Mold-pressing firework lead inserting machine

A fireworks, molding technology, applied in the direction of fireworks, offensive equipment, weapon types, etc., can solve the problems of continuous production, low production efficiency, manual operation, etc., to improve production efficiency, overcome insertion errors, and achieve the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

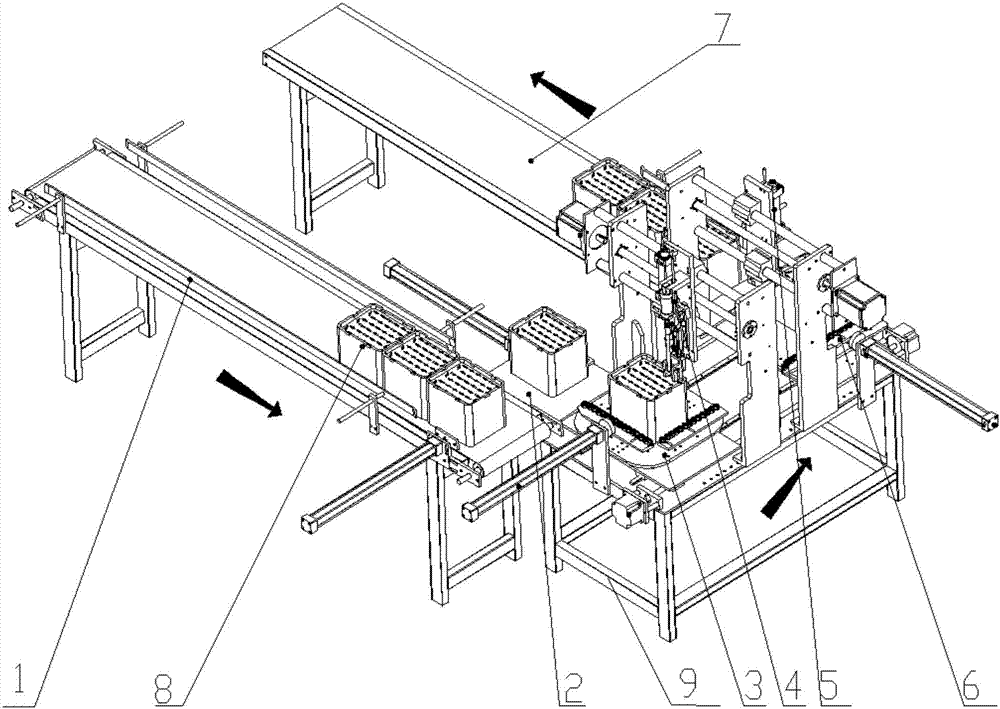

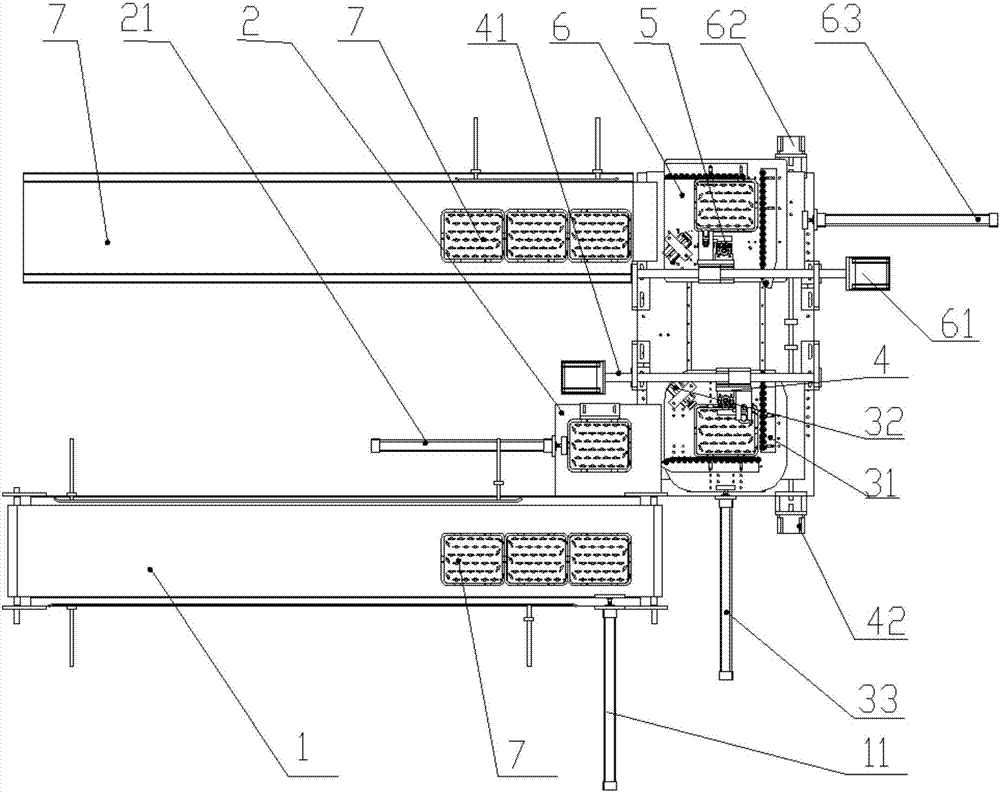

[0012] Referring to the accompanying drawings, a molded fireworks inserting machine of the present invention includes a frame 9, and is characterized in that: the frame 9 is sequentially installed with a cylinder feeding conveying line 1, a transfer table 2, a first rotary table 3, a second The rotary table 6 and the cylinder conveying line 7 are adapted respectively to the first rotary table 3 and the second rotary table 6, and the first punching and inserting device 4 and the second punching and inserting device 4 are installed on the frame 9. Leading device 5; a first push rod 11 is installed on one side of the front end of the barrel feeding line 1, and the movement direction of the first push rod 11 is perpendicular to the axis of the barrel feeding line 1; the other front end of the barrel feeding line 1 The side is the turntable 2, and a second push rod 21 is installed on one side of the turntable 2, and the moving direction of the second push rod 21 is perpendicular to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com