Yield highly effective oil-well pump for mechanical oil production

A technology for mechanical oil extraction and oil pumping, which is applied in mechanical equipment, liquid variable capacity machinery, pumps, etc., can solve the problems of increased leakage, failure of the oil well pump, stuck plunger, etc., to reduce the impact of gas on the pump, Prevent liquid strike and air lock phenomenon and ensure the effect of matching clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

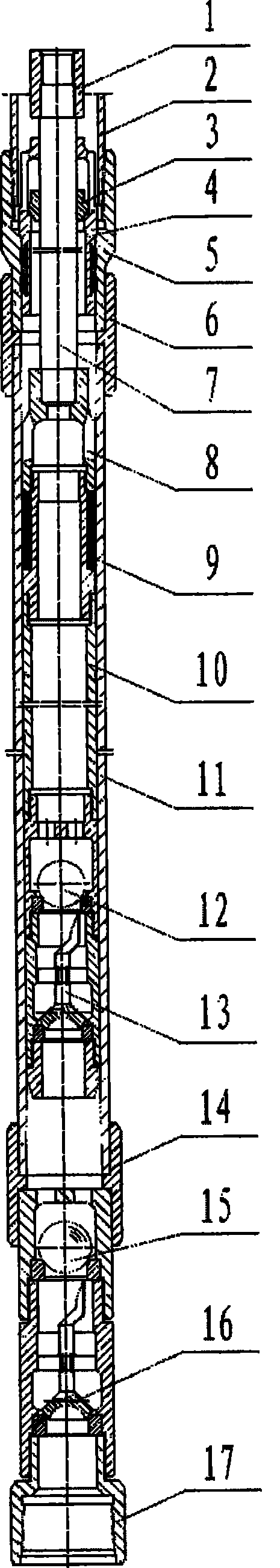

[0023] In the present invention, the soft seal plunger 9 is connected with the hard seal plunger 10, the upper part of the plunger is connected with the valve stem 7 through the upper open valve cover 8, the upper part of the valve stem is connected with the valve stem joint 1; the lower part of the plunger is connected with the oil outlet valve 12 , the lower part of the oil outlet valve is connected to the oil outlet speed opening valve 13.

[0024] The plunger is fitted with a pump barrel 11, the upper part of the pump barrel is connected to the support joint 5 through the upper pump barrel collar 6, and the upper part of the support joint is connected to the oil pipe 2; the lower part of the pump barrel is connected to the oil inlet valve 15 through the lower pump barrel collar 14, and the oil inlet The lower part of the valve is connected to the oil inlet quick opening valve 16, and the lower part of the oil inlet quick opening valve is connected to the oil inlet valve joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com