A rotary cylinder piston compressor

A compressor and piston technology, applied in the field of compressors, can solve problems such as affecting the assembly and performance of the compressor, poor fit between the piston and the piston sleeve, interference and even collision with the cylinder, etc., so as to improve efficiency, reduce leakage, reduce The effect of frictional power dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

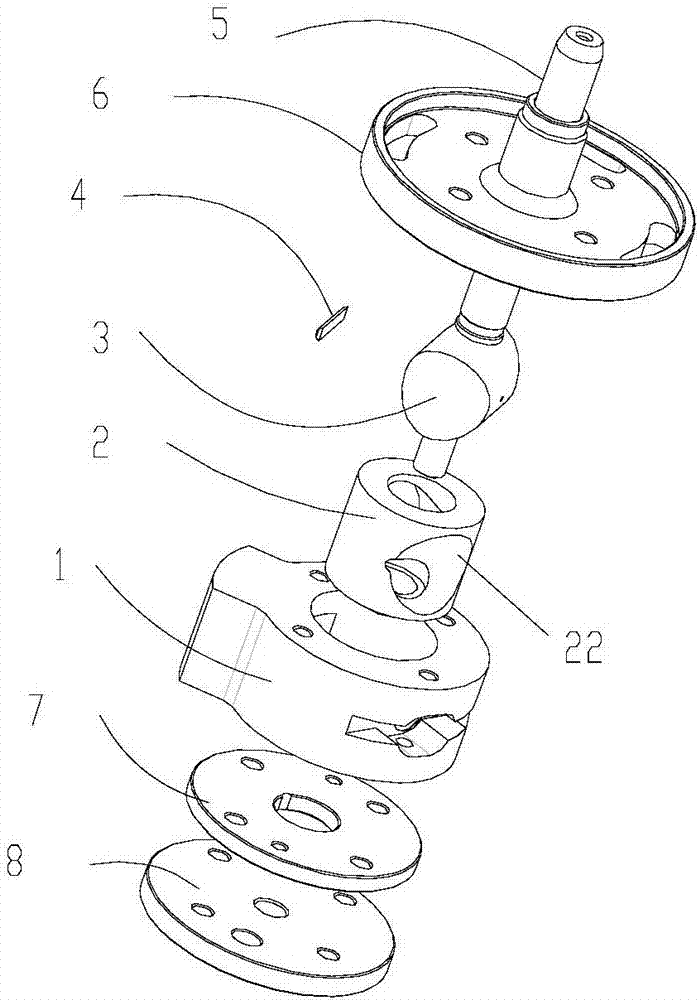

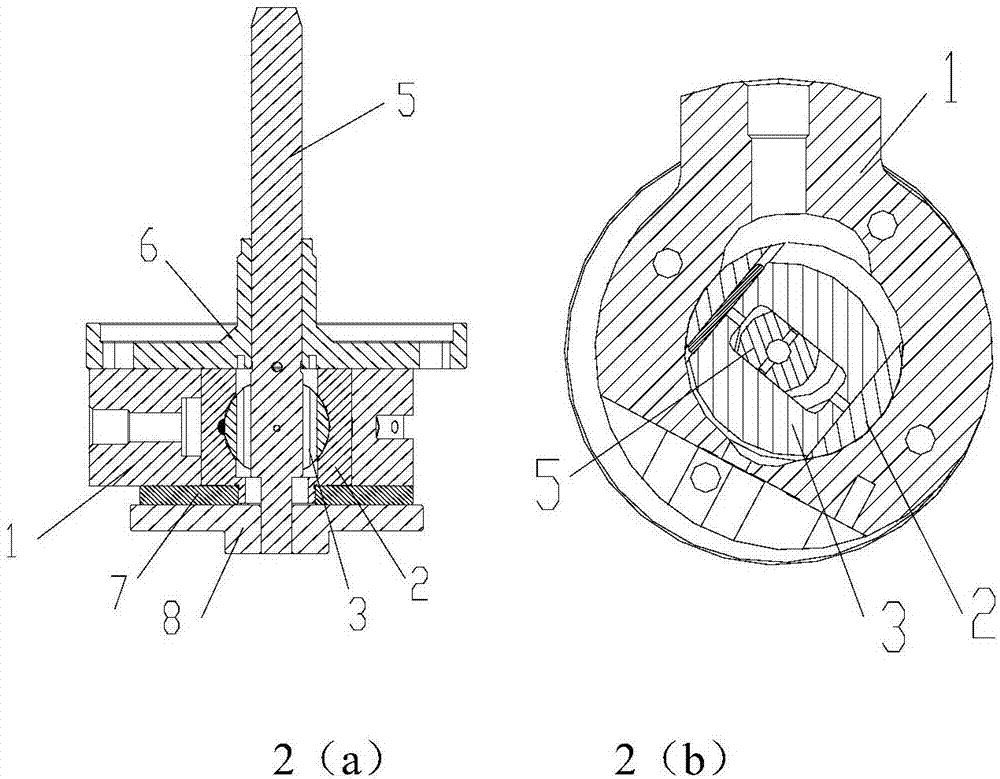

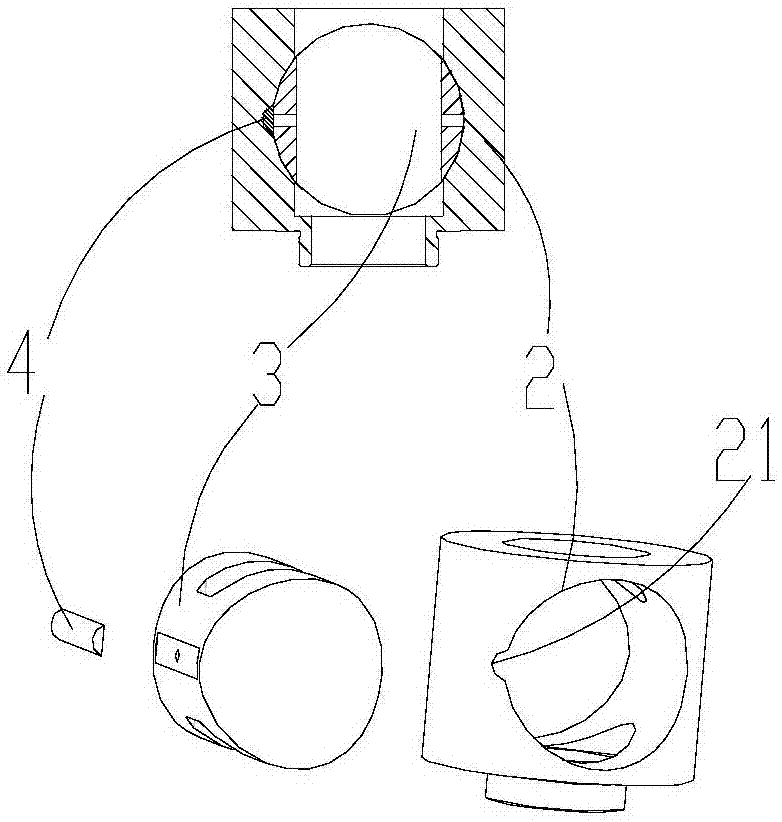

[0030] like Figure 1-3 As shown, the present invention provides a rotary cylinder piston compressor, which includes a cylinder liner 1, a cylinder 2 disposed in the cylinder liner 1, and a piston 3, wherein the axis of the cylinder 2 perpendicular to the cylinder 2 The direction is provided with a circular piston hole 22 that runs through the cylinder 2, the piston 3 is fitted in the piston hole 22, and the inner wall of the piston hole 22 is provided along the axial direction of the piston hole. The first groove 21, the side wall of the piston 3 is provided with a guide limiter 4, when the piston 3 and the cylinder 2 are assembled, the guide limiter 4 is slidably assembled on the first slot 21.

[0031] In the rotary cylinder piston compressor provided by the present invention, the piston hole is processed into a circle, and the piston is designed and processed into a shape matching with it, that is, a cylindrical structure, which can effectively ensure the gap between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com