Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good shape selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

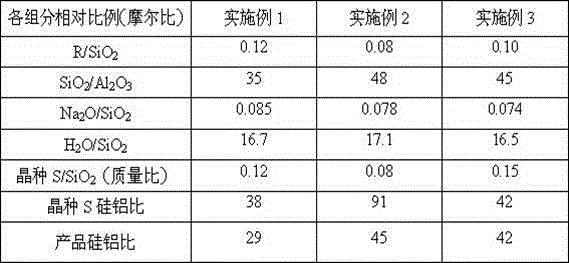

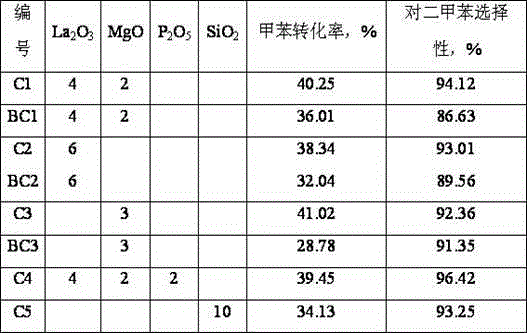

Toluene and methanol alkylation catalyst and preparation method and application thereof

ActiveCN104549452AIncrease acid density and acid volumeInhibit side effectsMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveLanthanum

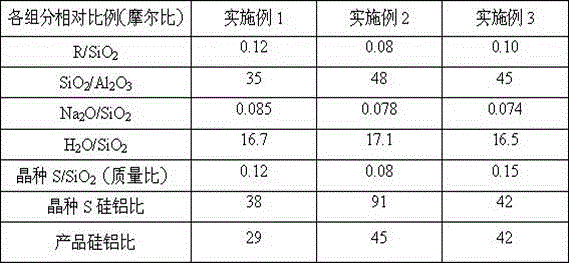

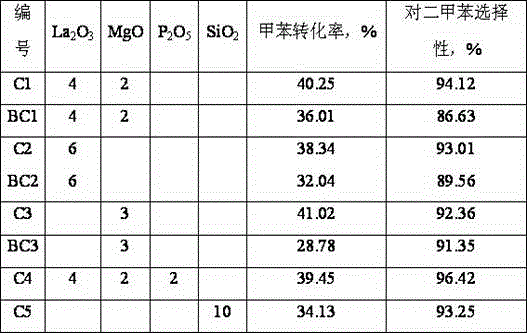

The invention discloses a toluene and methanol alkylation catalyst and a preparation method and application thereof. A catalyst carrier contains a hydrogen-type ZSM-48 molecular sieve and a modified element which comprises one or several of lanthanum, magnesium, phosphorus and silicon, the content (in percentage by weight ) of the hydrogen-type ZSM-48 molecular sieve in the carrier is 10wt%-90wt%, and preferably 20wt%-80wt%; the modified element contains one or several of lanthanum, magnesium, phosphorus and silicon and is calculated according to oxides, and the modified element accounts for 0.05%-60% of the weight of the carrier, and preferably 0.5%-40%. The catalyst is used for an alkylation reaction of toluene and methanol, and has the characteristics that the conversion rate of the toluene is high, the selectivity of paraxylene is high, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

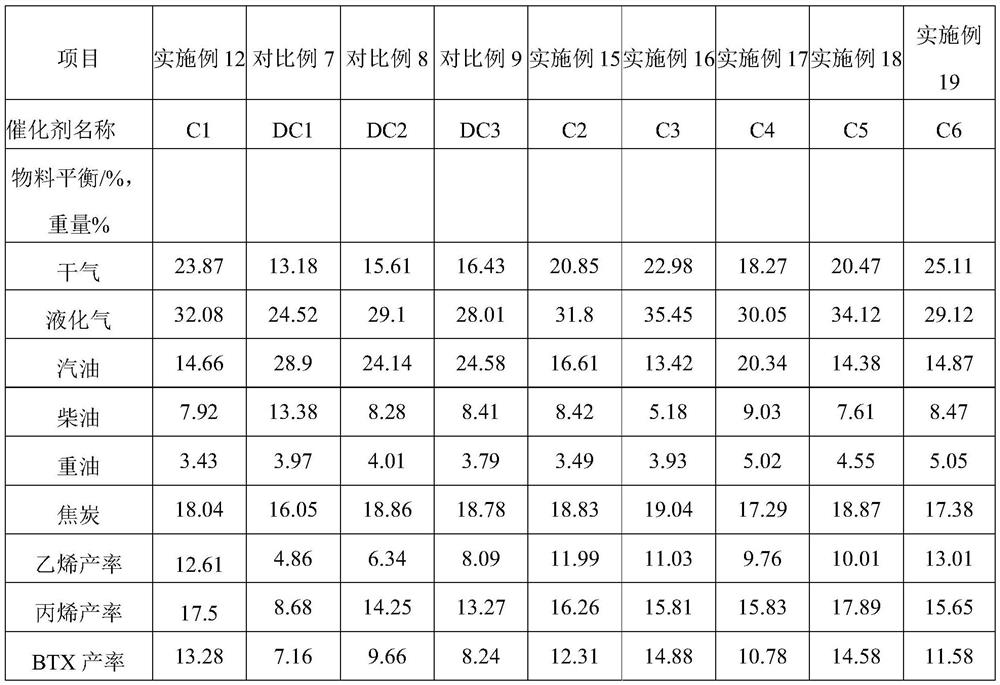

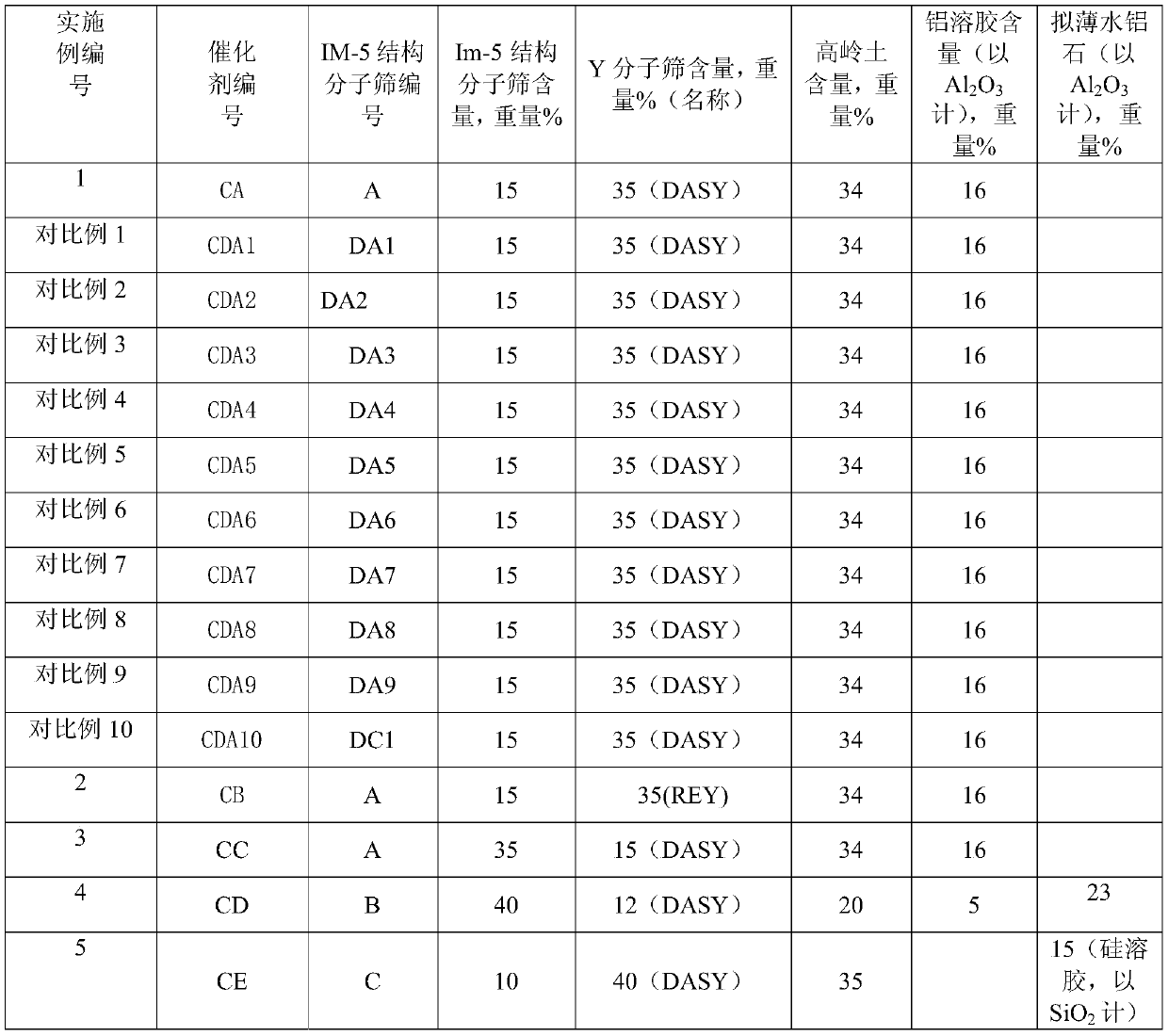

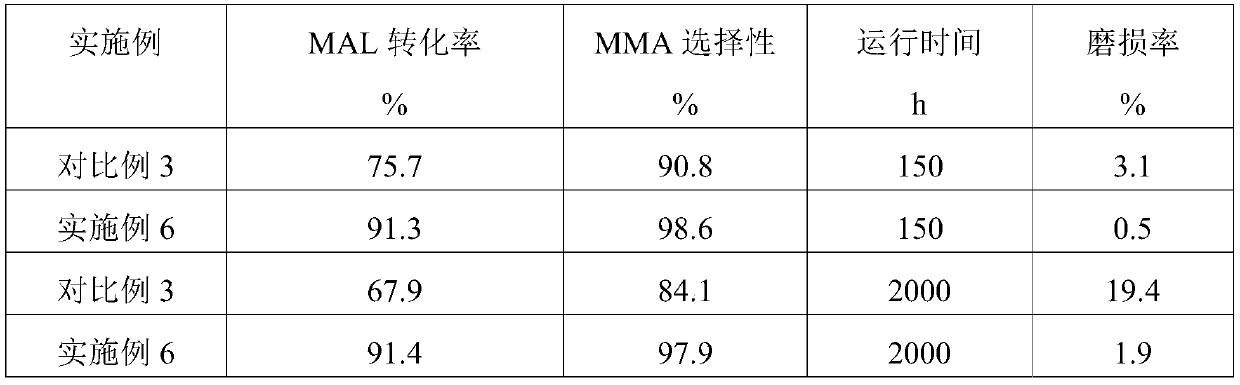

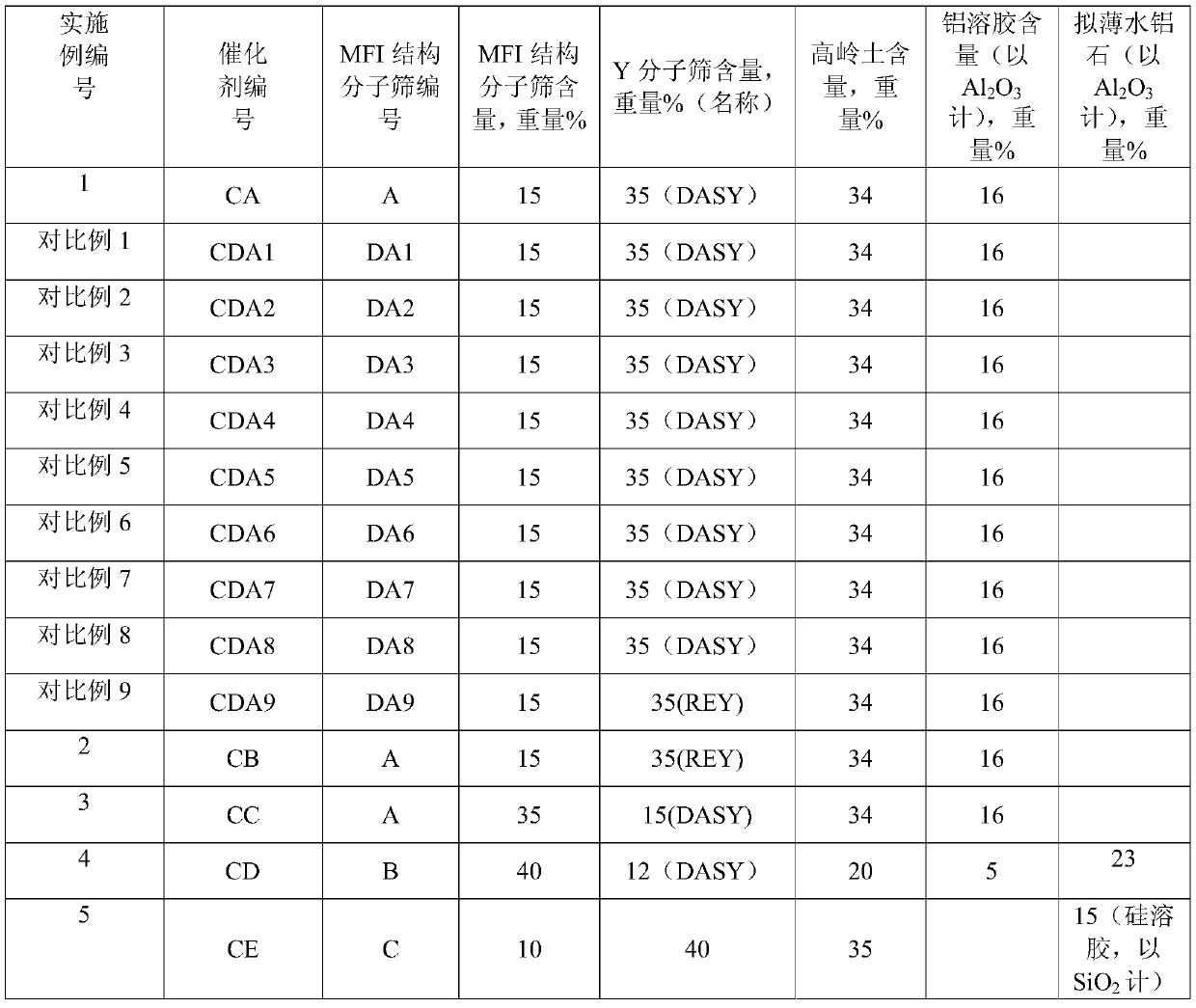

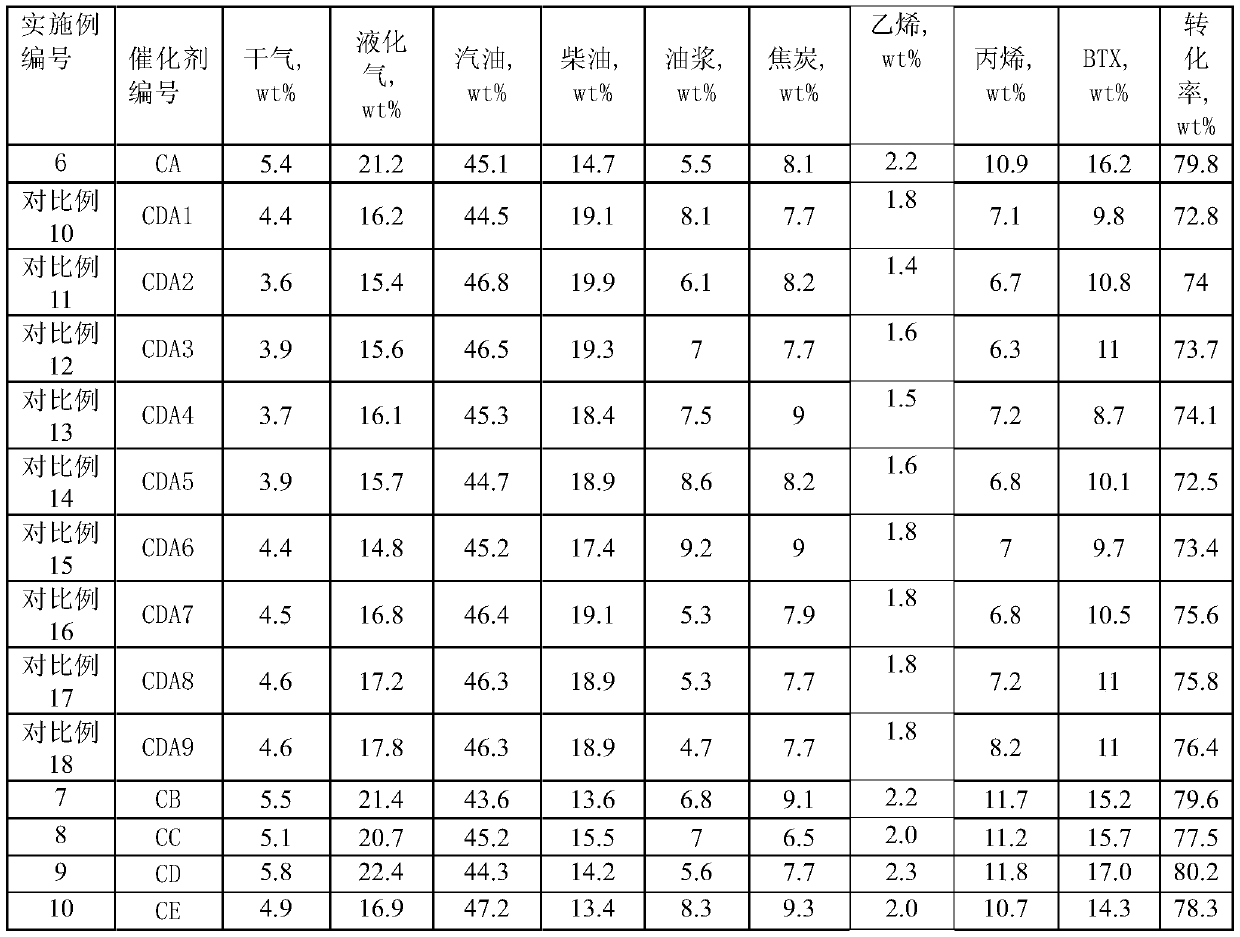

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971015AMesopore richPromote generationCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

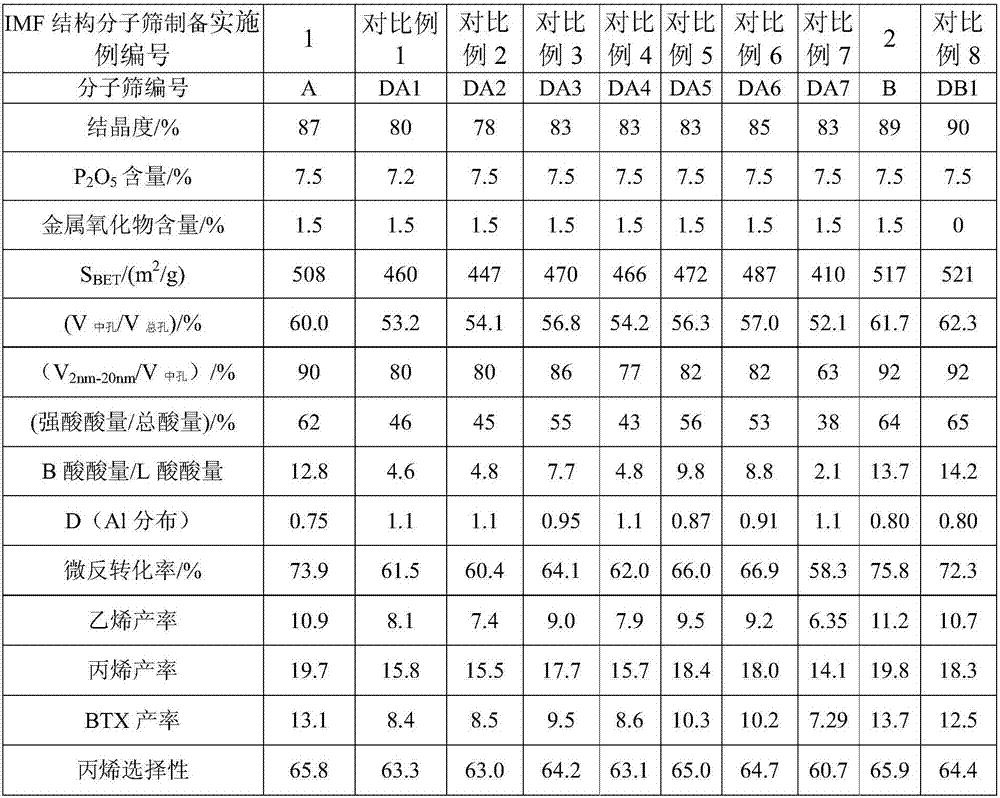

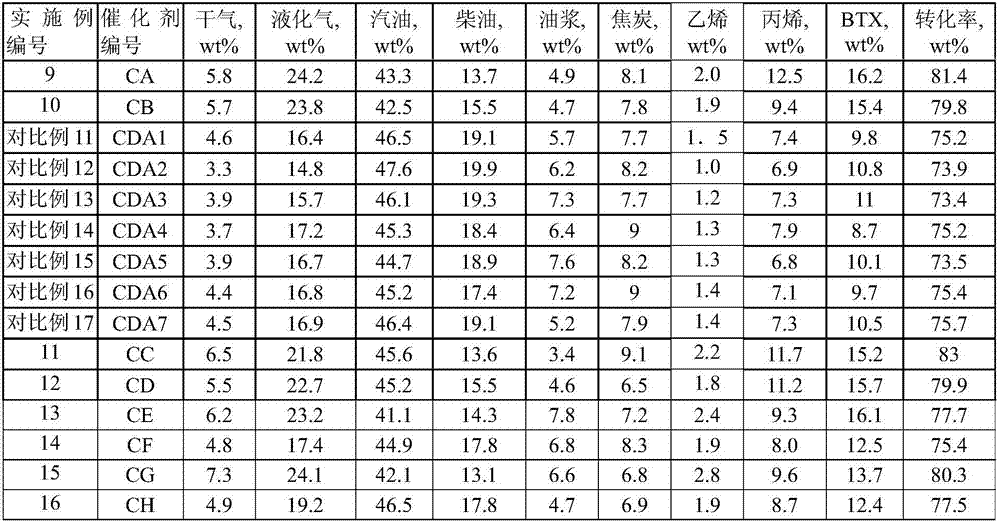

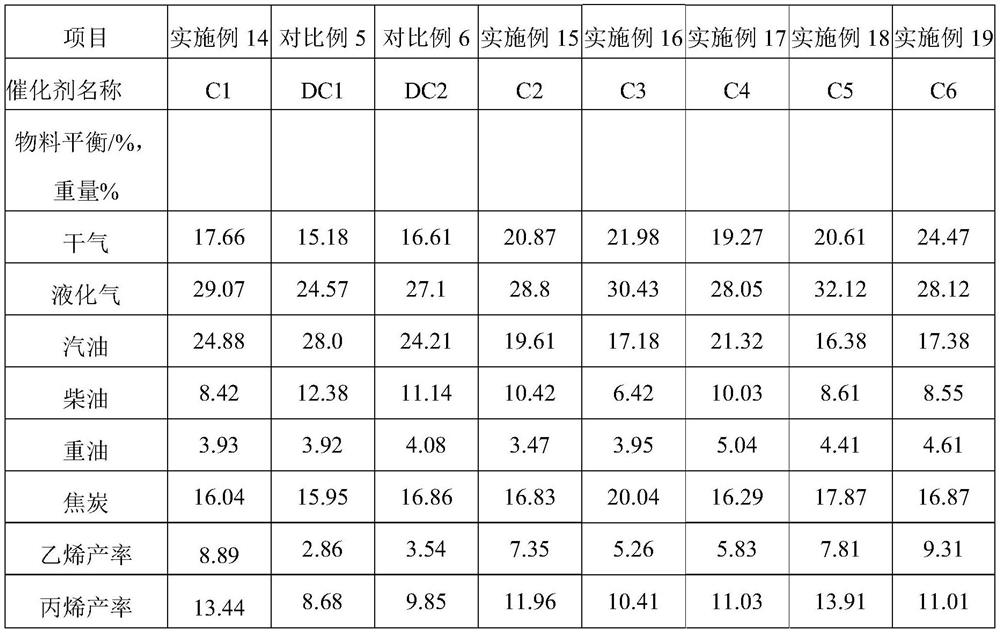

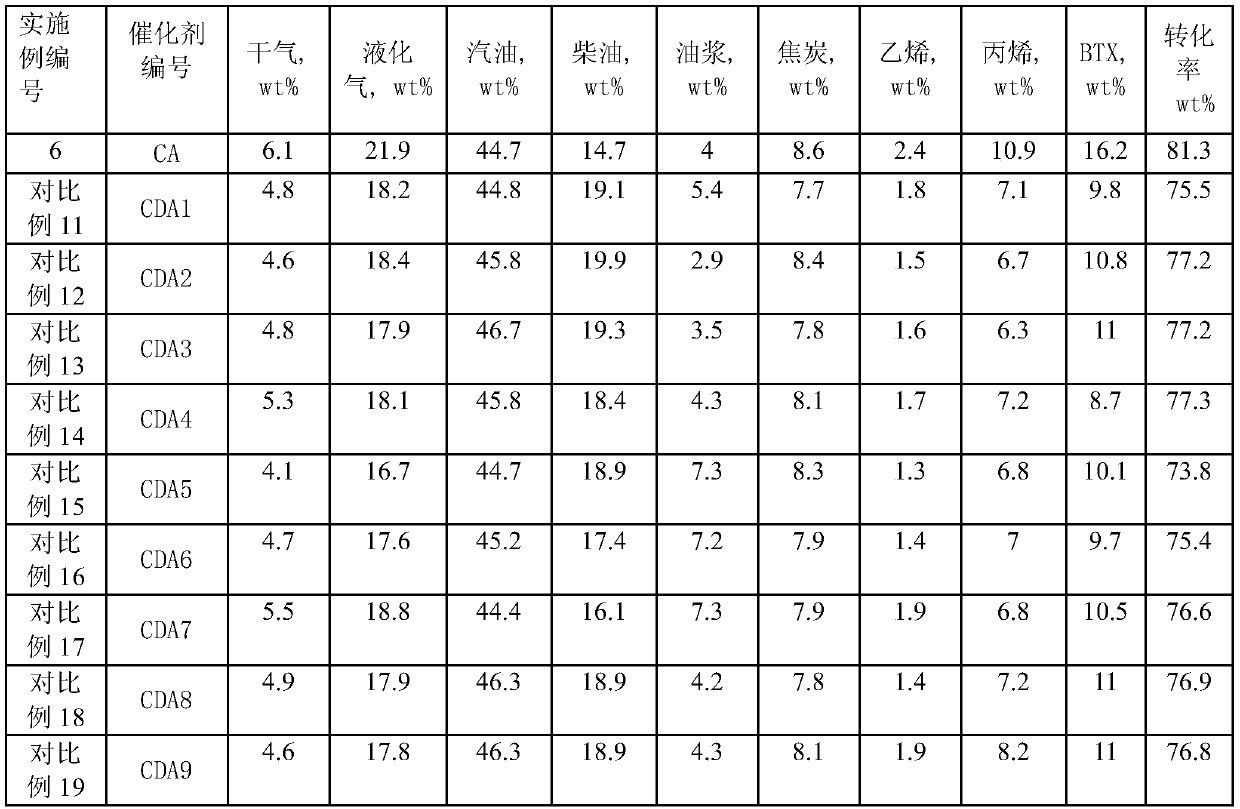

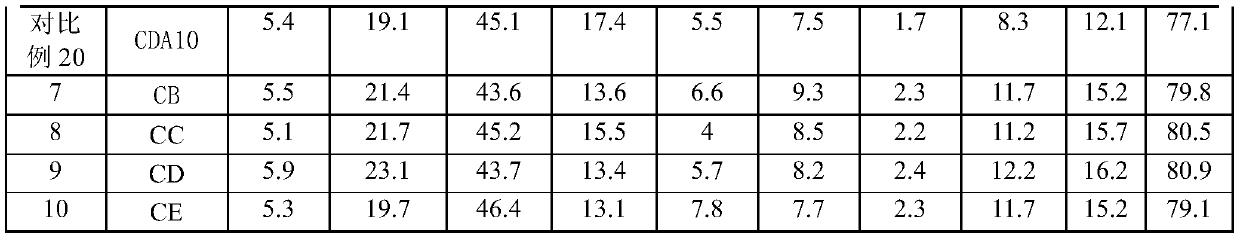

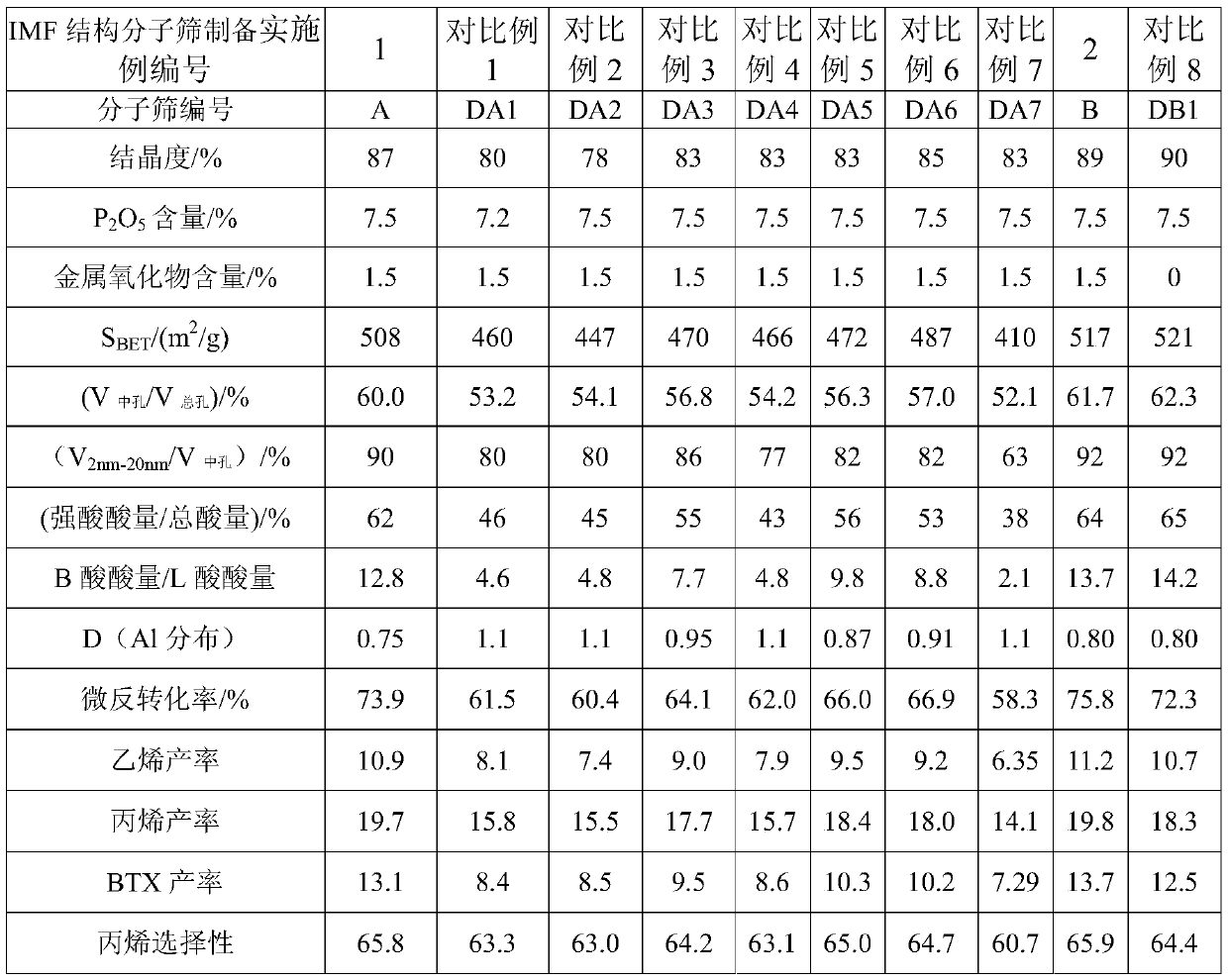

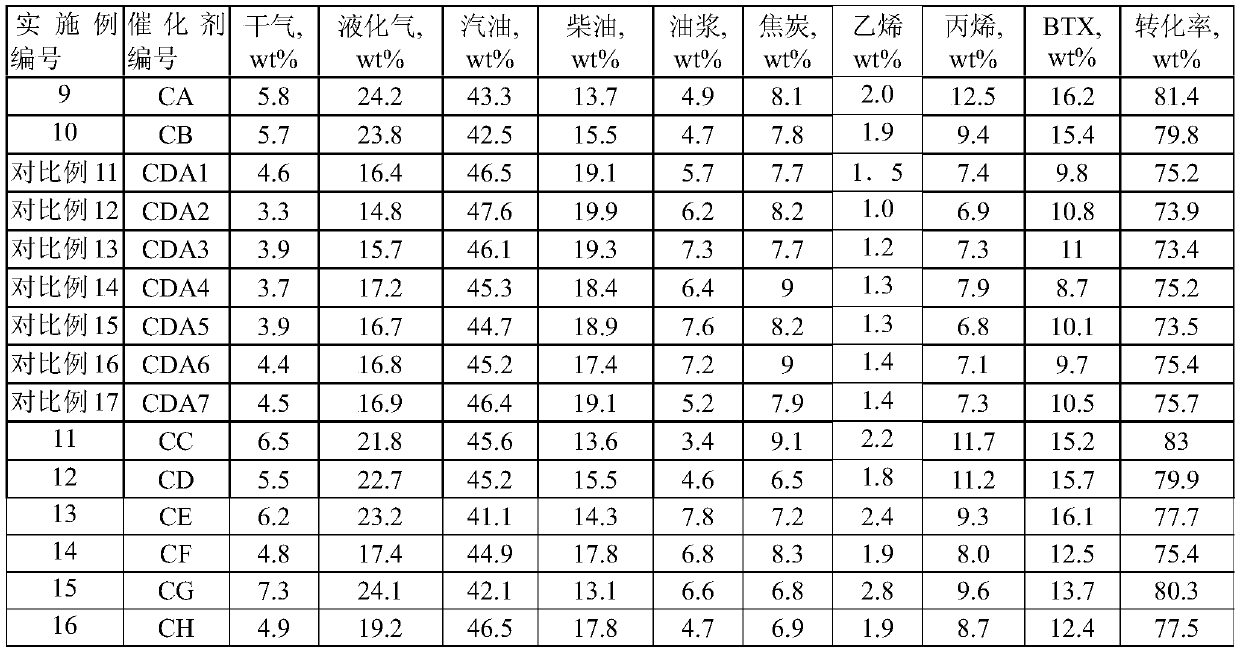

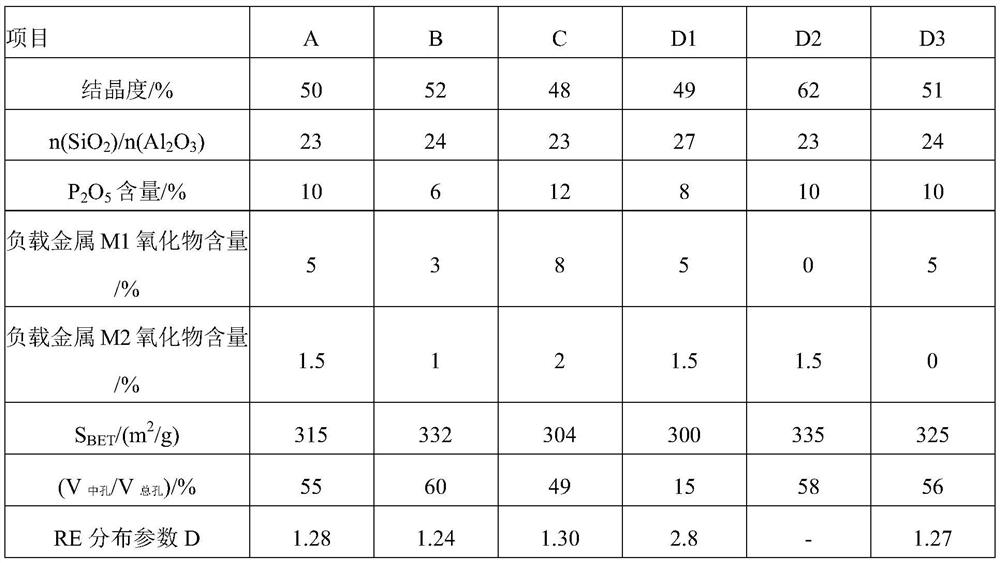

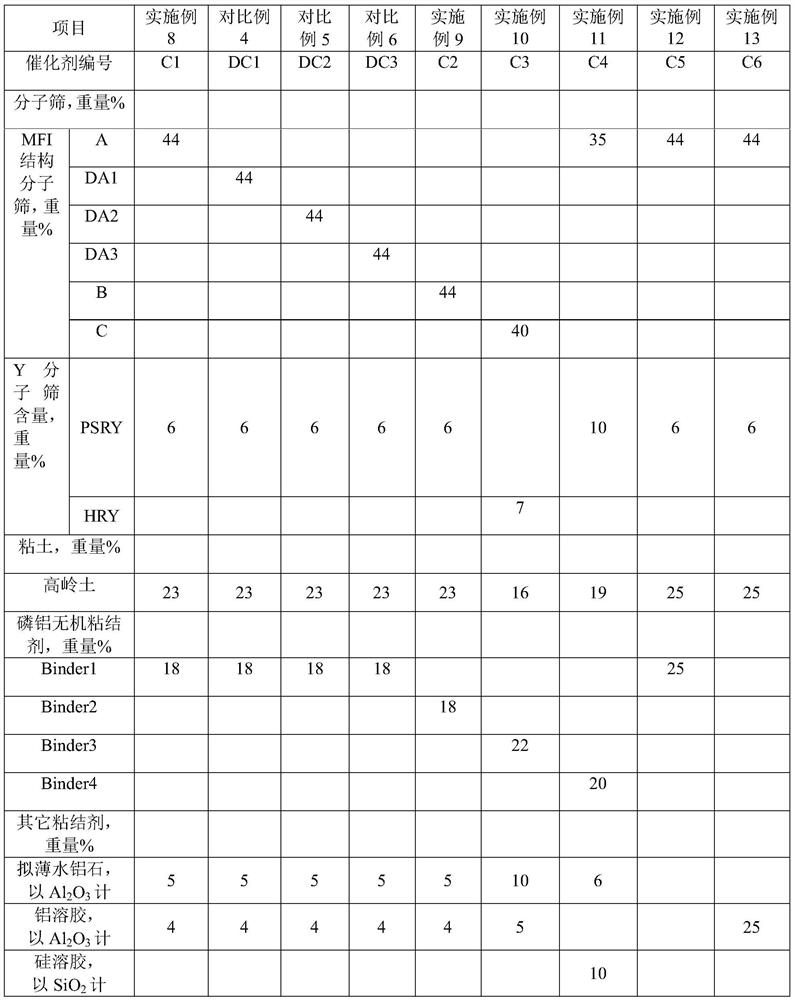

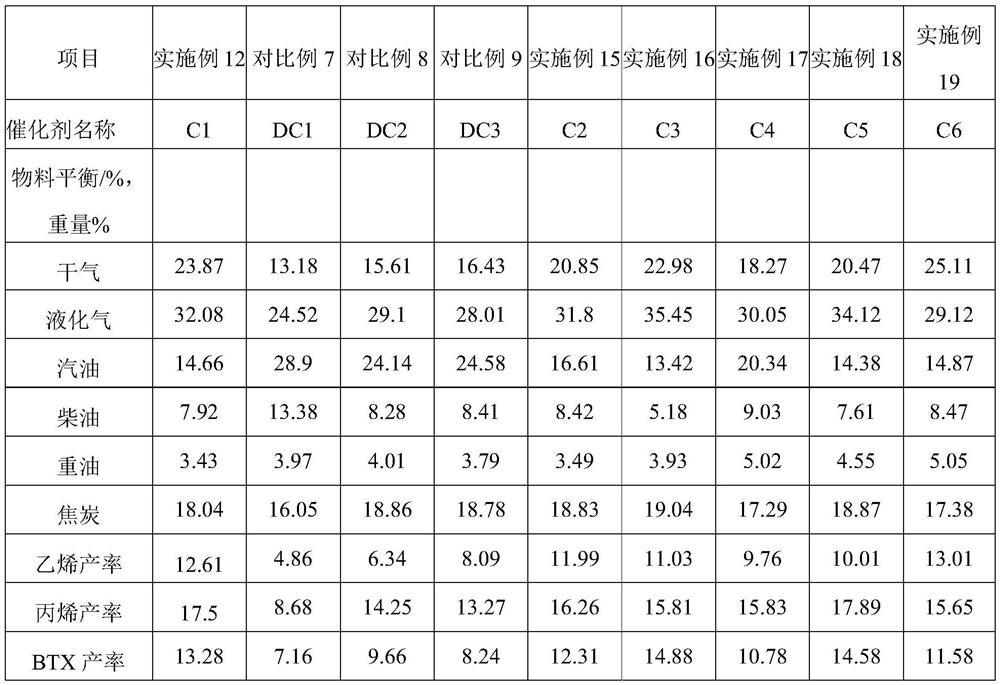

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y type molecular sieve and a phosphorus-containing and supported-metal-containing MFI-structure molecular sieve, wherein the n(SiO2) / n(Al2O3) of the phosphorus-containing and supported-metal-containing MFI-structure molecular sieve is more than 18 and less than 70, the Al distribution parameter D is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores accounts for 50-80% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strong acid accounts for 50-80% of the total acidamount, a ratio of the acid B to the acid L is 7-30, the phosphorus content is 1-15 wt%, and the supported metal content is 0.1-5 wt%. The preparation method comprises: carrying out mixing beating onthe phosphorus-containing and supported-metal-containing MFI-structure molecular sieve, the Y type molecular sieve, the natural minerals and an inorganic oxide binder, and carrying out spray drying.According to the present invention, the catalytic cracking catalyst has the high low-carbon olefin yield in the catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971028AMesopore richPromote cracking reactionCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y type molecular sieve and a phosphorus-containing IMF-structure molecular sieve, wherein the n(SiO2) / n(Al2O3) of the phosphorus-containing IMF-structure molecular sieve is more than 18 and less than 70, the phosphoruscontent is 1-15 wt%, the Al distribution parameter D is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores accounts for 40-70% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strong acid accounts for 45-75% of the total acid amount, and a ratio of the acid B to the acid L is 8-30. According to the present invention, the catalytic cracking catalyst has high low-carbon olefin yield and high BTX yield in the catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

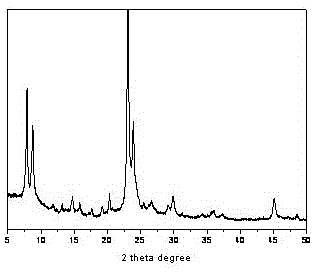

Novel drying agent

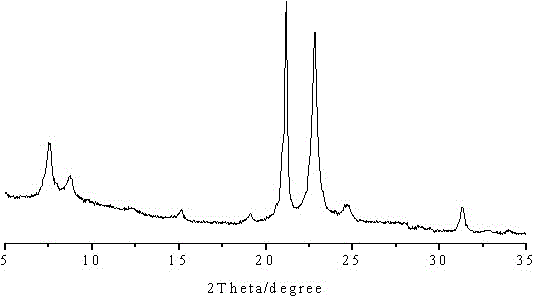

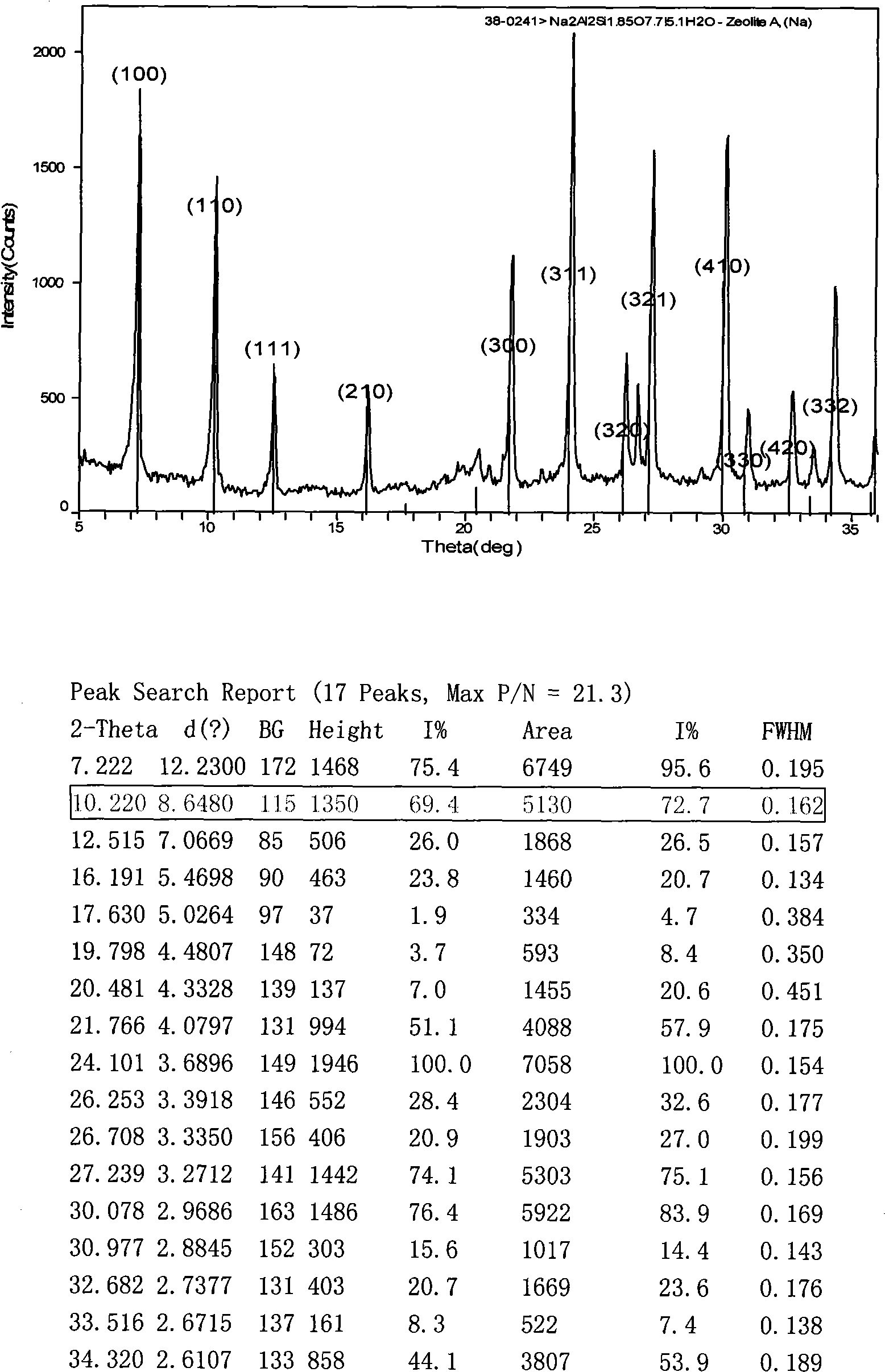

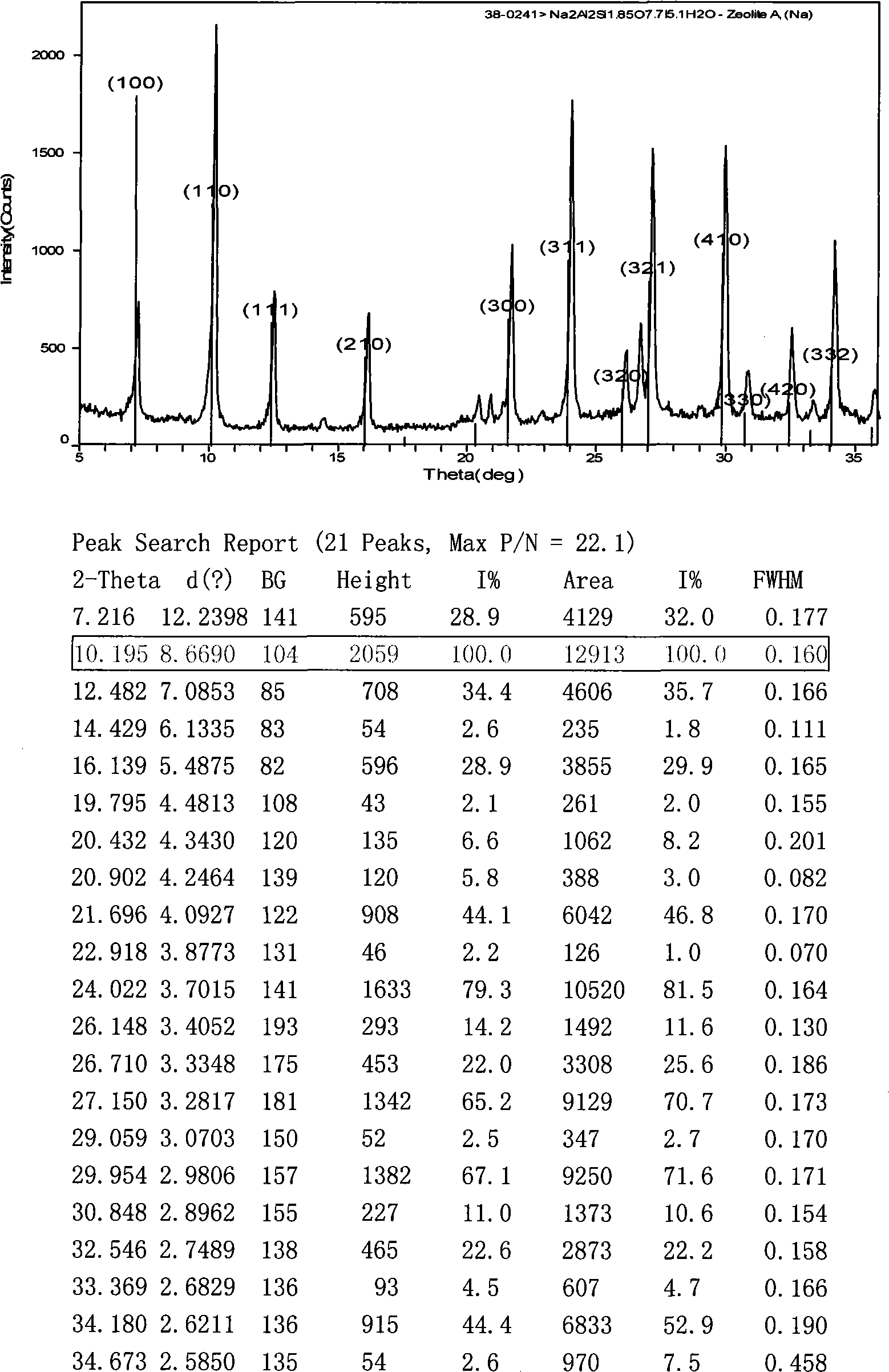

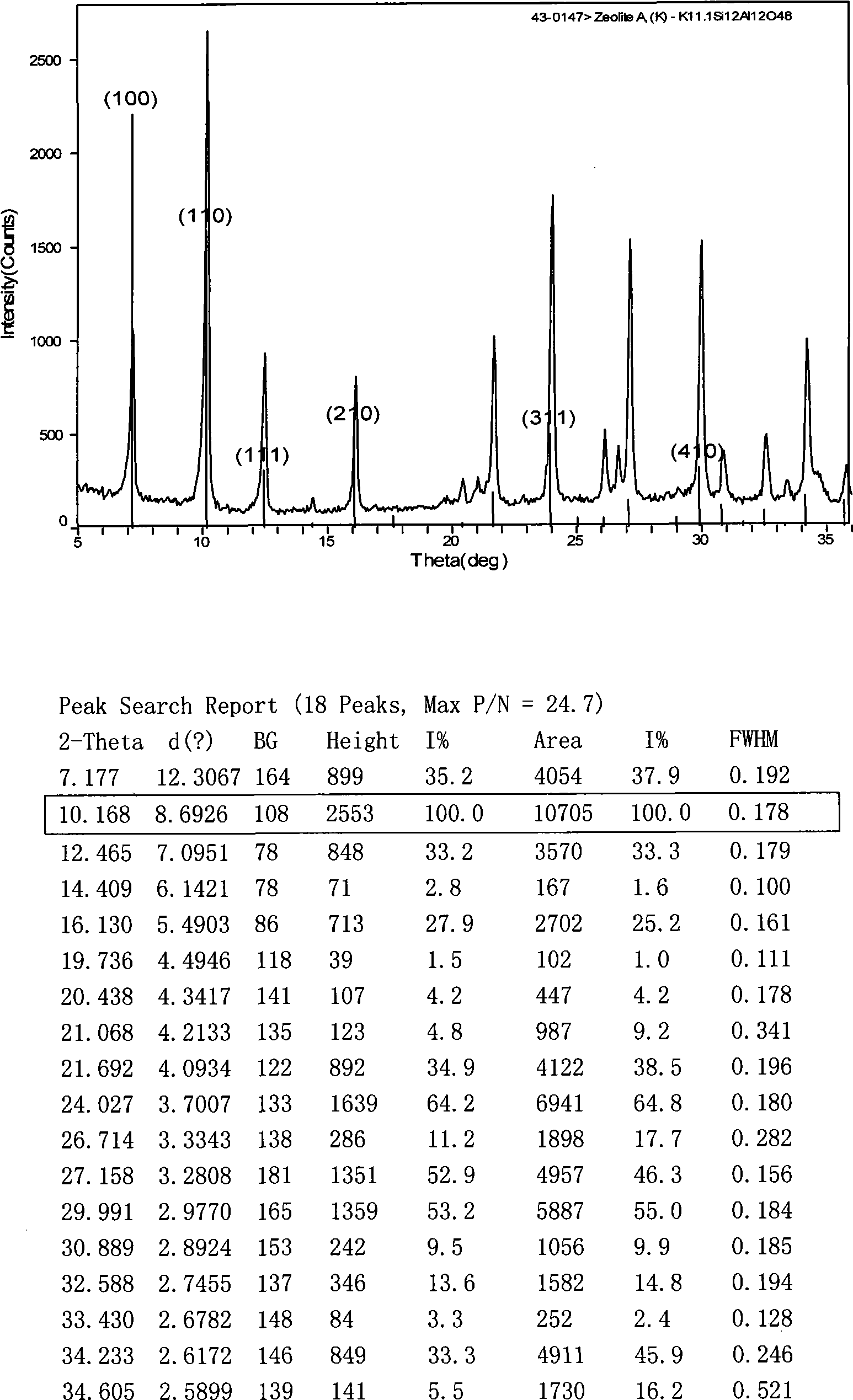

InactiveCN101543718AGood shape selectivityImprove featuresOther chemical processesDispersed particle separationMolecular sieveChemical modification

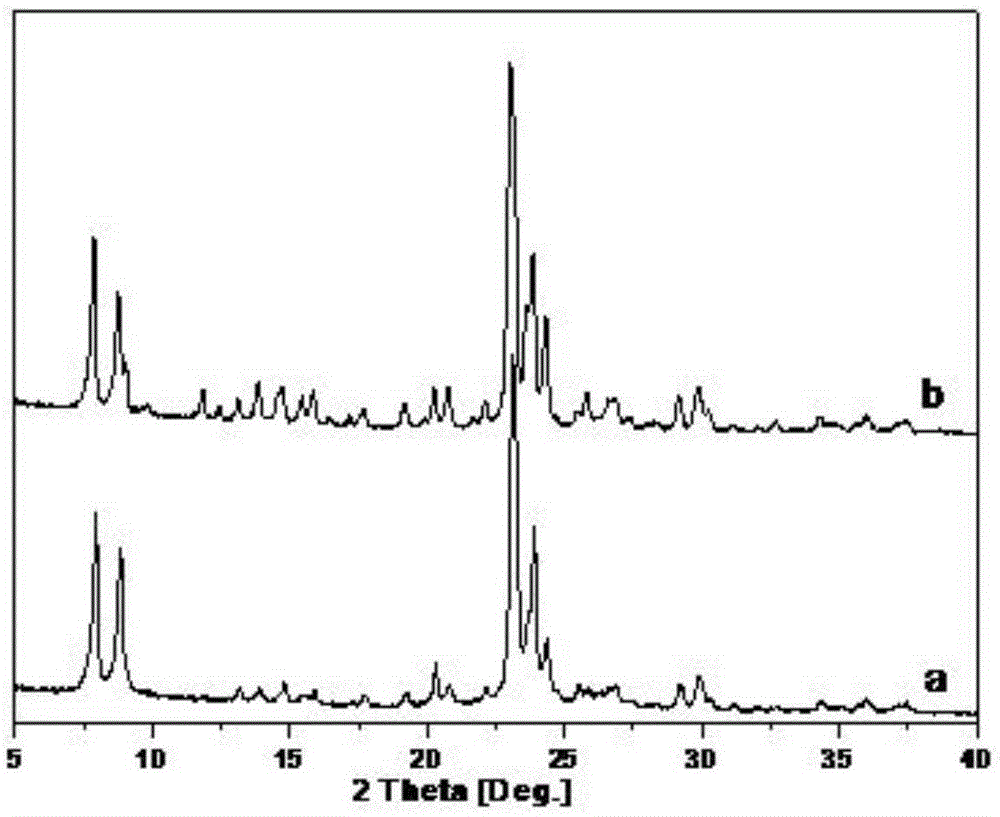

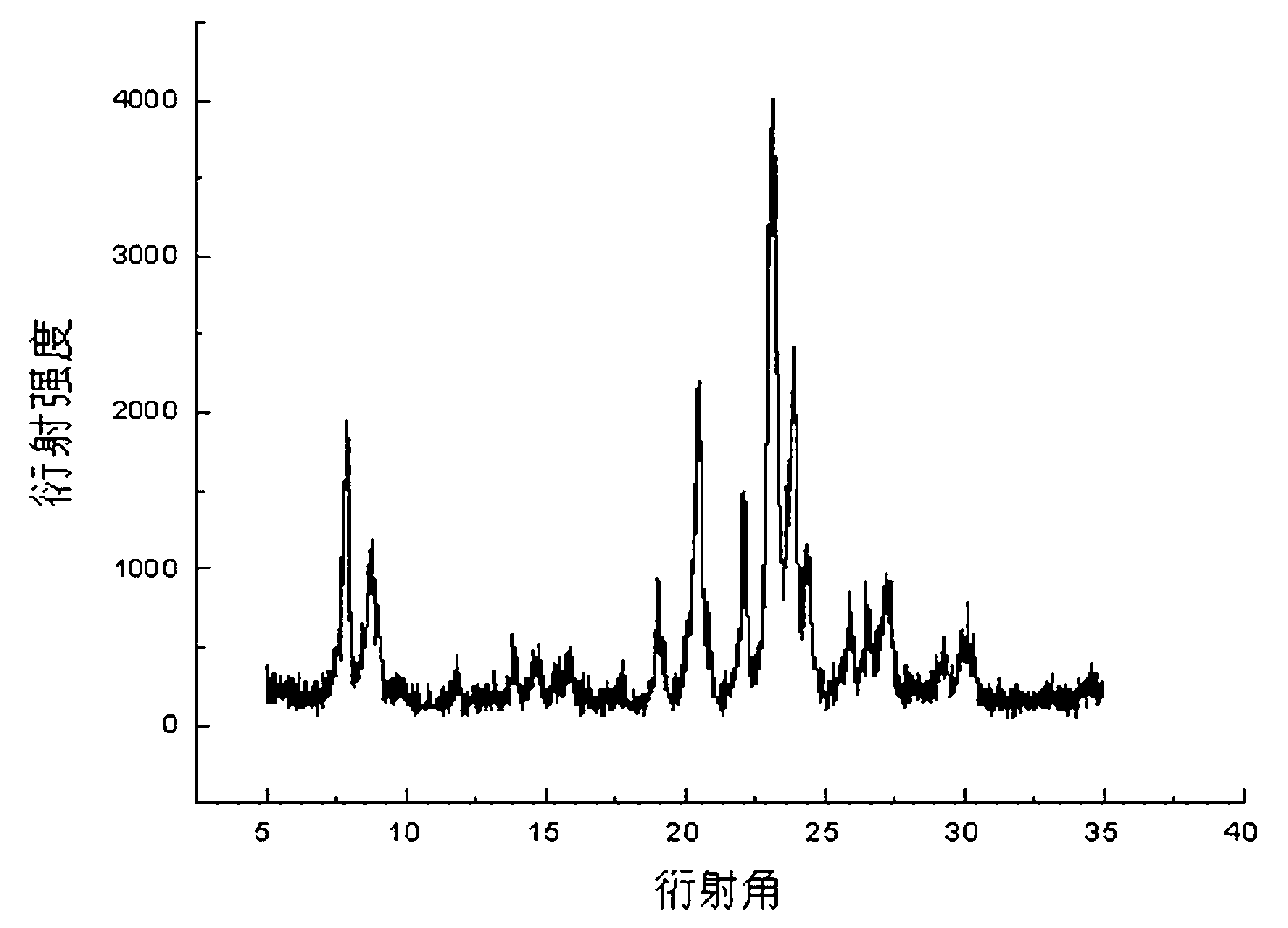

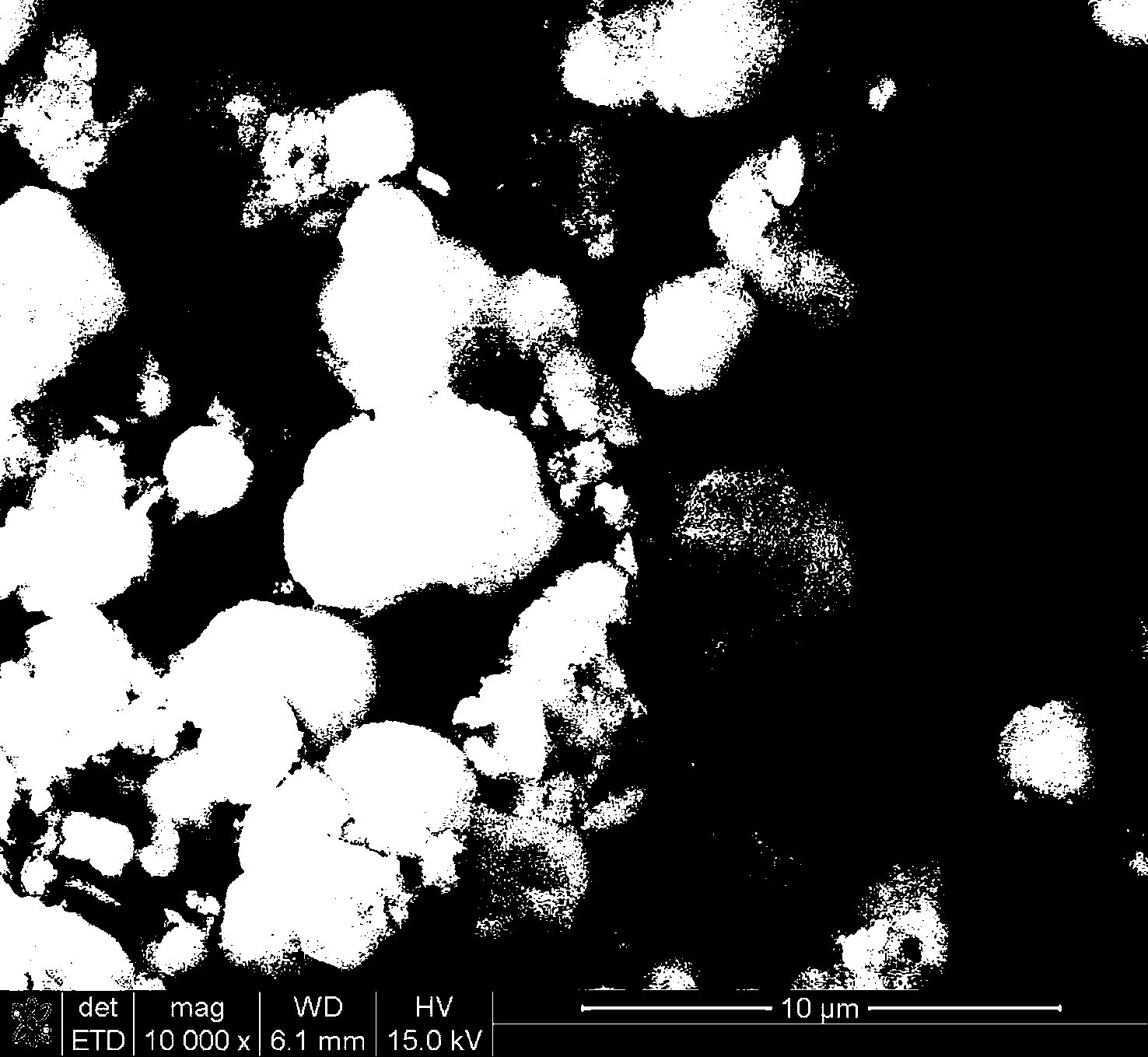

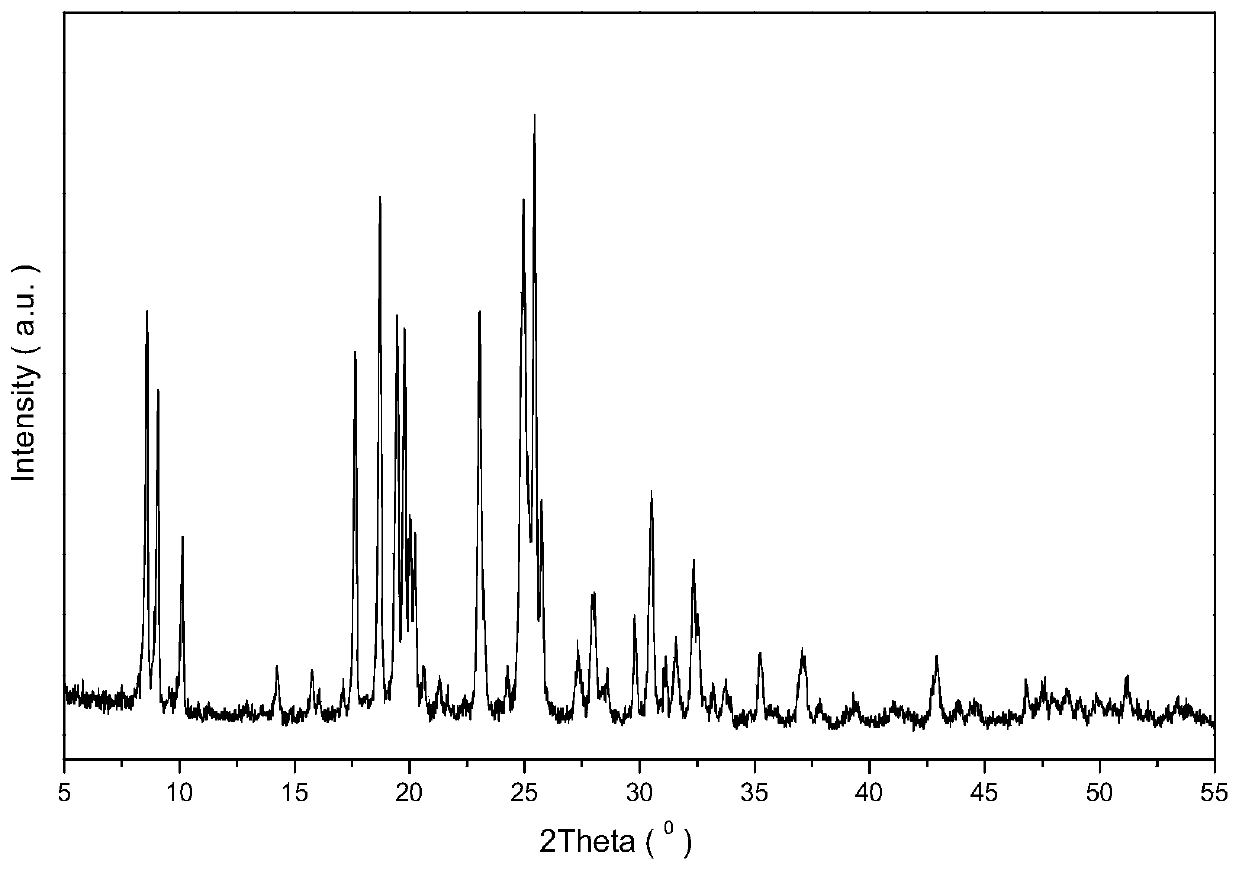

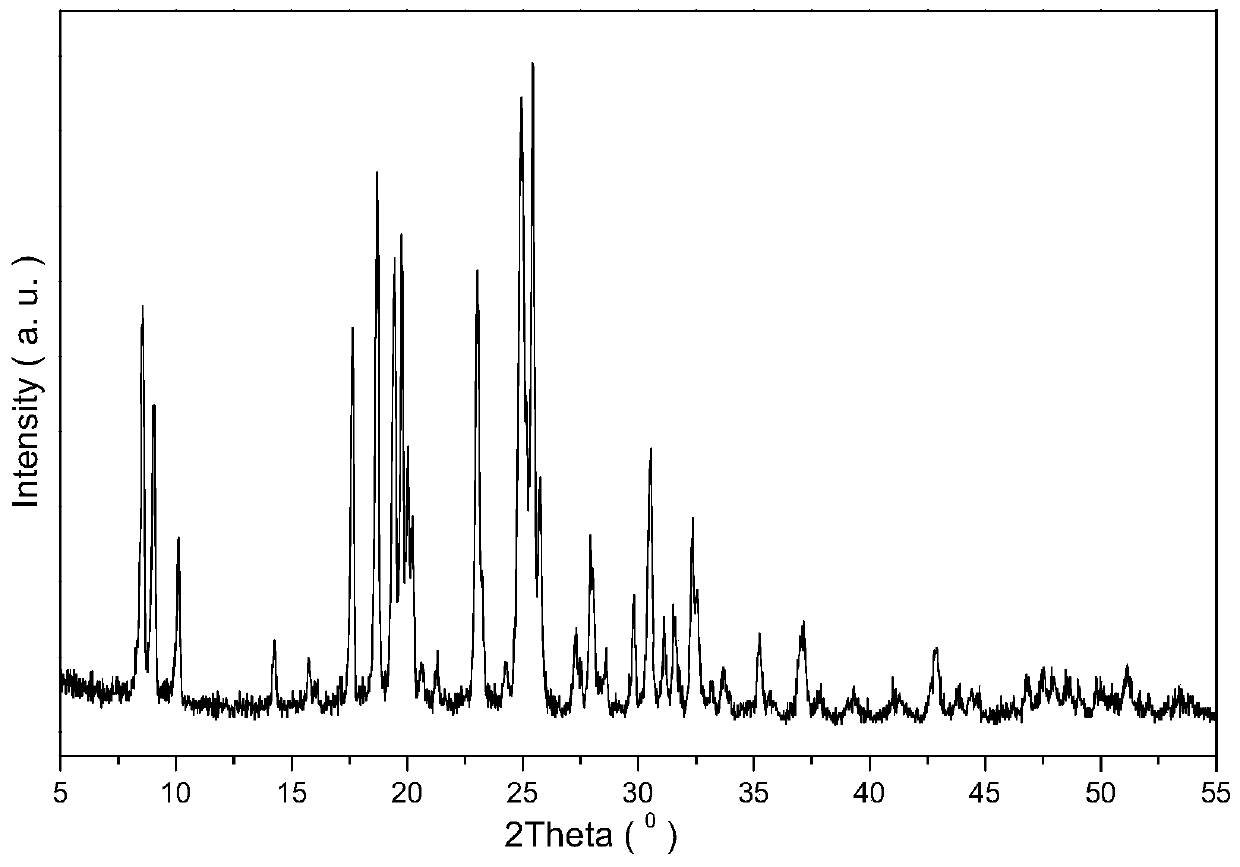

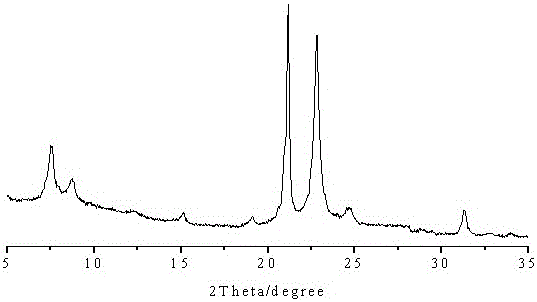

The invention belongs to an inorganic micropore new-material drying agent. The novel drying agent is a silicate A-type molecular sieve which has the diffracting strength value I of more than 75 but less than or equal to 100 on the 110 surface at an angle of 10 degrees of the 2 theta angle of the XRD diffracting peak . Besides the properties of the glass drying agent in a 3A-type molecular sieve, the inorganic micropore new-material molecular-sieve drying agent prepared by new chemical modification technology of the invention has the structural characteristics that the diffracting strength of the peak structure of the 110 surface at an angle of 10 degrees of the 2 theta angle in the XRD diffracting plot is obviously stronger than that of the glass drying agent in a 3A-type molecular sieve, thus, the novel drying agent only absorbs water and little O2 but not N2 and has the property of excellent type selectivity and selective absorption.

Owner:DALIAN HAIXIN CHEM IND

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971011AHigh hydrocarbon oil cracking cracking activityHigh selectivityMolecular sieve catalystsBulk chemical productionMolecular sieveStrong acids

The invention relates to a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 15-65% of natural minerals, 10-30% of an oxide, and 25-75% of a Y-type molecularsieve and a phosphorus-containing and supported metal-containing IMF structural molecular sieve, the Al distribution parameter D of the phosphorus-containing and supported metal-containing IMF structural molecular sieve is more than or equal to 0.6 and is less than or equal to 0.85, the volume of mesopores accounts for 50-80% of the total volume of pores, the volume of pores with a pore size of 2-20 nm accounts for more than 85% of the total volume of mesopores, the strong acid accounts for 50-80%, a ratio of an acid B to an acid L is 7-30, the phosphorus content is 0.1-15 wt%, and the supported metal content is 0.1-5 wt%. The preparation method comprises: carrying out mixing beating on the phosphorus-containing and supported metal-containing IMF structural molecular sieve, the Y-type molecular sieve, the natural minerals and an inorganic oxide binder, and carrying out spray drying. According to the present invention, with the application of the catalytic cracking catalyst in catalytic cracking of petroleum hydrocarbons, the yield of low-carbon olefins is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing mesoporous molecular sieve by sepiolite

InactiveCN1669926AIncrease surface areaLarge apertureCrystalline aluminosilicate zeolitesMetallic materialsSurface-active agents

The invention relates to the method for preparing mesoporous molecular sieve by sepiolite which consists of fragmenting sepiolite, treating with 2M-6M hydrochloric acid, sulfuric acid or nitric acid for 8-16h, removing magnesium compounds and obtaining non-shaped silicon dioxide, then subjecting aluminium salts and surface active agent to water thermal crystallization in water solution, filtering with crystallized sepiolite, washing with deionized water or extracting with organic solvent to obtain molecular sieve precursor, then burning the precursor for 3-18h in Muffle furnace at the temperature of 300-600 deg. C.

Owner:CENT SOUTH UNIV

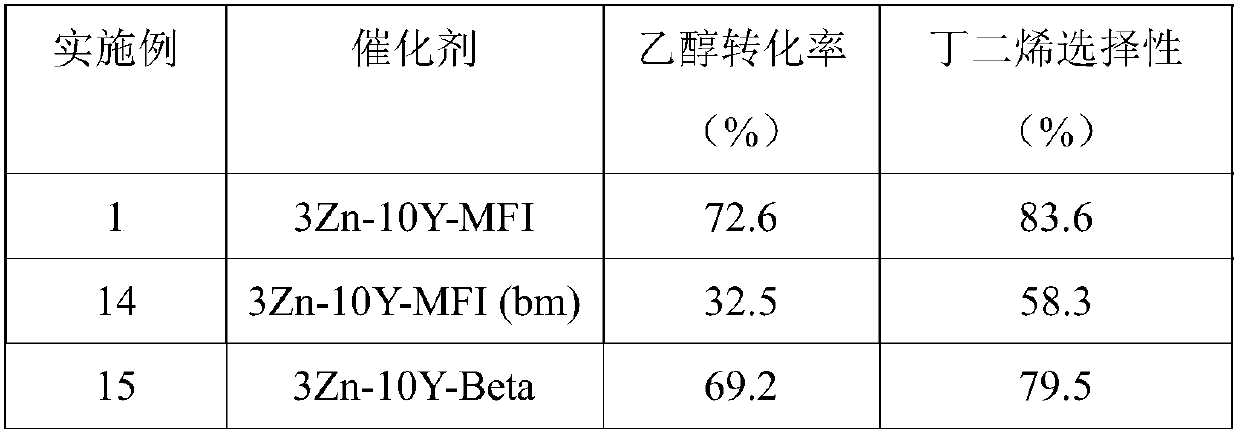

Synthesis method of 1,3-butadiene and preparation method of catalyst

ActiveCN109894144AImprove stabilitySimple preparation processMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveSynthesis methods

The invention relates to a method for preparing 1,3-butadiene, and a catalyst is a transition metal-containing MFI type molecular sieve. A raw material ethanol is in contact with the catalyst in a fixed bed manner, and is converted into butadiene in one step, wherein the reaction temperature is 250 to 550 DEG C. One of transition metal components X is one or more of transition metals Zn, Ni, Fe, Cu, Ag and Au, and the other component Y is one or more of acidic or basic metals Mg, Zr, Y, Hf, La, Ce, Sn and In. The catalyst according to the invention has the advantages of simple preparation process, low cost and easy availability. The method achieves the purpose of preparing butadiene from ethanol at high conversion and high selectivity and has an obvious industrial application value for theprocess of preparing butadiene from ethanol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

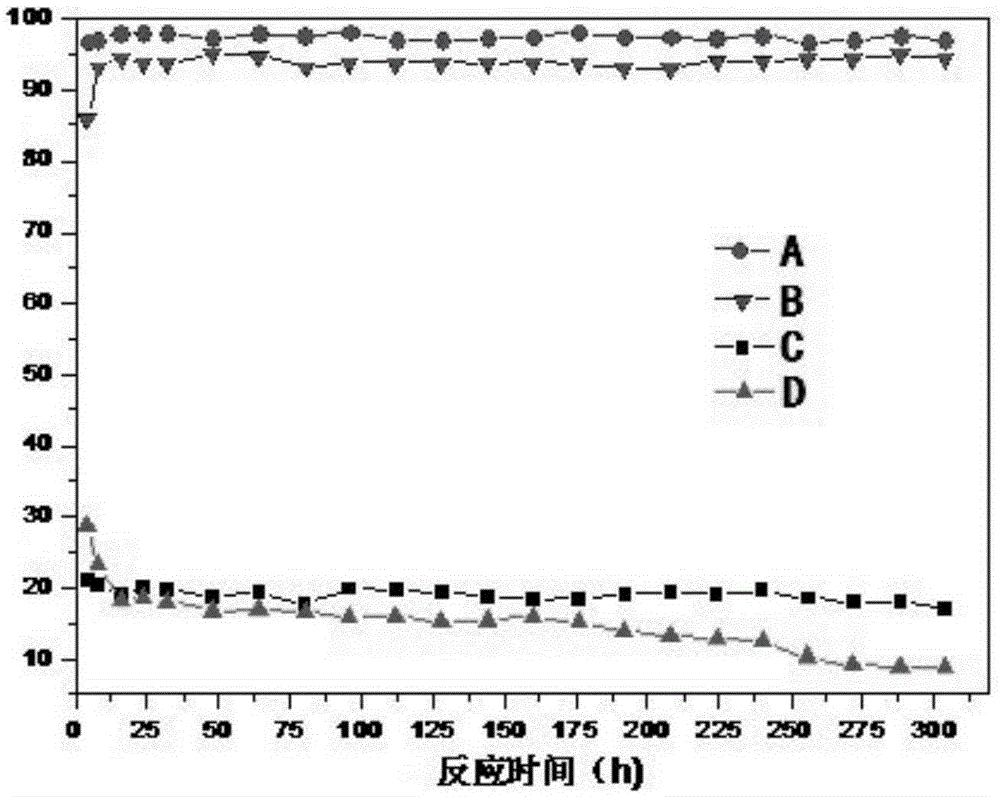

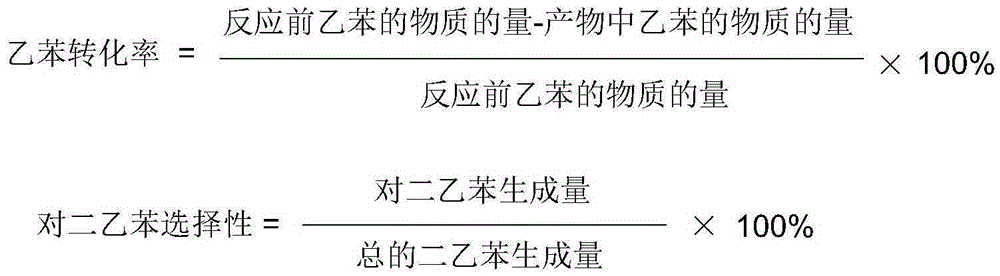

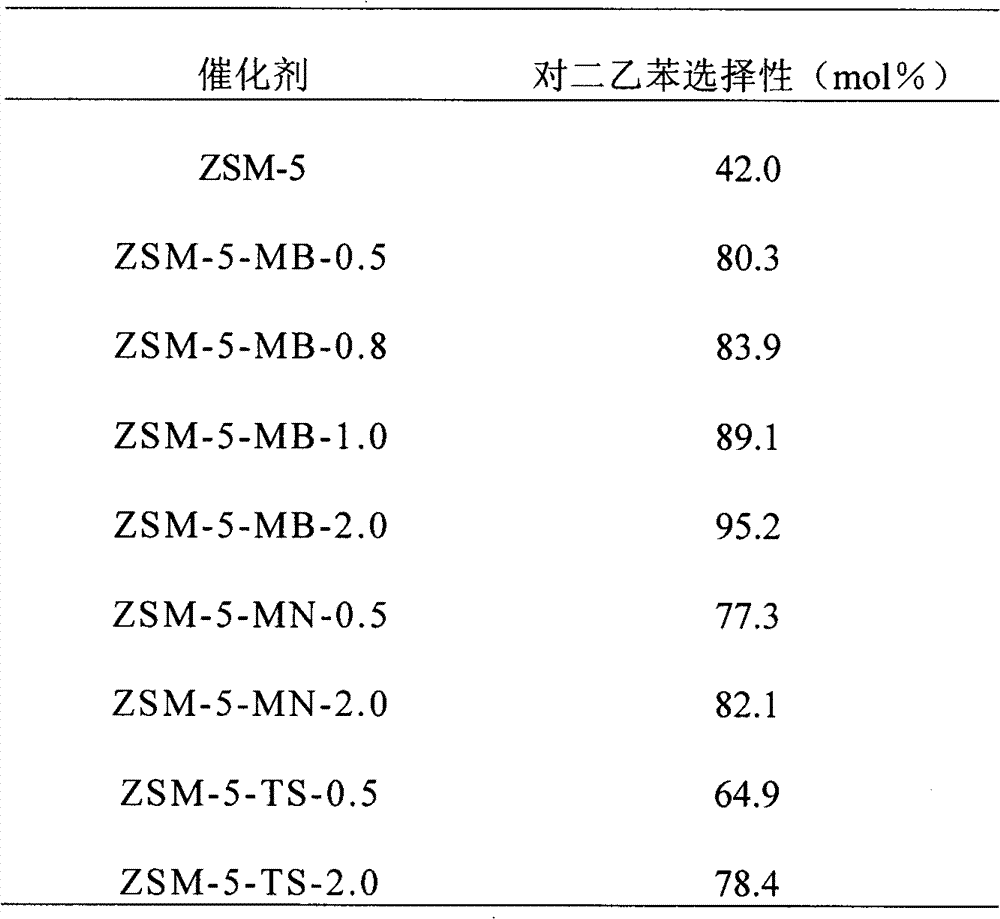

Catalyst used in alkylation reaction of ethylbenzene and ethanol and preparation method thereof

ActiveCN105381814AInhibition of transalkylationHigh selectivityMolecular sieve catalystsMolecular sieve catalystMolecular sieveAluminium oxide

The present invention discloses a catalyst in an alkylation reaction of ethylbenzene and ethanol. The catalyst comprises the following raw materials in percentages by weight: 10%-30% of aluminum oxide, and 70%-90% of a modified hydrogen form eutectic crystallization ZSM-5 / ZSM-11 molecular sieve; and the modified hydrogen form eutectic crystallization ZSM-5 / ZSM-11 molecular sieve is a citric acid modified hydrogen form ZSM-5 / ZSM-11 molecular sieve. Moreover, the present invention also discloses a preparation method of the catalyst. The method comprises the following steps: firstly, kneading the raw materials and baking the raw materials to obtain a mixture; and secondly, roasting the mixture in steam atmosphere to obtain the catalyst. The catalyst disclosed by the present invention is used in the alkylation reaction of ethylbenzene and ethanol to prepare p-diethylbenzene, a high ethylbenzene (ethanol) conversion rate can be obtained, side reactions such as transalkylation can be greatly suppressed, and the selectivity of reaction products diethylbenzene and p-diethylbenzene are improved.

Owner:JIANGSU EVERGREEN NEW MATERIAL TECH

Catalytic reforming catalyst for catalytic pyrolysis of waste plastic for preparing fuel oil and preparation method thereof

InactiveCN101954292AGood technical effectVersatilityMolecular sieve catalystsLiquid hydrocarbon mixture productionCatalytic reformingCatalytic pyrolysis

The invention relates to a catalytic reforming catalyst for catalytic pyrolysis of waste plastic for preparing fuel oil and a preparation method thereof. The catalyst consists of oxides and an MCM-22, ZSM-35, Beta or MOR molecular sieve, wherein the oxides are any two of molybdenum oxide, cerium oxide, bismuth oxide, zirconium oxide, tin oxide or lead oxide in a weight ratio of 1 / 10 to 10 / 1; and secondary catalytic pyrolysis, isomerization and an aromatized reforming reaction are performed on crude oil formed by cracking the waste plastic, so that the ratio of cracked gasoline fractions to cracked diesel fractions is increased. The catalyst of the invention has the advantages of high activity, high selectivity and particular suitability for pyrolysis of mixed waste plastic in urban and rural household garbage with complex components for preparing oil, wherein the yield of the qualified fuel oil is over 70 percent based on the weight of the waste plastic.

Owner:TONGJI UNIV

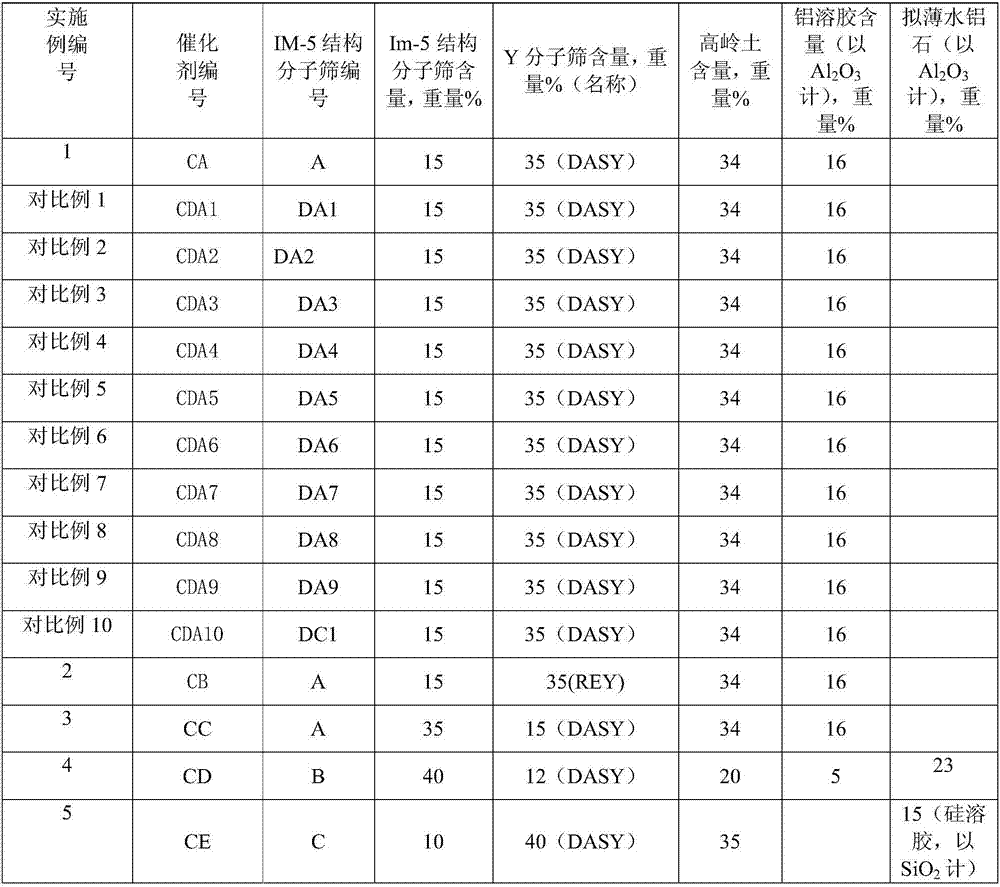

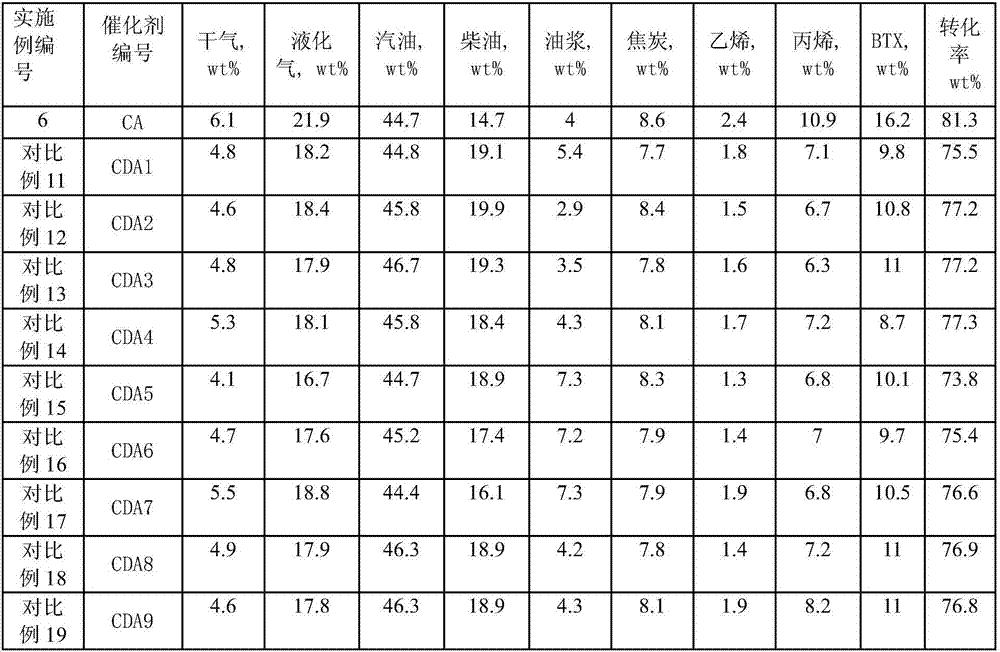

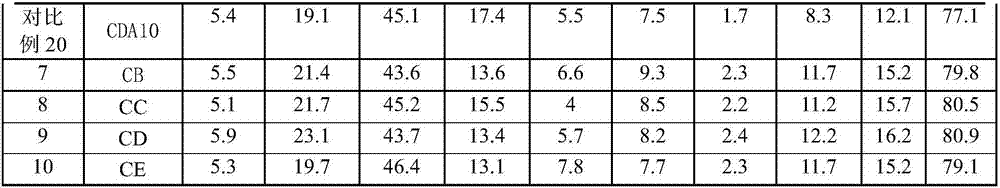

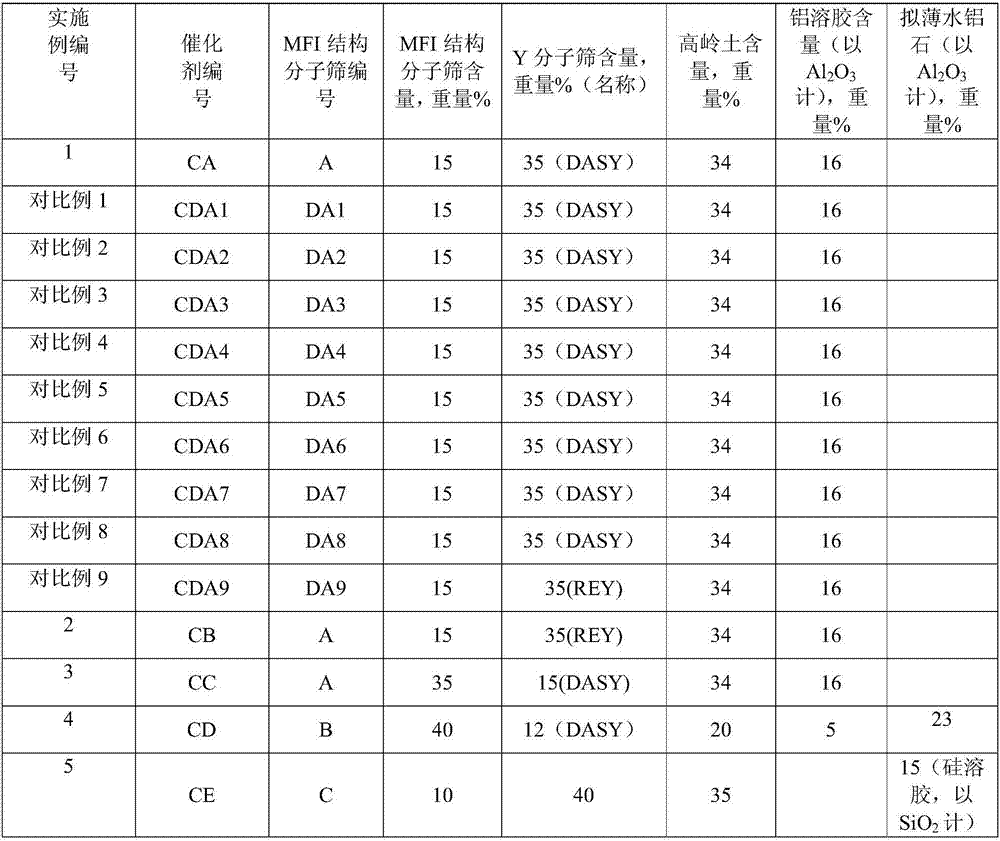

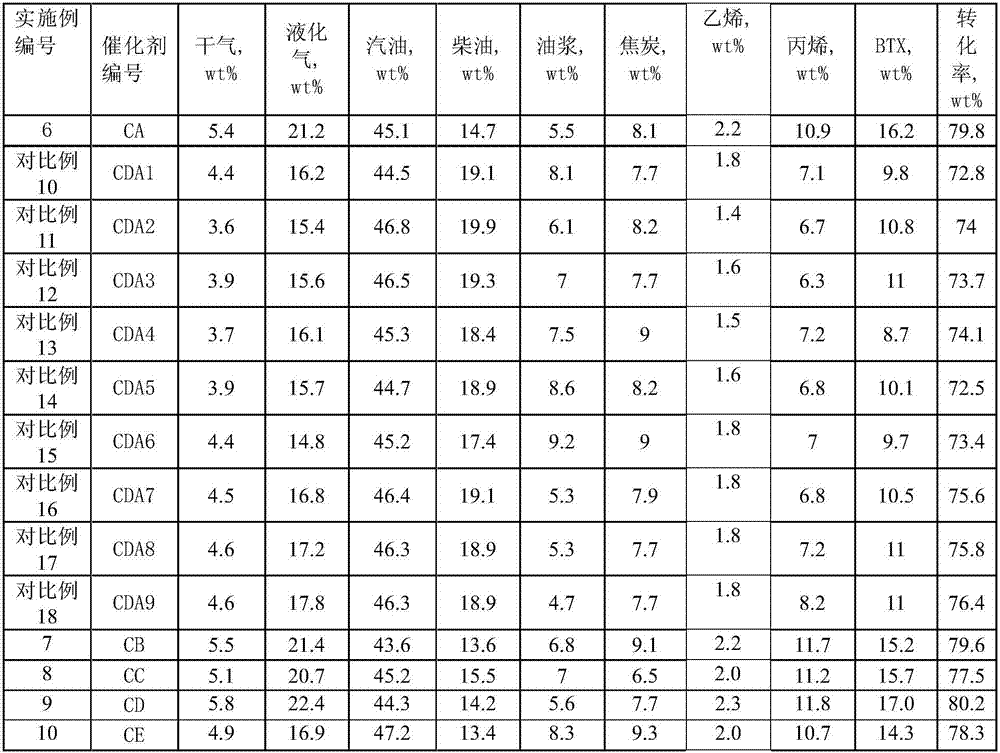

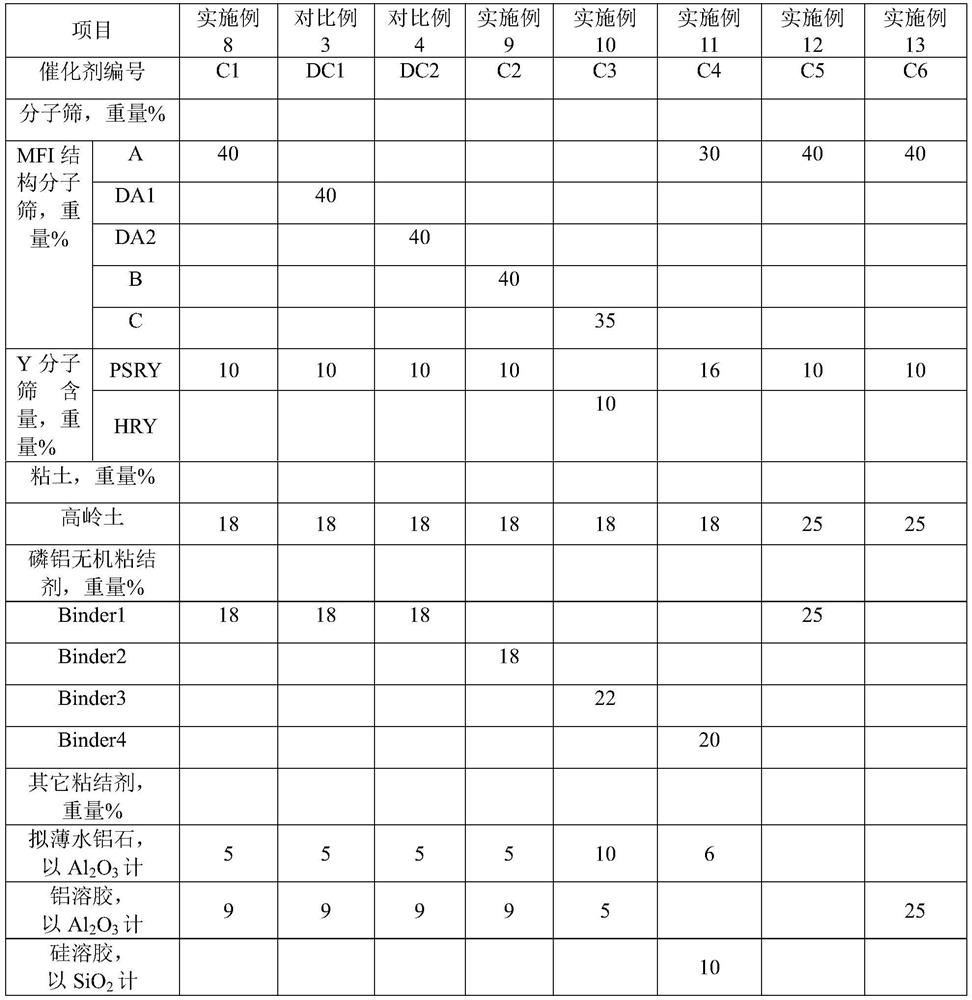

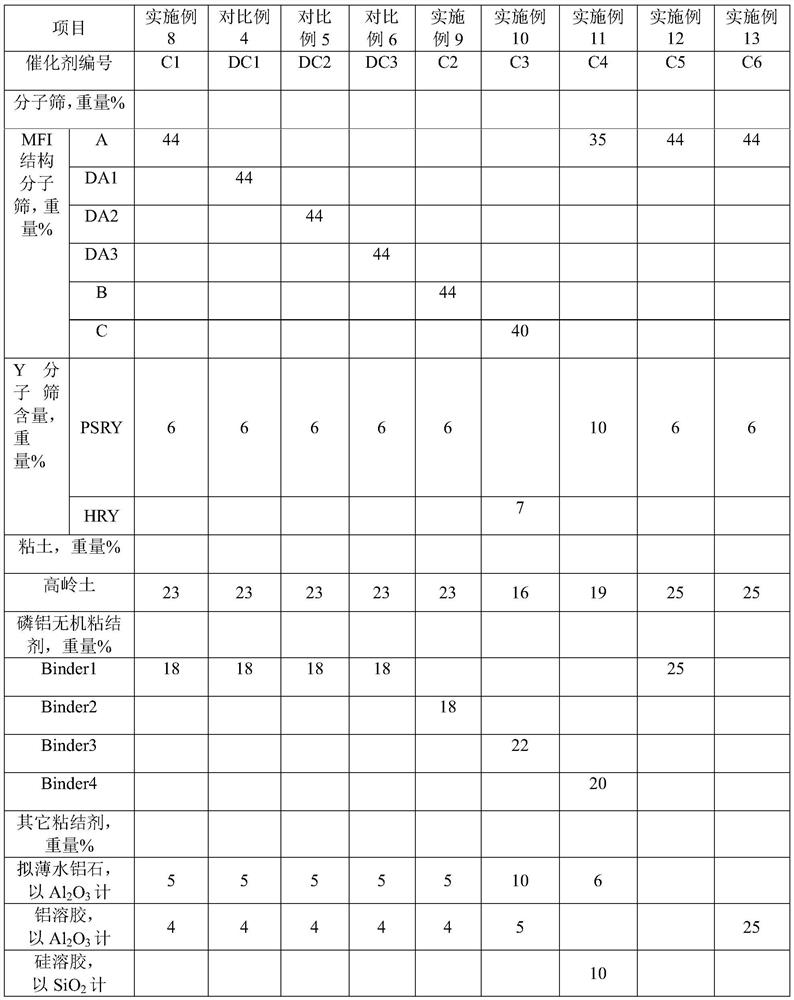

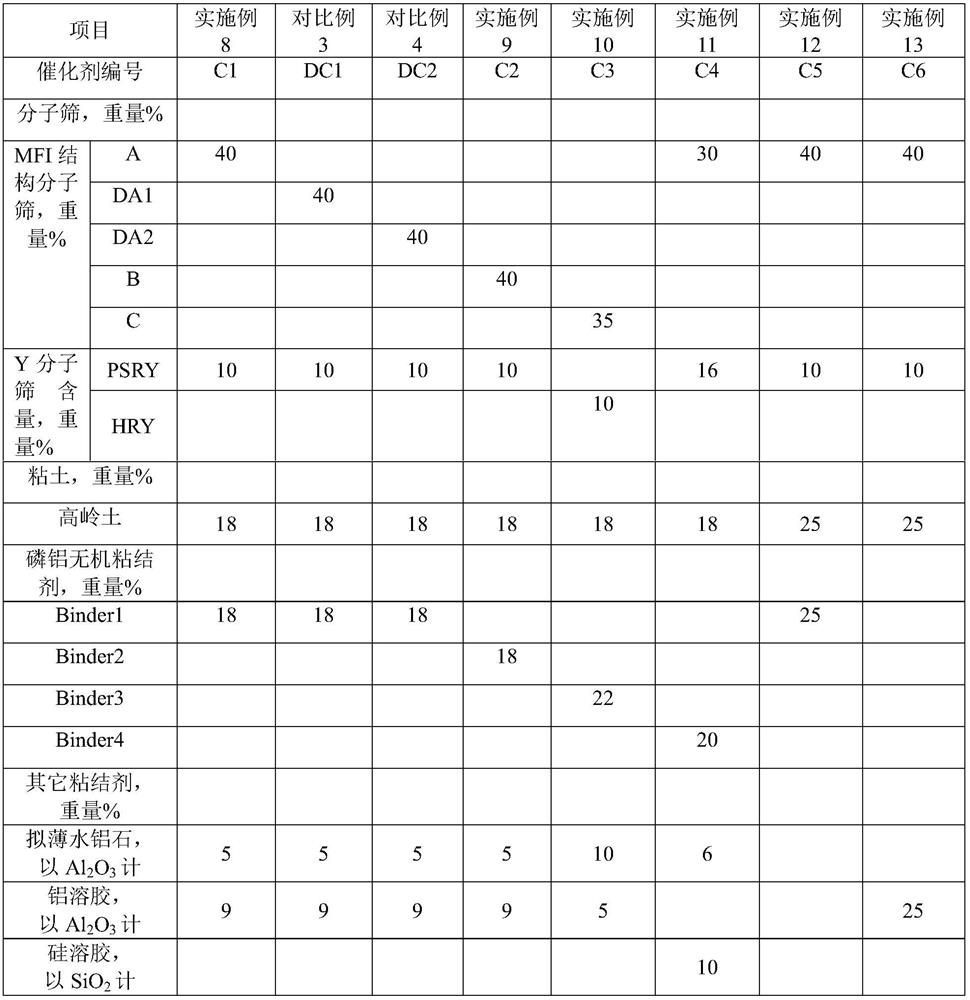

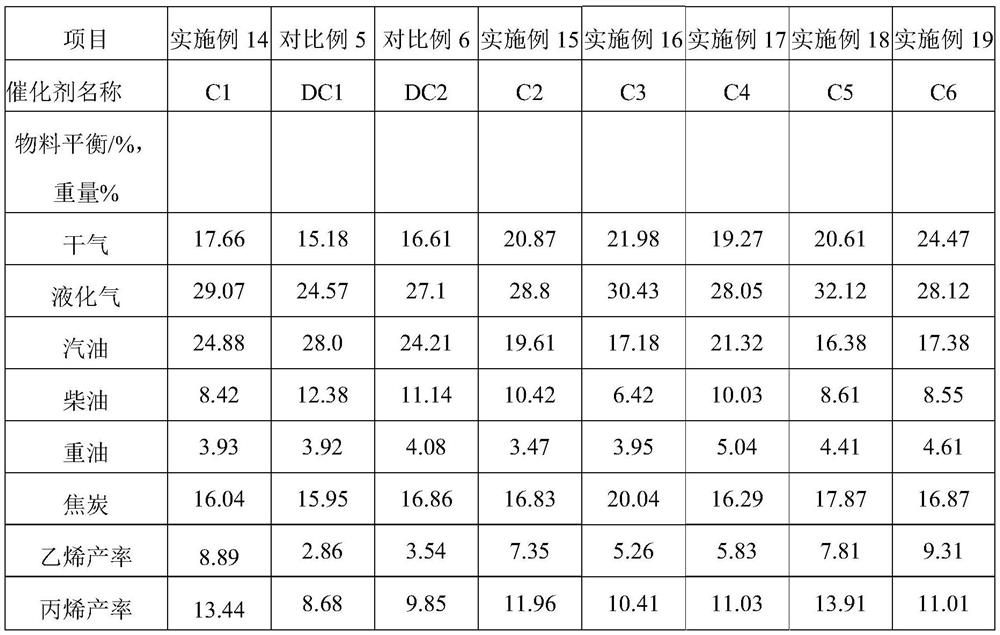

Catalytic cracking catalyst as well as preparation method and application thereof

ActiveCN112138710AStrong cracking abilityGood shape selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a catalytic cracking catalyst as well as a preparation method and application thereof. Based on the dry basis weight of the catalytic cracking catalyst, the catalytic crackingcatalyst comprises the following components in percentage by dry basis weight: 1-25wt% of Y-type molecular sieve, 5-50wt% of mesoporous-rich MFI structure molecular sieve, 1-60wt% of inorganic binderand optionally 0-60wt% of second clay, wherein the inorganic binder comprises a phosphorus-aluminum inorganic binder and / or other inorganic binders. The catalytic cracking catalyst provided by the invention has relatively high ethylene selectivity in a petroleum hydrocarbon catalytic cracking reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing dimethylbenzene by converting methanol and preparation method of catalyst

ActiveCN103212434AGood shape selectivityGood synergyMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMethanolNonmetal

The invention discloses a catalyst for preparing dimethylbenzene by converting methanol. The catalyst disclosed by the invention consists of a ZSM-5 / EU-1 composite molecular sieve and boron, wherein the ZSM-5 / EU-1 composite molecular sieve is 95-99.5wt% of the weight of the catalyst; the weight ratio of a ZSM-5 molecular sieve to an EU-1 molecular sieve is 1:(0.1-10); and the loading amount of the boron is 0.05-5wt% by measuring according to the element. Due to the mutual synergistic effect of different types of molecular sieves and non-metallic elements, the catalyst disclosed by the invention has a higher activity; and meanwhile, the selectivity of a target product dimethylbenzene for the dimethylbenzene is greatly improved, so that the catalyst disclosed by the invention can be applied to a process of preparing dimethylbenzene by converting methanol and has the advantage of being high in methanol conversion rate and dimethylbenzene selectivity.

Owner:TAIYUAN UNIV OF TECH +1

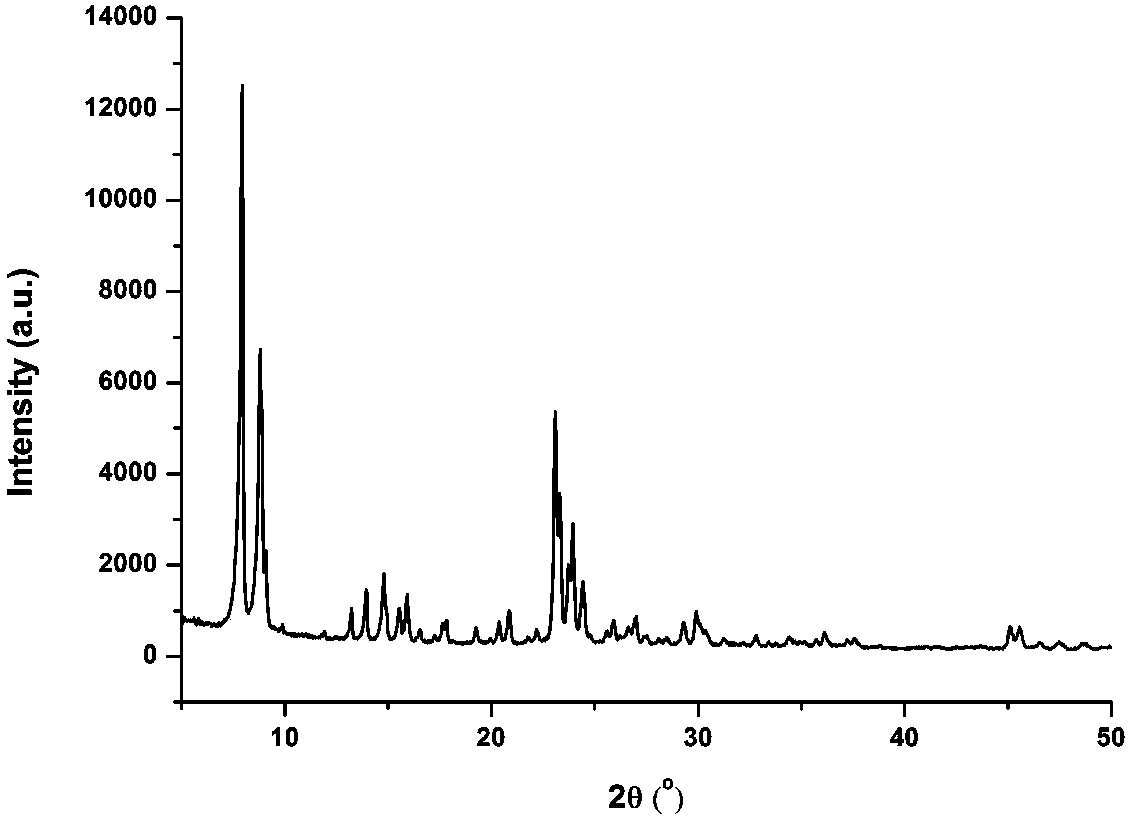

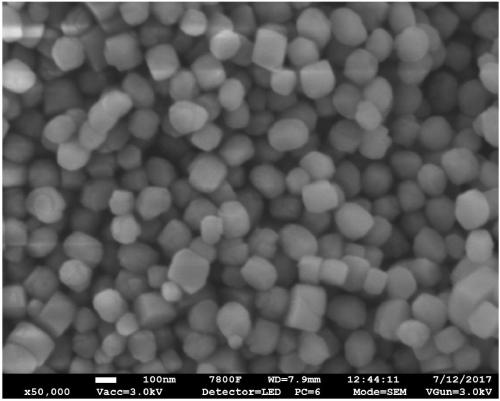

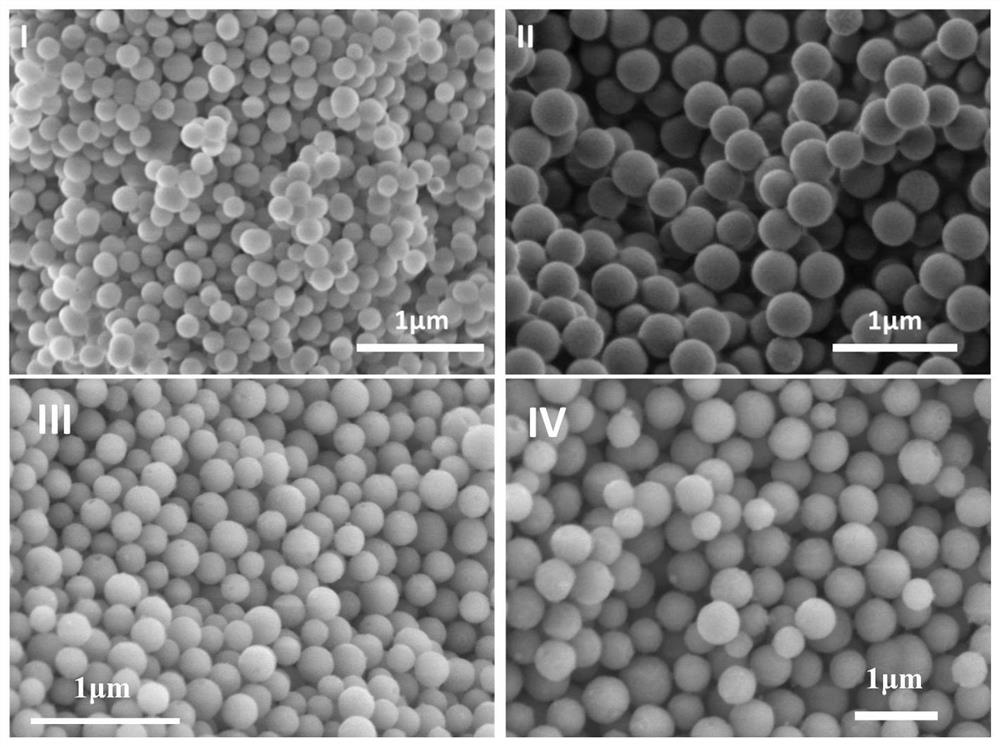

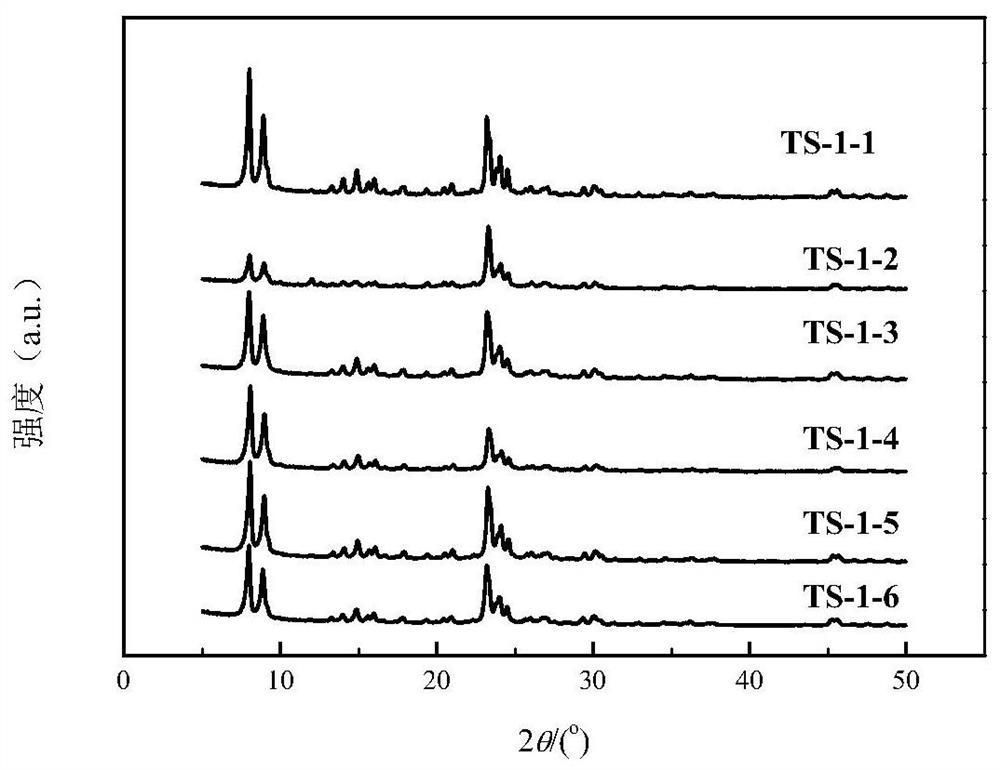

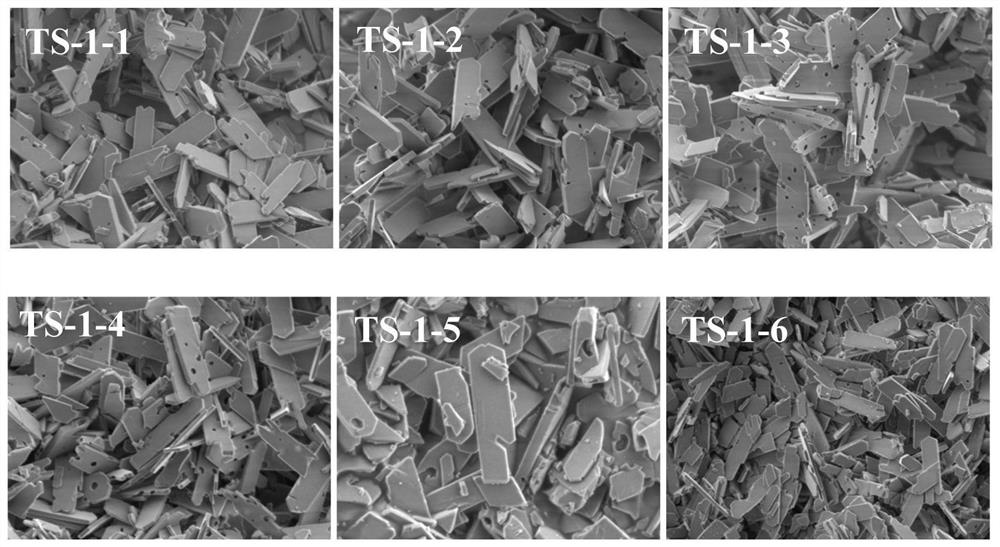

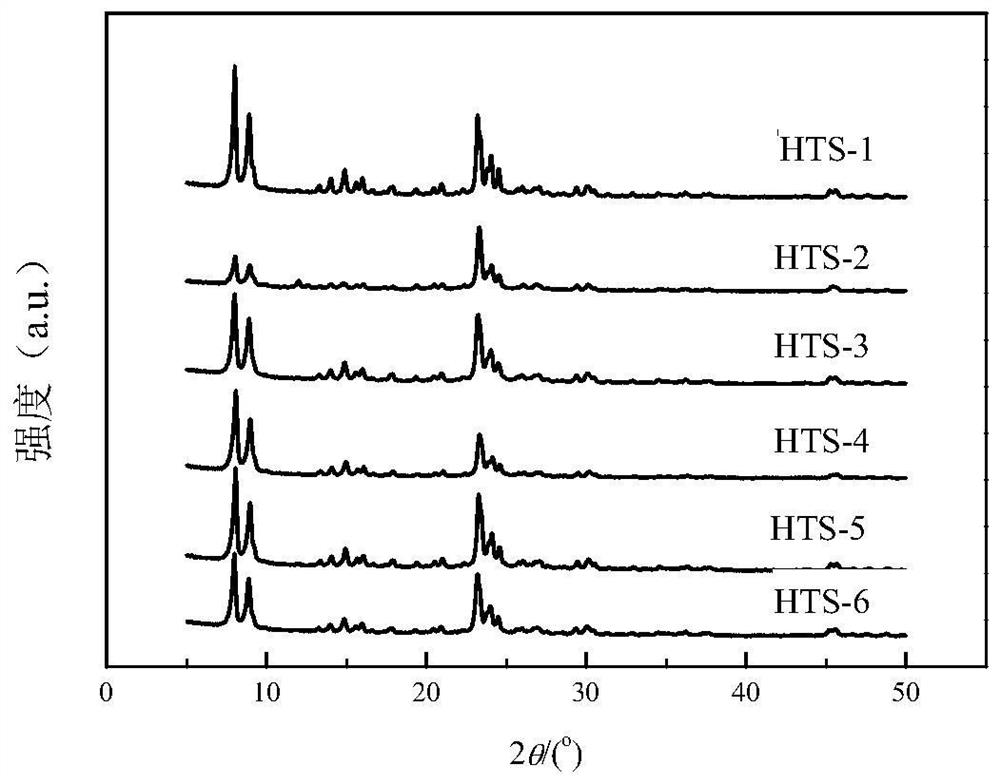

Lamellar TS-1 molecular sieve as well as preparation method and application thereof

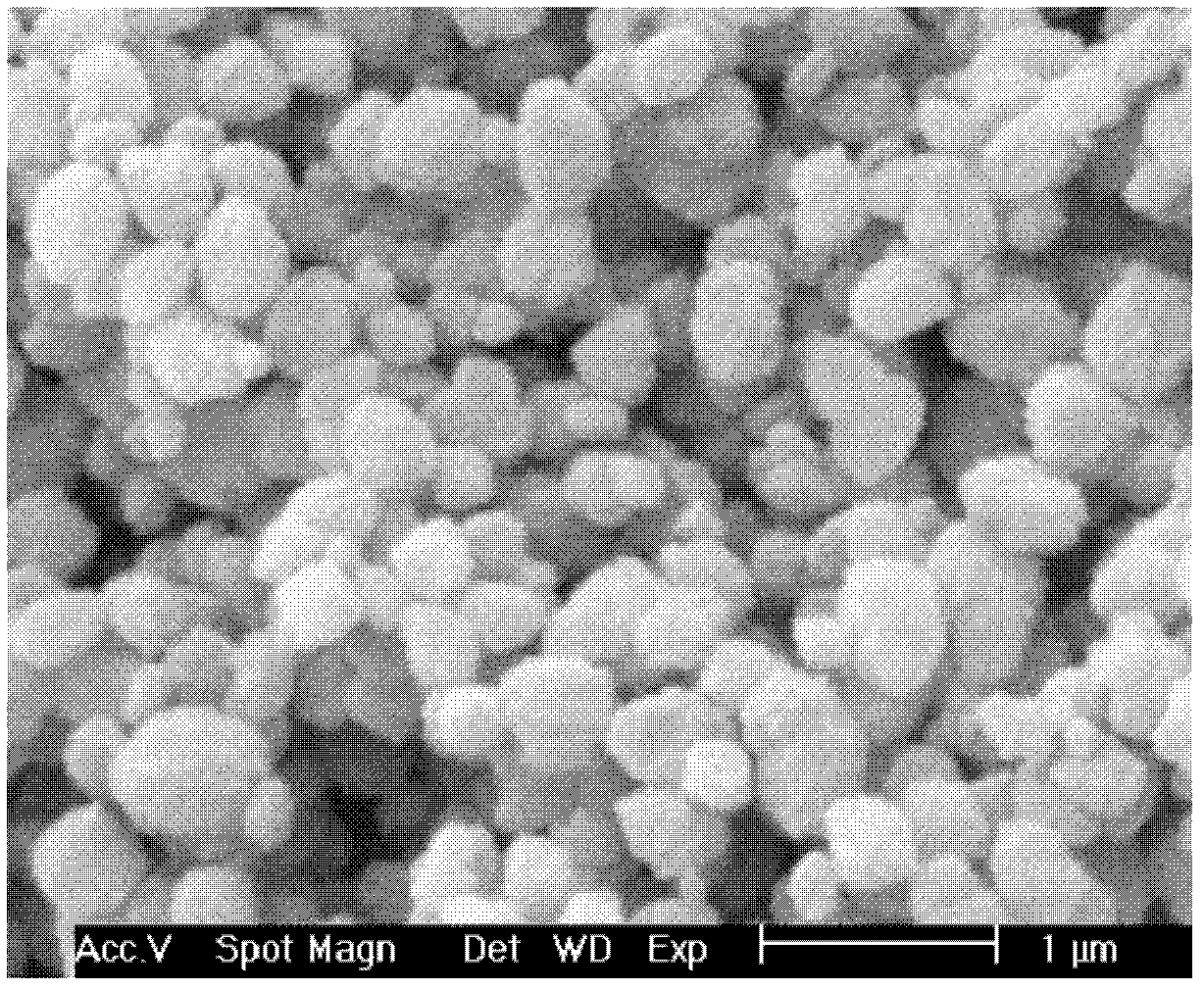

InactiveCN112978756AGrowth inhibitionSmall sizeOrganic chemistryMolecular sieve catalystsCrystallographyMolecular sieve

The invention discloses a lamellar TS-1 molecular sieve. The lamellar TS-1 molecular sieve has an MFI topological structure, the axis b of the lamellar TS-1 molecular sieve is shorter than the axis a and the axis c of the lamellar TS-1 molecular sieve, and the thickness of the lamellar TS-1 molecular sieve is 50-500 nm. The invention also provides a preparation method and application of the lamellar TS-1 molecular sieve. The lamellar TS-1 molecular sieve is relatively small in size in the b-axis direction, so diffusion of guest molecules is facilitated, and the lamellar TS-1 molecular sieve has excellent catalytic performance. The straight pore channel direction (b-axis) of the TS-1 molecular sieve is a main molecular diffusion path, so the diffusion efficiency of the product is improved due to the thinner b-axis thickness.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalytic cracking catalyst, preparation method thereof, and method for catalytic cracking of hydrocarbon oil

ActiveCN112138712BStrong cracking abilityGood shape selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a catalytic cracking catalyst and a preparation method thereof and a method for catalytic cracking of hydrocarbon oil. Based on the dry basis weight of the catalyst, the catalyst contains 1-30% by weight of Y-type molecular sieve based on the dry basis weight. 5-55% by weight of mesoporous-rich phosphorous and metal-containing MFI structured molecular sieve, 1-60% by weight of inorganic binder on dry basis and optionally 0-60% by weight of The second clay, the inorganic binder includes phosphorus aluminum inorganic binder and / or other inorganic binders. The catalyst of the invention has better ethylene selectivity in the petroleum hydrocarbon catalytic cracking reaction, and can produce more propylene and BTX at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

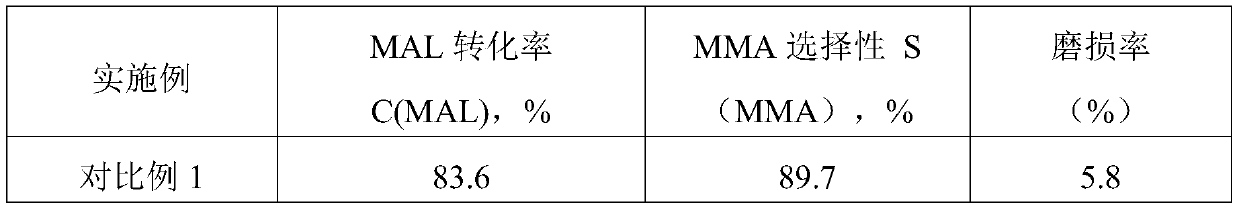

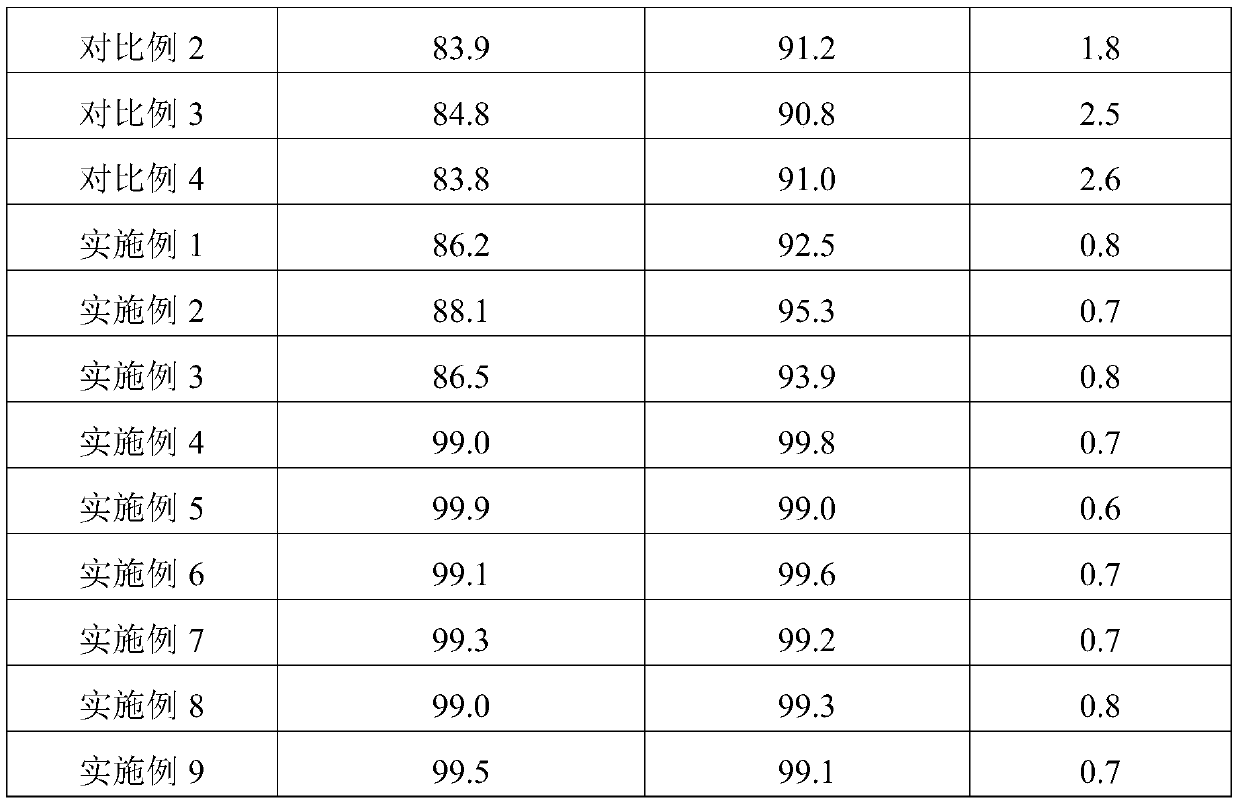

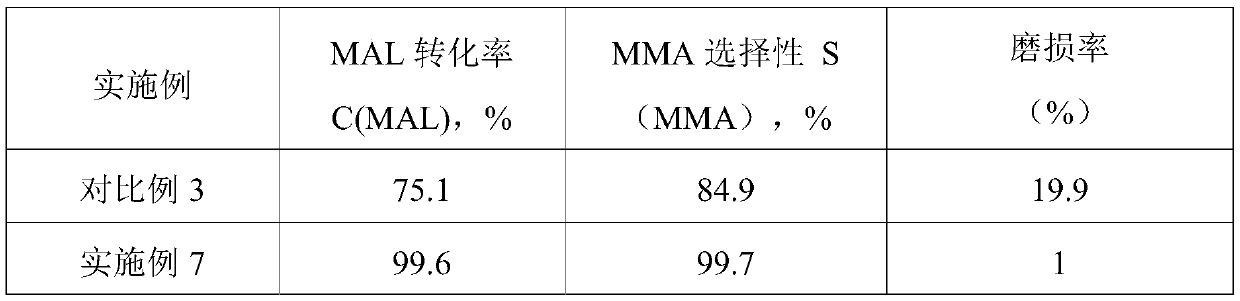

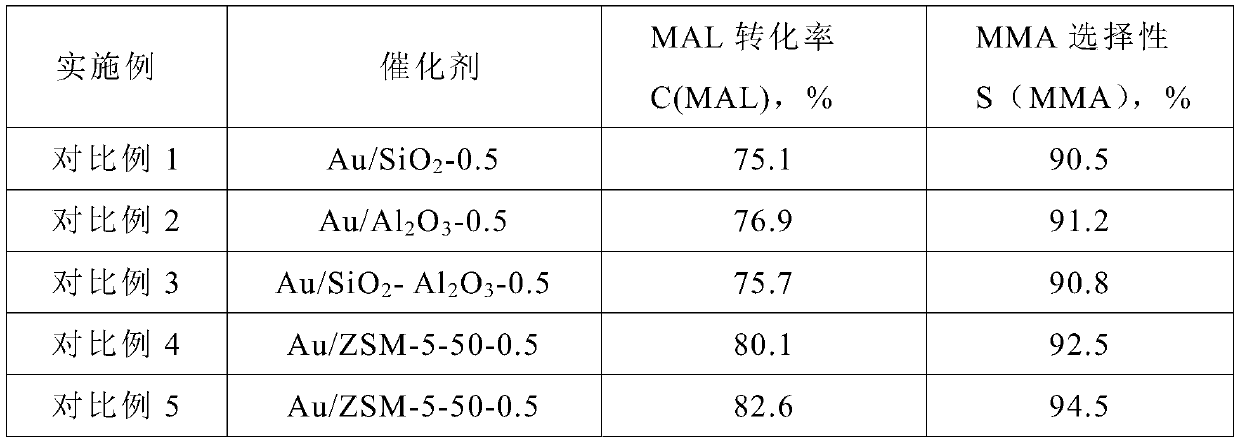

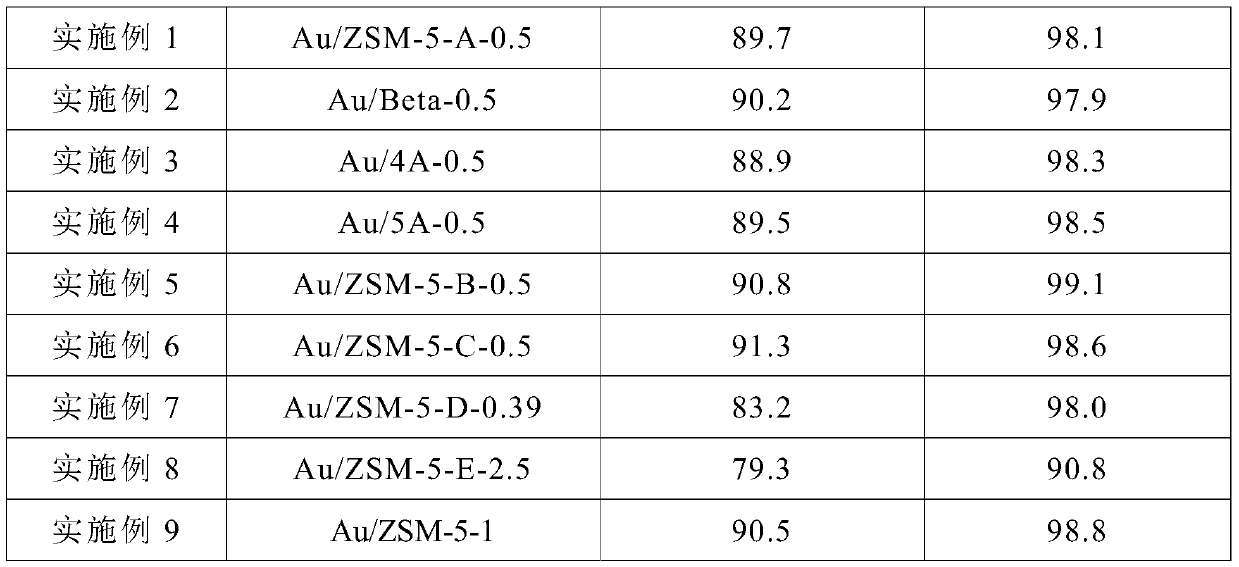

Preparation method and application of catalyst for synthesizing methyl methacrylate

InactiveCN110975929AImprove stabilityStrong loadMolecular sieve catalystsPreparation by aldehyde oxidation-reductionMolecular sievePolymer science

The invention discloses a preparation method of a catalyst for synthesizing methyl methacrylate. A ZSM-5 molecular sieves as a carrier, and an active center Au, and a transition metal and a lanthanidemetal are loaded on the molecular sieve; the prepared catalyst is good in catalytic effect, the conversion rate of methylacrolein is increased while the activity of the catalyst is improved, and theselectivity of methyl methacrylate is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method for eliminating acidity of external surface of ZSM-5 molecular sieve catalyst

InactiveCN102895989AStrong alkalineGood removal effectMolecular sieve catalystsHydrocarbonsGrignard reagentEvaporation

The invention provides a method for eliminating acidity of an external surface of a ZSM-5 molecular sieve catalyst. The method comprises the following steps that 3,5-dimethylbromobenzene, a magnesium rod, iodine and tetrahydrofuran as raw materials undergo a reaction without water and oxygen to produce a 3,5-dimethylphenylmagnesium bromide Grignard reagent; the 3,5-dimethylphenylmagnesium bromide Grignard reagent is added with a molecular sieve n-hexane turbid liquid in a nitrogen atmosphere; the mixed solution is subjected to reflux at a temperature of 80 DEG C for 4 hours and then is dried by evaporation; and a sample obtained by the previous step is calcinated at a temperature in air to form a MgO-modified ZSM-5 molecular sieve catalyst. The MgO-modified ZSM-5 molecular sieve catalyst obtained by the method can be used for reactions such as a toluene disproportionation reaction, an ethylbenzene disproportionation reaction, a toluene carbonylation reaction and an ethylbenzene carbonylation reaction, wherein the reactions can selectively produce a certain product because of shape selectivity. The method has simple processes, a low cost and a wide application prospect.

Owner:NANJING UNIV

A kind of catalytic cracking catalyst and its preparation method and application

ActiveCN112138710BPromote migrationGood synergyCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The present invention relates to a catalytic cracking catalyst and its preparation method and application. Based on the dry basis weight of the catalytic cracking catalyst, on a dry basis, the catalytic cracking catalyst contains 1-25 wt% Y-type molecular sieve, 5-50 wt% MFI structure molecular sieve rich in mesopores, 1-60% by weight of an inorganic binder and optionally 0-60% by weight of a second clay, the inorganic binders include phosphor-aluminum inorganic binders and / or other inorganic binders. The catalytic cracking catalyst provided by the invention has high ethylene selectivity in the catalytic cracking reaction of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971015BHigh hydrocarbon oil cracking cracking activityHigh yieldCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalytic cracking catalyst and preparation method thereof

ActiveCN107971011BHigh hydrocarbon oil cracking cracking activityHigh selectivityMolecular sieve catalystsBulk chemical productionMolecular sieveStrong acids

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of methyl methacrylate

ActiveCN110981728AHigh strengthImprove stabilityMolecular sieve catalystsPreparation by aldehyde oxidation-reductionPtru catalystCatalytic oxidation

The invention discloses a preparation method of methyl methacrylate, wherein the method comprises the steps: adding methylacrolein and methanol into an airtight continuous reactor, and sufficiently mixing until the mass concentration of methanol in the mixture is 45-80%; and adding a gold-based catalyst into the reactor in a stirring state, introducing an oxidant into the bottom of the reactor, controlling the reaction temperature to be 110-160 DEG C and the reaction pressure to be 0.5-2 MPa, and carrying out catalytic oxidation esterification to prepare methyl methacrylate. The preparation cost of the catalyst is reduced, the wear resistance of the catalyst is improved, the preparation conditions are more environment-friendly, and the catalytic activity is good. The methyl methacrylate product synthesized by catalysis has high yield and is not easy to polymerize in a reaction system.

Owner:潍坊三力本诺化学工业有限公司 +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971028BHigh hydrocarbon oil cracking cracking activityHigh selectivityCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y type molecular sieve and a phosphorus-containing IMF-structure molecular sieve, wherein the n(SiO2) / n(Al2O3) of the phosphorus-containing IMF-structure molecular sieve is more than 18 and less than 70, the phosphoruscontent is 1-15 wt%, the Al distribution parameter D is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores accounts for 40-70% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strong acid accounts for 45-75% of the total acid amount, and a ratio of the acid B to the acid L is 8-30. According to the present invention, the catalytic cracking catalyst has high low-carbon olefin yield and high BTX yield in the catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

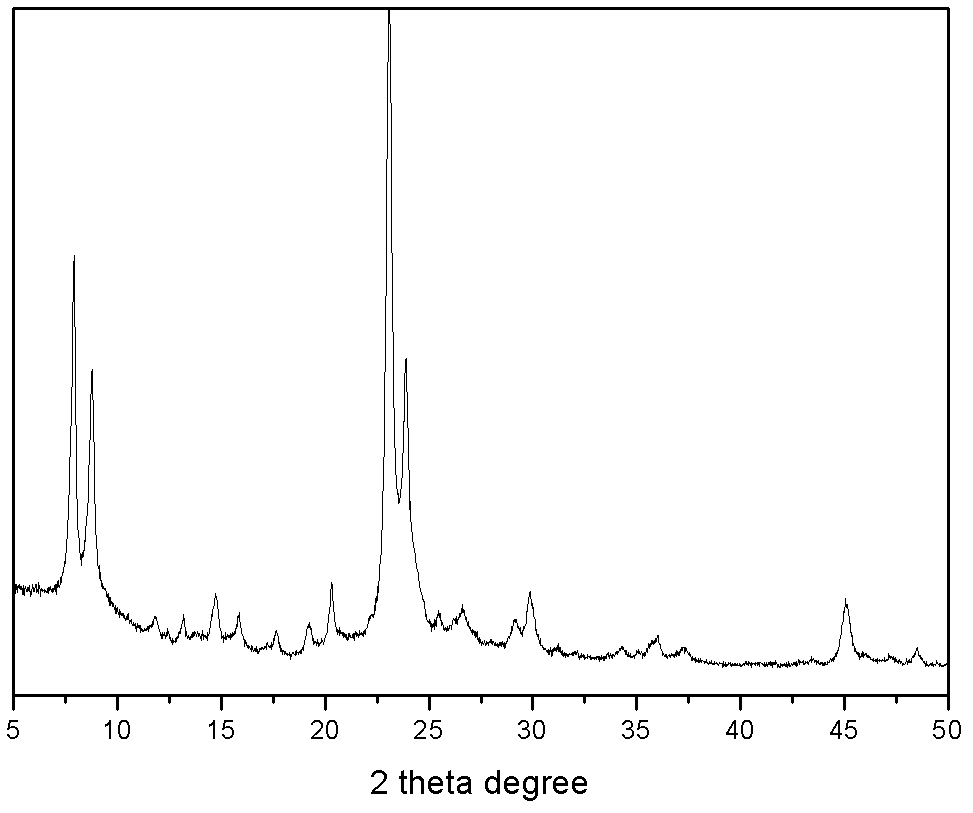

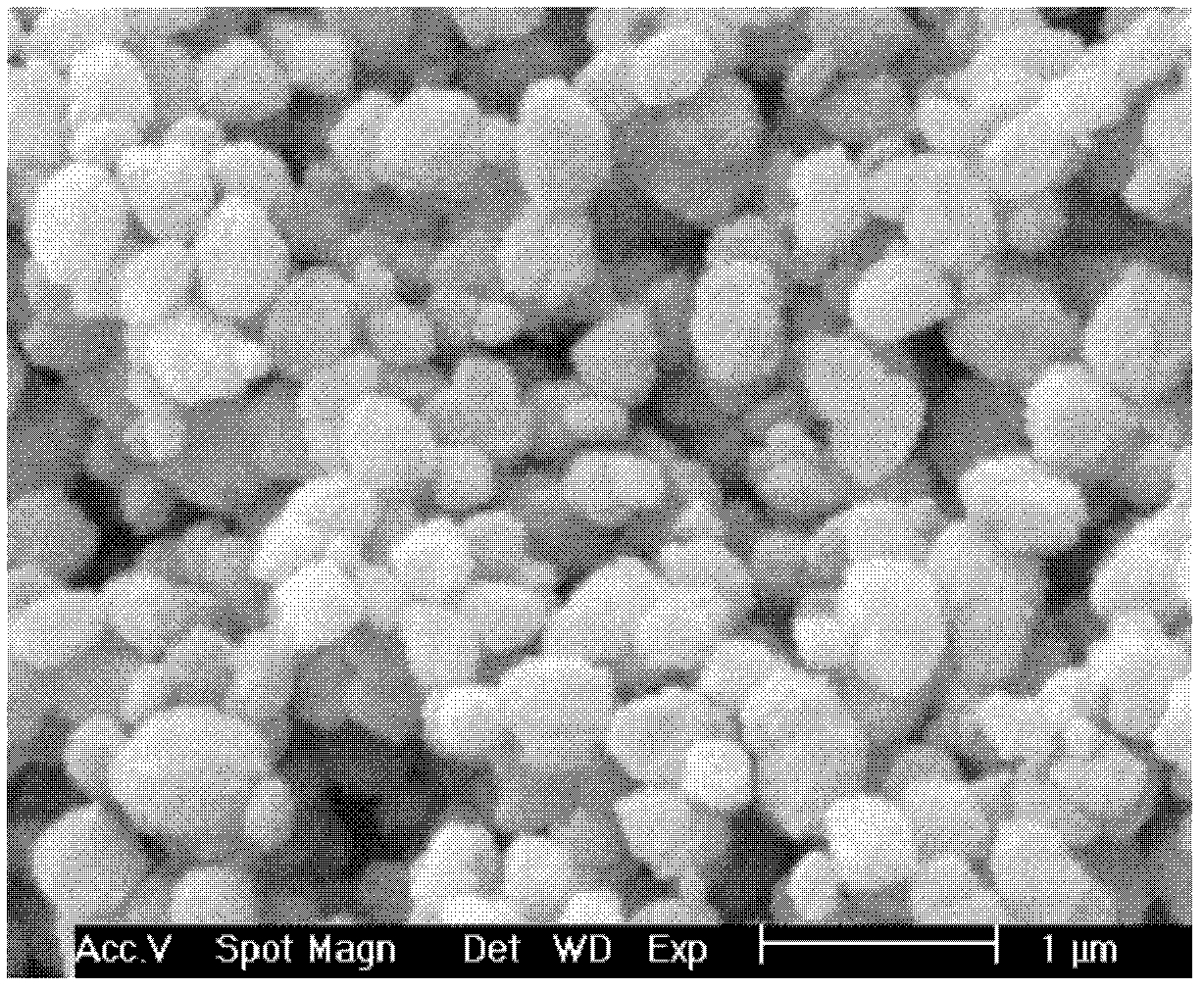

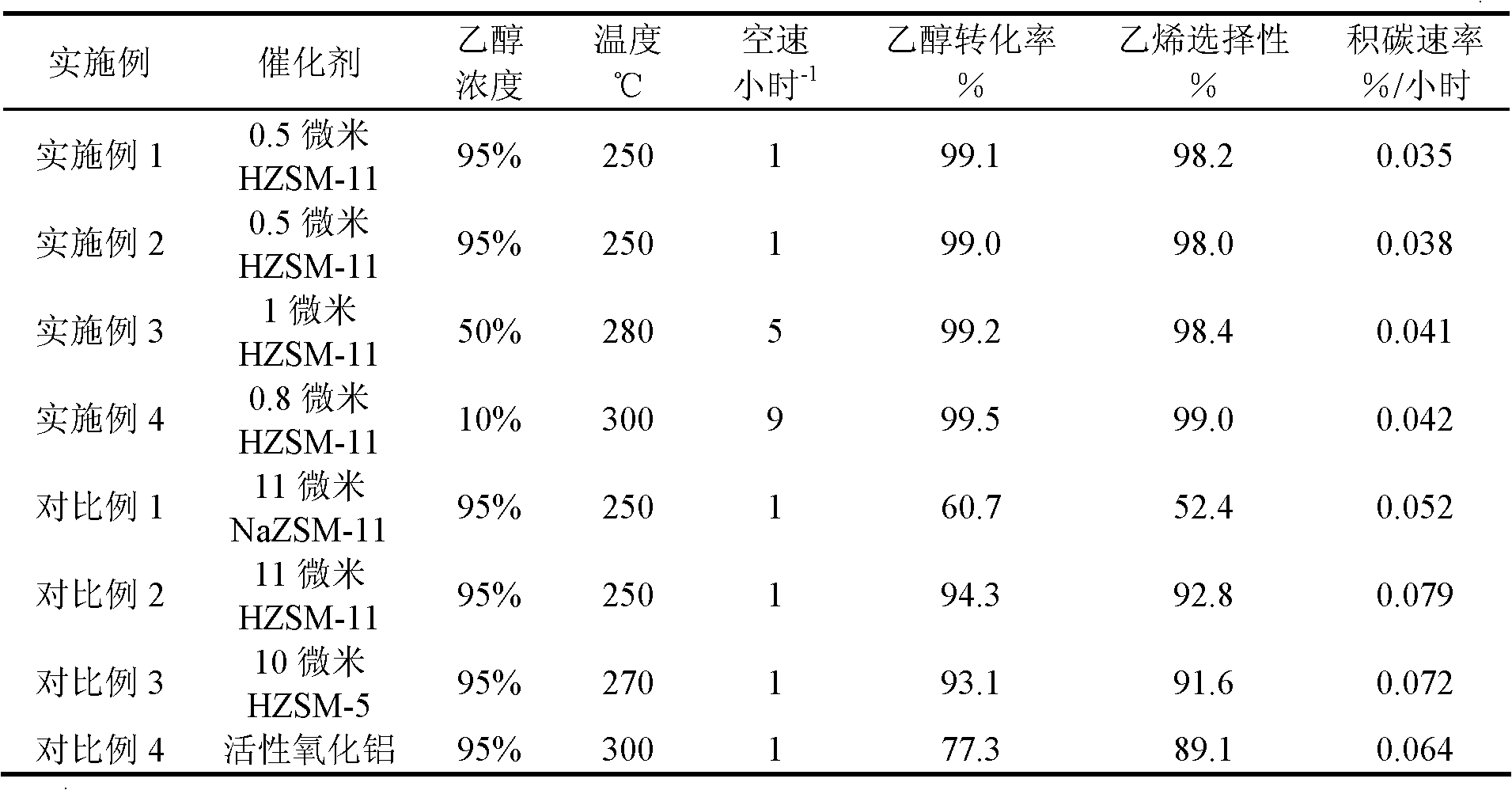

Method for preparing ethylene through ethanol dehydration

InactiveCN103030490AIncrease the external specific surface areaLarger surface areaMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAcid washing

The invention relates to a method for preparing ethylene through ethanol dehydration and mainly solves the problem of poor reaction stability in the prior part. According the method, ethanol with the weight percentage concentration being 5 to 100 percent is used as raw materials, reaction raw materials and catalysts are in contact to generate ethylene under the conditions that the reaction temperature is 200 to 400 DEG C, and the volume space velocity relative to the ethanol is 0.1 to 15 h<-1>, wherein the used catalysts comprise the following ingredients through be metered in parts by weight: a, 40 to 95 parts of ZSM-11 molecular sieves, wherein the silicon aluminum mol ratio (SiO2 / Al2O3) is 200-300, and the crystal grain diameter is smaller than or equal to 5 microns; and b, 5 to 60 parts of bonding agents; and the ZSM-11 molecular sieves are at least subjected to acid washing for once. Through the technical scheme, the problem is perfectly solved, and the method can be used in the industrial production of ethylene preparation through ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst, preparation method thereof and hydrocarbon oil catalytic cracking method

ActiveCN112138712AStrong cracking abilityGood shape selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePropene

The invention relates to a catalytic cracking catalyst, a preparation method of the catalytic cracking catalyst and a hydrocarbon oil catalytic cracking method. The catalyst contains 1-30 wt% of a Y-type molecular sieve based on dry basis weight, 5-55 wt% of a mesoporous-rich phosphorus and metal-containing MFI structure molecular sieve based on dry basis weight, 1-60 wt% of an inorganic binder based on dry basis weight, and optionally 0-60 wt% of second clay based on dry basis weight, wherein the inorganic binder comprises a phosphorus-aluminum inorganic binder and / or other inorganic binders.The catalyst provided by the invention has better ethylene selectivity in a petroleum hydrocarbon catalytic cracking reaction, and can produce more propylene and BTX at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

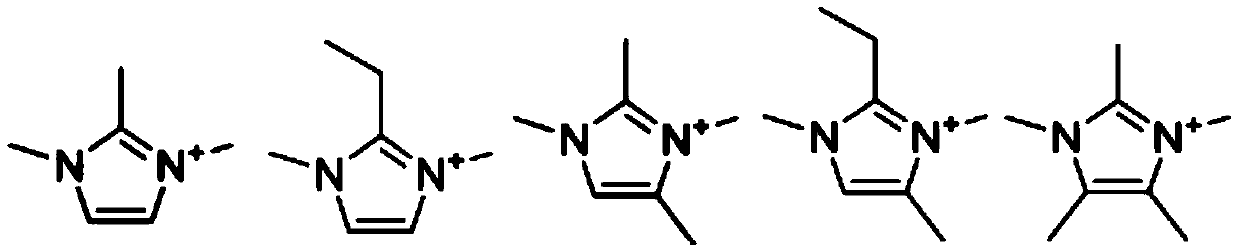

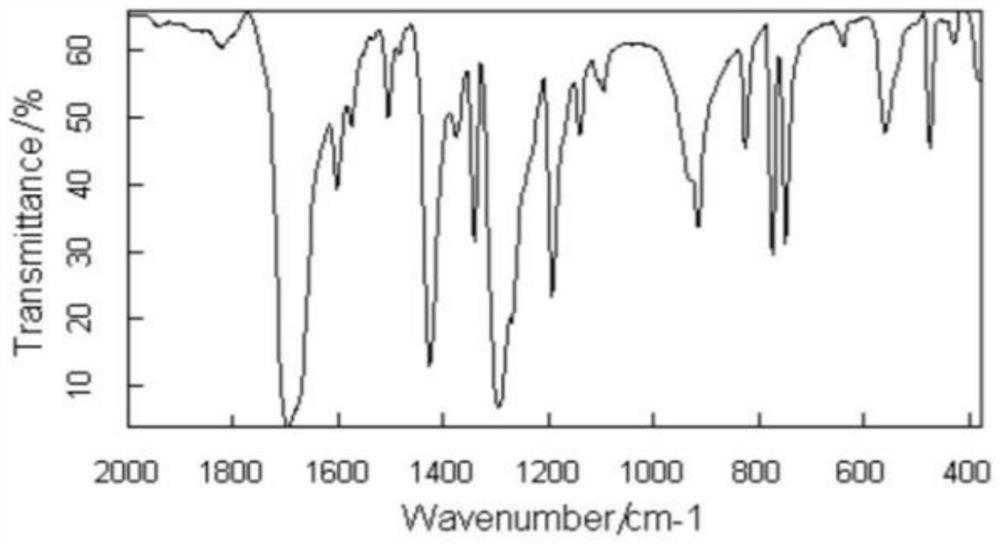

RTH type topology molecular sieve catalyst for dimethyl ether carbonylation reaction and its preparation method and application

ActiveCN106964396BSpecial pore structureExtend your lifeMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMethyl acetate

The invention discloses an RTH type molecular sieve catalyst for dimethyl ether carbonylation reaction and a preparation method thereof. Organic template agent (OSDA) and NaOH solution are formed into a mixed solution, silicon source is added thereto and mixed evenly, and then FAU type is added. The structural silica-aluminum zeolite provides a silicon source and an aluminum source and is stirred to form a mixed sol. It is dynamically crystallized at 140-180°C for 3-30 days and then recovered. It is then activated by ammonium ion exchange, drying and roasting to obtain RTH with two-dimensional eight-membered ring channels. Type molecular sieve topology, used as a catalyst for the carbonylation reaction of dimethyl ether. The molecular sieve catalyst of the present invention has a unique size pore structure and a catalytic shape-selective effect, so that the carbonylation of dimethyl ether to produce methyl acetate has a high conversion rate and selectivity, and at the same time greatly improves the catalyst life.

Owner:CHINA CATALYST HLDG CO LTD

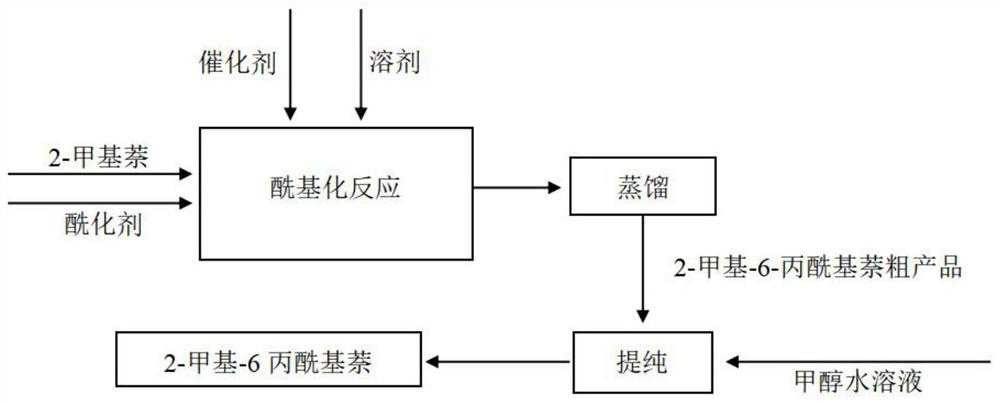

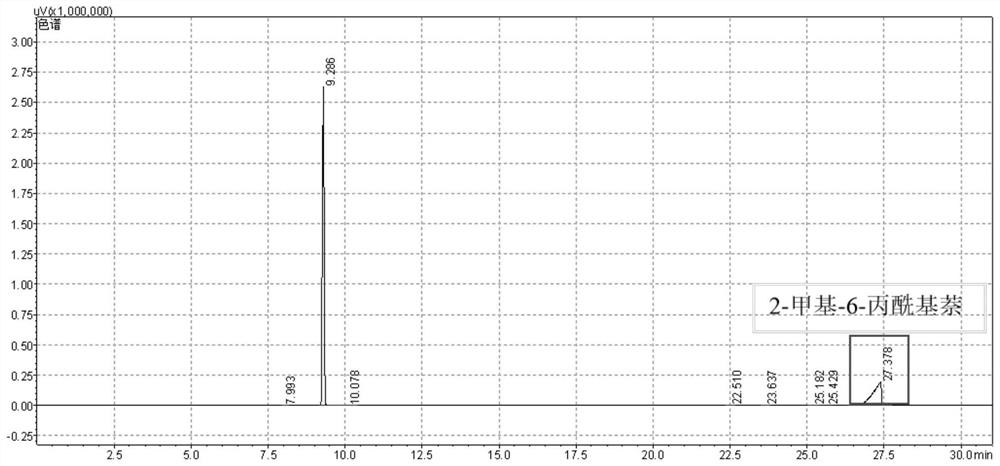

Preparation method of 2-methyl-6-propionyl naphthalene

PendingCN114213228AGood synergyImprove conversion rateMolecular sieve catalystsCarbonyl compound preparation by condensationMolecular sievePtru catalyst

The invention discloses a preparation method of 2-methyl-6-propionyl naphthalene. The method comprises the following steps: (1) preparing a modified H beta zeolite molecular sieve catalyst; (2) preparing 2-methyl-6-propionyl naphthalene; and (3) purification of the 2-methyl-6-propionyl naphthalene. According to the method disclosed by the invention, the modified H beta zeolite molecular sieve is used as the catalyst, so that the Friedel-Crafts acylation reaction is promoted, and the raw material conversion rate, the product yield and the product purity are improved. The conversion rate of the 2-methylnaphthalene can reach about 80.0%, and after purification, the 2-methyl-6-propionyl naphthalene with the yield of 70%-90% and the purity of 91%-93% can be obtained.

Owner:CCTEG CHINA COAL RES INST

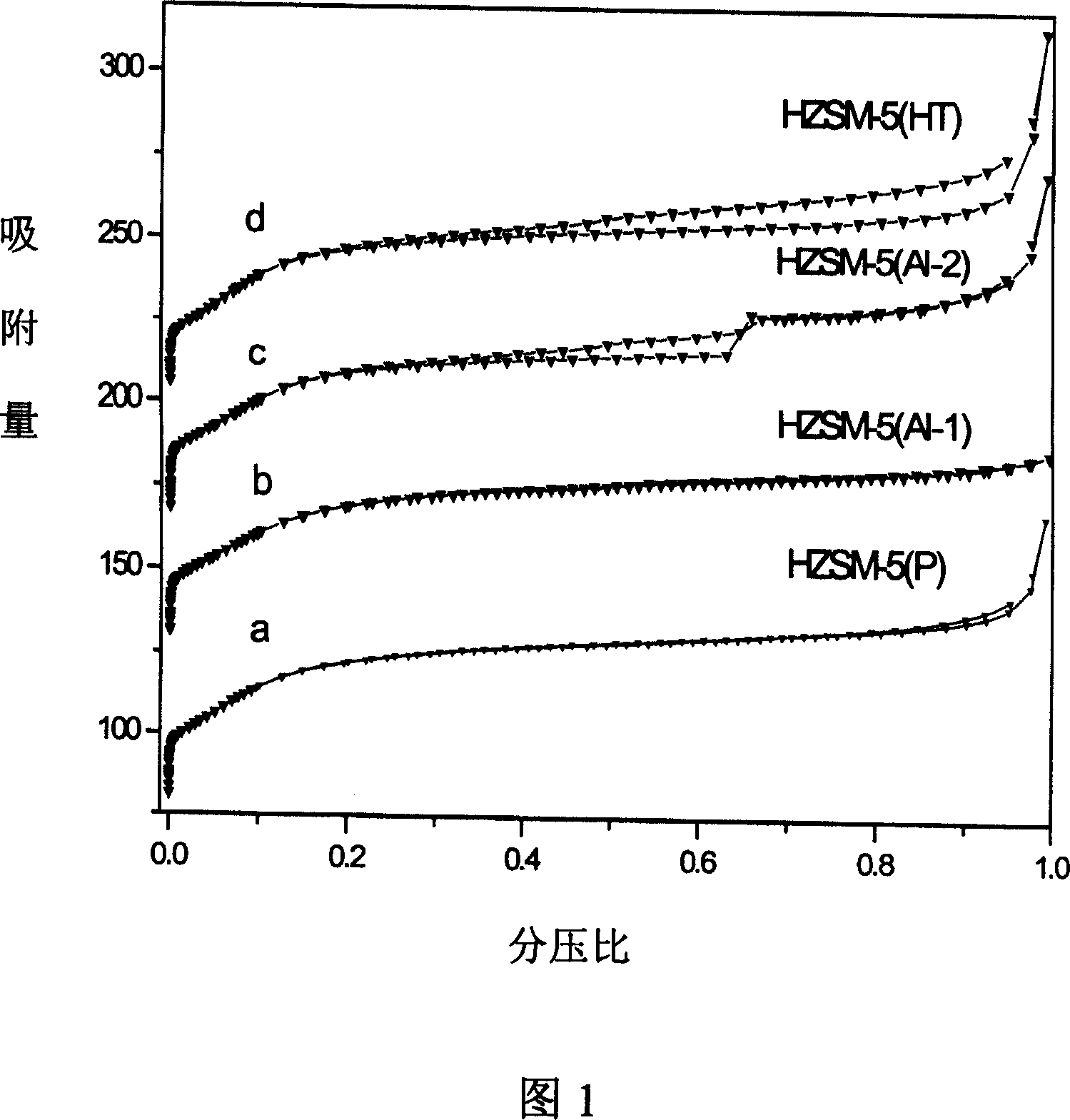

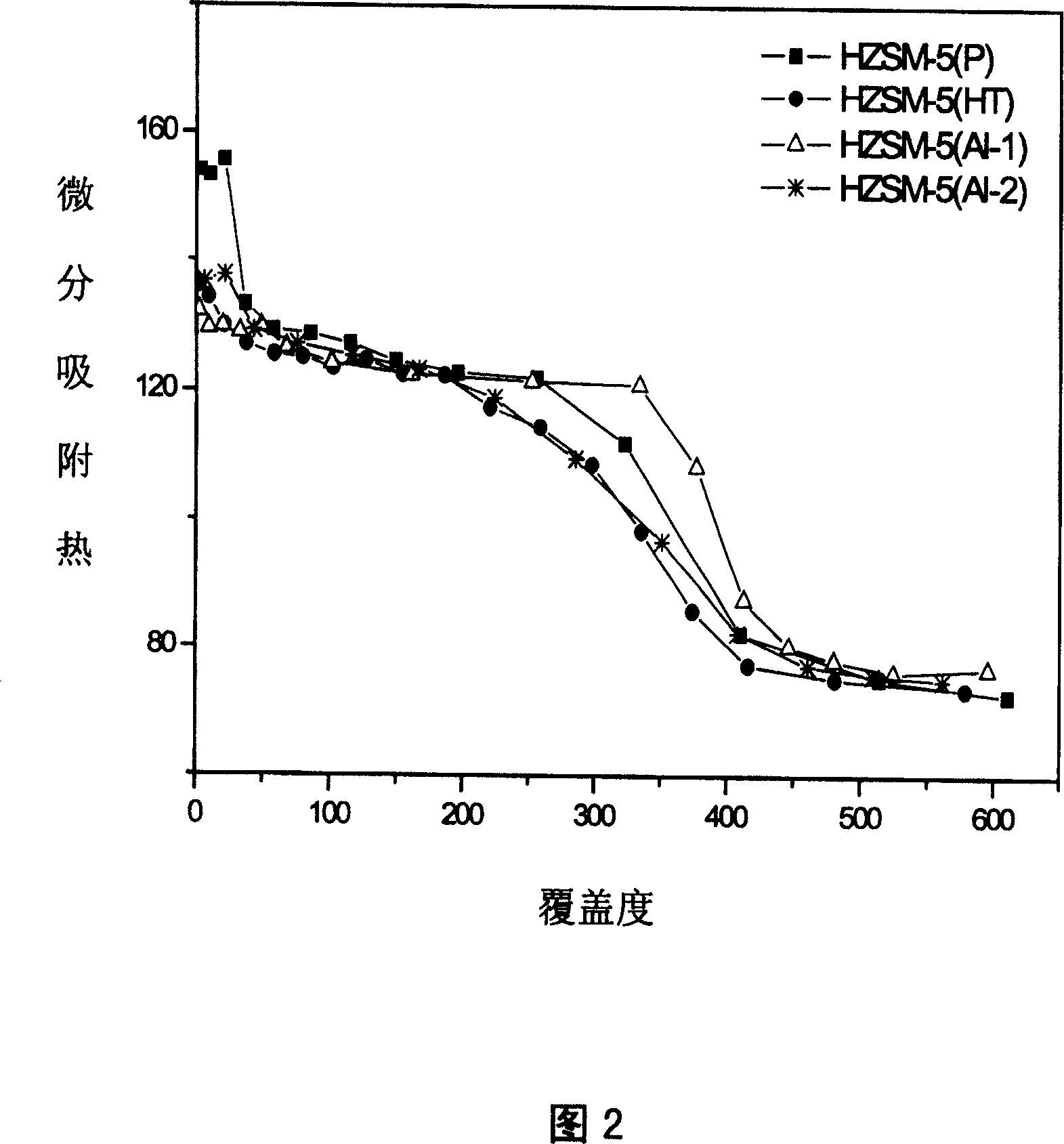

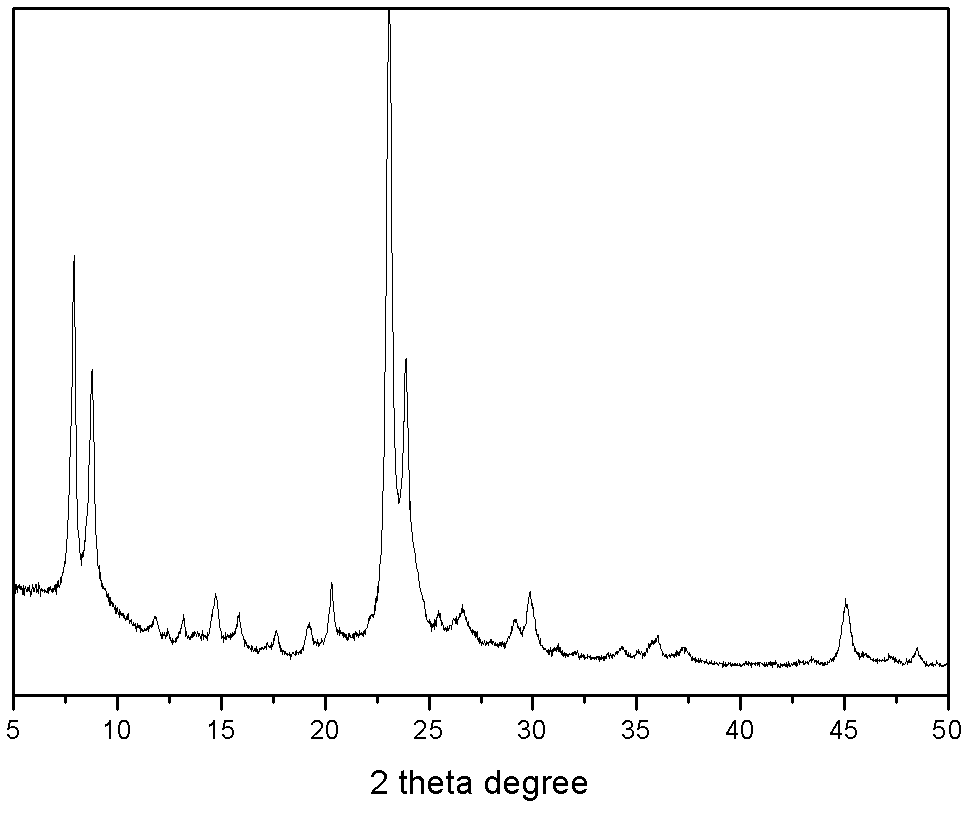

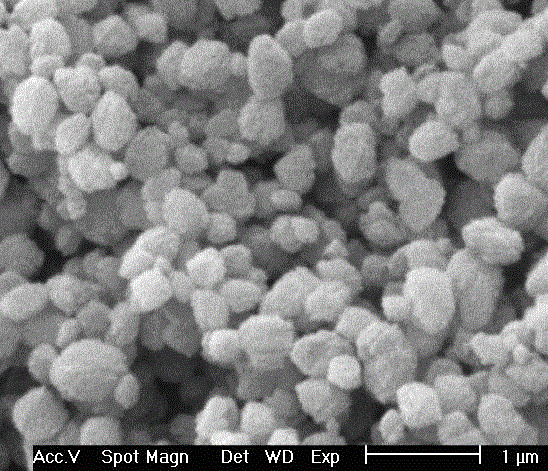

Method for preparing pure finely porous molecular sieve psosessing even distribution of acid strength

InactiveCN100340486CGood shape selectivityPentasil aluminosilicate zeoliteMolecular sieveAcid strength

A millipore HZSM-5 molecular sieve with uniform acid strength distribution features that the HZSM-5 molecular sieve taken from market is synthesized again in the aqueous solution of 3-valence al salt at 90-120 deg.C for 10-14 hr.

Owner:SHANTOU UNIV

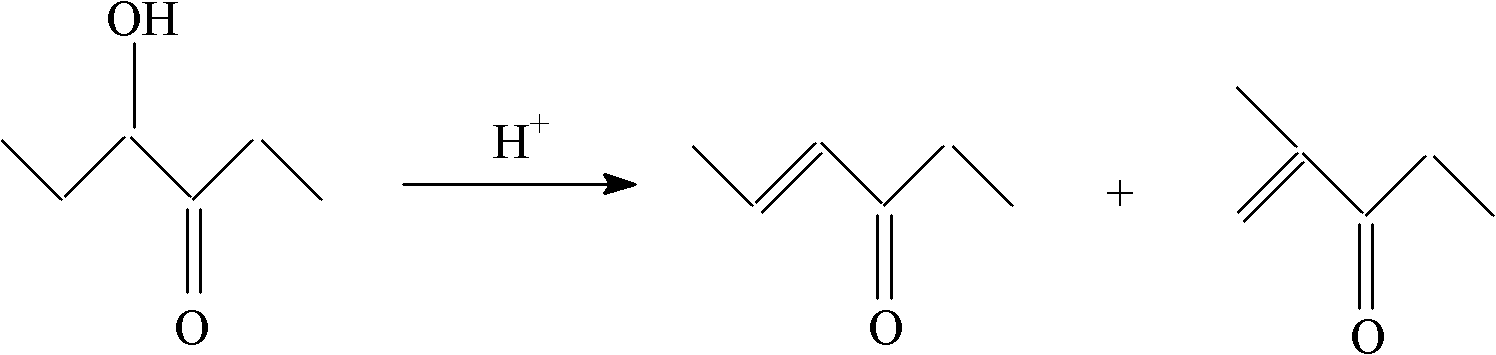

Preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone

ActiveCN103058838BIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone, and the method is mainly used for solving the problems in the prior art that the catalyst activity is low, the reaction temperature is high and the space velocity is low. The technical scheme adopted by the invention is as follows: according to the preparation method, 4-hydroxy-3-hexanone which is used as a raw material, is contacted with a catalyst so as to generate 4-hexene-3-ketone under the condition that the reaction temperature is 200-400 DEG C, and the space velocity relative to the liquid weight of 4-hexene-3-ketone is 0.5-15h<-1>, wherein the catalyst comprises the following components in parts by weight: a), 40-95 parts of ZSM-11 molecular sieve with the silicon aluminum mole ratio (SiO2 / Al2O3) of 20-300 and the crystal particle diameter of equal to or less than 5 microns and b), 5-6 parts of binding agent, and the ZSM-11 molecular sieve is at least subjected to once acid pickling, so that the problems in the prior art are better solved, and the method can be used in the industrial production of 4-hexene-3-ketone prepared by utilizing 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

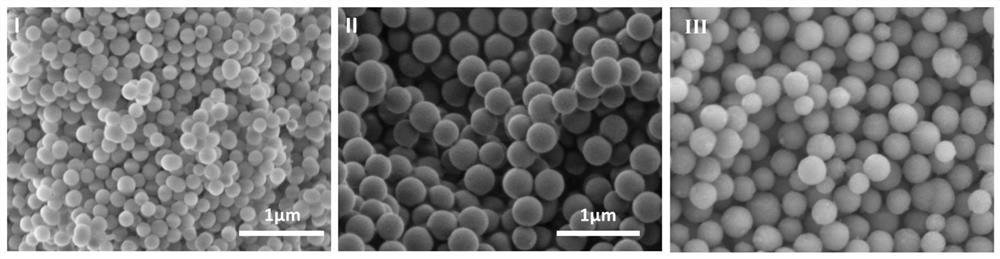

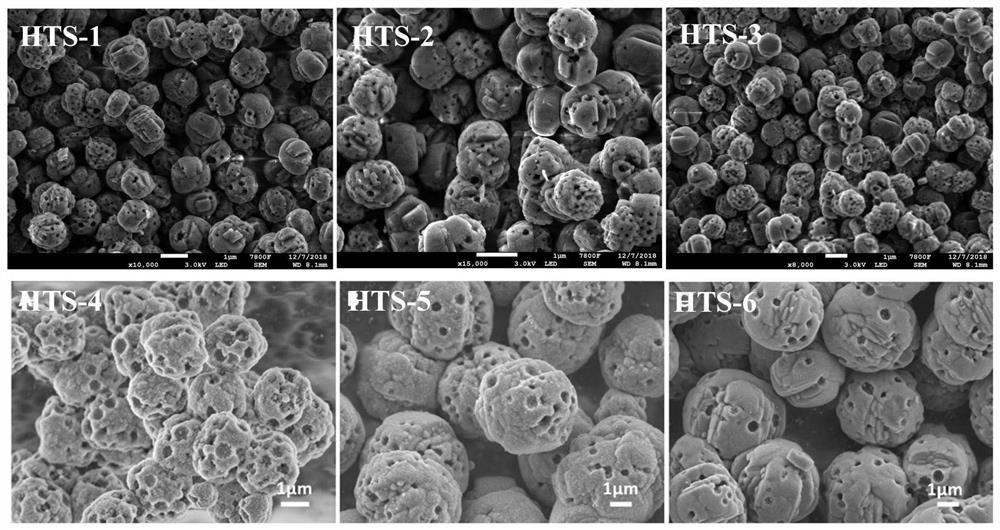

TS-1 molecular sieve with macroporous-microporous composite pore channel structure as well as preparation method and application of TS-1 molecular sieve

ActiveCN112978748ASolve the difficulty of introducingSolve the problem of low titanium content in the skeletonOrganic chemistryMolecular sieve catalystsMolecular sieveSingle crystal

The invention discloses a TS-1 molecular sieve with a macroporous-microporous composite pore channel structure. According to the invention, macropores and micropores are embedded in the TS-1 molecular sieve, and the pore diameters of the macropores are in a range of 50-500 nm. The TS-1 molecular sieve obtained by the method has the same excellent stability as a single crystal and an interpenetrating macroporous-microporous composite pore channel structure, the titanium content of the produced TS-1 molecular sieve can be controlled and adjusted in a wide range, the TS-1 molecular sieve shows excellent catalytic performance in an olefin epoxidation reaction, and the defect of a single microporous system is relieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

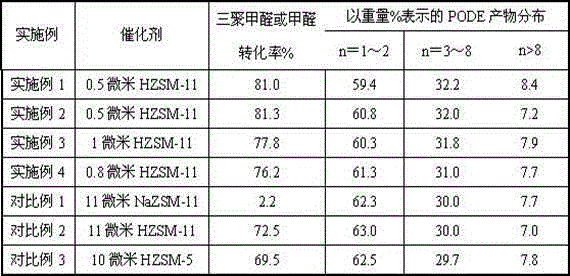

The preparation method of polyoxymethylene dimethyl ether

ActiveCN103539644BIncrease profitIncreased focus capacityOrganic chemistryMolecular sieve catalystsMolecular sieveAdhesive

The invention relates to a preparation method of polyoxy methylene dimethyl ether, which mainly solves the problem of corrosiveness of the catalyst in the prior art. The method comprises the following step: contacting raw materials methanol or dimethyl ether and formaldehyde or trioxymethylene in a mol ratio of 1:(0.1-10) with a catalyst to react at the reaction temperature of 50-200 DEG C under the reaction pressure of 0.1-10 MPa to generate the polyoxy methylene dimethyl ether. The catalyst comprises the following components in parts by weight: a) 40-95 parts of ZSM-11 molecular sieve of which the silicon / aluminum (SiO2 / Al2O3) mol ratio is 20-300 and the crystal grain diameter is at most 5 micrometers, and b) 5-60 parts of adhesive. The ZSM-11 molecular sieve is subjected to acid washing at least once. The technical scheme provided by the invention well solves the problem, and can be used for industrial production of the polyoxy methylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

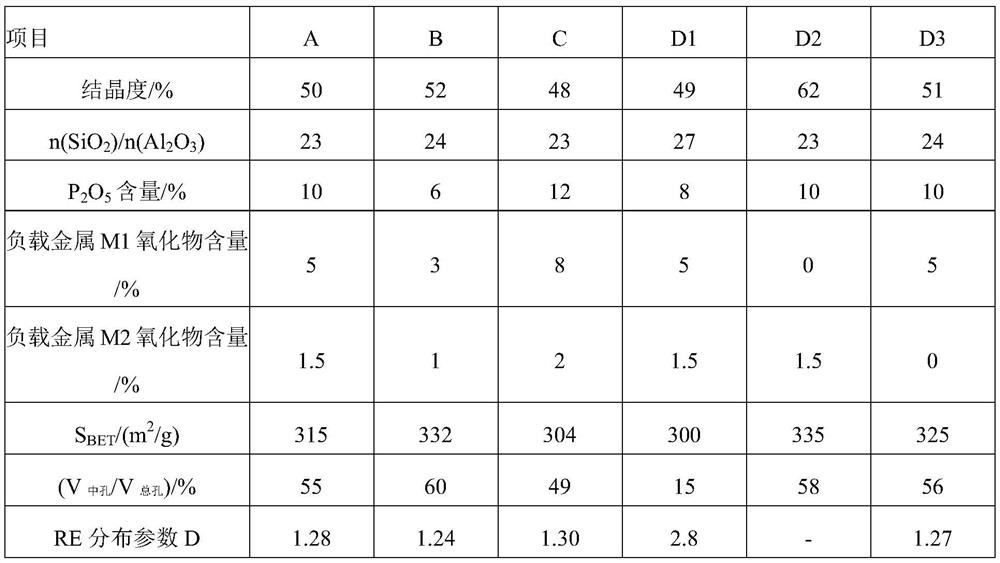

A kind of MFI structure molecular sieve rich in mesoporous phosphorus and rare earth and preparation method thereof

ActiveCN111068758BPromote migrationGood synergyCatalytic crackingMolecular sieve catalystsCeriumManganese

The present invention relates to a kind of MFI structure molecular sieve rich in mesoporous phosphorus and rare earth and preparation method thereof, the n(SiO 2 ) / n(Al 2 o 3 ) is greater than 15 and less than 70; with P 2 o 5 Calculated and based on the dry weight of the molecular sieve, the phosphorus content of the molecular sieve is 1-15% by weight; based on the oxide of the loaded metal and based on the dry weight of the molecular sieve, the content of the loaded metal M1 in the molecular sieve is 1-10% by weight, and the content of the loaded metal M2 is 0.1-5% by weight, wherein the loaded metal M1 is selected from one or both of lanthanum and cerium, and the loaded metal M2 is selected from iron, cobalt, nickel, copper, manganese, One of zinc, tin, bismuth and gallium; the proportion of the mesopore volume of the molecular sieve to the total pore volume is 40-70% by volume. The molecular sieve with MFI structure provided by the invention has better ethylene selectivity in the petroleum hydrocarbon catalytic cracking reaction, and can produce more propylene and BTX at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com