Method for preparing pure finely porous molecular sieve psosessing even distribution of acid strength

An acid strength, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of micropore blocking, reduction of the number of molecular sieve acid sites, molecular sieve pore structure and acid properties. Fully meet the requirements and other issues to achieve the effect of good shape selection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Sample Preparation

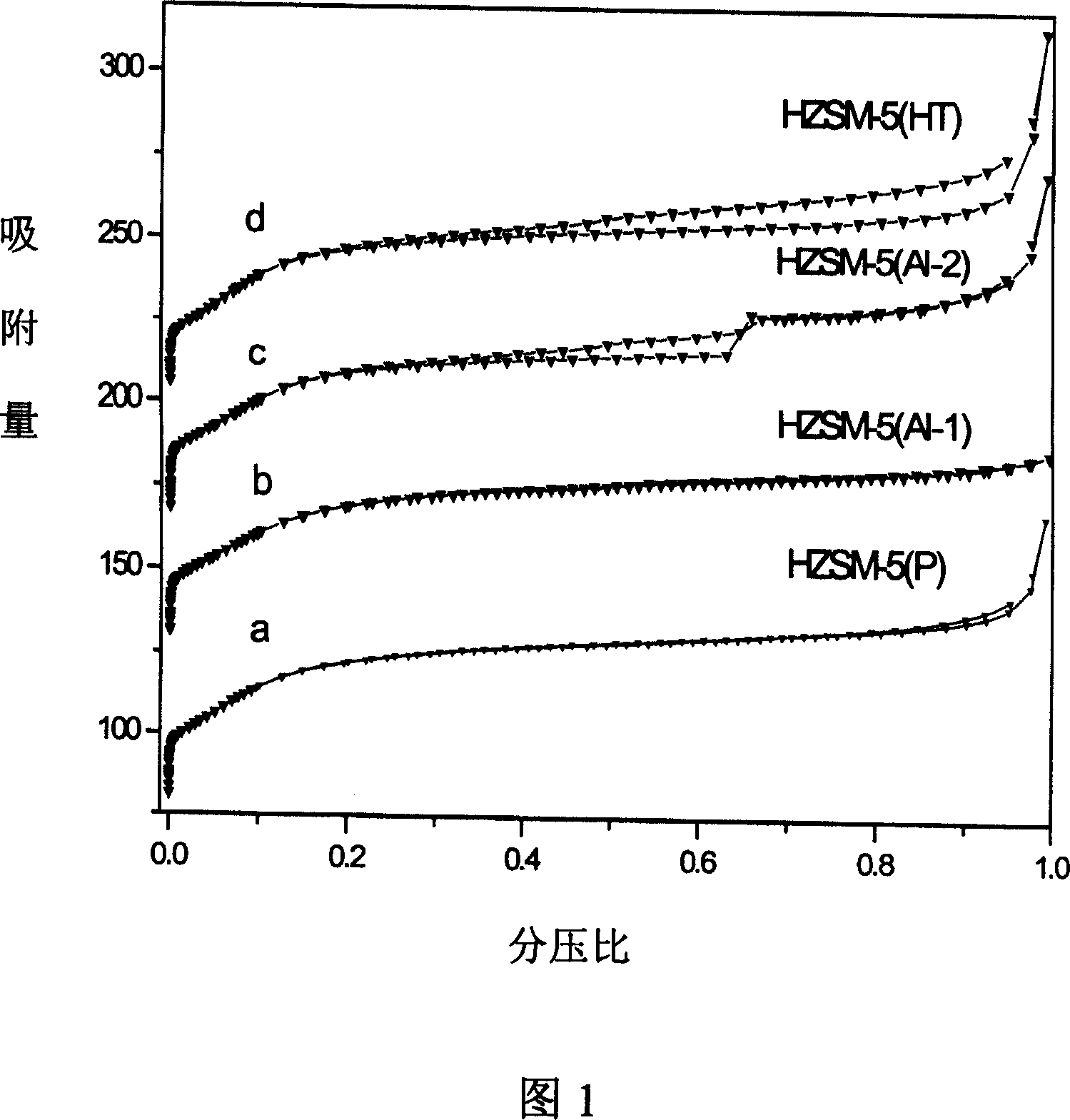

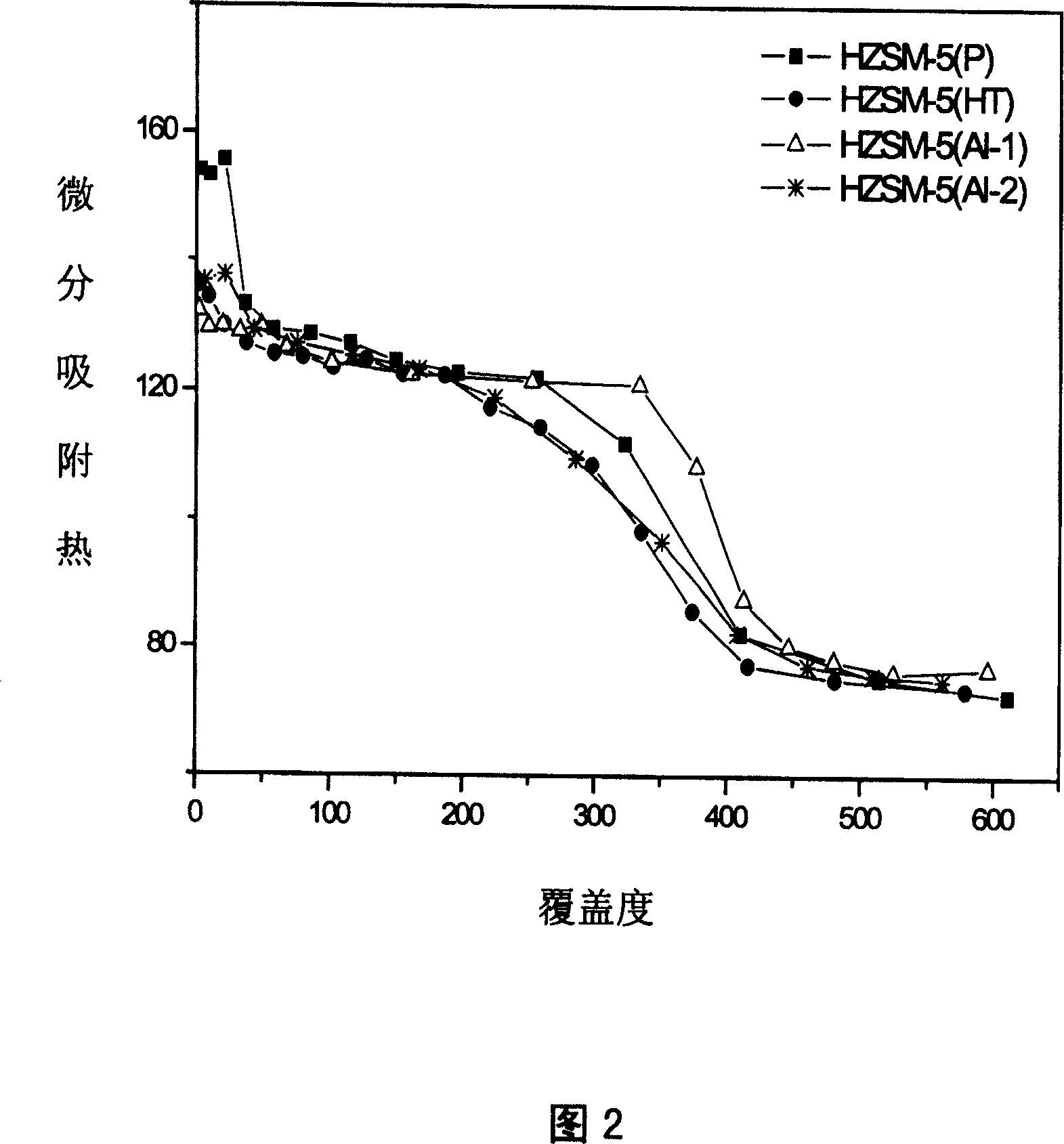

[0017] Pretreatment of parent HZSM-5 molecular sieve: In air atmosphere, put commercially available HZSM-5 molecular sieve (Si / Al=25, Shanghai Huaheng Molecular Sieve Co., Ltd.) -5 molecular sieve is heated to 350°C and kept at this temperature for 2 hours, and then raised to 530°C at 5°C / min and kept for 4 hours. The resulting molecular sieve was labeled HZSM-5(P).

[0018] The HZSM-5 molecular sieve prepared by the method of the present invention: take by weighing the HZSM-5 (P) molecular sieve of 5g, pack in the synthesis kettle, add 20mL, concentration is the Al(NO 3 ) 3 The aqueous solution was stirred and mixed, and then hydrothermally treated at a temperature of 100° C. for 12 hours. The solid sample was filtered and washed with deionized water. After drying, heat the HZSM-5 molecular sieve to 350°C at 2°C / min and keep it at this temperature for 2 hours, then raise it to 530°C at 5°C / min and keep it for 4 hours. The obtained sample is mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com