Motorcycle taillight base

A taillight base and motorcycle technology, applied to motor vehicles, road vehicles, lighting and heating equipment, etc., can solve the problems of light leakage and poor visibility, improve structural rigidity, improve appearance quality, and solve light leakage problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

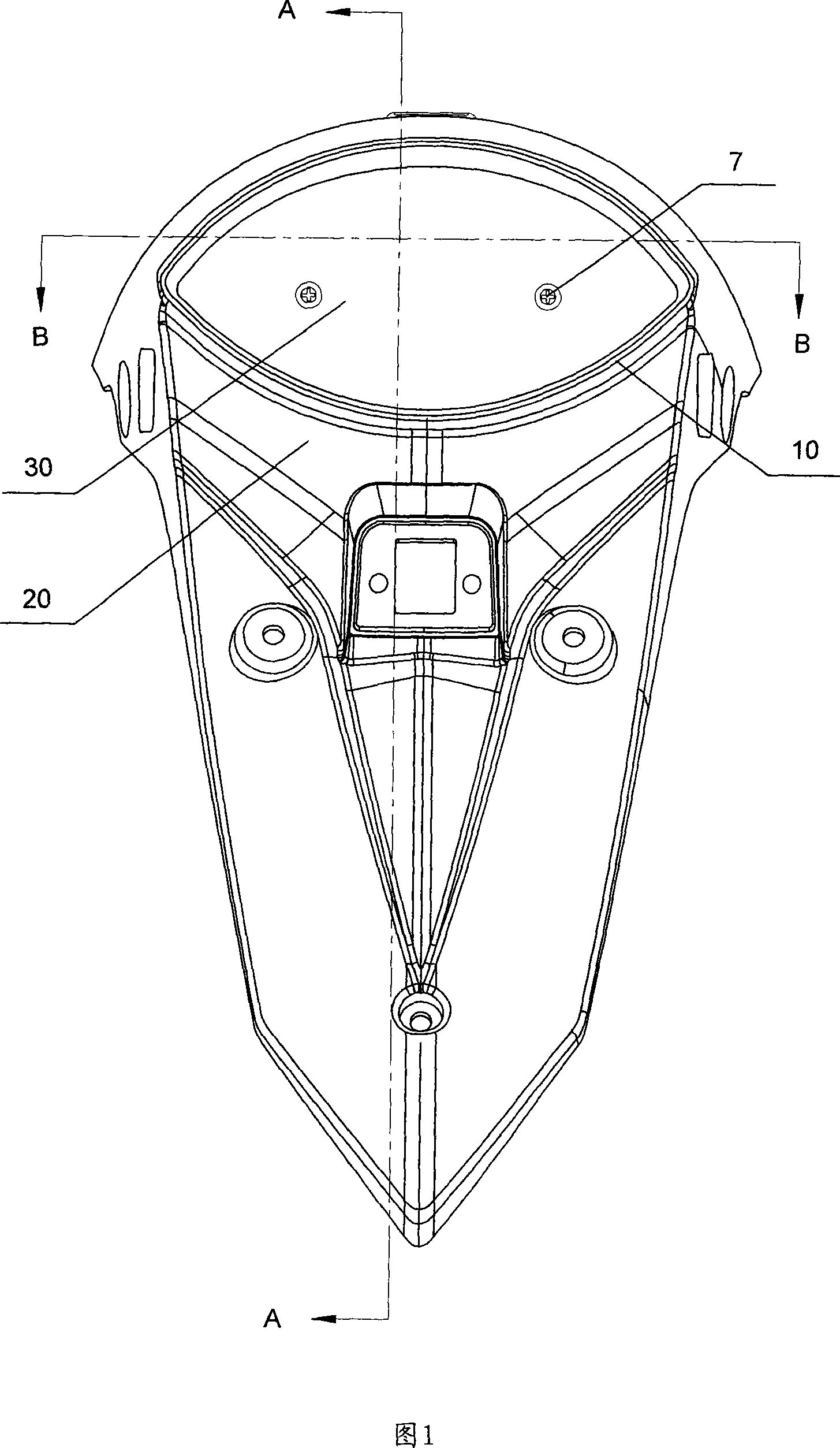

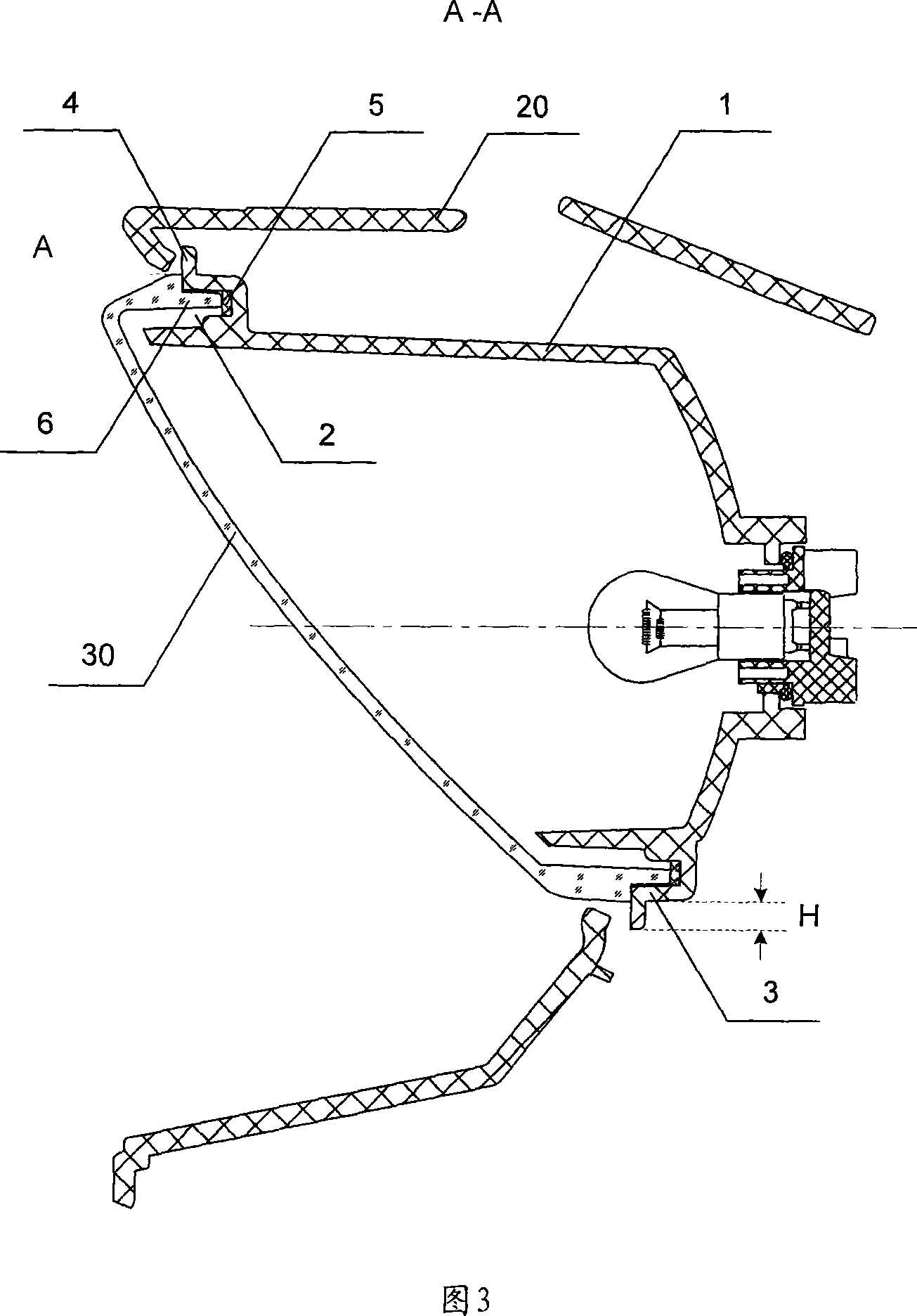

[0020] Fig. 1 is the assembling schematic diagram of motorcycle tail lamp base and lampshade, cover member of the present invention, Fig. 2 is the side view of Fig. 1 structure, Fig. 3 is A-A sectional view among Fig. 1, Fig. 4 is B-B sectional view among Fig. 1. Motorcycle tail light base 10 of the present invention comprises base body 1, and the outer edge of base body 1 is provided with a ring sealing groove 2, and a ring sealing rib 6 on the edge of lampshade 30 is inserted in sealing groove 2, and cover member 20 is buckled and is arranged on the ring shape of lampshade 30. On the surface. Specifically, a ring of sealing rubber strip 5 is arranged in the sealing groove 2 , which is pressed on the rear end of the sealing groove 2 by a ring of sealing ribs 6 on the edge of the lampshade 30 , and the lampshade 30 and the base body 1 are fastened and connected by two screws 7 . Since the manufacture of the lampshade requires that the annular surface A of the lampshade 30 shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com