Inclined plate ball groove drilling mechanism of corn harvester threshing device

A technology of a threshing device and a drilling mechanism, which is applied in the directions of harvesters, threshing equipment, agricultural machinery and implements, can solve the problems of not being able to meet the needs of development and not having direct threshing functions, and achieve the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

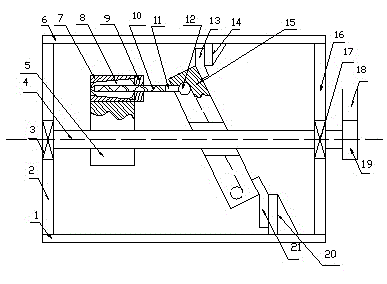

[0010] attached figure 1 A slant ball groove drilling mechanism of a corn harvester threshing device is characterized in that: the driving mechanism is fixed on the right side of the rotating shaft 4 as power to drive the rotating shaft to rotate, and the rotating shaft 4 is set in the left bearing seat 3 and the right bearing seat 16, Left bearing seat 3, right bearing seat 16 are fixed on left frame plate 2, right frame plate 17, on upper frame plate 6, lower frame plate 1 upper angle type support 15, lower angle type support 20 are set, Up-sloping positioning plate 14 and downward-sloping positioning plate 21 are respectively fixed on the upper angle bracket 15 and the lower angle bracket 20. On the inclined positioning plate 21, a ball groove is arranged in the ball groove inclined plate 13; the rotating disk 5 is fixed on the left side of the rotating shaft 4 and rotates thereupon, the rotating disk 5 is provided with a clamp 7, and the clamp 7 clamps the corn cob 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com