Sealing structure between stator and rotor of aero-engine

A technology for aero-engines and rotors, which is applied to engine components, machines/engines, mechanical equipment, etc. It can solve the problems of immature honeycomb and grate tooth repair technology and difficult maintenance, and achieve easy disassembly and maintenance and long service life , the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

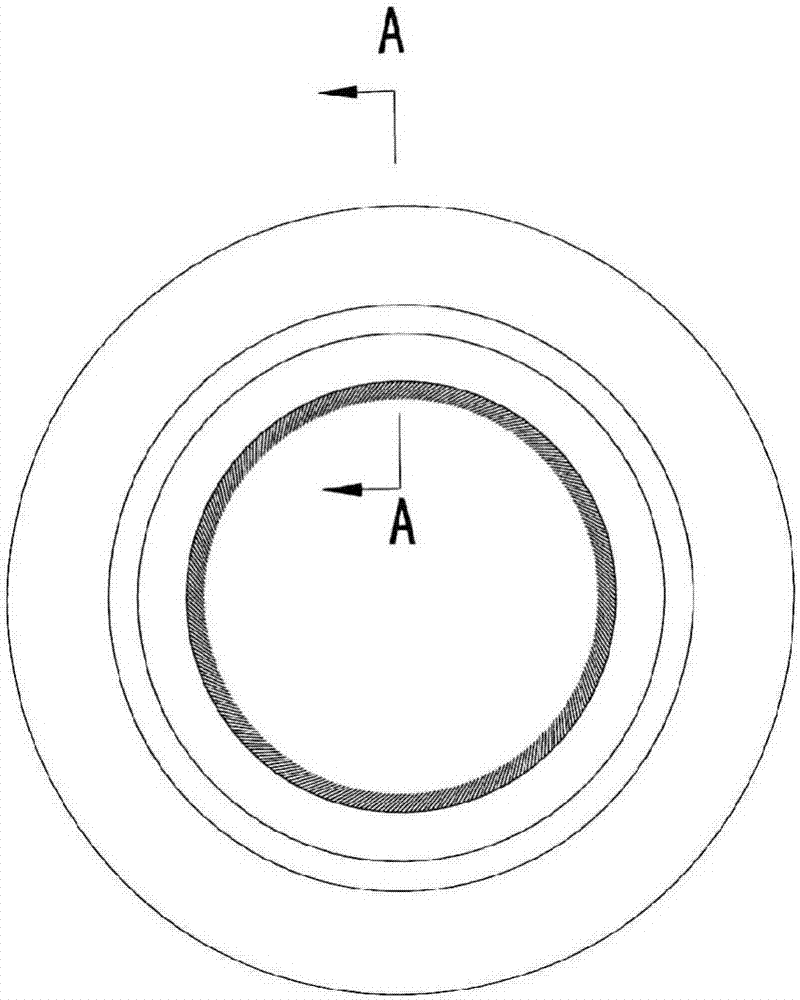

[0013] Such as figure 1 and figure 2 As shown, the sealing structure between the static rotors of an aero-engine of the present invention is in the form of a ring as a whole, and is fixed on the stator part 7 by a circle of screws 9 and a baffle 8, which is convenient for disassembly and maintenance. It specifically includes: an annular mandrel 1 , a brush wire 2 , a hoop 3 , an annular pressing plate 4 and an annular supporting plate 5 .

[0014] Multiple strands of the brush filaments 2 are wound on the annular mandrel 1 , and the ends of the brush filaments 2 face the inner side of the annular mandrel 1 . The hoop 3 is bent into an arc to fix the brush filament 2 on the annular mandrel 1 . The annular pressing plate 4 and the annular supporting plate 5 are assembled together to form an annular cavity, and an annular notch is formed on the inner peripheral surface of the annular cavity. The annular mandrel 1, the brush filament 2 and the hoop 3 are assembled in the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com