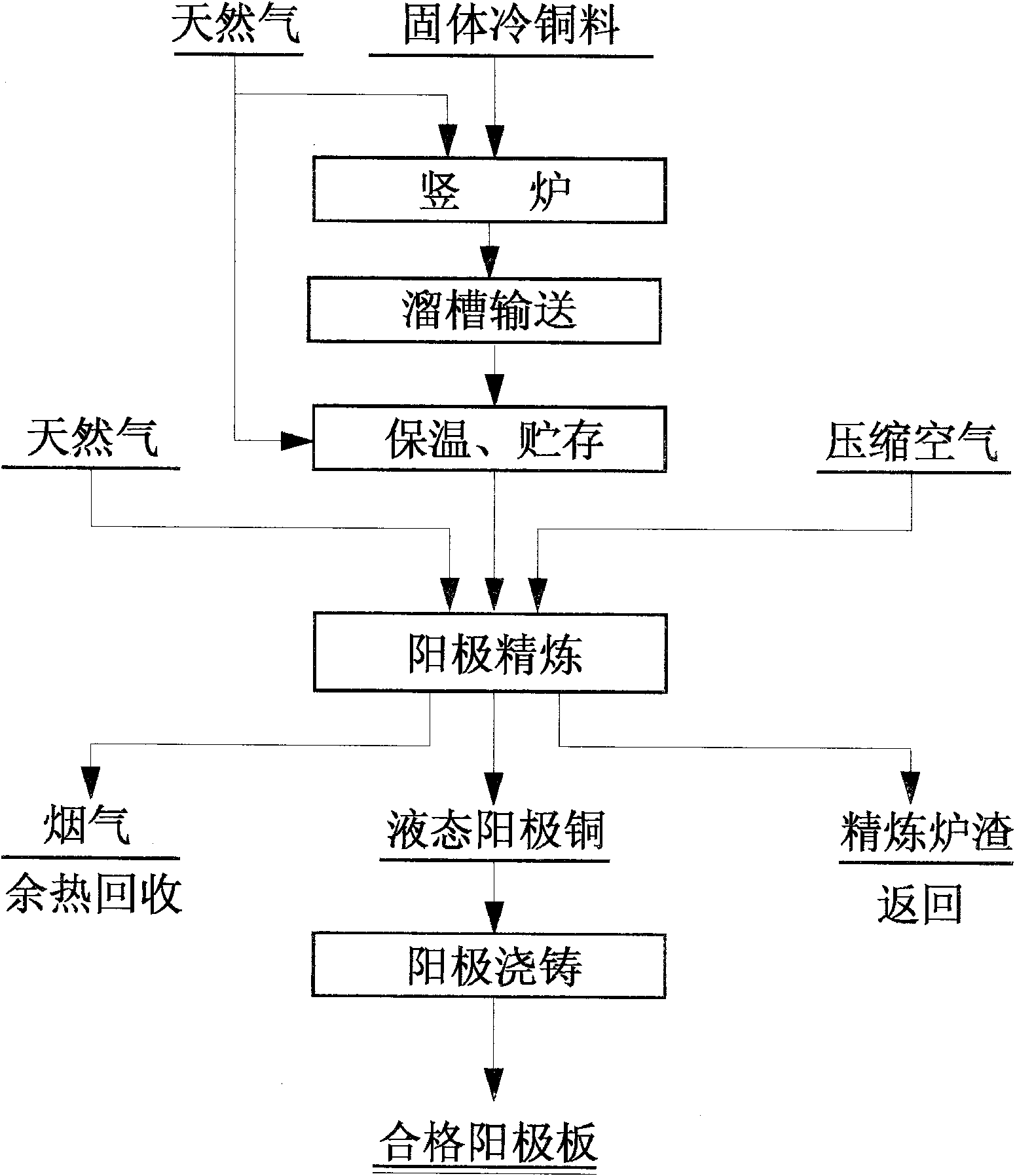

Solid copper material processing method and apparatus thereof

A processing method and technology of processing equipment, applied in the field of copper refining, can solve the problems of high energy consumption, slow melting speed, low thermal efficiency, etc., and achieve the effects of low cost, fast melting speed and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

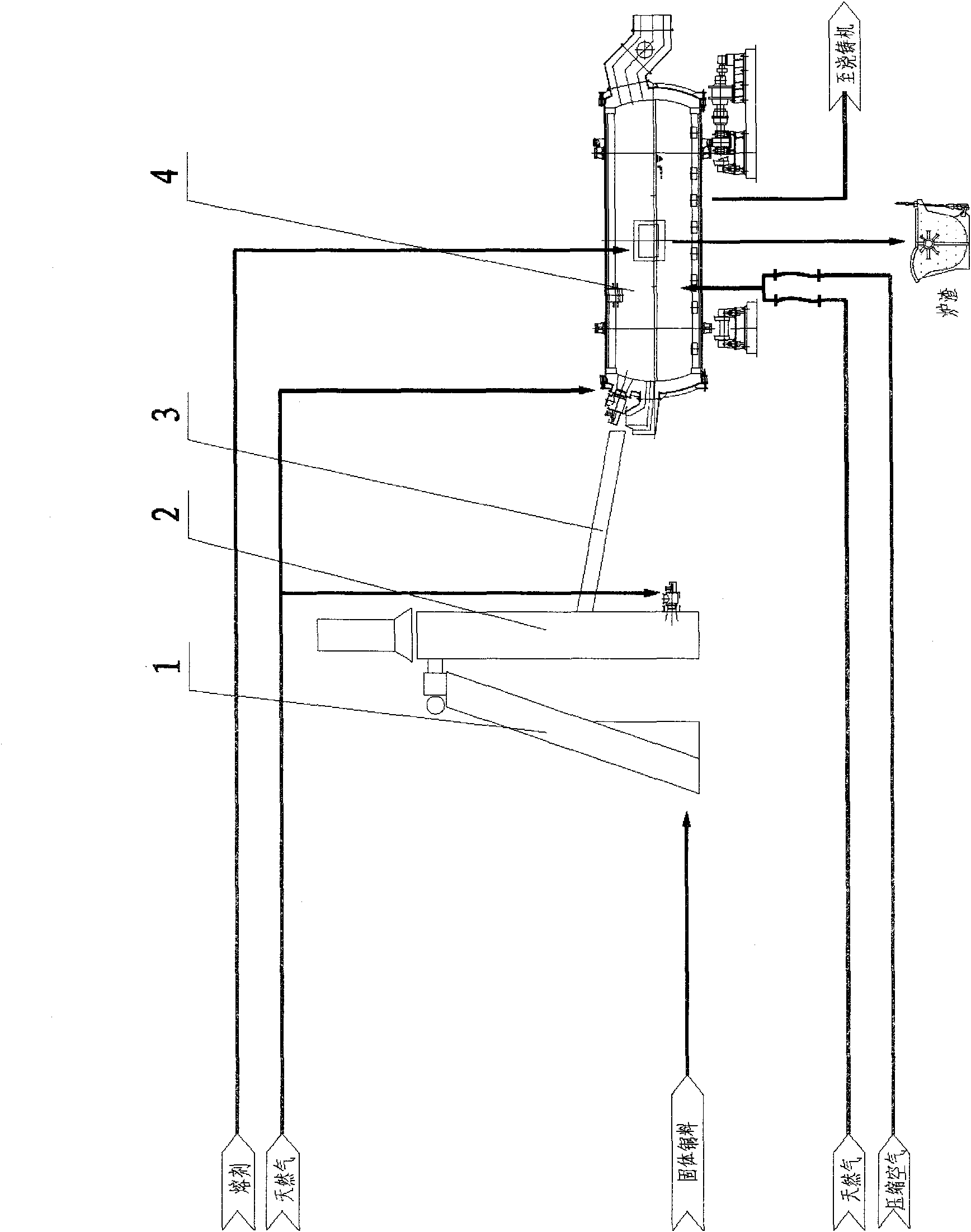

[0037] A device for treating solid copper materials in a large and medium-sized scrap copper recycling smelter, including a bucket elevator 1, a shaft furnace 2 with a height of 20m, a refining furnace 4, and an insulating room between the shaft furnace 2 and the refining furnace 4 Chute 3 and casting machine (not shown among the figure). The shaft furnace 2 is a shaft furnace that uses natural gas or coal gas as a fuel to provide a heat source.

[0038] The method that the equipment of this specific embodiment processes solid copper material has the following steps:

[0039] Feeding and melting: the packaged solid copper material with high impurity content that needs to be refined and removed is put into the hopper through a forklift, and then is lifted along the track through the bucket elevator 1 to the feeding port of the shaft furnace 2, and the melted liquid in the shaft furnace 2 The copper liquid enters the refining furnace 4 by gravity through the chute 3 .

[0040]...

specific Embodiment approach 2

[0042] It is basically the same as the specific embodiment 1, the difference is that the oxidation is through the oxidation-reduction tuyeres of 1500Nm 3 / h Compressed air oxidizes impurities.

specific Embodiment approach 3

[0043] It is basically the same as the specific embodiment 1, the difference is that the oxidation is through the oxidation-reduction tuyeres into 1800Nm 3 / h Compressed air oxidizes impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com