Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Fully mechanized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

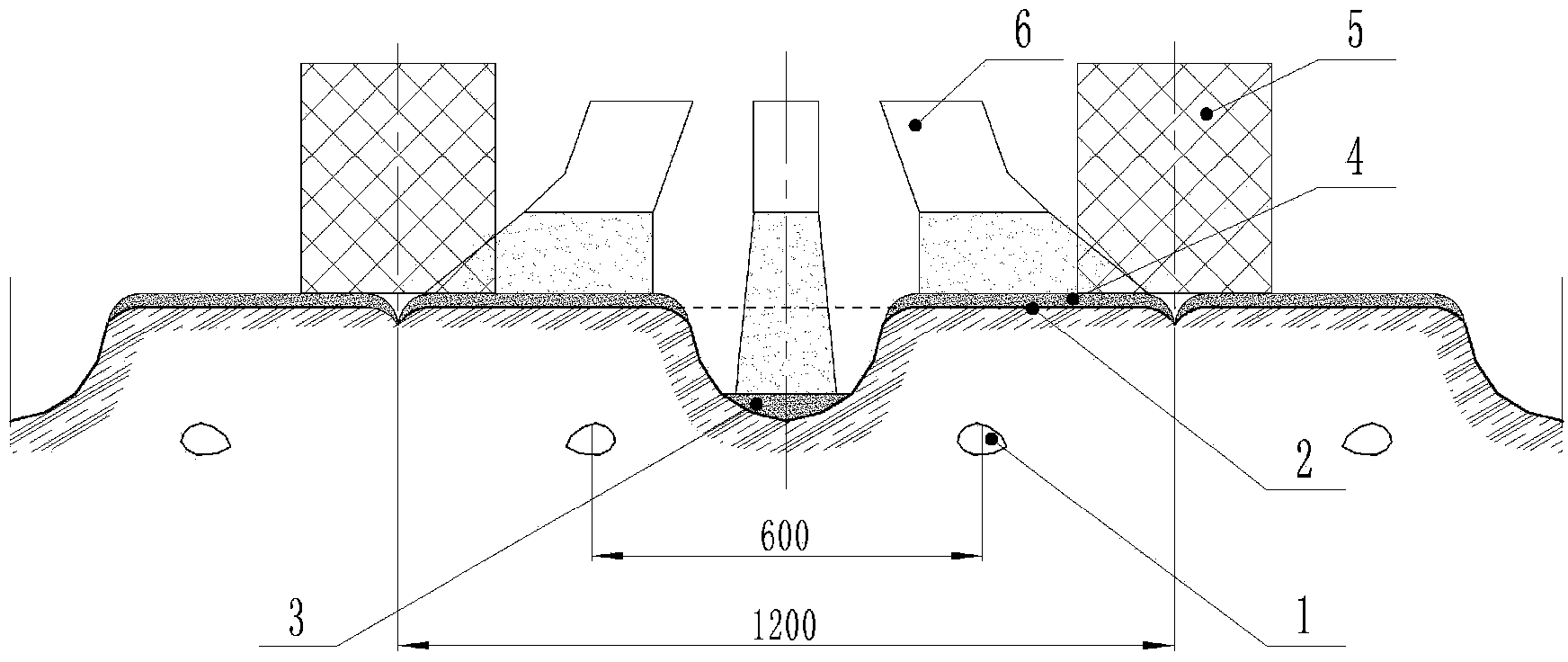

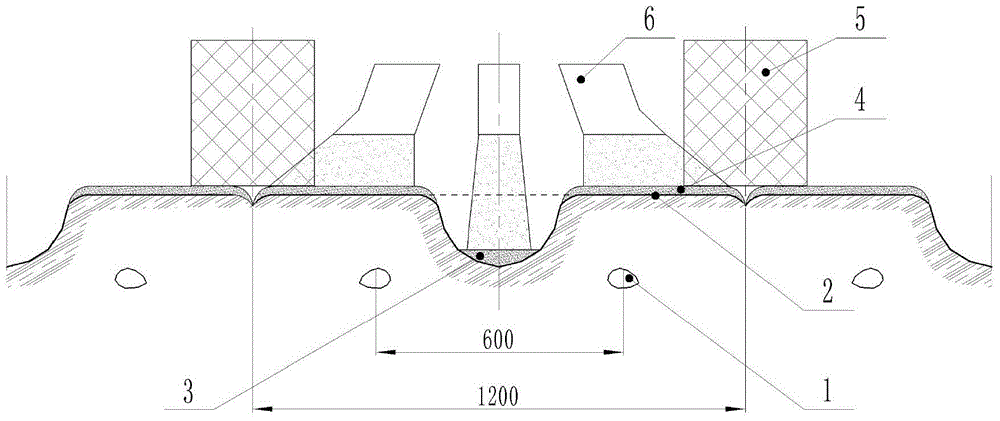

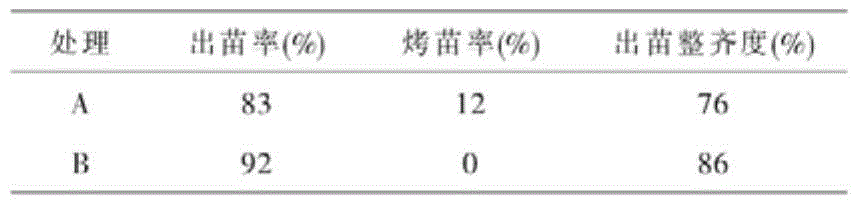

Dry-land potato mechanized full-film furrow-ridge cultivating method

ActiveCN104221682AAvoid pollutionSolve the problem that the membrane cannot be unearthedHorticultureRainwater harvestingSolanum tuberosum

The invention relates to the technical field of crop planting, in particular to a dry-land potato mechanized full-film furrow-ridge cultivating method. The dry-land potato mechanized full-film furrow-ridge cultivating method is mainly characterized by comprising the following steps of (1) preparation before planting; (2) film covering and planting: once finishing planting, fertilization, ridge forming, packing shaping, full-film covering, and soil-lifting soil-placing combined operation, and covering 3 to 5cm of soil on the top of a film above seed potatoes; (3) plant protection: spraying chemicals in 15 to 20 days after planting; using a wheel type tractor, enabling wheels to walk on small ridges, and arranging spray heads according to corresponding row distances; (4) potato harvest. The dry-land potato mechanized full-film furrow-ridge cultivating method has the advantages that mechanized soil lifting, soil separation and film-top soil placement can be realized by the technology, i.e. 3 to 5cm of soil covers the top of the film above the seed potatoes, so that the problem that seedlings cannot break through the film or come up out of soil and are burnt is solved; overall-process mechanization is realized, so that the labor force is saved; the pollution of the broken film for the soil is avoided; a mechanized full-film furrow-ridge cultivating technology is a new agricultural technology and has the advantages of rainwater harvesting, soil moisture preservation, temperature increase, yield increase and the like and has quite remarkable drought-resisting and yield-increasing effects.

Owner:GANSU AGRI UNIV

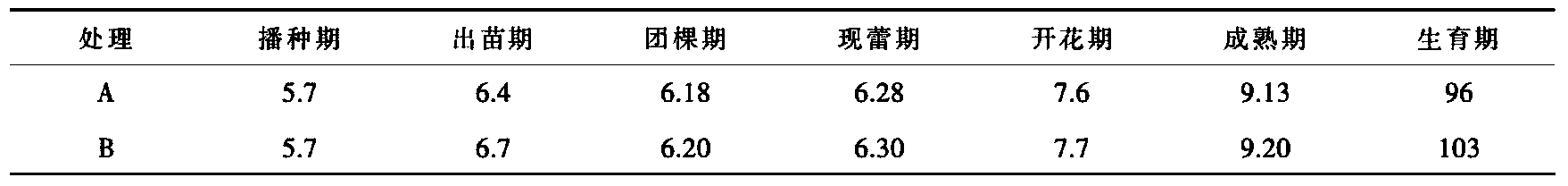

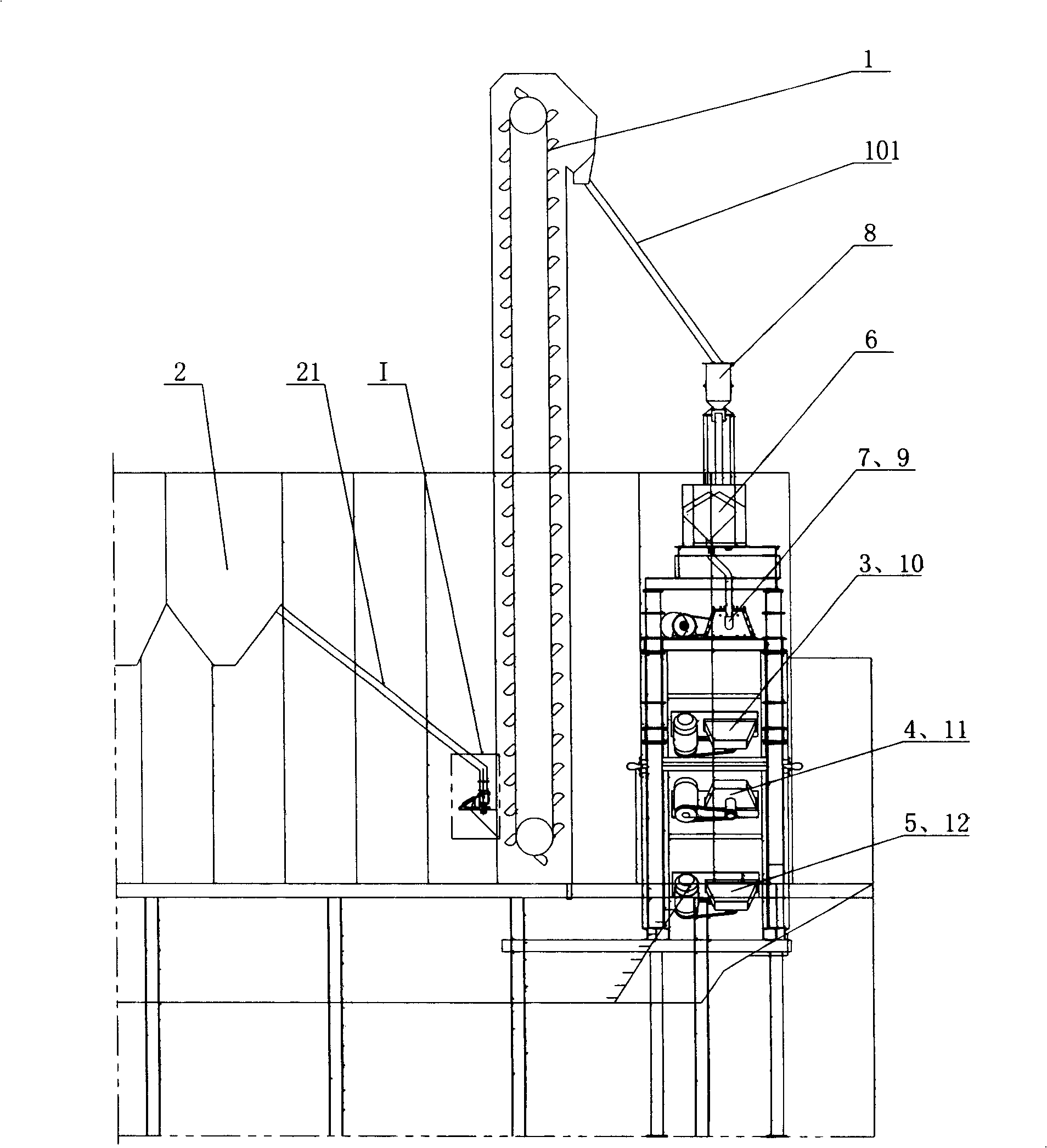

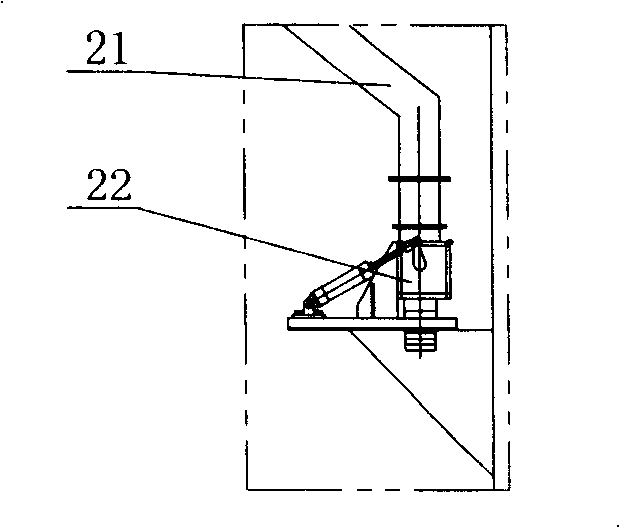

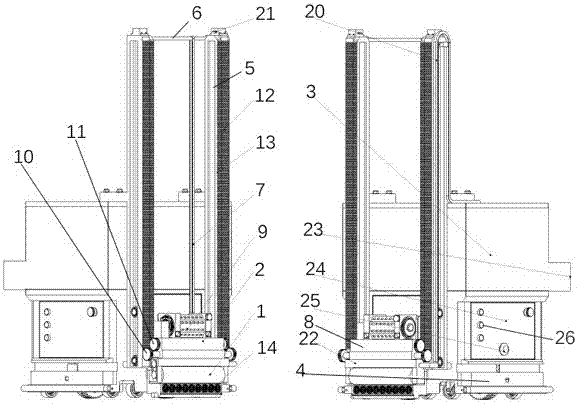

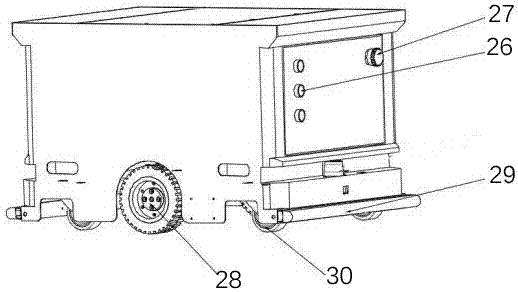

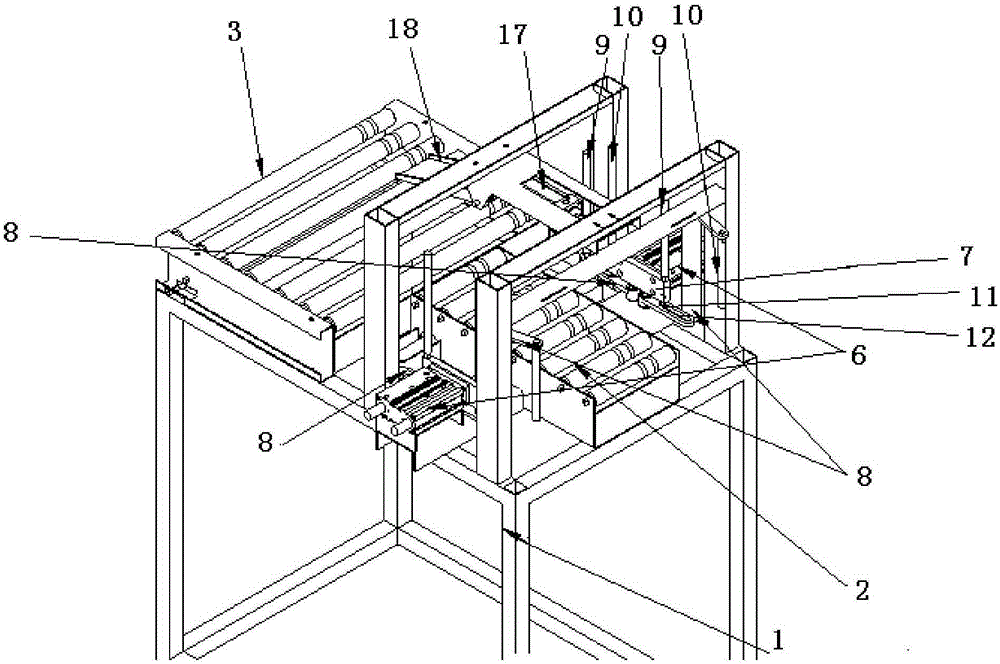

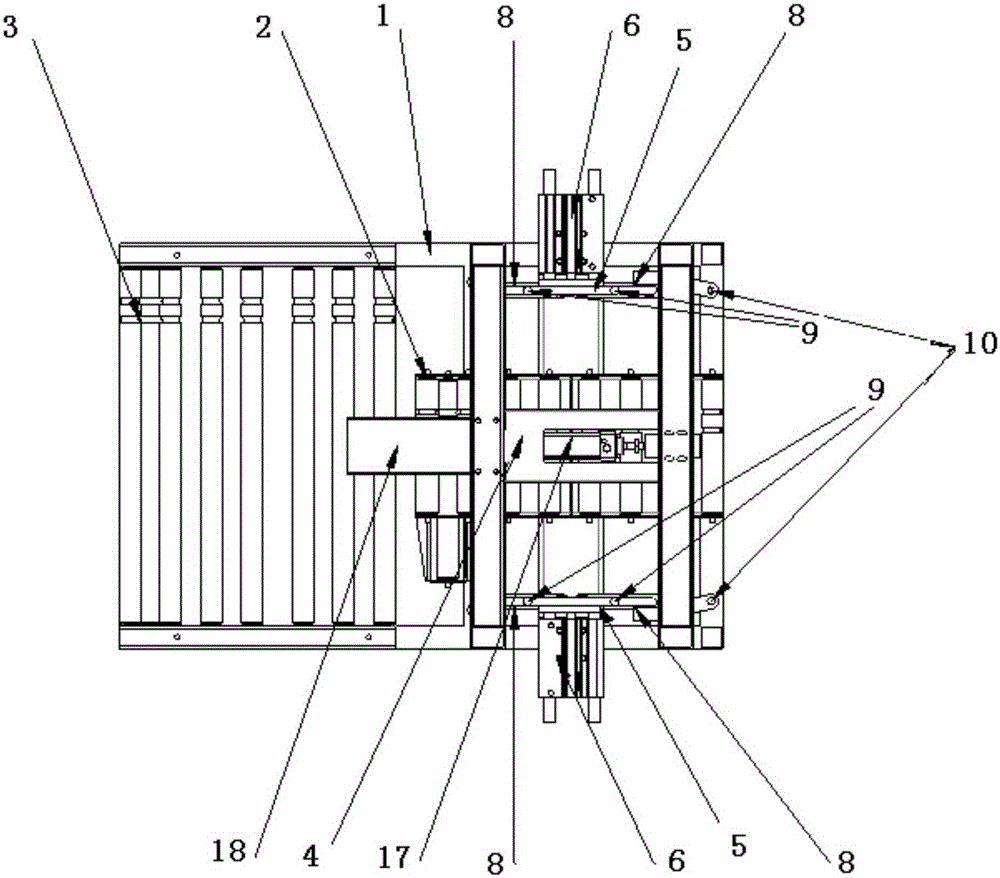

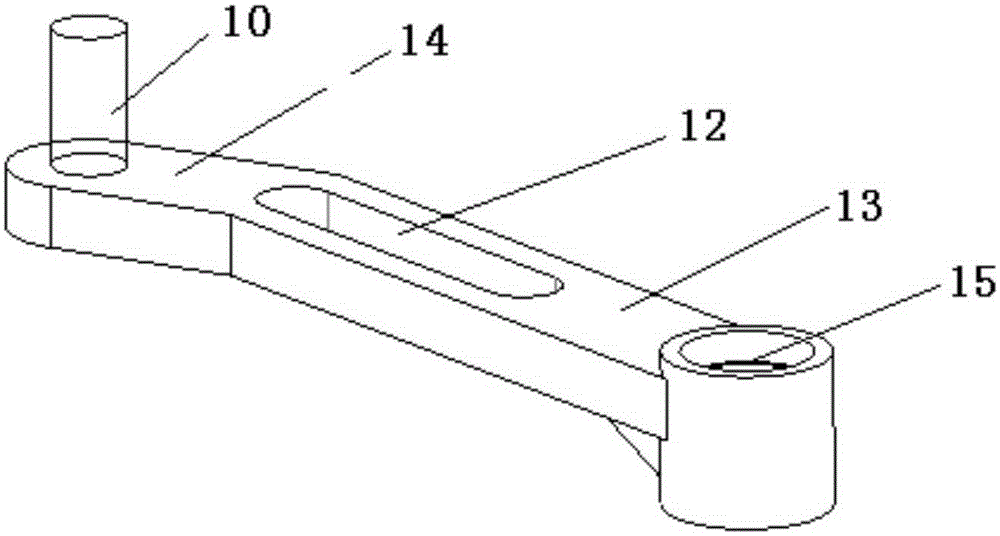

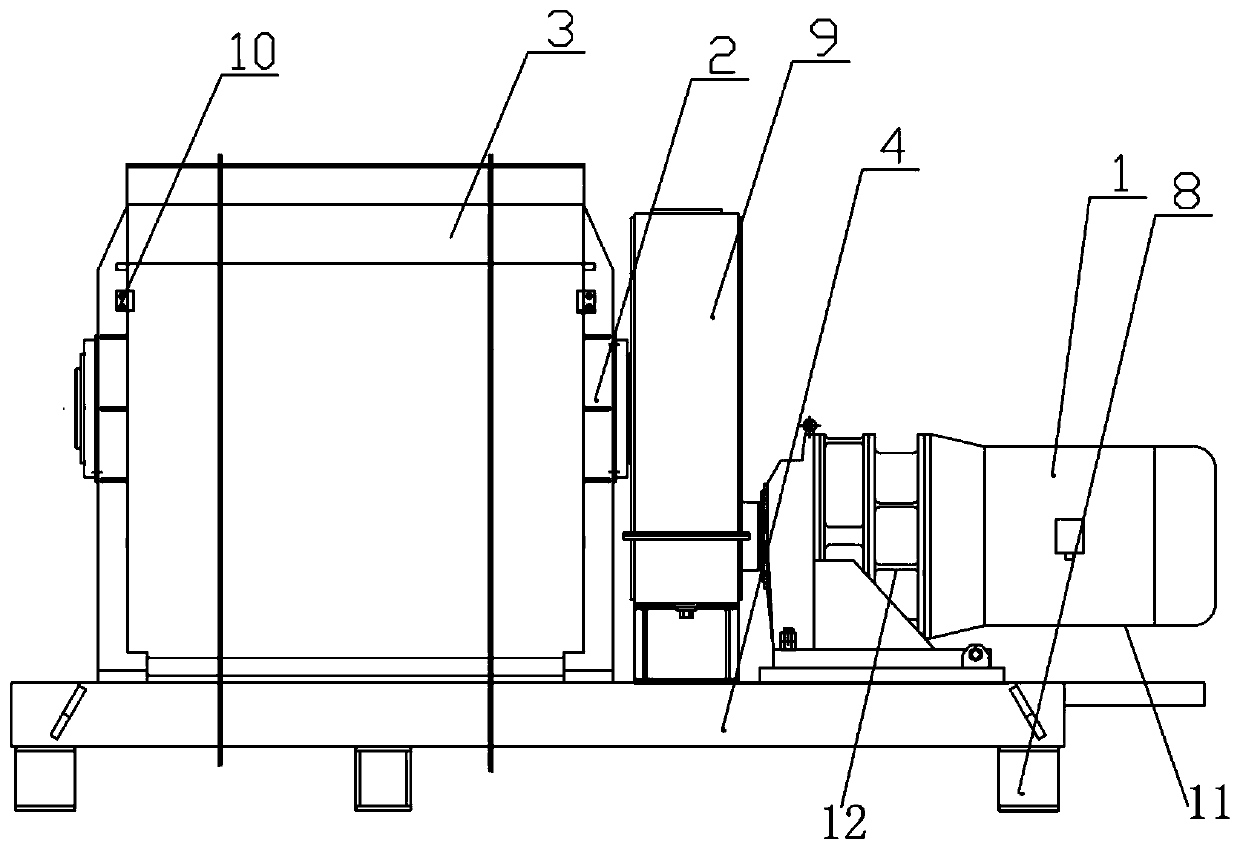

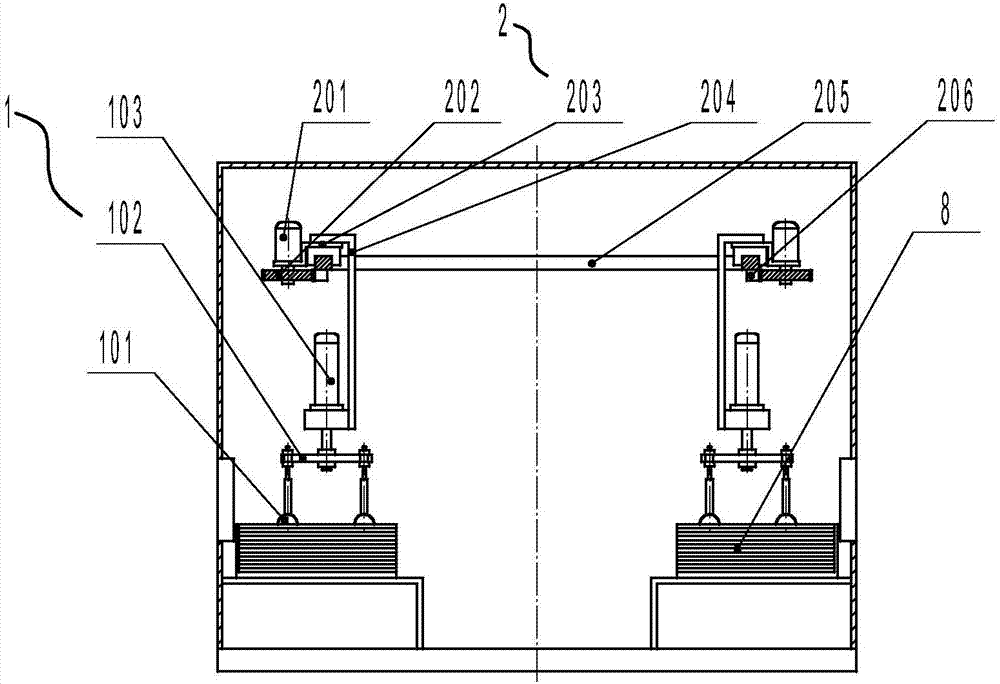

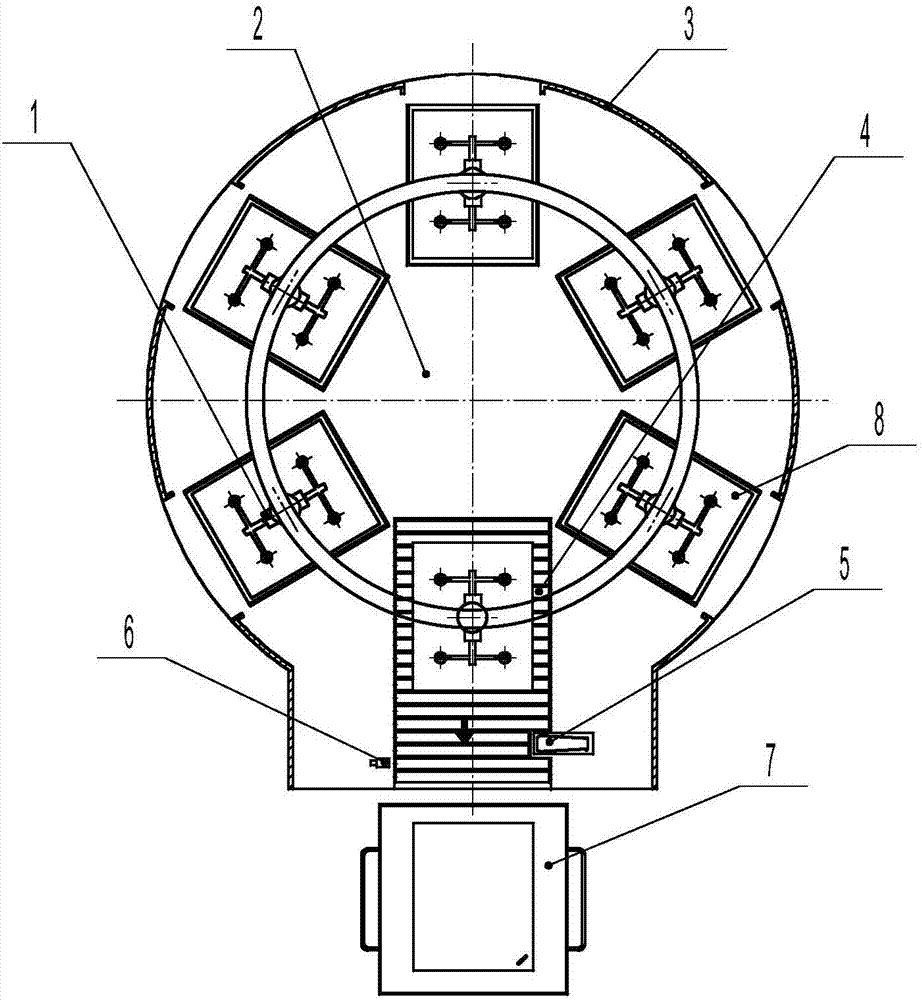

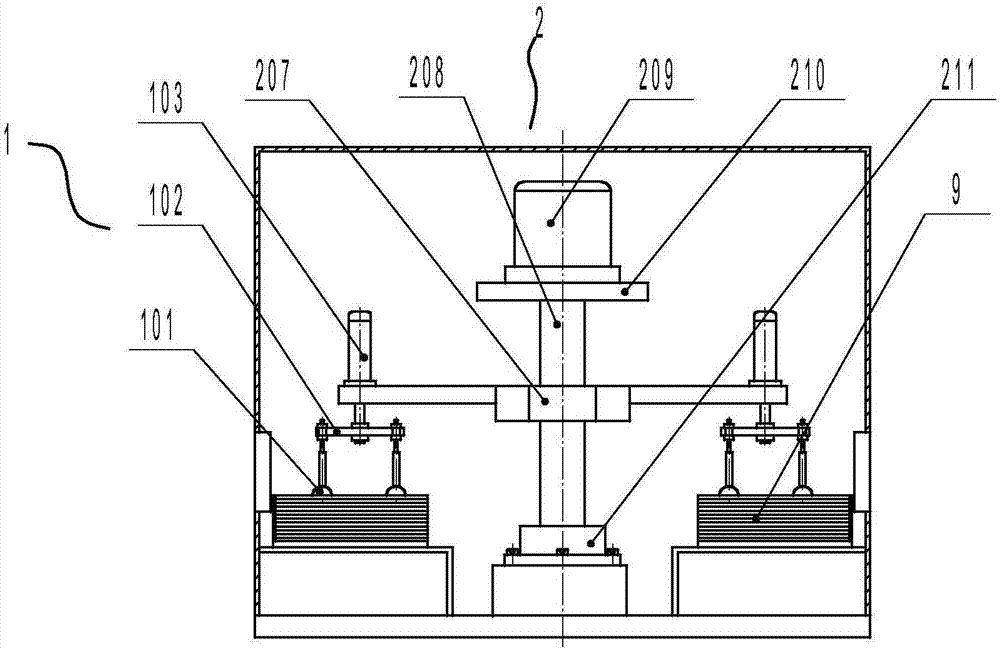

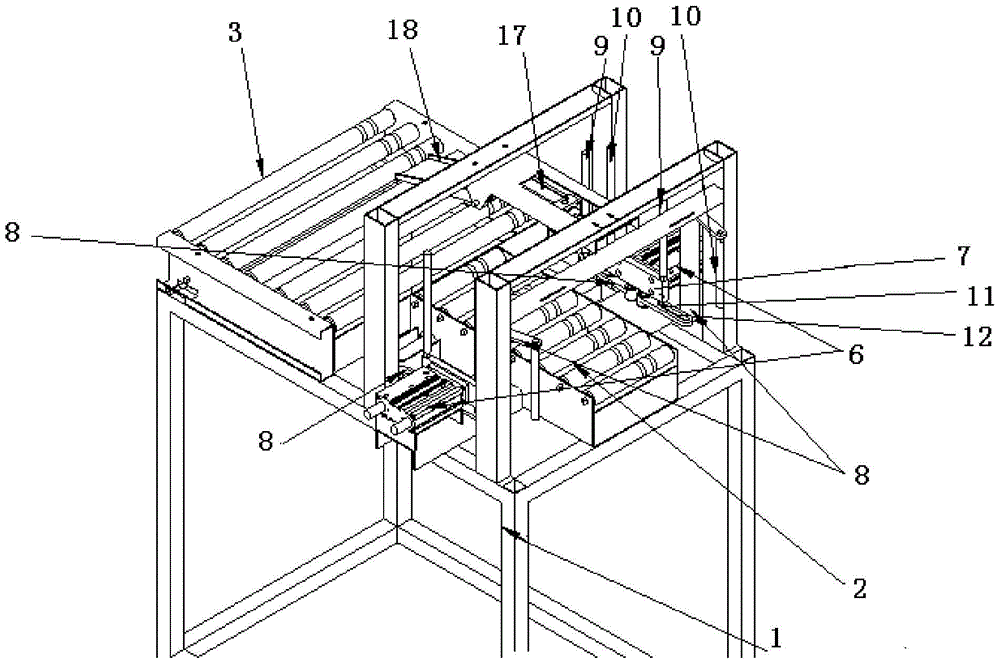

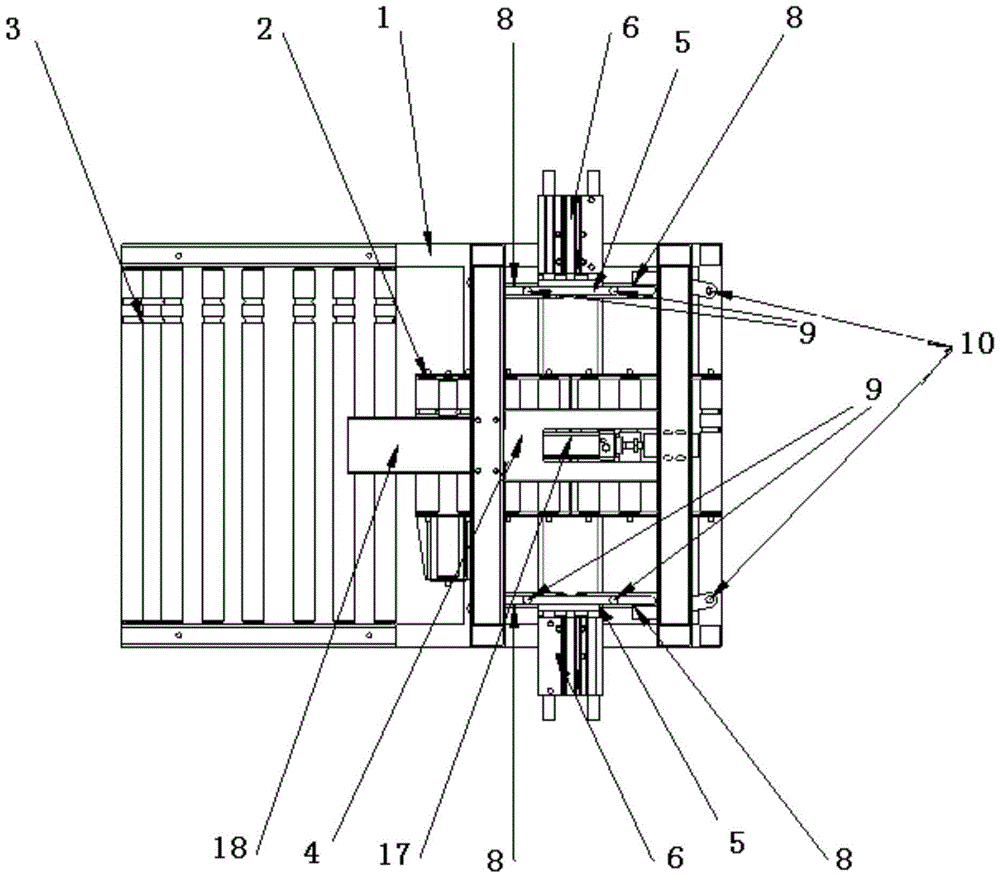

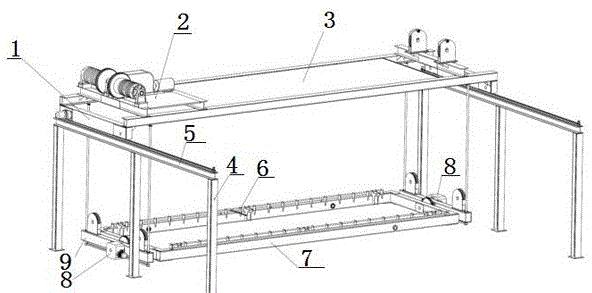

Laminated slab upending machine

ActiveCN103449151AAdvanced production technologyFully mechanizedConveyor partsIndustrial engineeringPrefabrication

The invention provides a laminated slab upending machine. Upright columns are fixedly installed on the ground; supporting beams are installed on the upper ends of the upright columns; a main beam or a walking board is guided to walk on the supporting beams by a walking mechanism; a dual-drum winding and lifting mechanism is installed on the main beam or the walking board; a fixing frame is installed on the dual-drum winding and lifting mechanism in a lifting way through steel ropes and a pulley; an upending framework and upending machines are installed on the fixing frame; the upending machines are connected with and drive the upending framework; a hydraulic clamping device for clamping a steel trolley and a workpiece is installed on the upending framework. By the adoption of the laminated slab upending machine, the fully mechanical automation can be realized; therefore, the production efficiency is improved greatly, as well as the prefabrication rate of a plant with industrialized dowelling.

Owner:QINGDAO SHANGLIU YUANDA HOUSE IND CO LTD

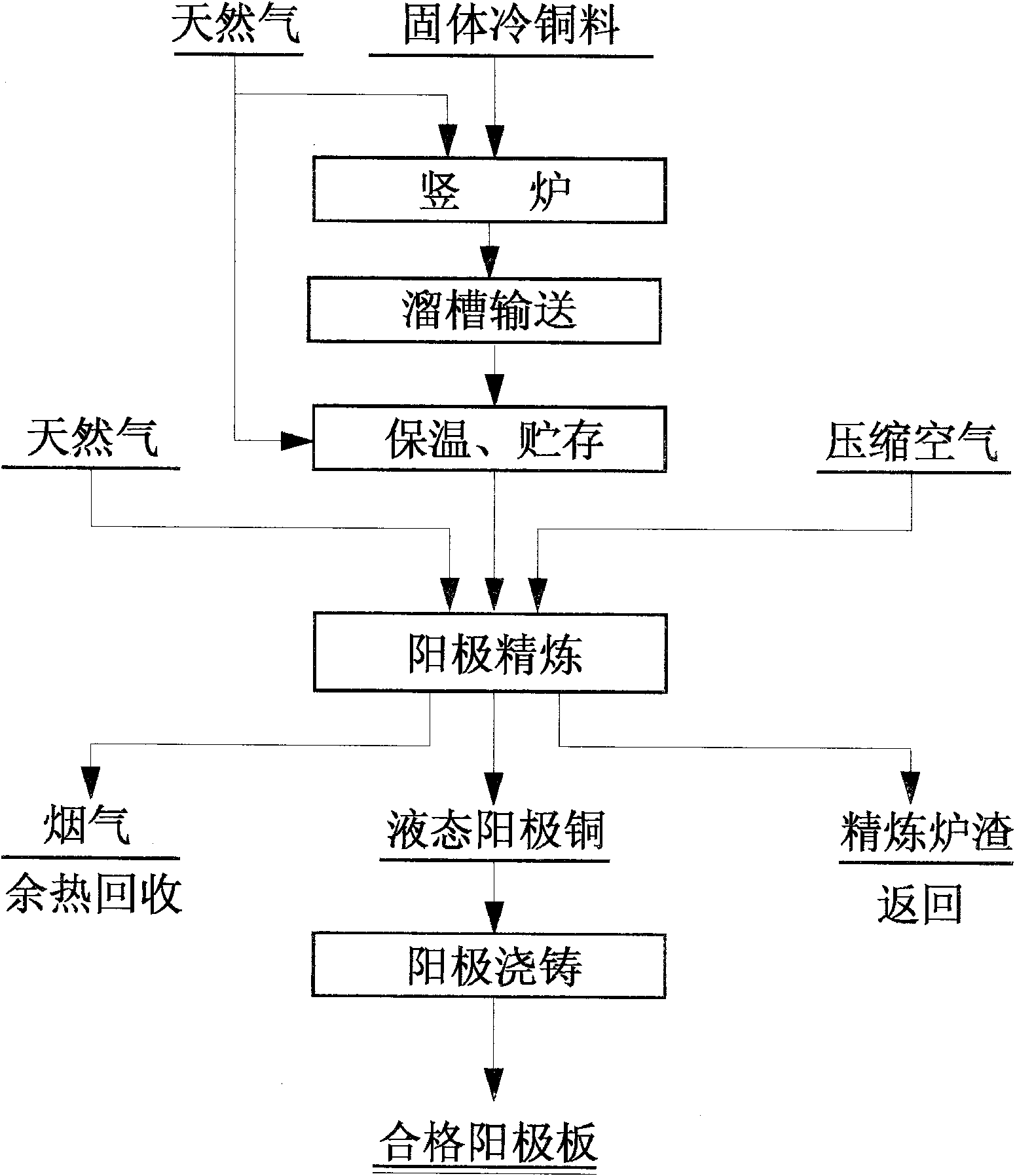

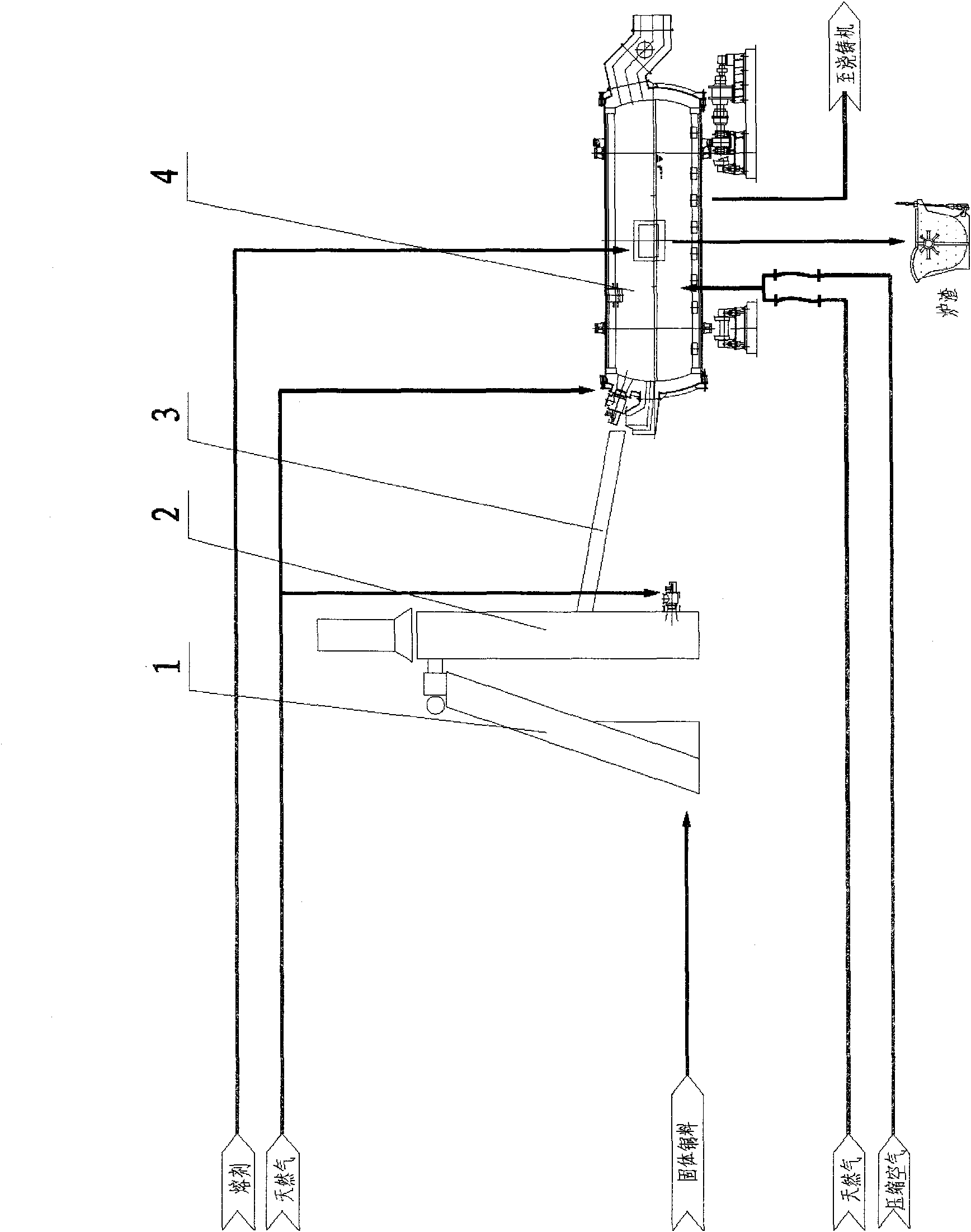

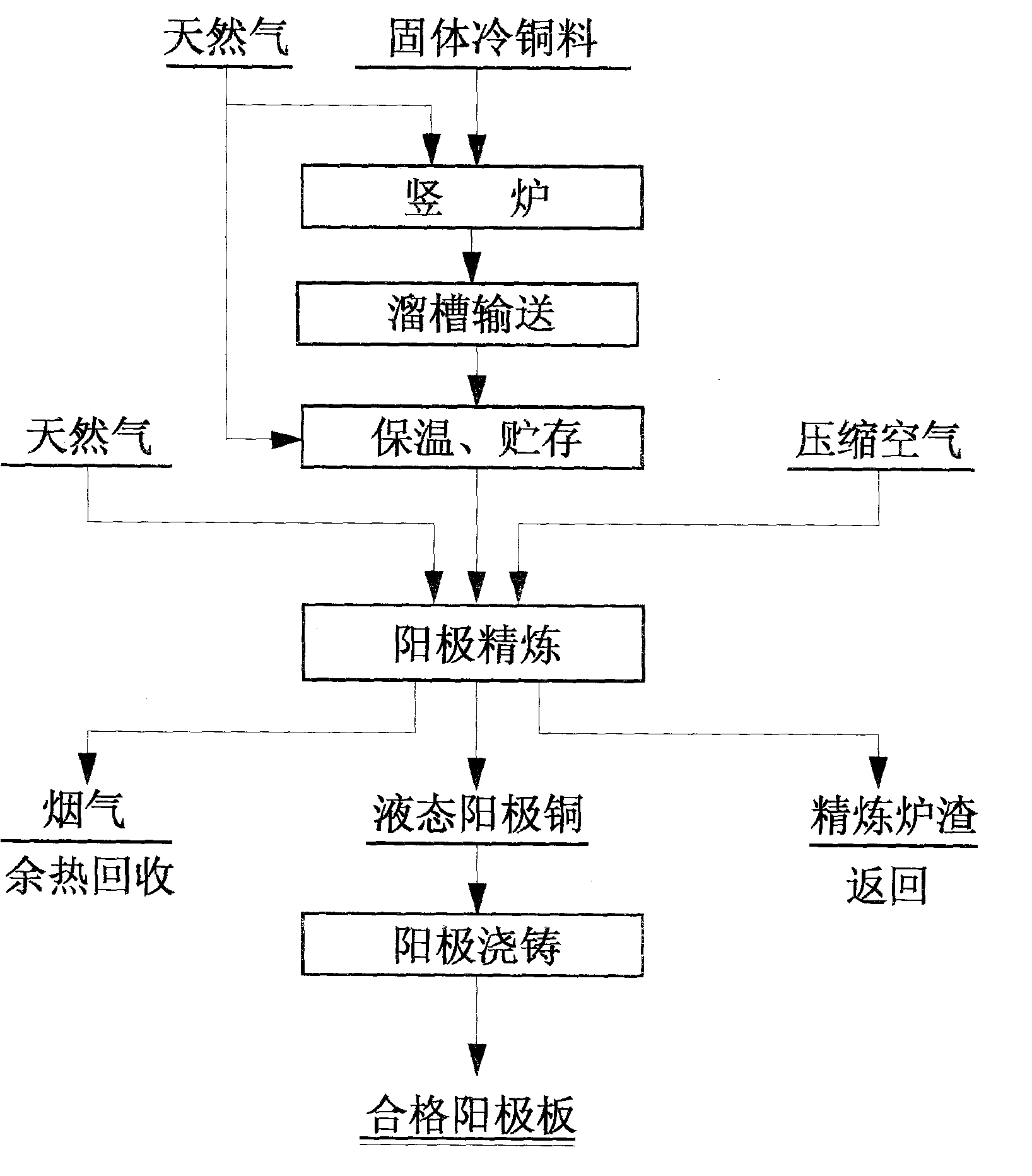

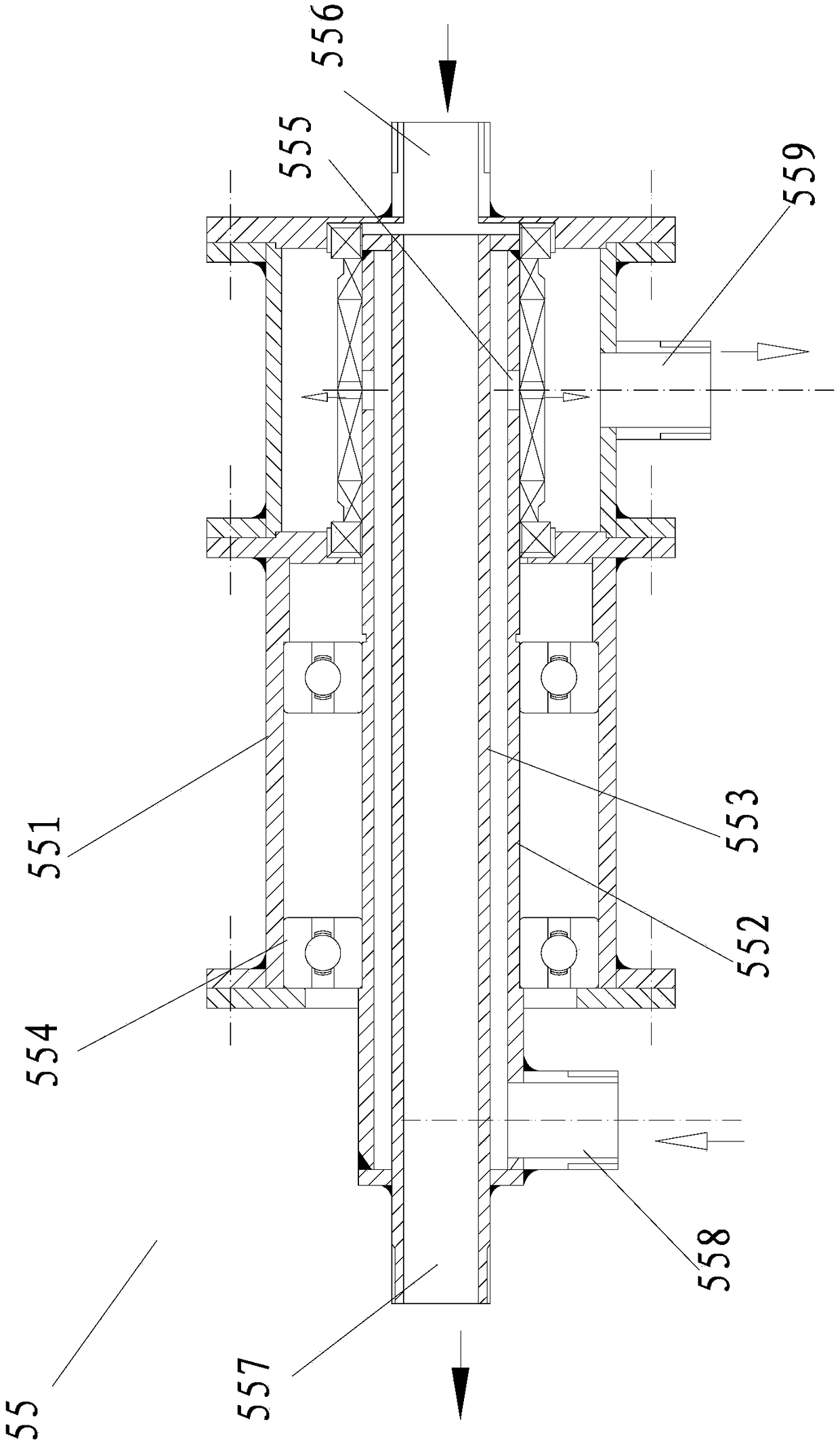

Solid copper material processing method and apparatus thereof

InactiveCN101880779AFlexible sizeHigh degree of automationFurnace typesProcess efficiency improvementFlue gasShaft furnace

The invention discloses a solid copper material processing method and an apparatus thereof. In the step of feeding and melting, a feeder is utilized to feed solid copper material into a shaft furnace which is at least 16 meters high, and the solid copper material is molten into molten copper; and the molten copper automatically flows into a refining furnace via a connecting chute between the shaft furnace and the refining furnace, and is refined. Refining includes the steps of oxidation and reduction. The method utilizes the height of the shaft furnace to constantly heat the solid copper material in the process of emitting high-temperature flue gas, the temperature of the finally emitted flue gas is only 250DEG C, consequently, the residual heat of the flue gas is sufficiently utilized, the heat efficiency is increased, energy consumption is reduced, and the melting speed is increased. The invention also discloses a solid copper material processing apparatus, which adopts the combination of the shaft furnace and the refining furnace and sufficiently utilizes the characteristics of the shaft furnace and the refining furnace, i.e. high melting speed, high mechanization and automation degree, safe operation, flexible furnace body size, good environment protection effect and low fabrication cost, and the apparatus is particularly applicable to the processing of solid copper material in large and medium waste copper recovery smelteries.

Owner:CHINA NERIN ENG

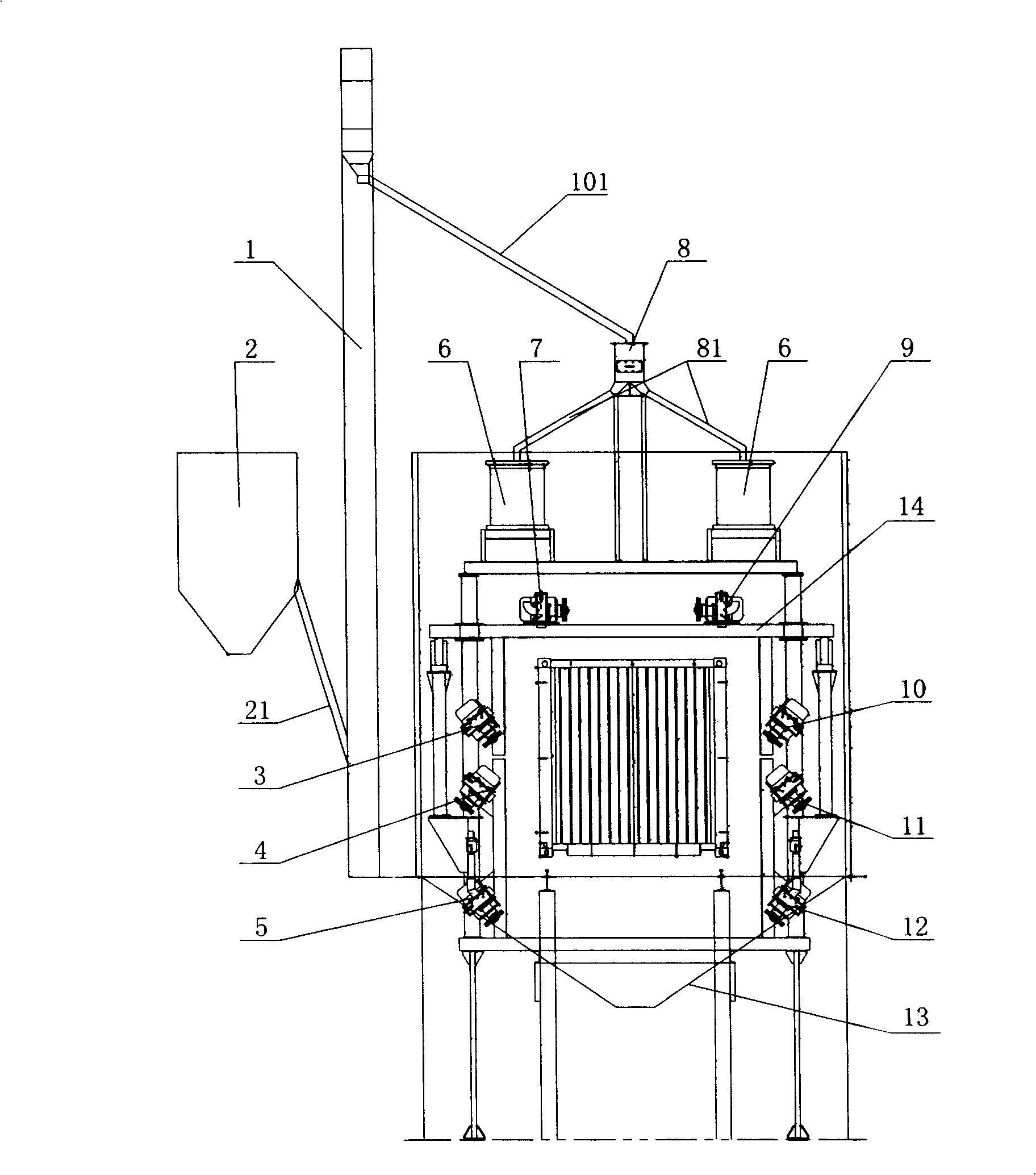

Sanding system of container soldering joint

InactiveCN101244543AIncrease profitImprove working conditionsAbrasive feedersAbrasive blasting machinesSand blastingWorking environment

The invention relates to a welding line sanding system for containers, which comprises a sand conveying workshop section, a sand separating workshop section, and a sanding workshop section which are all connected in sequence; wherein, the sanding workshop section comprises a door-shaped frame arranged on a container conveyor line for allowing the containers to pass through, and a plurality of electric shot-blasting devices arranged on the two sides and upper part of the door-shaped frame; the electric shot-blasting devices are arranged according to the container welding lines to be cleared, and the sand slinging openings of the electric shot-blasting devices are facing towards the container welding line to be cleared. The sand separating workshop section comprises a distribution bin, a distribution device for connecting the distribution bin and the electric shot-blasting devices; the distribution bin and the distribution device distribute the stored sands by use of potential energy, and the sand conveyor workshop section conveys the sand into the distribution bin. The welding line sanding system in the invention has the advantages of enhancing the energy utilization rate, realizing the fully mechanized sanding, getting rid of manual operations, improving the working environment for workers, stabilizing and further bettering the sanding quality compared with the pneumatic sand blasting system, and reducing the investment and operation costs compared with the pneumatic sand blasting system.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

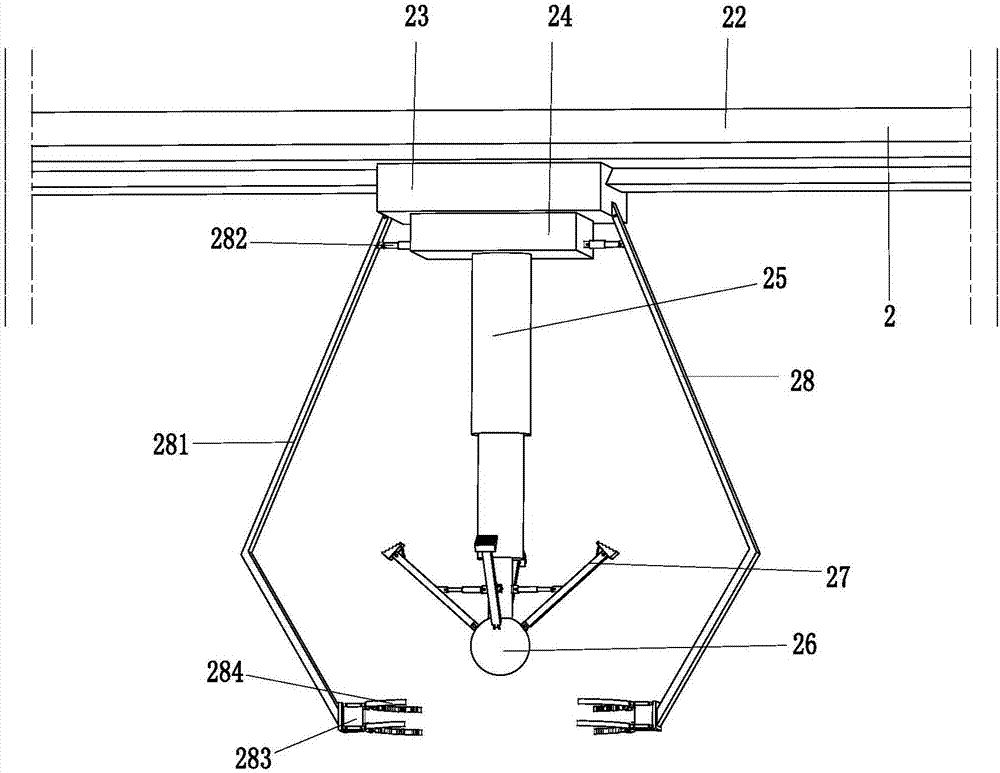

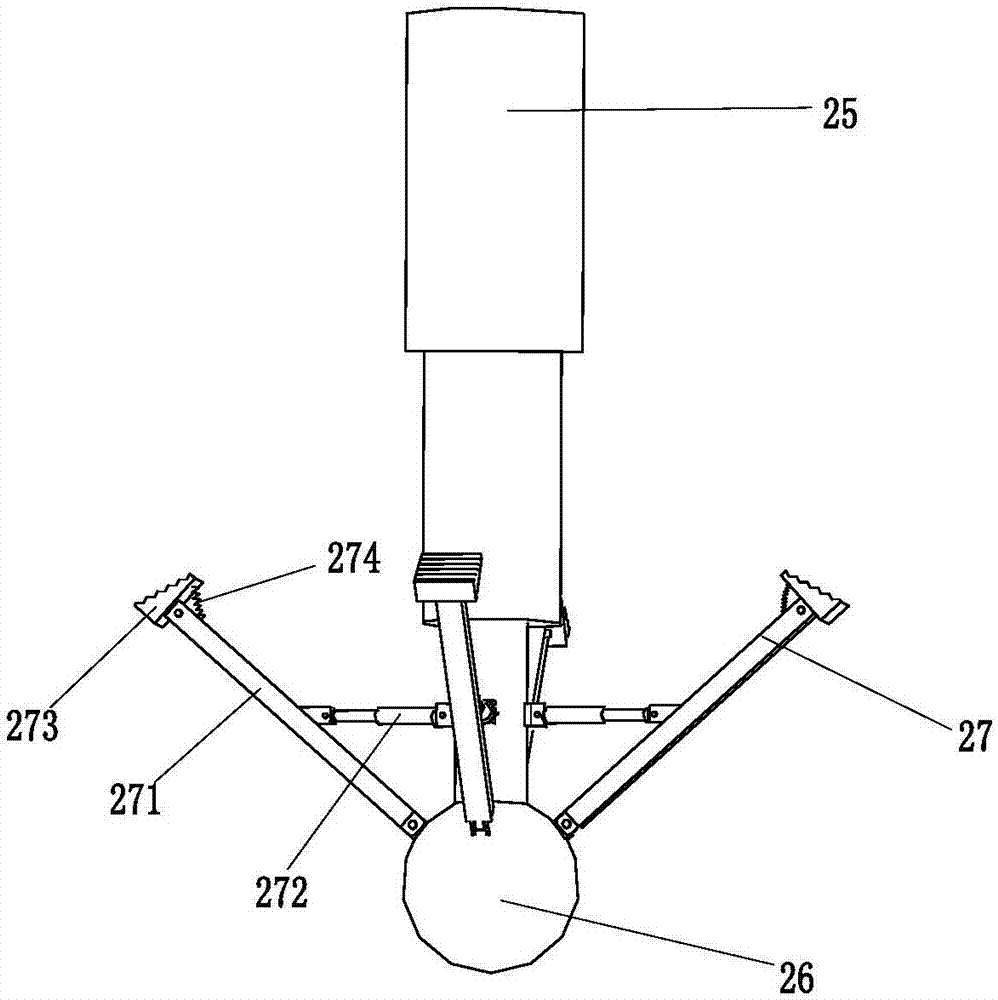

Intelligentized building painting equipment

ActiveCN107327131ARealize brushing and polishingRealize sanding and brushingBuilding constructionsArchitectural engineeringMaterial resources

The invention provides intelligentized building painting equipment. The intelligentized building painting equipment comprises a rotatable painting device, a polishing device, a lifting device, a material conveying device and a base frame device. According to the intelligentized environment-friendly building painting equipment, manpower and material resources are saved, and the accident rate is reduced.

Owner:隽秀新材料科技(苏州)有限公司

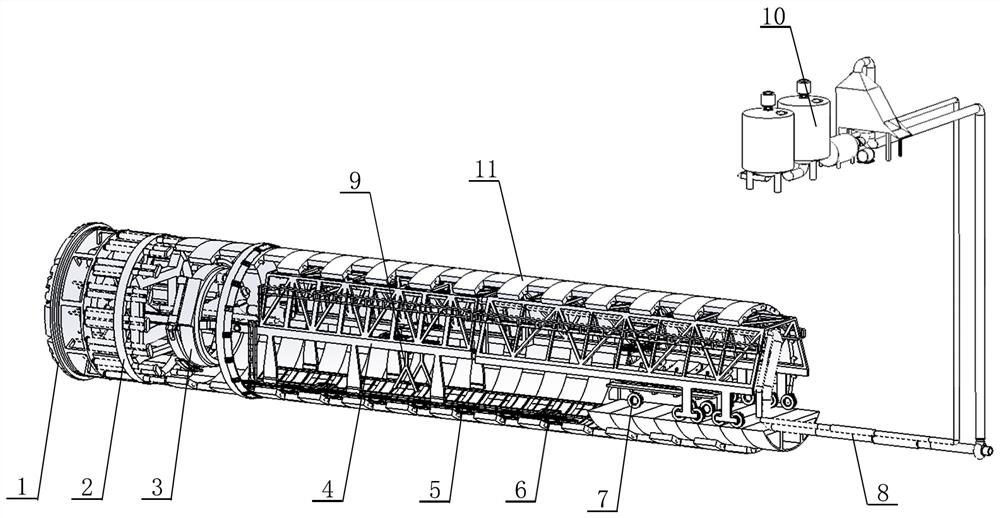

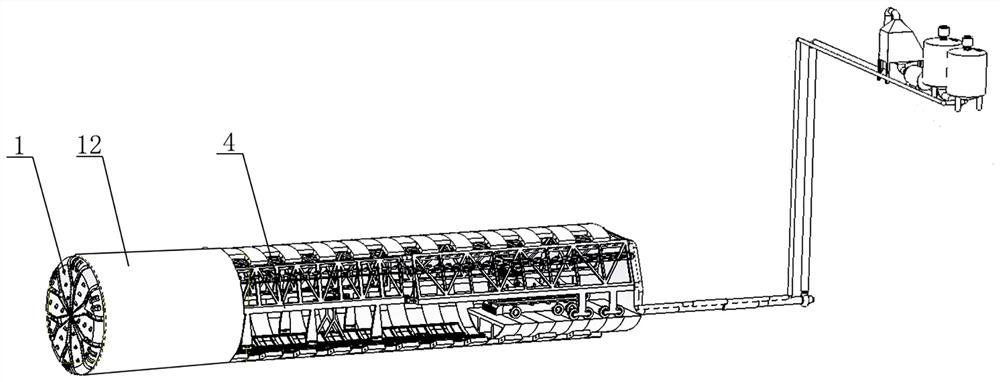

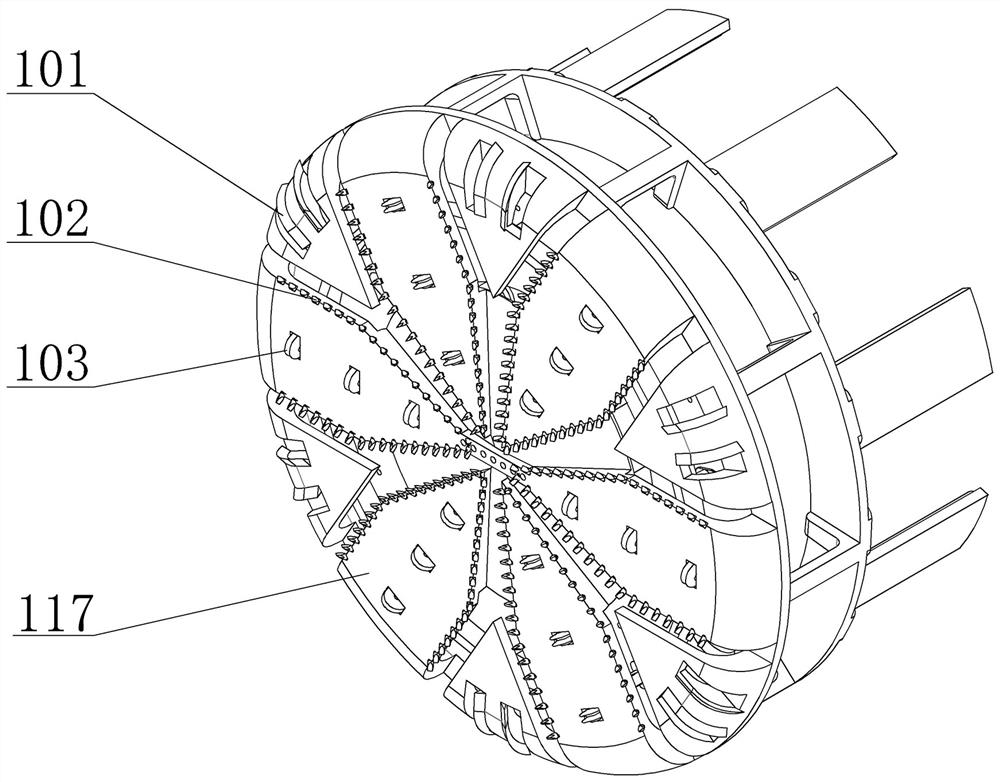

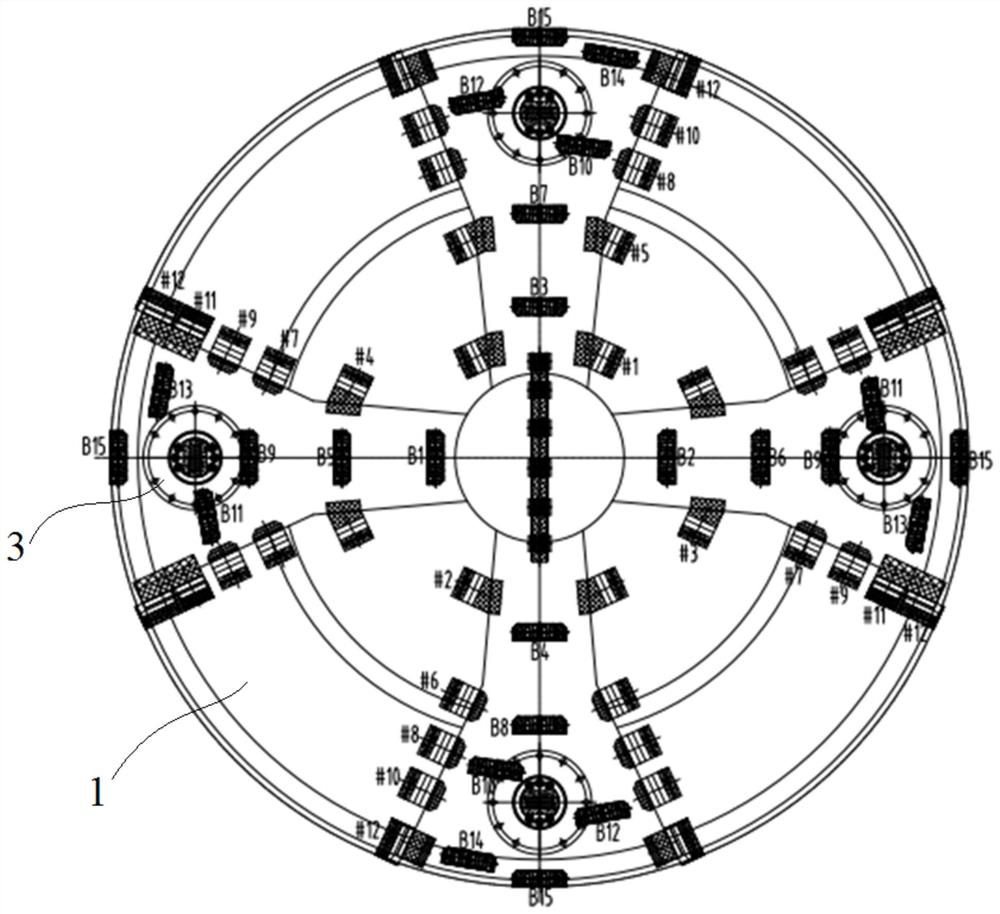

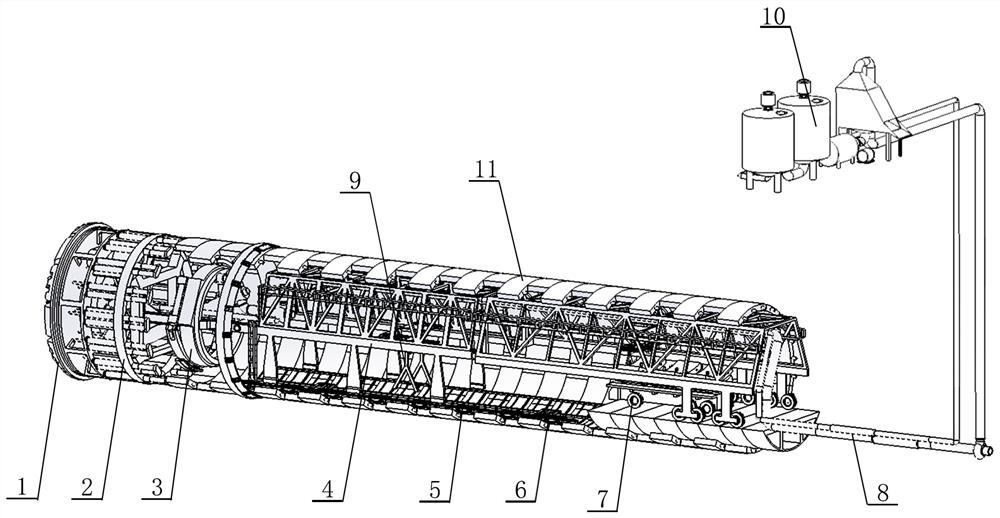

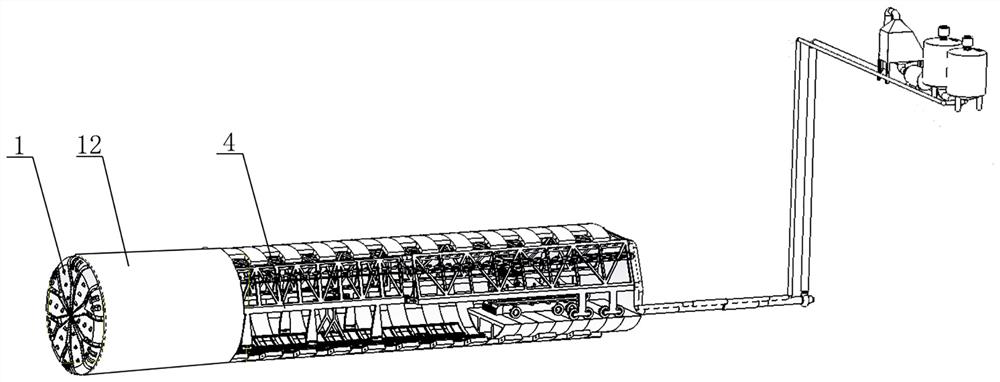

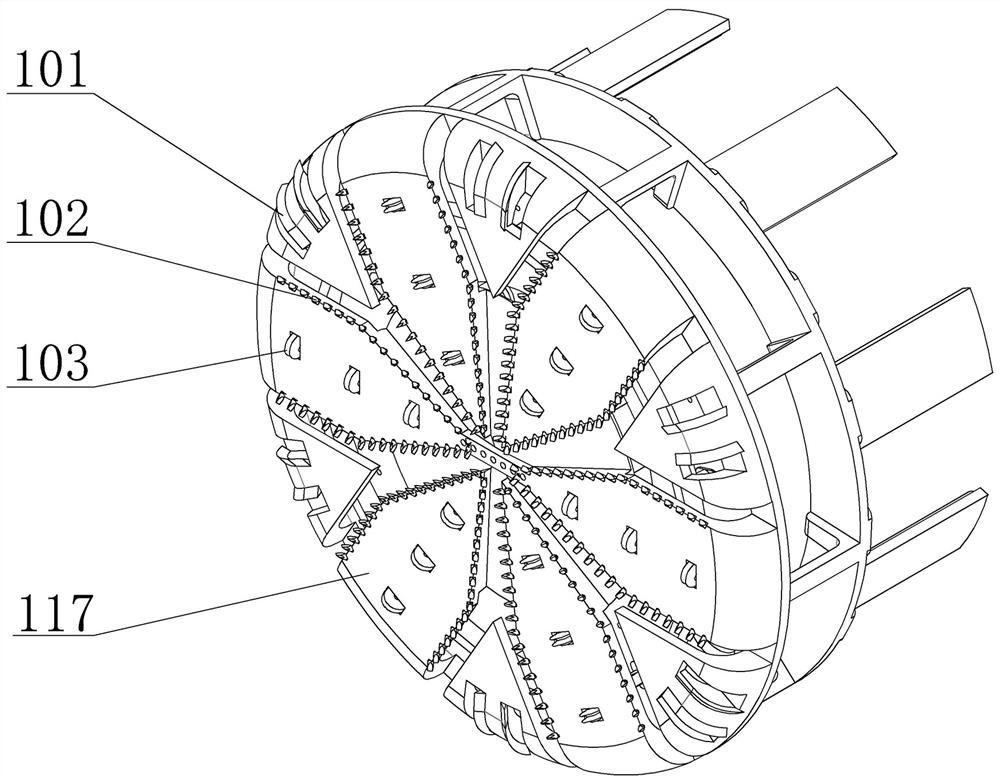

Novel slurry type shield tunneling all-in-one machine

ActiveCN111946359AImprove protectionHigh stability guaranteeUnderground chambersTunnel liningSteel frameTunnel boring machine

The invention relates to a novel slurry type shield tunneling all-in-one machine. The novel slurry type shield tunneling all-in-one machine comprises a cutterhead driving system, a shield shell, a hydraulic propelling system, a segment assembling mechanism, a U-shaped steel frame, a bottom segment, a segment transporting trolley, a segment transporting plate trailer, a segment hoisting mechanism,a slurry circulating system and a mud overground treatment mechanism, wherein the cutterhead driving system is connected with the hydraulic propelling system, the hydraulic propelling system is connected with the segment assembling mechanism, the hydraulic propelling system and the segment assembling mechanism are arranged in the shield shell, the segment assembling mechanism is connected with theU-shaped steel frame, one end of the slurry circulating system is connected with the cutterhead driving system, the other end of the slurry circulating system is connected with the mud overground treatment mechanism, and the segment assembling mechanism and the U-shaped steel frame are arranged in a circular cavity formed by connecting a plurality of segments. The tunneling machine is large-scalehigh-tech construction equipment specially used for excavating underground passage engineering, and has the advantages of being fast in excavation, high in quality, safe, economical, conductive to environmental protection and capable of reducing labor intensity.

Owner:BINZHOU UNIV

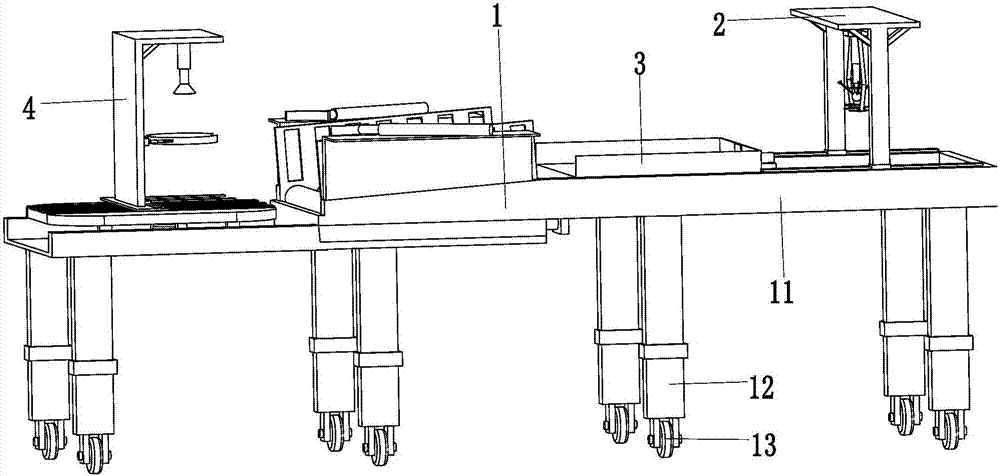

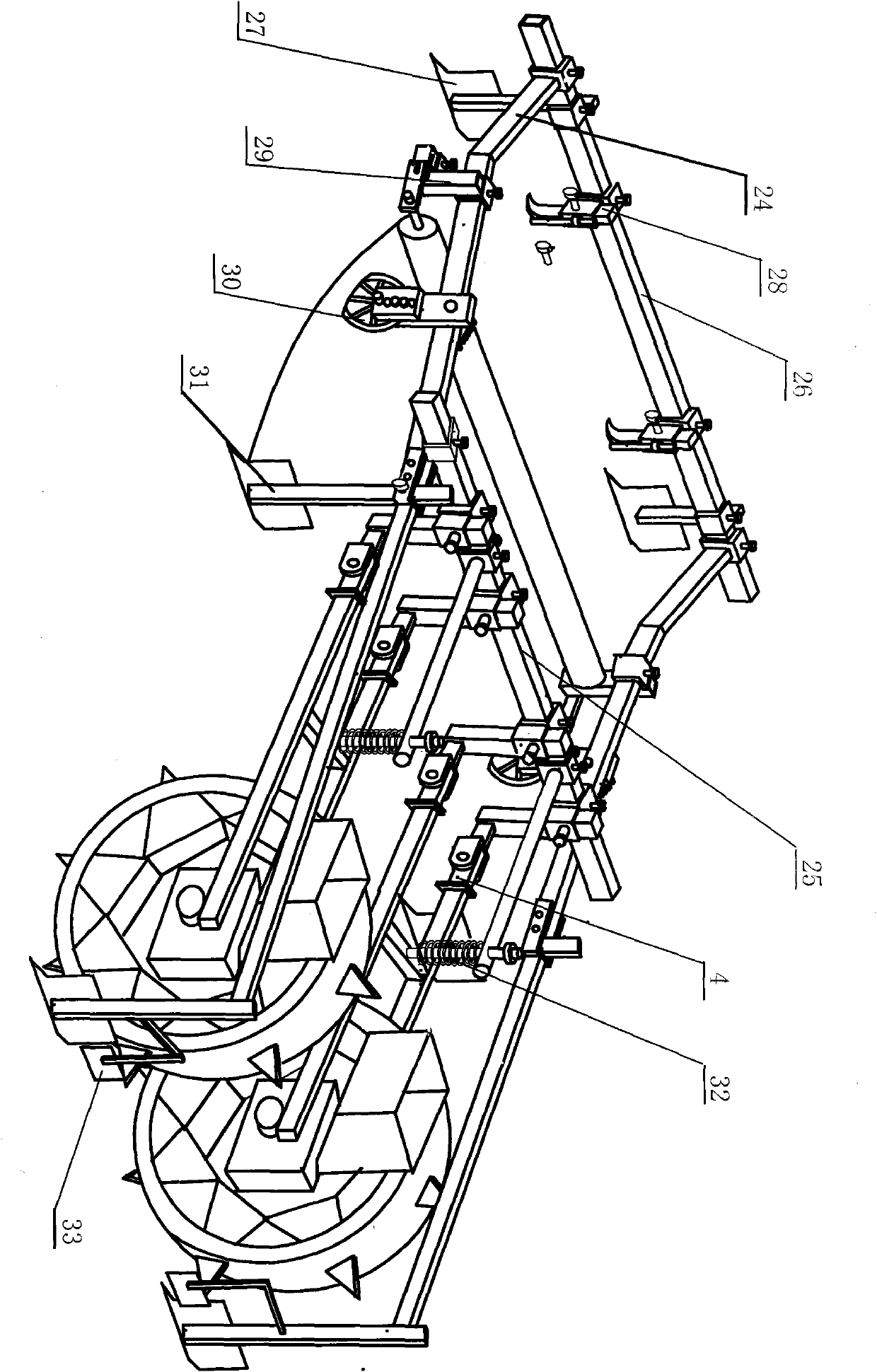

Automatic hoisting and placing trolley for special traffic road cones for isolating warning road construction section

InactiveCN107217618ASolve efficiency problemsSolve labor intensityTraffic signalsRoad signsEngineeringAutomatic testing

The invention relates to an automatic hoisting and placing trolley for special traffic road cones for isolating a warning road construction section. The automatic hoisting and placing trolley comprises a movable base, a hoisting device, a conveying device and a grabbing device; the hoisting device is installed on the right side of a supporting frame, the conveying device is installed in the middle of the supporting frame, and the grabbing device is installed on the left side of the supporting frame. The automatic hoisting and placing trolley can solve the problems that the road cones are gathered manually in the prior art, accordingly the work efficiency is low, the labor intensity is large, dangers are likely to happen during manual gathering of the road cones, and manual grabbing, stacking and placing of the road cones are complex; the functions of fully mechanically hoisting, stacking, conveying and placing the road cones in different models are achieved, and the automatic hoisting and placing trolley has the advantages that the work efficiency is high, the labor intensity is low, dangers are not caused during mechanical road cone gathering, and the road cones are grabbed, stacked and placed in a fully mechanical mode.

Owner:合肥集知网信息技术有限公司

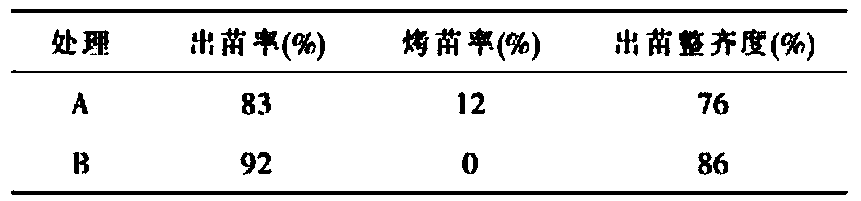

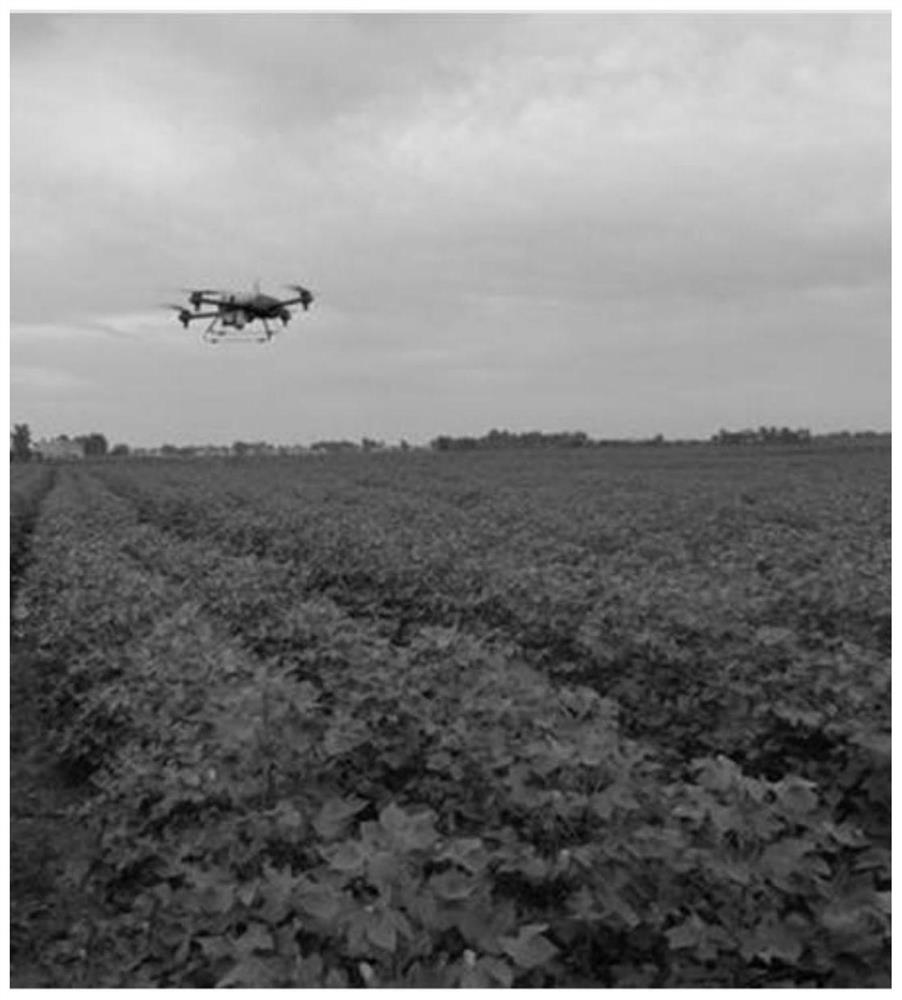

Cultivation method of high-yield, high-quality and early-maturing cotton

ActiveCN111011071ARapid vegetative growthMeet the nutrient needs of the growing seasonFertilising methodsCotton cultivationLand levelingSeedling

The present invention discloses a cultivation method of high-yield, high-quality and early-maturing cotton. The cultivation method of the high-yield, high-quality and early-maturing cotton comprises the following steps: (1) selection of limited fruit branch-type direct-sowing cotton varieties in Yangtze river basin; (2) a mechanized sowing technology; (3) a one-time balanced fertilization technology; (4) an unmanned aerial vehicle prevention and control technology; and (5) a whole-process chemical regulation and control technology. In the step (2), after previous crops are harvested, stubble cleaning and land leveling are carried out, before sowing, cotton seeds are delinted and coated, and the sowing amount is controlled; a seed germination rate is 90% or more, one sowing is conducted 1-2grains every time, row spacing is 55-65 cm, plant spacing is 15-20 cm, the total sowing amount is 13-17 thousand grains / mu, density is 7,300-7,700 plant / mu and an effect of not needing thinning afterone sowing of full seedling is reached. The used method promotes growth of cotton plants, reduces manual and labor intensity and improves cotton yield.

Owner:安徽省农业科学院棉花研究所

Corn cultivation method

PendingCN111374000AGuaranteed growth qualityConvenient irrigation and drainageBiocidePlant growth regulatorsSoil scienceFarmyard manure

The invention discloses a corn cultivation method. The corn cultivation method specifically comprises the following steps: (1) variety selection: a step of selecting a proper corn variety with good quality, disease resistance, pest resistance and stress resistance in a growth period; (2) land preparation: a step of cleaning a planting area, removing weeds, stones and sundries, adjusting the pH value of soil, plowing the soil, and digging drainage ditches; (3) ditching and soil covering: a step of arranging wide rows and narrow rows at intervals, applying decomposed farmyard manure according tothe area of a land parcel, uniformly spreading the farmyard manure into furrows, covering the furrows with loam, and compacting the loam; (4) precision sowing: a step of sowing corn seeds in a double-row wide-narrow-hole double-grain mode at the inner sides of two ridges, and compacting the soil after sowing is finished; and (5) field management, which comprises field management in a seedling stage, field management in an ear stage and field management in a flower and grain stage. According to the corn cultivation method provided by the invention, a density and a distance are increased; ventilation and light transmission are achieved; moisture is preserved; soil moisture is increased; full stand is realized; the fertilizer efficiency is improved, so plant strengthening is achieved; the corn cultivation method is especially applicable to northeast regions in China; whole-process mechanization is achieved, so the purposes of labor saving, fertilizer saving, water saving and high yield are achieved.

Owner:QIQIHAR BRANCH OF HEILONGJIANG ACADEMY OF AGRI SCI +1

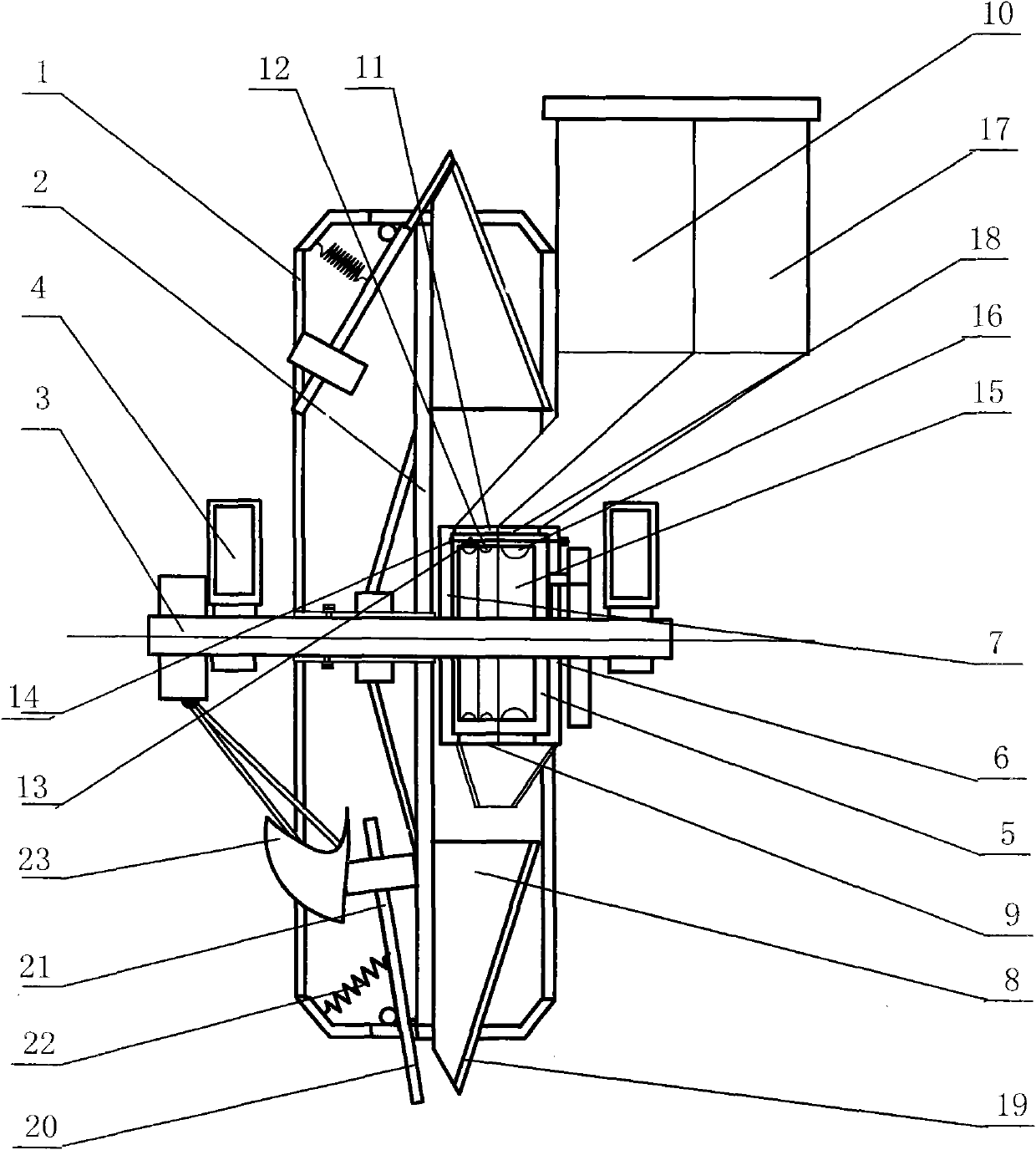

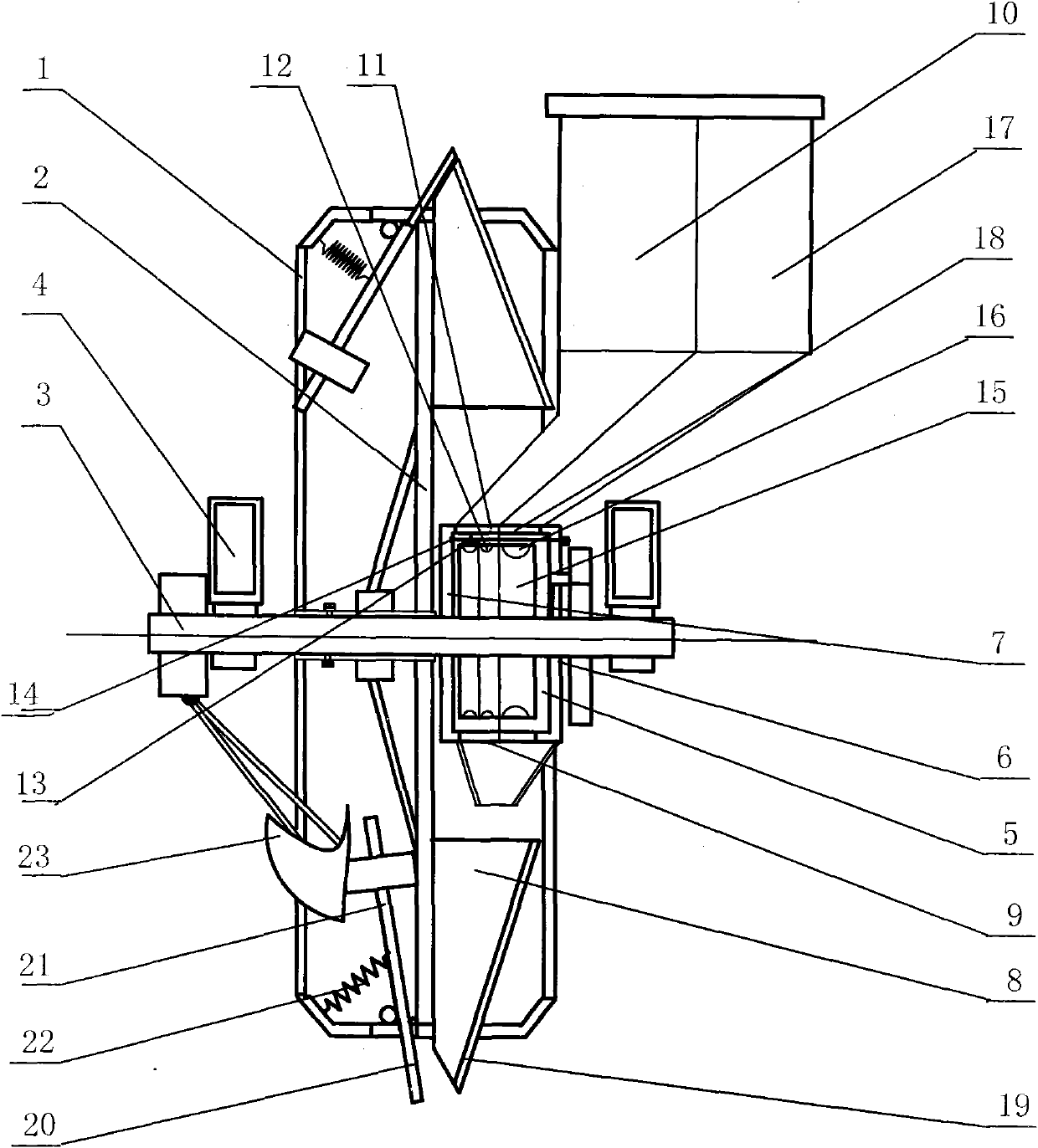

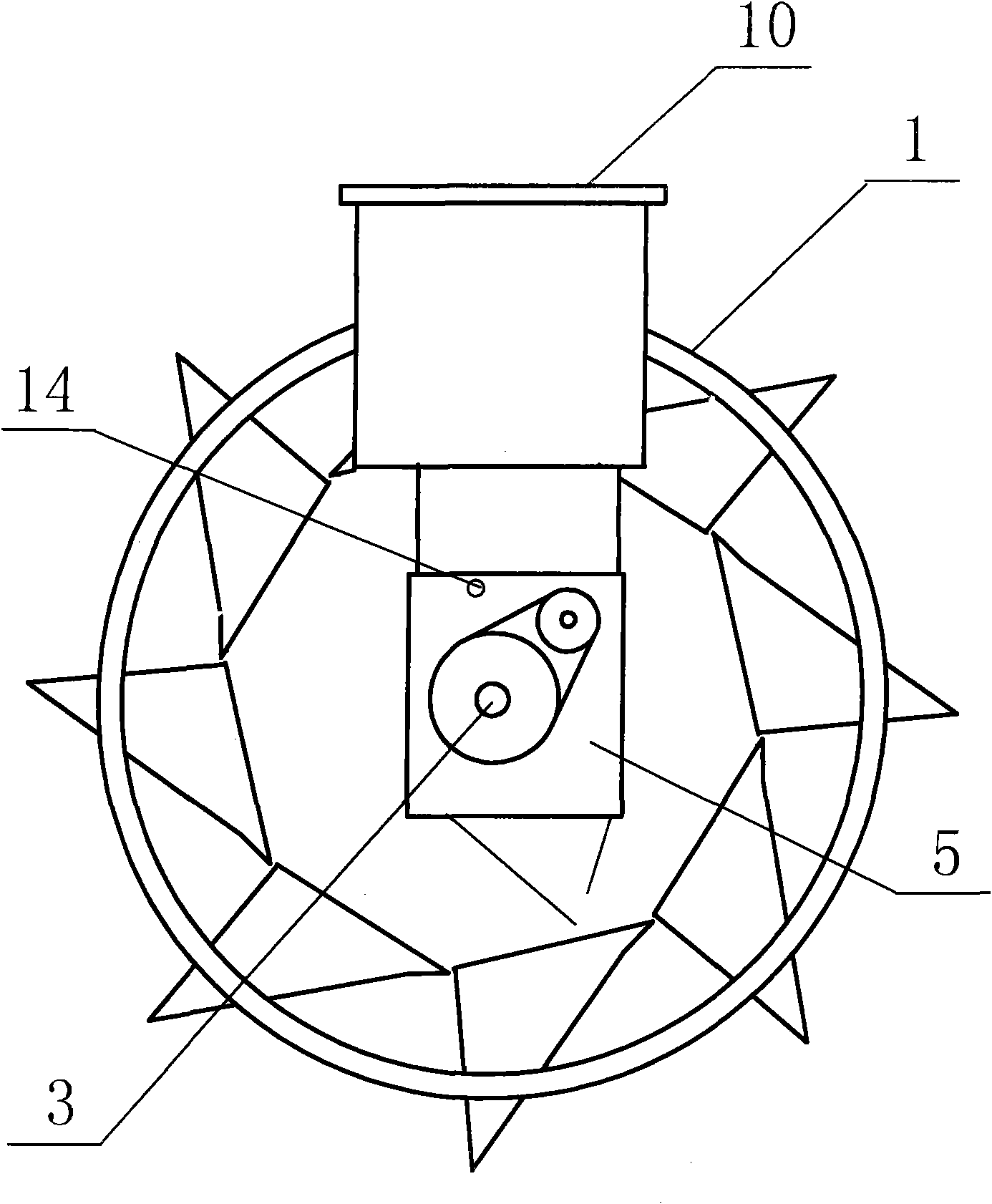

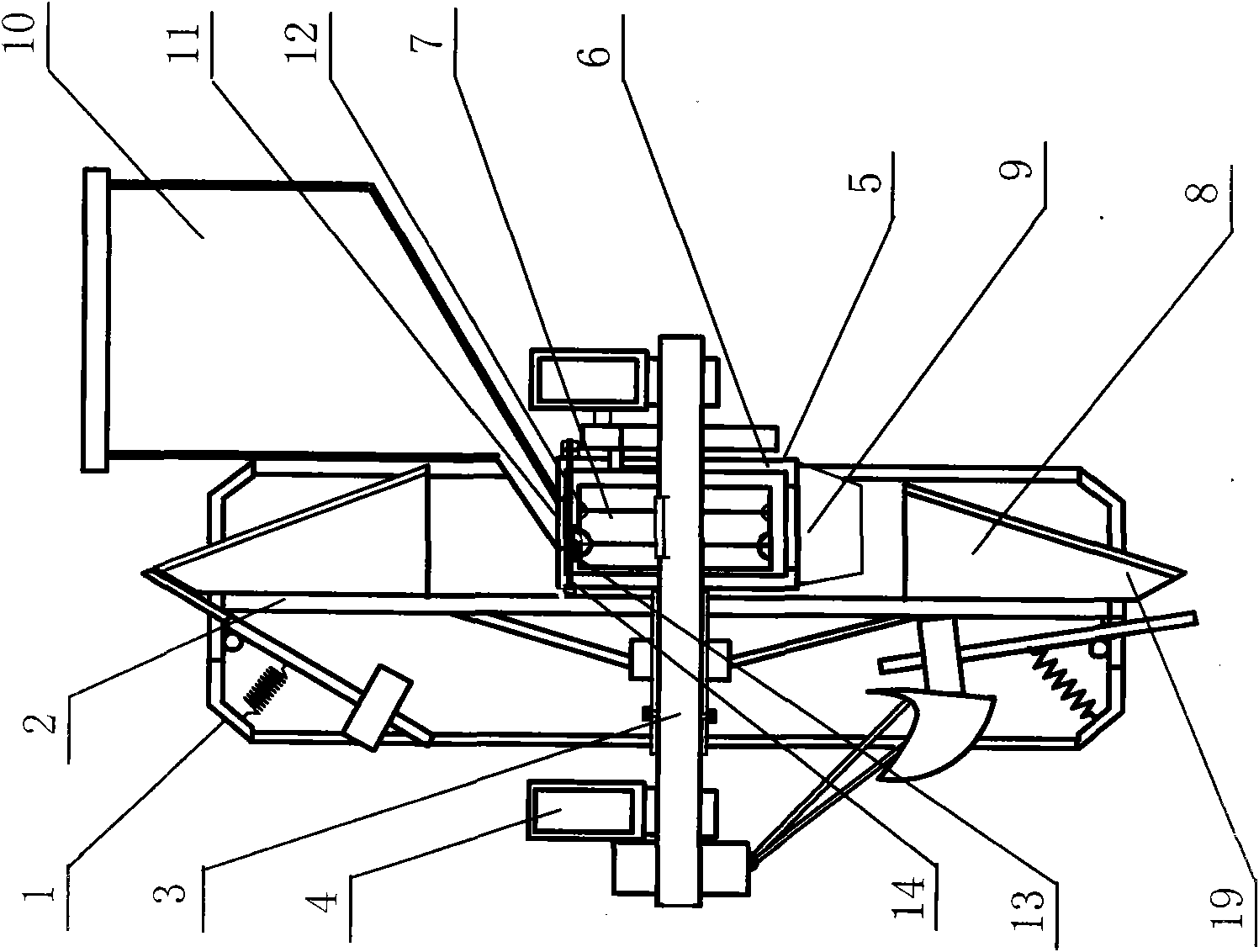

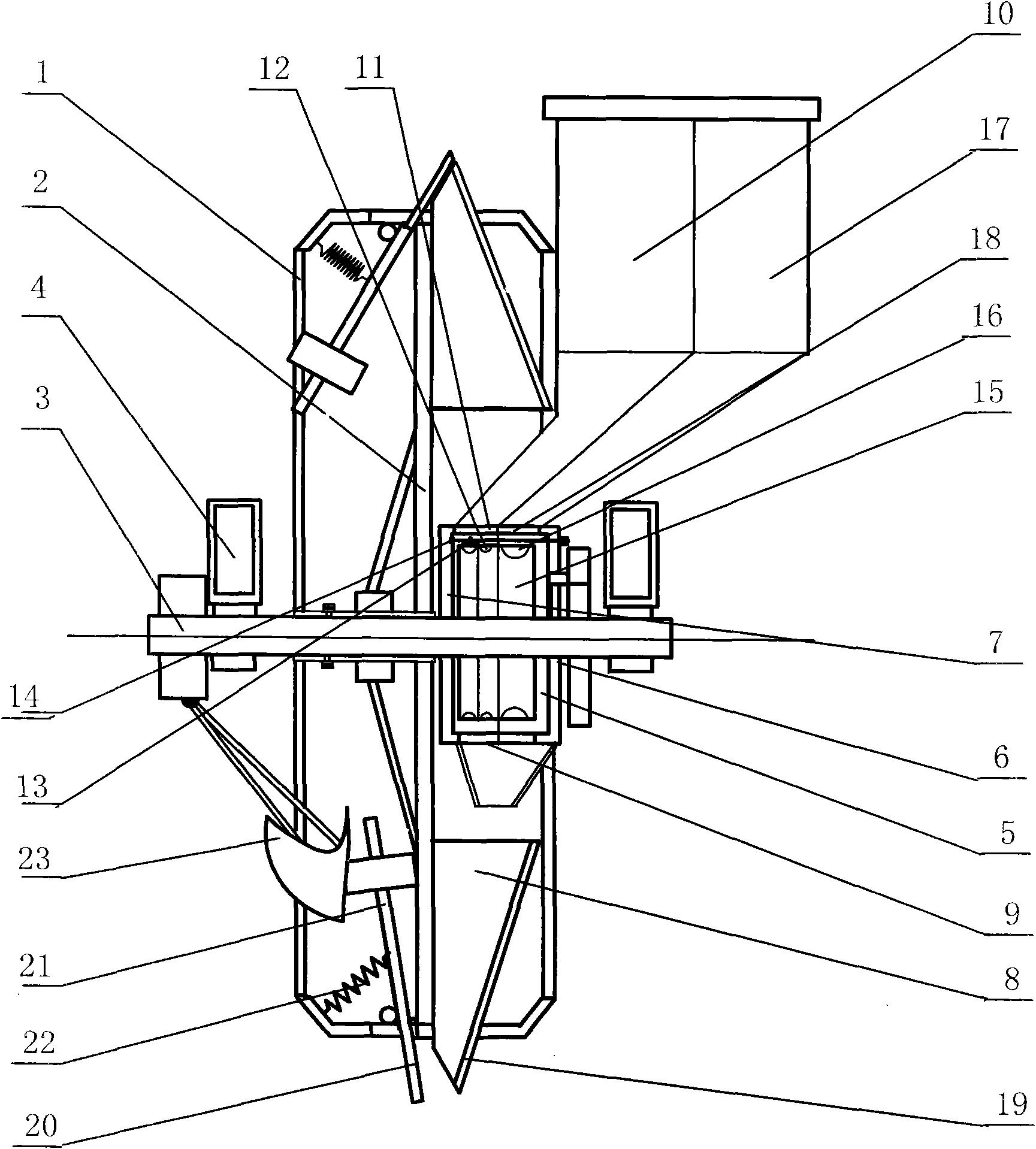

Uniset direct seeding machine and on-film hole-leveling direct seeding machine containing same

ActiveCN101904240AInnovative designReduce labor intensityPlantingAgriculture gas emission reductionAgricultural engineeringTraction frame

The invention discloses a uniset direct seeding machine and an on-film hole-leveling direct seeding machine containing the same. The uniset direct seeding machine comprises a roller and a wheel disc fixed on the inner wall of the roller, a rotating shaft is fixed on the wheel disc, and two ends of the rotating shaft are strung on a traction frame; the roller is internally provided with a seed sowing gate plate starting mechanism, a seed rationing mechanism and a seed conveying mechanism; the bottom openings of discharging hoppers at the bottom of a rationing seed sowing machine are arranged slantways and correspond to seed distribution hoppers in advance, and seed grooves on a seed distribution wheel one-to-one corresponds to the seed distribution hoppers. The invention has the advantage of novel design of the uniset direct seeding machine exactly satisfies hole sowing requirements because the seed grooves on the seed distribution wheel accurately and simply correspond to the seed distribution hoppers, greatly improves sowing efficiency, reduces labor intensity of farmers, and remarkably improves germination rate. By utilizing the sowing and fertilizing all-in-one machine of the design, multiple operations, such as sowing, fertilizing, and the like can be synchronously completed, and the problem of difficultly fertilizing grain fertilizers, which troubles the farmers for many years, is well solved.

Owner:聂长军

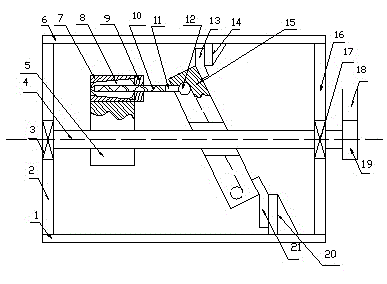

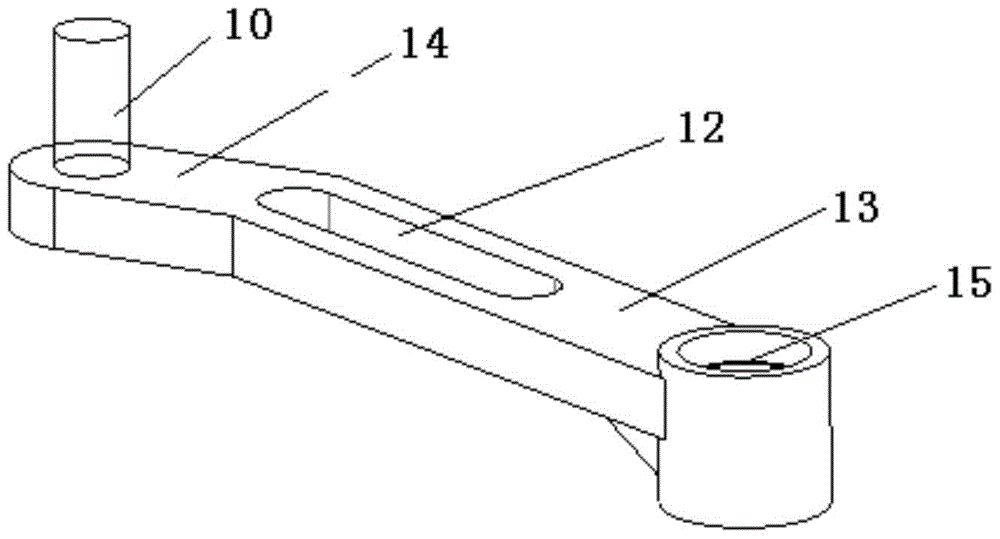

Inclined plate ball groove drilling mechanism of corn harvester threshing device

InactiveCN104429397AMechanizationHas the function of direct threshingMowersThreshersDrill bitDrill bushing

The invention provides an inclined plate ball groove drilling mechanism of a corn harvester threshing device. The inclined plate ball groove drilling mechanism aims at solving the problem that due to the fact that a semi-mechanized corn harvester mechanism on the market does not have the threshing function, the development requirement can not be met. The inclined plate ball groove drilling mechanism of the corn harvester threshing device is characterized in that a driving mechanism is fixed to the right side of a rotating shaft, the rotating shaft is sleeved with a left bearing pedestal and a right bearing pedestal, the left bearing pedestal and the right bearing pedestal are fixed to a left machine frame plate and a right machine frame plate, an upper angle type support and a lower angle type support are arranged on the upper machine frame plate and the lower machine frame plate, an upper inclined type positioning plate and a lower inclined type positioning plate are fixed to the upper angle type support and the lower angle type support respectively, a ball groove inclined plate is arranged on the right side of the rotating shaft in a sleeving mode and fixed to the upper inclined type positioning plate and the lower inclined type positioning plate, a ball groove is formed in the ball groove inclined plate, a rotating disc is fixed to the left side of the rotating shaft, a clamp is arranged on the rotating disc, a drill bushing is arranged on the right side of the clamp, the front end of a drill bit is sleeved with the dill bushing, the rear end of the drill bit is connected with a swing rod, and a swing head is arranged at the tail end of the swing rod and placed in the ball groove of the ball groove inclined plate. The inclined plate ball groove drilling mechanism has the direct threshing function, and full mechanization of the corn harvester mechanism is achieved.

Owner:赵松辰

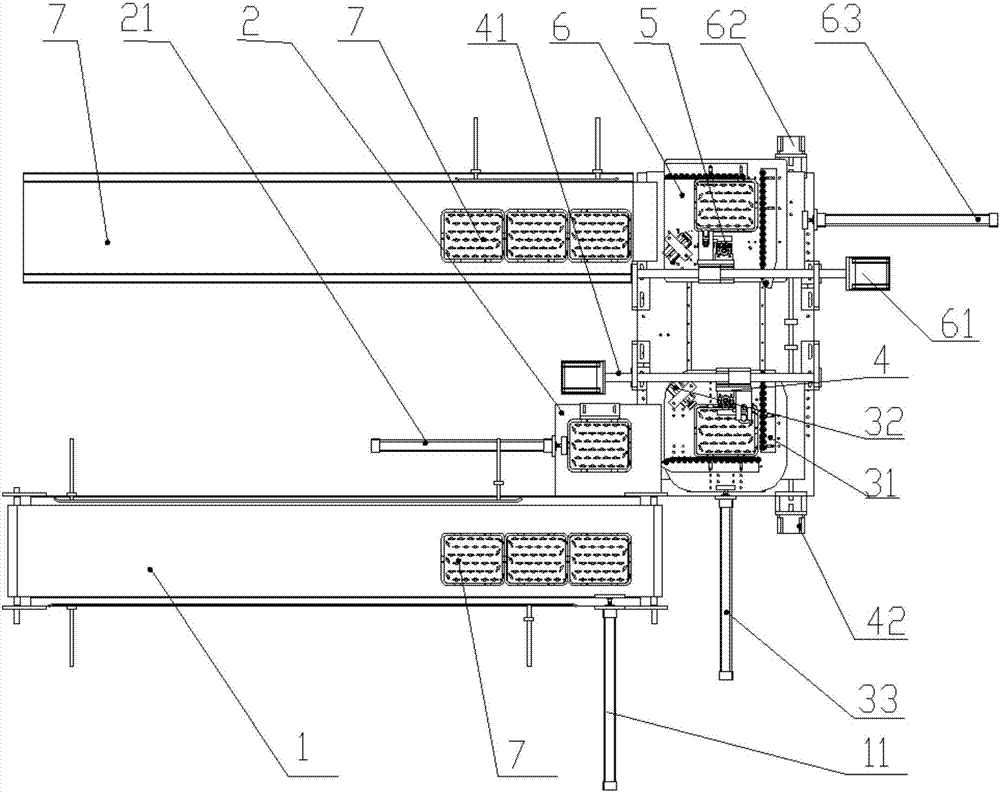

Connecting-rod type automatic neatening device for plastic packages of express-delivery file mails

The invention discloses a connecting-rod type automatic neatening device for plastic packages of express-delivery file mails, and relates to the technical field of automatic neatening equipment for the shapes of thermoplastic packages of mail piles. The automatic neatening device is characterized in that driving devices drive fixed plates to move in a direction which is perpendicular to the conveying direction of file piles, so that connecting-rod swing arms are driven to rotate relative to a machine frame in the horizontal plane through sliding guide devices; first neatening rods and second neatening rods are respectively positioned on lateral sides of adjacent file piles, and the file piles which are piled up in an irregular shape can be neatened by squeezing action. Four corners of the file piles are neatened by the neatening rods which are symmetrically arranged in the fore-and-aft direction and the left-and-right direction. Through the adoption of the automatic neatening device provided by the embodiment of the invention, the full mechanization and full automation of shape neatening operation for thermoplastic packages of express-delivery file mails can be realized, and unmanned operation is realized; the automatic neatening device technically fills a gap at home and abroad, and the labor cost of enterprises in economic benefits is greatly lowered.

Owner:CHINA POST SCI & TECH

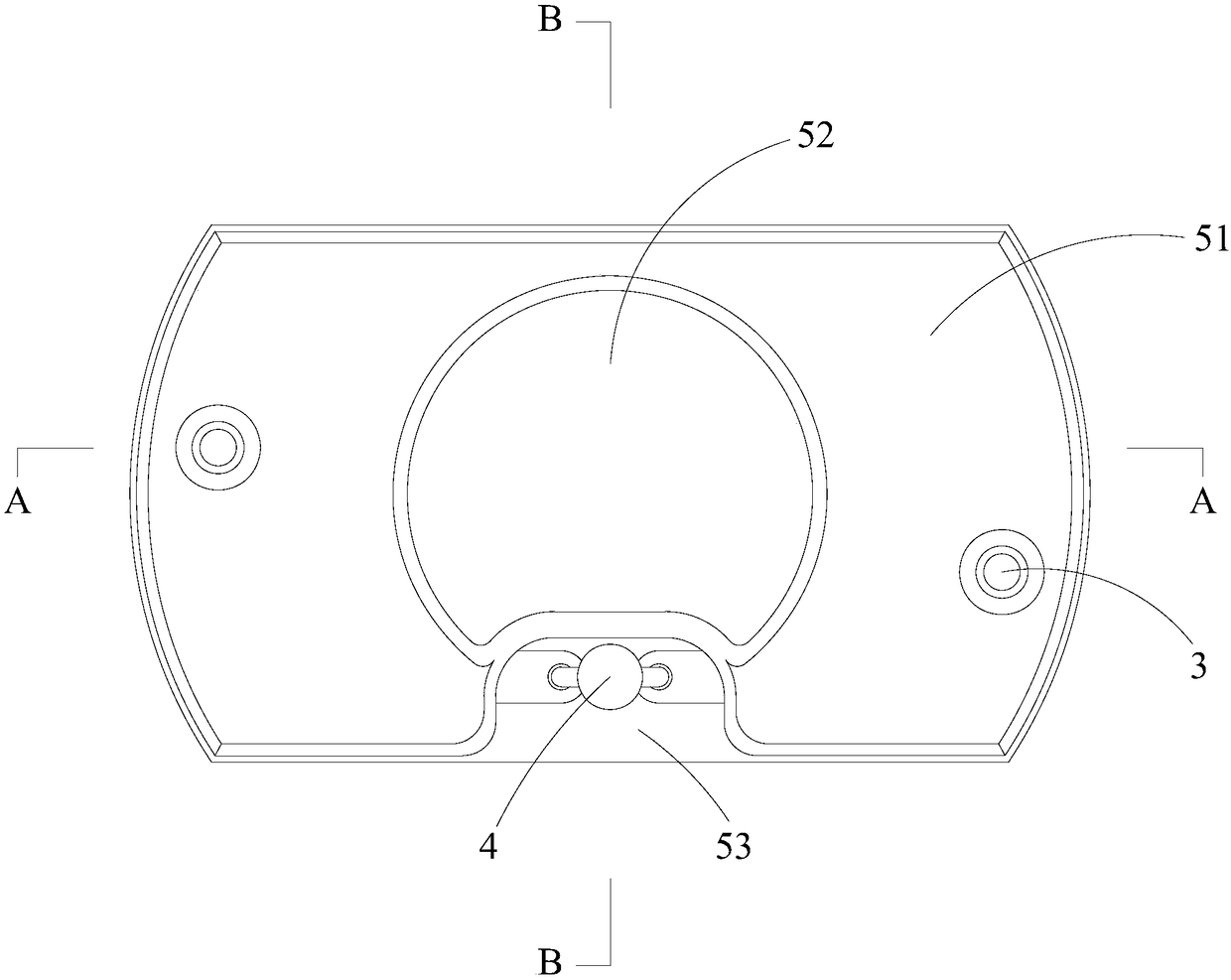

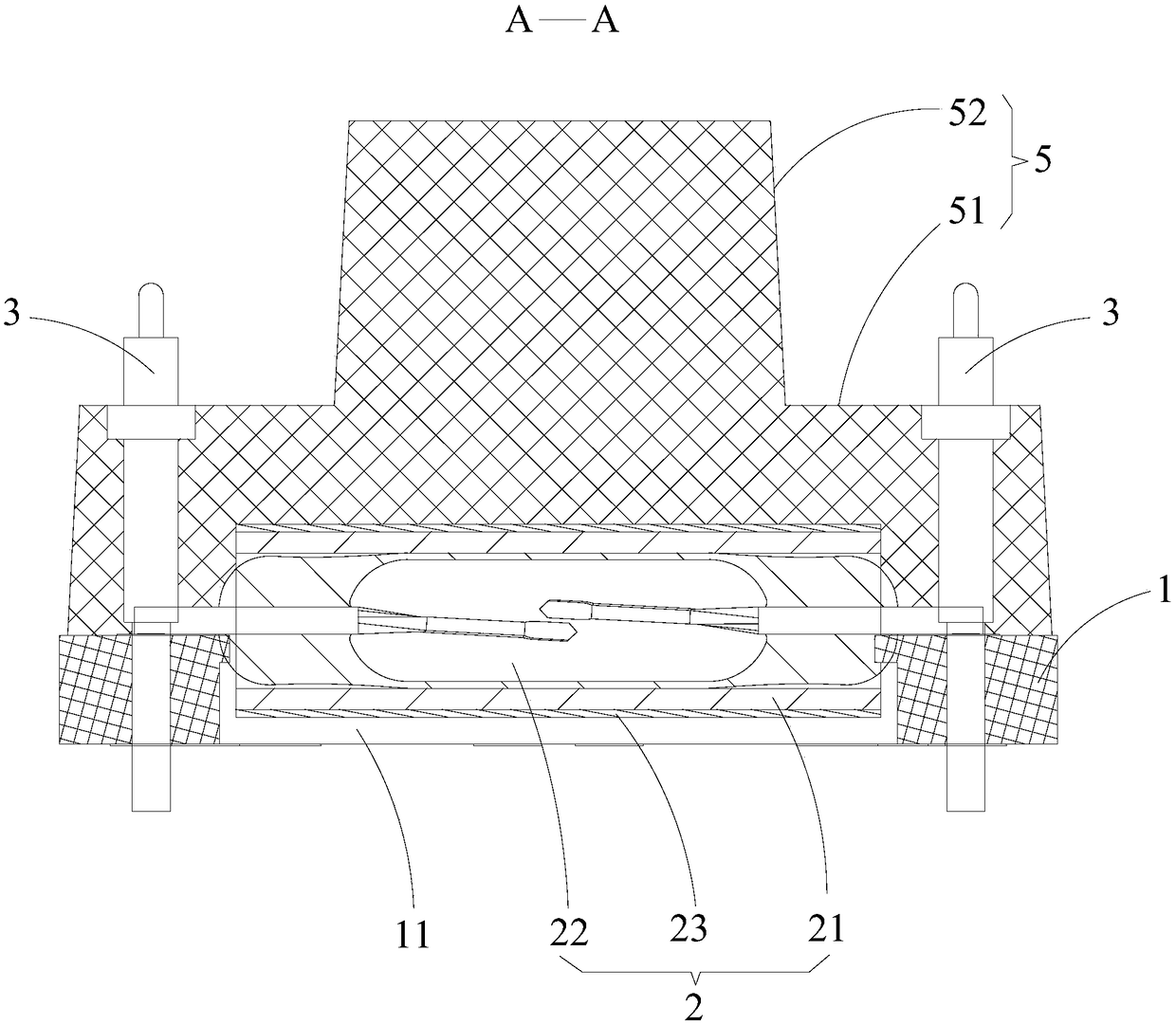

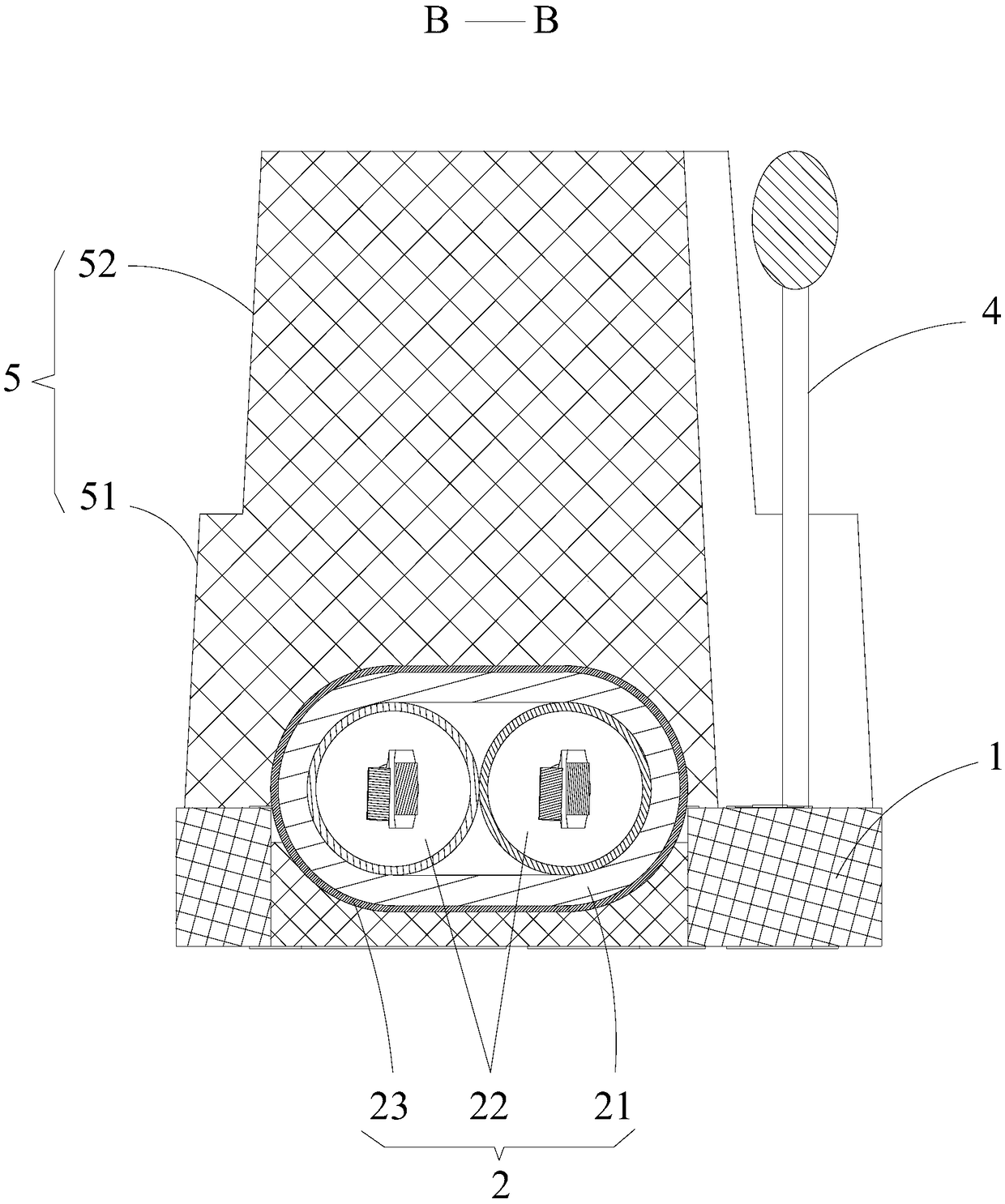

A dry reed relay

InactiveCN106104739BGuaranteed positionGuaranteed accuracyFinal product manufactureCasings with display/control unitsPosition toleranceEconomic benefits

A dry reed relay, including a PCB base (1), and a control component (2) electrically connected to the PCB base, the control component is mounted on the PCB base through a surface packaging process, and the control component includes a The air-core coil (21) on the PCB base, the dry reed switch (22) installed in the hollow coil, and the shielding layer (23) sleeved on the outer peripheral surface of the hollow coil, the reed switch has pins, and the shielding layer Electrically connected to the pins of the reed switch. The reed relay is assembled with the control component and the PCB base through the surface packaging process, which ensures the position tolerance and accuracy of the reed switch, realizes the full mechanization of product production, improves production efficiency, and meets the requirements of mass production. needs, thereby improving economic efficiency.

Owner:GUANGDONG HUACHAN RES INST OF INTELLIGENT TRANSPORTATION SYST CO LTD

Dyeing mechanism with quick dyeing function

InactiveCN110314576ASimple structureIngenious designRotary stirring mixersTransportation and packagingDyeingEngineering

The invention provides a dyeing mechanism with a quick dyeing function. The dyeing mechanism comprises a transmission device, a stirring device, a stirring tank, a chassis, an unloading gate, an unloading mechanism, a first oil supply system, mounting supports, a gear cover and a second oil supply system; the three mounting supports are uniformly distributed and fixedly mounted at the lower end ofthe chassis; the transmission device is fixedly mounted at one side of the upper end of the chassis, is in connection cooperation with the stirring device and is used for providing power support forthe stirring device. The dyeing mechanism is simple in structure and ingenious in design, quick unloading can be achieved, the labor intensity is lowered, and full mechanization is achieved.

Owner:储海霞

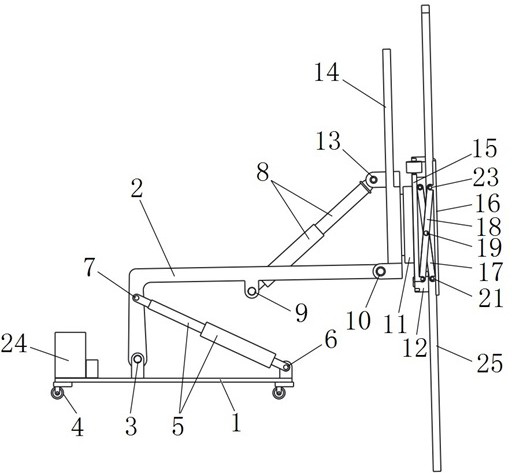

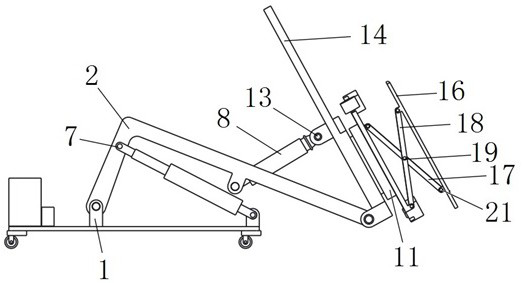

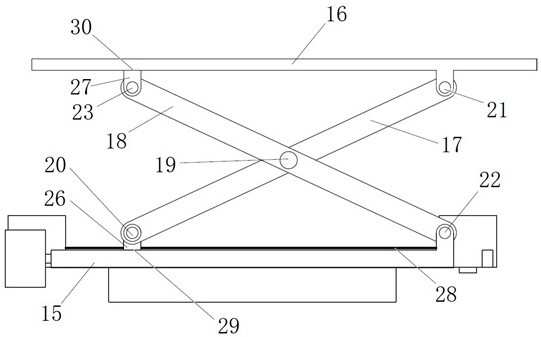

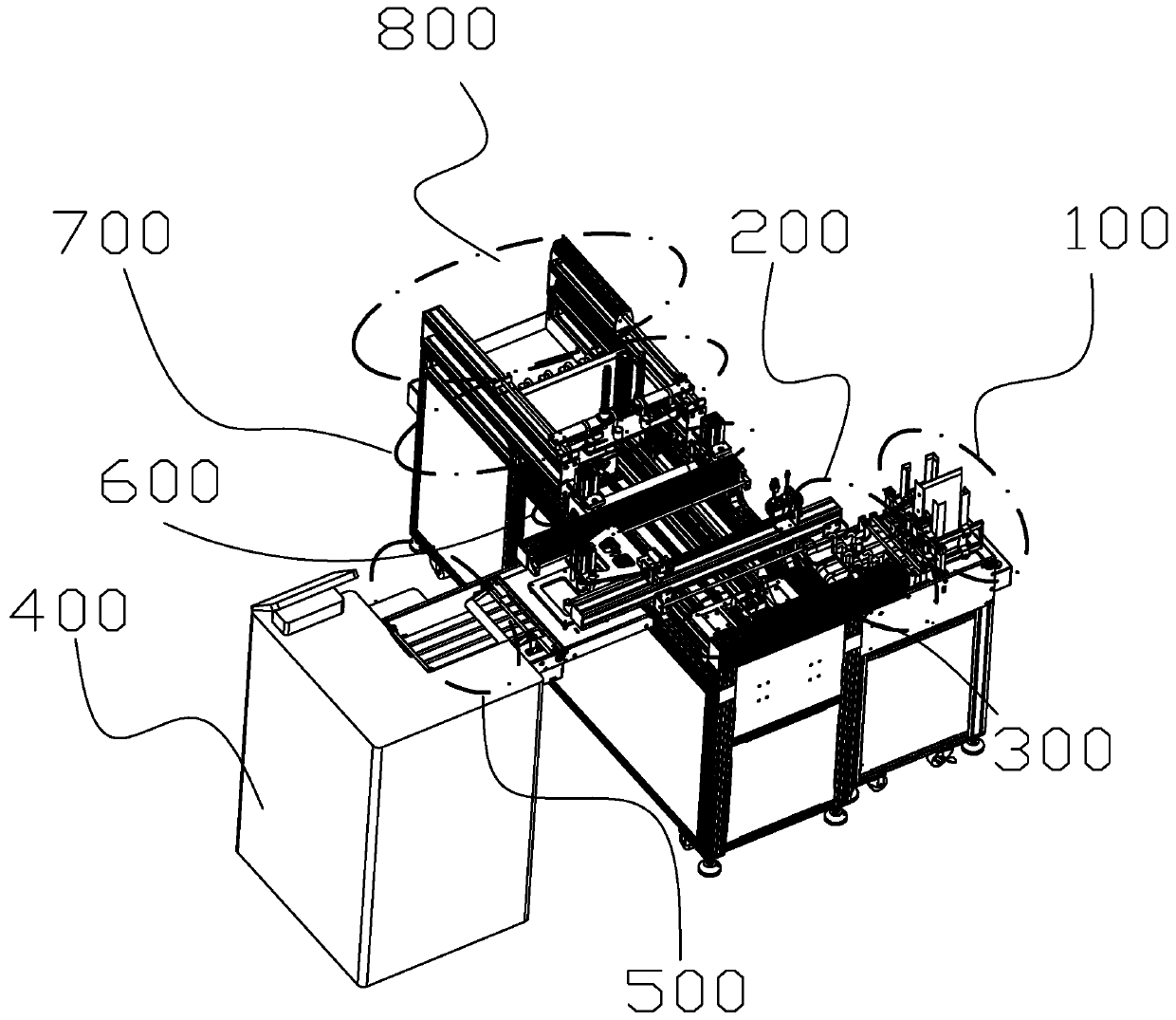

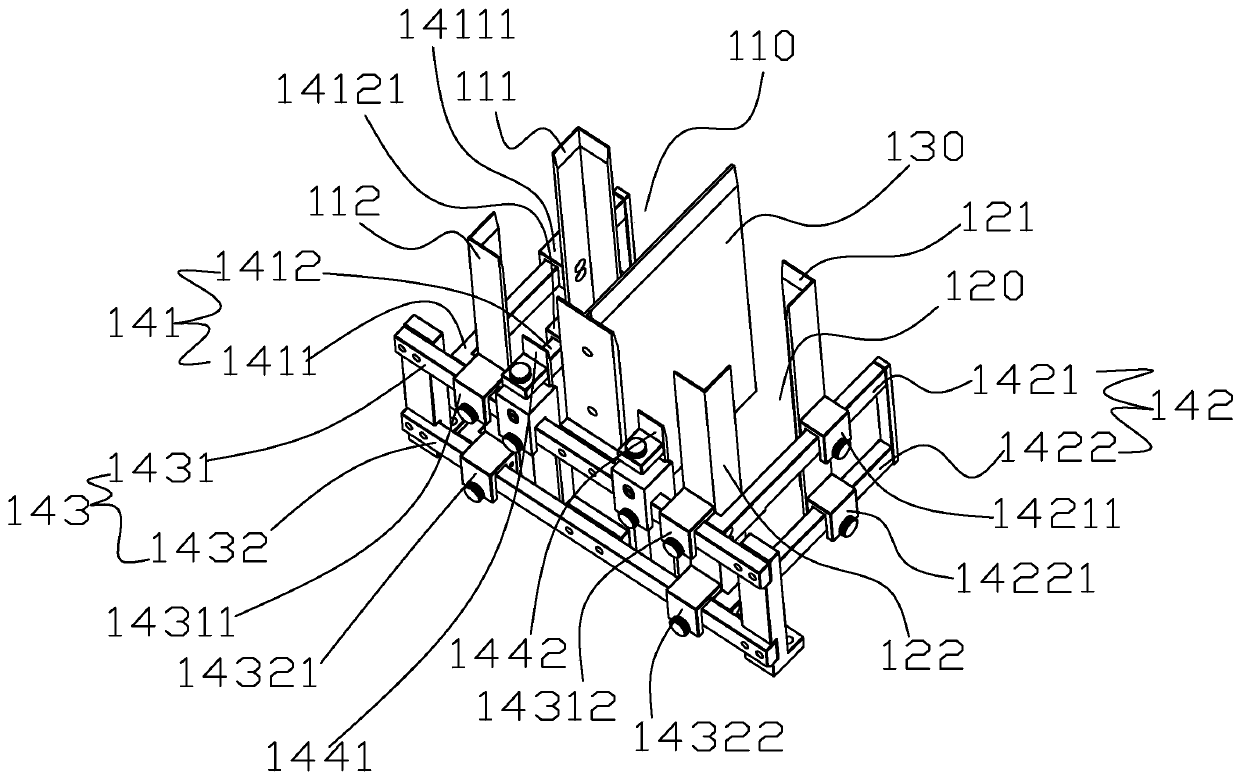

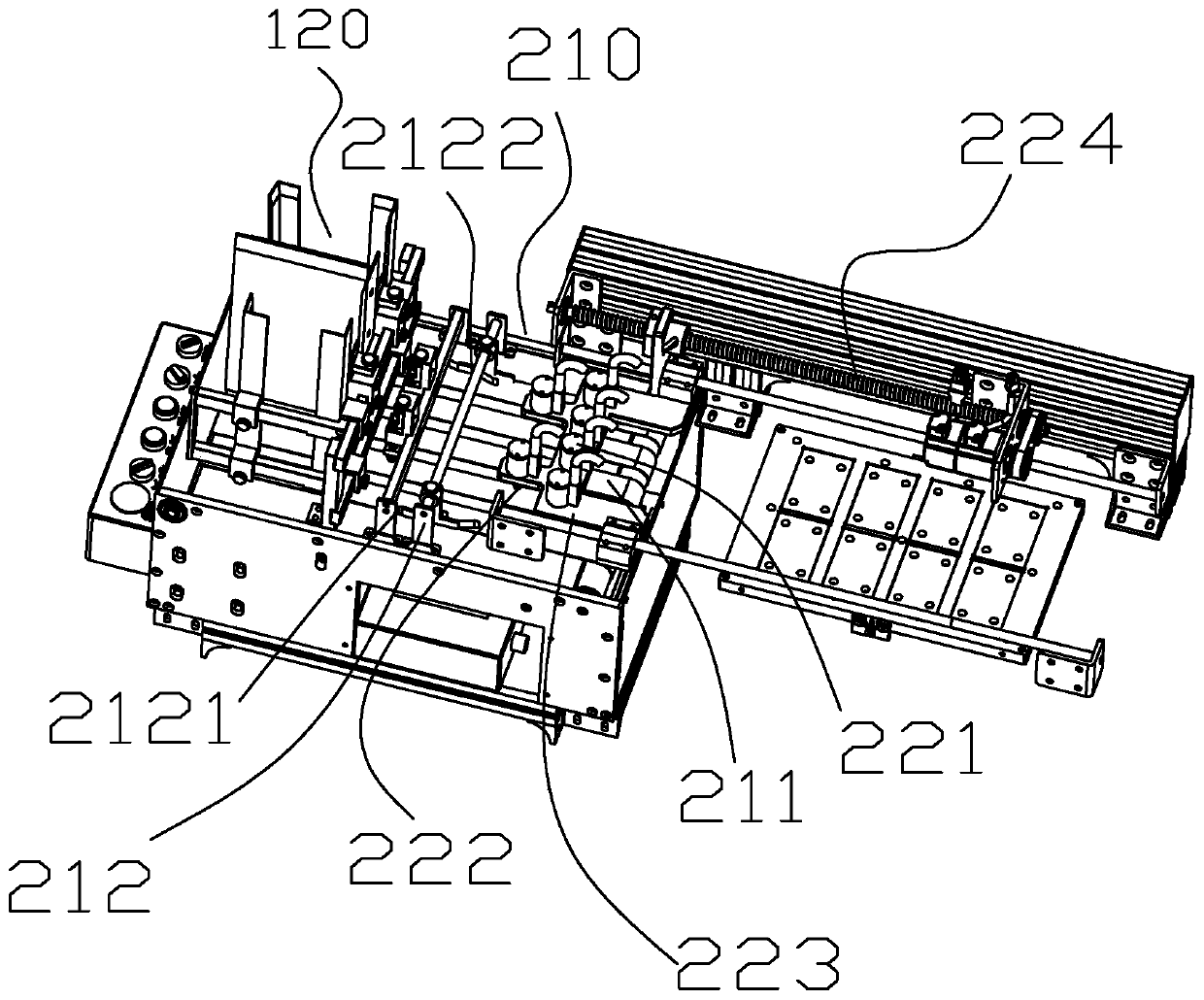

Shear-fork structure type wallboard grabbing and installing mechanism

PendingCN113374272AFully mechanizedReduce labor intensityBuilding material handlingArmsEngineeringControl theory

The invention discloses a shear-fork structure type wallboard grabbing and installing mechanism. The shear-fork structure type wallboard grabbing and installing mechanism comprises a supporting arm adjusting mechanism and a grabbing mechanism, the supporting arm adjusting mechanism is a planar two-degree-of-freedom series mechanism and comprises a rack, a movable arm, a first linear driver, a second linear driver and a supporting arm, the movable arm is installed on the rack, the supporting arm is installed on the movable arm through a rotating pair, the first linear driver controls the movable arm to swing up and down relative to the rack, and the second linear driver controls the supporting arm to swing relative to the movable arm; and the grabbing mechanism comprises a rotary table, a first connecting rod, a second connecting rod, a first sliding block, a second sliding block and a lower pressing plate, the rotary table is installed on the supporting arm through a rotating pair and can rotate relative to the supporting arm, and under the action of the sliding blocks, the lower pressing plate can move relative to the rotary table, so that clamping or releasing of the wallboard is achieved. Under the cooperation of the supporting arm adjusting mechanism and the grabbing mechanism, four-range-of-motion posture adjustment of the wallboard can be achieved, automation and mechanization of wallboard installation are achieved, and the labor intensity of workers is reduced.

Owner:SHANDONG TIANYI MACHINERY

Card printing equipment

PendingCN110683386AImprove work efficiencyReduce labor costsLamination ancillary operationsLaminationLaser printingMemory module

The invention provides card manufacturing equipment. The card manufacturing equipment comprises a blank card base memory module, a first conveying module, a film coating platform, a holographic film printing module, a second conveying assembly and a laminating assembly, the first conveying assembly comprises a first conveying belt platform connected to a blank card base and a first lead screw conveying mechanism provided with a card adsorbing device, the film coating platform comprises a groove for storing the blank card base, and the second conveying assembly connected to the holographic filmprinting module comprises a second conveying belt platform and a second lead screw conveying mechanism provided with a holographic film absorbing device. The card manufacturing equipment has the beneficial effects that integrated molding technology of holographic film laser printing and card manufacturing is achieved, the waste of manpower, time and space due to decentralized operation is avoided, the work efficiency is greatly improved, the labor costs are reduced, moreover, the technical scheme of the card manufacturing equipment achieves full mechanization, the rate of a waste card is greatly reduced, and the material costs are saved.

Owner:SHENZHEN HUAZHENGLIAN INDAL

Automatic examination paper binding machine

PendingCN107539820AReduce labor costsImprove binding qualitySheet bindingArticle deliveryPulp and paper industryUltimate tensile strength

The invention discloses an automatic examination paper binding machine and relates to a binding device. The automatic examination paper binding machine comprises an examination paper conveying mechanism, an automatic examination paper binding mechanism, an examination paper receiving device, a plurality of examination paper stations and a control mechanism and further comprises examination paper catching mechanisms and rotary examination paper stacking mechanisms, wherein the number of the examination paper catching mechanisms and the number of the rotary examination paper stacking mechanismsare consistent with the number of the examination paper stations. Examination papers are arranged on the different examination paper stations paper by paper according to sequence, and the examinationpaper catching mechanisms are arranged above the examination paper stations and connected with the corresponding rotary examination paper stacking mechanisms. The examination paper catching mechanisms, the rotary examination paper stacking mechanisms, the examination paper conveying mechanism and the automatic examination paper binding mechanism are connected with the output end of the control mechanism. By means of the automatic examination paper binding machine, teachers can be liberated from a large number of fussy and repetitive labor. The automatic examination paper binding machine has the beneficial effects of being high in binding working efficiency, low in binding labor intensity, low in labor cost, high in binding quality and wide in application range and is easy to use and popularization.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

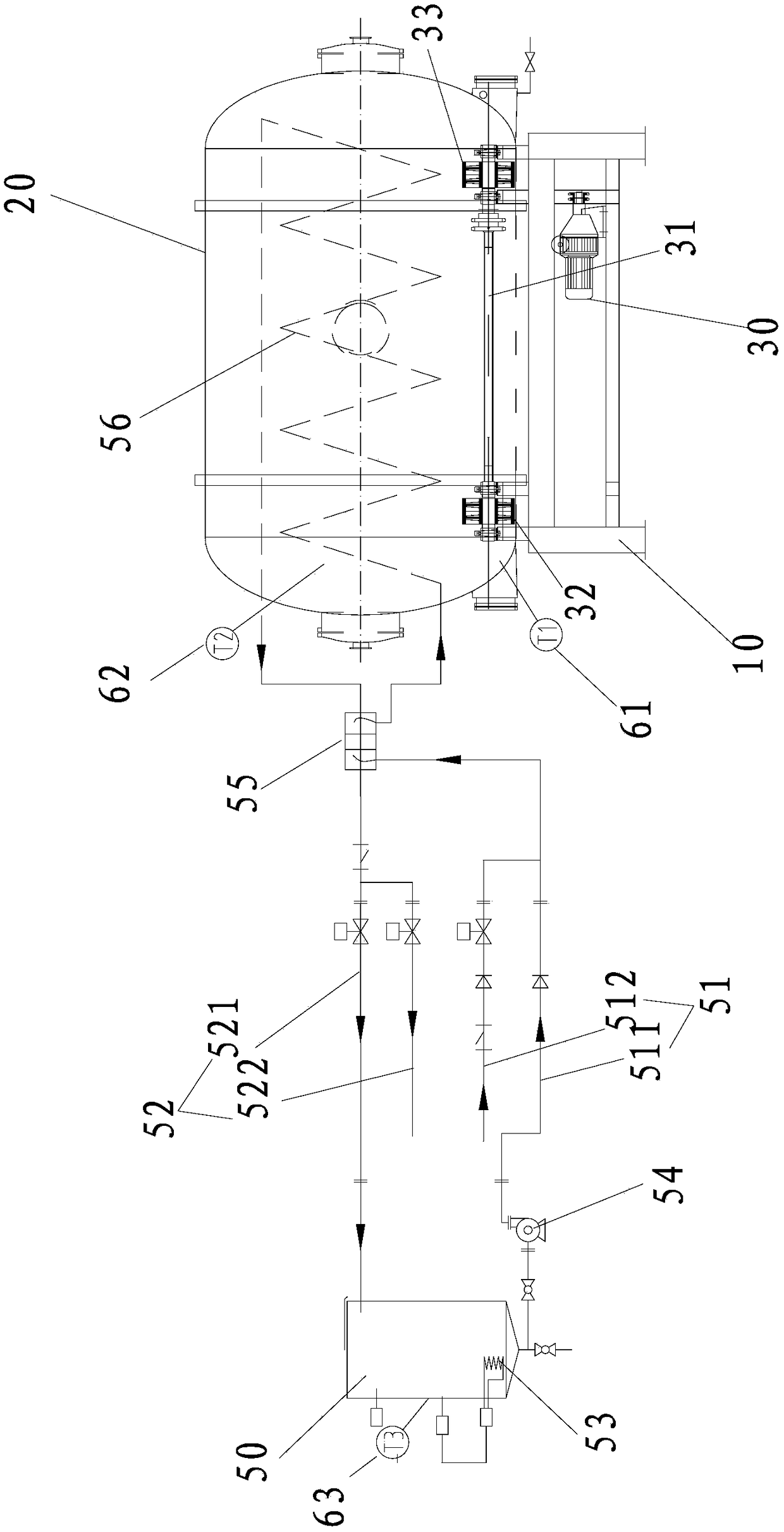

Rapid solid-state fermentation process of vinegar

InactiveCN108707530AConvenient and timely closingImprove utilizationVinegar preparationAcetic acidAlcohol

The invention relates to a rapid solid-state fermentation process of vinegar. The rapid solid-state fermentation process of the vinegar includes saccharification process, alcohol fermentation processand acetic acid fermentation process. The rapid solid-state fermentation process of the vinegar is characterized in that the process conducts the fermentation by using a vinegar solid-state fermentation machine capable of cooking, cooling, inoculation, alcohol fermentation, acetic acid fermentation, automatic turning over fermenting grains, oxygen supply, vinegar drenching and slag discharging; inthe alcohol fermentation process, fermentation temperature is 28-37 DEG C, and fermentation time is 100-168 hours; in the acetic acid fermentation process, fermentation temperature is 26-37 DEG C, and fermentation time is 48-120 hours. The rapid solid-state fermentation process of the vinegar has the advantages of greatly shortening the fermentation time, improving the utilization of raw Materials and accessories and increasing productivity, efficiency and cost-effectiveness with the raw materials and product quality not changed.

Owner:泉州中翔生物技术有限公司

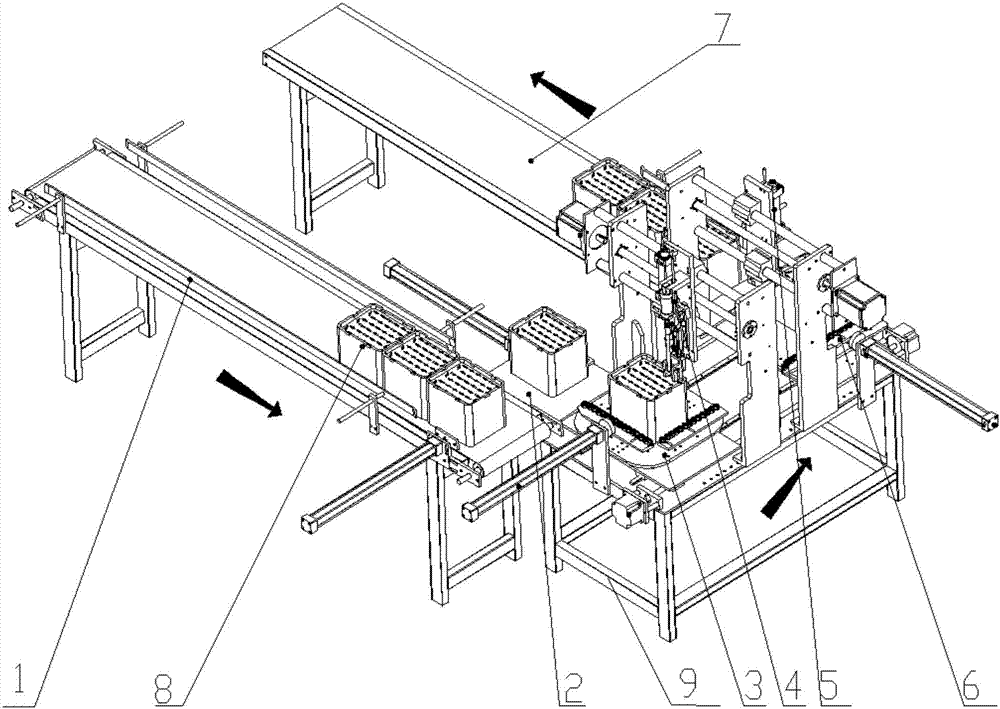

Mold-pressing firework lead inserting machine

ActiveCN107339917AFully mechanizedTo overcome the weak connectionWaste based fuelFireworksMachineWorkbench

The invention discloses a mold-pressing firework lead inserting machine. A feeding cylinder conveying line, a transferring table, a first rotating working table, a second rotating working table and a discharging cylinder conveying line are sequentially installed on a machine frame, and a first punching lead inserting device and a second punching lead inserting device are also installed on the machine frame; workpieces are conveyed to all stations through a first pushing rod, a second pushing rod, a third pushing rod and a fourth pushing rod respectively, and the first rotating working table and the second rotating working table are rotatably installed on the machine frame; the first punching lead inserting device and the second punching lead inserting device are movably connected to two X-direction moving mechanisms respectively, and the two X-direction moving mechanisms are movably connected to two Y-direction moving mechanisms respectively. The mold-pressing firework lead inserting machine has the advantages that full mechanization of lead inserting production of firework cylinders is achieved, the production efficiency is improved, and the defects that errors exist in lead inserting, leads and holes cannot be closely matched, inserting connection of the leads is not firm, and loosing and falling off are prone to occurrence are overcome.

Owner:鲁佰战 +2

Mechanized full film furrow and ridge cultivation method of dry-farmed potato

ActiveCN104221682BAvoid pollutionSolve the problem of burning seedlingsHorticultureRainwater harvestingSolanum tuberosum

The invention relates to the technical field of crop planting, in particular to a dry-land potato mechanized full-film furrow-ridge cultivating method. The dry-land potato mechanized full-film furrow-ridge cultivating method is mainly characterized by comprising the following steps of (1) preparation before planting; (2) film covering and planting: once finishing planting, fertilization, ridge forming, packing shaping, full-film covering, and soil-lifting soil-placing combined operation, and covering 3 to 5cm of soil on the top of a film above seed potatoes; (3) plant protection: spraying chemicals in 15 to 20 days after planting; using a wheel type tractor, enabling wheels to walk on small ridges, and arranging spray heads according to corresponding row distances; (4) potato harvest. The dry-land potato mechanized full-film furrow-ridge cultivating method has the advantages that mechanized soil lifting, soil separation and film-top soil placement can be realized by the technology, i.e. 3 to 5cm of soil covers the top of the film above the seed potatoes, so that the problem that seedlings cannot break through the film or come up out of soil and are burnt is solved; overall-process mechanization is realized, so that the labor force is saved; the pollution of the broken film for the soil is avoided; a mechanized full-film furrow-ridge cultivating technology is a new agricultural technology and has the advantages of rainwater harvesting, soil moisture preservation, temperature increase, yield increase and the like and has quite remarkable drought-resisting and yield-increasing effects.

Owner:GANSU AGRI UNIV

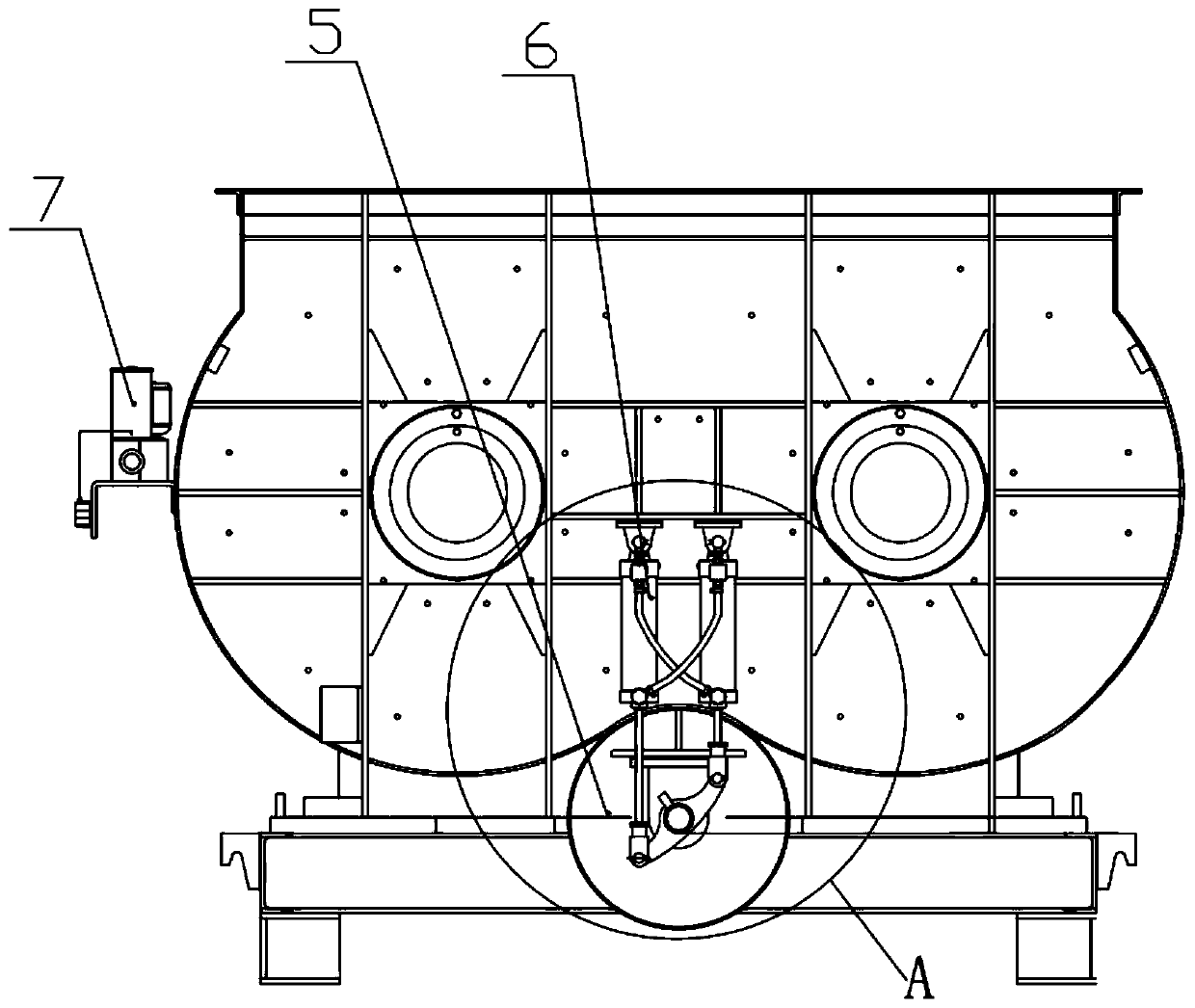

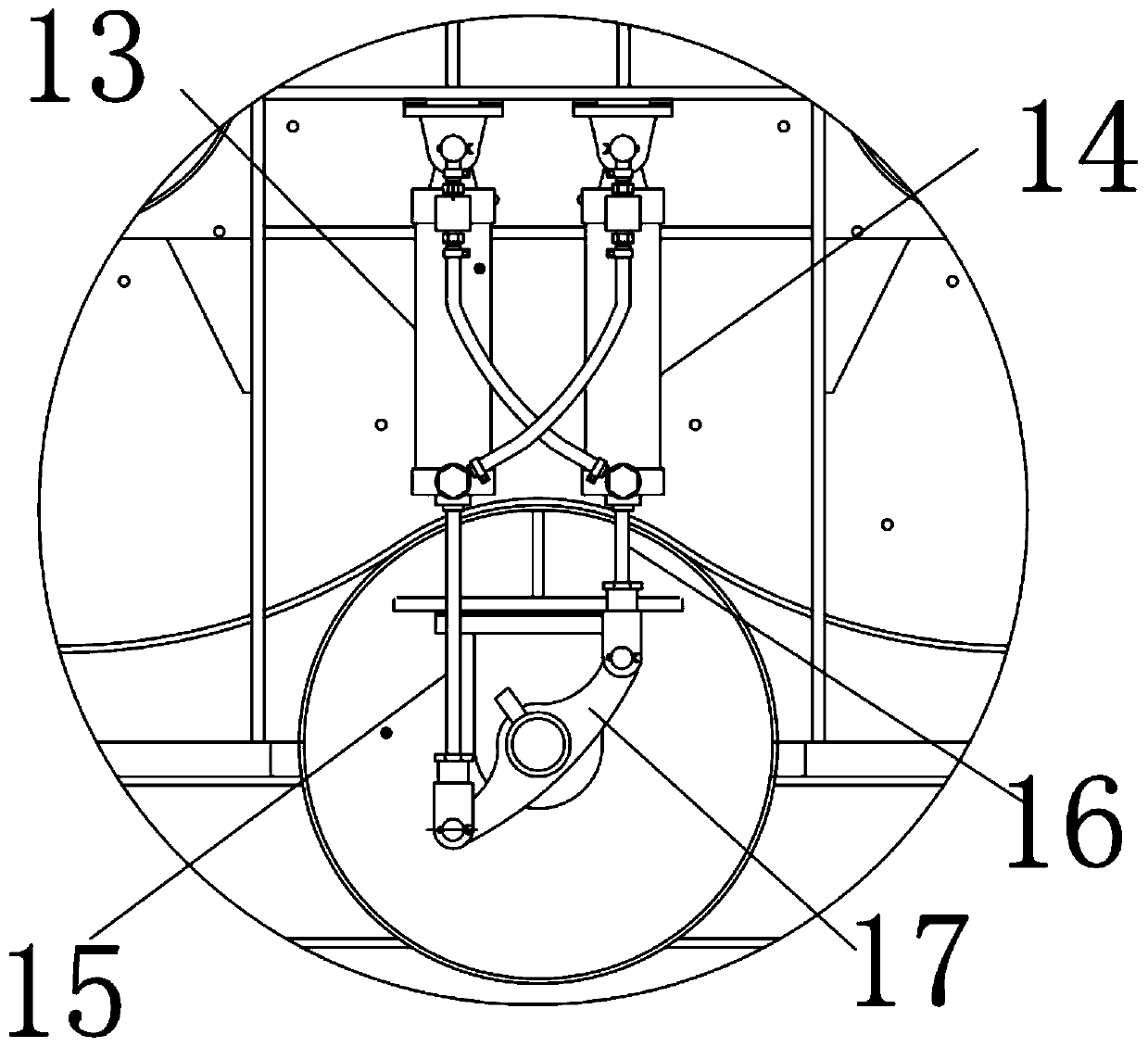

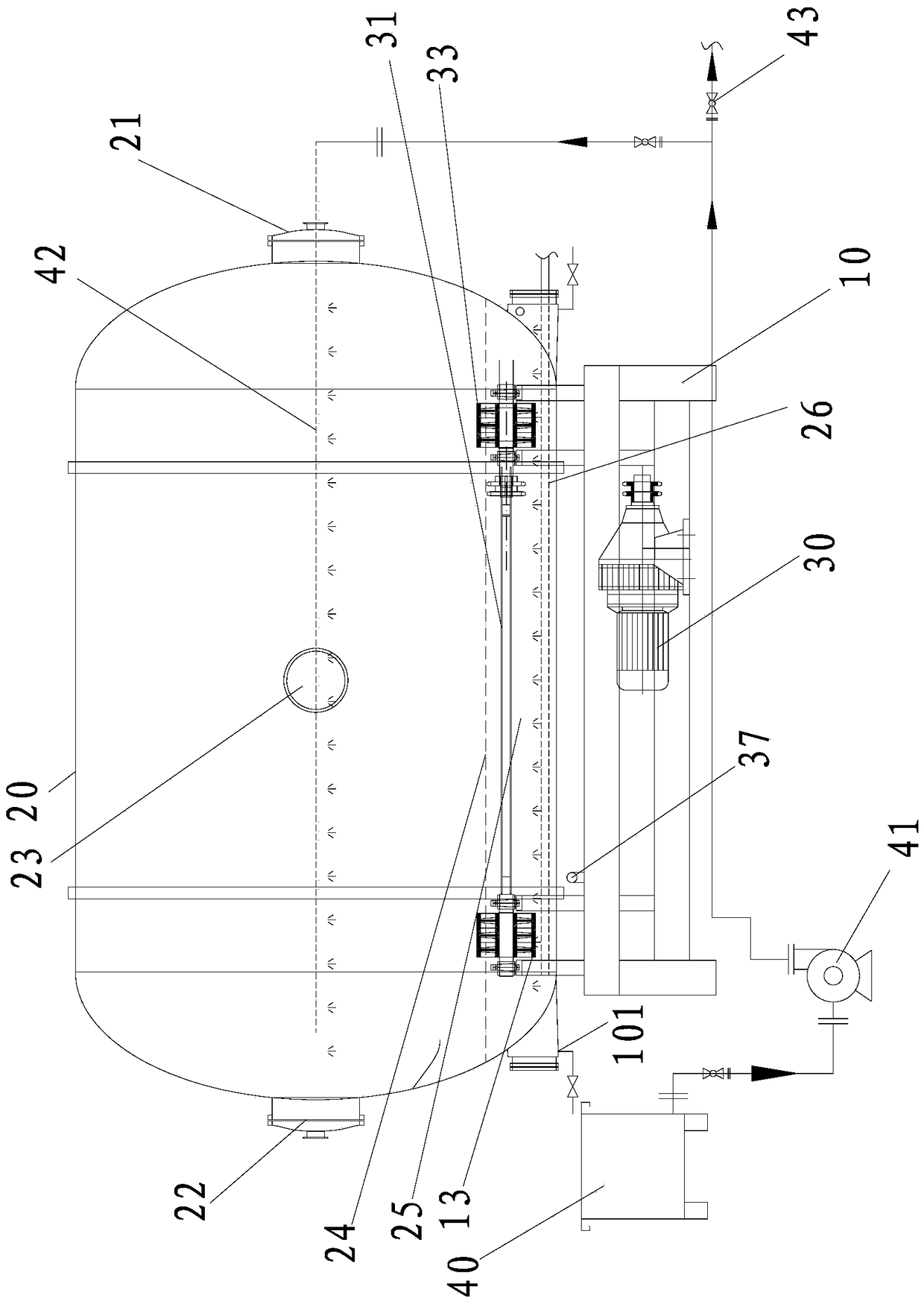

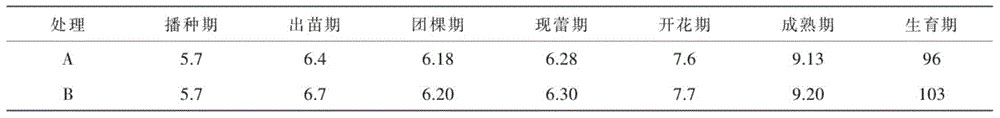

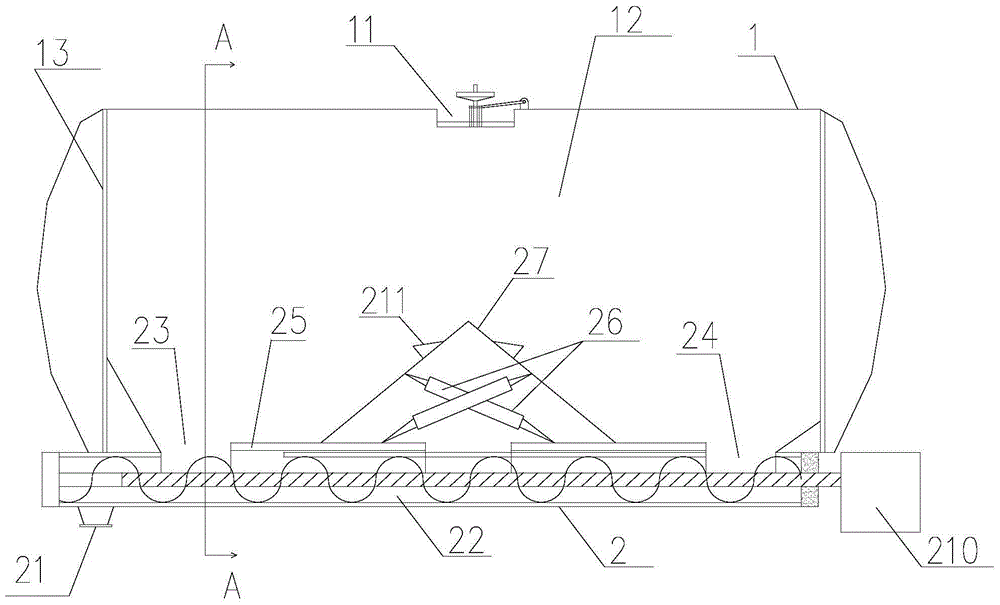

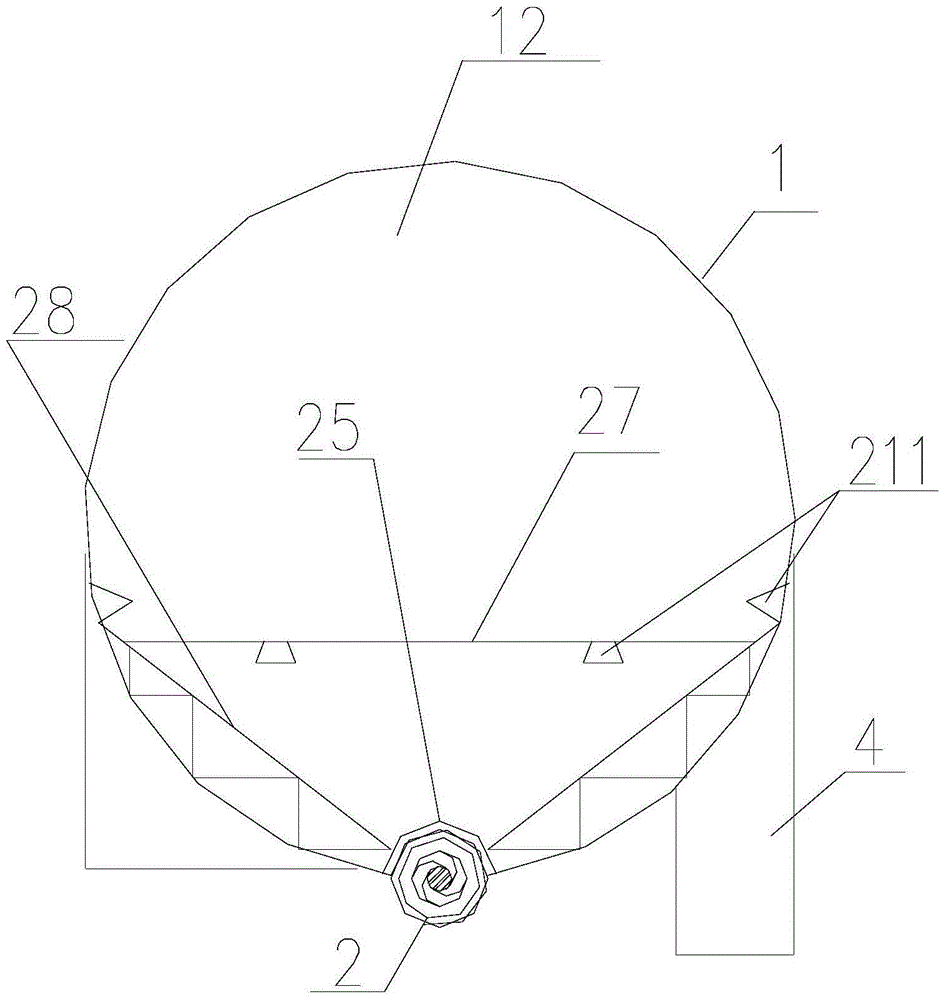

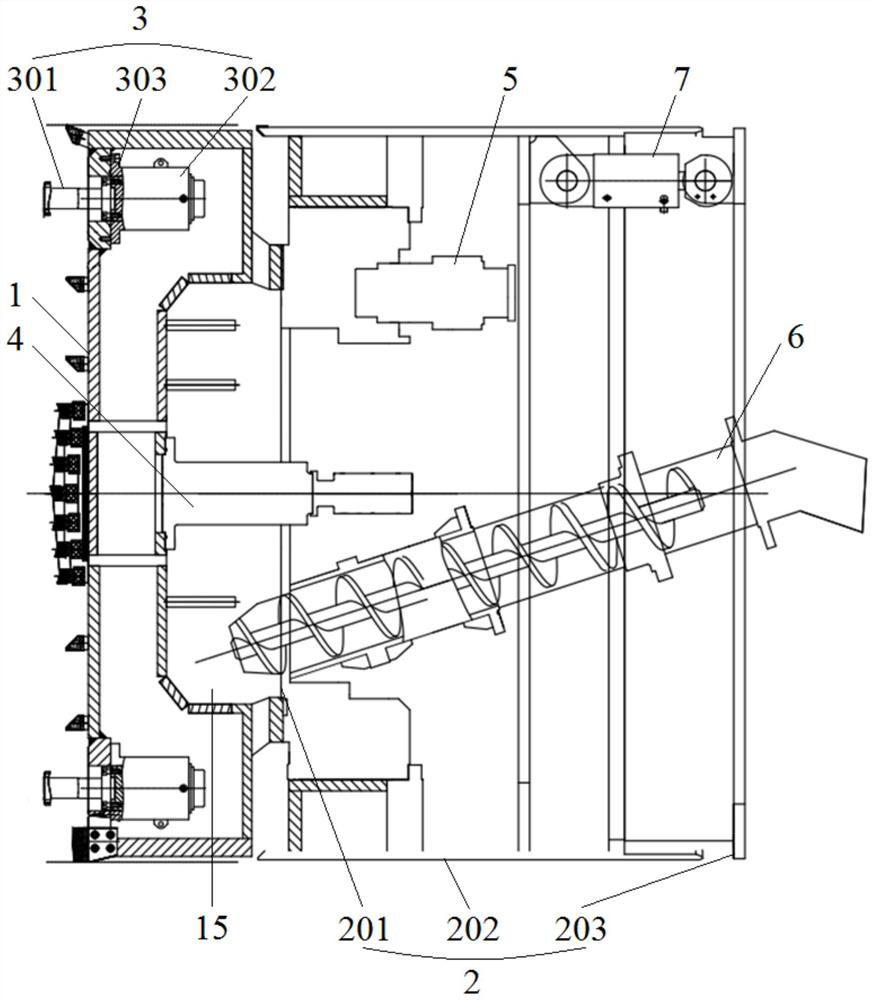

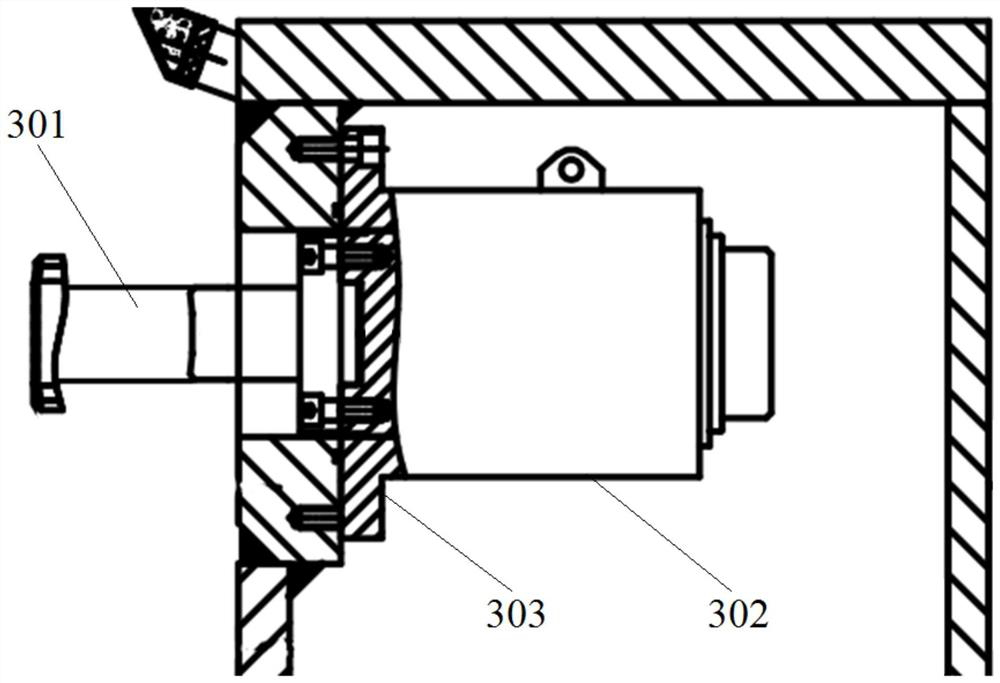

Shotcrete tanker

InactiveCN105291941BReduce work intensityAvoid harmConcrete transportationUnderground chambersShotcreteWaste management

The invention discloses a concrete spraying tank truck. The concrete spraying tank truck comprises a truck body, wherein a tank is arranged on the truck body, a stock bin is arranged in the tank, a feed inlet is formed in the top of the tank, a spiral feeder is arranged on the bottom of the tank, a first discharge outlet is formed in the portion, close to the tail of the tank, of the spiral feeder and is connected with a wind and material mixer, and the wind and material mixer is connected with a spray gun; a front-end receiving port and a rear-end receiving port are formed in the upper portion of the spiral feeder, both the front-end receiving port and the rear-end receiving port are located in the stock bin of the tank, receiving port sliding cover plates are arranged on the front-end receiving port and the rear-end receiving port respectively in a sliding mode, and the two receiving port sliding cover plates are driven by corresponding cover plate cylinders respectively to slide. The concrete spraying tank truck has the advantages that the stock bin, the spiral feeder, the wind and material mixer and the spray gun are integrated, full mechanization of the shotcreting technology including material preparation, blending, transportation, feeding and delivery is achieved, the working intensity of operating staff is relieved greatly, and harm of flying dust to operating staff is avoided.

Owner:金川

A link-type automatic collating device for courier documents and mail plastic general packages

The invention discloses a connecting-rod type automatic neatening device for plastic packages of express-delivery file mails, and relates to the technical field of automatic neatening equipment for the shapes of thermoplastic packages of mail piles. The automatic neatening device is characterized in that driving devices drive fixed plates to move in a direction which is perpendicular to the conveying direction of file piles, so that connecting-rod swing arms are driven to rotate relative to a machine frame in the horizontal plane through sliding guide devices; first neatening rods and second neatening rods are respectively positioned on lateral sides of adjacent file piles, and the file piles which are piled up in an irregular shape can be neatened by squeezing action. Four corners of the file piles are neatened by the neatening rods which are symmetrically arranged in the fore-and-aft direction and the left-and-right direction. Through the adoption of the automatic neatening device provided by the embodiment of the invention, the full mechanization and full automation of shape neatening operation for thermoplastic packages of express-delivery file mails can be realized, and unmanned operation is realized; the automatic neatening device technically fills a gap at home and abroad, and the labor cost of enterprises in economic benefits is greatly lowered.

Owner:CHINA POST SCI & TECH

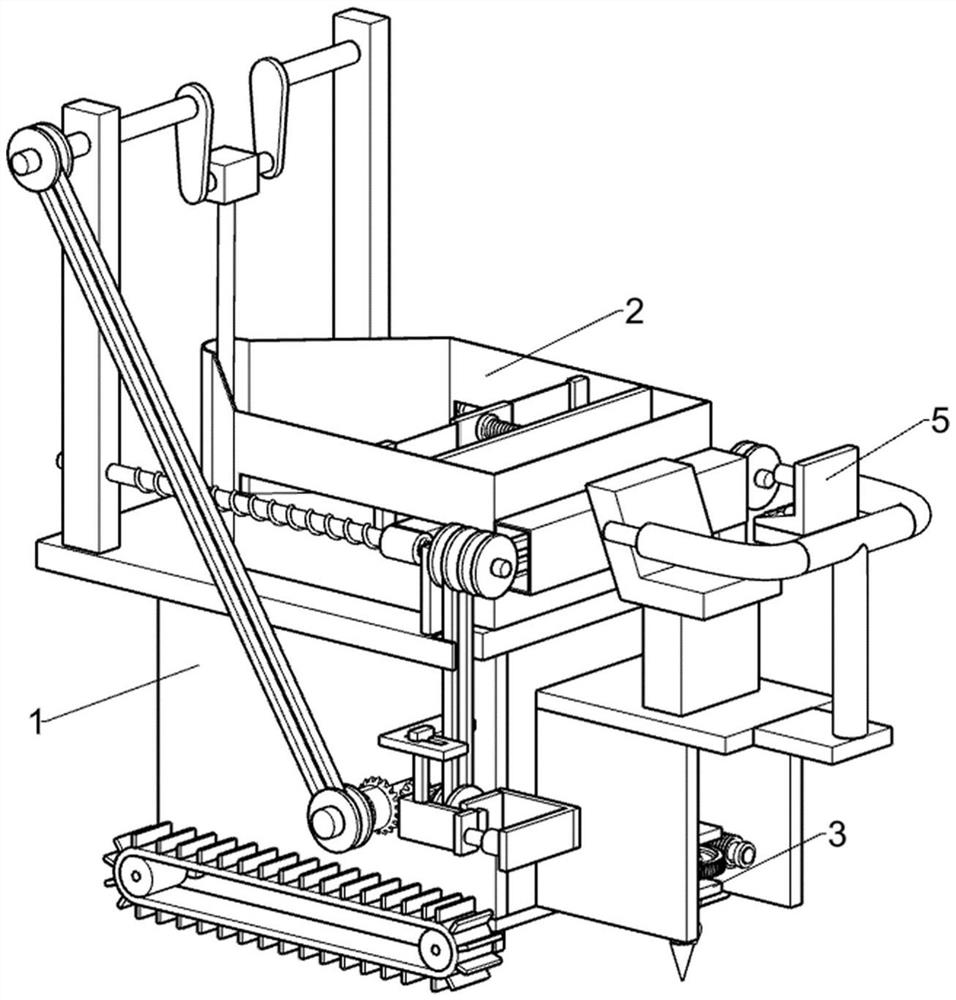

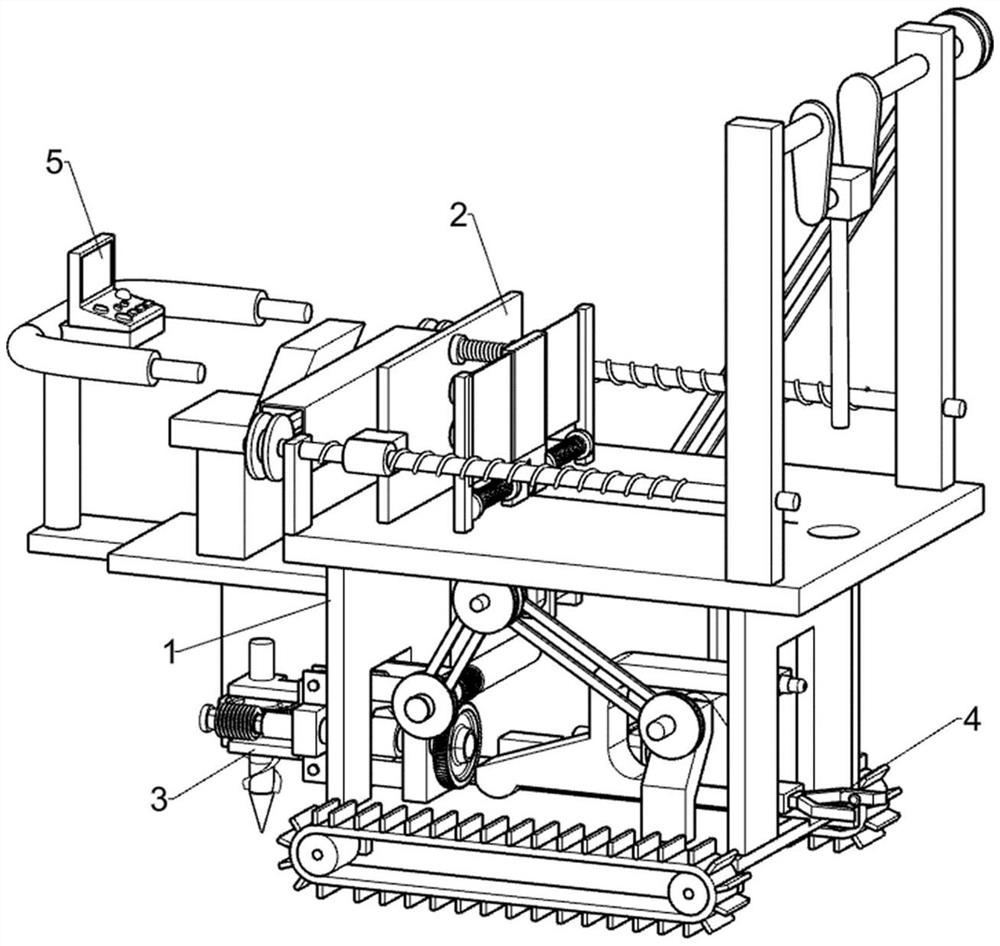

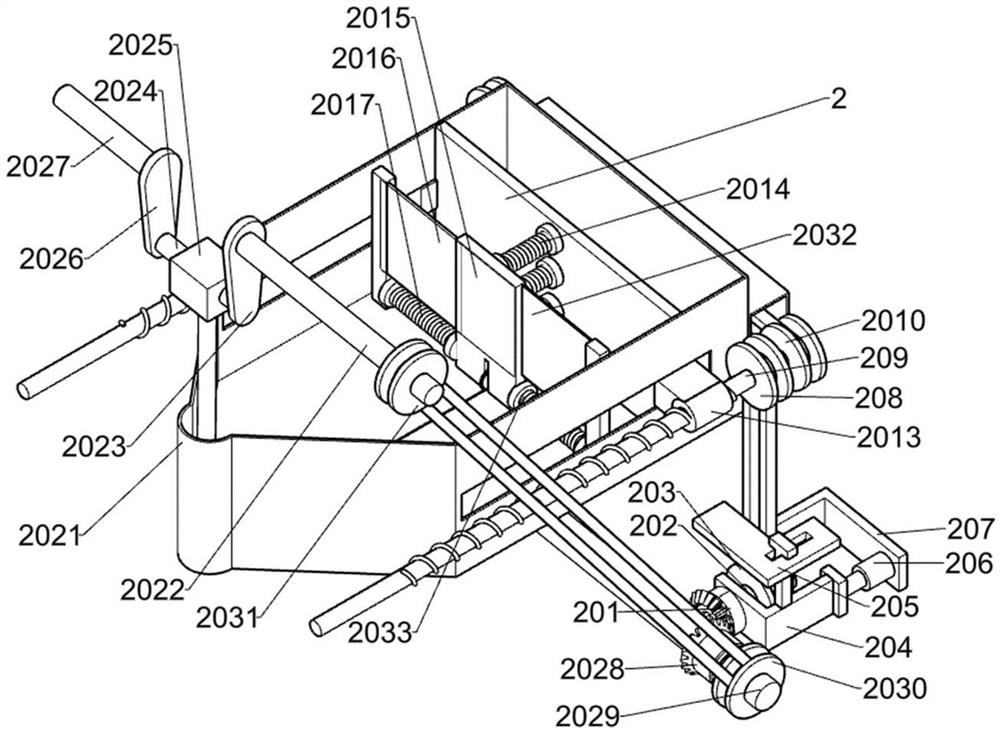

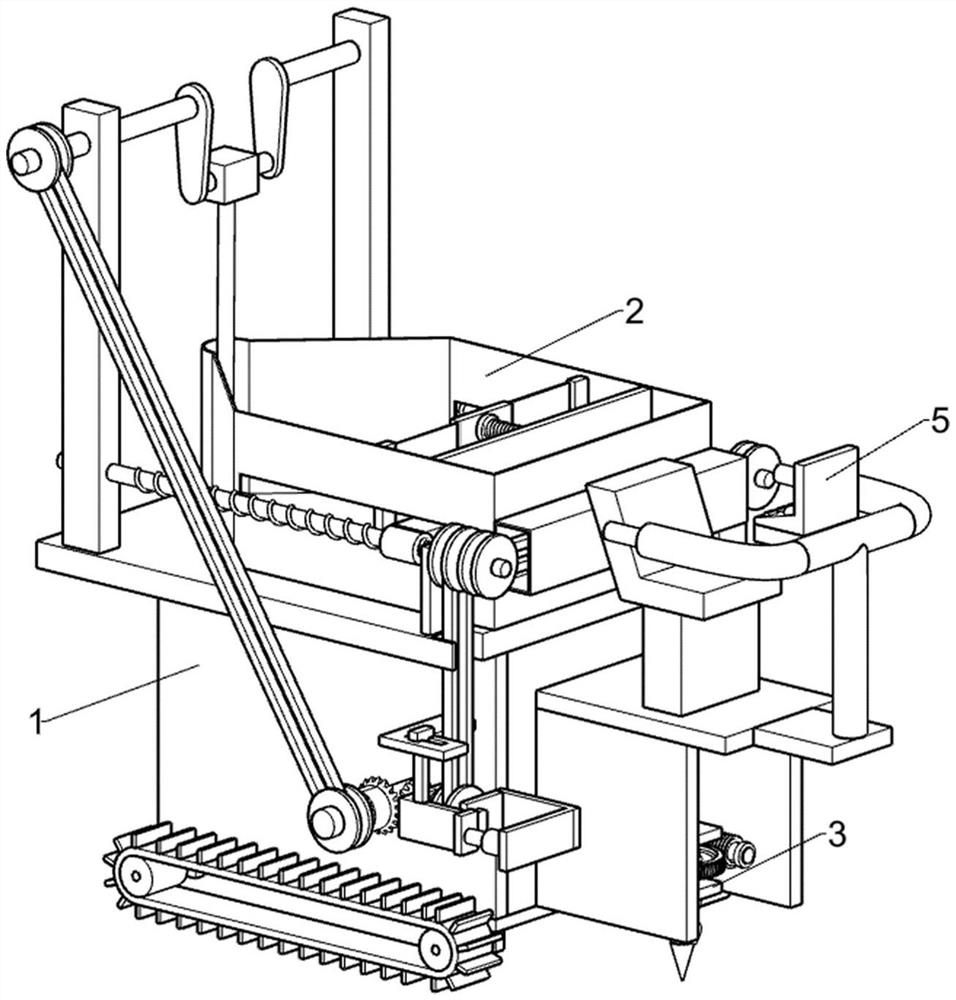

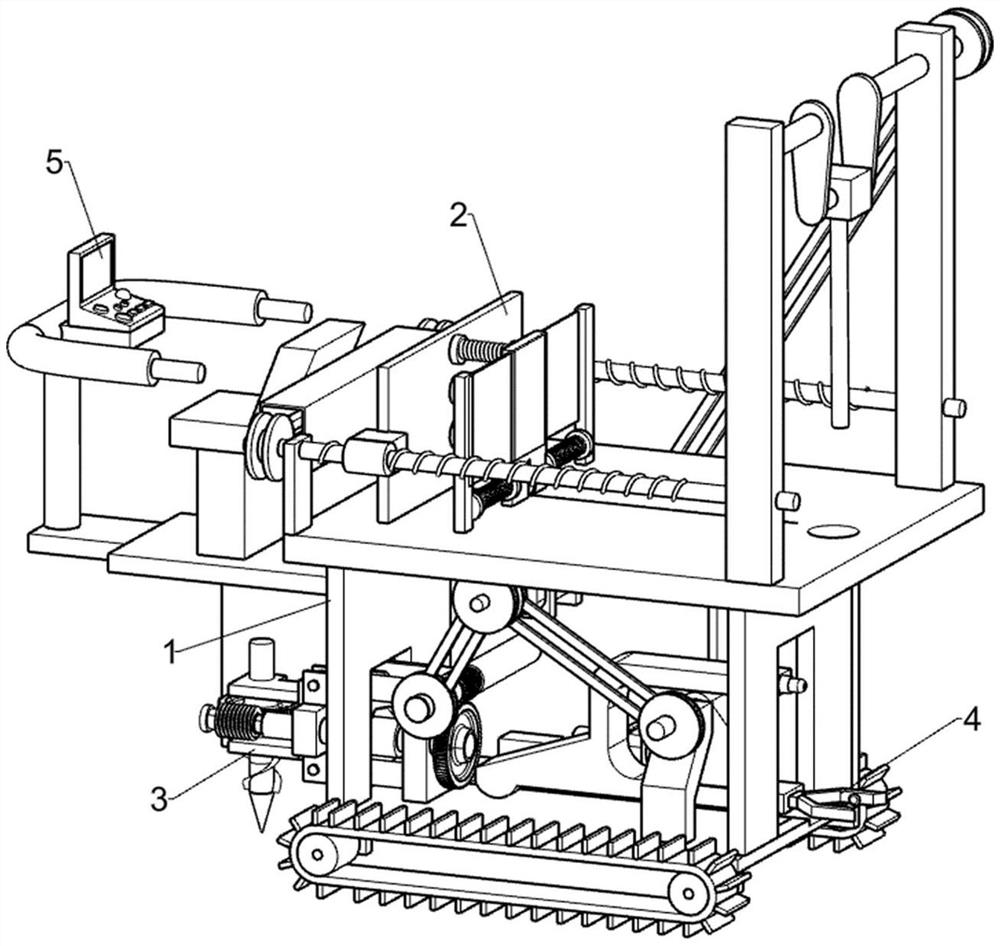

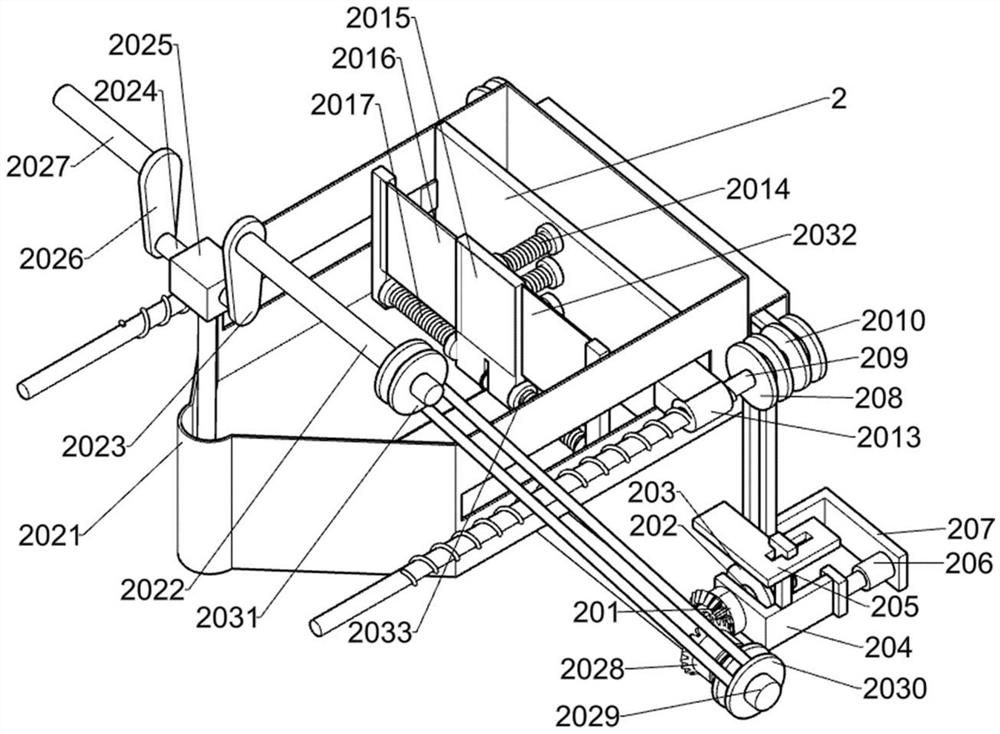

Nursery stock planting device

ActiveCN111990077ALabor intensiveDecrease productivityPlantingFurrow making/coveringForest industryAgricultural science

The invention relates to the field of forestry, in particular to a nursery stock planting device. The technical problem to be solved is to provide the nursery stock planting device. According to the technical scheme, the nursery stock planting device comprises a moving mechanism, a feeding mechanism, a punching mechanism, a cutting mechanism and a control screen. The moving mechanism is connectedwith the feeding mechanism, the punching mechanism and the cutting mechanism. The feeding mechanism is connected with the punching mechanism. The punching mechanism is connected with the cutting mechanism. The whole cutting work is fully mechanized, the labor intensity of workers is greatly reduced, the production efficiency is improved, and the upper end and the lower end of a seed branch can beeffectively protected in the cutting process and cannot be damaged.

Owner:山东润昌生态科技有限公司

Laminated plate turning machine

ActiveCN103449151BAdvanced production technologyFully mechanizedConveyor partsAgricultural engineeringWinch

A kind of turning machine for laminated slabs, the column is installed and fixed on the ground, the upper end of the column is installed with a support beam, the main beam and the walking platform are guided to walk on the supporting beam through the walking mechanism, and a double-drum hoisting mechanism is installed on the main beam and the walking platform , the double-drum hoisting mechanism is hoisted with a fixed frame through a wire rope and a pulley, and a turning frame and a turning machine are installed on the fixing frame. The turning machine is connected to drive the turning frame, and a hydraulic clamp for clamping the steel trolley and the workpiece is installed on the turning frame tighten the device. The invention can realize full mechanization and automation, greatly improves the production efficiency, and greatly improves the factory prefabrication rate of residential industrialization.

Owner:QINGDAO SHANGLIU YUANDA HOUSE IND CO LTD

Connection channel construction equipment and method thereof

The invention discloses connection channel construction equipment and a method thereof.The connection channel construction equipment comprises an equipment host used for excavating a connection channel from a starting end tunnel to a receiving end tunnel, the equipment host is provided with a shield body, the front end of the shield body is provided with a cutterhead and a plurality of sets of overbreak cutter devices, and the overbreak cutter devices can stretch out and retract back. According to the connection channel construction equipment, the mode of the cutter head and the telescopic overbreak cutter device is utilized, the pipe piece can be directly cut, accurate breaking of the pipe piece is achieved, meanwhile, the equipment conducts tunneling normally, the requirement for integration of excavation, deslagging and supporting is met, and full-mechanical efficient construction is achieved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

device for planting seedlings

ActiveCN111990077BLabor intensiveDecrease productivityPlantingFurrow making/coveringForest industryAgricultural science

The invention relates to the field of forestry, in particular to a seedling planting device. The technical problem of the present invention is to provide a seedling planting device. The technical embodiment of the present invention is: a seedling planting device, including a moving mechanism, a feeding mechanism, a punching mechanism, a cutting mechanism and a control screen; the moving mechanism is connected with the feeding mechanism; the moving mechanism is connected with the punching mechanism ; The moving mechanism is connected with the cutting mechanism; the feeding mechanism is connected with the punching mechanism; the punching mechanism is connected with the cutting mechanism. The invention realizes the full mechanization of the whole cutting work, greatly reduces the labor intensity of people, improves the production efficiency, and the upper and lower ends of the seed strips can be effectively protected from damage during the cutting process.

Owner:山东润昌生态科技有限公司

A kind of cultivation method of high-yield and high-quality early-maturing cotton

ActiveCN111011071BEasy to useProduction is light and simplifiedFertilising methodsCotton cultivationChemical controlThinning

The invention discloses a high-yield and high-quality early-maturing cotton cultivation method, which comprises the following steps: (1) selection of direct-broadcast cotton varieties with limited fruit branch types in the Yangtze River Basin; (2) mechanized sowing technology; (3) one-time balanced fertilization technology; (4) ) UAV prevention and control technology; (5) Whole-process chemical control technology. In step (2), after the previous crops are harvested, the stubble is promptly removed to level the land, and the cottonseed is develored and coated before sowing to control the seeding rate; the seed germination rate is more than 90%, and 1-2 grains are sown each time, and the row spacing The plant spacing is 55-65cm, the plant spacing is 15-20cm, the total seeding rate is 1.3-17,000 grains / mu, and the density is 7300-7700 plants / mu, so as to achieve the effect of no need for thinning after sowing full seedlings. The method of the invention promotes the growth of cotton plants, reduces labor and labor intensity, and increases cotton yield.

Owner:安徽省农业科学院棉花研究所

Uniset direct seeding machine and on-film hole-leveling direct seeding machine containing same

ActiveCN101904240BInnovative designReduce labor intensityPlantingAgriculture gas emission reductionTraction frameAgricultural engineering

The invention discloses a uniset direct seeding machine and an on-film hole-leveling direct seeding machine containing the same. The uniset direct seeding machine comprises a roller and a wheel disc fixed on the inner wall of the roller, a rotating shaft is fixed on the wheel disc, and two ends of the rotating shaft are strung on a traction frame; the roller is internally provided with a seed sowing gate plate starting mechanism, a seed rationing mechanism and a seed conveying mechanism; the bottom openings of discharging hoppers at the bottom of a rationing seed sowing machine are arranged slantways and correspond to seed distribution hoppers in advance, and seed grooves on a seed distribution wheel one-to-one corresponds to the seed distribution hoppers. The invention has the advantage of novel design of the uniset direct seeding machine exactly satisfies hole sowing requirements because the seed grooves on the seed distribution wheel accurately and simply correspond to the seed distribution hoppers, greatly improves sowing efficiency, reduces labor intensity of farmers, and remarkably improves germination rate. By utilizing the sowing and fertilizing all-in-one machine of the design, multiple operations, such as sowing, fertilizing, and the like can be synchronously completed, and the problem of difficultly fertilizing grain fertilizers, which troubles the farmers for many years, is well solved.

Owner:聂长军

A kind of production method of improved salted egg yolk

The invention discloses an improved salted egg yolk and a production method thereof. Its raw materials mainly include raw salted duck egg yolk treated with low-temperature water control, salted duck egg yolk roasted and cured and treated with oil control, duck egg powder, and edible salt. It is processed by mixing, rounding, vacuum packaging, sterilization, freezing and other processes. The improved salted egg yolk provided by the present invention has attractive color, delicious taste and high oil yield after baking, and solves the problems of the existing egg yolk wrapped in moon cakes and other products that do not penetrate the center or become sticky.

Owner:HUBEI SHENDAN HEALTHY FOOD

A New Slurry Shield Tunneling Integrated Machine

ActiveCN111946359BImprove protectionHigh stability guaranteeUnderground chambersTunnel liningMarine engineeringTunnel boring machine

The new mud-water type shield tunneling integrated machine of the present invention includes a cutter head drive system, a shield shell, a hydraulic propulsion system, a segment assembly mechanism, a U-shaped steel frame, a bottom segment, a segment transport trolley, a segment transport cart, Segment hoisting mechanism, mud water circulation system and mud ground processing mechanism, cutter head drive system is connected with hydraulic propulsion system, hydraulic propulsion system is connected with segment assembly mechanism, hydraulic propulsion system and segment assembly mechanism are set in the shield shell; The segment assembling mechanism is connected with the U-shaped steel frame, one end of the mud water circulation system is connected with the cutter head drive system, and the other end is connected with the mud processing mechanism on the ground; the segment assembling mechanism and the U-shaped steel frame are arranged on multiple segments Connected to form a circular cavity. Tunnel boring machine is a large-scale high-tech construction equipment specially used for excavating underground passages. It has the advantages of fast excavation, high quality, safety, economy, environmental protection and reduced labor intensity.

Owner:BINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com