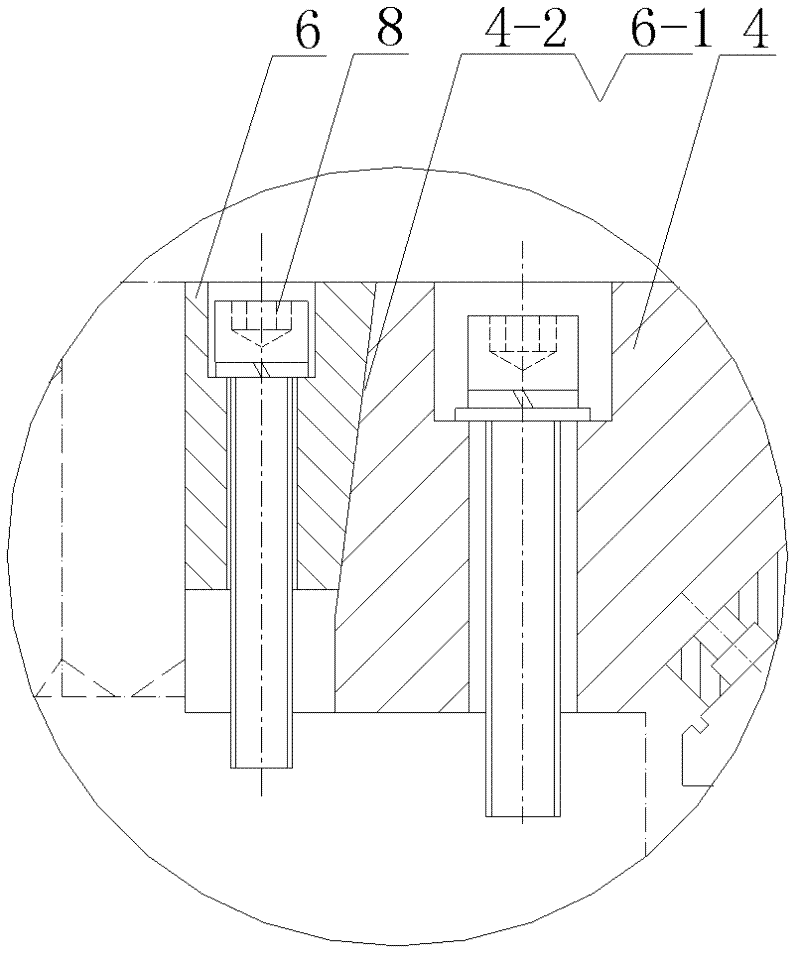

Slide block guiding device for powder hydraulic machine

The invention relates to a slide block guiding device for a powder hydraulic machine. The slide block guiding device comprises a guide rail which is vertically and fixedly arranged on the inner side face of a vertical post and a baffle block which is arranged on the side face of a slide block, wherein the guide rail and the baffle block are provided with a first wedge surface and a second wedge surface with consistent oblique angles respectively; and a guide plate which is fixedly arranged on the baffle block is arranged between the two wedge surfaces. The slide block guiding device is characterized by further comprising an adjusting block, wherein the adjusting block and the baffle block are provided with a third wedge surface and a fourth wedge surface with consistent oblique angles respectively; and the third wedge surface is tightly pressed on the fourth wedge surface through a jack screw and a pull screw which are connected to the side face of the slide block. Due to the adoption of the structure, compared with the baffle block guide rail structure in the prior art, the slide block guiding device has the characteristics of convenience for adjusting and saving in time because the guide rail is taken as a positioning benchmark and the fit clearance along the entire travel of the guide rail can be ensured by adjusting the clearance between the guide plate and the guide rail at a certain space position; and moreover, the adjusting block and the baffle block are contacted with each other through the wedge surfaces, so that parallel movement of the baffle block along the side face of the slide block is ensured during adjusting, and the consistence of the fit clearance between the guide plate and the guide rail is further ensured.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Guide shell structure for water pumps

InactiveCN104847701AThe structure of the diversion shell is compact and tightImprove qualityPump componentsPumpsImpellerEngineering

The invention belongs to the technical field of pump supplies, in particular to a guide shell structure for water pumps. The guide shell structure comprises a plurality of guide blades; the left and right of and the outside of the guide blades are fixed through a left cover and a right cover; the inner sides of the guide blades are fixed through inner braces so that the guide blades are evenly distributed between the left cover and the right cover; a left shell and a right shell are provided outside the left cover and the right cover; an impeller ring seat is fitted to the upper ends of the left and right covers; a moving impeller ring is arranged on the impeller ring seat; an impeller ring cover is disposed above the moving impeller ring and is fitted to the impeller ring seat; an inner sleeve seat is welded to the inner braces; guide blade sleeves are embedded in the inner sleeve seat. The guide shell structure has the advantages that a fit gap between the impeller ring and an impeller in the guide shell can be effectively guaranteed, coaxiality of the impeller is also ensured after a pump shaft is mounted, and operating efficiency of a pump can be relatively improved and ensured.

Owner:ZHEJIANG NANYUAN PUMP IND CO LTD

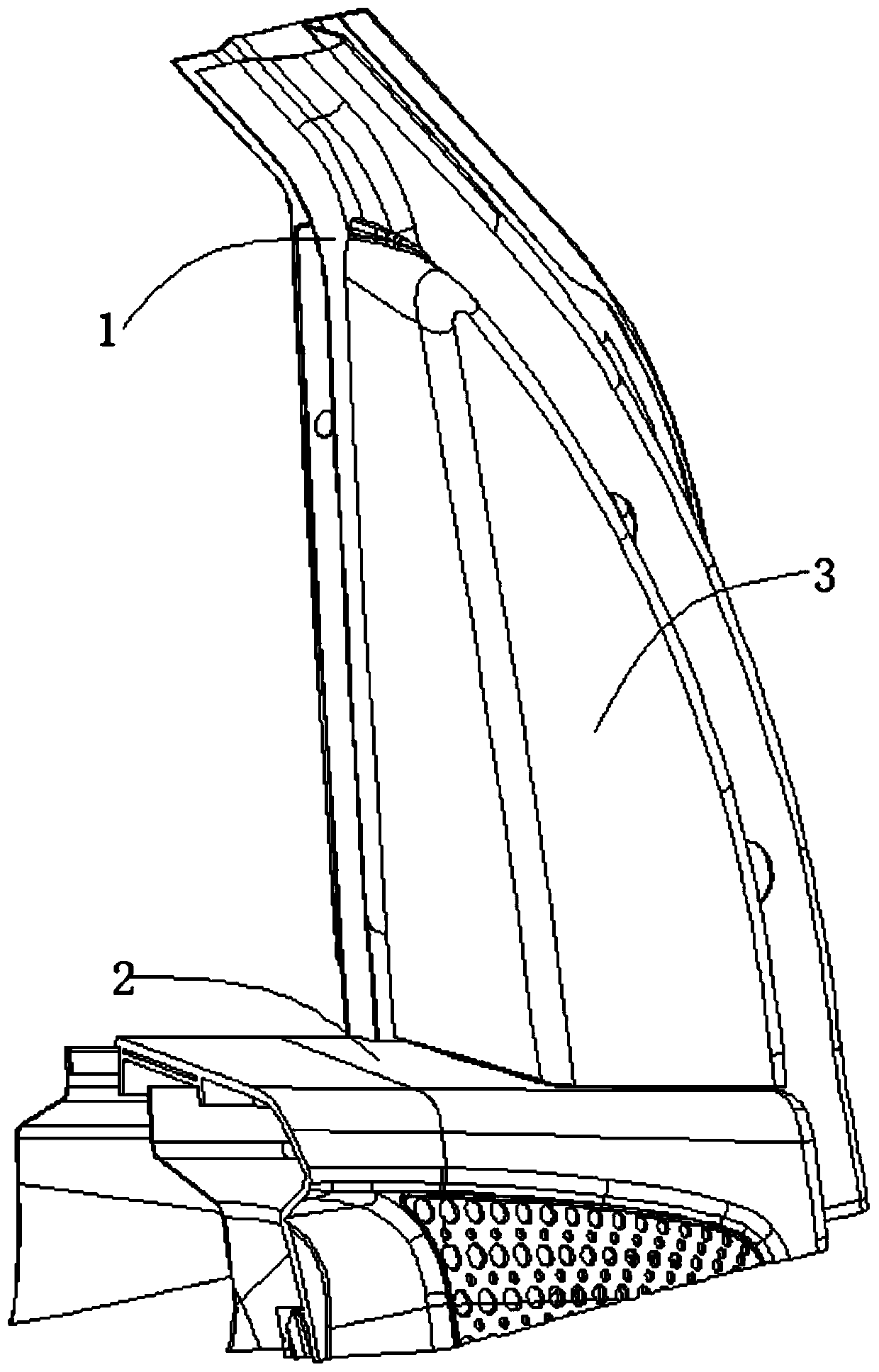

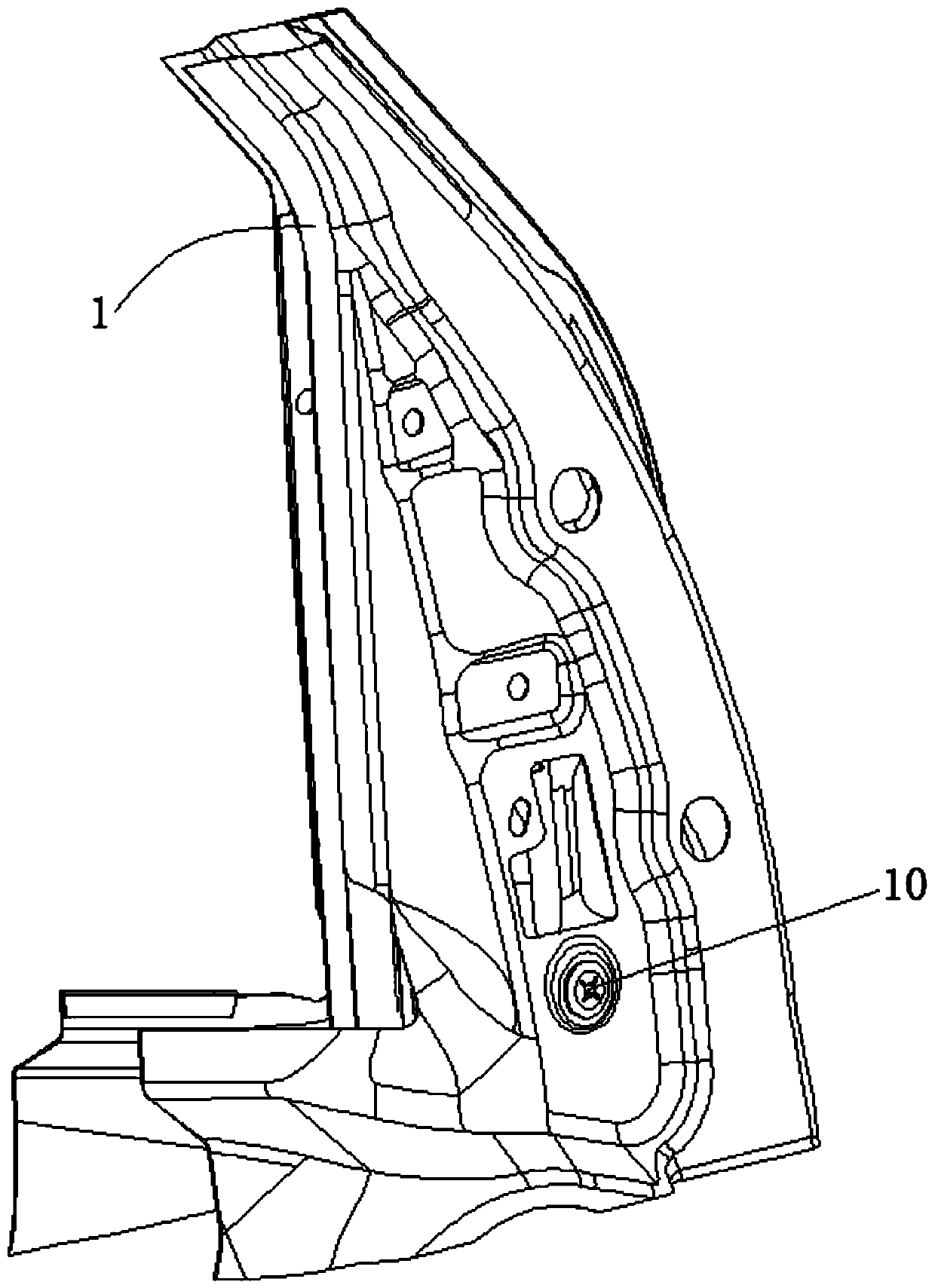

Matching structure of door guard plate and inner triangular block and assembling process of matching structure

PendingCN111469637AGuaranteed Y-direction positionAvoid large gapsDoorsVehiclesScrew threadEngineering

The invention discloses a matching structure of a door protection plate and an inner triangular block and an assembling process of the matching structure. The matching structure comprises a door metalplate, a door guard plate, an inner triangular block and a screw, wherein a threaded hole is formed in the door metal plate, a cylindrical hole is formed in the middle of the upper end of the door guard, the screw penetrates through the cylindrical hole and is screwed in the threaded hole so as to enable the door guard plate to be tightly matched with the door metal plate, a cross-shaped positioning hole is formed beside the cylindrical hole, a first clamping groove and a second clamping groove are formed in the two sides of the upper end of the door guard plate, a third clamping groove is formed in the side edge of the door guard plate, a cross-shaped positioning pin is arranged in the middle of the lower end of the inner triangular block, a first inserting buckle and a second insertingbuckle are arranged on the two sides of the cross-shaped positioning pin respectively, a third inserting buckle is arranged on the side edge of the lower end of the inner triangular block, the inner triangular block is connected with the door guard plate in a matched mode, the cross-shaped positioning pin is inserted into the cross-shaped positioning hole for positioning, the first inserting buckle is inserted into the first clamping groove for clamping, the second inserting buckle is inserted into the second clamping groove for clamping, the third inserting buckle is inserted into the third clamping groove for clamping, and the position degree of the door guard plate in the Y direction is ensured; and the position degree of the inner triangular block in the X direction or the Z directionis ensured.

Owner:ZHEJIANG UFO AUTOMOBILE MFG CO LTD +1

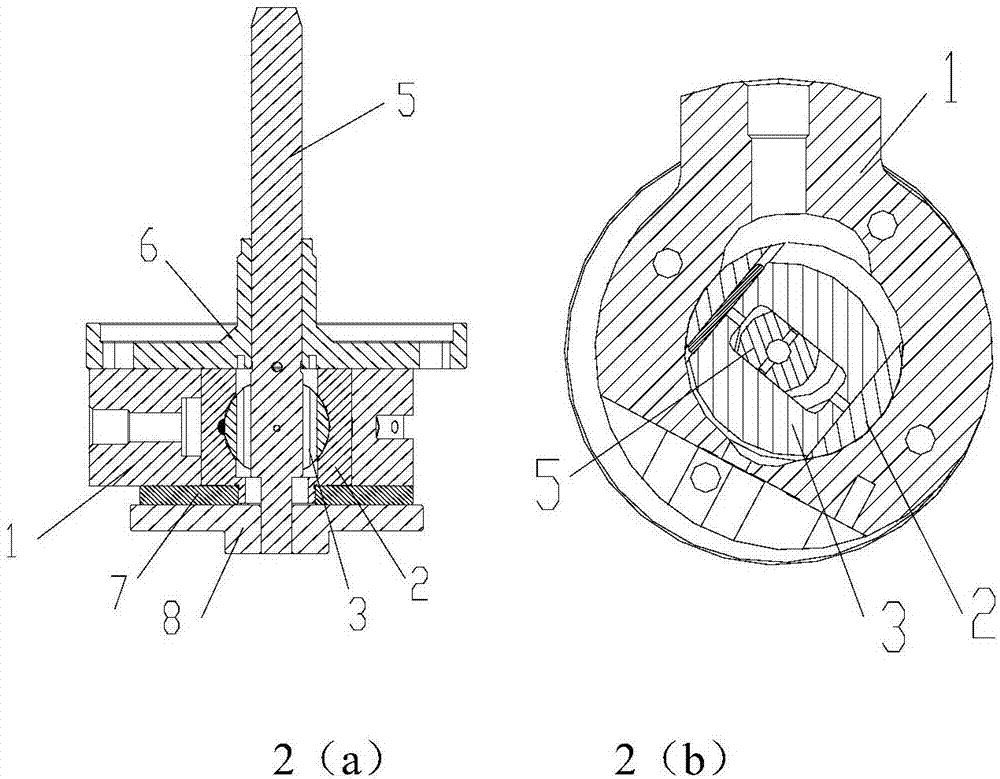

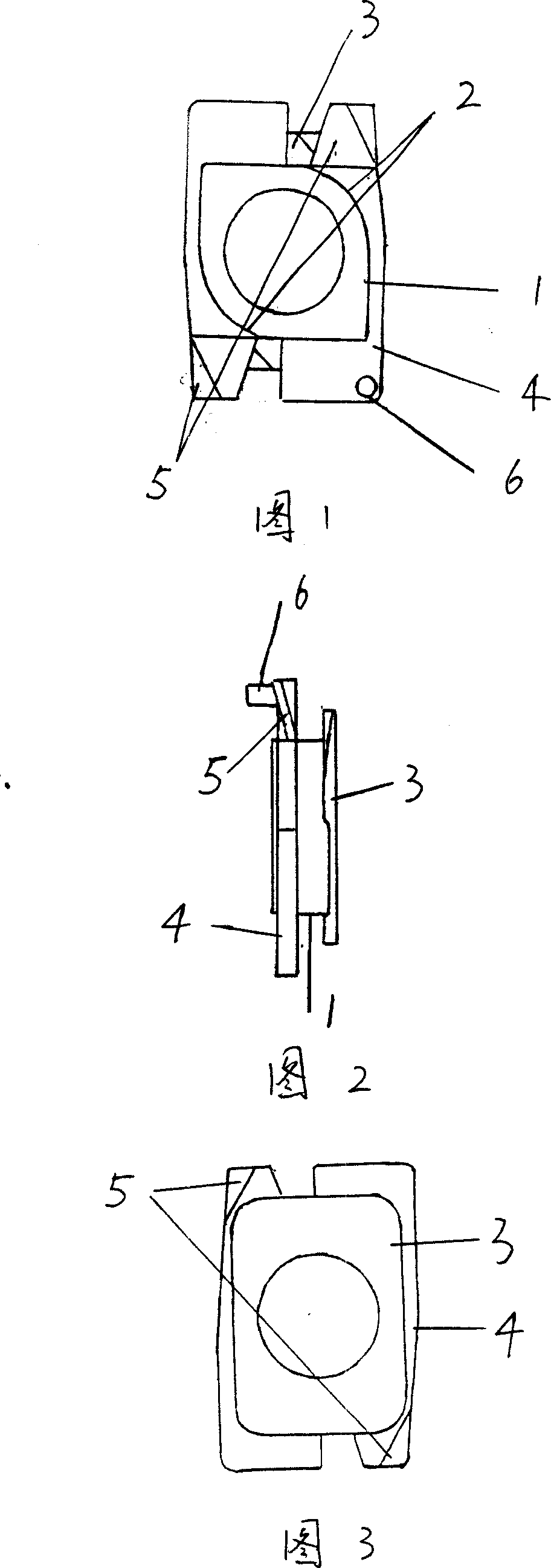

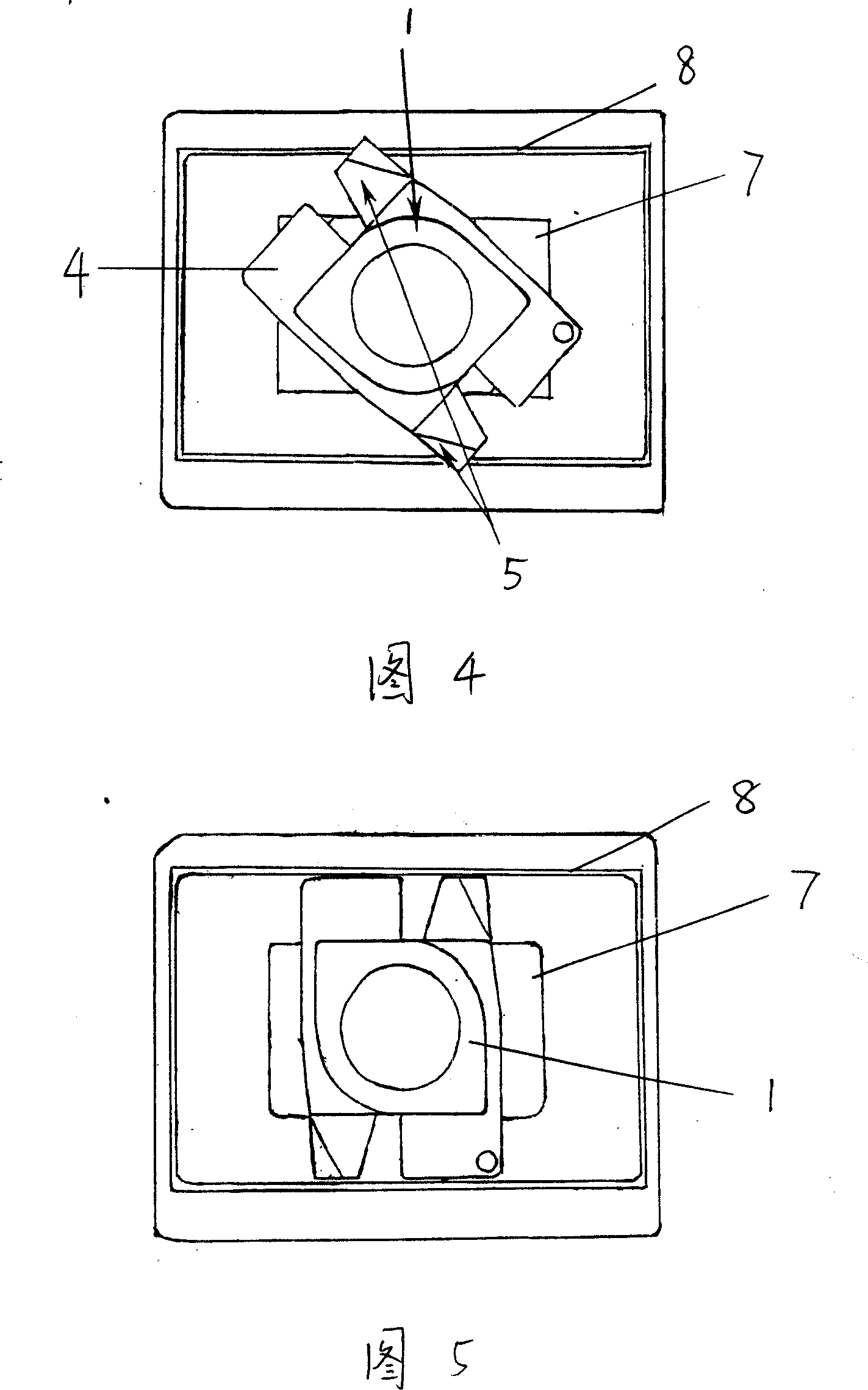

A rotary cylinder piston compressor

ActiveCN106065854BPrevent rotationEasy to assemblePositive displacement pump componentsMulti-stage pumpsControl theoryPiston

The invention provides a rotating cylinder piston compressor. The rotating cylinder piston compressor comprises an air cylinder sleeve (1), an air cylinder (2) arranged in the air cylinder sleeve (1) and a piston (3); a round piston hole (22) penetrating the air cylinder (2) is arranged on the air cylinder (2) in a manner of being perpendicular to the axis direction of the air cylinder (2), and the piston (3) is arranged in the piston hole (22) in a manner of being matched in shape; a first groove (21) is formed in the inner wall of the piston hole in the axial direction of the piston hole, and a guide limiting piece (4) is arranged on the side wall of the piston (3); and when the piston (3) and the air cylinder (2) are assembled, the guide limiting piece (4) is assembled in the first groove (21) in a sliding manner. By means of the rotating cylinder piston compressor, autoroatation of the piston can be prevented, furthermore, interference even air cylinder collision between the head of the piston and the inner circle of the air cylinder can be prevented from occurring, a fit clearance between the piston and the piston sleeve can be effectively guaranteed, the assembling performance of the compressor is improved accordingly, and the efficiency of the compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Sealing structure between stator and rotor of aero-engine

InactiveCN107965391AGuaranteed work performanceImprove safety and reliabilityLeakage preventionGas turbine plantsEngineeringAero engine

The invention relates to a sealing structure between a stator and a rotor of an aero-engine. The sealing structure is fixed on a stator piece and comprises an annular mandrel, brushing wires, a hoop ring, an annular pressing plate and an annular supporting plate; the multiple strands of brushing wires are wounded around the annular mandrel, the tail ends of the brushing wires face the inner side of the annular mandrel, the hoop ring is bent into an arc shape to fix the brushing wires on the annular mandrel, and the annular supporting plate and the annular pressing plate are assembled togetherto form an annular cavity; and an annular groove opening is formed in the inner circumferential surface of the annular cavity, the annular mandrel, the brushing wires and the hoop ring are assembled in the annular cavity, and the brushing wires stretch out from the annular groove opening. According to the sealing structure between the stator and the rotor of the aero-engine, the air leakage rate between the rotor and the stator can be effectively reduced, performance of the engine original design state is kept, and safety and reliability of engine work are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Block type energy-saving DC ceiling fan motor

PendingCN110380541AImprove efficiencyConcentration of magnetic densityWindingsMagnetic circuit rotating partsCeiling fanPower mode

The invention discloses a block type energy-saving DC ceiling fan motor. A core is a split structure, the structure of a ceiling fan motor is made to be more reasonable through an improved matching structure, production is more convenient, and energy saving and environmental protection are achieved. The ceiling fan motor includes a housing assembled by an upper housing and a lower housing, whereina plastic ring is mounted inside the housing, an inner wall of the plastic ring is fixedly equipped with an iron ring, a magnet is fixed to an inner wall of the iron ring through a fixing ring, a core is fixedly mounted at the iron ring center, the core is respectively fixed with an upper winding frame and a lower winding frame up and down, the core is assembled from four one fourth arc-shaped core bodies, a shaft penetrating through the center of the housing is further included, the shaft penetrates through a rear bottom end of the upper housing and is rotatably mounted on a bearing, the bearing is fixedly mounted at the center of the lower housing, the position where the shaft penetrates through is further equipped with the bearing, a control board is driven in a multi-power mode, and the more convenient wider use environment is provided for a user.

Owner:FOSHAN NANHAI YUANZUAN ELECTRIC APPLIANCE CO LTD

Method and equipment thereof for buckling-riveting outer sleeve of push-pull flexible shaft

The invention discloses a method and equipment thereof for buckling-riveting an outer sleeve of a push-pull flexible shaft, which are used for automobiles or engineering machinery and the like. Through the method and the equipment, an inner hole of an inner lining tube can be effectively prevented from deformation, the tensile force bearing capacity of a pipe joint is improved, and the service life of the push-pull flexible shaft is prolonged. The method comprises the following steps of: inserting the inner lining tube of a pressure hose inserted into a sleeve joint and placing the sleeve joint onto a buckling-riveting mold; starting a hydraulic system, making an external mold axially move to force an elastic mold pressing element set, so that mold pressing elements are radically retracted to rivet and press the sleeve joint; and changing a direction, making a piston rod of an oil cylinder drive the external mold to reversely move, expanding the elastic mold pressing element set and pulling a core rod out. The buckling-riveting equipment comprises the hydraulic system, the buckling-riveting mold, a stander and the like, wherein the buckling-riveting mold is provided with the external mold with an inner taper hole and the elastic mold pressing sheet set formed into an outer conical surface; springs are arranged between every two mold sleeves; the elastic mold pressing element set is in contact with a stopper; the piston rod of the oil cylinder is connected with the external mold; and a core pulling device comprising a cylinder and the core rod is arranged axially.

Owner:LIUZHOU JINYUAN MACHINERY MFG

A ground wire assembly

ActiveCN105703097BGuaranteed path of movementAvoid offsetElectric connection structural associationsSwitchgearEngineeringMechanical engineering

The invention discloses a ground wire assembly comprising a main rod body and an auxiliary rod body which are arranged in parallel. The top end of the main rod body is provided with a fixing head restraint matched with a wiring terminal. The top end of the auxiliary rod body is provided with a movable head restraint clamped and matched with the fixing head restraint. A guiding aperture is arranged in the fixing head restraint along an axial direction of the main rod body. The tail end of the movable head restraint is movably inserted in the guiding aperture and is in hinged connection with the auxiliary rod body. The middle portion of the main rod body is provided with an adjusting gear in a rotatable mode. The axis of the adjusting gear is perpendicular to the axis of the main rod body. A matched surface between the tail end of the auxiliary rod body and the main rod body is provided with a tooth bar engaged with the adjusting gear in a matched mode. The connection structure of the ground wire assembly is safe and reliable, and the operation process is simple to perform.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +2

A laser repair method for heavy-duty gas turbine hub mortise teeth

ActiveCN106757005BLittle impact on working statusGuaranteed fit clearanceContinuous combustion chamberMetallic material coating processesCrack freeEngineering

Owner:沈阳大陆激光工程技术有限公司

A Stator Core Lamination Welding Die

ActiveCN109702403BGuaranteed roundnessWon't strainWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a stator core lamination welding mold. The stator core includes a stator upper ring, a stator lower ring, a stator punch and a plurality of stator pull plates, and the stator punch is arranged between the stator upper ring and the stator lower ring. , a plurality of stator pull plates are evenly distributed on the outer periphery of the stator punching sheet, the welding mold includes an upper pressing plate, a lower pressing plate, an inner tube and an outer tire, the inner tube and the outer tire are arranged between the upper pressing plate and the lower pressing plate, and the outer tire includes a plurality of fan-shaped blocks, the fan-shaped blocks The number is equal to the number of stator pull plates, the inner surface and outer surface of the sector block are arc-shaped, multiple sector blocks are evenly arranged along the outer circumference of the inner tube, and the outer circumference of the plurality of sector blocks is provided with limit pieces, the outer surface of the inner tube is The tapered surface of the inner tube, the inner surface of the sector block is the tapered surface of the outer tire matched with the tapered surface of the inner tube, and the outer surface of the sector block is matched with the inner surface of the stator punch. The invention only applies anti-deformation to the welding deformation position of the stator pull plate, thereby effectively offsetting the welding deformation and ensuring the inner roundness of the stator iron core.

Owner:湖南中车商用车动力科技有限公司

Positioning fixture and processing method for rotor cover of gyro motor dynamic pressure air bearing

ActiveCN114589520BPrecise positioningRestricted freedom of movementWork clamping meansPositioning apparatusAir bearingElectric machinery

The invention relates to a precision turning processing method and a positioning fixture for thin-walled parts, in particular to a positioning fixture and a processing method for a rotor cover of a dynamic pressure air bearing of a gyro motor. The positioning fixture includes a spherical positioning mandrel, a positioning collar, a vibration damping pad, and a back-facing support seat. The spherical positioning mandrel is a stepped shaft with top holes provided on both ends, and includes a clamping section, a large thread section, a second guide cylinder section, a spherical positioning section, a ball table end face, and a first guide cylinder arranged in sequence from left to right. segments and small thread segments. The processing method includes the steps of the first step processing of the rotor cover, processing a series of spherical positioning mandrels, processing the positioning collar and the back support seat, selecting a suitable spherical positioning mandrel, and turning the rotor cover. The invention solves the problems of poor positioning accuracy, low processing efficiency, and crushing of the concave spherical surface in the existing processing methods, avoids the damage of the concave spherical surface by limiting 6 degrees of freedom, and ensures the processing accuracy of the rotor cover.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Detachable goods shelf cross beam

PendingCN111503104AEasy to assemble and disassembleReduce volumeRod connectionsShow shelvesStructural engineeringMechanical engineering

The invention discloses a detachable goods shelf cross beam. According to the technical scheme, the detachable goods shelf cross beam is characterized by comprising a cross beam pipe, the two ends ofthe cross beam pipe are detachably connected with buckle plates, the buckle plates are provided with inserting parts inserted into an inner cavity of the cross beam pipe, the inserting parts are matched with the inner wall of the cross beam pipe, and fixing structures are arranged between the inserting parts and the cross beam pipe. According to the detachable goods shelf cross beam, the weighingstrength of the goods shelf cross beam is ensured while the cross beam pipe and the buckle plates are convenient to disassemble and assemble, and the carrying size of the goods shelf cross beam is reduced.

Owner:浙江上虹货架有限公司

Motorcycle taillight base

InactiveCN100489380CImprove structural rigidityImprove appearance qualityRoad vehiclesLight fasteningsEngineeringImpurity

The motorcycle tail lamp base comprises the base body with sealed slot outside the base with protruding light block rib. It can be installed from inside the covering piece to outside, through setting a ring of extending light block rib to avoid the impurities inside the vehicle to effectively solve the issue of light leakage to ensure the convenience for light bulb change.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

Sliding bracket for automobile lamp fixture mounting groove

Owner:华域视觉科技(重庆)有限公司

Eccentric sleeve mechanism with support bearing

The invention provides an eccentric sleeve mechanism with a support bearing. The mechanism comprises an outer sleeve, an eccentric inner sleeve, an upper roller bearing, a lower roller bearing and a large bevel gear; the outer sleeve is fixedly mounted at the bottom of a cone machine frame; the eccentric inner sleeve is movably mounted in the outer sleeve through the upper roller bearing and the lower roller bearing; and the large bevel gear for driving the eccentric sleeve mechanism is mounted at the bottom of the eccentric inner sleeve. The mechanism is characterized by further comprising anupper end cover, a plane bearing, a bottom end cover and adjusting gaskets; the bottom end cover is fixedly mounted at the bottom of the outer sleeve; the plane bearing for supporting the eccentric inner sleeve is mounted on the upper end surface of the bottom end cover; and multiple adjusting gaskets for adjusting a gear matching gap are mounted in the connected place of the outer sleeve with the cone machine frame. The mechanism can guarantee the stability of the eccentric sleeve in the rotary moving process, so that the stability of the gear gap between the large bevel gear and the drivingbevel gear is improved, and the stop time in the production process and the maintenance cost are reduced.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

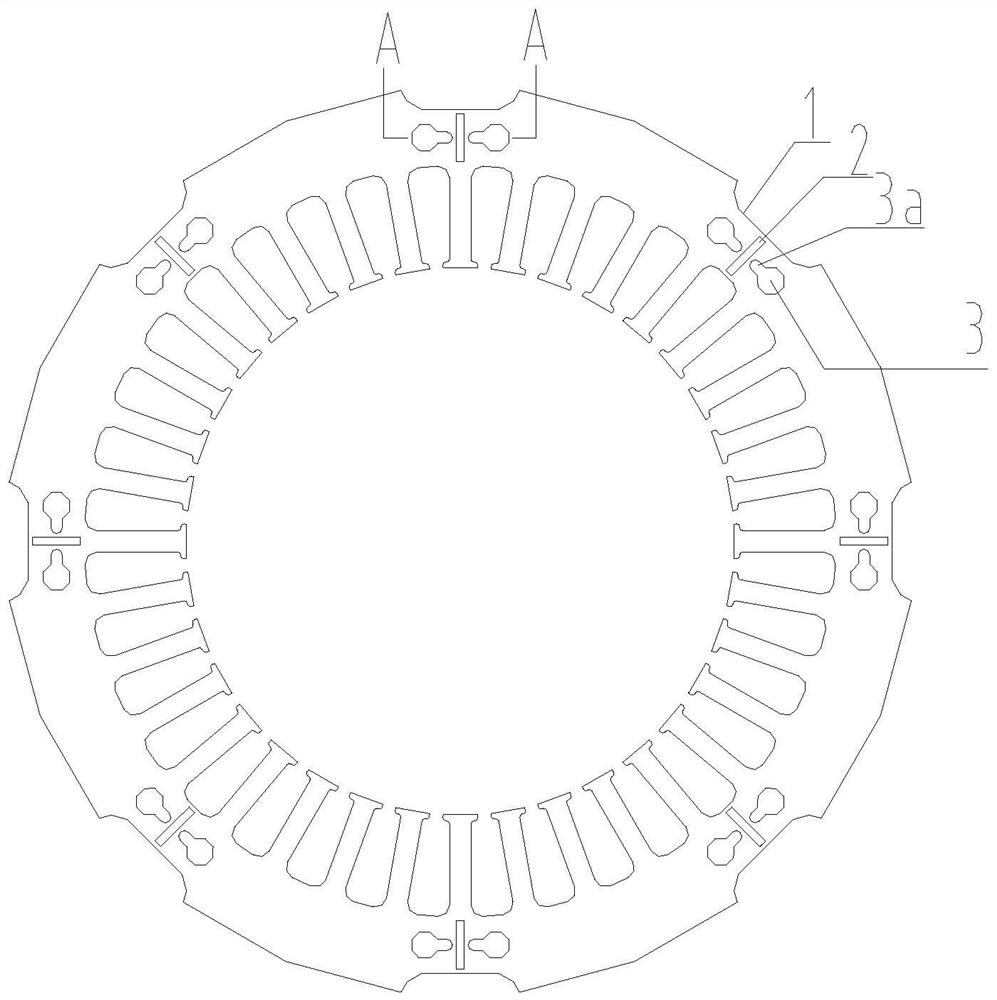

Motor stator, motor and compressor

ActiveCN114243956AStable structureGuaranteed fit clearanceMagnetic circuit stationary partsSupports/enclosures/casingsPunchingElectric machine

The invention provides a motor stator, a motor and a compressor, the motor stator comprises a plurality of punching sheets which are overlapped and buckled, the edge of each punching sheet is provided with n grooves at intervals, and the opening of each groove faces the outer side of the motor stator, so that a non-contact gap is formed between the motor stator and a motor shell; and a buckling point is correspondingly arranged on the inner side of each groove. The U-shaped groove is formed in the outer circle of the iron core of the motor stator, so that a non-contact gap is formed between the iron core and the motor shell, that is, the motor shell is not in hard contact with the buckling point on the punching sheet through a tangible structure, and therefore extrusion stress generated when the motor stator and the motor shell are assembled through a hot jacket cannot be transmitted to the buckling point, and the reliability of the motor stator is improved. Therefore, the buckling points are not loosened or deformed, the stability of the overall structure of the stator is ensured, and the fit clearance between the inner circle of the stator core and the rotor is kept.

Owner:GREE ELECTRIC APPLIANCES INC

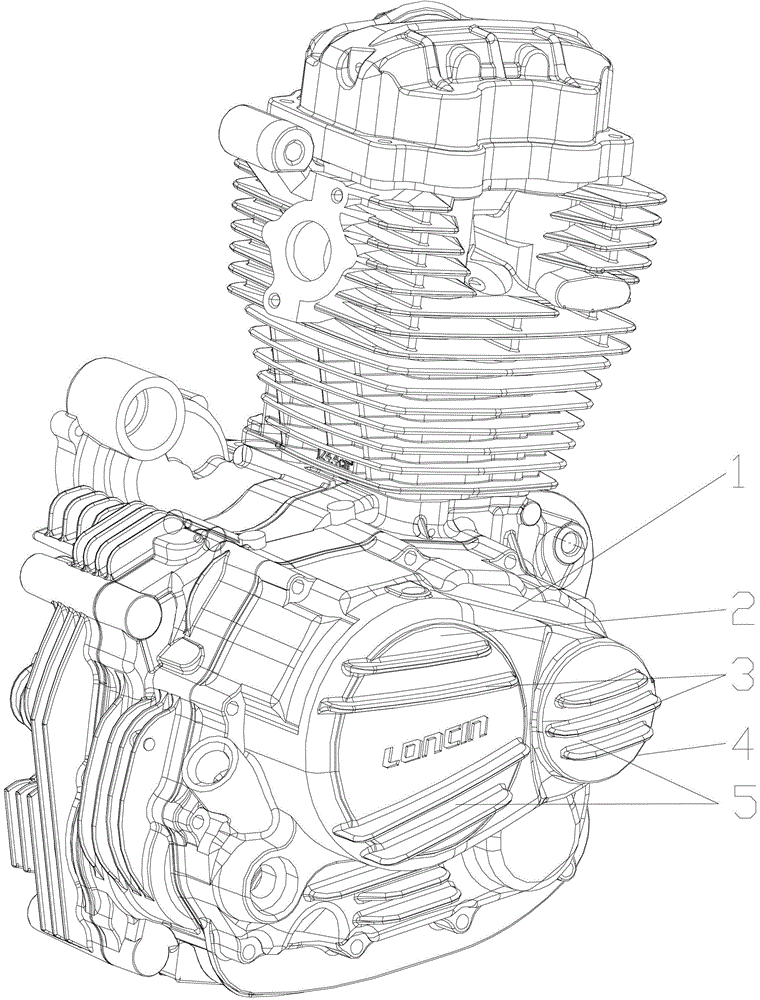

Cooling type motorcycle engine crankcase side cover, crankcase and its motorcycle

The invention provides a radiating crankcase side cover of a motorcycle motor. The radiating crankcase side cover comprises a side cover body; and radiating fins are arranged on the external surface of the side cover body. By the arrangement of the fins, radiating area of crankcase side cover is increased, heat of the crankcase can be rapidly radiated, so that deterioration of lubricating oil in the crankcase is avoided and fit clearance between driving pieces is maintained in a normal range; and further structure is simple, and production is convenient.

Owner:LONCIN MOTOR

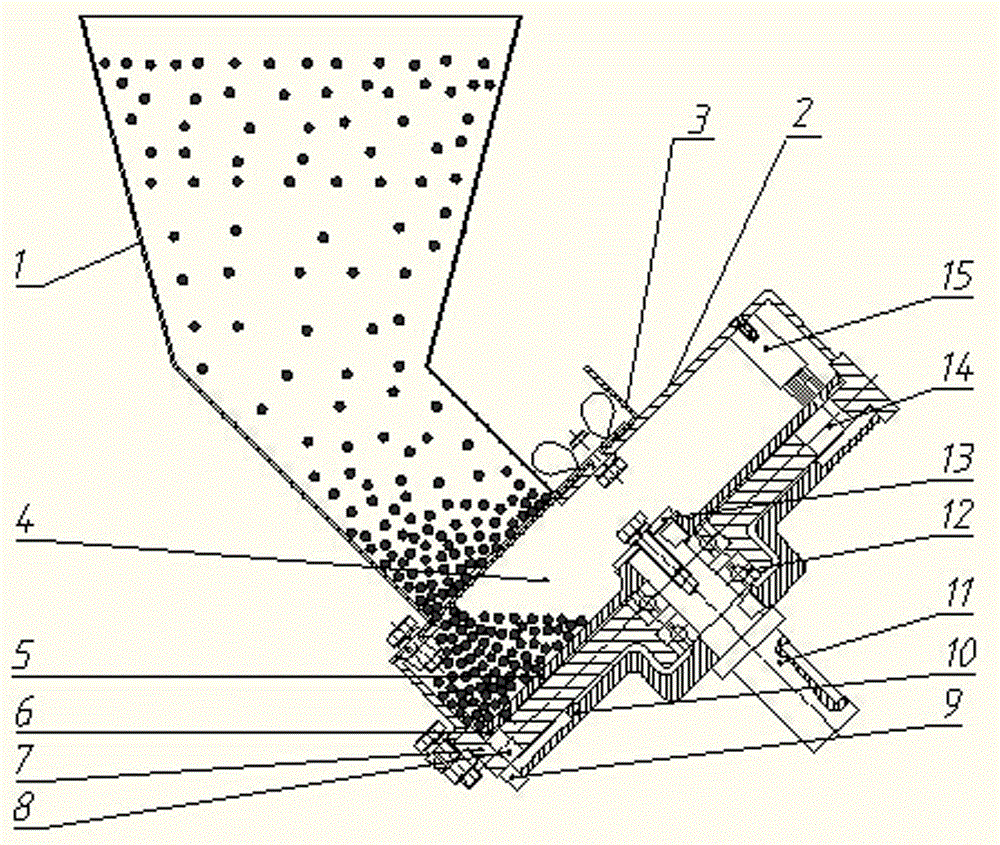

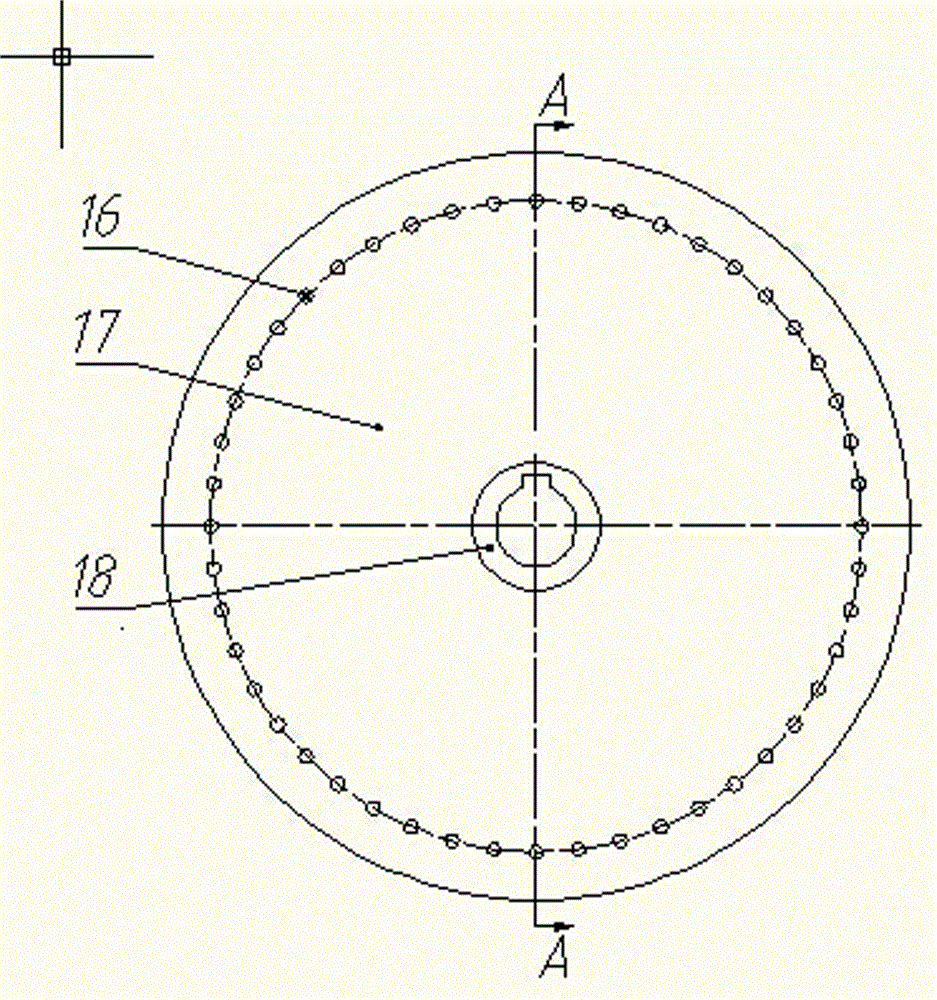

Inclined disc type small grain fine seed meter

ActiveCN104938105BReasonable design principleReliable design principleClimate change adaptationSeed depositing seeder partsEngineeringSeed drill

The invention discloses an inclined disk type small seed small-amount seed sowing device. The inclined disk type small seed small-amount seed sowing device comprises a seeding box, a seed filling room case, a seed entering quantity adjusting plate, a seed filling disk, a seed sowing device shell, a seed sowing disk and a seed sowing device shaft. The seed sowing device is installed on a seed sowing machine in a mode of inclining 30 to 60 degrees. The structures of the seed filling disk and the seed sowing disk are utilized, the whole seed sowing process is divided into four steps of seed filling, seed cleaning, seed inputting and seed sowing, the seeds are guaranteed to be sowed in the lowest position, the seed sowing height is lowered, the time on seed sowing is shortened, and seeds per bunch and intervals can be guaranteed effectively; according to the inclined disk type small grain small-amount seed sowing device, seed filling is conducted softly and automatically depending on the gravity, seed cleaning is conducted softly and automatically by utilizing the gravity, a seed cleaning brush is arranged, few seeds clamped in seed filling holes can be brushed down, and seed clamping and seed damaging are avoided; the seed filling disk and the seed sowing disk are exquisite in structure and are both provided with two bosses, positioning with rolling bearings is reliable, fit clearance with the seed sowing device shell can be guaranteed, friction with the seed sowing device shell is avoided, and the service life of the seed sowing device is prolonged greatly.

Owner:SHANXI AGRI UNIV

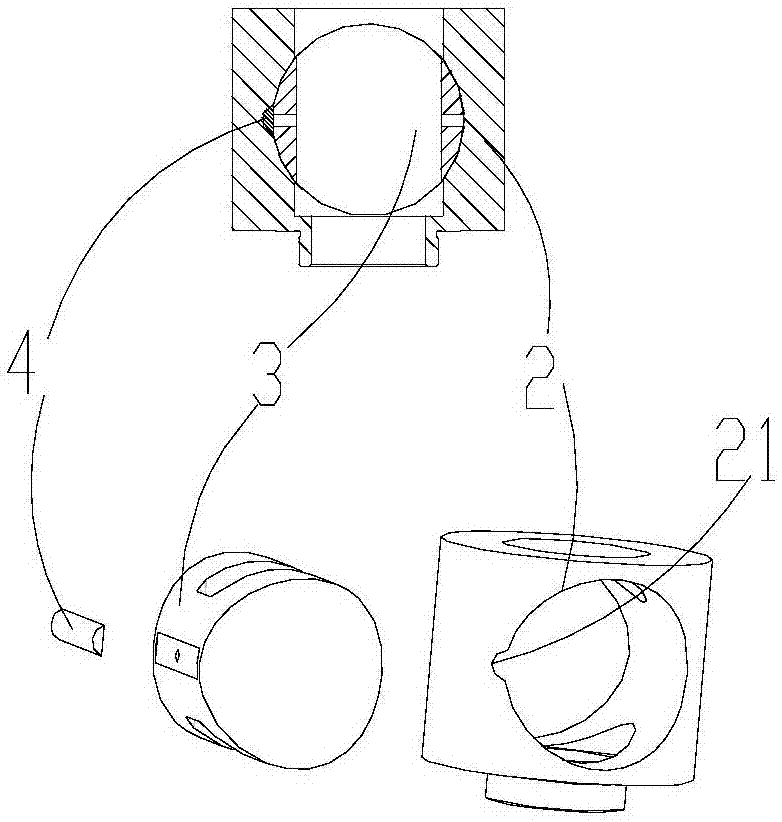

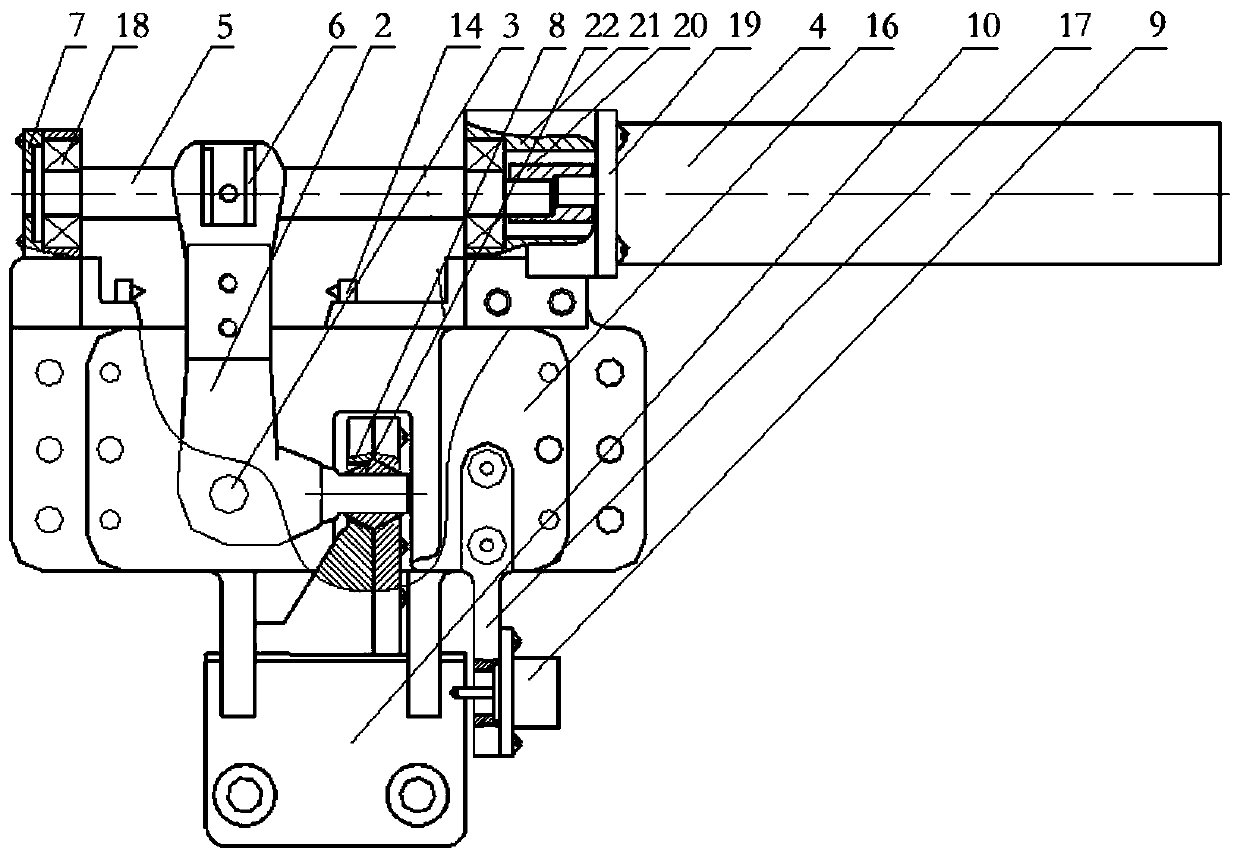

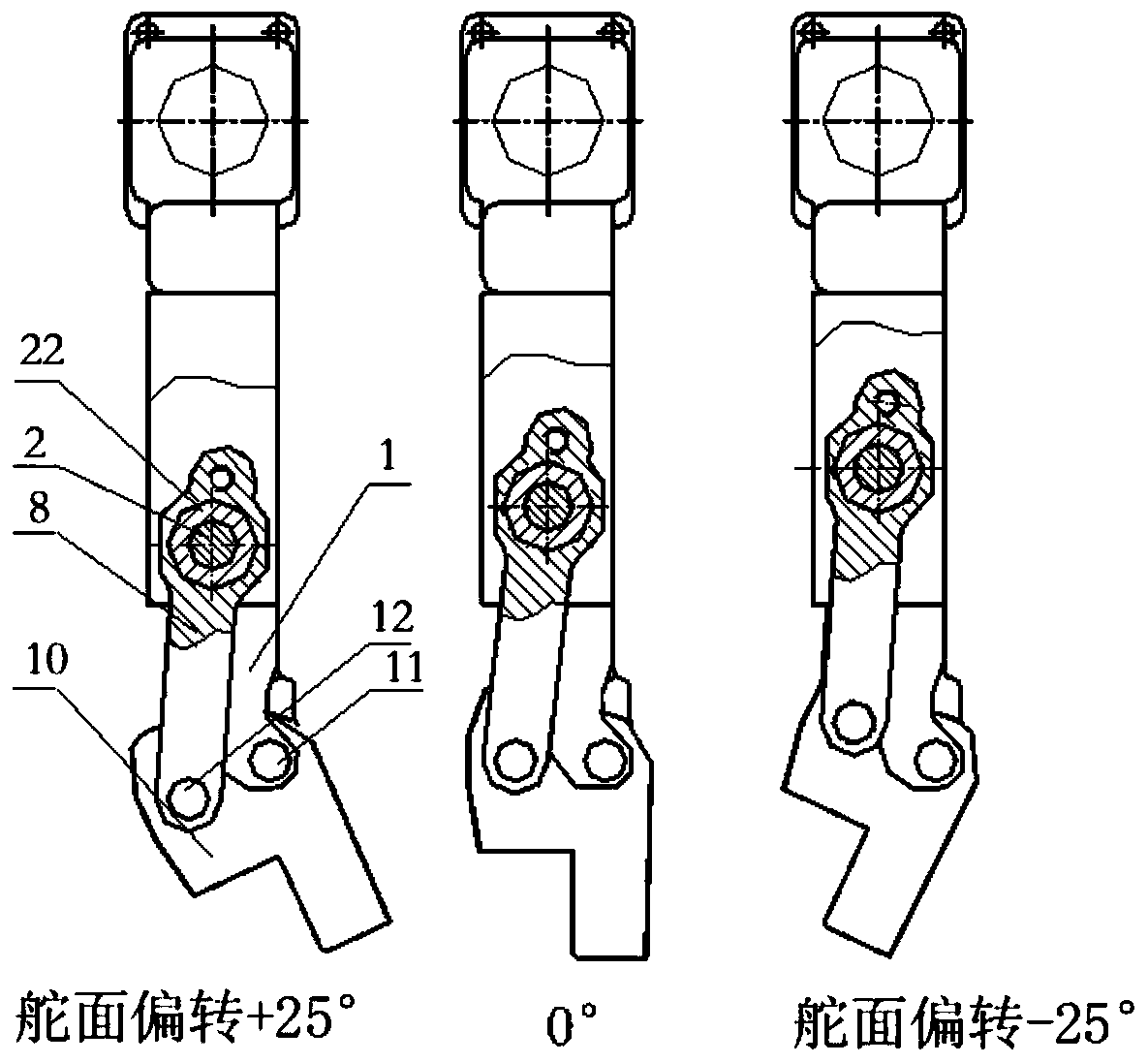

Automatic variable control surface speed reducing mechanism with feedback for pneumatic test

InactiveCN111337219AAchieve high torque transmissionGuaranteed angle adjustment accuracyAerodynamic testingAircraft components testingPush and pullAutomatic control

The invention discloses an automatic control surface changing speed reducing mechanism with feedback for a pneumatic test. Two cover plates in the mechanism respectively form a mounting cavity which is through up and down on the front and rear surfaces of the left and right supports; a shifting fork is mounted in the cavity through a rotating shaft; the upper end of the shifting fork is matched with a nut on a screw rod; the tail end of the shifting fork is matched with a ball socket of a spherical push rod through a ball head, the lower end of the spherical push rod is connected with a control surface mounting base through a movable shaft, the control surface mounting base is movably connected to the lower ends of the left support and the right support through a fixed shaft, and the center of the ball head is located between the center of the movable shaft and the center of the fixed shaft. A motor drives the screw rod to rotate forwardly and reversely, the nut linearly moves along the screw rod and drives the shifting fork to rotate forwardly and reversely around the rotating shaft, the lower end of the shifting fork drives the spherical push rod to push and pull the control surface mounting base, and the control surface mounting base angularly deflects around the fixed shaft. According to the invention, the conversion from high rotating speed and low torque to low rotating speed and high torque of the motor in a variable-control-surface steering engine can be realized in a limited space.

Owner:珠海伺动科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com