Stator iron core overlaying welding mold

A stator core and welding die technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of roundness not meeting the requirements, easy to strain molds, and non-expansion molds failing to meet the roundness requirements, etc. Achieve the effect of reducing roundness deformation, ensuring supporting force, and ensuring inner roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

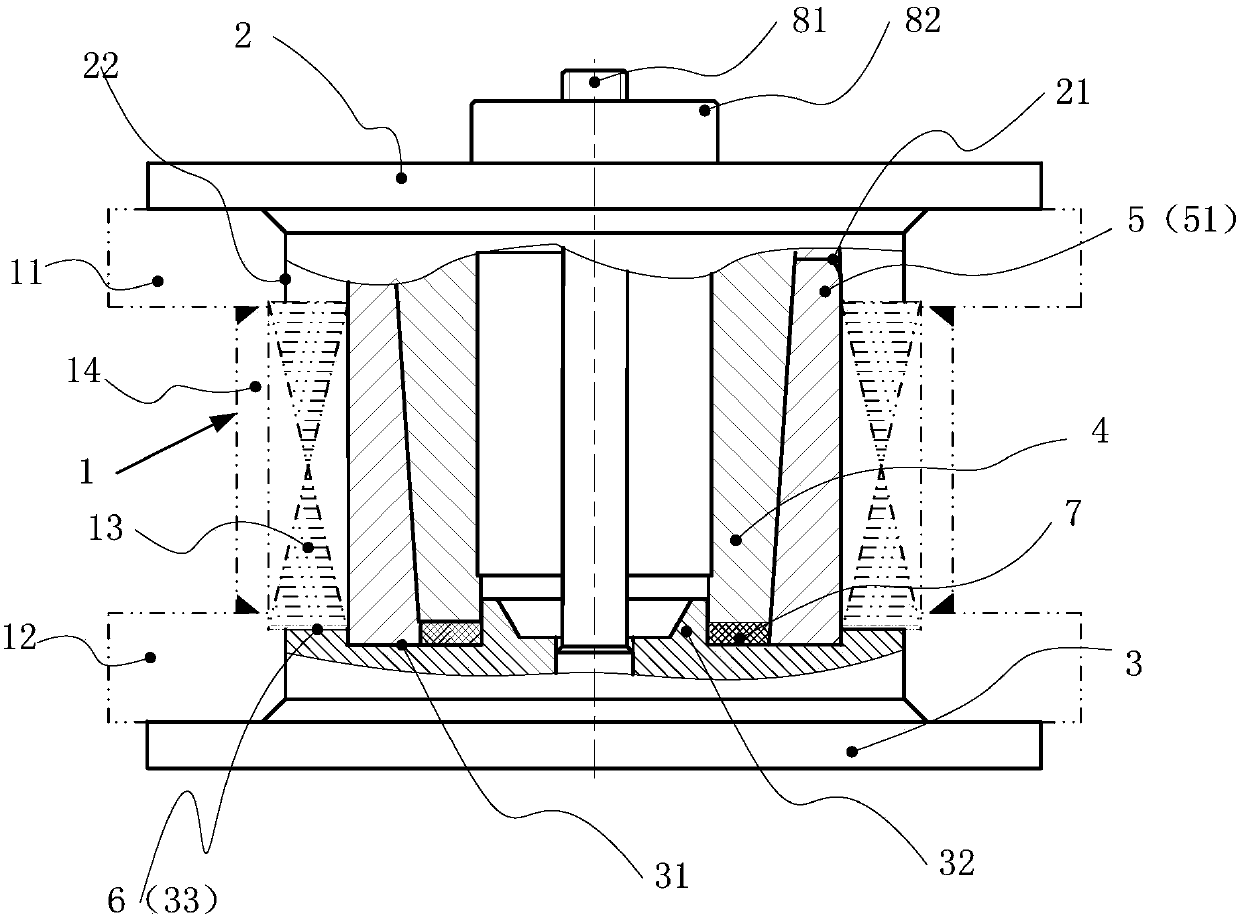

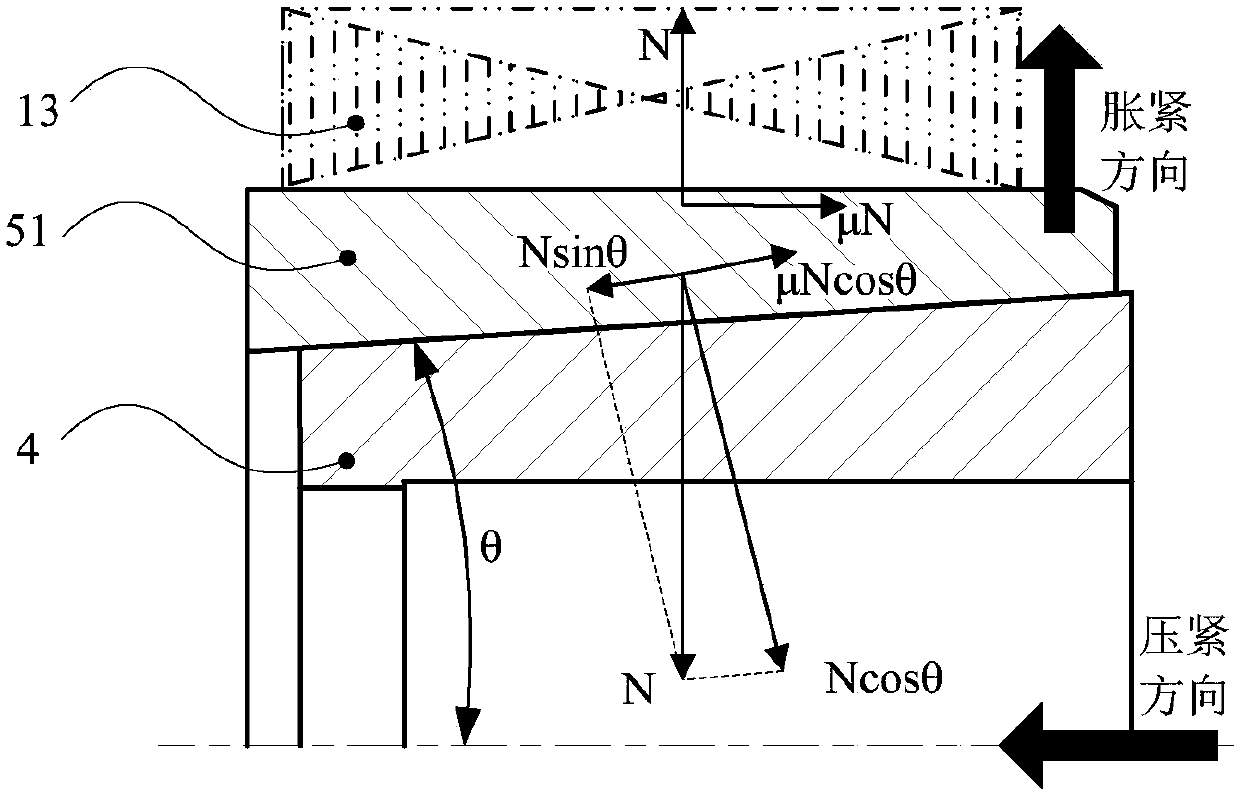

[0025] Such as Figure 1 to Figure 3 As shown, in the stator core lamination welding mold of this embodiment, the stator core 1 includes a stator pull-up ring 11, a stator pull-down ring 12, a stator punch 13 and a plurality of stator pull plates 14, and the stator punch 13 is arranged on the stator pull-up ring 11. Between the ring 11 and the stator pull-down ring 12, a plurality of stator pull plates 14 are evenly distributed on the outer periphery of the stator punching sheet 13, and the welding mold includes an upper pressing plate 2, a lower pressing plate 3, an inner tire 4 and an outer tire 5, and the inner tire 4 and the outer tire 5 are arranged on Between the upper pressing plate 2 and the lower pressing plate 3, the tire 5 includes a plurality of sector blocks 51, the number of sector blocks 51 is equal to the number of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com