Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Even heating and drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

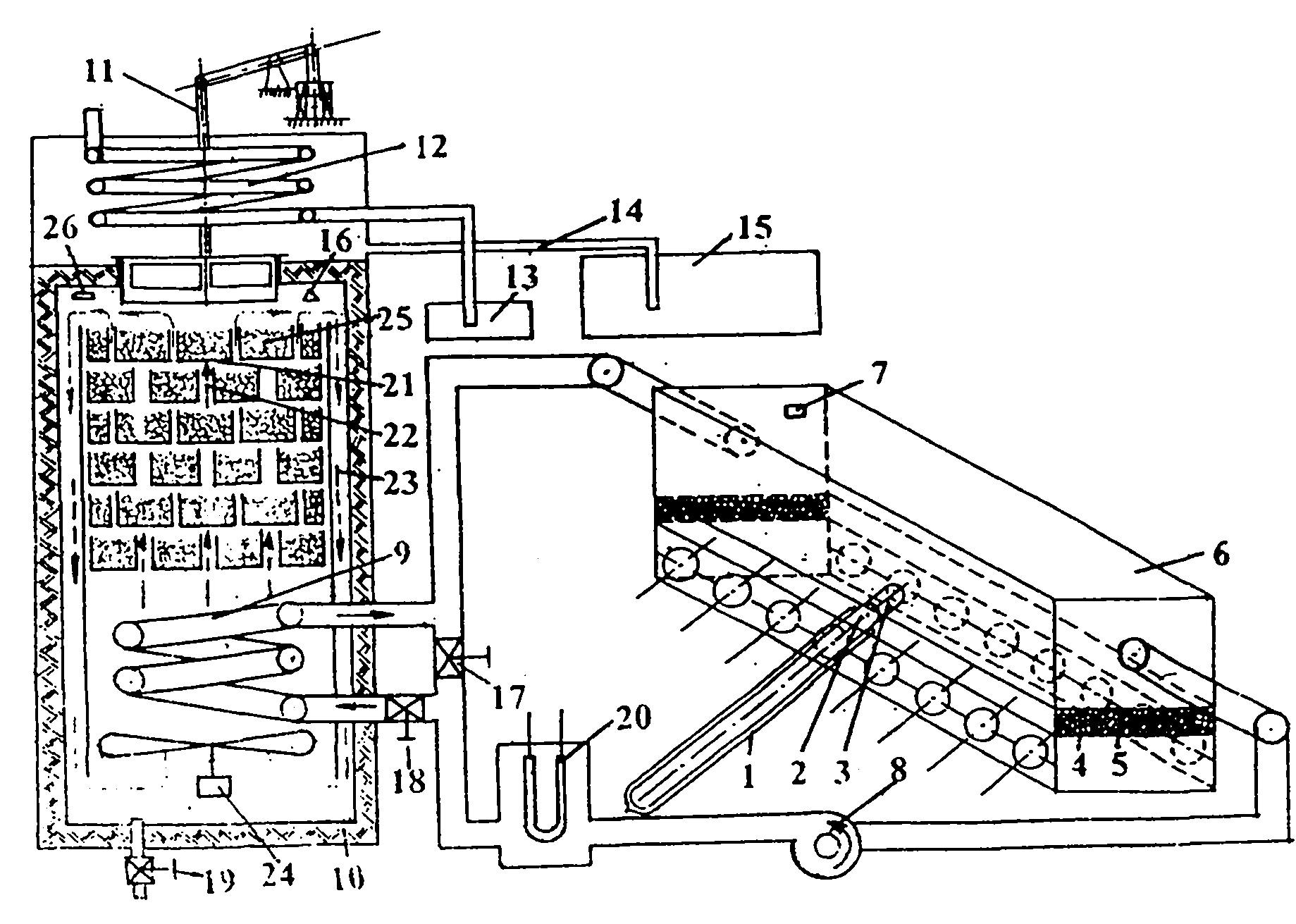

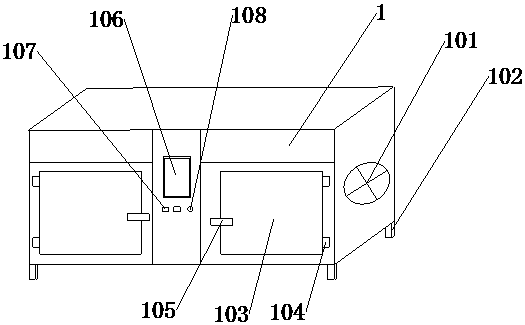

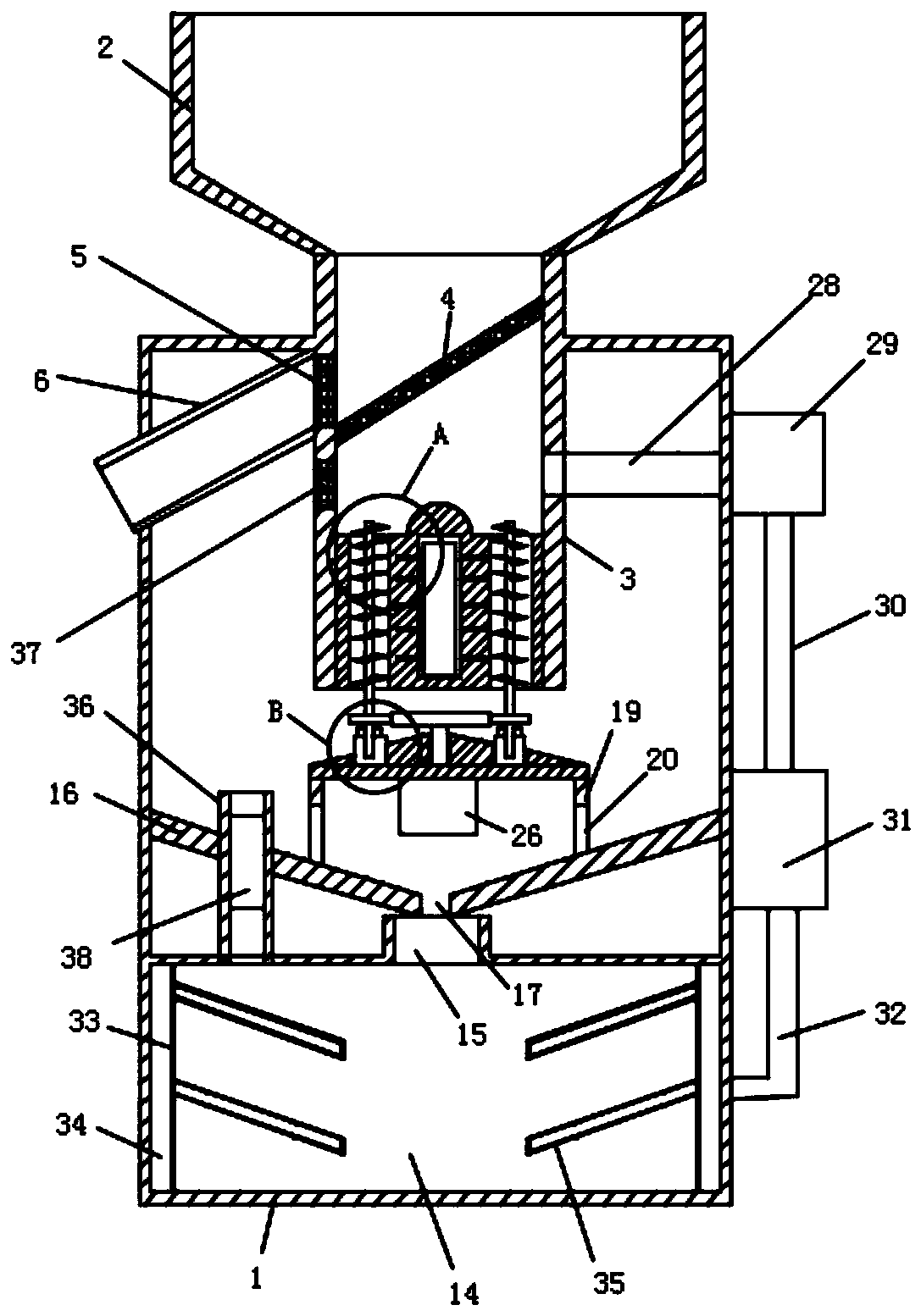

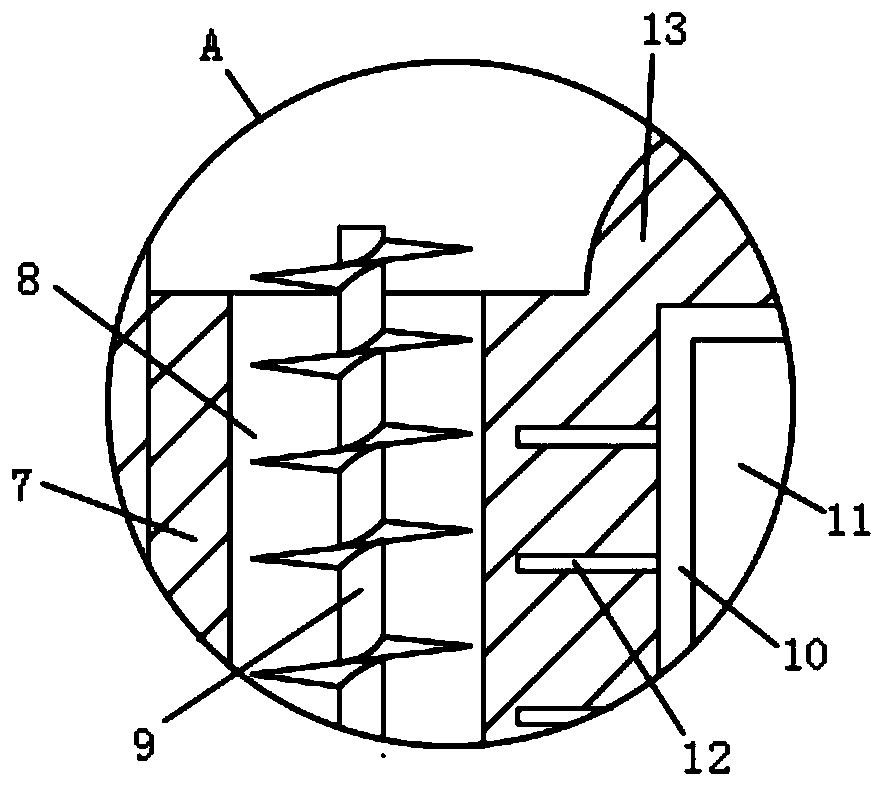

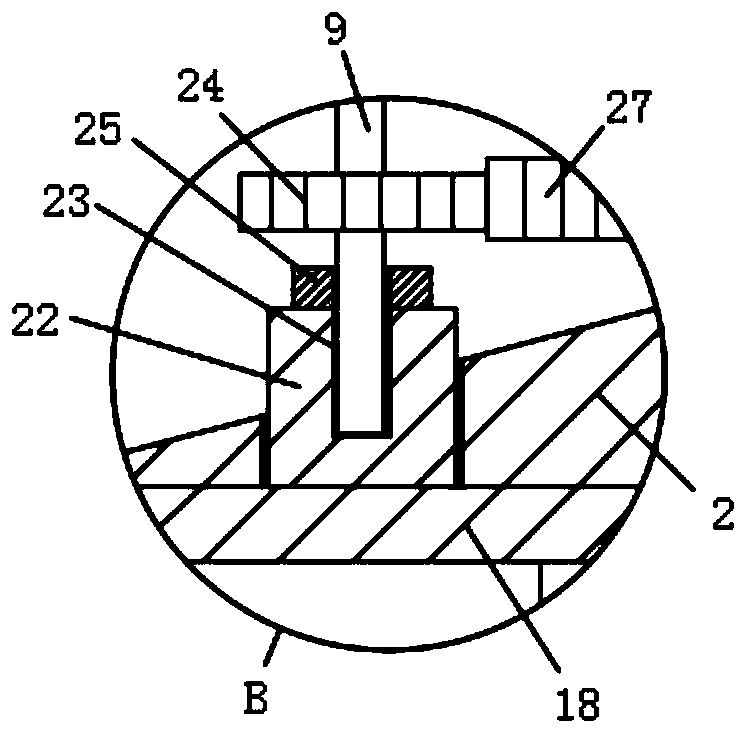

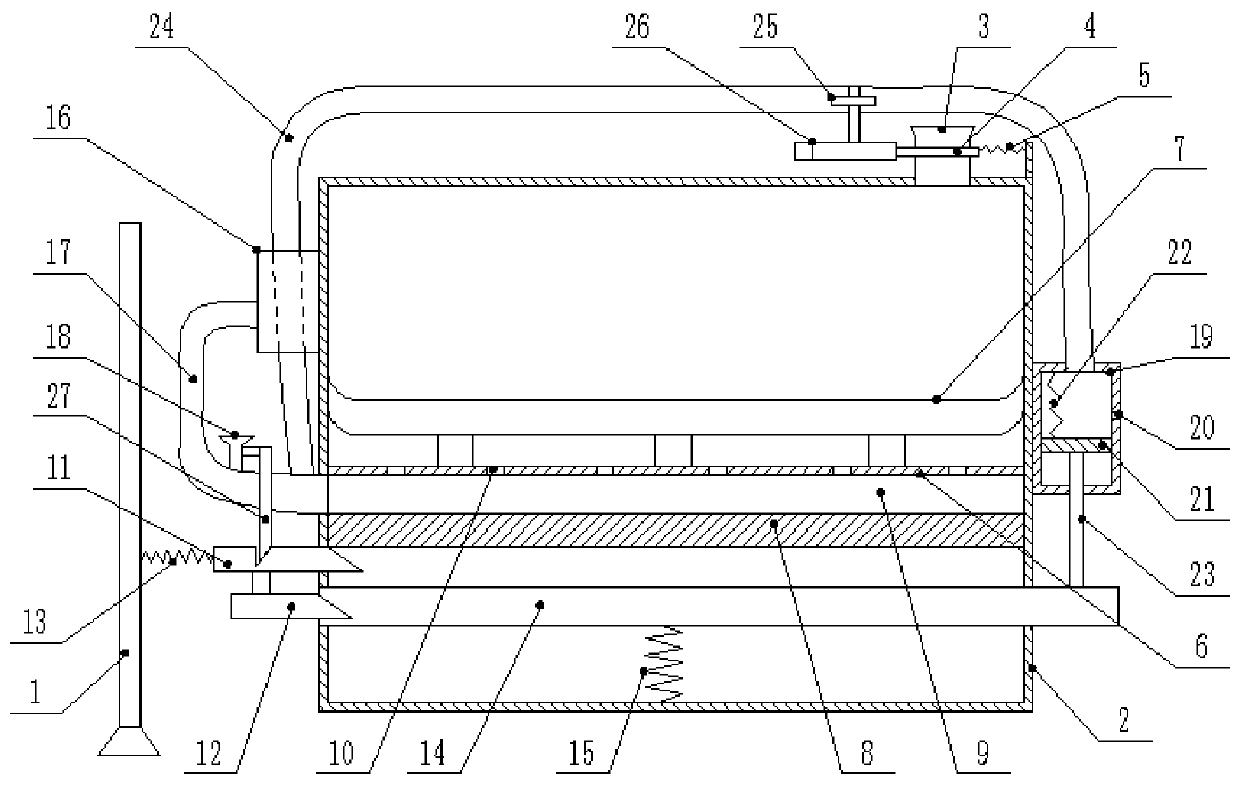

Energy-saving explosion-proof drying furnace and its drying monitoring system

InactiveCN101307982AReduce startup timeExtended service lifeDrying solid materials with heatDrying gas arrangementsThermal energyMonitoring system

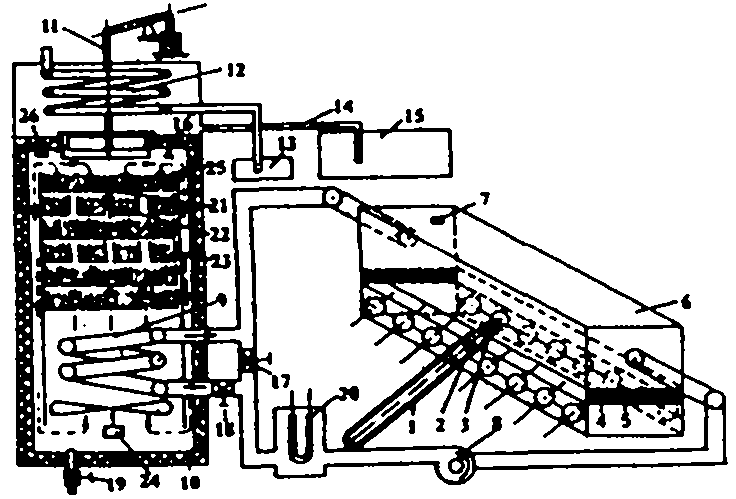

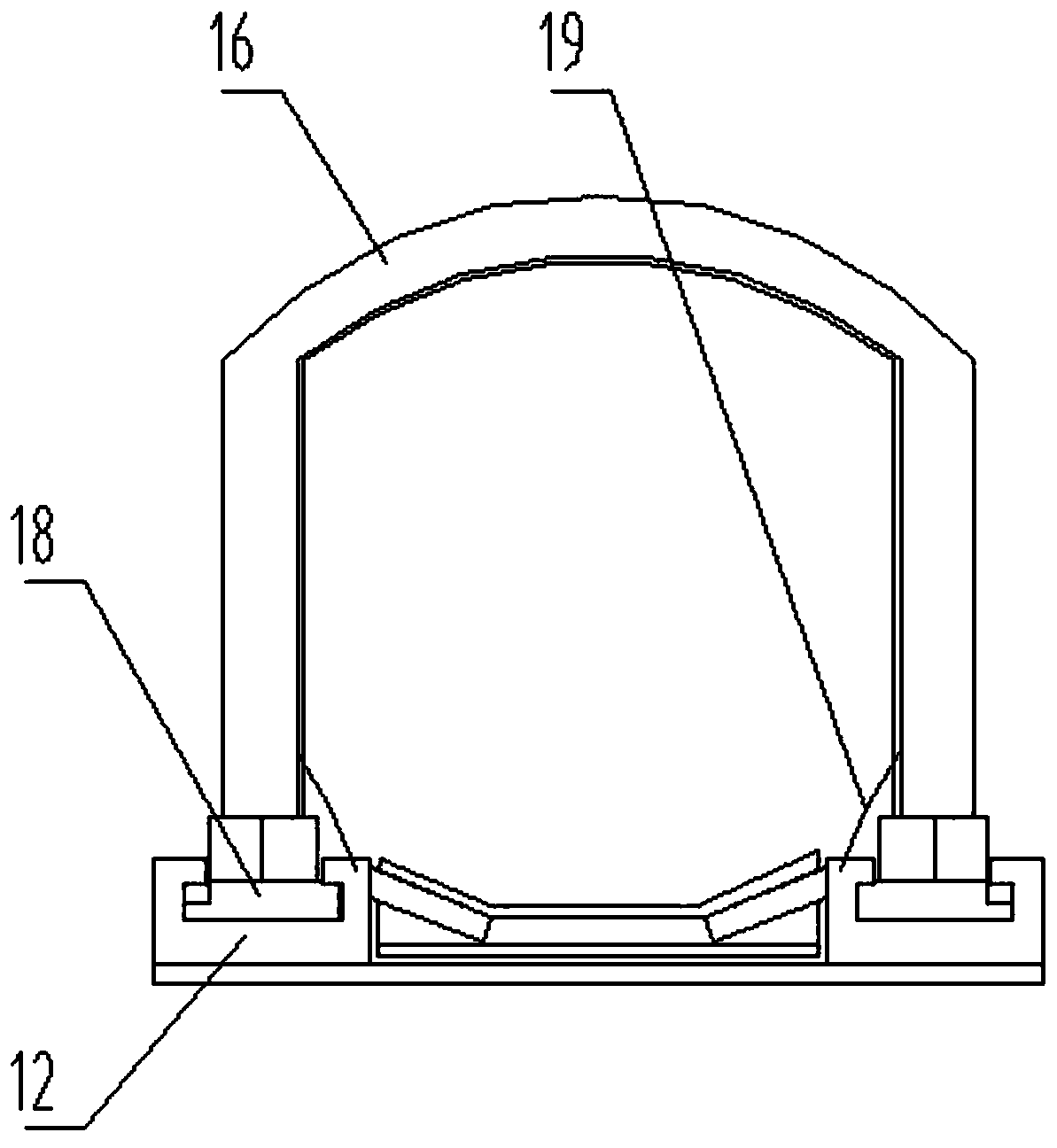

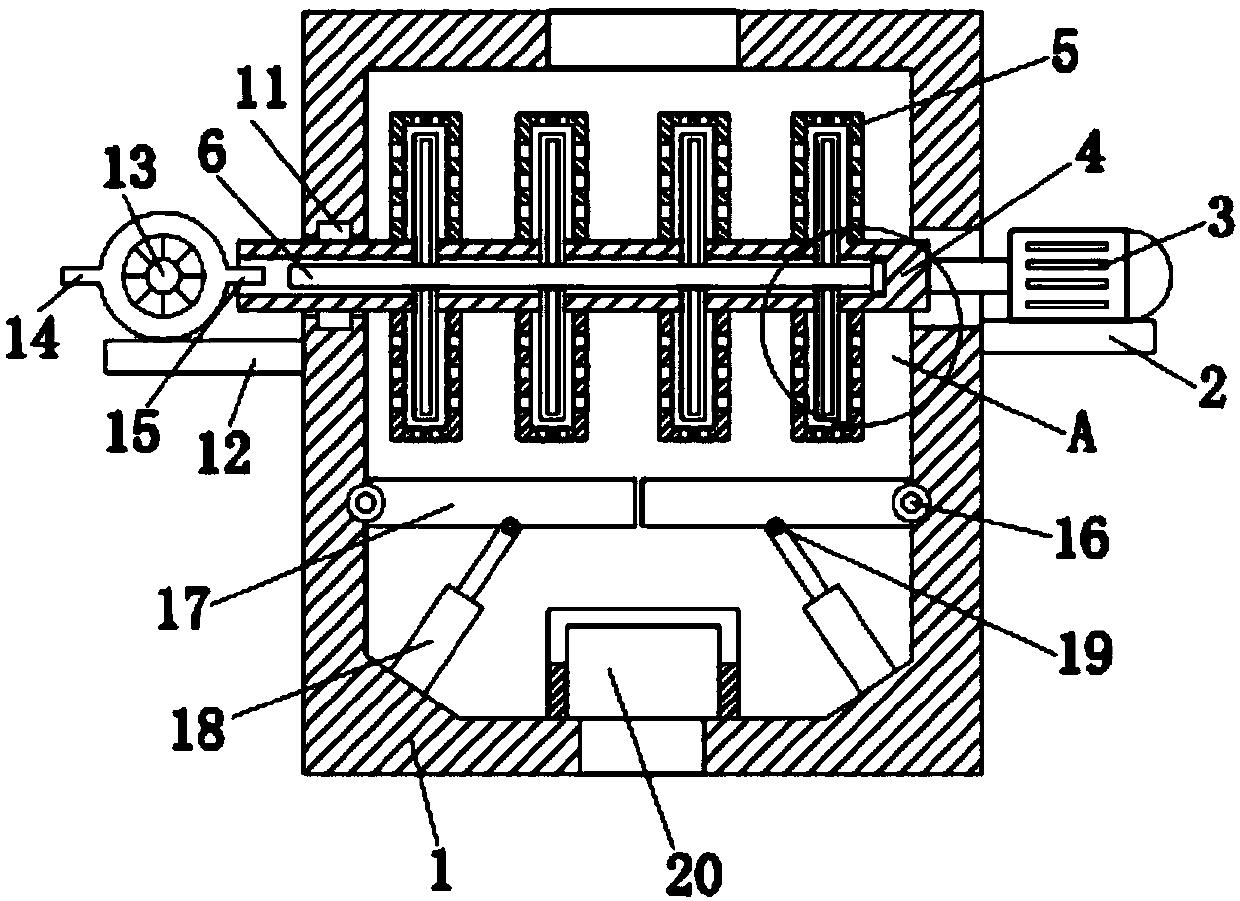

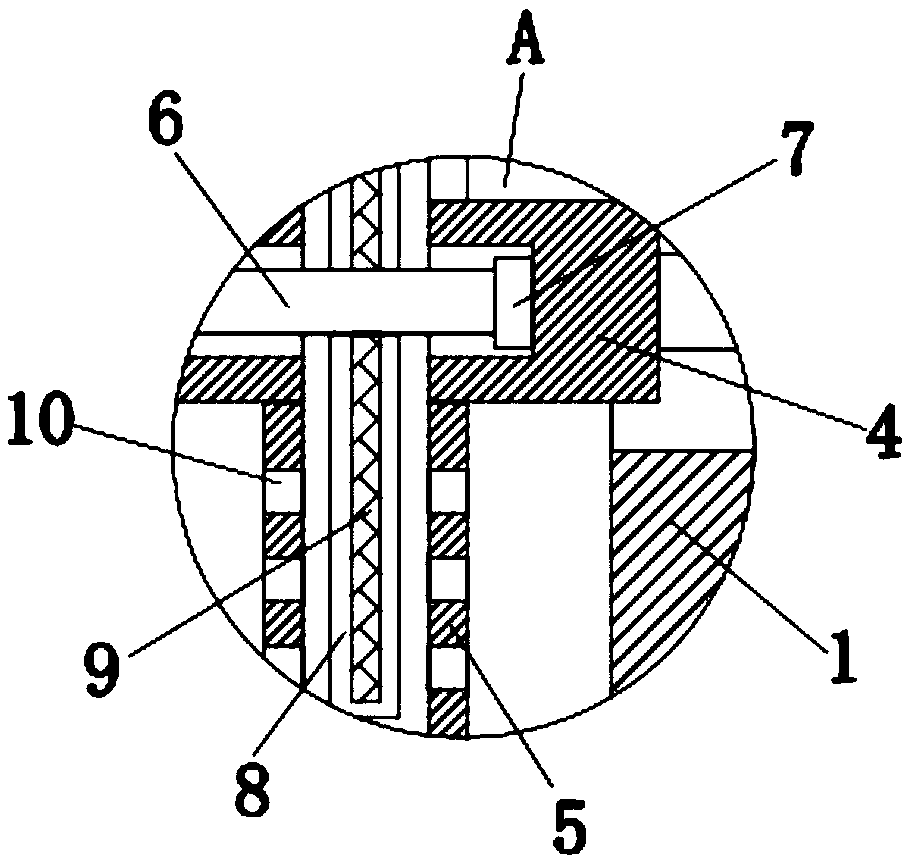

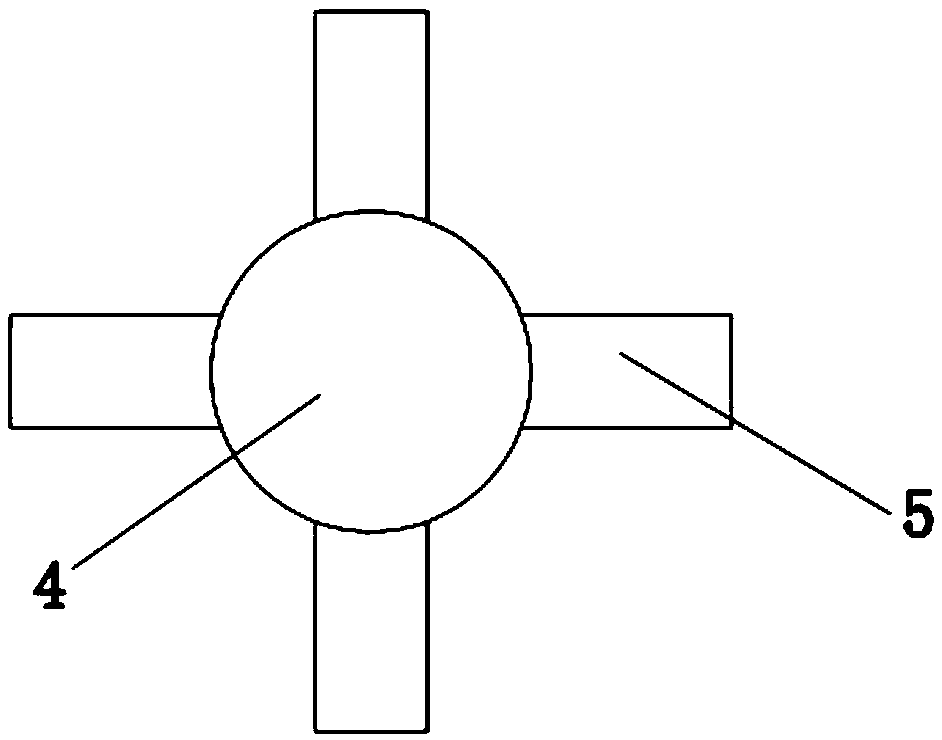

The invention relates to an energy-saving explosionproof drying furnace and a monitoring system thereof. The drying furnace is provided with a furnace body, a heating element, a trolley and a chimney, wherein the furnace body is provided with a heating chamber body; the top of the furnace body is provided with a circular hot-air generator; the heating element is positioned in the heating chamber body; the chimney is sleeved with a preheating sleeve communicated with the heating chamber body; and the bottom of the furnace body is provided with a trolley lifting mechanism. The furnace has a rational and novel structure, a unique air channel design, and is provided with the complete drying automation monitoring system, thereby having the advantages of high heat energy utilization rate, convenient operation, labor conservation and quick drying speed, ensuring that the whole drying process is effectively monitored and maintained in an optimal running state, particularly effectively eliminating the hidden trouble of a burning and explosion accident and effectively guaranteeing the safety of a person and equipment.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

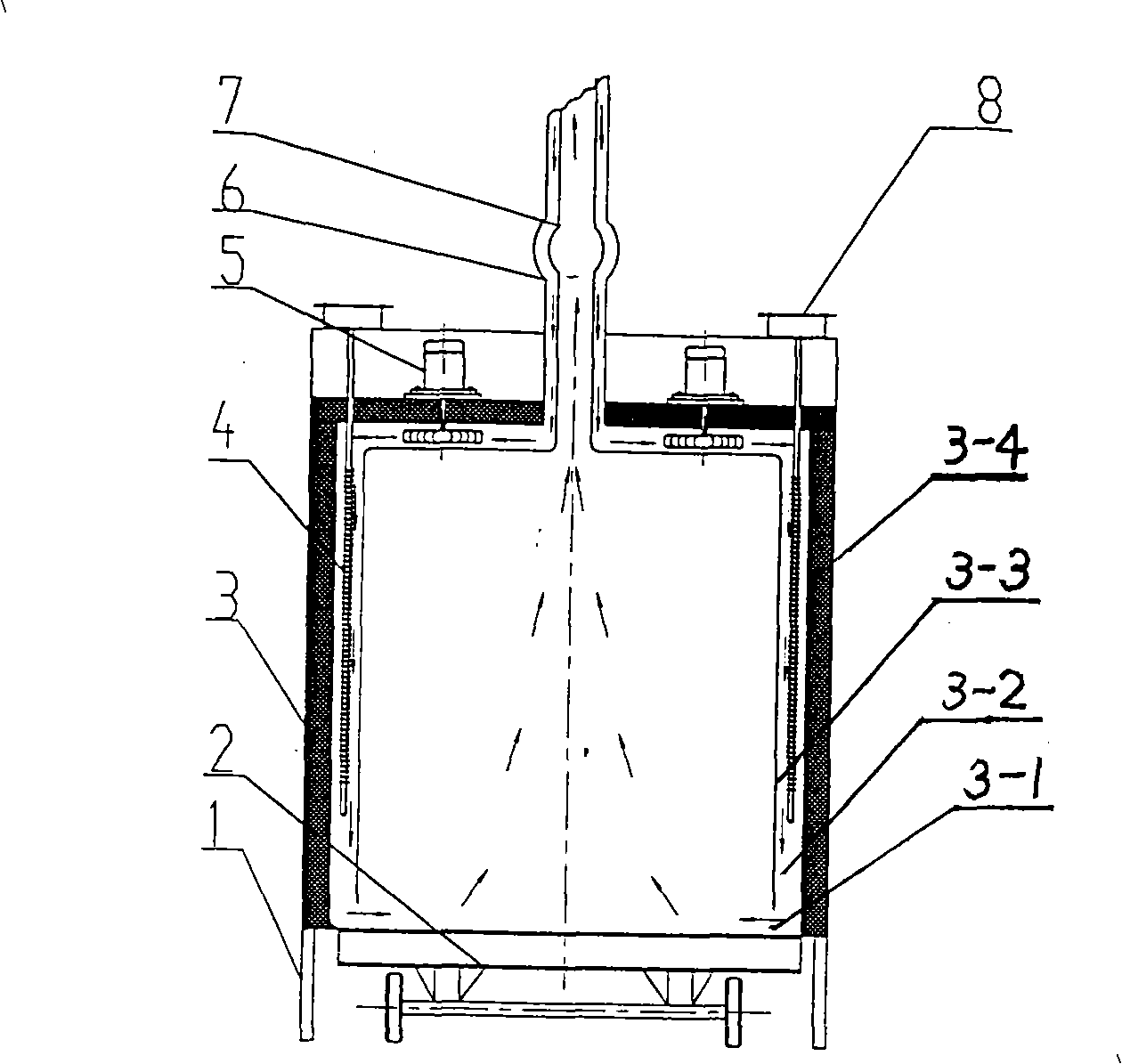

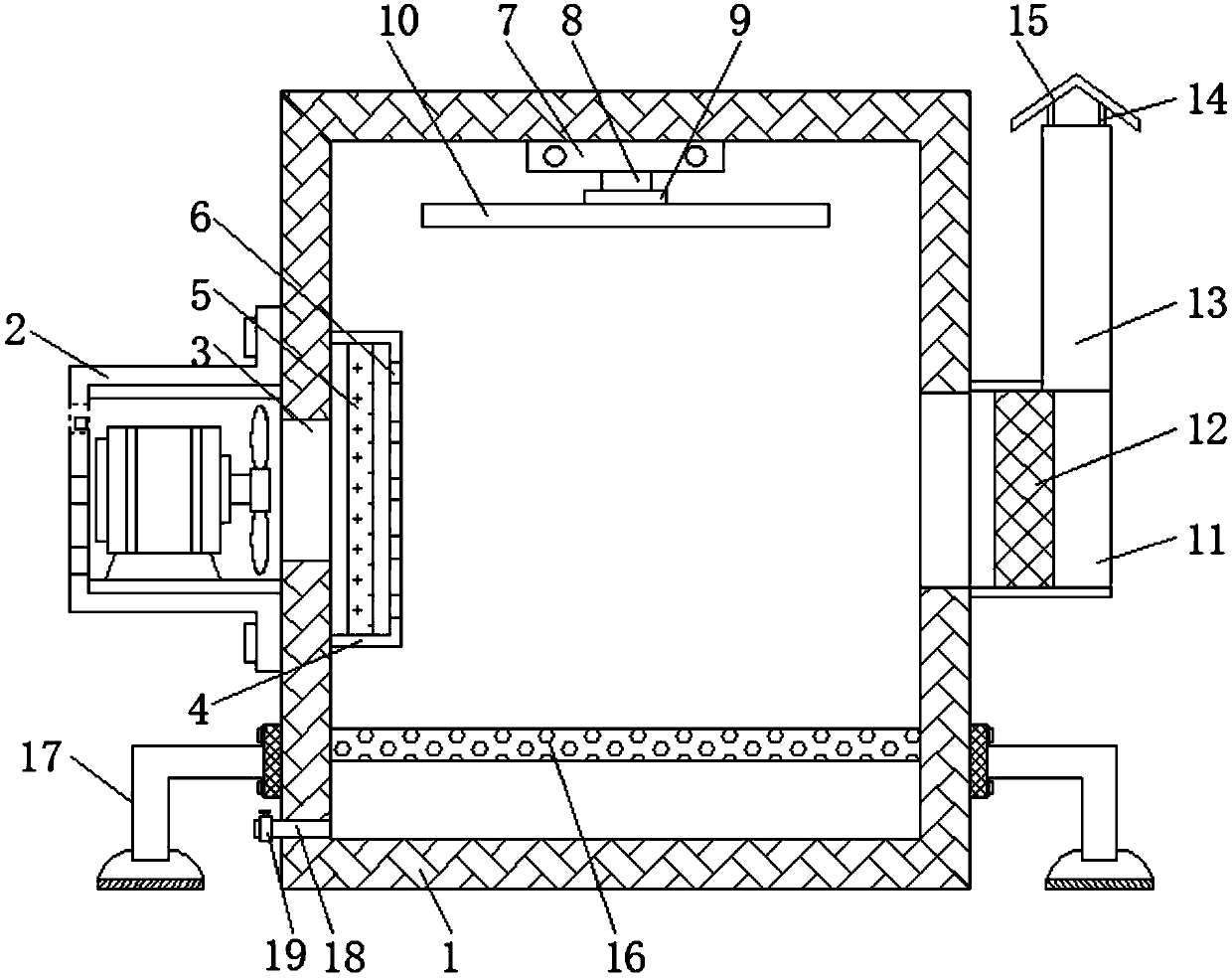

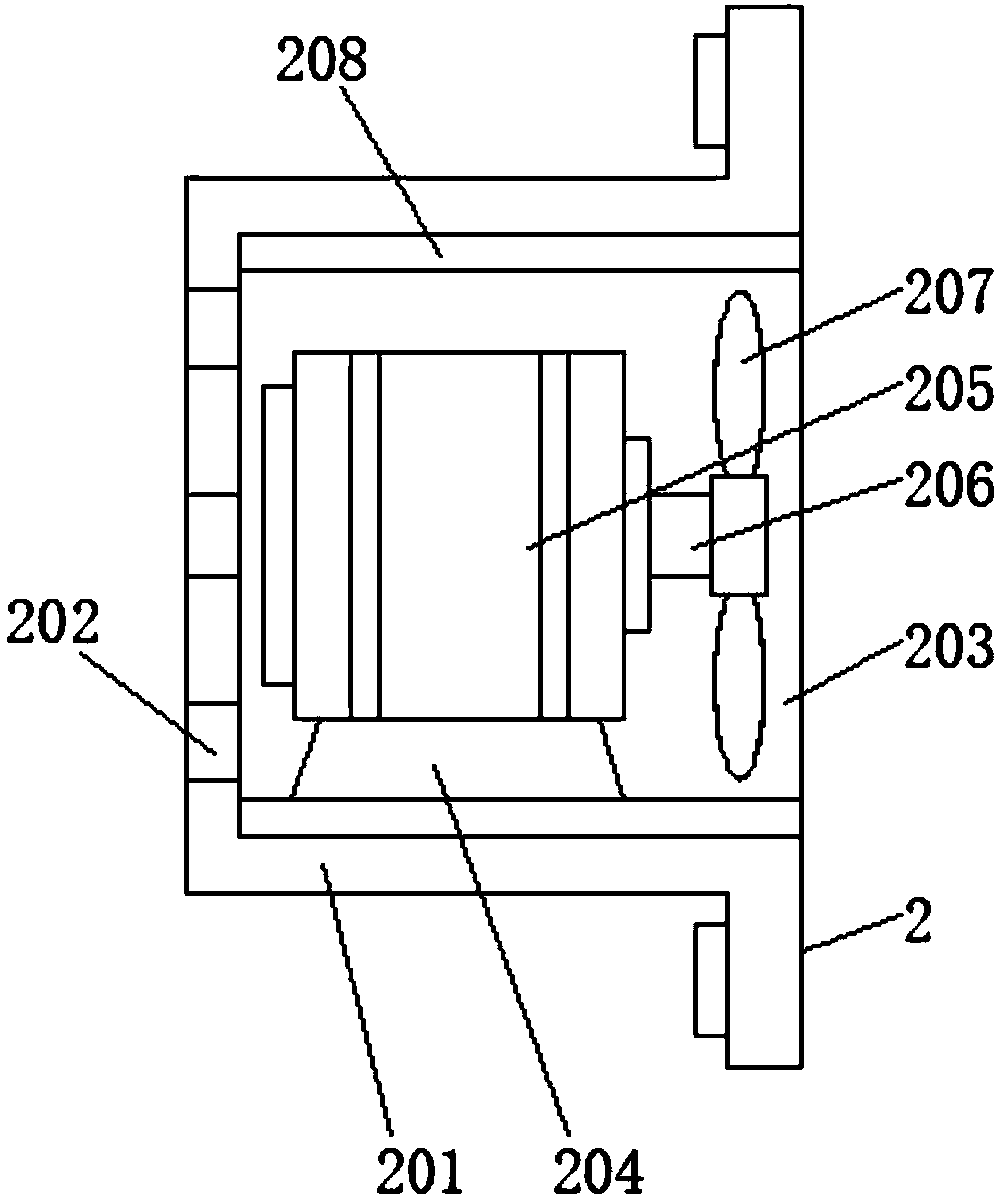

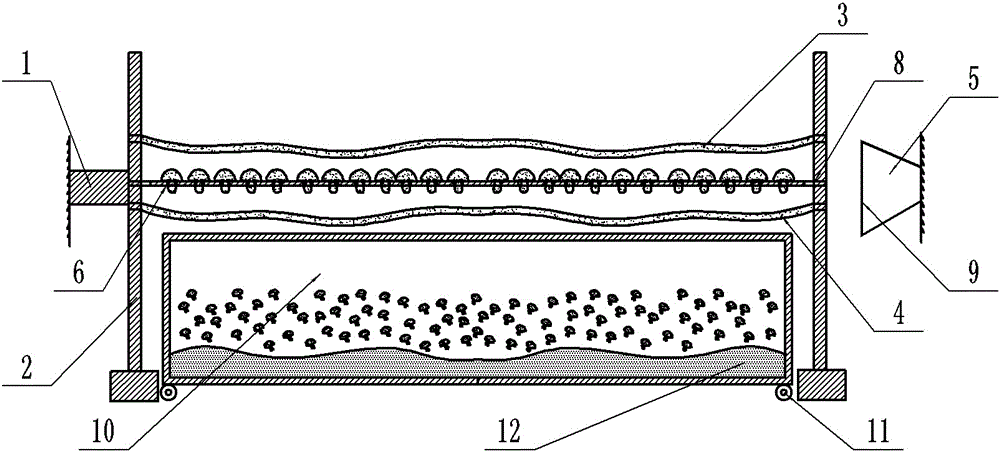

Recovery type solar drying device

InactiveCN101839616AIncrease the heat collecting areaIncrease profitSolar heating energyDrying solid materials with heatElectricitySolar drying

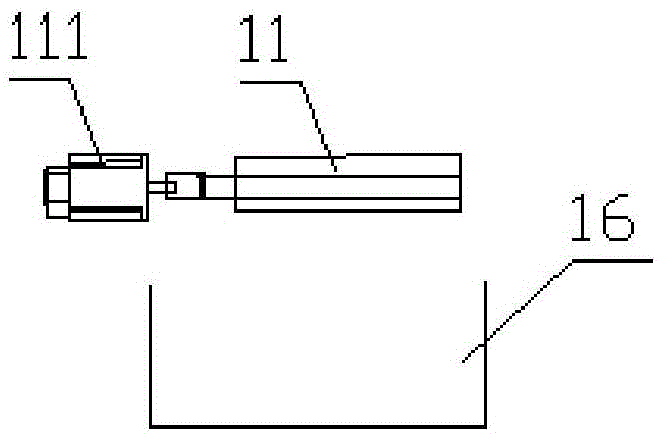

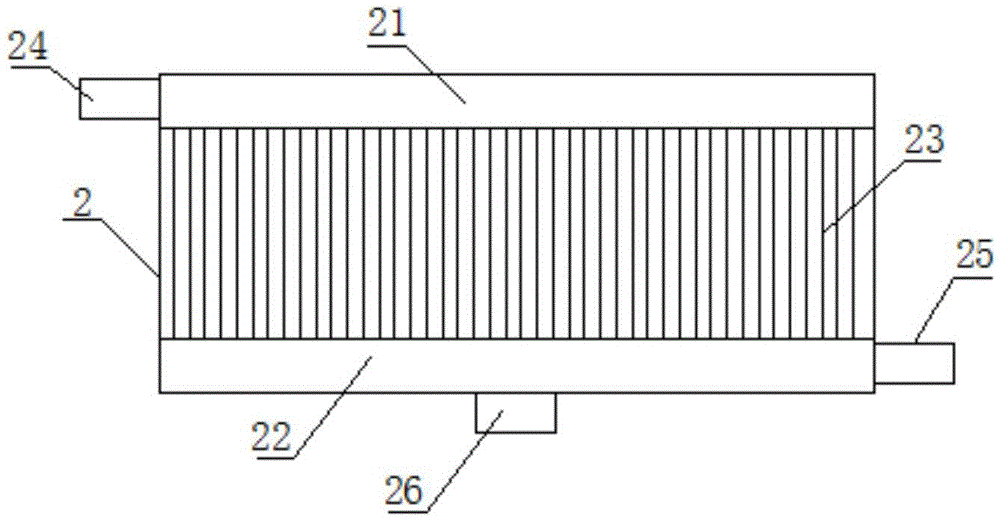

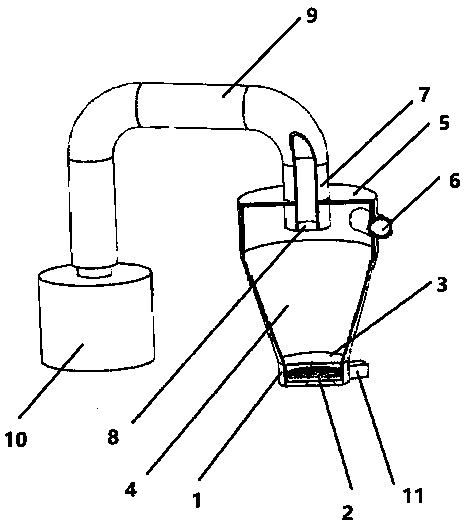

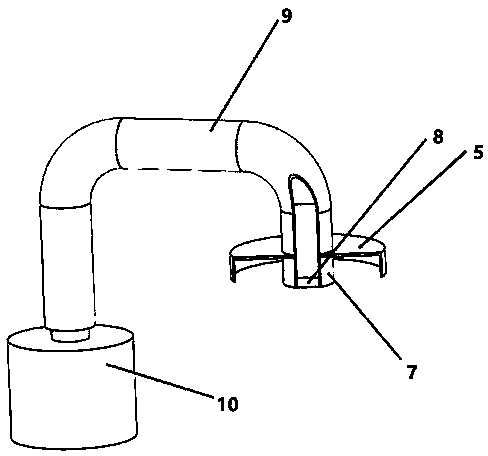

The invention relates to a recovery type solar drying device, comprising: 1. a hot air flow heat-collecting and heat-storing circulating system implemented by components such as an all-glass vacuum heat-collecting tube, a heat tube (2), a heat-dissipating piece (3), a metal net layer (4), a pebble heat-storing device (5), a heat exchange device (9), a variable-frequency speed-regulating fan (8) and the like; 2. a material drying system implemented by components such as a material drying insulating box (10), a netty material drying box (21), a fan (24), a material (25) to be dried and the like; 3. a dried material water recovery system implemented by components such as a dried material steam discharge device (11), a condensing device (12), a dried material water recovery pipeline (14) and the like; and 4. components including a valve, an electric auxiliary heating device, a sensor and the like. The recovery type solar drying device has wide application range, can dry different types of materials and form series of products of the solar drying device.

Owner:沈晓莉

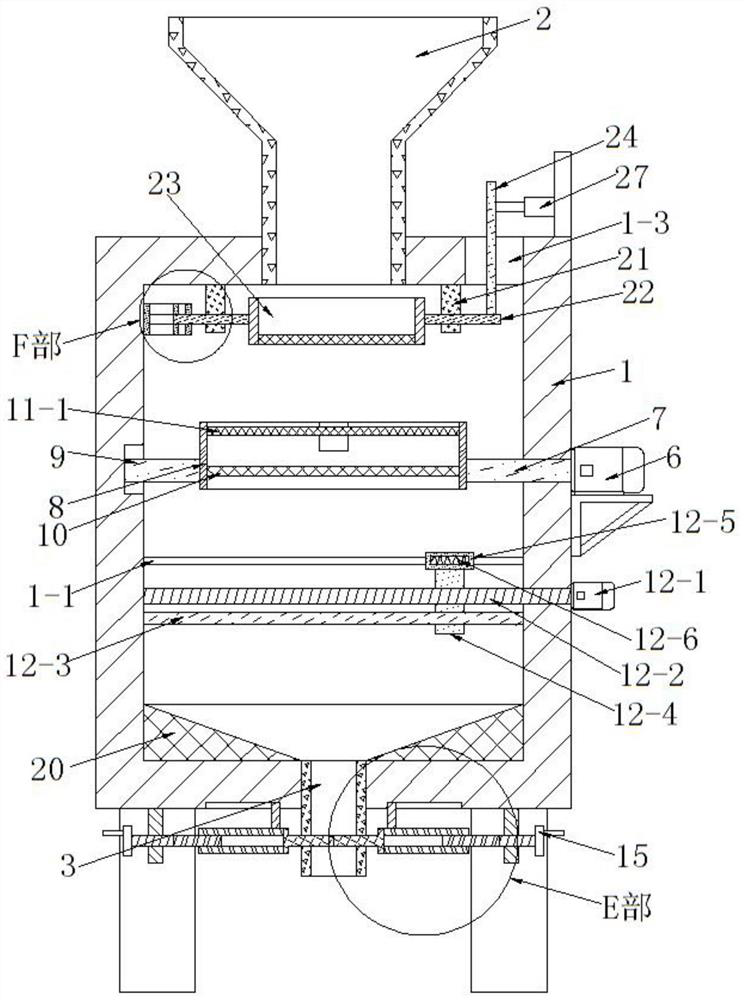

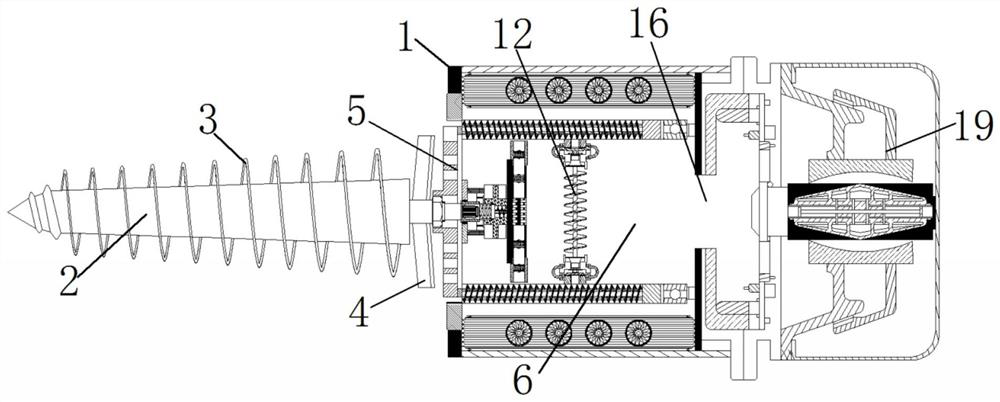

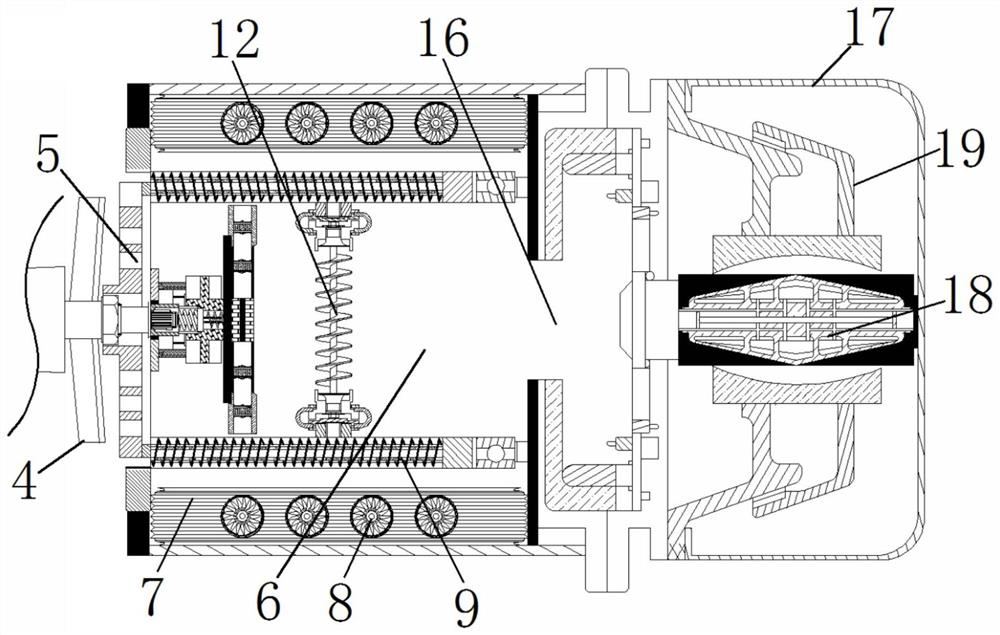

Grain dryer

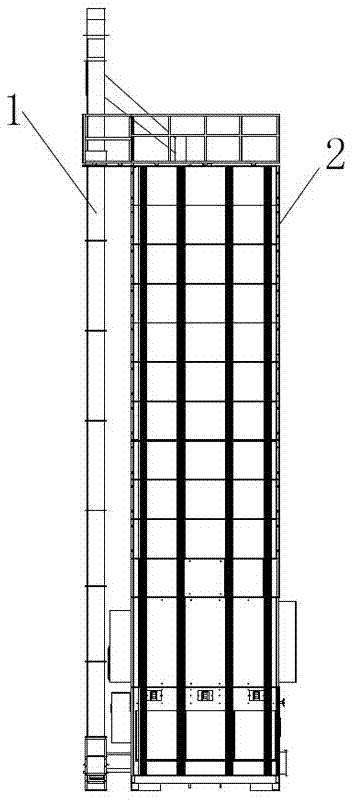

PendingCN105432782AImprove working environmentReduce the difficulty of food cleaningSeed preservation by dryingDrying solid materialsTowerPulp and paper industry

The invention discloses a grain dryer. The grain dryer comprises a hoisting machine and a dryer tower body, wherein a feed opening is formed in an upper cover plate of the dryer at the top end of the dryer tower body, and a disk throwing mechanism and a feeding device are also mounted on the upper cover plate of the dryer; a grain storing layer is arranged under the feed opening; the upper end of the grain storing layer is butted with the feed opening, and a drying box is connected to the lower end of the grain storing layer; a discharging hopper is mounted at the lower part of the drying box. The grain dryer is characterized in that a grain viewing device is arranged on the dryer tower body; the feeding device comprises a gravity type oblique feeding pipe, a vibration plate and a vibration device; a dust removing device is also arranged on an oblique plate of the discharging hopper, and comprises a dust removing exhaust fan, a dust removing pipeline, dust collection hoops and a dust removing sieve plate; an air guiding device is mounted outside the drying box. The invention aims to provide the grain dryer which is convenient to use.

Owner:ANHUI DONGKE AGRI MACHINERY TECH CO LTD

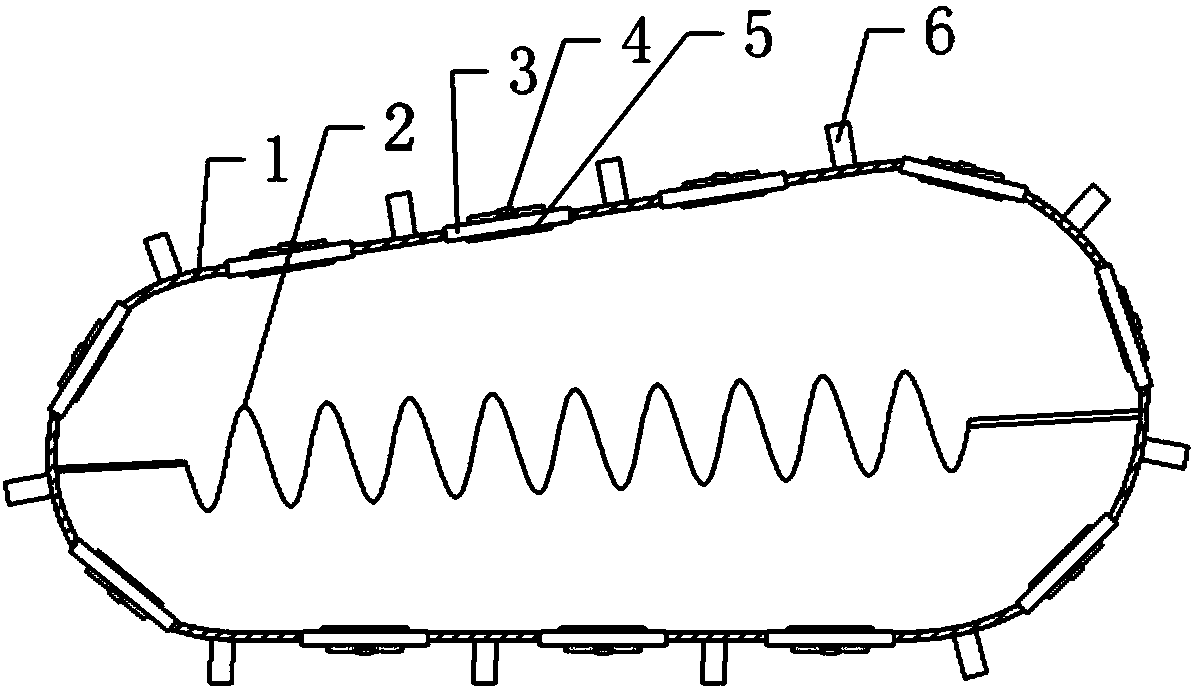

Telescopic shoes dryer

InactiveCN108143384AEasy accessHigh currentFootwear cleanersElectrical resistance and conductanceHeat conducting

The invention relates to the technical field of shoes drying devices, in particular to a telescopic shoes dryer. The shoes dryer comprises a heating element, and further comprises an elastic airbag, wherein the heating element is located inside the elastic airbag, the outer surface of the elastic airbag is provided with a plurality of protruding rods, a plurality of aluminum heat sinks are embedded in the elastic airbag, the heat sinks are provided with through holes, one end, close to the elastic airbag, of each through hole is sealedly and fixedly connected with a copper heat conducting block, each through hole is slidably covered with a first sliding block and second sliding block made of aluminum, each first sliding block and the corresponding second sliding block are both slidably connected to the heat sink, a water absorption expansion block is connected between each first sliding block and the corresponding second sliding block, a slide rheostat is connected between each first sliding block and the corresponding second sliding block, the slide rheostat is connected in series with the heating element, and as the distance between each first sliding block and the correspondingsecond sliding block increases, the resistance value of the resistor in series with the heating element on the slide rheostat decreases. The problem that the shoes dryer in the prior art cannot dry shoes of different sizes is solved.

Owner:宁波隆锐机械制造有限公司

Drying device capable of turning over for machining traditional Chinese medicine decoction pieces

InactiveCN111664686ANo falling phenomenonImprove drying qualitySievingScreeningMedicinal herbsEngineering

The invention provides a drying device capable of turning over for processing traditional Chinese medicine decoction pieces, and relates to the technical field of traditional Chinese medicinal material production. A turnover motor is fixed to the right side of a box body, an output shaft of the left side of the turnover motor penetrates through the right side wall of the box body and is arranged in the box body, a rotating shaft is fixed on the output shaft, and a placing frame is fixed at the other end of the rotating shaft; and a screen is embedded in the placing frame, a supporting shaft isfixed to the left side of the placing frame, the supporting shaft is rotatably arranged in the box body through a bearing, the supporting shaft and the rotating shaft are arranged on the same axis, apressing device is arranged on the upper side of the placing frame, and a drying device is arranged on the lower side of the placing frame. By driving a heating plate to move back and forth, medicinal materials are uniformly dried, when the medicinal materials are dried, the medicinal materials can be driven to be turned over, and the drying quality and efficiency are improved.

Owner:湖南一方天江药业有限公司

Drying device for textile dyeing and finishing

InactiveCN107794668AEven heating and dryingQuality improvementTextile treatment machine partsLiquid/gas/vapor removal by gas jetsEngineeringTextile printer

The invention relates to the technical field of textile printing and dyeing, and discloses a drying device for textile printing and dyeing, which includes a body, a blowing device is fixedly connected to the middle part of one side of the body, and a blowing port is opened in the middle part of one side of the body. The blowing device communicates with the blowing outlet, a heating chamber is fixedly connected to one side inside the body, the heating chamber communicates with the blowing outlet, and a heater is fixedly connected inside the heating chamber. The drying device for textile printing and dyeing blows the heat generated by the heater inside the heating chamber out of the blowing holes through the blowing device, and hangs the textiles on the placing rod inside the placing box, because the top of the placing box is inserted through the supporting column Inside the rotator, the blown heat can make the storage box rotate slowly and heat the textile, which can make the textile heating and drying more uniform, improve the quality of the product, and further increase the production efficiency.

Owner:绍兴世潮涂层有限公司

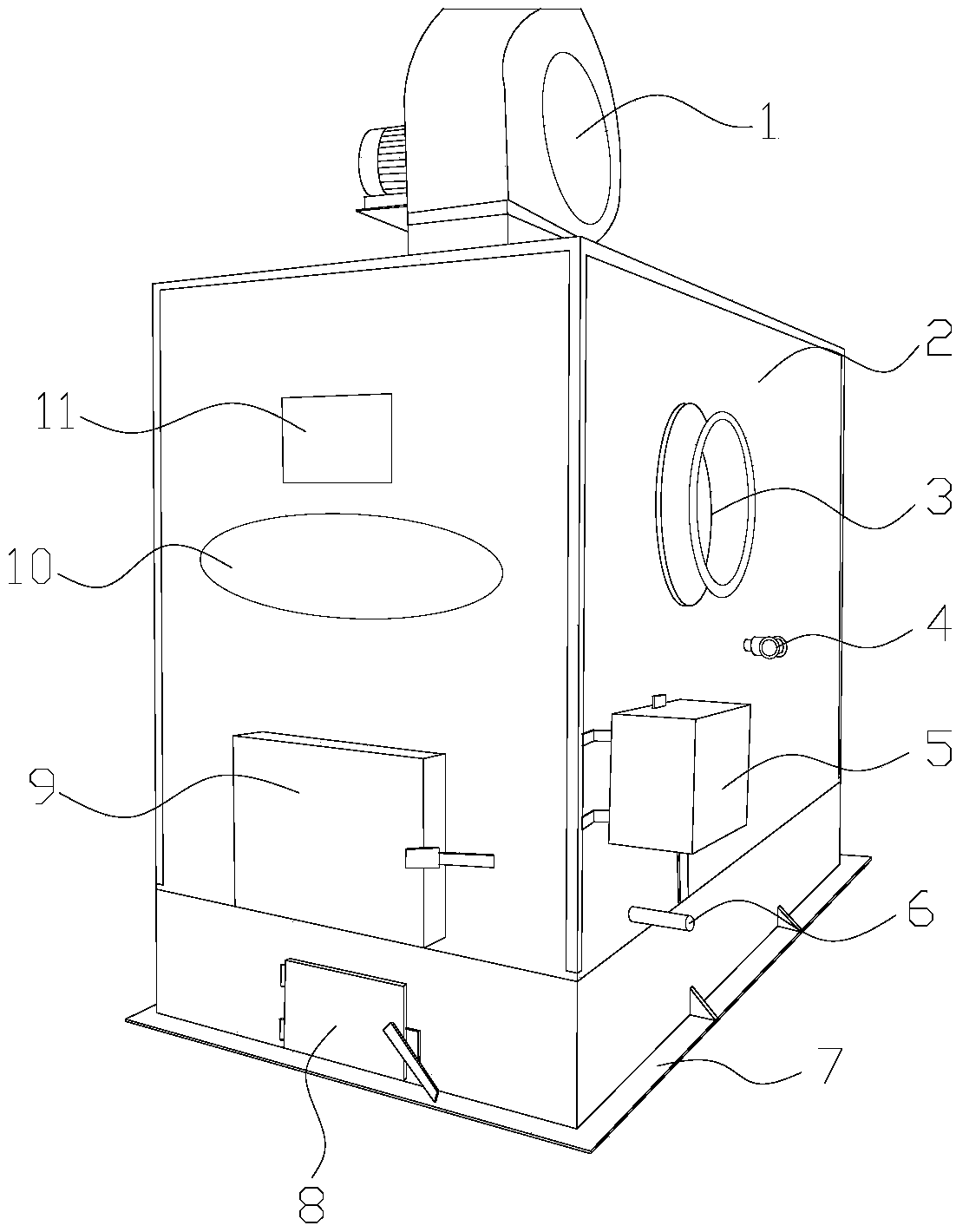

Wood drying device

InactiveCN109000446ADry evenlySpeed up dryingDrying gas arrangementsDrying solid materialsInterference fitSlag

The invention discloses a wood drying device. The wood drying device structurally comprises a fan, an automatic steam drying mechanism, a hot air outlet, a steam outlet, an automatic water replenisher, a water drainage port, a fixing bottom plate, a slag removing port, a coal inlet, a nameplate and a dust removing port, the fan is fixedly welded to the upper end of the automatic steam drying mechanism and is in interference fit with the automatic steam drying mechanism, the left side of the hot air outlet is fixedly welded to the surface of the right side of the automatic steam drying mechanism, and the hot air outlet communicates with the automatic steam drying mechanism. According to the wood drying device, wood drying acceleration is achieved, air exhaust outlets rotatably and evenly blow hot air to a drying cylinder, a high-pressure air jetting mechanism jets high-pressure air from the side face, drying is accelerated, damp and hot steam in a movable frame is exhausted through a strong exhaust fan, the purpose of even heating and drying through rotation is achieved, the phenomenon that deforming and cracking are generated due to the fact that wood can not be fully heated is effectively prevented, and the production efficiency and the drying quality are improved.

Owner:朱皖卉

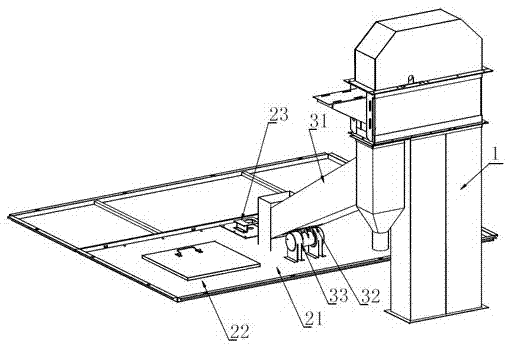

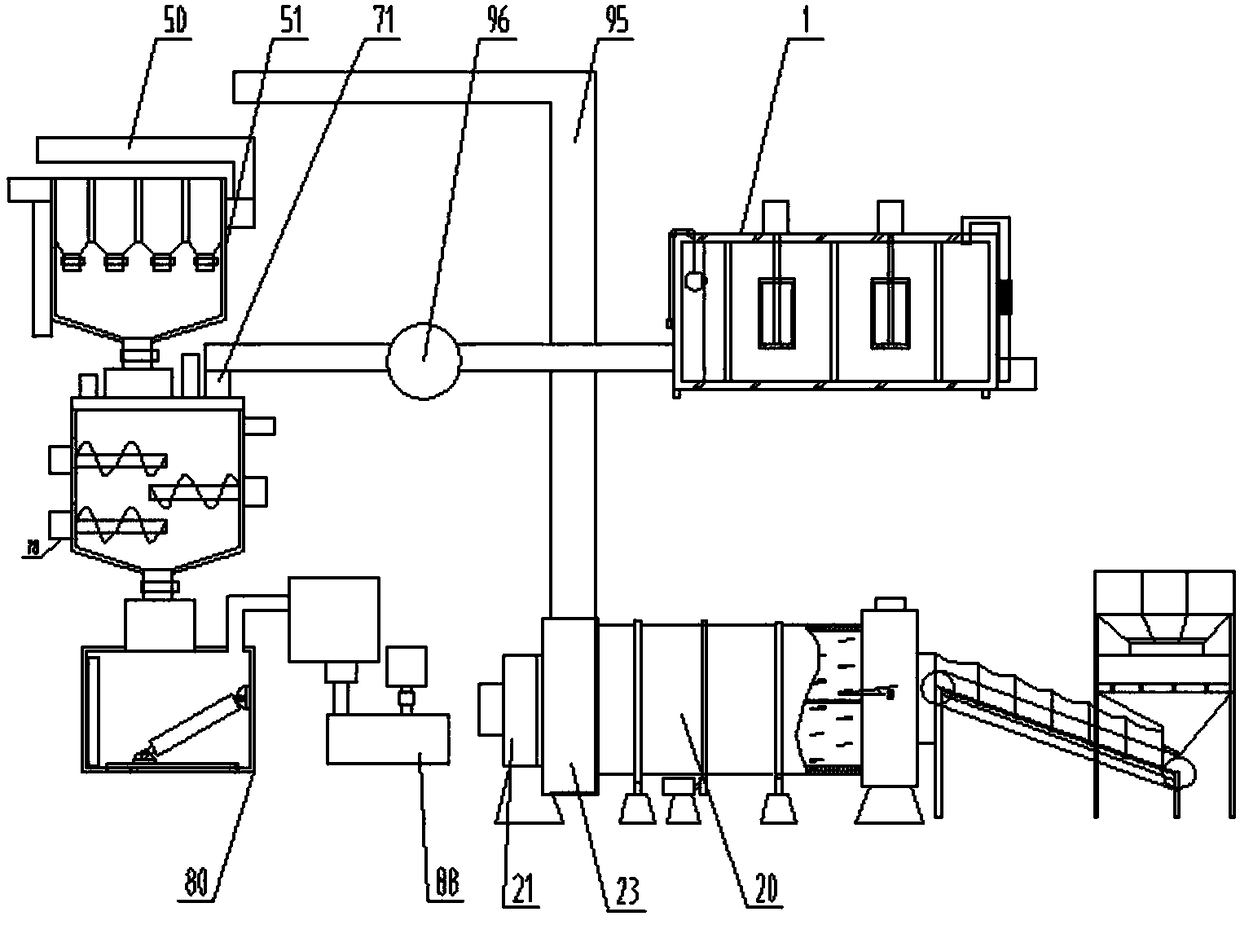

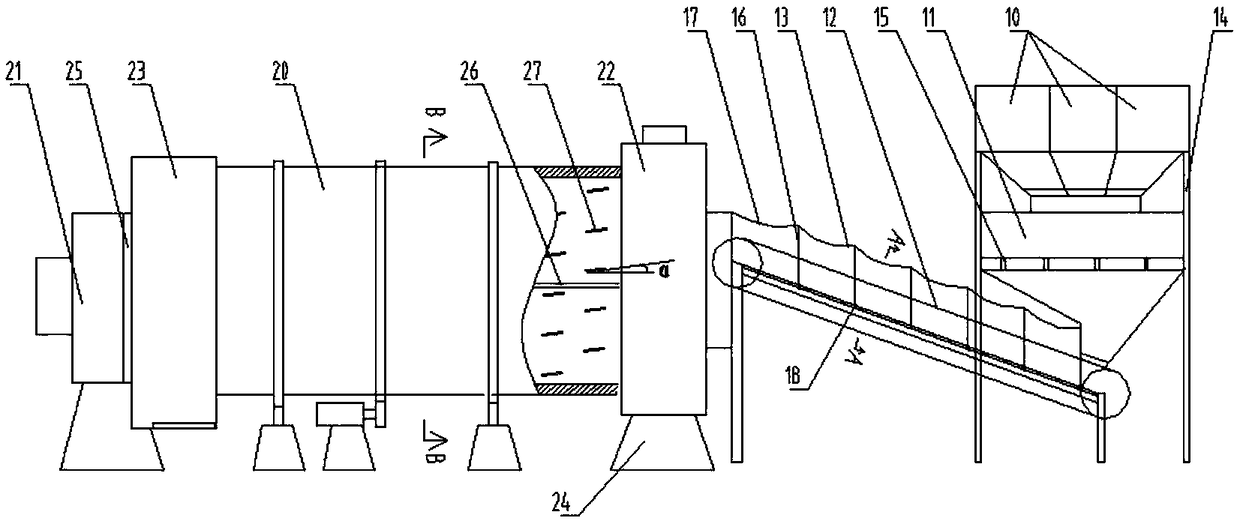

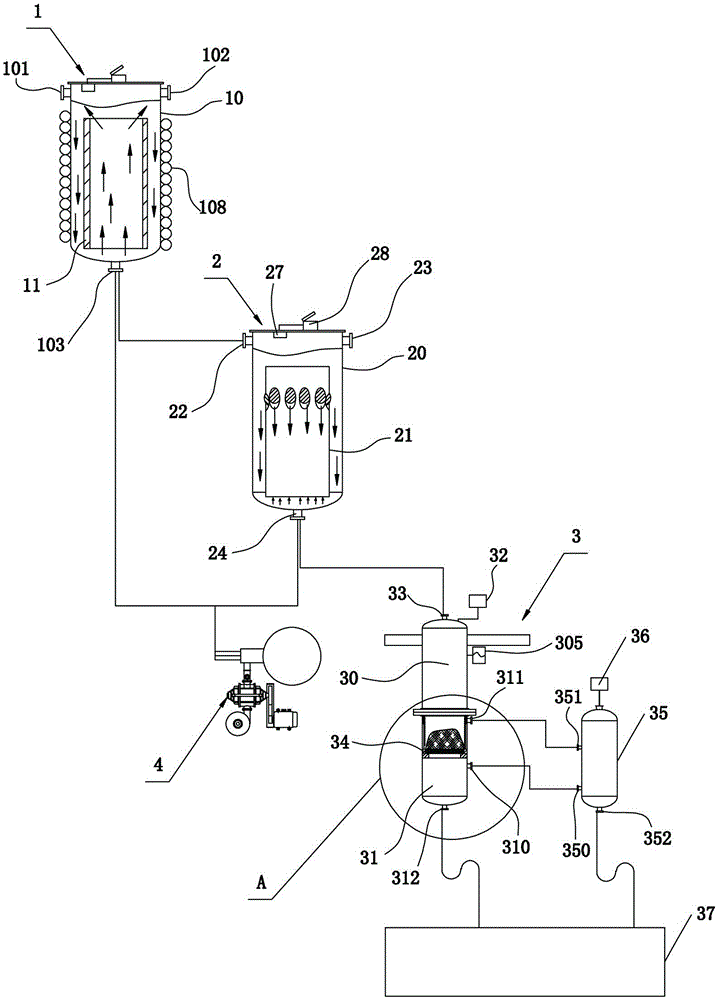

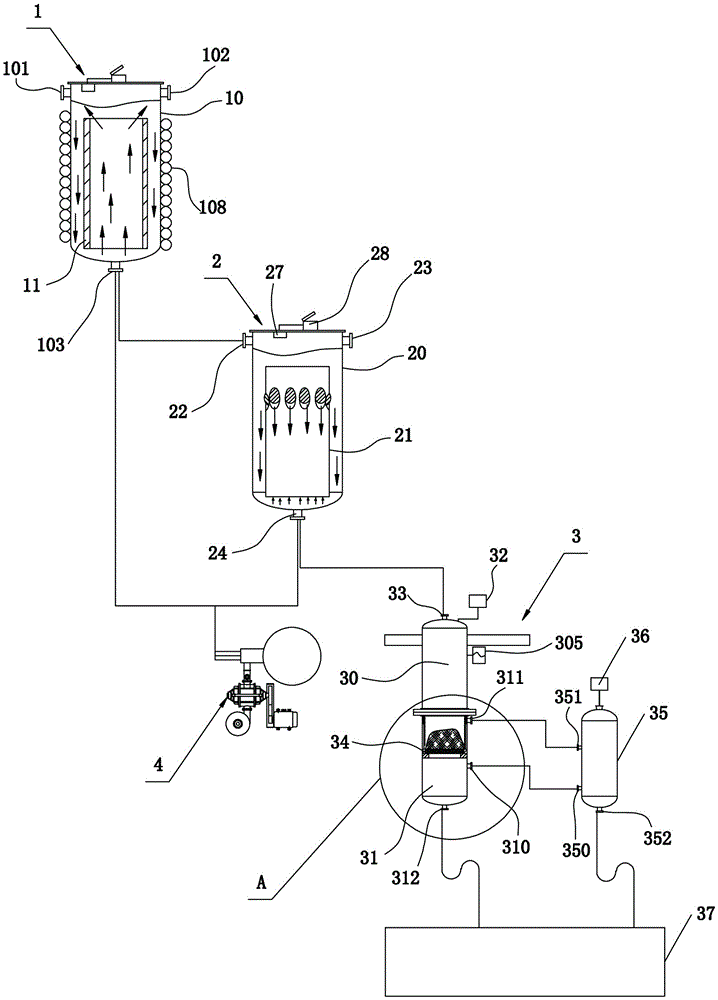

Modified asphalt production line

InactiveCN109423944AHigh degree of automationIncrease productivityRoads maintainenceEngineeringAsphalt

A modified asphalt production line is composed of a stone discharging and drying system, an asphalt tank, a stone hoist, an asphalt delivery pump and an asphalt dividing, mixing and discharging system. The stone discharging and drying system comprises a discharging device and a dryer, the discharging device comprises a set of hopper scales, a mixing hopper, a belt conveyor and a dust hood, the setof hopper scales and the mixing hopper are respectively installed on a rack, discharging openings of the set of hopper scales respectively communicate with the feeding end of the mixing hopper, the feeding end of the belt conveyor is positioned below the discharging opening of the mixing hopper, the positions, on two sides of the belt conveyor, of the rack are provided with inverted T-shaped sliding grooves, and the dust hood comprises a group of U-shaped skeletons and filter cloth connected with the U-shaped skeletons. The modified asphalt production line has reasonable structure design, high automation degree, high production efficiency and low dust raising, and has good practical value.

Owner:诸暨马谷亲科技有限公司

Agricultural product drying equipment

InactiveCN111219967AImprove drying efficiencyImprove heating efficiencyDrying gas arrangementsDrying machines with non-progressive movementsAgricultural scienceHeat conducting

The invention discloses agricultural product drying equipment. The agricultural product drying equipment comprises a shell, a first rectangular plate is arranged on the upper part of the outer wall ofthe right side of the shell, a motor is connected with the top end of the first rectangular plate, a connecting rod is connected with the output end of the motor through a coupler, and the connectingrod is located at the top end of an inner cavity of the shell. According to the agricultural product drying equipment, the interior of stacked agricultural products can be stirred, heated and dried through a stirring rod, the drying efficiency of the agricultural products is improved, and heating and drying are more uniform;a heat dissipation rod can be heated through an electric heating rod, andthe heating efficiency of the heat dissipation rod can be improved through a heat conducting medium; and according to the device, the agricultural products are uniformly heated and dried in the stirring process, so that the agricultural products are effectively prevented from being deteriorated and mildewed due to non-uniform local heating and drying, the stirring and drying are more uniform, thedrying efficiency of the agricultural products is improved, and the storage time of the agricultural products is prolonged.

Owner:重庆市维森电气有限公司

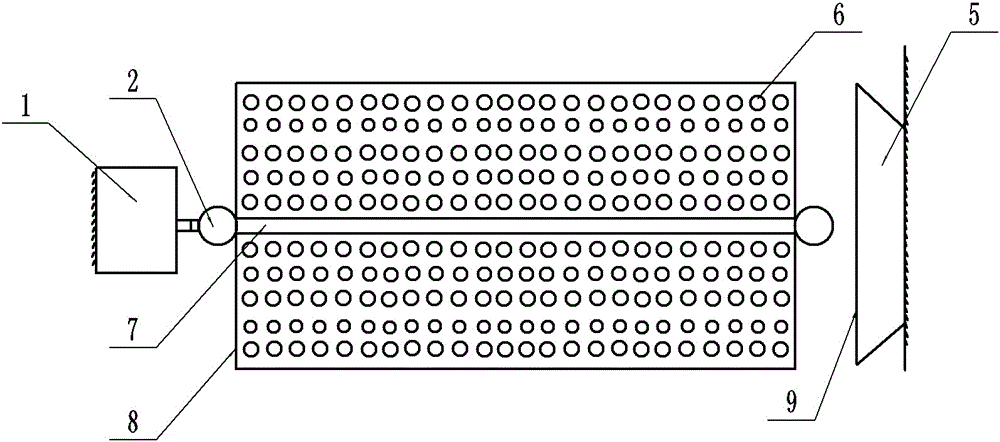

Lentinula edodes drying mechanism

InactiveCN106723189AEven heating and dryingImprove drying effectFood treatmentPulp and paper industryLentinula edode

The invention belongs to the technical field of food processing, and discloses a lentinula edodes drying mechanism. The lentinula edodes drying mechanism comprises a control mechanism, a motor, a rack, two support columns, two tin foil layers, a vibrator and a drying fan; each tin foil layer comprises an elastic net and tin foil paper arranged on the elastic net, and the upper tin foil layer, a drying rack and the lower tin foil layer are arranged between the two supporting columns from top to bottom; the drying rack is provided with multiple lentinula edodes clamping openings with the diameter being 1.8 cm, a rotating shaft is arranged in the middle of the drying rack, the drying rack is rotationally connected to the supporting columns through the rotating shaft, and one end of the rotating shaft penetrates through one support column to be connected to the motor; the vibrator is fixed to the drying rack, the drying fan is arranged on the portion, opposite to the motor, of the rack, and a blow-off nozzle aims at the drying rack between the upper tin foil layer and the lower tin foil layer; a collection box is arranged below the lower tin foil layer. Accordingly, by means of automated exquisite arrangement, uniform heating and drying of lentinula edodes are completed, the drying effect is good, and the efficiency is high.

Owner:CHONGQING RUIFUNONG EDIBLE MUSHROOMS PLANTATION CO LTD

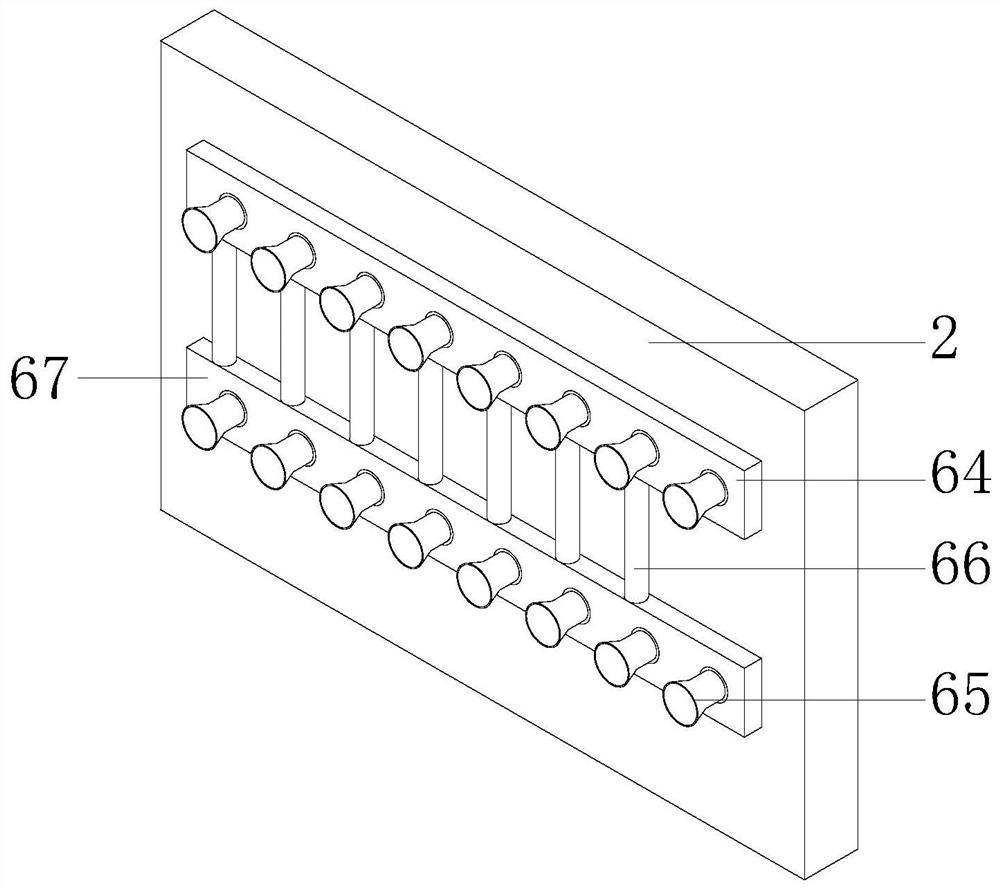

Sorting system after molding of fine ceramic product

ActiveCN110524708ARealize processingAchieve recyclingGrinding carriagesGrinding drivesMetalMaterials science

The invention discloses a sorting system after the molding of a fine ceramic product. The system comprises a rapid cooling device after the fine ceramic molding, a drying device for producing the fineceramic sealed with the metal, a fine ceramic grinding device witha dust collection function, a fine ceramic polishing device, a storing, taking and placing device for producing the fine ceramic sealed with the metal and a conveying device for producing and machining the fine ceramic. Through the reasonable arrangement and cooperation of the above several processes, the finished ceramic productsare sorted, and the percent of pass of the products is increased.

Owner:湖南福易达电子科技有限公司

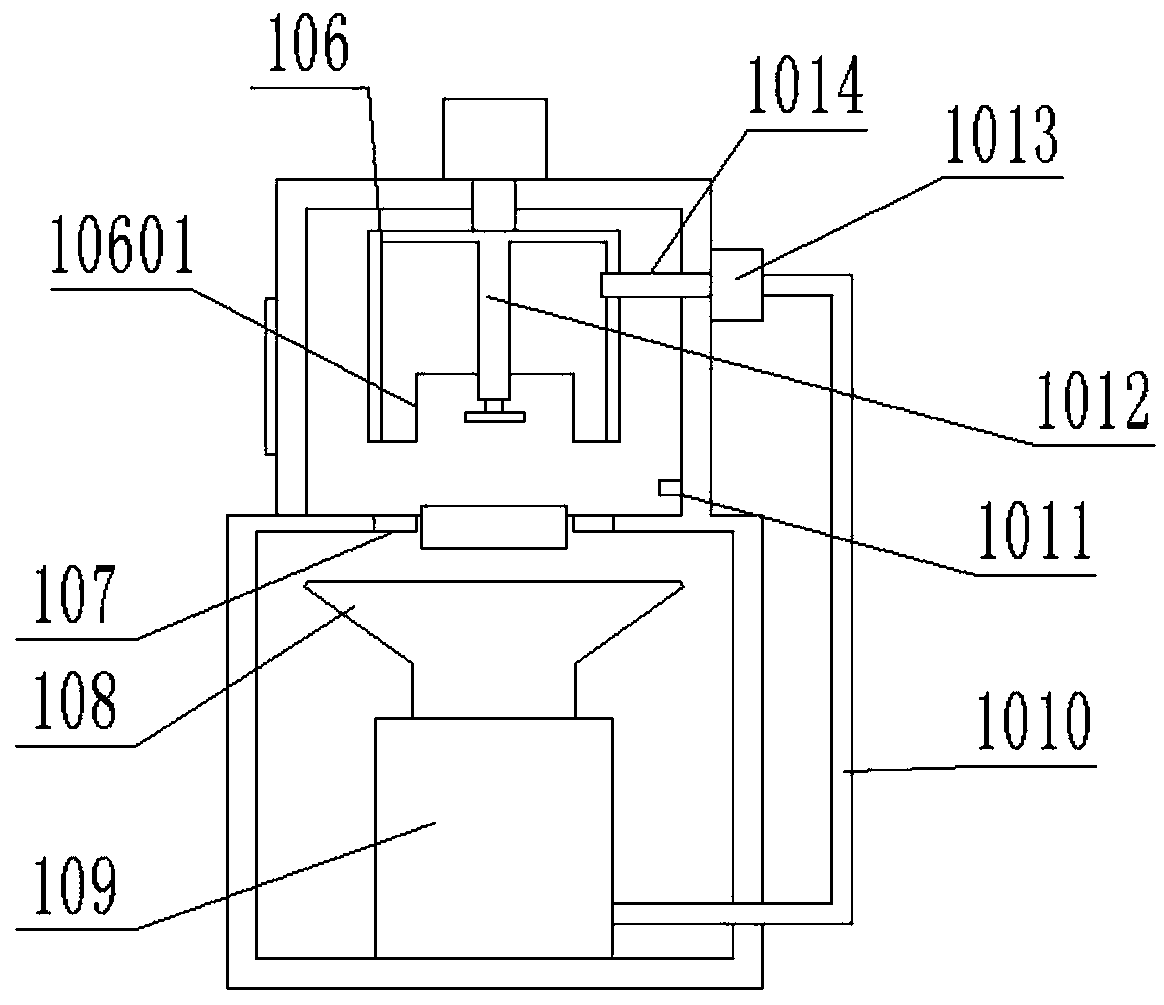

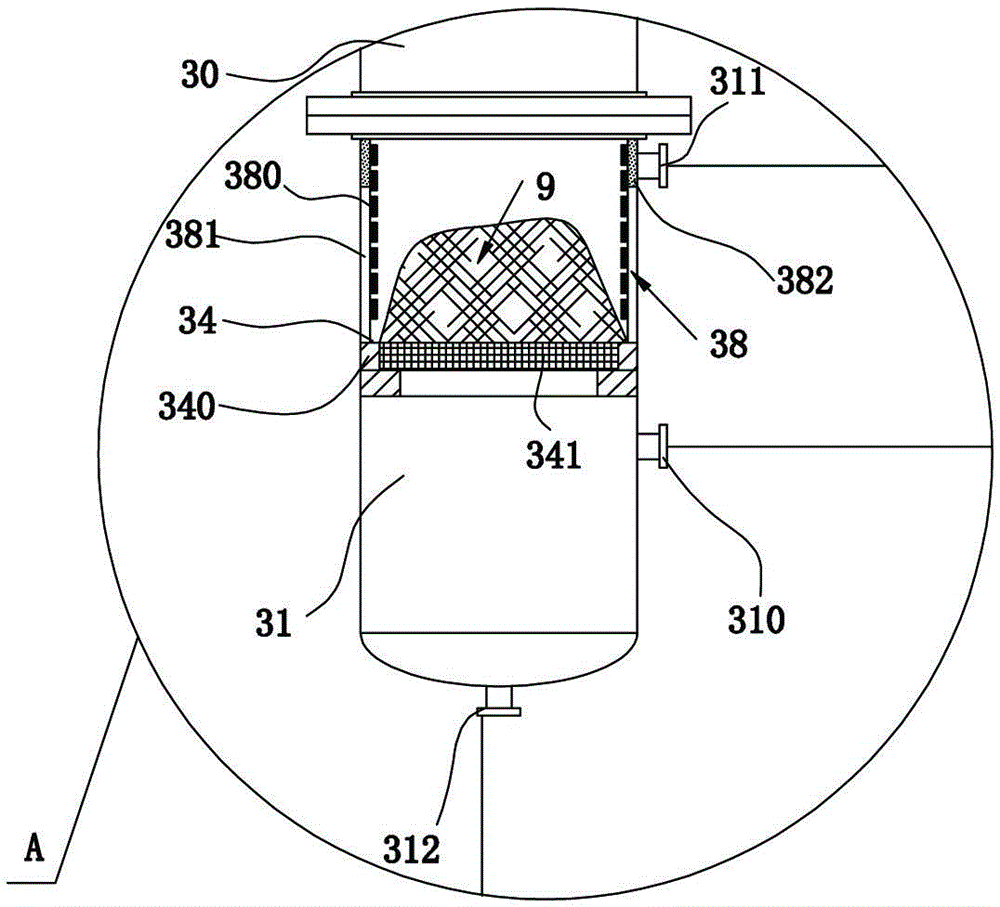

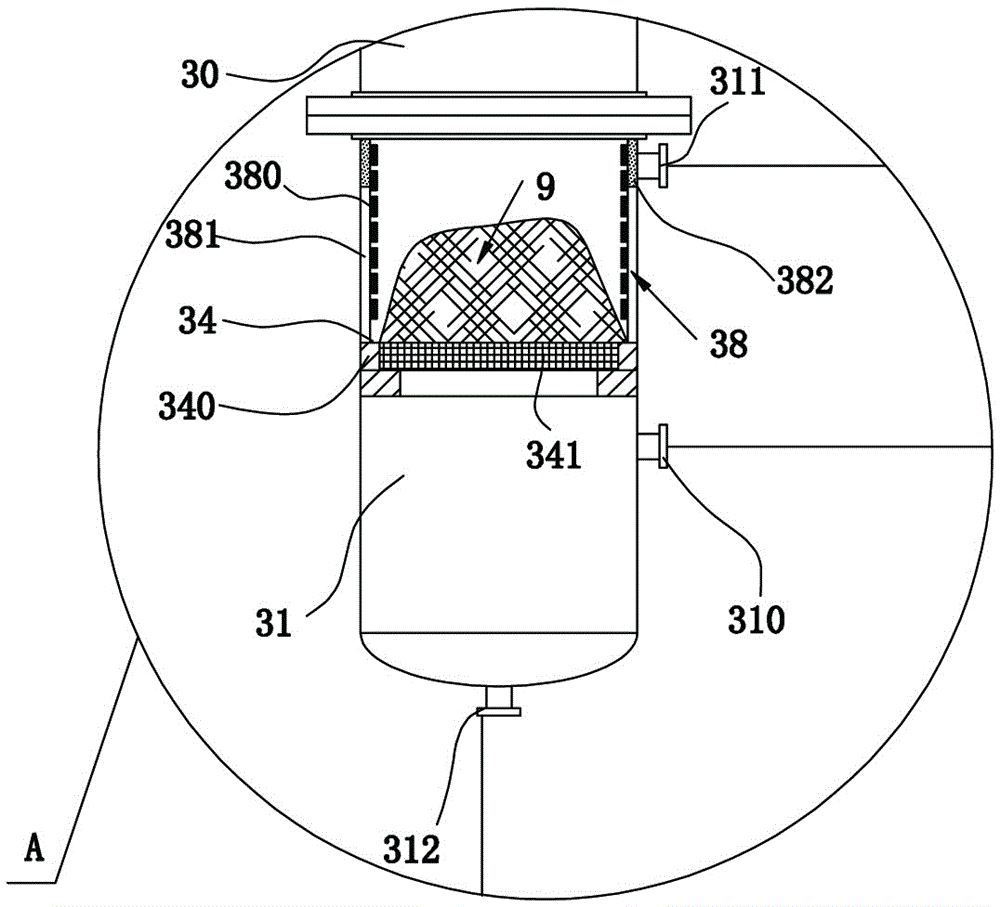

Sludge treatment method improving dehydration efficiency

ActiveCN105366901ASimple processPracticalSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHeavy metalsMicrowave

A sludge treatment method improving dehydration efficiency includes the following steps of 1, biochemical treatment of heavy metal, 2, dehydration conditioning of sludge, and 3, dehydration drying of the sludge. In the step of dehydration drying of the sludge, the pressure in an upper tank body is increased through a pressurization device, the pressure in a lower tank body is decreased through a vacuum tank till the interior of the lower tank body is in a vacuum state, and thus a large pressure difference is formed between the upper tank body and the lower tank body; water in water-containing sludge mixed liquid in the upper tank body can pass through a filter layer quickly, the sludge remains on the filter layer, and quick solid-liquid separation is guaranteed due to the fact that the pressure difference can be formed between the upper tank body and the lower tank body; after solid-liquid separation is finished, a microwave emitting device is started to release microwaves, and the microwaves interact with water molecules in the sludge to heat the water molecules, so that the water molecules in the sludge disperse and volatilize into the air, and the effect of drying the sludge is achieved.

Owner:JINJIANG SHILONG KITCHEN EQUIP CO LTD

Rapid drying device for dried bamboo shoots

The invention discloses a quick drying device for dried bamboo shoots, which comprises a device main body. The bottom of the device main body is provided with a base, and the base and the device main body are tightly welded. The left and right sides of the front end of the device main body are provided with drying box doors. The door is movably connected with the main body of the device. There is a connection end on the right side of the drying box door, and the connecting end is tightly welded with the drying box door. There is a handle on the left side of the drying box door, and the handle is closely attached to the drying box door. combine. Compared with ordinary dried bamboo shoots drying equipment, this kind of dried bamboo shoots quick drying device is equipped with two drying box assemblies inside the main body of the device, and the two drying boxes The components can operate independently, which can effectively dry a small amount or a large amount of dried bamboo shoots. There are receiving ends on the left and right sides of the drying box components, through which the inside of the drying box can be layered. Effect.

Owner:广西华竹生物科技有限公司

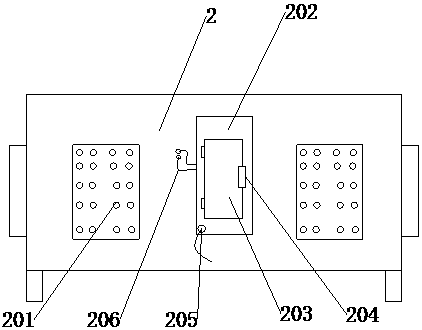

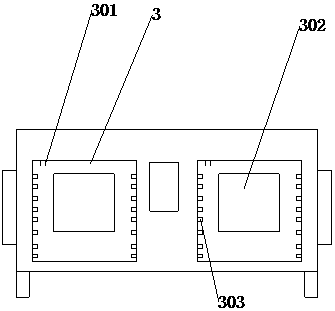

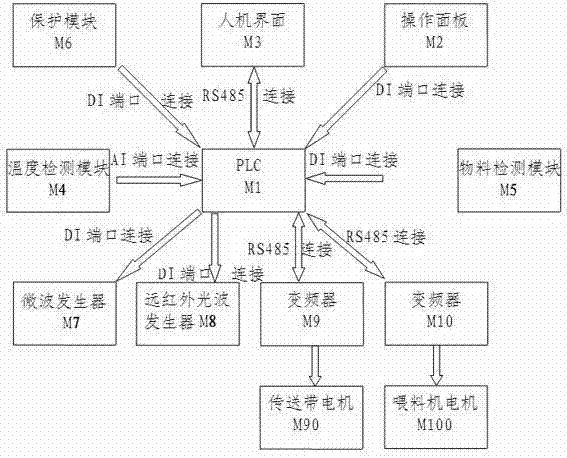

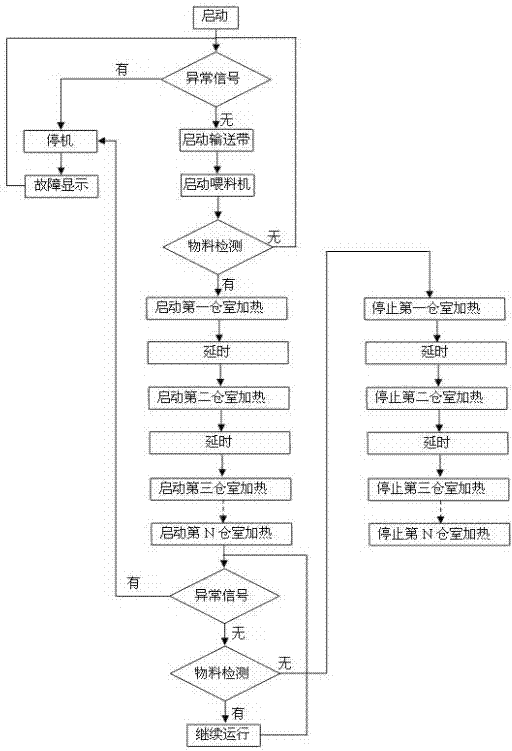

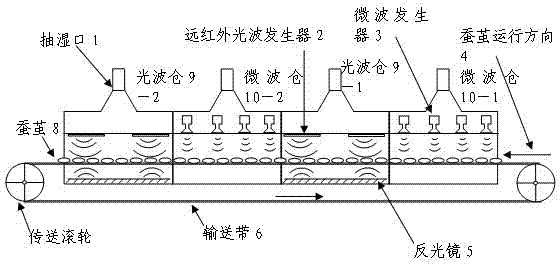

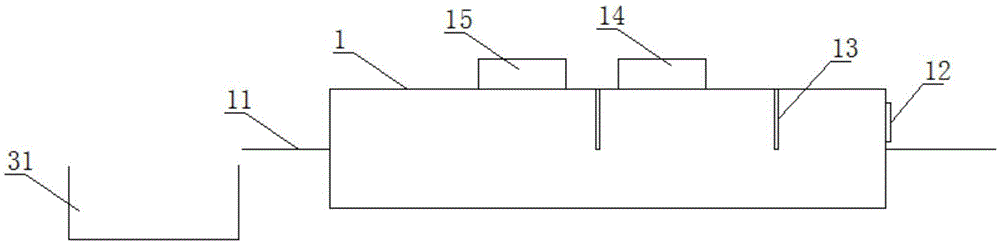

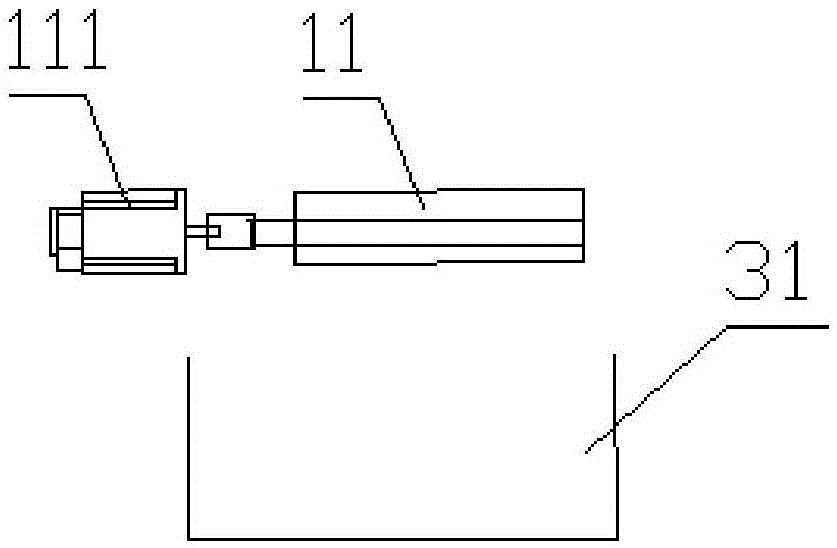

Method and control system for drying silkworm cocoons by microwaves and far infrared waves

InactiveCN103759503AEven heating and dryingQuality improvementDrying solid materials with heatHearth type furnacesControl systemEconomic benefits

The invention discloses a method and a control system for drying silkworm cocoons by microwaves and far infrared waves. The method is characterized by including the steps: drying the cocoons by the far infrared waves: setting a far infrared wave cocoon drying bin, placing a far infrared wave generator in the far infrared wave cocoon drying bin and treating the silkworm cocoons by the far infrared waves; drying the cocoons by the microwaves: setting a microwave cocoon drying bin, placing a microwave generator in the microwave cocoon drying bin and treating the silkworm cocoons by the microwaves; firstly heating a first bin and secondly heating a second bin until the final bin is heated; adjusting microwave power; adjusting far infrared wave power. The method has the advantages that the insides and the outsides of the silkworm cocoons can be synchronously heated by drying the cocoons through the microwaves and the far infrared waves, so that uniform heating and drying are achieved, a high-quality cocoon drying effect is achieved, cocoon drying efficiency and quality can be improved, energy is saved, environments are protected, and comprehensive economic benefits of sericulture industry are improved.

Owner:柳州市自动化科学研究所

Uniform-heat energy-saving type grain dryer

InactiveCN111023714AEven heating and dryingAvoid wastingDrying solid materials without heatDrying gas arrangementsThermodynamicsEngineering

The invention discloses a uniform-heat energy-saving type grain dryer. The dryer comprises a dryer box body, wherein a feeding bin is communicated with an upper part of the dryer box body, a discharging barrel communicated with the feeding bin is mounted at the top in the dryer box body, a heating base is fixedly mounted at a lower part in the discharging barrel, a plurality of channels are evenlyformed in the heating base and located on the periphery of a semicircular protruding part, a device cavity is formed in the middle of the interior of the heating base, a heating pipe is installed inthe device cavity, a spiral conveying rod is movably inserted into the channel, an air draft end of a draught fan is communicated with an air inducing pipe, the other end of the air inducing pipe is communicated with the discharging barrel, and the other end of the air outlet pipe is communicated with the air cavity. The dryer is advantaged in that the heating base is heated through the heating pipe, grains in the channels can be evenly heated and dried, the hot air generated in the heating process is exhausted into the drying box through the draught fan to be dried and then enters the air cavity, the grains can be dried again, the drying effect is improved, and heat waste is avoided.

Owner:安徽麦稻之星机械科技有限公司

Drying device for producing dried flowers

InactiveCN112595064AReduce manufacturing costImprove the heating effectDrying gas arrangementsDrying chambers/containersEngineeringHeating effect

The invention discloses a drying device for producing dried flowers, and belongs to the technical field of dried flower production. The drying device for producing the dried flowers comprises a box body, wherein the outer wall of the box body is connected with a box door through hinges, the inner wall of the box body is fixedly connected with a shell, circulation holes which are evenly distributedare dug in the top of the shell, the inner wall of the shell is connected with a threaded rod, the outer wall of the threaded rod is connected with movable sleeves in a threaded mode, and the bottomwalls of the movable sleeves are connected with connecting rods. A clamping assembly is connected to the end, far away from the corresponding movable sleeve, of each connecting rod, the top of the boxbody is connected with a supporting base, the outer wall of the supporting base is connected with a motor, the output end of the motor is connected with a rotating shaft, the end, far away from the motor, of the rotating shaft penetrates through the supporting base and is connected with a rotary shaft, the rotary shaft penetrates through the box body and extends inwards, and the outer wall of therotary shaft is connected with a heating piece and a rotary base. According to the drying device, the heating effect of the device on flowers can be improved advantageously, heating can be uniform, the energy consumption is reduced through circulating flow of the hot air, and then the production cost of the dried flowers is reduced.

Owner:颍上县红绿园家庭农场有限公司

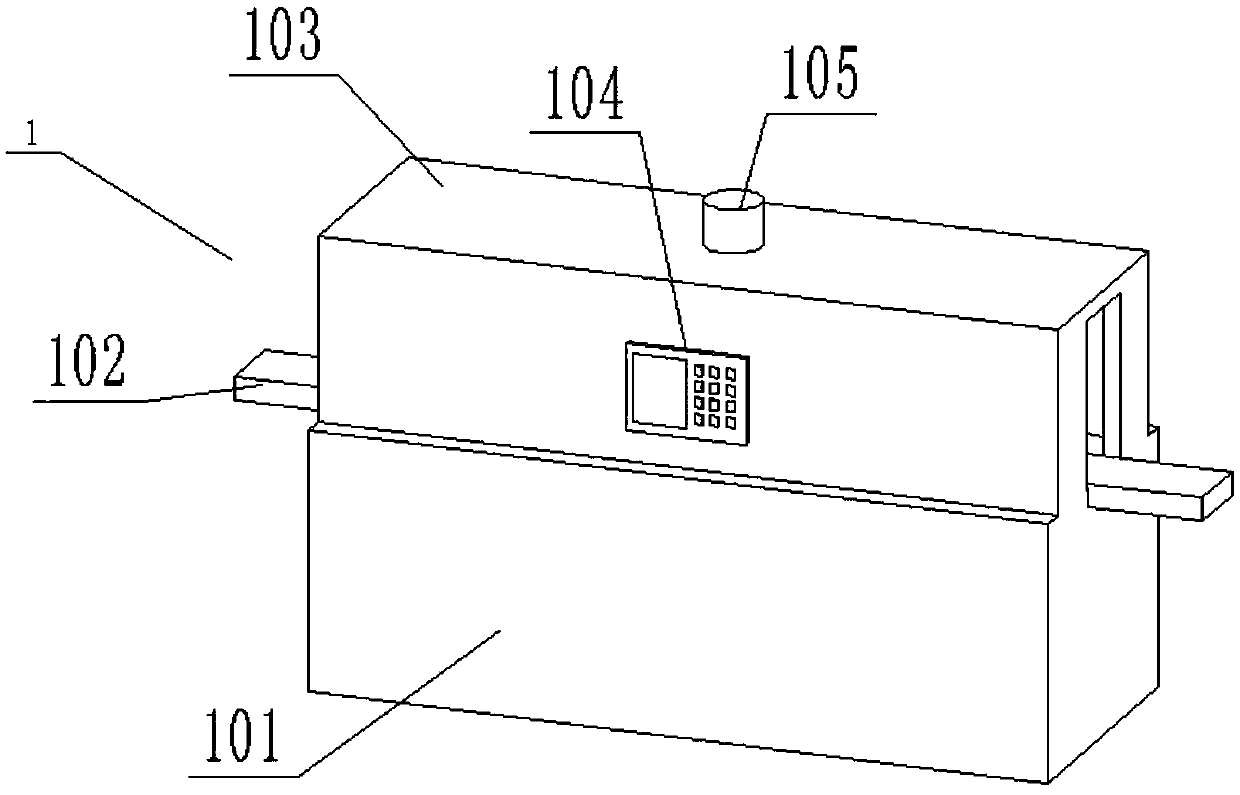

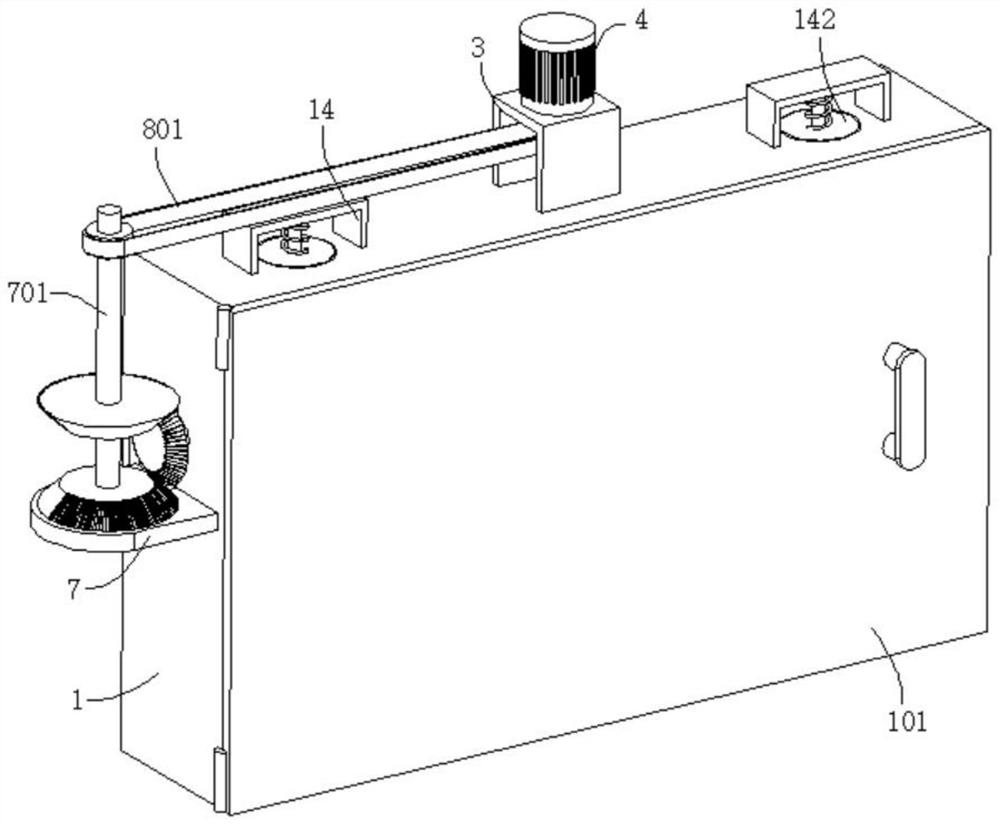

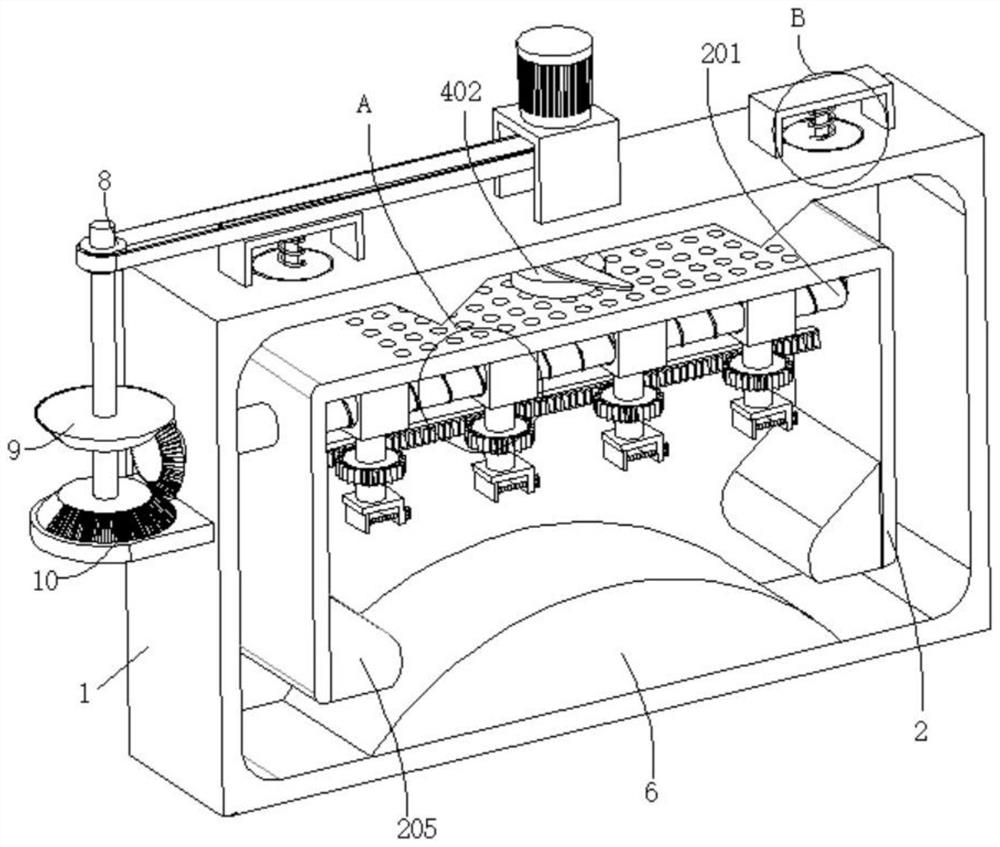

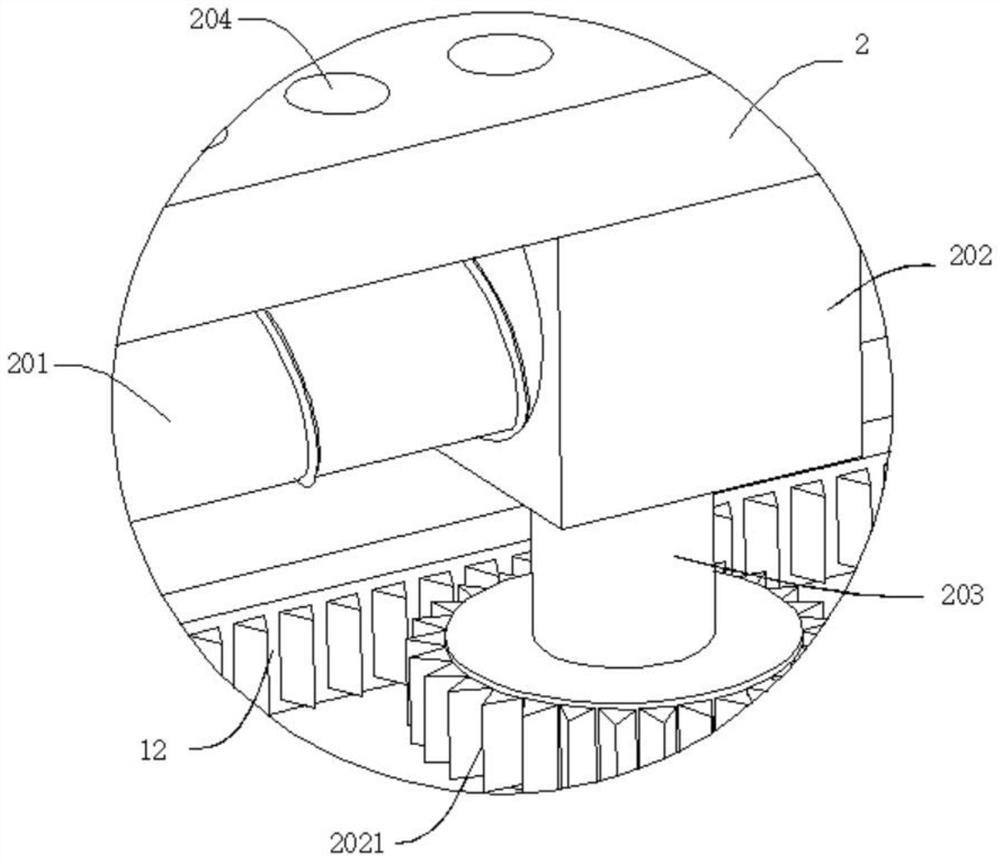

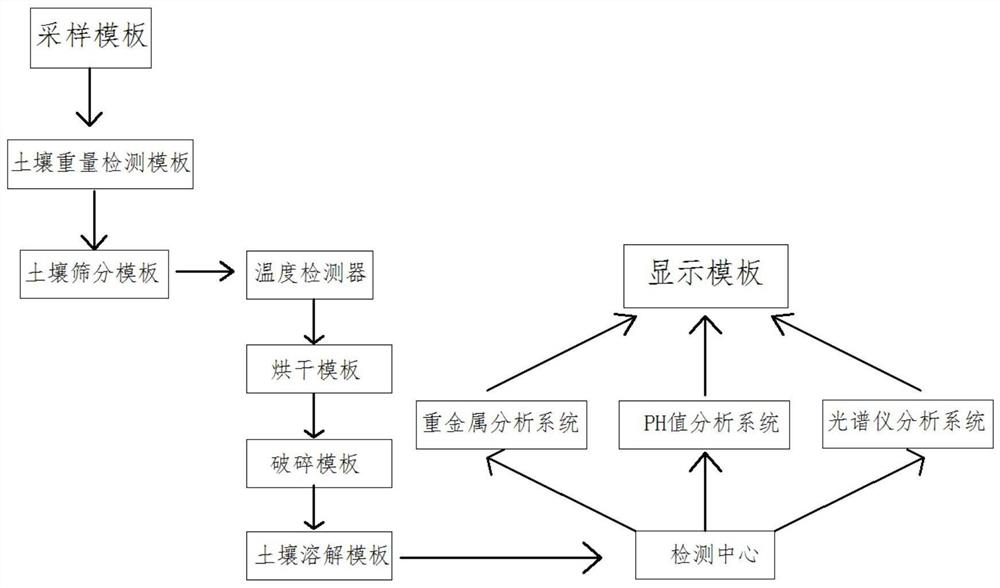

Intelligent analysis system and analysis device for soil component content detection

InactiveCN113075388ARealize the purpose of heating and dryingEven heating and dryingWithdrawing sample devicesPreparing sample for investigationSoil scienceOptical spectrometer

The invention relates to the technical field of soil detection, and discloses an intelligent analysis system and analysis device for soil component content detection which comprises a sampling template, a soil collection template, a spectrometer analysis system and a display template which are connected in sequence.The soil analysis template is used for receiving the soil information collected by the sampling template; the spectrograph analysis system is used for analyzing and acquiring nutrients in the soil through the spectral signals. According to the intelligent analysis device for soil component content detection, by starting a driving motor, the driving motor drives a driving spring to rotate immediately, then the driving spring abuts against a pushing plate towards the outer side, and the pushing plate moves in a soil collecting box immediately to push dried soil in the soil collecting box towards a discharging channel; and thus, the dried soil is pushed into the soil analysis mechanism, the component content of the soil is intelligently analyzed through a soil analyzer, and the component information of the soil is obtained.

Owner:SHANGHAI CHIZUN STATIONERY CO LTD

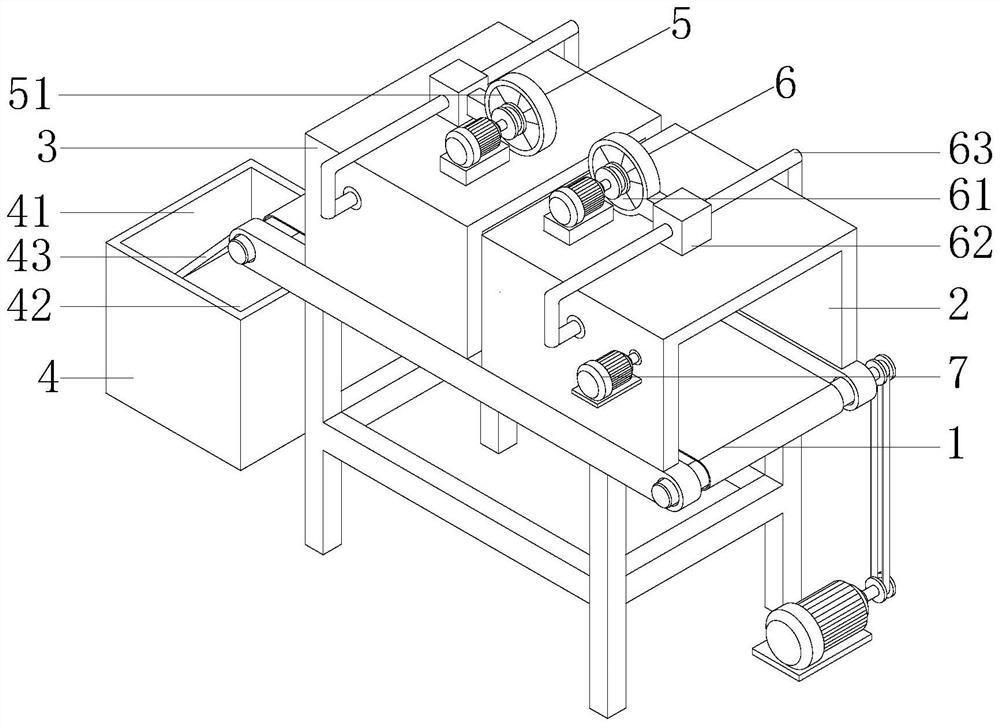

Automatic mortar raw material screening equipment

InactiveCN105478341AEven heating and dryingIncrease productivitySievingSand dryingDry heatEngineering

The invention discloses automatic mortar raw material screening equipment. The automatic mortar raw material screening equipment comprises a drying box and a vibration screen device. A drying box inlet is formed in the front side of the drying box. A drying box outlet is formed in the rear side of the drying box. A mortar raw material conveying mechanism is arranged in the drying box and comprises a conveyor belt. A smoke pipeline is arranged adjacent to the inner side wall of an inner cavity of the drying box. Smoke with waste heat is introduced through the smoke pipeline to heat the drying box. The vibration screen device is provided with a coarse screen and a fine screen. The coarse screen is arranged below the conveying tail end of the conveyor belt and the fine screen is arranged below the coarse screen. By the adoption of the automatic mortar raw material screening equipment, gas with the waste heat is used as a drying heat source, mortar is evenly heated and dried in the conveying process, energy is saved, environmental friendliness is achieved, and efficiency is high; and in addition, a dried mortar raw material is directly conveyed to the vibration screen device through the conveyor belt to be screened and finally directly conveyed to a material barrel to be stored, and the production efficiency of the mortar is improved.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

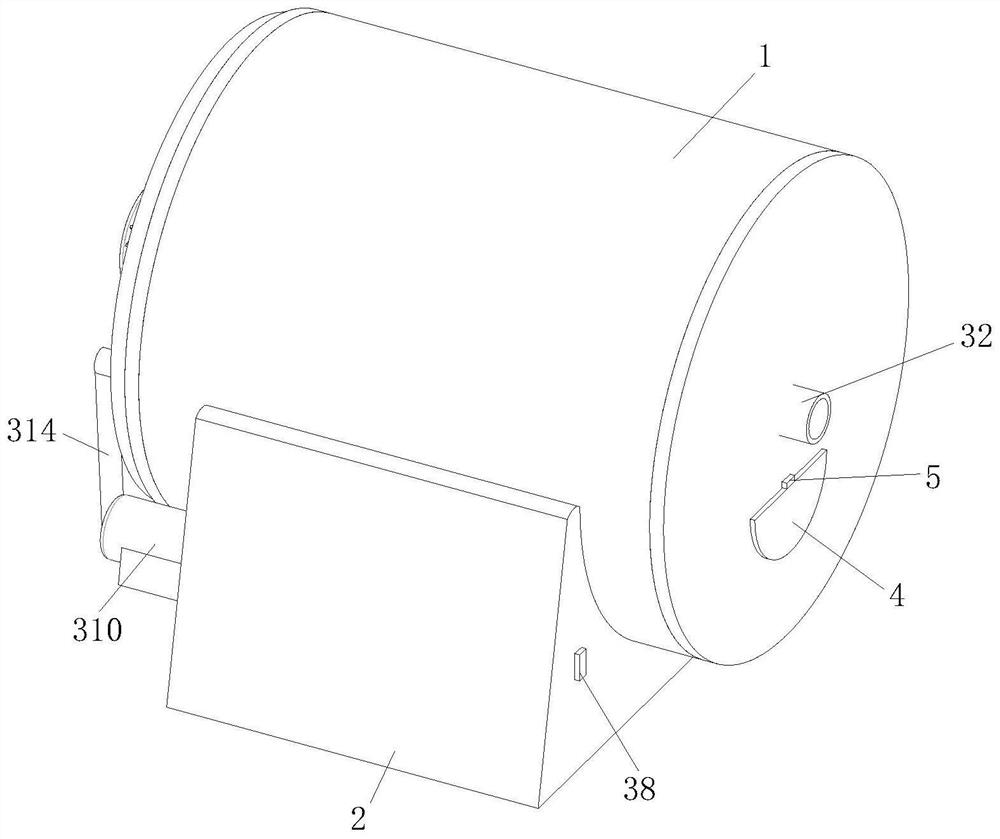

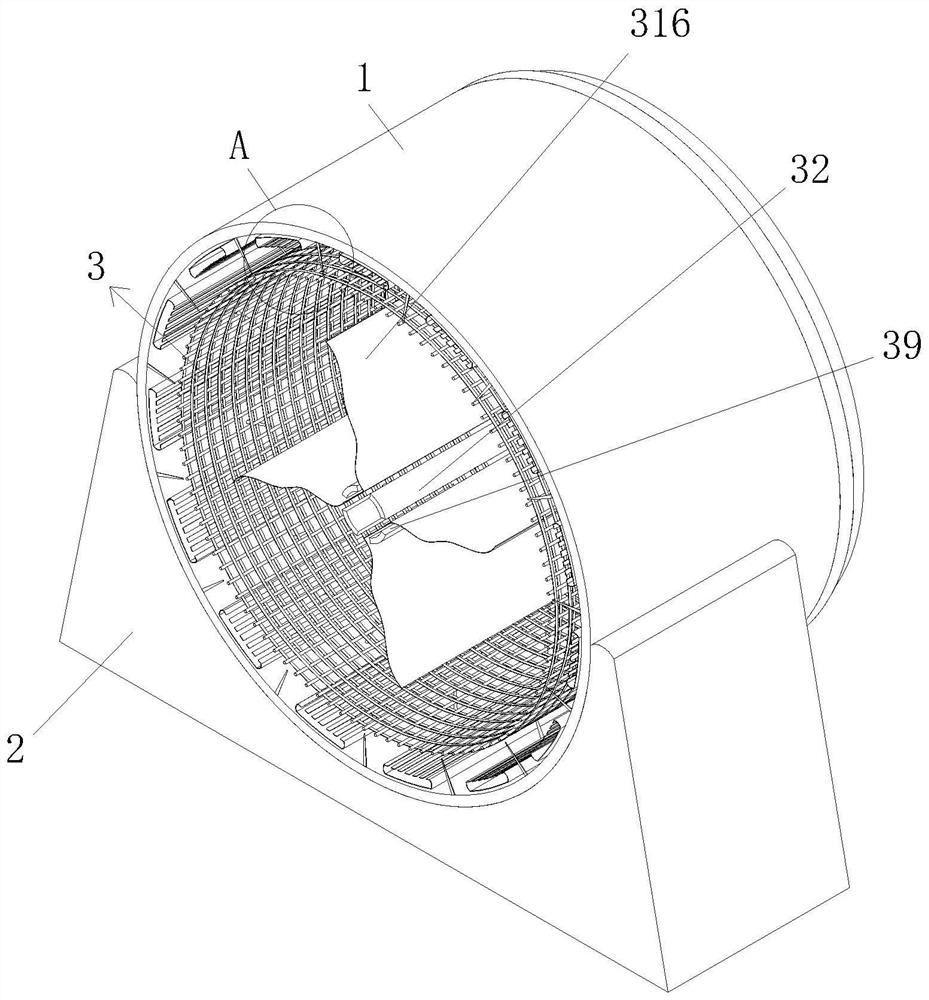

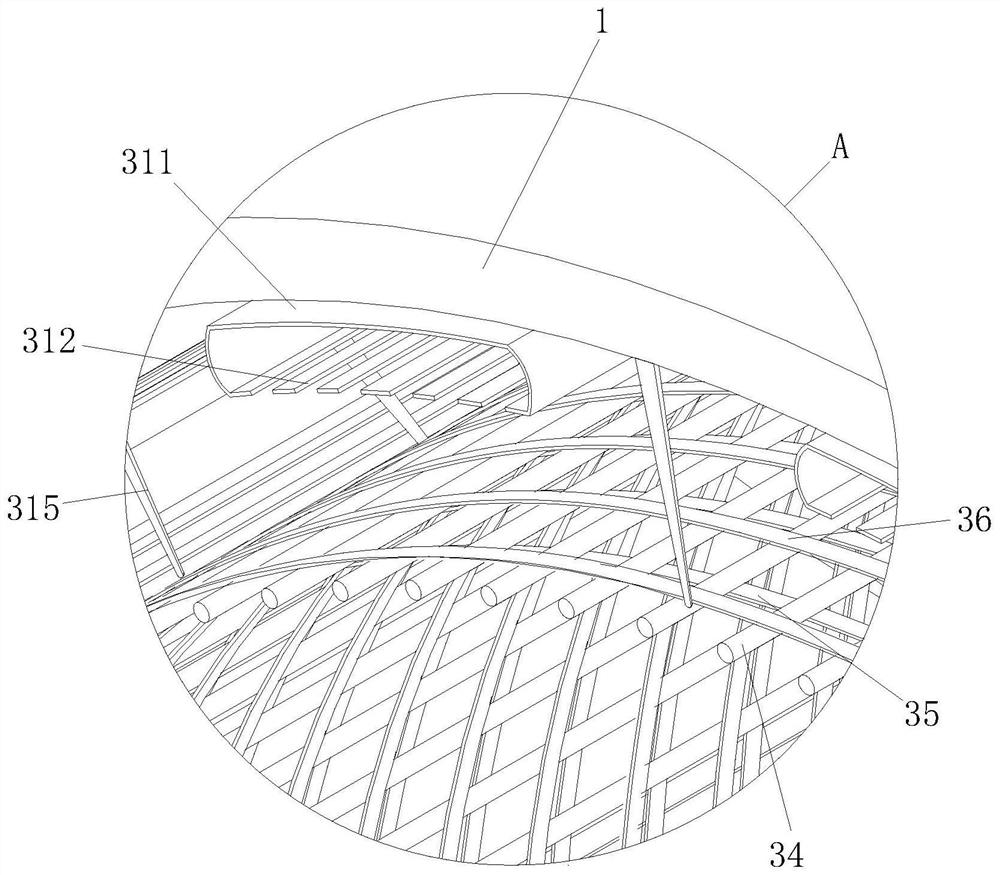

Floating separation type agricultural product drying device

InactiveCN113758194AReduce adsorptionEven heating and dryingDrying solid materials without heatTea dryingAgricultural scienceAgricultural engineering

The invention provides a floating separation type agricultural product drying device. The floating separation type agricultural product drying device comprises a drying cylinder used for drying tea leaves, a supporting base and a floating drying mechanism used for drying the tea leaves, the bottom of the drying cylinder is fixedly connected with the supporting base, and the floating drying mechanism is arranged on the drying cylinder and the supporting base. The surface of the drying cylinder is in a horizontal cylindrical shape, and the invention relates to the field of agricultural product processing. According to the floating separation type agricultural product drying device, a special structure capable of uniformly turning over the tea leaves and reducing tea leaf loss is designed according to the problems that in the existing tea leaf drying process, the loss is large, and the efficiency is low, so that the problems that the amount of the tea leaves dried by a common drying device at a time is small, the tea leaves are stacked and are difficult to make full contact with hot air, the tea leaf drying efficiency is low, and in the drying process, a stir-frying structure is prone to causing tea leaf damage and high in loss are solved.

Owner:陈泽源

Material drying device

ActiveCN108007097BWell mixedReduce mixDrying gas arrangementsDrying solid materialsEngineeringMaterials processing

The invention relates to the technical field of material processing devices, and discloses a material drying device. The material drying device comprises a rack and a drying box. A separation plate isarranged at a feeding port, a receiving plate and an object loading plate are arranged in the drying box, ventilation holes are formed in the receiving plate, a first wedge rod and a second wedge rodare arranged on the inner wall of the drying box, the wedge part of the first wedge rod abuts against an elastic plate, and a push plate is arranged in the drying box; a third spring is arranged at the bottom of the interior of the drying box, the end, away from the bottom, of the third spring abuts against the push plate, an air supply box is fixedly installed on the outer side of the drying box, a first guide pipe is arranged between the air supply box and a cavity in a communicating mode, and a cartridge valve abutting against the first wedge rod is arranged on the first guide pipe; a piston cylinder is fixedly installed on the outer side of the drying box, a second guide pipe is connected with the position, between the cartridge valve and the drying box, of the first guide pipe in a tapped mode, and the second guide pipe communicates with the piston cylinder; and a turbine is rotatably connected with the interior of the second guide pipe, a cam coaxial with the turbine is arrangedon the drying box, and the cam abuts against the separation plate. According to the material drying device, the problem that material drying is not even is solved, and meanwhile the drying efficiencyis improved.

Owner:宁波江北文增新材料科技有限公司

Sludge dewatering and drying method

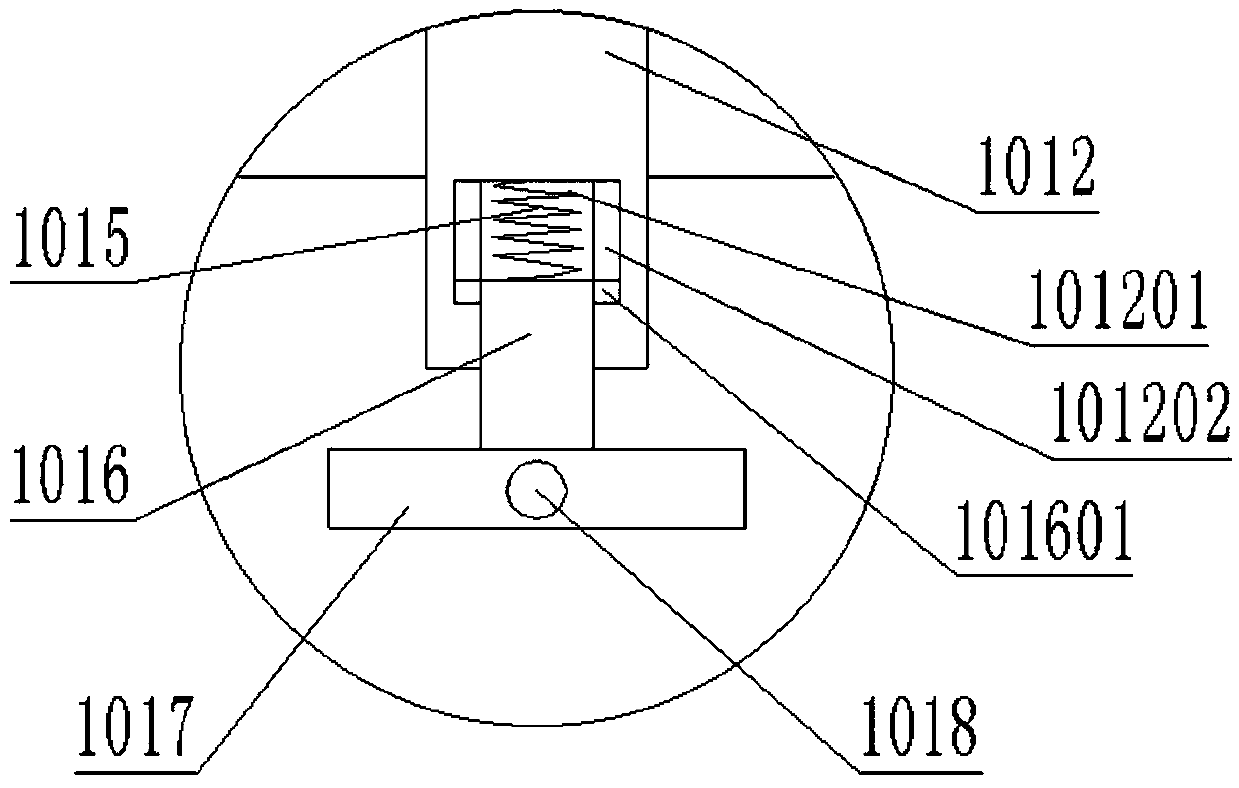

InactiveCN105540636ARelieve pressureDischarge fullySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPressure differenceMoisture

The invention provides a sludge dewatering and drying method. The method comprises the following steps: a pressurization apparatus enhances pressure in an upper tank, a vacuum tank reduces pressure in a lower tank to a vacuum state, so that a large pressure difference is formed between the upper tank and the lower tank; water in mixed liquid with sludge containing water in the upper tank can rapidly pass a filter layer, and the sludge remains in the upside of the filter layer; the pressure difference formed between the upper tank and the lower tank ensures rapid solid-liquid separation; after the solid-liquid separation finishes, a microwave emitter is started for emitting microwave, action between microwave and water molecules in the sludge is carried out for heating, so that moisture in the sludge diffuses and volatilizes to air, and efficacy for drying sludge is realized.

Owner:JINJIANG SHILONG KITCHEN EQUIP CO LTD

Cyclic drying device for lithium battery raw materials

ActiveCN110411177AEasy to dryDry evenlyDrying gas arrangementsDrying chambers/containersPulp and paper industryElectrode material

The invention belongs to the field of lithium batteries, and particularly relates to a cyclic drying device for lithium battery raw materials. The following scheme is proposed for solving the problemsthat in an existing drying device, cyclic drying treatment can not be conveniently conducted on positive electrode materials, negative electrode materials and diaphragms simultaneously, and the drying efficiency is poor. The cyclic drying device for the lithium battery raw materials comprises two first supporting plates which are symmetrically arranged, the two first supporting plates are both vertically arranged, the lower ends of the two first supporting plates are jointly and fixedly connected with a second supporting plate which is horizontally arranged, the upper ends of the two first supporting plates are provided with a third supporting plate which is horizontally arranged, a first drying tank is arranged between the two first supporting plates, and a first drying mechanism matchedwith the first drying tank is arranged on the third supporting plate. According to the cyclic drying device for the lithium battery raw materials, cyclic drying treatment can be conducted on the positive electrode materials, the negative electrode materials and the diaphragms simultaneously, and the drying treatment efficiency of the lithium battery raw materials is improved.

Owner:JIANGSU OLITER ENERGY TECH

Novel online oven for steel wires

InactiveCN106568312AGood guiding effectEven heating and dryingDrying gas arrangementsDrying machines with progressive movementsHeating timeEngineering

The invention relates to a novel online oven for steel wires. The novel online oven for the steel wires comprises an oven body. The upper end and the lower end of the interior of the oven body are each provided with a row of heat transfer pipes arranged horizontally. The two ends of the heat transfer pipes penetrate through the two ends of the oven body. Two rows of electric heating pipes are arranged between the two rows of heat transfer pipes. The electric heating pipes are sleeved with electric heating wires. The steel wires to be dried are arranged in the heat transfer pipes in a penetrating mode. Supporting seats are arranged at the two ends of the oven body. Wire passing wheels are placed on the supporting seats, and the two ends of the steel wires are arranged on the wire passing wheels in a sleeving mode. A draught fan is installed at the front end of the oven body, and the draught fan is connected with an air inlet formed in the front end face of the oven body. The novel online oven for the steel wires is convenient to operate, short in heating time, high in drying efficiency and low in energy consumption.

Owner:YANGZHOU JINCHEN STAINLESS STEEL MFR

Rice conveyor with grain moisture-proof function

The invention provides a rice conveyor with a grain moisture-proof function. The rice conveyor with the grain moisture-proof function comprises a conveyor body, wherein a drying box is arranged at thetop of the conveyor body, a moisture-proof device is arranged on one side of the drying box, the moisture-proof device comprises a driving motor, a first driving wheel is arranged at the output end of the driving motor, a first threaded rod is arranged at the center of one side of the first driving wheel, one side of the first driving wheel is provided with a first driven wheel, a second threadedrod is arranged at the center of one side of the first driven wheel, a second driving wheel is arranged at one end of the second threaded rod, a second driven wheel is arranged at one side of the second driving wheel, a third threaded rod is arranged at the center of one side of the second driven wheel, moving blocks are arranged at one ends of the third threaded rod, the second threaded rod andthe first threaded rod respectively, and heating lamps are arranged at the bottom of the moving blocks. According to the rice conveyor with the grain moisture-proof function, the heating lamps are driven by the multiple threaded rods to uniformly dry and heat rice, so that the quality of the rice is improved.

Owner:界首市金龙机械设备有限公司

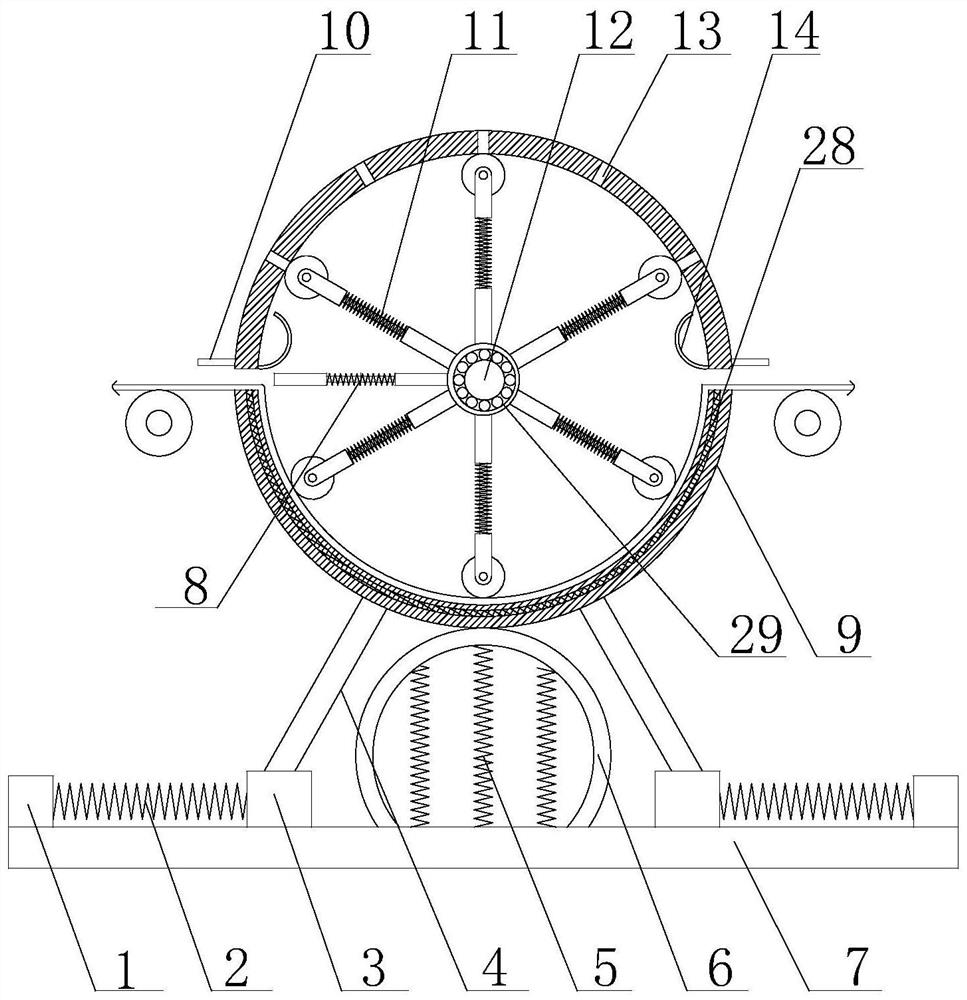

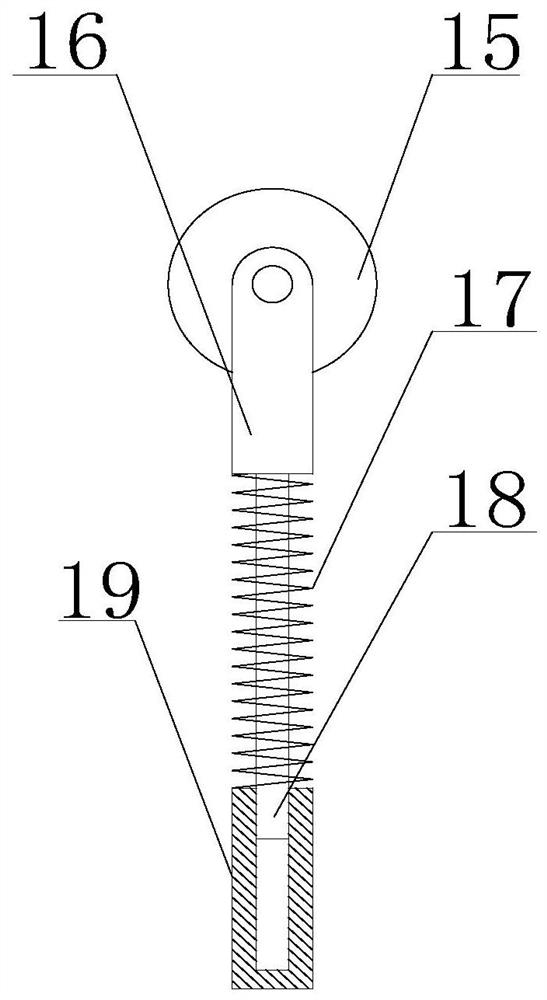

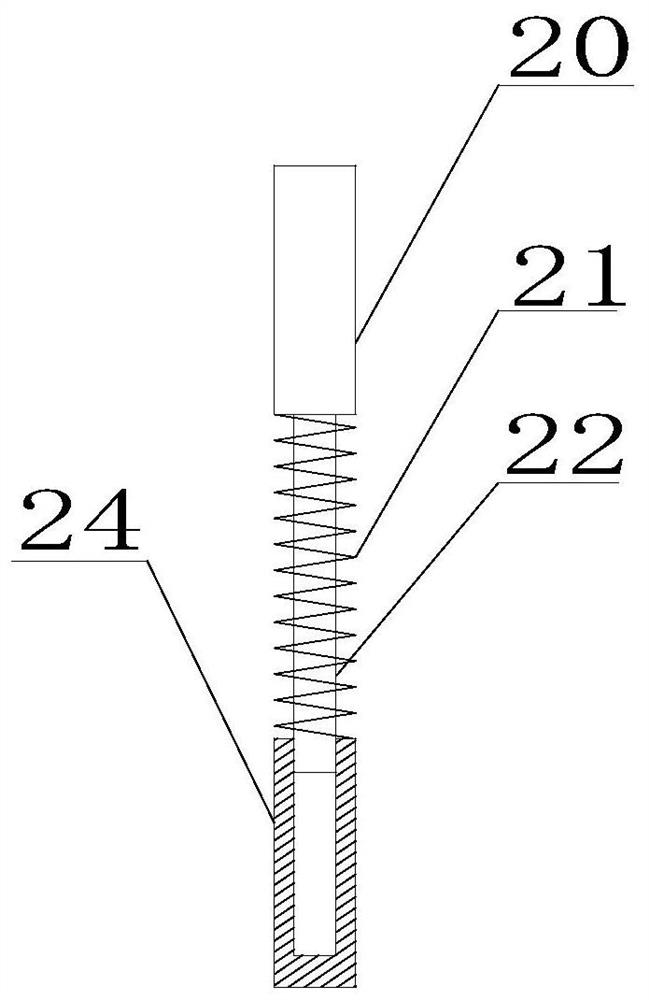

A drying device based on glass fiber cloth processing application

ActiveCN111501259BEfficient heatingMeet the needs of useLiquid/gas/vapor removalTextile treatment machine arrangementsGlass fiberFiber

The invention discloses a drying device based on the processing and application of glass fiber cloth. There are cloth inlets on both sides of the outer wall, and the two cloth inlets are located in the horizontal direction. There is also a heating wire inside the inner wall of the drying cylinder. There is a fixed rod inside the drying cylinder. Distributed in the direction, the fixed rod is equipped with a bearing that matches the fixed rod, and the outer wall of the bearing is provided with a number of telescopic rods. The telescopic rods are distributed in a circular array around the axis of the fixed rod, and the telescopic rods are facing the inner wall of the drying cylinder. There are rollers at the end of the direction; both sides of the inner wall of the drying cylinder are equipped with liquid collecting plates; the outer wall of the bearing is also equipped with a holding assembly for holding the fiber cloth. The invention can evenly heat the fiber cloth, and can effectively benefit the residual heat to reheat the fiber cloth, so as to improve the drying efficiency of the fiber cloth.

Owner:台嘉成都玻纤有限公司

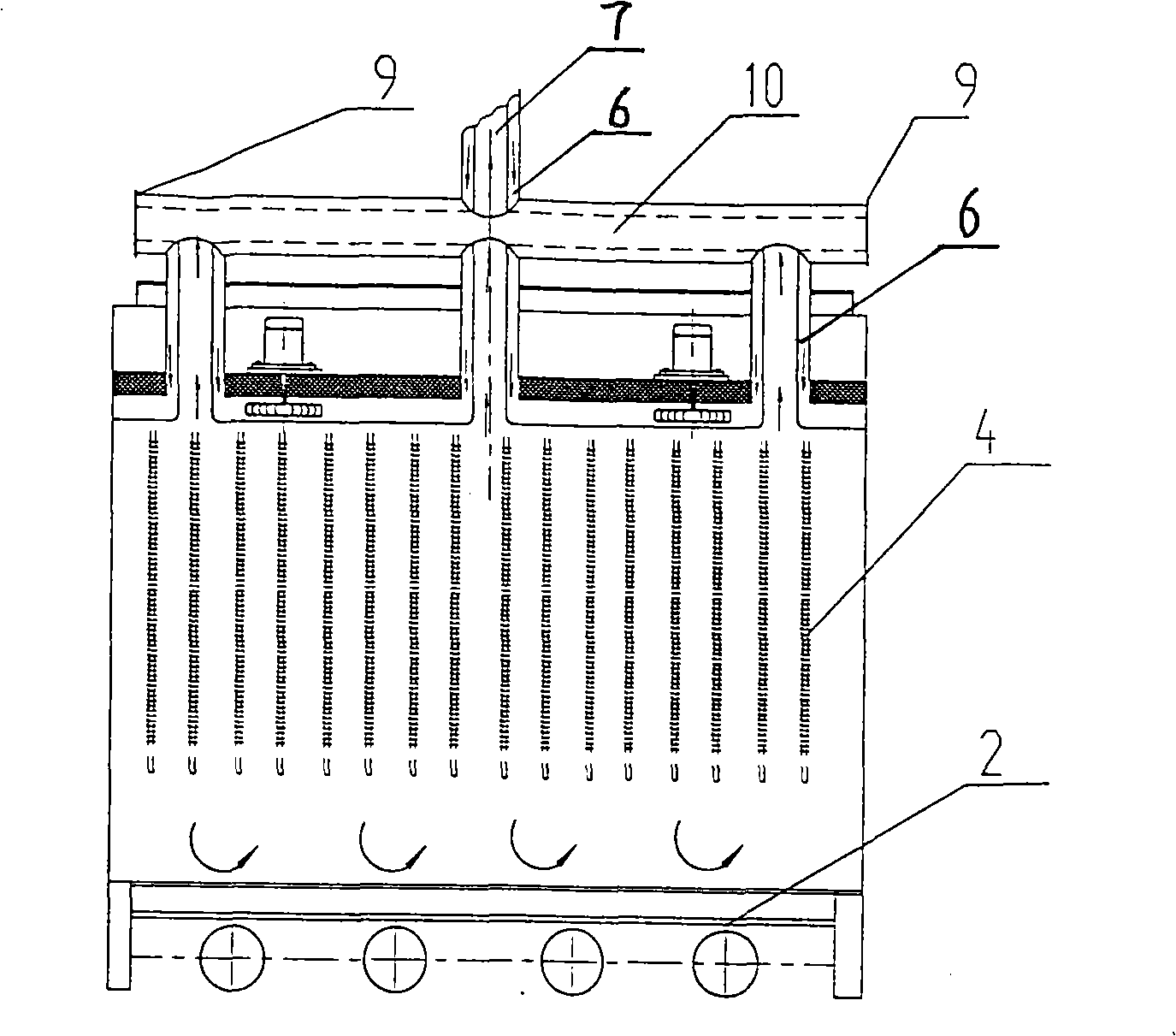

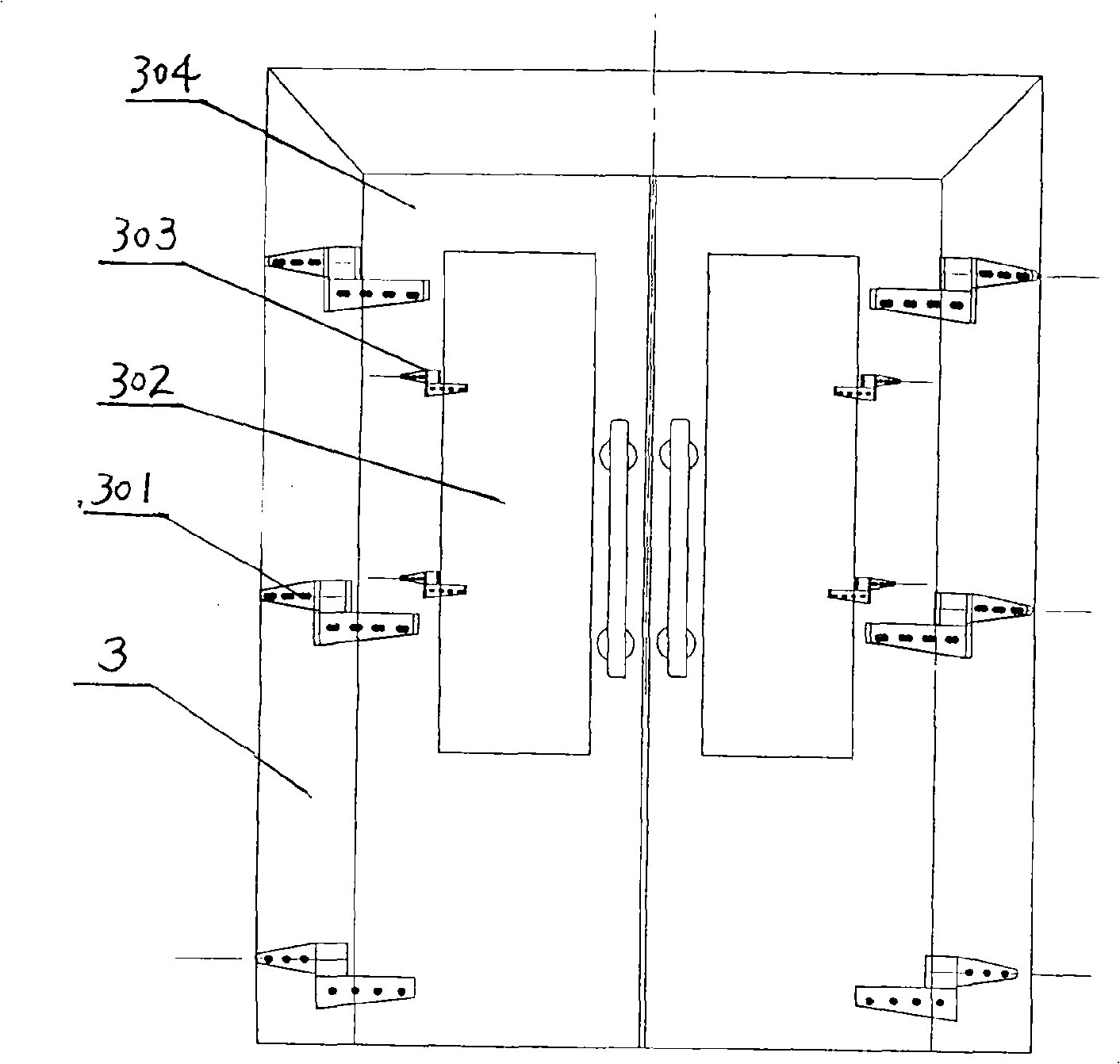

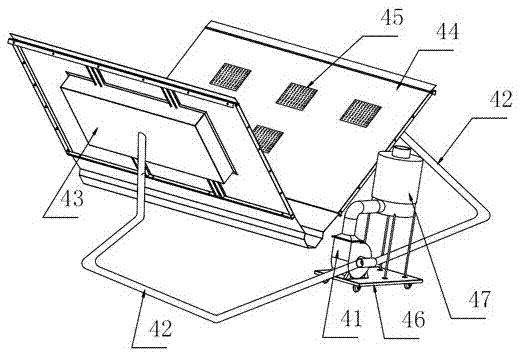

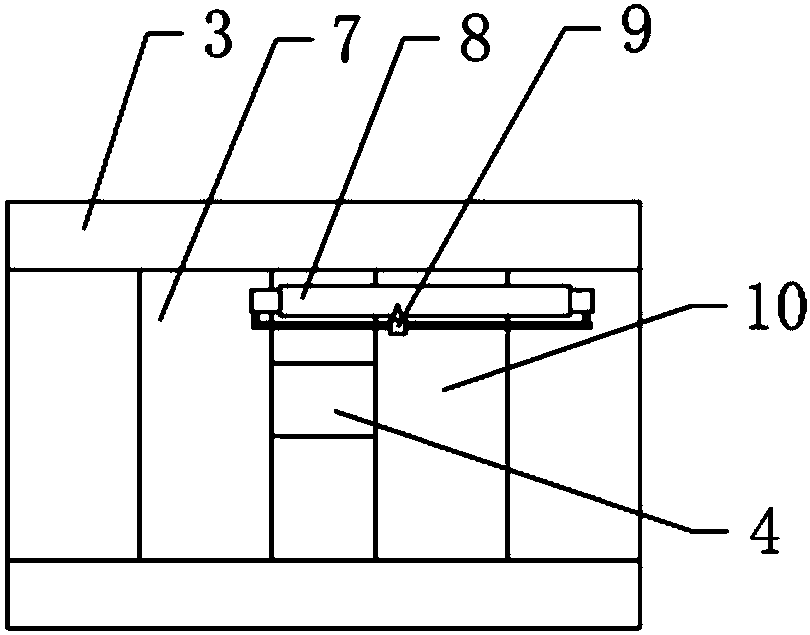

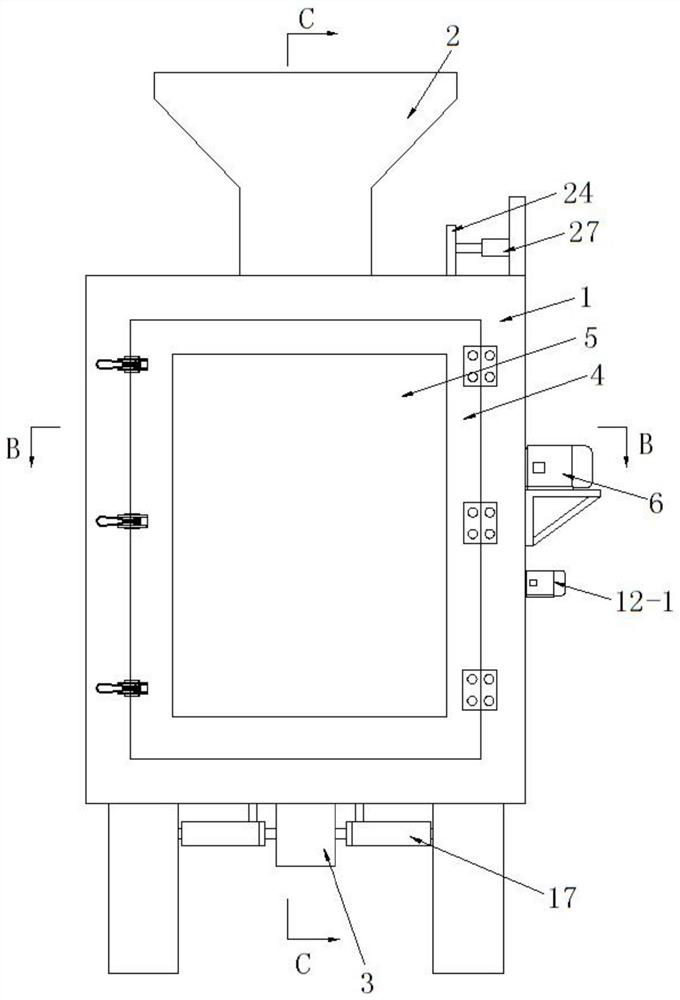

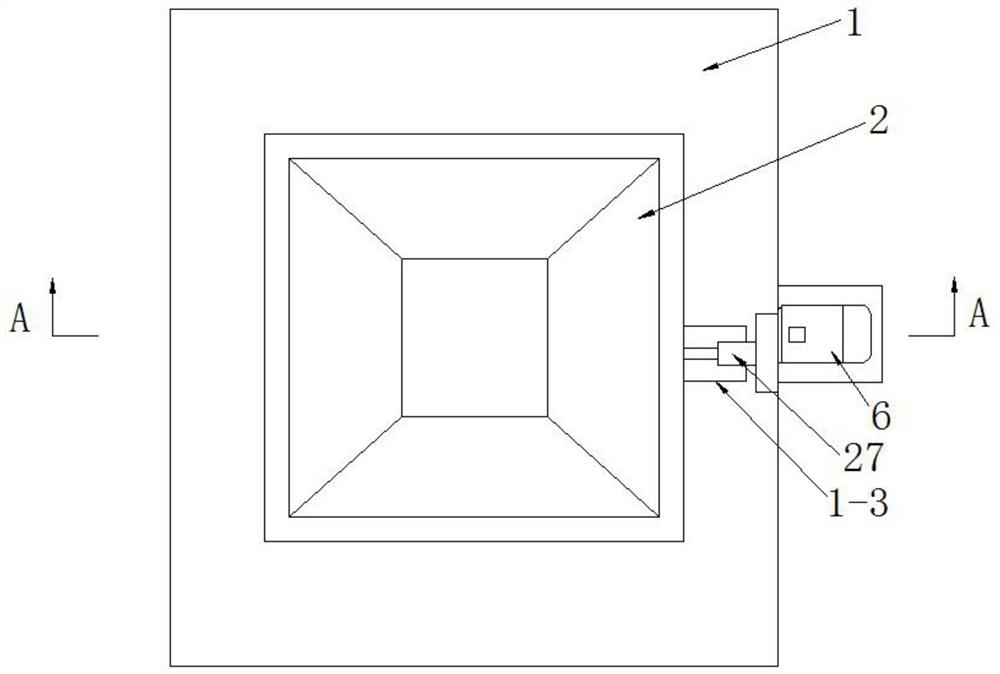

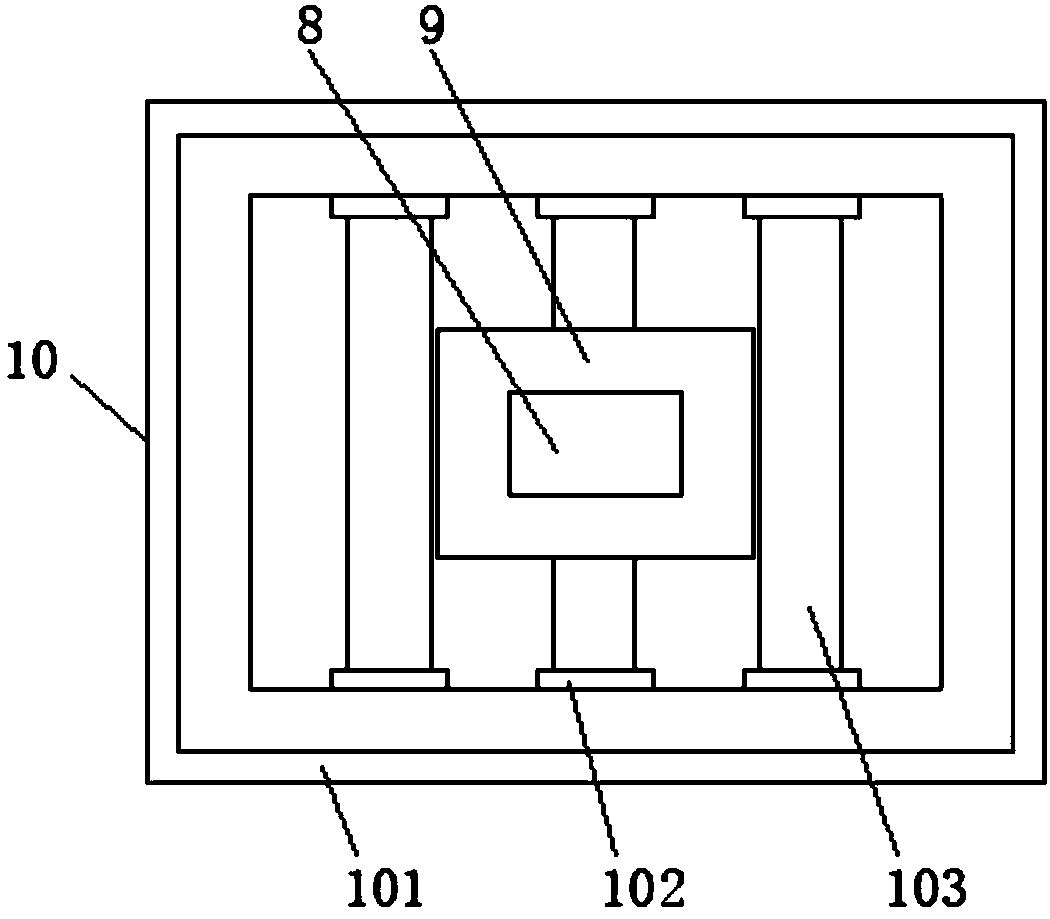

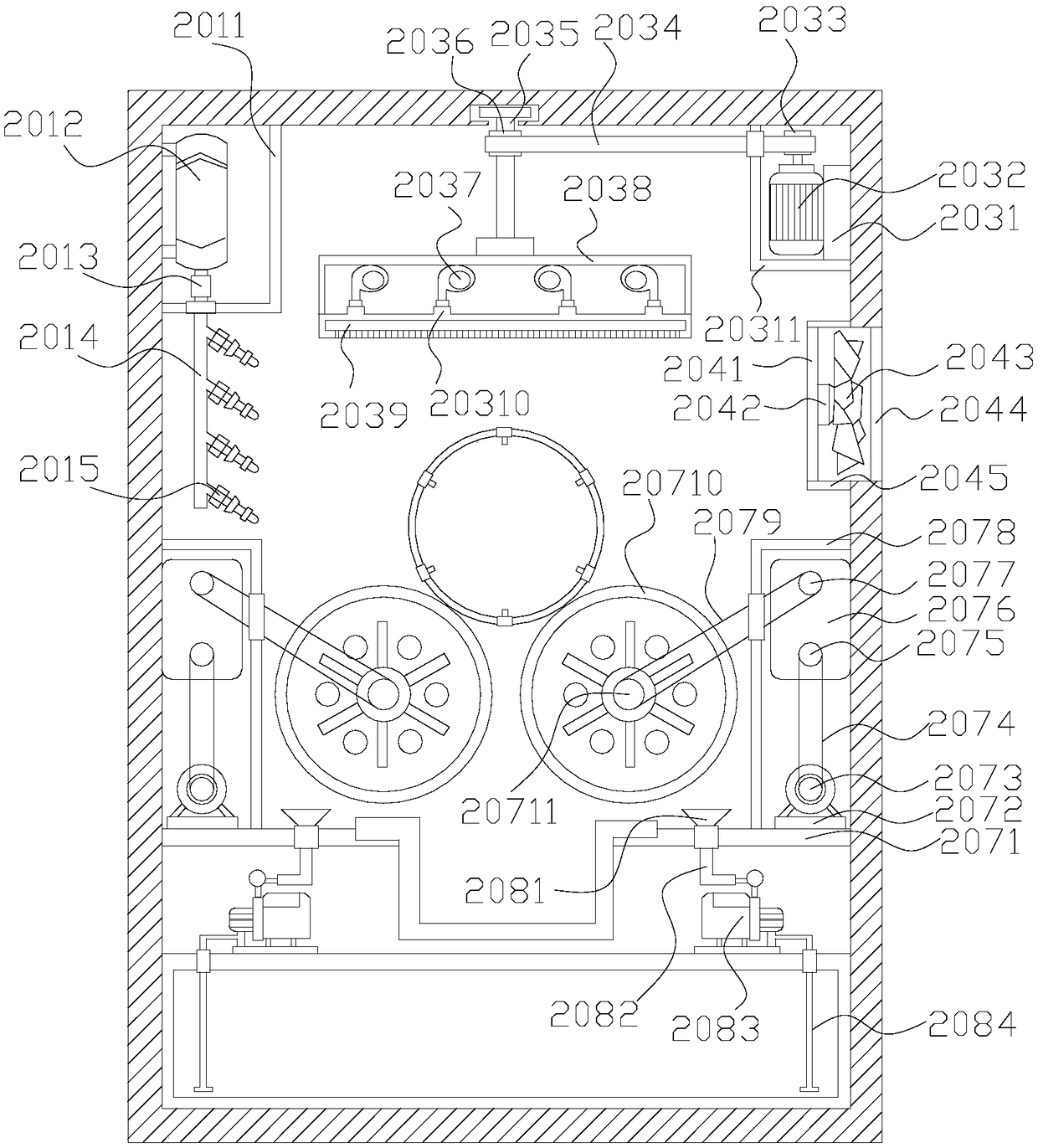

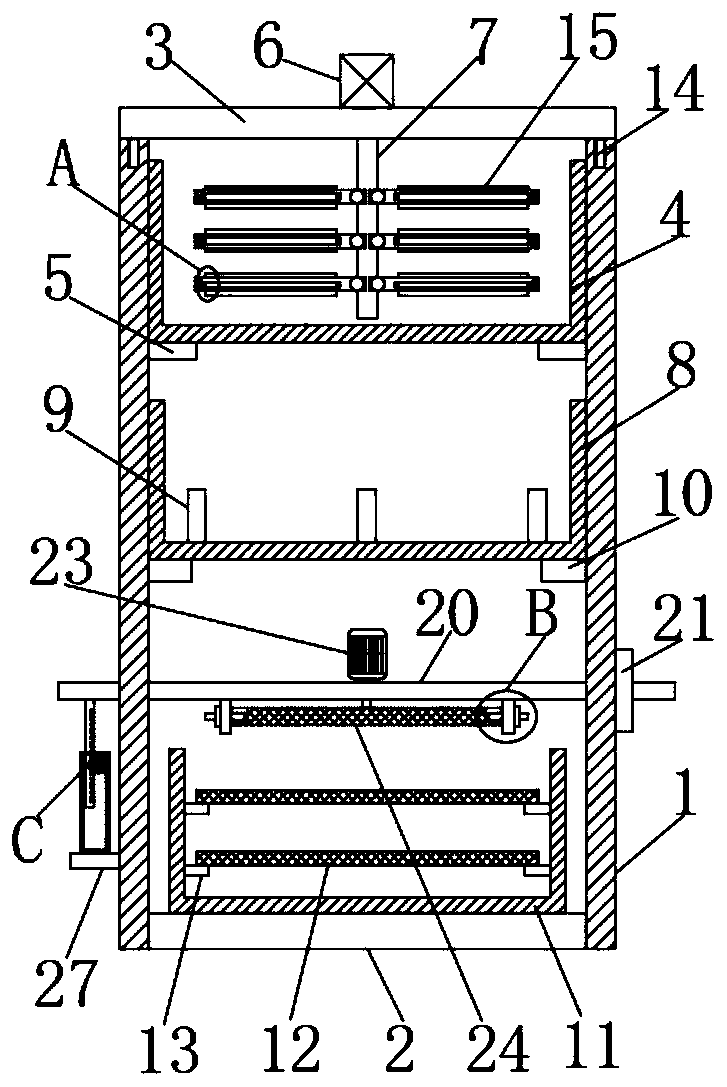

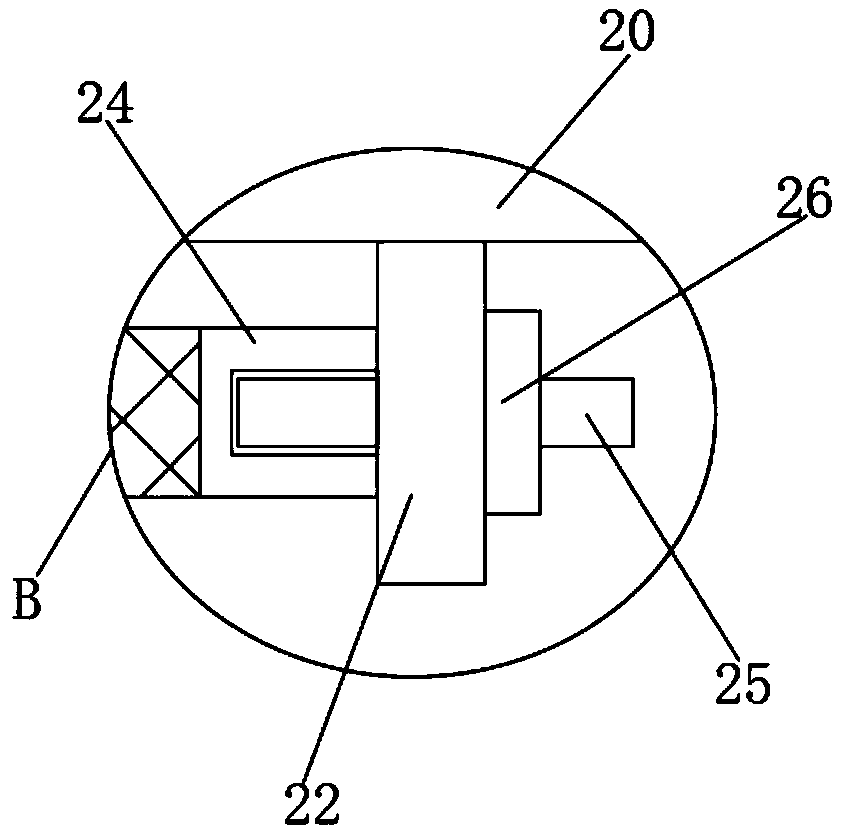

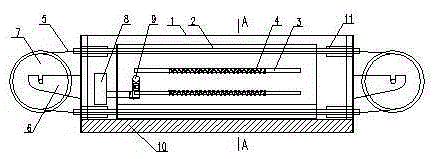

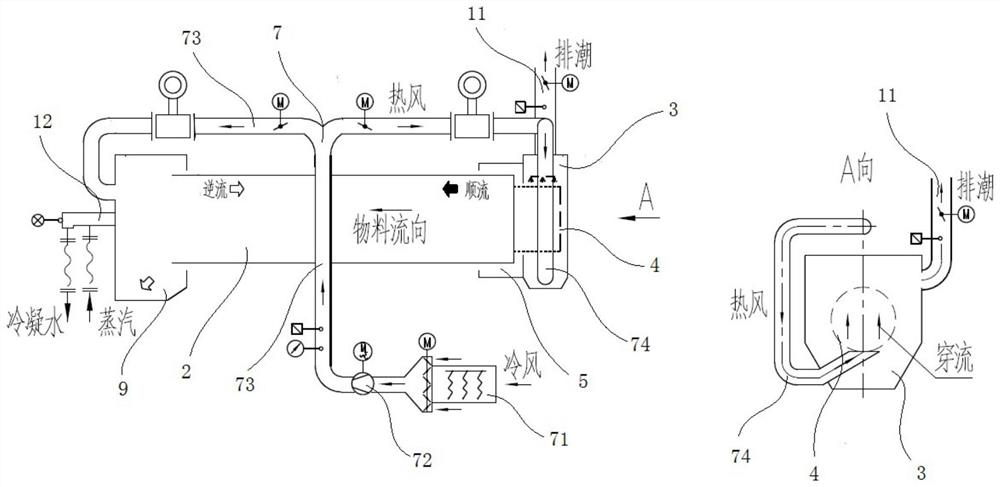

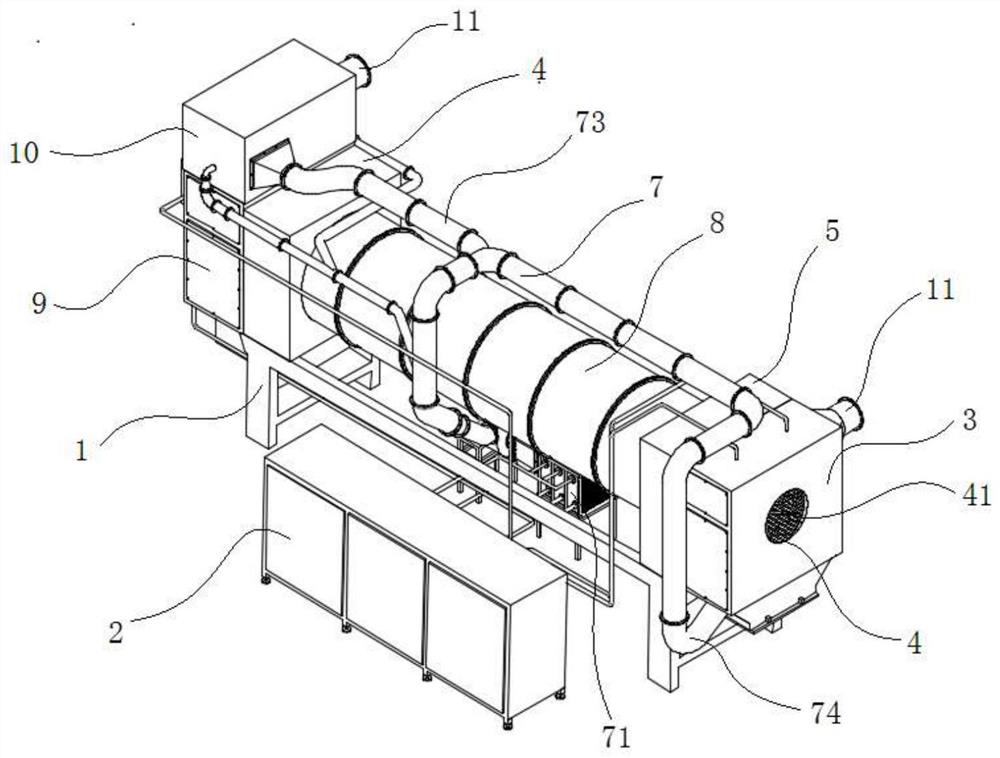

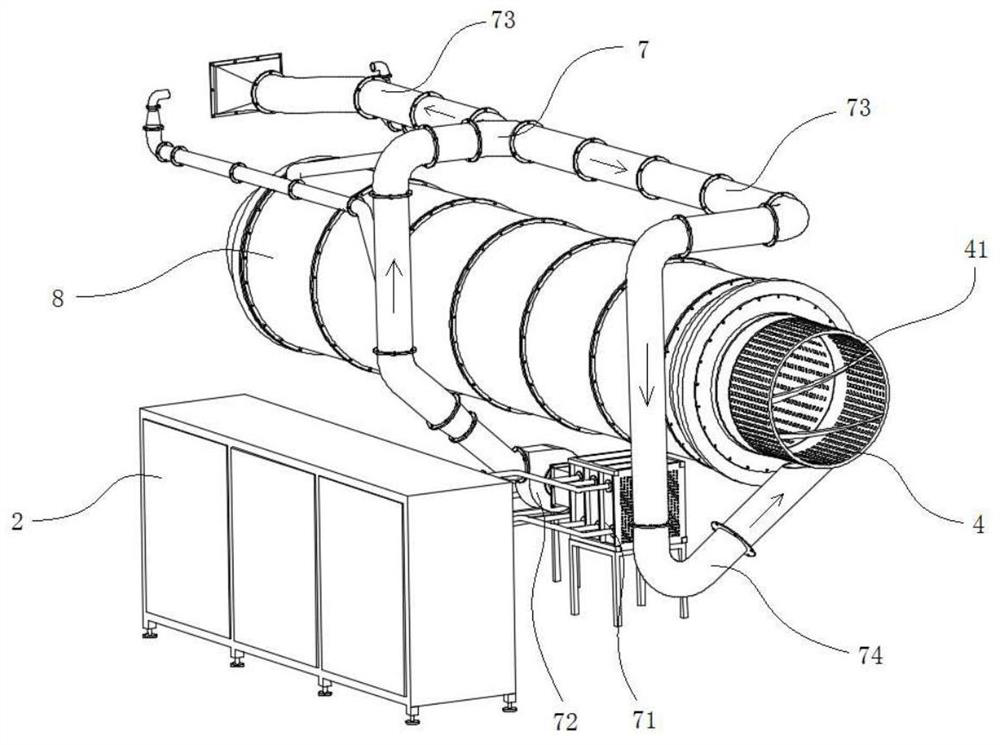

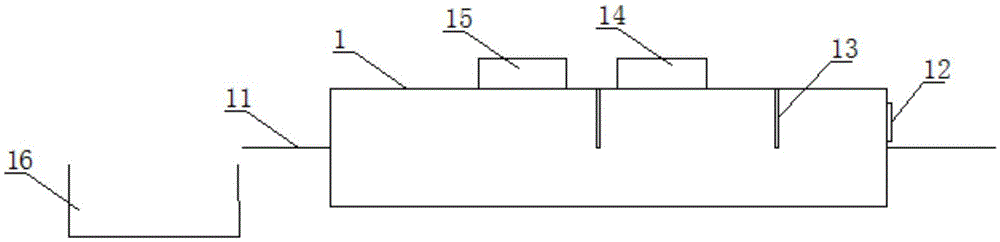

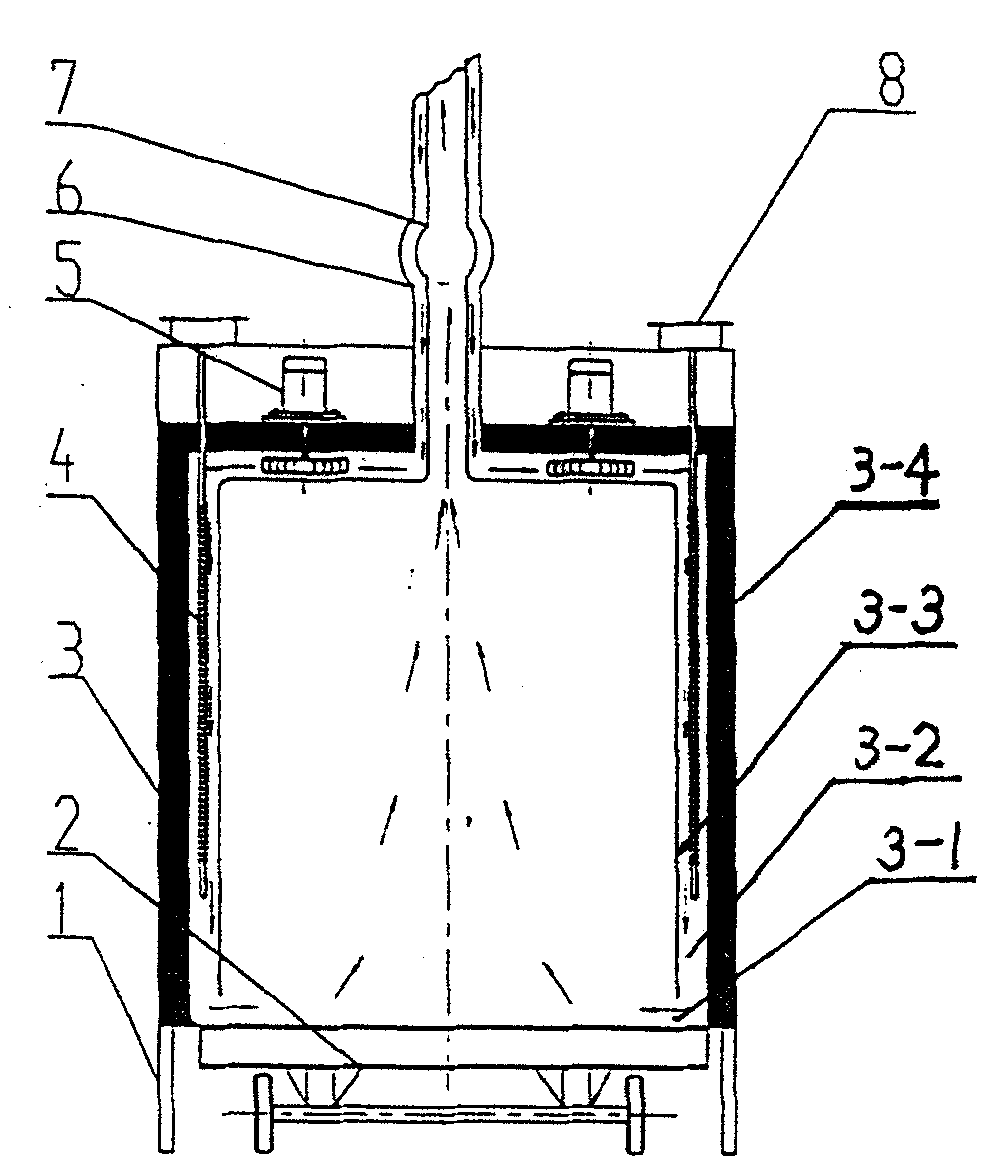

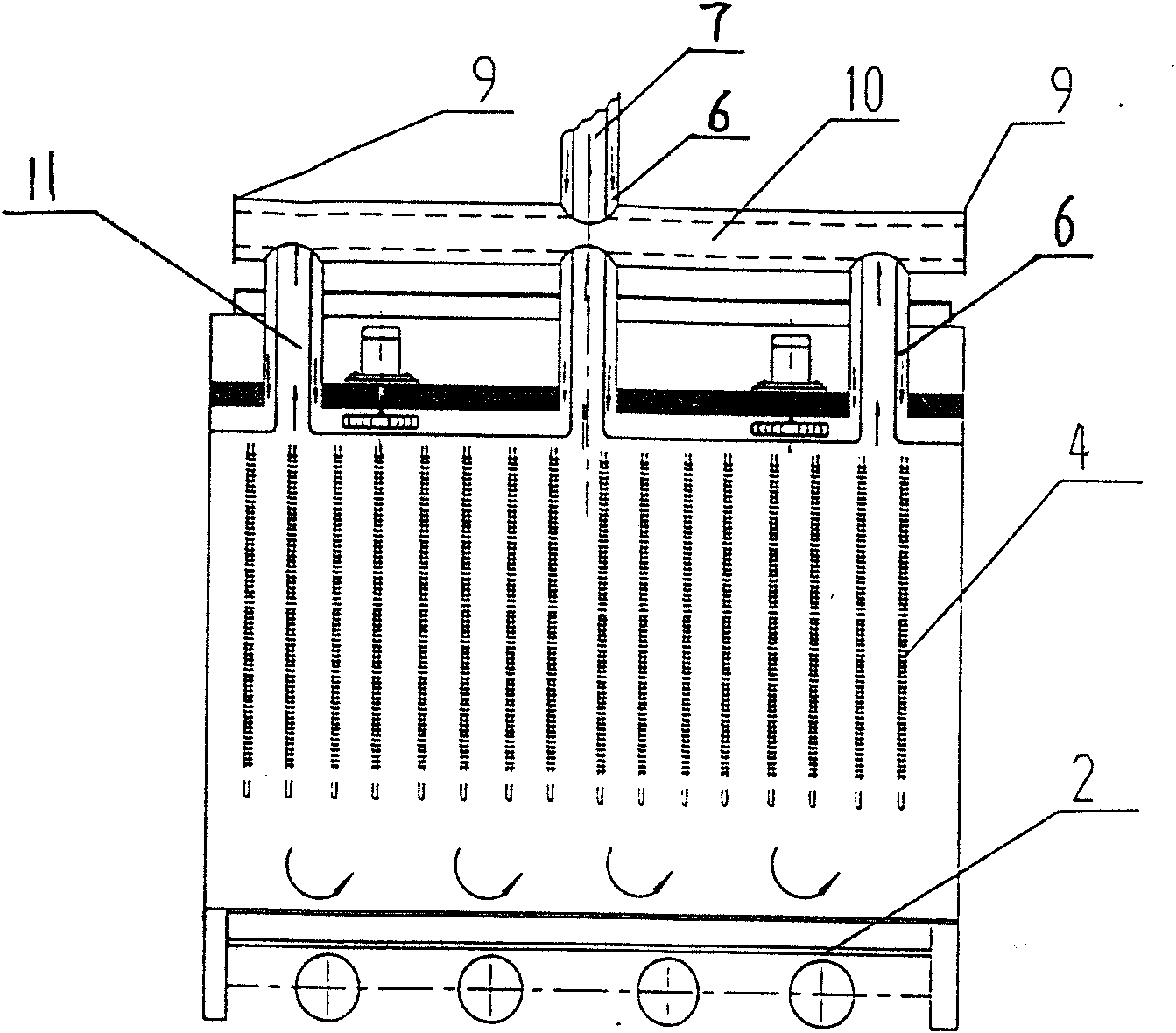

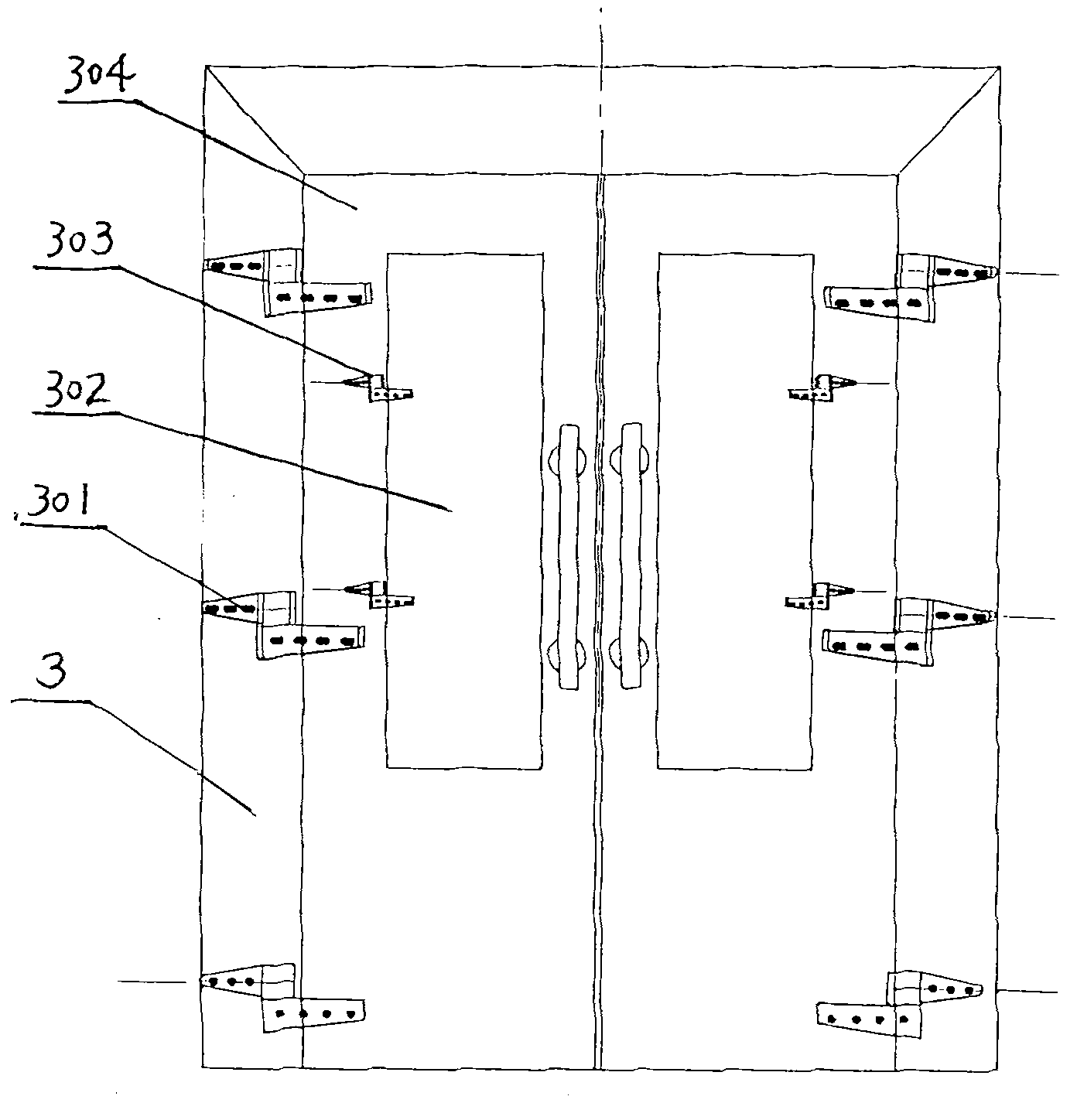

Thin plate cut tobacco drying equipment with cross-flow section

PendingCN112273699AEven heating and dryingRealize the purpose of high-efficiency and high-quality dehydrationTobacco preparationEngineeringMechanical engineering

The invention discloses thin plate cut tobacco drying equipment with a cross-flow section, which comprises a frame component (1) and a cut tobacco drying device arranged on the frame component (1), wherein the cut tobacco drying device mainly comprises a front chamber (3), a guide cylinder (4), a fan cover (5), a cut tobacco drying cylinder rotating mechanism (6), a hot air system (7), a cut tobacco drying cylinder (8), a rear chamber (9), a steam dust suction box (10) and a moisture removal air pipe (11). By means of the characteristic of fast drying and dewatering of airflow, high-temperature hot air penetrates into the drying cylinder in the radial direction of the drying cylinder from bottom to top, under the action of the axial inclination angle of the drying cylinder and high-point material throwing dredging of a heat exchange shoveling plate in the cylinder, the controllable high-temperature airflow penetrating into the cylinder evenly penetrates through the cylinder, assists insupporting and loosening the materials, and evenly heats and dries the materials, and through the combination of cross-flow hot air section drying and a traditional cut tobacco dryer, the purpose ofefficient and high-quality dehydration of cut tobacco is achieved.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

Automatic drying device for raw mortar material

InactiveCN105486062AEven heating and dryingSave energyDrying gas arrangementsDrying machines with progressive movementsMotor driveProduct gas

The invention discloses an automatic drying device for raw mortar material. The automatic drying device comprises a drying box, wherein a drying box inlet is formed in the front of the drying box, and a drying box outlet is formed in the back of the drying box; a raw mortar material conveying mechanism is arranged in the drying box and comprises a conveying belt, a conveying motor and a hopper, wherein the conveying motor drives the conveying belt to convey the material along the drying box from front to back, and the hopper is arranged below the conveying tail end of the conveying belt; a smoke pipeline is arranged on the inner side wall adjacent to the cavity of the drying box and guides smoke with waste heat for heating the drying box. According to the invention, the waste heat gas generated in industrial production serves as a drying heat source, mortar is uniformly heated and dried in the conveying process, the energy is saved, and the effect of environmental friendliness and high efficiency is realized.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

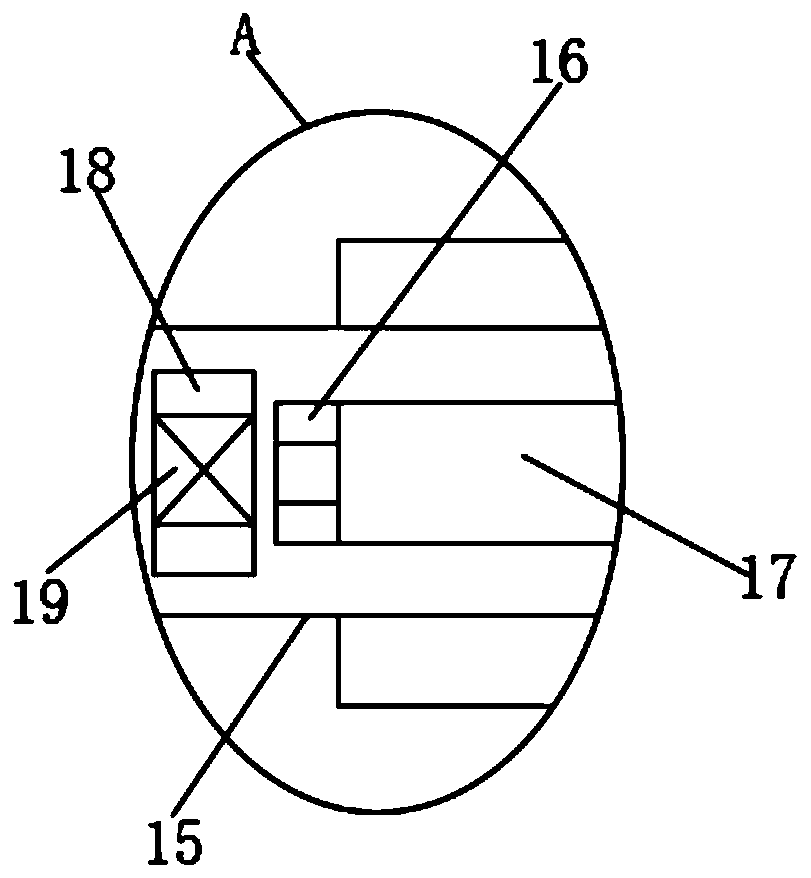

Traditional Chinese medicine drying machine based on airflow flowing and drying method thereof

InactiveCN109539700AHigh speedEven heating and dryingDrying solid materials with heatDrying gas arrangementsAtmospheric pressurePressure difference

The invention discloses a traditional Chinese medicine drying machine based on airflow flowing and a drying method thereof. The drying machine comprises a heating chamber, a heater is arranged in theheating chamber, a dustproof pad is arranged above the heater, a drying box is arranged above the heating chamber, a box cover is arranged above the drying box, an air inlet is formed in the tangent direction of the side wall of the box cover, an inner pipe is arranged on the box cover, a filter layer is arranged on an air suction opening of the inner pipe, the inner pipe is connected with a vacuum pump through an outer pipe, the drying box is subjected to air suction through the vacuum pump to generate the pressure difference, and traditional Chinese medicines in the drying box ascend along with the airflow; due to the fact that the air pressure in the drying box is reduced, exterior air flows into the drying box through the air inlet, on the basis of the circular-table-shaped drying box,rotating type flowing is formed, and the traditional Chinese medicines rotatably flow in the drying box along with the airflow; through the heater arranged on the bottom of the drying box, the traditional Chinese medicines rotatably ascending and flowing along with the airflow are dried; and the advantages of being high in heating efficiency and high in drying speed are achieved, the simple structure is adopted, mounting is easy, and operation is convenient.

Owner:WENZHOU MEDICAL UNIV

Energy-saving explosion-proof drying furnace and its drying monitoring system

InactiveCN101307982BReduce startup timeExtended service lifeDrying solid materials with heatDrying gas arrangementsThermodynamicsMonitoring system

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

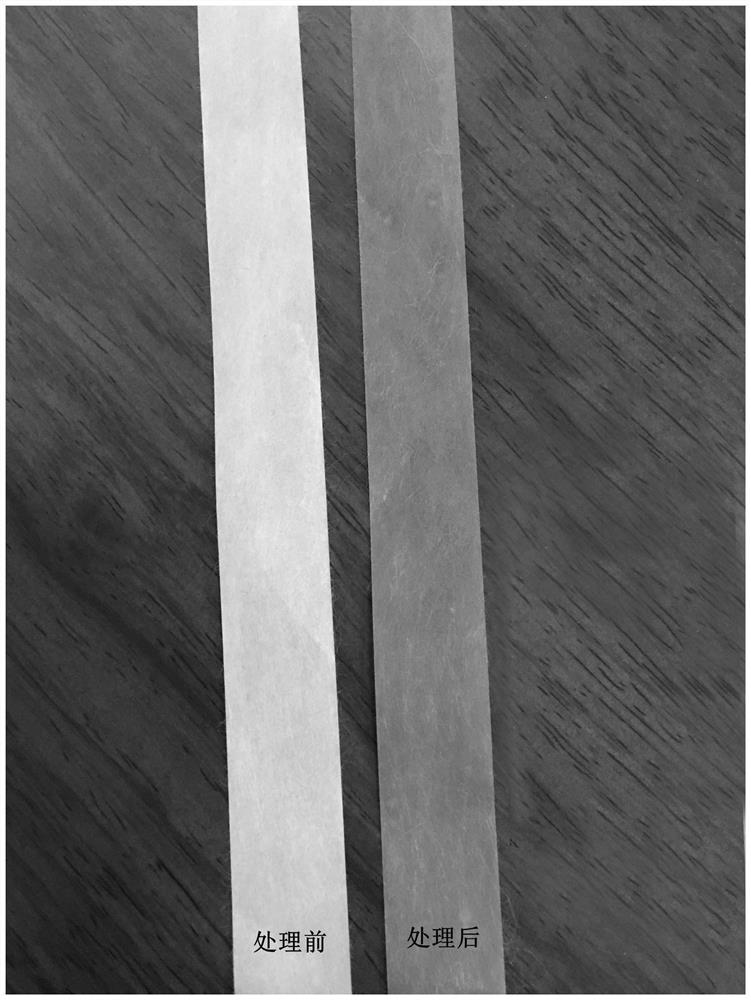

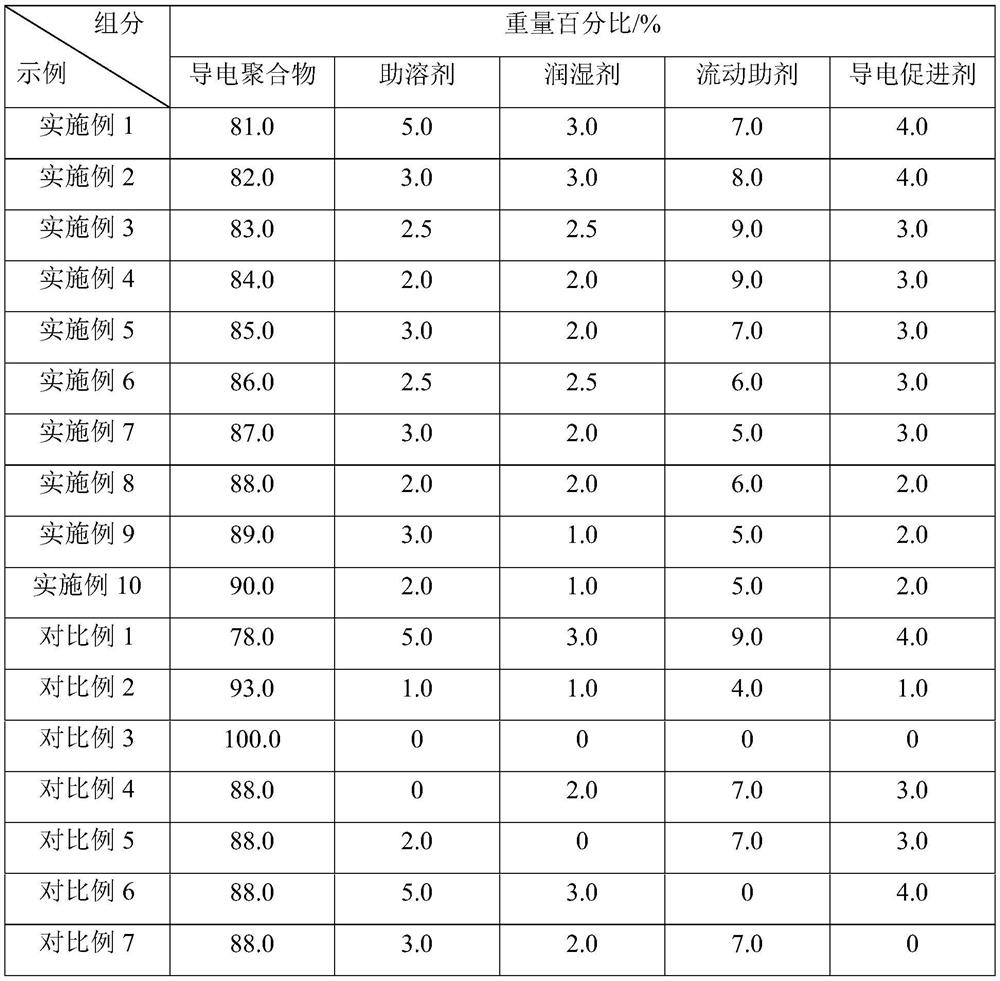

Conductivity enhancing liquid for paper substrate of supercapacitor, paper substrate and preparation method

ActiveCN114334473AIncreased polarizationImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureConductive polymerPolyethylene glycol

The invention relates to the field of paper-based supercapacitors, and particularly discloses a conductive enhancing liquid for a paper substrate of a supercapacitor, the paper substrate and a preparation method. The conductive enhancing liquid comprises the following components in percentage by weight: 81-90% of a conductive polymer, 2-5% of a cosolvent, 1-3% of a wetting agent, 5-9% of a flow promoter and 2-4% of a conductive accelerant, the cosolvent is monohydric alcohol and / or polyhydric alcohol, the wetting agent is polyethylene glycol, the flow promoter is sugar alcohol, and the conductive accelerant is sulfate and / or carbonic ester; the surface of the paper substrate is coated with the conductive enhancing liquid. The conductive enhancing liquid is excellent in conductivity and can form a conductive film on the paper substrate, so that the conductivity of the paper substrate is greatly improved, and the paper substrate is simple in preparation process and low in production cost.

Owner:SHENZHEN JIANGHAO ELECTRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com