Eccentric sleeve mechanism with support bearing

A technology for supporting bearings and eccentric sleeves, which is applied in the direction of grain processing, etc., can solve the problems of roller bearing wear and affect the service life of bearings, and achieve the effects of stable operation, reduced maintenance costs, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

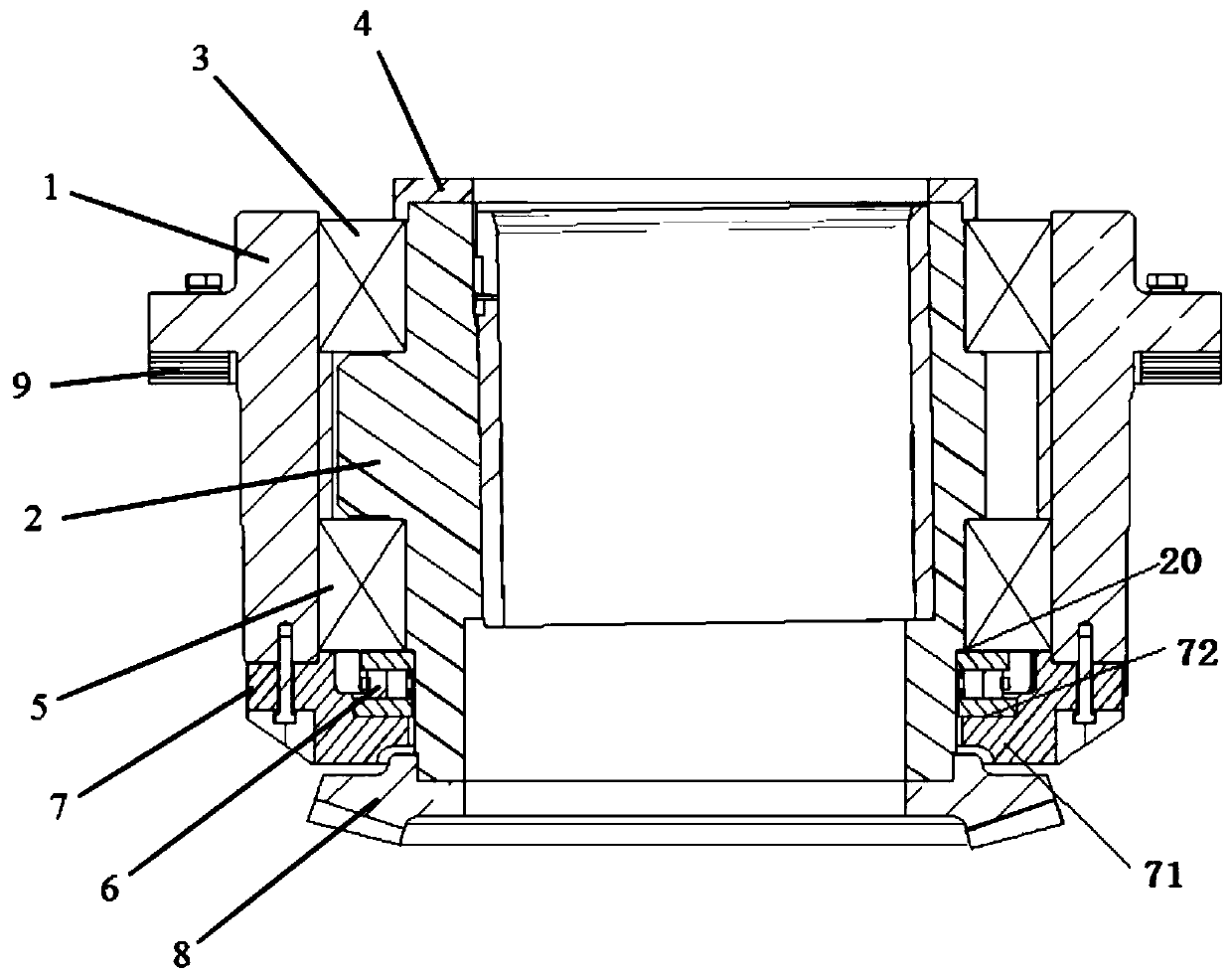

[0026] refer to Figure 1 to Figure 3 An eccentric sleeve mechanism with supporting bearings in the present invention comprises an outer sleeve 1, an eccentric inner sleeve 2, an upper roller bearing 3, a lower roller bearing 5 and a large bevel gear 8, and the outer sleeve 1 is fixedly mounted on a cone machine At the bottom of the frame 10, the inner wall of the outer sleeve 1 is provided with an upper roller bearing 3 and a lower roller bearing 5 sequentially from top to bottom, and the eccentric inner sleeve 2 passes through the upper roller bearing 3 and the lower roller bearing. 5 is movably installed in the outer sleeve 1, and the bottom of the eccentric inner sleeve 2 is equipped with a large bevel gear 8 for driving the eccentric sleeve mechanism, which is characterized in that it also includes an upper end cover 4, a plane bearing 6, a bottom end cover 7 and adjustment Gasket 9, the bottom end cover 7 is fixedly installed on the bottom of the outer sleeve 1, the uppe...

Embodiment 2

[0031] refer to Figure 4 , The difference from Embodiment 1 is that the plane bearing 6 is a plane ball bearing.

Embodiment 3

[0033] refer to Figure 5 , The difference from Embodiment 1 is that the plane bearing 6 is a plane sliding bearing.

[0034] Working process of the present invention:

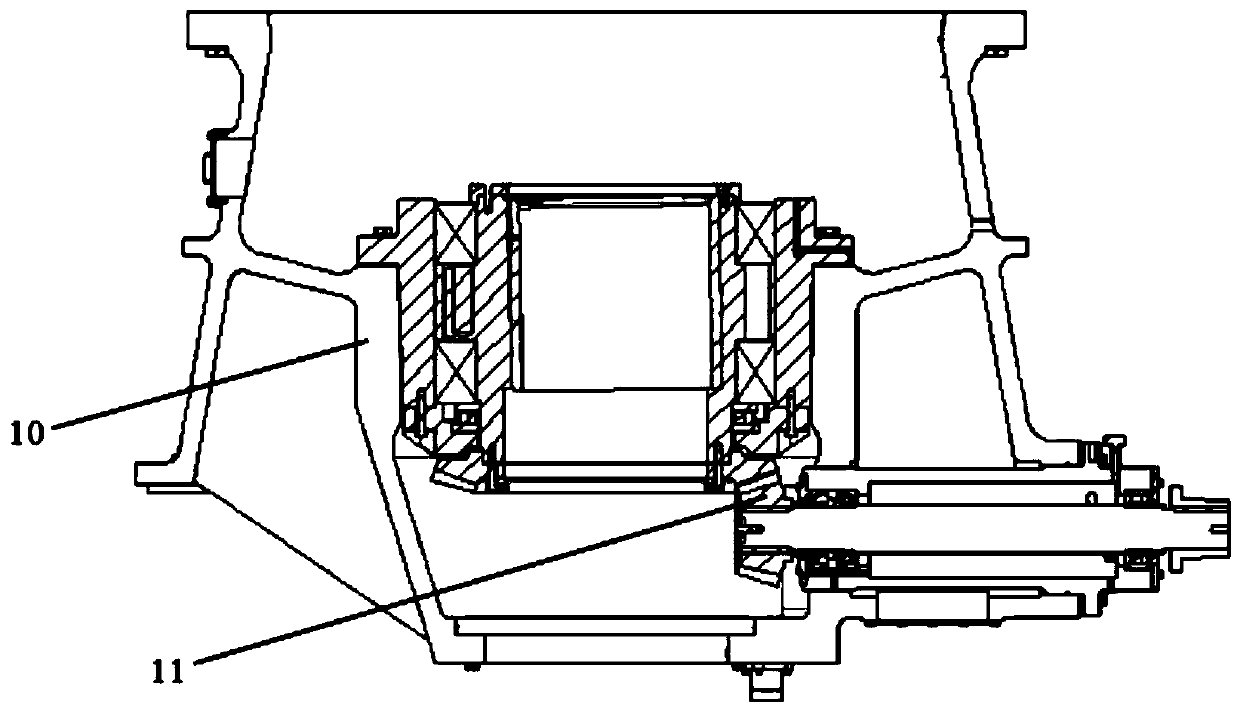

[0035] The present invention is an eccentric sleeve mechanism with supporting bearings. When installing, the entire eccentric mechanism is assembled and installed on the bottom cone machine frame 10, and then the gear installation gap is adjusted by increasing or decreasing the adjustment gasket 9, and the movement of the eccentric mechanism is driven by The bevel gear 11 drives the driven large bevel gear 8, thereby driving the eccentric inner sleeve 2 to form a rotary motion. Due to the existence of the plane bearing 6, the sliding force generated by the eccentric inner sleeve 2 due to its own weight and the movement of the rotary motion process is absorbed by the plane bearing 6. Support, thereby ensuring the stability of the eccentric inner sleeve 2 during the rotary motion, thereby ensuring the stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com